Deposition of Multicomponent AlTiCrMoN Protective Coatings for Metal Cutting Applications

Abstract

1. Introduction

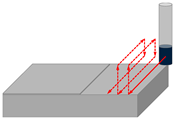

2. Experimental Details

3. Results and Discussion

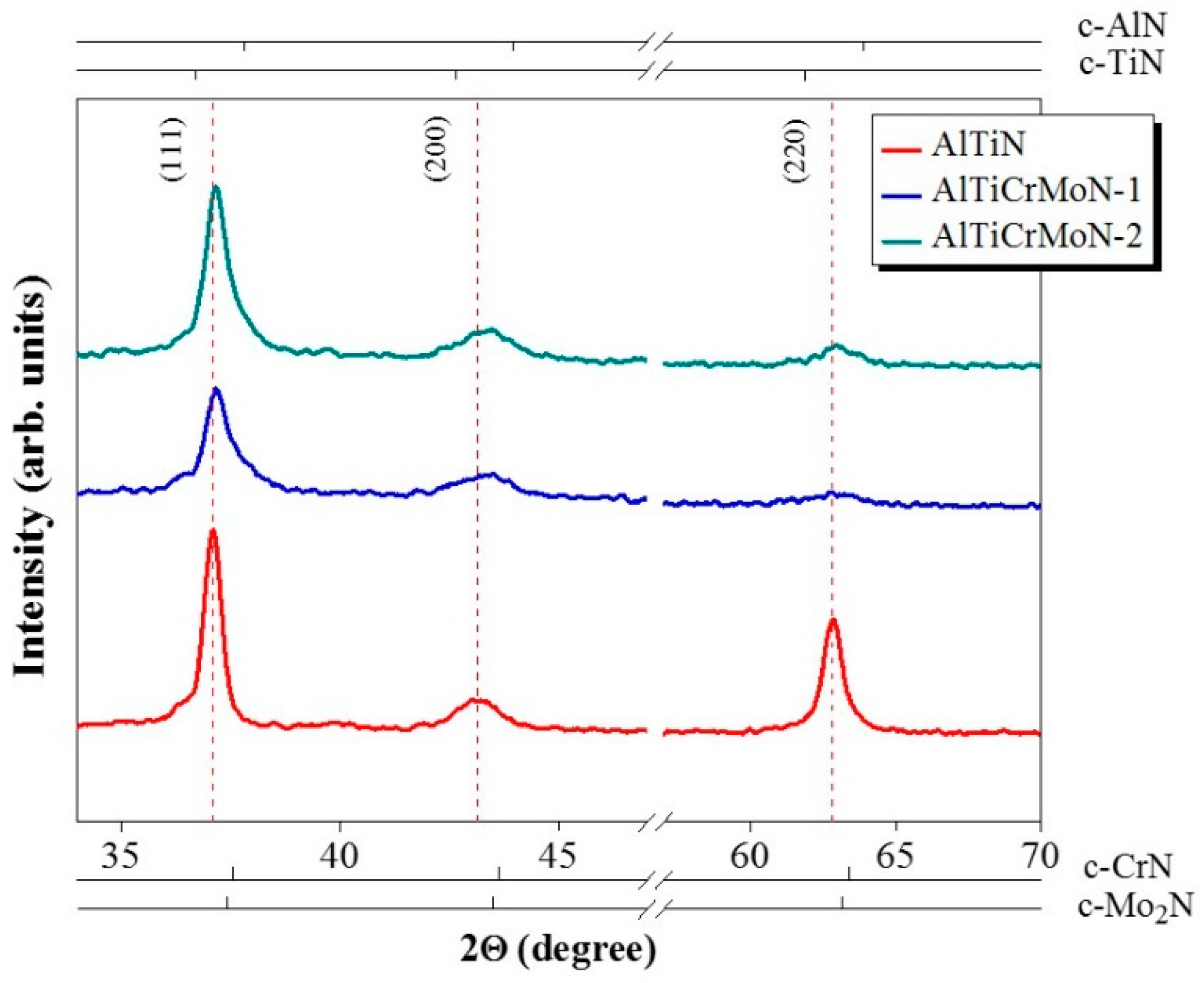

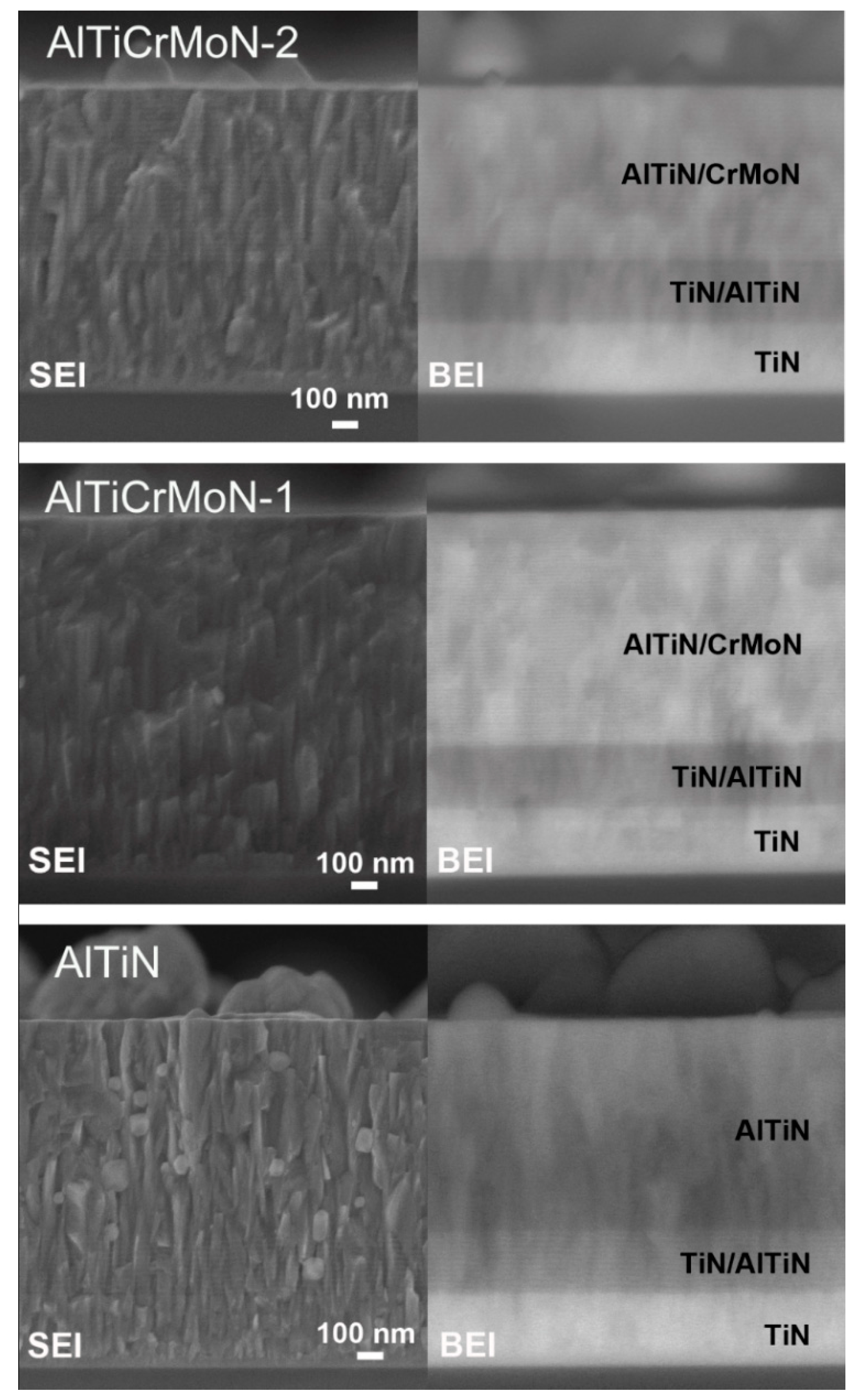

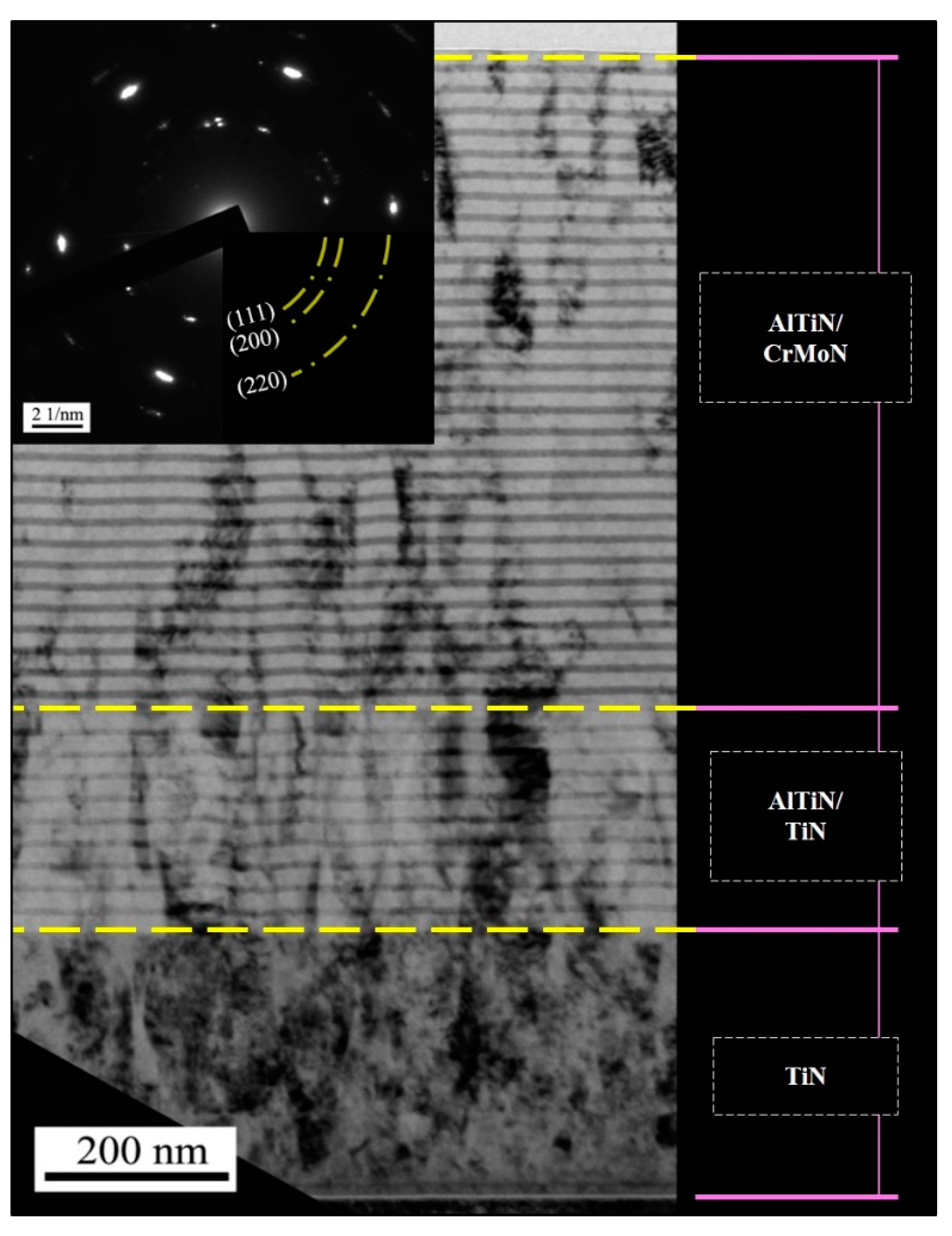

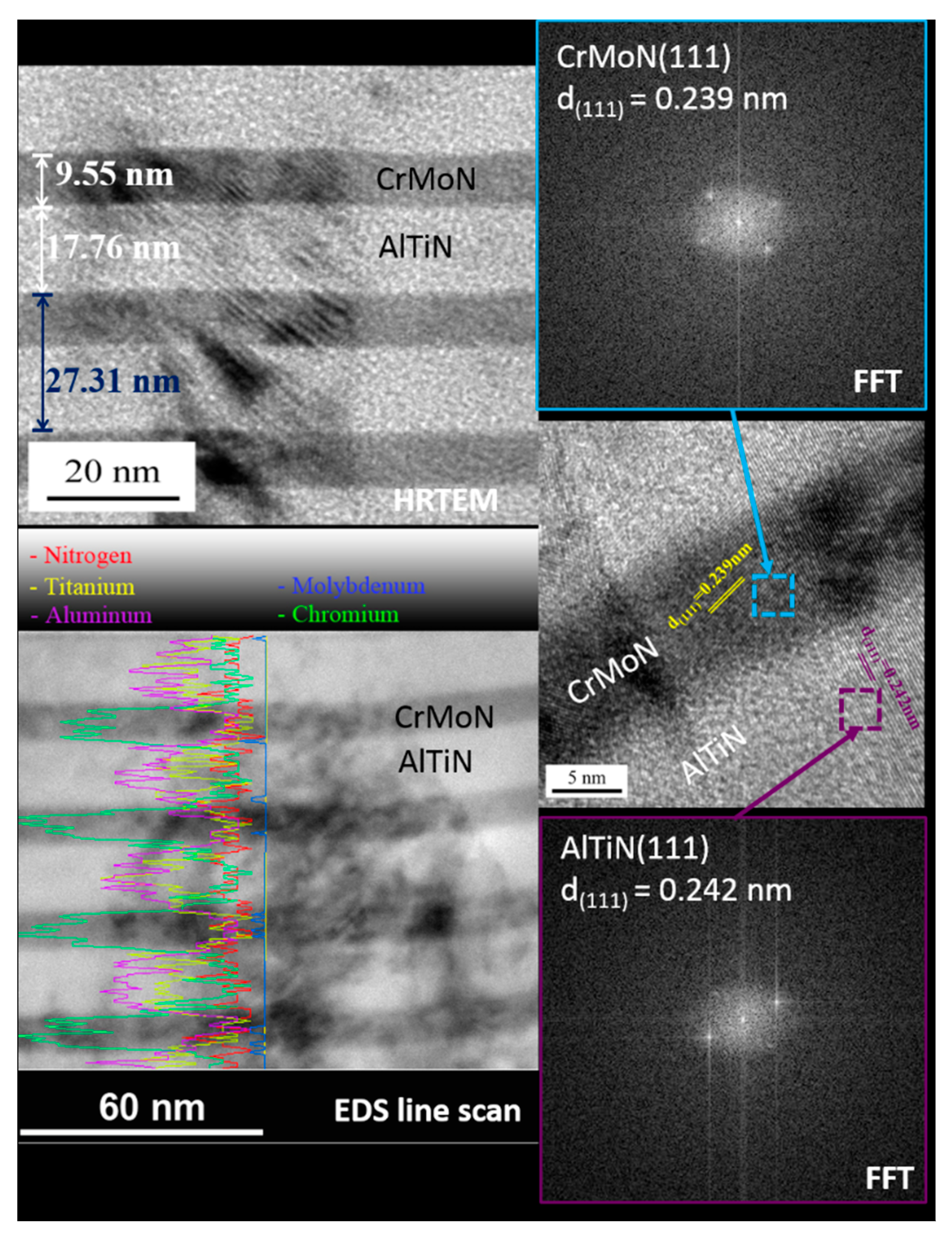

3.1. Microstructure Characterization of the Deposited Coatings

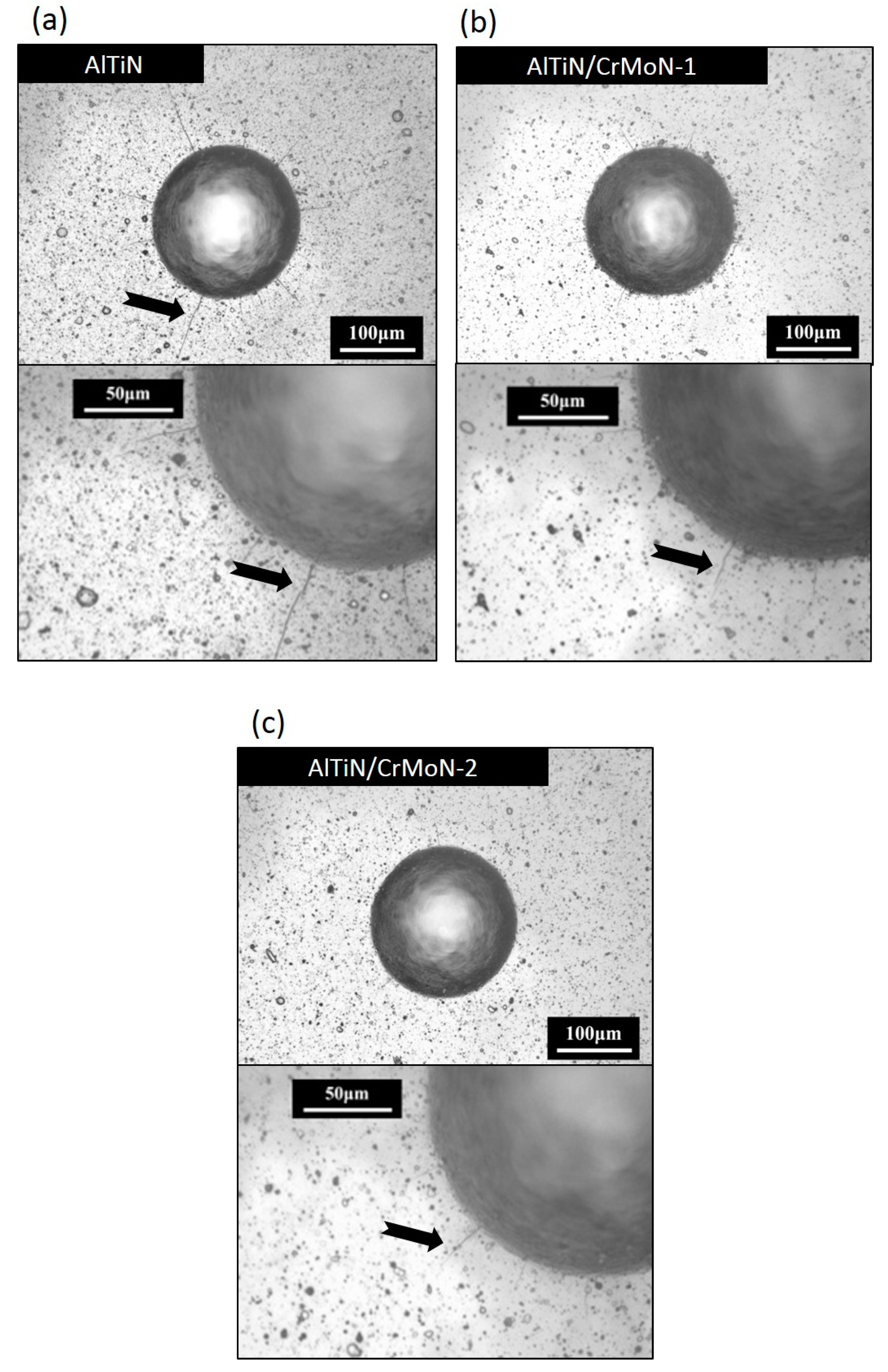

3.2. Mechanical Properties and Cutting Performances of the AlTiN, AlTiCrMoN-1 and AlTiCrMoN-2 Coatings

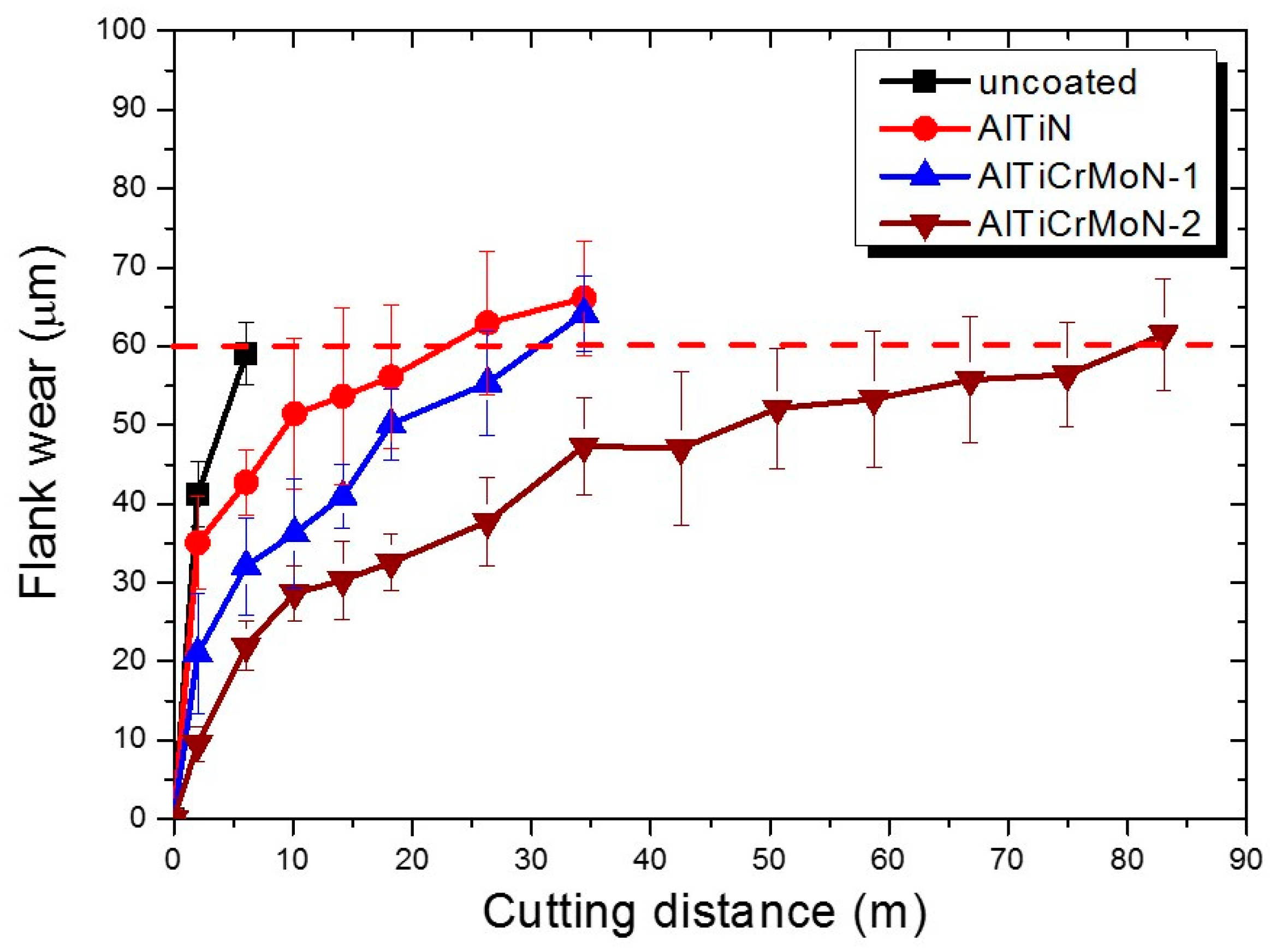

