Microstructure Evolution and Mechanical Behavior of Mo–Si–N Films

Abstract

1. Introduction

2. Materials and Methods

3. Results and Discussion

3.1. Chemical Composition

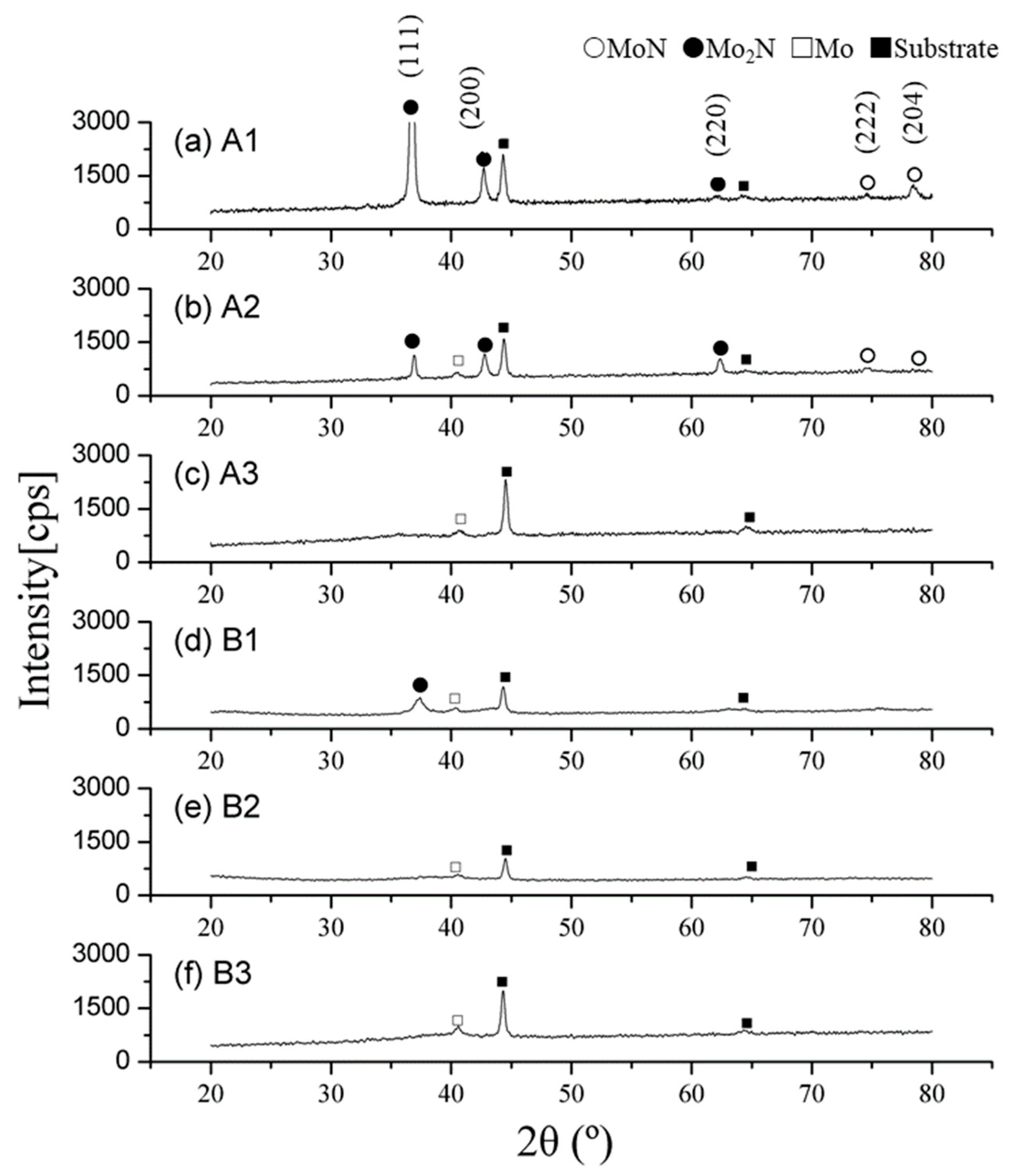

3.2. Phase Identification

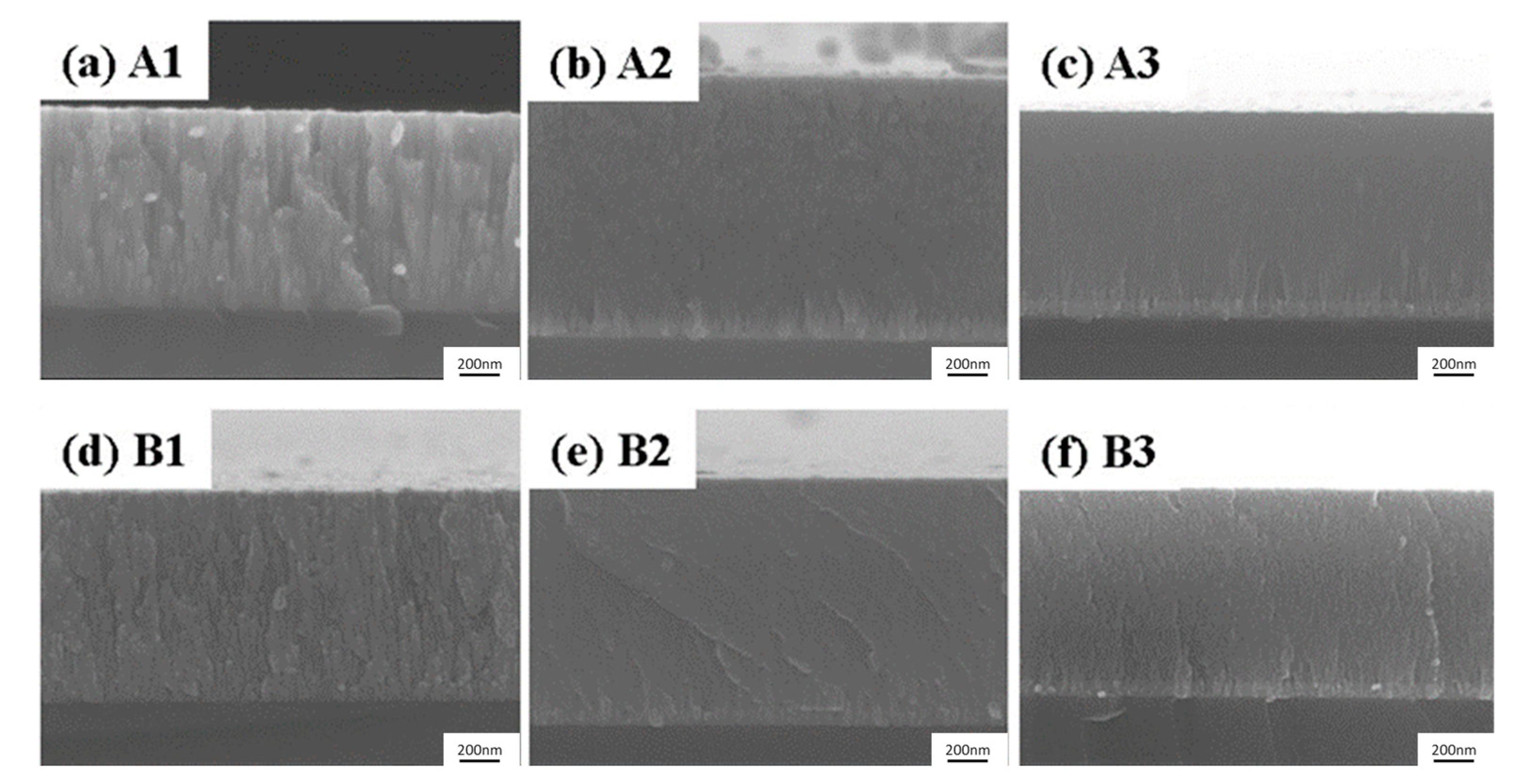

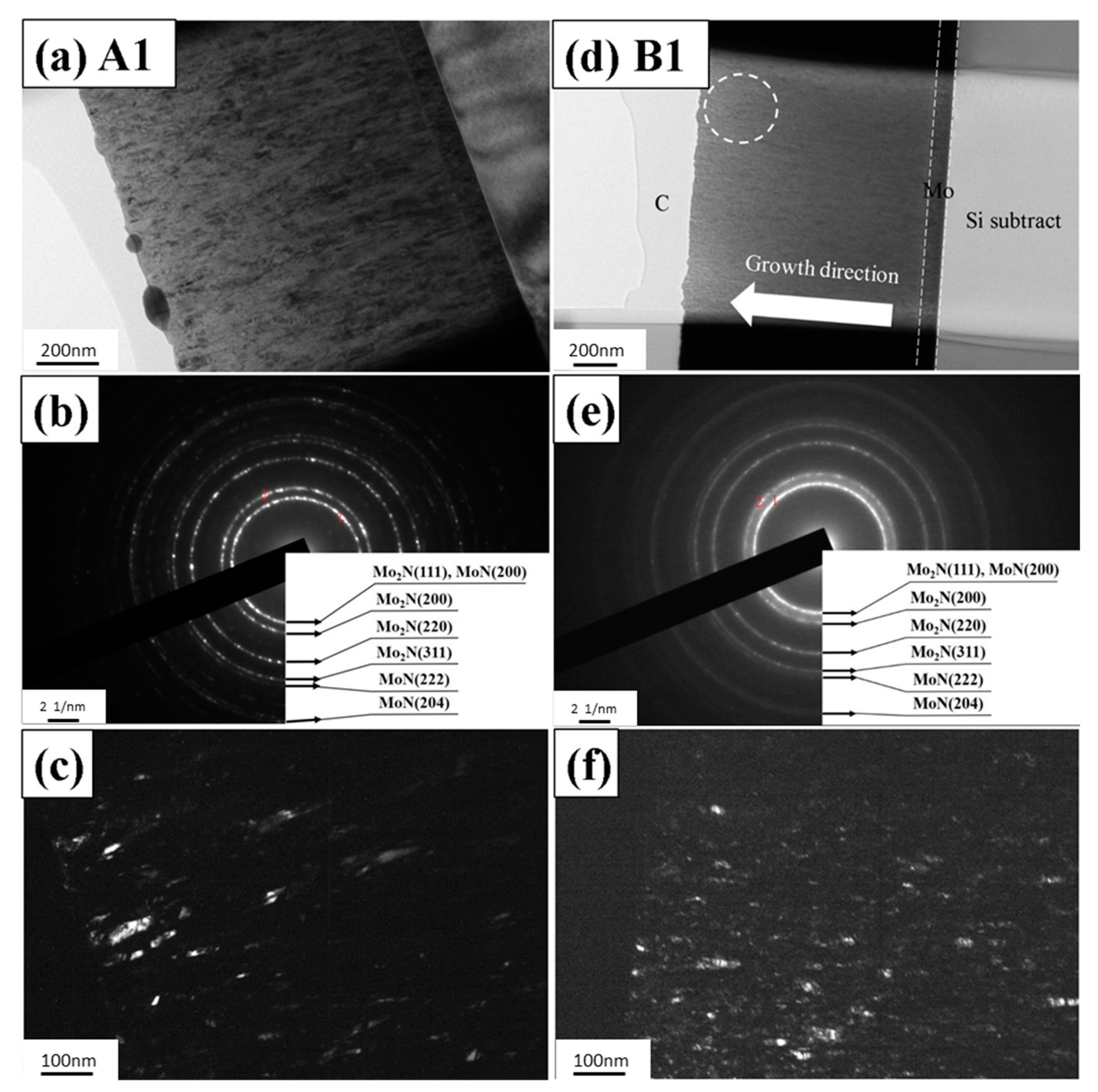

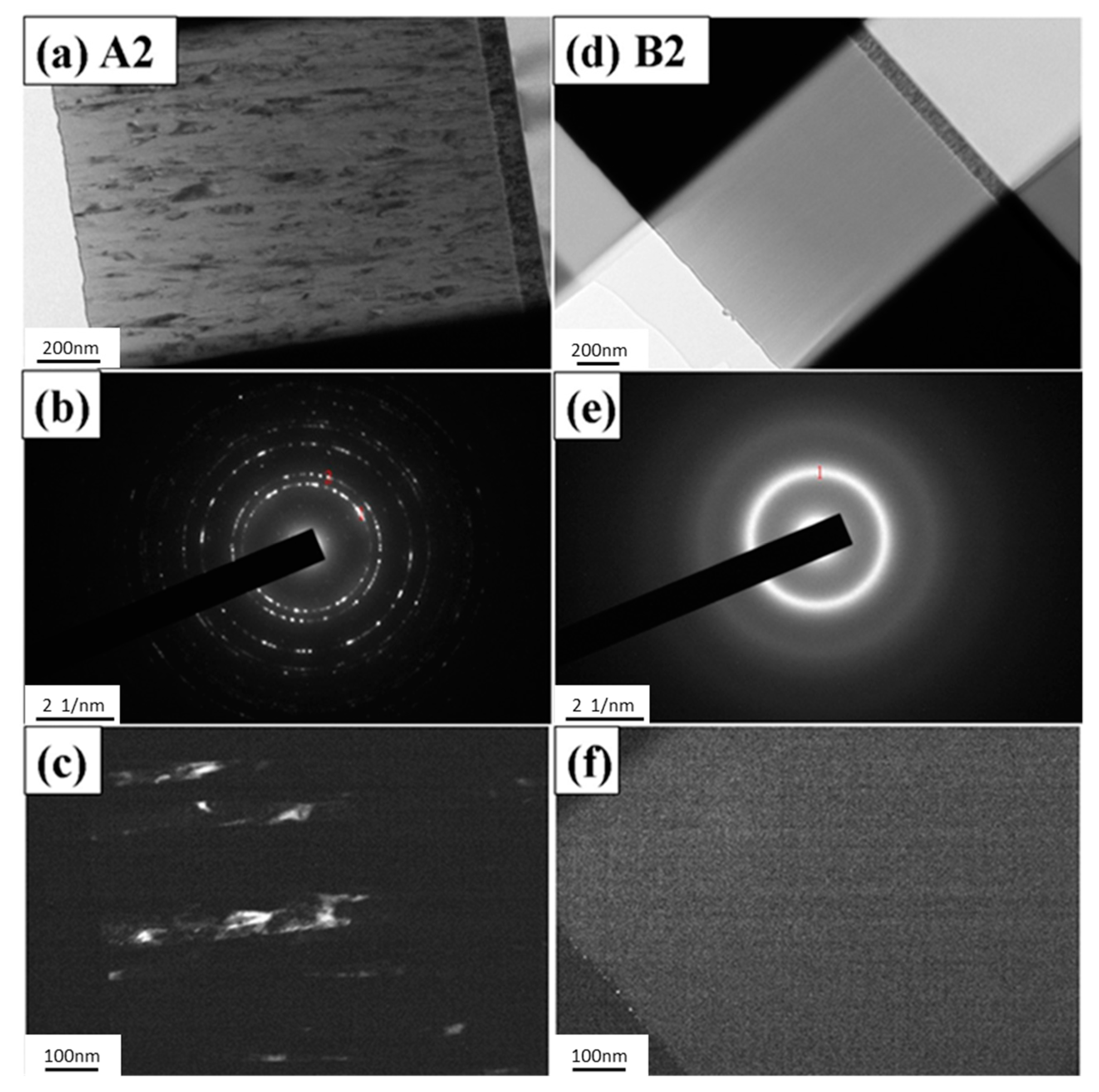

3.3. Microstructure

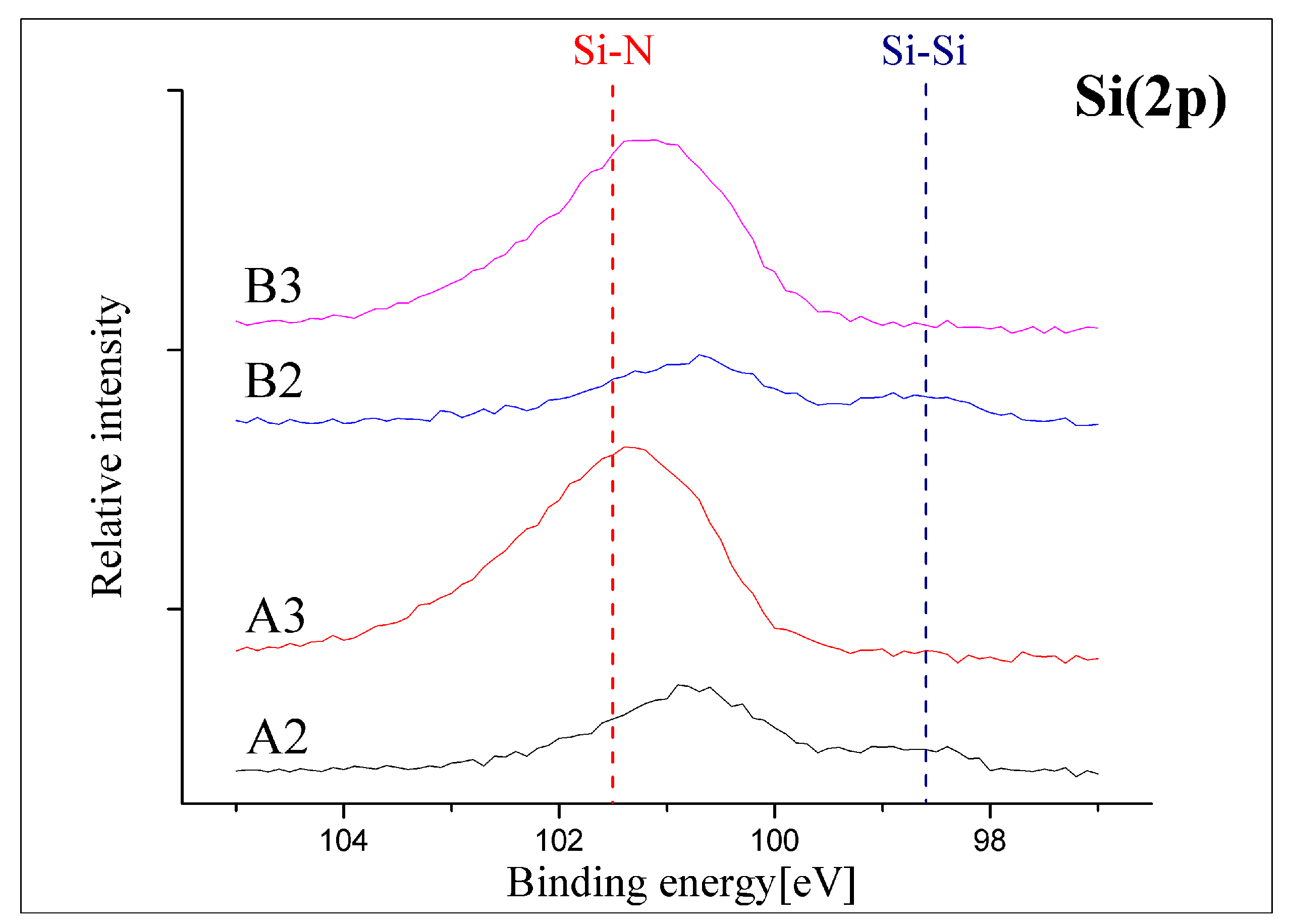

3.4. Chemical Bondings

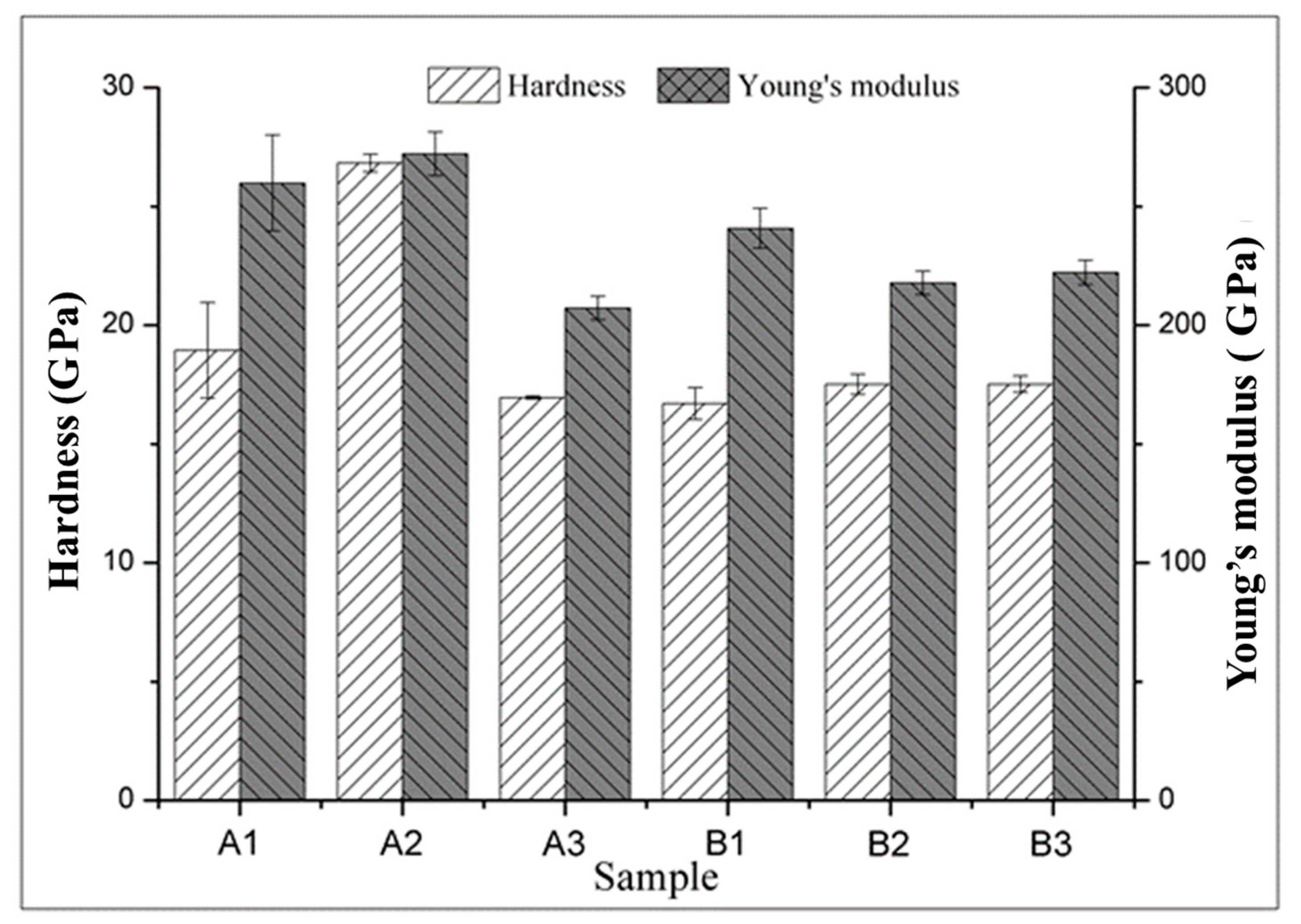