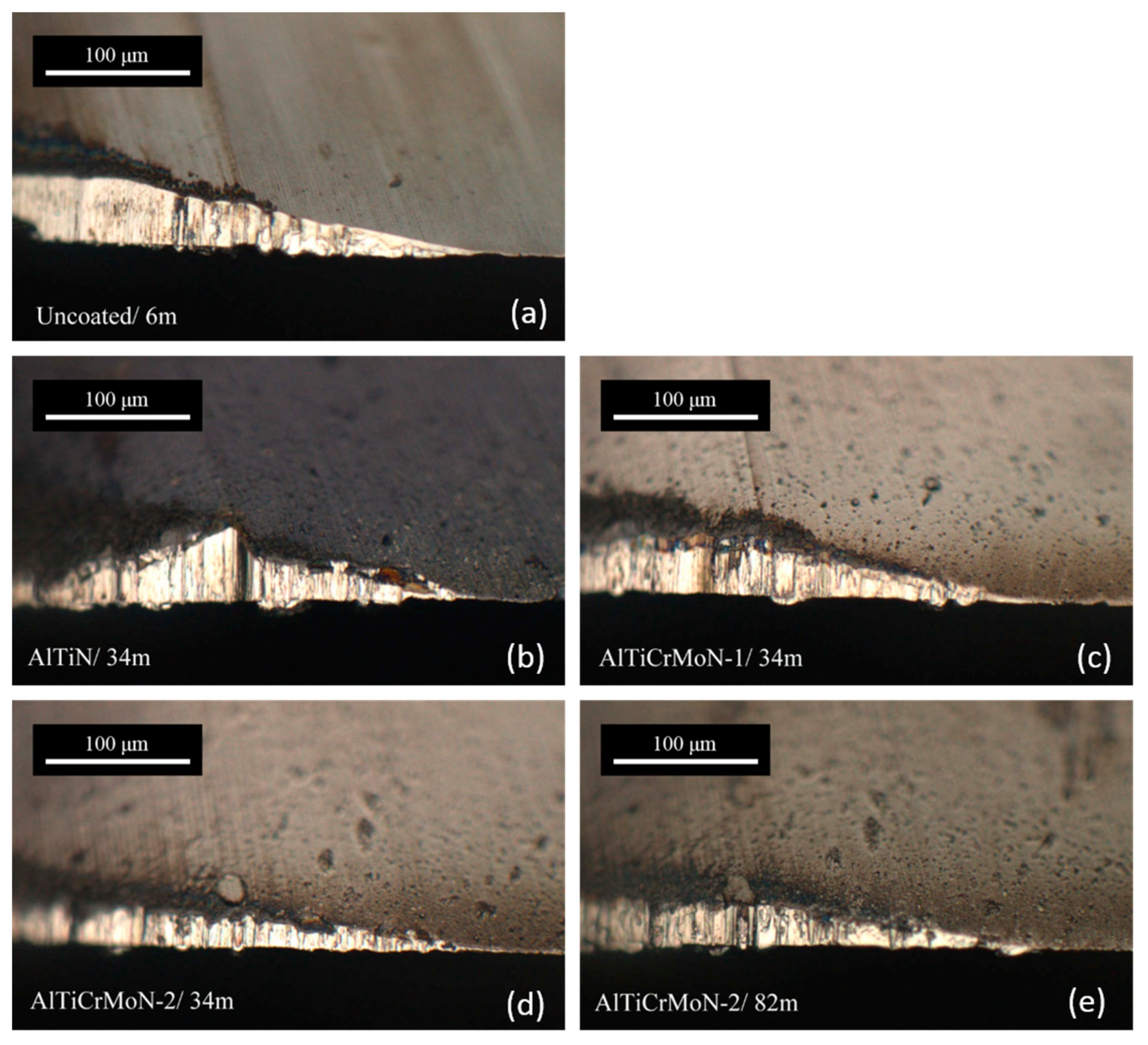

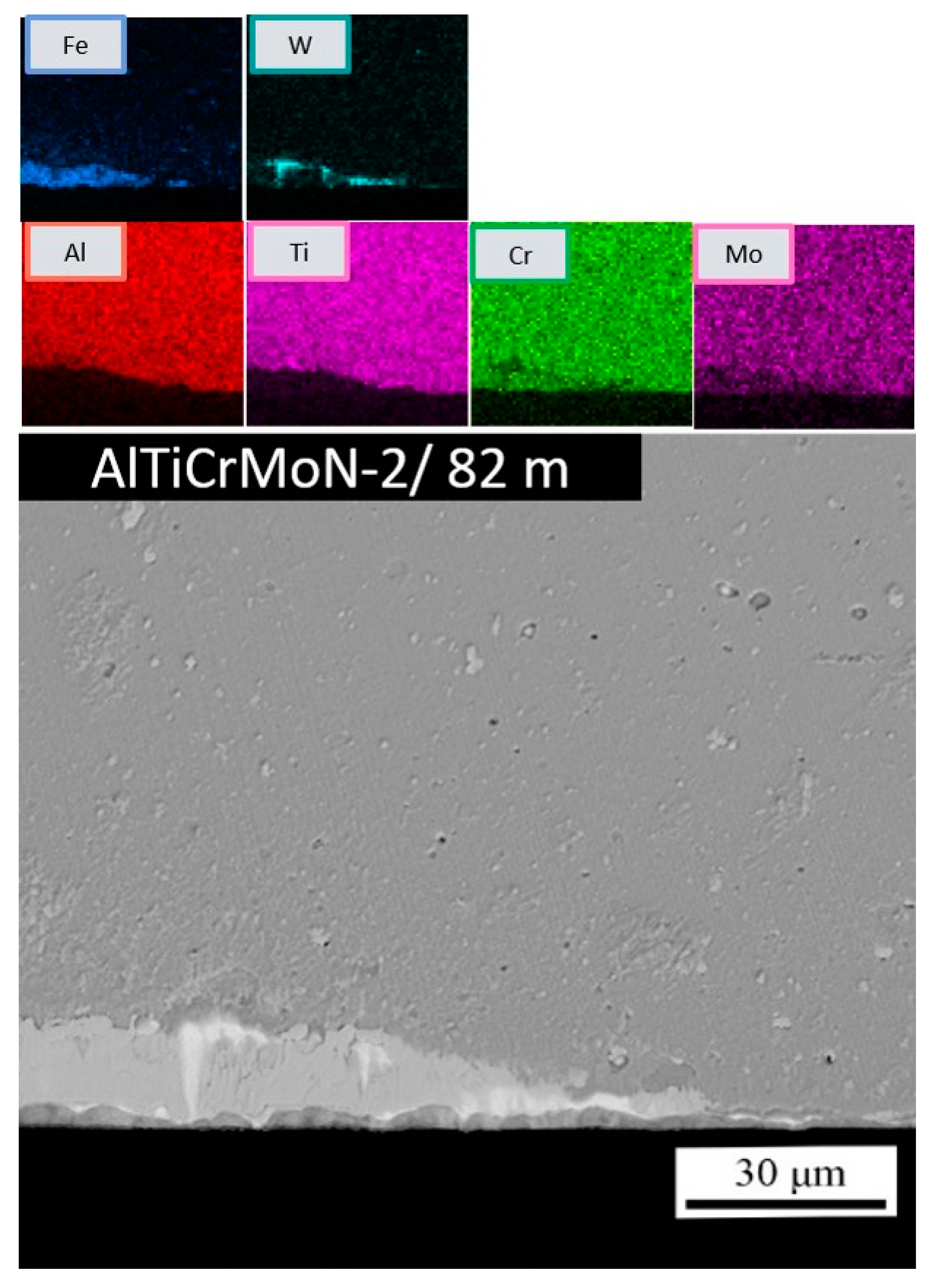

3.3. Comparison of the Cutting Performance of the End Mills Coated with the AlTiN, AlTiCrMoN-1 and AlTiCrMoN-2 Coatings

4. Conclusion

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- PalDey, S.; Deevi, S.C. Single layer and multilayer wear resistant coatings of (Ti,Al) N: A review. Mater. Sci. Eng. A 2003, 342, 58–79. [Google Scholar] [CrossRef]

- Elmkhah, H.; Zhang, T.F.; Abdollah-zadeh, A.; Kim, K.H.; Mahboubi, F. Surface characteristics for the TiAlN coatings deposited by high power impulse magnetron sputtering technique at the different bias voltages. J. Alloys Compd. 2016, 688, 820–827. [Google Scholar] [CrossRef]

- Cao, X.; He, W.; He, G.; Liao, B.; Zhang, H.; Chen, J.; Lv, C. Sand erosion resistance improvement and damage mechanism of TiAlN coating via the bias-graded voltage in FCVA deposition. Surf. Coat. Technol. 2019, 378, 125009. [Google Scholar] [CrossRef]

- Hao, G.; Liu, Z. Experimental study on the formation of TCR and thermal behavior of hard machining using TiAlN coated tools. Int. J. Heat Mass Transf. 2019, 140, 1–11. [Google Scholar] [CrossRef]

- Souza, P.S.; Santos, A.J.; Cotrim, M.A.P.; Abrão, A.M.; Câmara, M.A. Analysis of the surface energy interactions in the tribological behavior of ALCrN and TIAlN coatings. Tribol. Int. 2020, 146, 106206. [Google Scholar] [CrossRef]

- Mo, J.L.; Zhu, M.H.; Leyland, A.; Matthews, A. Impact wear and abrasion resistance of CrN, AlCrN and AlTiN PVD coatings. Surf. Coat. Technol. 2013, 215, 170–177. [Google Scholar] [CrossRef]

- Mo, J.L.; Zhu, M.H.; Lei, B.; Leng, Y.X.; Huang, N. Comparison of tribological behaviours of AlCrN and TiAlN coatings—Deposited by physical vapor deposition. Wear 2007, 263, 1423–1429. [Google Scholar] [CrossRef]

- Lee, S.-H.; Son, B.-S.; Park, G.-T.; Ryu, J.-S.; Lee, H. Investigation of short-term, high-temperature oxidation of AlCrN coating on WC substrate. Appl. Surf. Sci. 2020, 505, 144587. [Google Scholar] [CrossRef]

- Lin, J.; Moore, J.J.; Wang, J.; Sproul, W.D. High temperature oxidation behavior of CrN/AlN superlattice films. Thin Solid Films 2011, 519, 2402–2408. [Google Scholar] [CrossRef]

- Lin, J.; Mishra, B.; Moore, J.J.; Sproul, W.D. A study of the oxidation behavior of CrN and CrAlN thin films in air using DSC and TGA analyses. Surf. Coat. Technol. 2008, 202, 3272–3283. [Google Scholar] [CrossRef]