3.5. Surface Hardness and Elastic Modulus

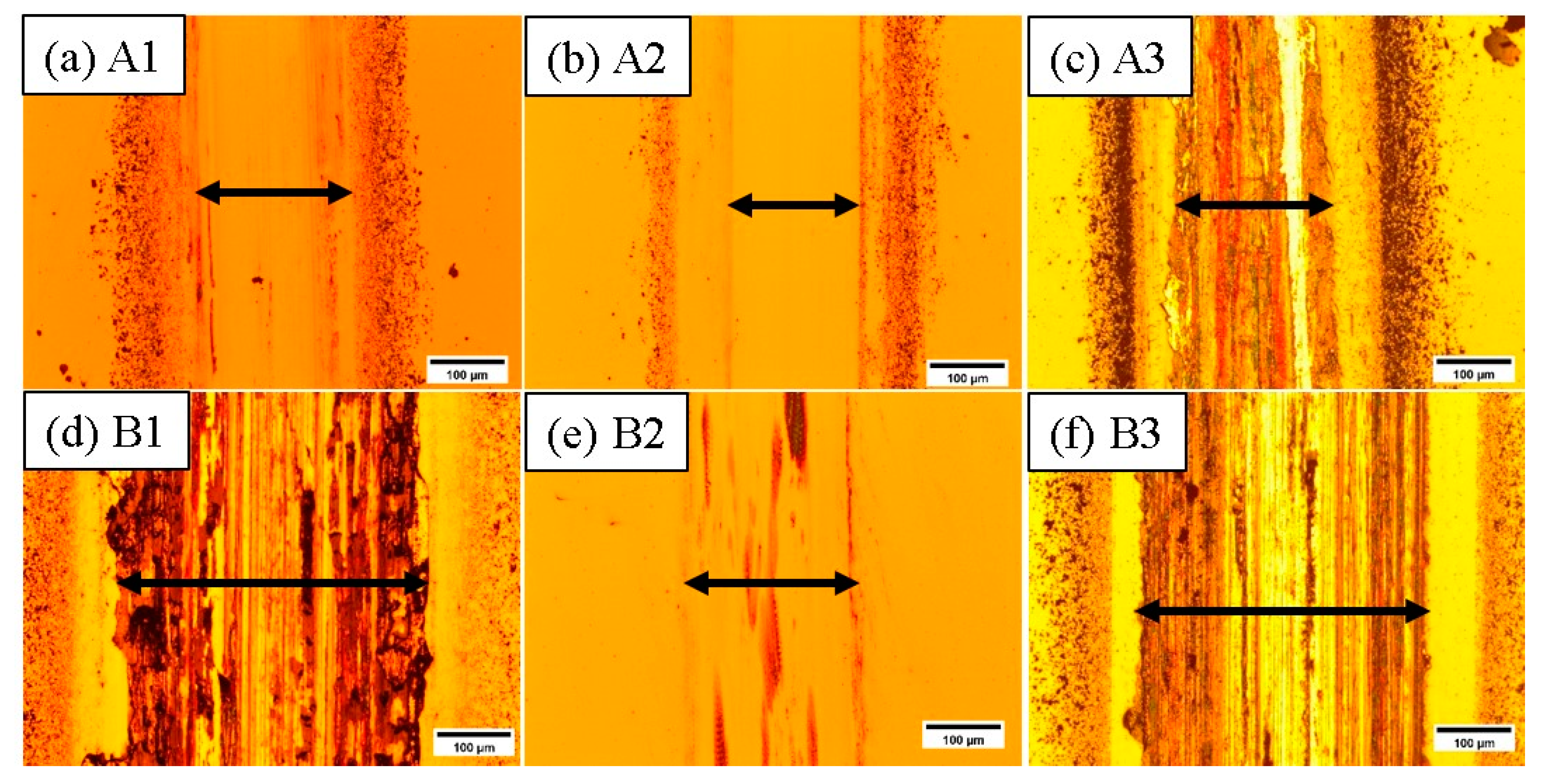

3.6. Wear Resistance Behavior

4. Summary

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Chen, L.; Moser, M.; Du, Y.; Mayrhofer, P.H. Compositional and structural evolution of sputtered Ti–Al–N. Thin Solid Films 2009, 517, 6635–6841. [Google Scholar] [CrossRef]

- Tan, S.; Zhang, X.; Wu, X.; Fang, F.; Jiang, J. Effect of substrate bias and temperature on magnetron sputtered CrSiN films. Appl. Surf. Sci. 2011, 257, 1850–1853. [Google Scholar] [CrossRef]