- Tang, J.-F.; Lin, C.-Y.; Yang, F.-C.; Tsai, Y.-J.; Chang, C.-L. Effects of nitrogen-argon flow ratio on the microstructural and mechanical properties of AlCrN coatings prepared using high power impulse magnetron sputtering. Surf. Coat. Technol. 2020, 386, 125484. [Google Scholar] [CrossRef]

- Singh, A.; Ghosh, S.; Aravindan, S. Investigation of oxidation behaviour of AlCrN and AlTiN coatings deposited by arc enhanced HIPIMS technique. Appl. Surf. Sci. 2020, 508, 144812. [Google Scholar] [CrossRef]

- Hones, P.; Consiglio, R.; Randall, N.; Lévy, F. Mechanical properties of hard chromium tungsten nitride coatings. Surf. Coat. Technol. 2000, 125, 179–184. [Google Scholar] [CrossRef]

- Yang, Q.; Zhao, L.R.; Patnaik, P. Erosion performance, corrosion characteristics and hydrophobicity of nanolayered and multilayered metal nitride coatings. Surf. Coat. Technol. 2019, 375, 763–772. [Google Scholar] [CrossRef]

- Postolnyi, B.O.; Beresnev, V.M.; Abadias, G.; Bondar, O.V.; Rebouta, L.; Araujo, J.P.; Pogrebnjak, A.D. Multilayer design of CrN/MoN protective coatings for enhanced hardness and toughness. J. Alloys Compd. 2017, 725, 1188–1198. [Google Scholar] [CrossRef]

- Yeh-Liu, L.-K.; Hsu, S.-Y.; Chen, P.-Y.; Lee, J.-W.; Duh, J.-G. Improvement of CrMoN/SiNx coatings on mechanical and high temperature Tribological properties through biomimetic laminated structure design. Surf. Coat. Technol. 2020, 393, 125754. [Google Scholar] [CrossRef]

- Lu, Y.-C.; Chen, H.-W.; Chang, C.-C.; Wu, C.-Y.; Duh, J.-G. Tribological properties of nanocomposite Cr-Mo-Si-N coatings at elevated temperature through silicon content modification. Surf. Coat. Technol. 2018, 338, 69–74. [Google Scholar] [CrossRef]

- Bobzin, K.; Brögelmann, T.; Kalscheuer, C. Arc PVD (Cr, Al, Mo)N and (Cr, Al, Cu)N coatings for mobility applications. Surf. Coat. Technol. 2020, 384, 125046. [Google Scholar] [CrossRef]

- Gilewicz, A.; Warcholinski, B. Deposition and characterisation of Mo2N/CrN multilayer coatings prepared by cathodic arc evaporation. Surf. Coat. Technol. 2015, 279, 126–133. [Google Scholar] [CrossRef]

- Yang, Q. Wear resistance and solid lubricity of molybdenum-containing nitride coatings deposited by cathodic arc evaporation. Surf. Coat. Technol. 2017, 332, 283–295. [Google Scholar] [CrossRef]

- Klimashin, F.; Riedl, H.; Primetzhofer, D.; Paulitsch, J.; Mayrhofer, P.H. Composition driven phase evolution and mechanical properties of Mo-Cr-N hard coatings. J. Appl. Phys. 2015, 118, 025305. [Google Scholar] [CrossRef]

- Choi, E.Y.; Kang, M.C.; Kwon, D.H.; Shin, D.W.; Kim, K.H. Comparative studies on microstructure and mechanical properties of CrN, Cr-C-N and Cr-Mo-N coatings. J. Mater. Process. Technol. 2007, 187–188, 566–570. [Google Scholar] [CrossRef]

- Zha, X.; Chen, F.; Jiang, F.; Xu, X. Correlation of the fatigue impact resistance of bilayer and nanolayered PVD coatings with their cutting performance in machining Ti6Al4V. Ceram. Int. 2019, 45, 14704–14717. [Google Scholar] [CrossRef]

- Vereschaka, A.A.; Grigoriev, S.N.; Sitnikov, N.N.; Batako, A.D. Delamination and longitudinal cracking in multi-layered composite nano-structured coatings and their influence on cutting tool life. Wear 2017, 390–391, 209–219. [Google Scholar] [CrossRef]

- Shuai, J.; Zuo, X.; Wang, Z.; Guo, P.; Xu, B.; Zhou, J.; Wang, A.; Ke, P. Comparative study on crack resistance of TiAlN monolithic and Ti/TiAlN multilayer coatings. Ceram. Int. 2020, 46, 6672–6681. [Google Scholar] [CrossRef]

- Chang, Y.-Y.; Yang, Y.-J.; Weng, S.-Y. Effect of interlayer design on the mechanical properties of AlTiCrN and multilayered AlTiCrN/TiSiN hard coatings. Surf. Coat. Technol. 2020, 389, 125637. [Google Scholar] [CrossRef]

- Chang, Y.-Y.; Wu, C.-J. Mechanical properties and impact resistance of multilayered TiAlN/ZrN coatings. Surf. Coat. Technol. 2013, 231, 62–66. [Google Scholar] [CrossRef]

- Qiu, L.; Du, Y.; Wu, L.; Wang, S.; Zhu, J.; Cheng, W.; Tan, Z.; Yin, L.; Liu, Z.; Layyous, A. Microstructure, mechanical properties and cutting performances of TiSiCN super-hard nanocomposite coatings deposited using CVD method under the guidance of thermodynamic calculations. Surf. Coat. Technol. 2019, 378, 124956. [Google Scholar] [CrossRef]

- Vereschaka, A.A.; Grigoriev, S.N.; Sitnikov, N.N.; Oganyan, G.V.; Batako, A. Working efficiency of cutting tools with multilayer nano-structured Ti-TiCN-(Ti,Al)CN and Ti-TiCN-(Ti,Al,Cr)CN coatings: Analysis of cutting properties, wear mechanism and diffusion processes. Surf. Coat. Technol. 2017, 332, 198–213. [Google Scholar] [CrossRef]

- Sanchette, F.; Ducros, C.; Schmitt, T.; Steyer, P.; Billard, A. Nanostructured hard coatings deposited by cathodic arc deposition: From concepts to applications. Surf. Coat. Technol. 2011, 205, 5444–5453. [Google Scholar] [CrossRef]

- Deng, Y.; Chen, W.; Li, B.; Wang, C.; Kuang, T.; Li, Y. Physical vapor deposition technology for coated cutting tools: A review. Ceram. Int. 2020, 46, 18373–18390. [Google Scholar] [CrossRef]

- Sanders, D.M.; Anders, A. Review of cathodic arc deposition technology at the start of the new millennium. Surf. Coat. Technol. 2000, 133–134, 78–90. [Google Scholar] [CrossRef]

- Kutschej, K.; Mayrhofer, P.H.; Kathrein, M.; Polcik, P.; Tessadri, R.; Mitterer, C. Structure, mechanical and tribological properties of sputtered Ti1–xAlxN coatings with 0.5 ≤ x ≤ 0.75. Surf. Coat. Technol. 2005, 200, 2358–2365. [Google Scholar] [CrossRef]

- Chang, Y.-Y.; Wang, D.-Y. Characterization of nanocrystalline AlTiN coatings synthesized by a cathodic-arc deposition process. Surf. Coat. Technol. 2007, 201, 6699–6701. [Google Scholar] [CrossRef]

- Chang, Y.-Y.; Chang, C.-P.; Kao, H.-Y. High temperature oxidation resistance of multilayered AlxTi1−xN/CrN coatings. Thin Solid Films 2011, 519, 6716–6720. [Google Scholar] [CrossRef]

- Gao, B.; Du, X.; Li, Y.; Wei, S.; Zhu, X.; Song, Z. Effect of deposition temperature on hydrophobic CrN/AlTiN nanolaminate composites deposited by Multi-Arc-Ion Plating. J. Alloys Compd. 2019, 797, 1–9. [Google Scholar] [CrossRef]

- Mo, J.; Wu, Z.; Yao, Y.; Zhang, Q.; Wang, Q. Influence of Y-addition and multilayer modulation on microstructure, oxidation resistance and corrosion behavior of Al0.67Ti0.33N coatings. Surf. Coat. Technol. 2018, 342, 129–136. [Google Scholar] [CrossRef]

- Yang, Q.; McKellar, R. Nanolayered CrAlTiN and multilayered CrAlTiN–AlTiN coatings for solid particle erosion protection. Tribol. Int. 2015, 83, 12–20. [Google Scholar] [CrossRef]

- Liu, Z.R.; Xu, Y.X.; Peng, B.; Wei, W.; Chen, L.; Wang, Q. Structure and property optimization of Ni-containing AlCrSiN coatings by nano-multilayer construction. J. Alloys Compd. 2019, 808, 151630. [Google Scholar] [CrossRef]

- Zhang, Q.; Wu, Z.; Xu, Y.X.; Wang, Q.; Chen, L.; Kim, K.H. Improving the mechanical and anti-wear properties of AlTiN coatings by the hybrid arc and sputtering deposition. Surf. Coat. Technol. 2019, 378, 125022. [Google Scholar] [CrossRef]

- Wang, L.; Wang, M.; Chen, H. Corrosion mechanism investigation of TiAlN/CrN superlattice coating by multi-arc ion plating in 3.5 wt% NaCl solution. Surf. Coat. Technol. 2020, 391, 125660. [Google Scholar] [CrossRef]

- Sadeghi-Khosravieh, S.; Robbie, K. Morphology and crystal texture in tilted columnar micro-structured titanium thin film coatings. Thin Solid Films 2017, 627, 69–76. [Google Scholar] [CrossRef]

- von Fieandt, K.; Riekehr, L.; Osinger, B.; Fritze, S.; Lewin, E. Influence of N content on structure and mechanical properties of multi-component Al-Cr-Nb-Y-Zr based thin films by reactive magnetron sputtering. Surf. Coat. Technol. 2020, 389, 125614. [Google Scholar] [CrossRef]

- Chen, L.; Xu, Y.X.; Du, Y.; Liu, Y. Effect of bilayer period on structure, mechanical and thermal properties of TiAlN/AlTiN multilayer coatings. Thin Solid Films 2015, 592, 207–214. [Google Scholar] [CrossRef]

- Tillmann, W.; Fehr, A.; Stangier, D.; Dildrop, M. Influences of substrate pretreatments and Ti/Cr interlayers on the adhesion and hardness of CrAlSiN and TiAlSiN films deposited on Al2O3 and ZrO2-8Y2O3 thermal barrier coatings. Results Phys. 2019, 12, 2206–2212. [Google Scholar] [CrossRef]

- Du, H.; Zhao, H.; Xiong, J.; Xian, G. Effect of interlayers on the structure and properties of TiAlN based coatings on WC-Co cemented carbide substrate. Int. J. Refract. Met. Hard Mater. 2013, 37, 60–66. [Google Scholar] [CrossRef]

- Xu, Y.X.; Chen, L.; Pei, F.; Du, Y. Structure and thermal properties of TiAlN/CrN multilayered coatings with various modulation ratios. Surf. Coat. Technol. 2016, 304, 512–518. [Google Scholar] [CrossRef]

- Chang, Y.-Y.; Chang, C.-P. Microstructural and mechanical properties of graded and multilayered AlxTi1-xN/CrN coatings synthesized by a cathodic-arc deposition process. Surf. Coat. Technol. 2009, 204, 1030–1034. [Google Scholar] [CrossRef]

- Yashar, P.C.; Sproul, W.D. Nanometer scale multilayered hard coatings. Vacuum 1999, 55, 179–190. [Google Scholar] [CrossRef]

- Ziebert, C.; Stüber, M.; Leiste, H.; Ulrich, S.; Holleck, H. Nanoscale PVD Multilayer Coatings. In Encyclopedia of Materials: Science and Technology; Buschow, K.H.J., Cahn, R.W., Flemings, M.C., Ilschner, B., Kramer, E.J., Mahajan, S., Veyssière, P., Eds.; Elsevier: Oxford, UK, 2011; pp. 1–8. [Google Scholar]

- Lin, Y.-W.; Chih, P.-C.; Huang, J.-H. Effect of Ti interlayer thickness on mechanical properties and wear resistance of TiZrN coatings on AISI D2 steel. Surf. Coat. Technol. 2020, 394, 125690. [Google Scholar] [CrossRef]

- Sprute, T.; Tillmann, W.; Grisales, D.; Selvadurai, U.; Fischer, G. Influence of substrate pre-treatments on residual stresses and tribo-mechanical properties of TiAlN-based PVD coatings. Surf. Coat. Technol. 2014, 260, 369–379. [Google Scholar] [CrossRef]

- Wang, Q.; Zhou, F.; Zhou, Z.; Li, L.K.-Y.; Yan, J. An investigation on the crack resistance of CrN, CrBN and CrTiBN coatings via nanoindentation. Vacuum 2017, 145, 186–193. [Google Scholar] [CrossRef]

- Musil, J.; Kunc, F.; Zeman, H.; Poláková, H. Relationships between hardness, Young’s modulus and elastic recovery in hard nanocomposite coatings. Surf. Coat. Technol. 2002, 154, 304–313. [Google Scholar] [CrossRef]

- Leyland, A.; Matthews, A. On the significance of the H/E ratio in wear control: A nanocomposite coating approach to optimised tribological behaviour. Wear 2000, 246, 1–11. [Google Scholar] [CrossRef]

- Musil, J. Hard nanocomposite coatings: Thermal stability, oxidation resistance and toughness. Surf. Coat. Technol. 2012, 207, 50–65. [Google Scholar] [CrossRef]

- Ou, Y.X.; Ouyang, X.P.; Liao, B.; Zhang, X.; Zhang, S. Hard yet tough CrN/Si3N4 multilayer coatings deposited by the combined deep oscillation magnetron sputtering and pulsed dc magnetron sputtering. Appl. Surf. Sci. 2020, 502, 144168. [Google Scholar] [CrossRef]