- Chen, L.; Du, Y.; Mayrhofer, P.H.; Wang, S.Q.; Li, J. The influence of age-hardening on turning and milling performance of Ti–Al–N coated inserts. Surf. Coat. Technol. 2008, 202, 5158–5161. [Google Scholar] [CrossRef]

- Heo, S.J.; Kim, K.H.; Kang, M.C.J.; Suh, H.; Park, C.G. Syntheses and mechanical properties of Mo–Si–N coatings by a hybrid coating system. Surf. Coat. Technol. 2006, 201, 4180–4184. [Google Scholar] [CrossRef]

- Sundgren, J.E. Structure and properties of TiN coatings. Thin Solid Films 1985, 128, 21–44. [Google Scholar] [CrossRef]

- Lee, S.C.; Ho, W.Y.; Lai, F.D. Effect of substrate surface roughness on the characteristics of CrN hard film. Mater. Chem. Phys. 1996, 43, 266–273. [Google Scholar] [CrossRef]

- Liu, K.Y.; Lee, J.W.; Wu, F.B. Fabrication and tribological behavior of sputtering TaN coatings. Surf. Coat. Technol. 2014, 259, 123–128. [Google Scholar] [CrossRef]

- Kazmanli, M.K.; Ürgen, M.; Cakir, A.F. Effect of nitrogen pressure, bias voltage and substrate temperature on the phase