- Zhang, K.; Guo, X.; Sun, L.; Meng, X.; Xing, Y. Fabrication of coated tool with femtosecond laser pretreatment and its cutting performance in dry machining SLM-produced stainless steel. J. Manuf. Process. 2019, 42, 28–40. [Google Scholar] [CrossRef]

- Endrino, J.L.; Fox-Rabinovich, G.S.; Gey, C. Hard AlTiN, AlCrN PVD coatings for machining of austenitic stainless steel. Surf. Coat. Technol. 2006, 200, 6840–6845. [Google Scholar] [CrossRef]

- Lai, Z.; Wang, C.; Zheng, L.; Huang, W.; Yang, J.; Guo, G.; Xiong, W. Adaptability of AlTiN-based coated tools with green cutting technologies in sustainable machining of 316L stainless steel. Tribol. Int. 2020, 148, 106300. [Google Scholar] [CrossRef]

- Zhang, K.; Deng, J.; Sun, J.; Jiang, C.; Liu, Y.; Chen, S. Effect of micro/nano-scale textures on anti-adhesive wear properties of WC/Co-based TiAlN coated tools in AISI 316 austenitic stainless steel cutting. Appl. Surf. Sci. 2015, 355, 602–614. [Google Scholar] [CrossRef]

- Wang, T.; Zhang, J.; Li, Y.; Gao, F.; Zhang, G. Self-lubricating TiN/MoN and TiAlN/MoN nano-multilayer coatings for drilling of austenitic stainless steel. Ceram. Int. 2019, 45, 24248–24253. [Google Scholar] [CrossRef]

- Beake, B.D.; Ning, L.; Gey, C.; Veldhuis, S.C.; Komarov, A.; Weaver, A.; Khanna, M.; Fox-Rabinovich, G.S. Wear performance of different PVD coatings during hard wet end milling of H13 tool steel. Surf. Coat. Technol. 2015, 279, 118–125. [Google Scholar] [CrossRef]

- Varghese, V.; Chakradhar, D.; Ramesh, M.R. Micro-mechanical characterization and wear performance of TiAlN/NbN PVD coated carbide inserts during End milling of AISI 304 Austenitic Stainless Steel. Mater. Today Proc. 2018, 5, 12855–12862. [Google Scholar] [CrossRef]

- Bag, R.; Panda, A.; Sahoo, A.K.; Kumar, R. Cutting tools characteristics and coating depositions for hard part turning of AISI 4340 martensitic steel: A review study. Mater. Today Proc. 2020, 26, 2073–2078. [Google Scholar] [CrossRef]

- Li, G.; Li, L.; Han, M.; Luo, S.; Jin, J.; Wang, L.; Gu, J.; Miao, H.J.M. The performance of TiAlSiN coated cemented carbide tools enhanced by inserting Ti interlayers. Metals 2019, 9, 918. [Google Scholar] [CrossRef]

| Parameters | Value |

|---|---|

| Rotational speed, N (rpm) | 9000 |

| Cutting speed, V (m/min) | 226.19 |

| Feed rate, fz (mm/tooth) | 0.0138 |

| Axial depth of cut, ap (mm) | 0.17 |

| Radial depth of cut, ae (mm) | 3 |

| Coatings | Al(at %) | Ti(at %) | Cr(at %) | Mo(at %) | N(at %) |

|---|---|---|---|---|---|

| AlTiN | 30.06 | 17.74 | – | – | 52.2 |

| AlTiCrMoN-1 | 14.79 | 8.77 | 23.17 | 3.99 | 49.28 |

| AlTiCrMoN-2 | 19.01 | 13.47 | 14.81 | 2.32 | 50.39 |

| Coatings | Hardness (GPa) | Young’s Modulus (GPa) | H/E* | H3/E*2 |

|---|---|---|---|---|

| AlTiN | 35.6 ± 1.5 | 565.0 ± 37.9 | 0.059 ± 0.007 | 0.124 ± 0.037 |

| AlTiCrMoN-1 | 29.4 ± 0.2 | 404.8 ± 45.8 | 0.068 ± 0.009 | 0.137 ± 0.040 |

| AlTiCrMoN-2 | 32.0 ± 1.5 | 428.6 ± 41.2 | 0.071 ± 0.011 | 0.157 ± 0.064 |

| Coating | Deposition Method | Cutting Performance | Reference |

|---|---|---|---|

| TiAlN | Physical vapor deposition (PVD) with the selective laser melting (SLM) technique | Decrease of 10–20% in cutting forces, a decrease of 10–15% in cutting temperature and a high surface quality of the machined workpieces at the high cutting speed. | [54] |

| AlTiN | Cathodic arc vapor deposition technique | The nano-crystalline AlTiN coating outperformed the traditional AlTiN coating that almost doubled the tool life due to the reduction of the sticking of the stainless steel to the tool’s surface. | [55] |

| AlTiN AlTiCrN AlTiSiN | Cathodic arc vapor deposition technique | Effectively resists thermal shock and severe abrasive wear at the tool–chip interface due to the high H3/E2 ratio. | [56] |

| TiAlN | Cathodic arc vapor deposition with laser irradiation technique | The anti-adhesive wear properties of laser textured TiAlN coated tool were significantly improved over that of the conventional TiAlN. | [57] |

| TiN/MoN (Multilayer) | Magnetron sputtering | The numbers of drilling holes the coated drills were 4.2 times larger than that of uncoated high speed steel (HSS) drills. Adhesive friction and the formation of the build-up edge was avoided. | [58] |

| AlTiN/CrMoN (Multilayer) | Cathodic arc vapor deposition technique | The nanolayered AlTiCrMoN-2 coated tools outperformed the AlTiN that had a tool life 3.6 times longer than that of AlTiN. And it possessed the best cutting performance. | This study |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chang, Y.-Y.; Chuang, C.-C. Deposition of Multicomponent AlTiCrMoN Protective Coatings for Metal Cutting Applications. Coatings 2020, 10, 605. https://doi.org/10.3390/coatings10070605

Chang Y-Y, Chuang C-C. Deposition of Multicomponent AlTiCrMoN Protective Coatings for Metal Cutting Applications. Coatings. 2020; 10(7):605. https://doi.org/10.3390/coatings10070605

Chicago/Turabian StyleChang, Yin-Yu, and Chih-Cheng Chuang. 2020. "Deposition of Multicomponent AlTiCrMoN Protective Coatings for Metal Cutting Applications" Coatings 10, no. 7: 605. https://doi.org/10.3390/coatings10070605

APA StyleChang, Y.-Y., & Chuang, C.-C. (2020). Deposition of Multicomponent AlTiCrMoN Protective Coatings for Metal Cutting Applications. Coatings, 10(7), 605. https://doi.org/10.3390/coatings10070605