structure of Mo–N coatings produced by cathodic arc PVD. Surf. Coat. Technol. 2003, 167, 77–82. [Google Scholar] [CrossRef]

- Lin, Z.X.; Liu, Y.C.; Huang, C.R.; Guillon, M.; Wu, F.B. Input power effect on microstructure and mechanical properties of Mo–Si—N multilayer coatings. Surf. Coat. Technol. 2020, 383, 125222. [Google Scholar] [CrossRef]

- Suryanarayana, C. Structure and properties of ultrafine-grained MoSi2 + Si3N4 composites synthesized by mechanical alloying. Mater. Sci. Eng. A Struct. 2008, 479, 23–30. [Google Scholar] [CrossRef]

- Ding, J.C.; Zhang, T.F.; Wang, Q.M.; Song, C.W.; Wang, T.G.; Kim, K.H. Microstructure and mechanical properties of the Cr–Mo–Si–N nanocomposite coatings prepared by a hybrid system of AIP and HiPIMS technologies. J. Alloys Compd. 2018, 740, 774–783. [Google Scholar] [CrossRef]

- Bartosik, M.; Hahn, R.; Zhang, Z.L.; Ivanov, I.; Arndt, M.; Polcik, P.; Mayrhofer, P.H. Fracture toughness of Ti–Si–N thin films. Int. J. Refract. Hard Met. 2018, 72, 78–82. [Google Scholar] [CrossRef]

- Chen, Y.I.; Gao, Y.X.; Chang, L.C.; Ke, Y.E.; Liu, B.W. Mechanical properties, bonding characteristics, and oxidation behaviors of Nb–Si–N coatings. Surf. Coat. Technol. 2018, 350, 831–840. [Google Scholar] [CrossRef]

- Yang, Q.; Zhao, L.R.; Patnaik, P.C.; Zeng, X.T. Wear resistant TiMoN coatings deposited by magnetron sputtering. Wear 2006, 261, 119–125. [Google Scholar] [CrossRef]

- Lyo, I.W.; Ahn, H.S.; Lim, D.S. Microstructure and tribological properties of plasma-sprayed chromium oxide–molybdenum oxide composite coatings. Surf. Coat. Technol. 2003, 163–164, 413–421. [Google Scholar] [CrossRef]

- Suszko, T.; Gulbiṅski, W.; Jagielski, J. The role of surface oxidation in friction processes on molybdenum nitride thin films. Surf. Coat. Technol. 2005, 194, 319–324. [Google Scholar] [CrossRef]

- Yang, J.F.; Prakash, B.; Jiang, Y.; Wang, X.P.; Fang, Q.F. Effect of Si content on the microstructure and mechanical properties of Mo–Al–Si–N coatings. Vacuum 2012, 86, 2010–2013. [Google Scholar] [CrossRef]

- Solak, N.; Ustel, F.; Urgen, M.; Aydin, S.; Cakir, A.F. Oxidation behavior of molybdenum nitride coatings. Surf. Coat. Technol. 2003, 174–175, 713–719. [Google Scholar] [CrossRef]

- Xu, J.; Ju, H.; Yu, L. Influence of silicon content on the microstructure, mechanical and tribological properties of magnetron sputtered Ti–Mo–Si–N films. Vacuum 2014, 110, 47–53. [Google Scholar] [CrossRef]

- Lin, J.; Wang, B.; Ou, Y.; Sproul, W.D.; Dahan, I.; Moore, J.J. Structure and properties of CrSiN nanocomposite coatings deposited by hybrid modulated pulsed power and pulsed dc magnetron sputtering. Surf. Coat. Technol. 2013, 216, 251–258. [Google Scholar] [CrossRef]

- Liu, Q.; Fang, Q.F.; Liang, F.J.; Wang, J.X.; Yang, J.F.; Li, C. Synthesis and properties of nanocomposite MoSiN hard films. Surf. Coat. Technol. 2006, 201, 1894–1988. [Google Scholar] [CrossRef]

- Yuan, Z.G.; Yang, J.F.; Wang, X.P.; Cheng, Z.J.; Fang, Q.F. Characterization and properties of quaternary Mo–Si–C–N coatings synthesized by magnetron sputtering technique. Surf. Coat. Technol 2011, 205, 3307–3312. [Google Scholar] [CrossRef]

- Liu, Y.H.; Chang, L.C.; Liu, B.W.; Chen, Y.I. Mechanical properties and oxidation behavior of W–Si–N coatings. Surf. Coat. Technol. 2019, 375, 727–738. [Google Scholar] [CrossRef]

- Chang, L.C.; Zheng, Y.Z.; Chen, Y.I.; Chang, S.C.; Liu, B.W. Bonding characteristics and chemical Inertness of Zr–Si–N coatings with a high Si content in glass molding. Coatings 2018, 8, 181. [Google Scholar] [CrossRef]

- Monclús, M.A.; Yang, L.; López-Cabañas, I.; Castillo-Rodríguez, M.; Zaman, A.; Wang, J.; Meletis, E.I.; Gonzalez-Arrabal, R.; Llorca, J.; Molina-Aldareguía, J.M. High temperature mechanical properties and microstructure of hard TaSiN coatings. Mater. Sci. Eng. A 2020, 797, 139976. [Google Scholar] [CrossRef]

- Gu, J.; Li, L.; Ai, M.; Xu, Y.; Xu, Y.; Li, G.; Deng, D.; Peng, H.; Luo, S.; Zhang, P. Improvement of solid particle erosion and corrosion resistance using TiAlSiN/Cr multilayer coatings. Surf. Coat. Technol. 2020, 402, 126270. [Google Scholar] [CrossRef]

- Chang, L.C.; Liu, B.W.; Chen, Y.I. Mechanical properties and oxidation behavior of multilayered Hf–Si–N coatings. Coatings 2018, 8, 354. [Google Scholar] [CrossRef]

- Musil, J.; Dohnal, P.; Zeman, P. Physical properties and high-temperature oxidation resistance of sputtered Si3N4/MoNx nanocomposite coatings. J. Vac. Sci. Technol. B 2005, 23, 1568–1575. [Google Scholar] [CrossRef]

- Choi, J.B.; Cho, K.; Lee, M.H.; Kim, K.H. Effects of Si content and free Si on oxidation behavior of Ti–Si–N coating layers. Thin Solid Films 2014, 447–448, 365–370. [Google Scholar] [CrossRef]

- Ju, H.; He, S.; Yu, L.; Asempah, I.; Xu, J. The improvement of oxidation resistance, mechanical and tribological properties of W2N films by doping silicon. Surf. Coat. Technol. 2017, 317, 158–165. [Google Scholar] [CrossRef]

- Zhao, H.; Ye, F. Effect of Si-incorporation on the structure, mechanical, tribological and corrosion properties of WSiN coatings. Appl. Surf. Sci. 2015, 256, 958–966. [Google Scholar] [CrossRef]

- Zaman, A.; Shen, Y.; Meletis, E.I. Microstructure and mechanical property investigation of TaSiN thin films deposited by reactive magnetron sputtering. Coatings 2019, 9, 338. [Google Scholar] [CrossRef]

- Hahn, R.; Kirnbauer, A.; Bartosik, M.; Kolozsvári, S.; Mayrhofer, P.H. Toughness of Si alloyed high-entropy nitride coatings. Mater. Lett. 2019, 251, 238–240. [Google Scholar] [CrossRef]

- Yuan, Z.G.; Sun, L.; Gong, W.B.; Xu, Z.L.; Wu, X. Synthesis and mechanical properties of Mo–Al–Si–N films deposited by direct current magnetron sputtering. Thin Solid Films 2016, 603, 75–79. [Google Scholar] [CrossRef]

- Jiang, N.; Shen, Y.G.; Zhang, H.J.; Bao, S.N.; Hou, X.Y. Superhard nanocomposite Ti–Al–Si–N films deposited by reactive unbalanced magnetron sputtering. Mater. Sci. Eng. B-Solid 2006, 135, 1–9. [Google Scholar] [CrossRef]

- Oliver, W.C.; Pharr, G.M. An improved technique for determining hardness and elastic modulus using load and displacement sensing indentation experiments. J. Mater. Res. 1992, 7, 1564–1583. [Google Scholar] [CrossRef]

- Leyland, A.; Matthews, A. On the significance of the H/E ratio in wear control: A nanocomposite coating approach to optimised tribological behavior. Wear 2000, 246, 1–11. [Google Scholar] [CrossRef]

- Leyland, A.; Matthews, A. Optimization of nanostructured tribological coatings. In Nanostructured Coat; Springer: Berlin/Heidelberg, Germany, 2007; pp. 511–538. [Google Scholar]

| Sample Designation | Gas Inlet N2/(Ar + N2) (sccm/sccm) | Power Input (W) | Composition (at.%) | Deposition Rate (nm/s) | |||

|---|---|---|---|---|---|---|---|

| Mo | Si | Mo | Si | N | - | ||

| A1 | 10/20 | 135 | 0 | 66.4 ± 0.8 | 0 | 33.6 ± 0.8 | 0.133 |

| A2 | 100 | 41.9 ± 1.0 | 13.2 ± 0.4 | 44.9 ± 1.4 | 0.177 | ||

| A3 | 150 | 34.9 ± 0.5 | 19.8 ± 0.2 | 45.3 ± 0.7 | 0.213 | ||

| B1 | 5/20 | 135 | 0 | 75.8 ± 0.6 | 0 | 24.2 ± 0.6 | 0.134 |

| B2 | 100 | 46.5 ± 0.6 | 22.6 ± 0.5 | 30.9 ± 1.1 | 0.146 | ||

| B3 | 150 | 41.1 ± 0.4 | 33.7 ± 0.3 | 25.2 ± 0.6 | 0.268 | ||

| Sample | Hardness, H (GPa) | Young’s Modulus, E (GPa) | H/E | H3/E2 |

|---|---|---|---|---|

| A1 | 19.1 ± 2.0 | 260 ± 21 | 0.073 | 0.103 |

| A2 | 26.9 ± 0.4 | 273 ± 9 | 0.099 | 0.261 |

| A3 | 17.1 ± 0.1 | 208 ± 5 | 0.082 | 0.116 |

| B1 | 16.5 ± 0.6 | 241 ± 9 | 0.068 | 0.077 |

| B2 | 17.5 ± 0.5 | 219 ± 5 | 0.080 | 0.112 |

| B3 | 17.5 ± 0.4 | 213 ± 6 | 0.082 | 0.118 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, Y.-C.; Liang, B.-H.; Huang, C.-R.; Wu, F.-B. Microstructure Evolution and Mechanical Behavior of Mo–Si–N Films. Coatings 2020, 10, 987. https://doi.org/10.3390/coatings10100987

Liu Y-C, Liang B-H, Huang C-R, Wu F-B. Microstructure Evolution and Mechanical Behavior of Mo–Si–N Films. Coatings. 2020; 10(10):987. https://doi.org/10.3390/coatings10100987

Chicago/Turabian StyleLiu, Yu-Cheng, Bing-Hao Liang, Chi-Ruei Huang, and Fan-Bean Wu. 2020. "Microstructure Evolution and Mechanical Behavior of Mo–Si–N Films" Coatings 10, no. 10: 987. https://doi.org/10.3390/coatings10100987

APA StyleLiu, Y.-C., Liang, B.-H., Huang, C.-R., & Wu, F.-B. (2020). Microstructure Evolution and Mechanical Behavior of Mo–Si–N Films. Coatings, 10(10), 987. https://doi.org/10.3390/coatings10100987