Effects of Graphene-Based Fillers on Cathodic Delamination and Abrasion Resistance of Cataphoretic Organic Coatings

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. fGO Synthesis

2.3. Deposition of Acrylic-fGO Coatings

2.4. Characterization

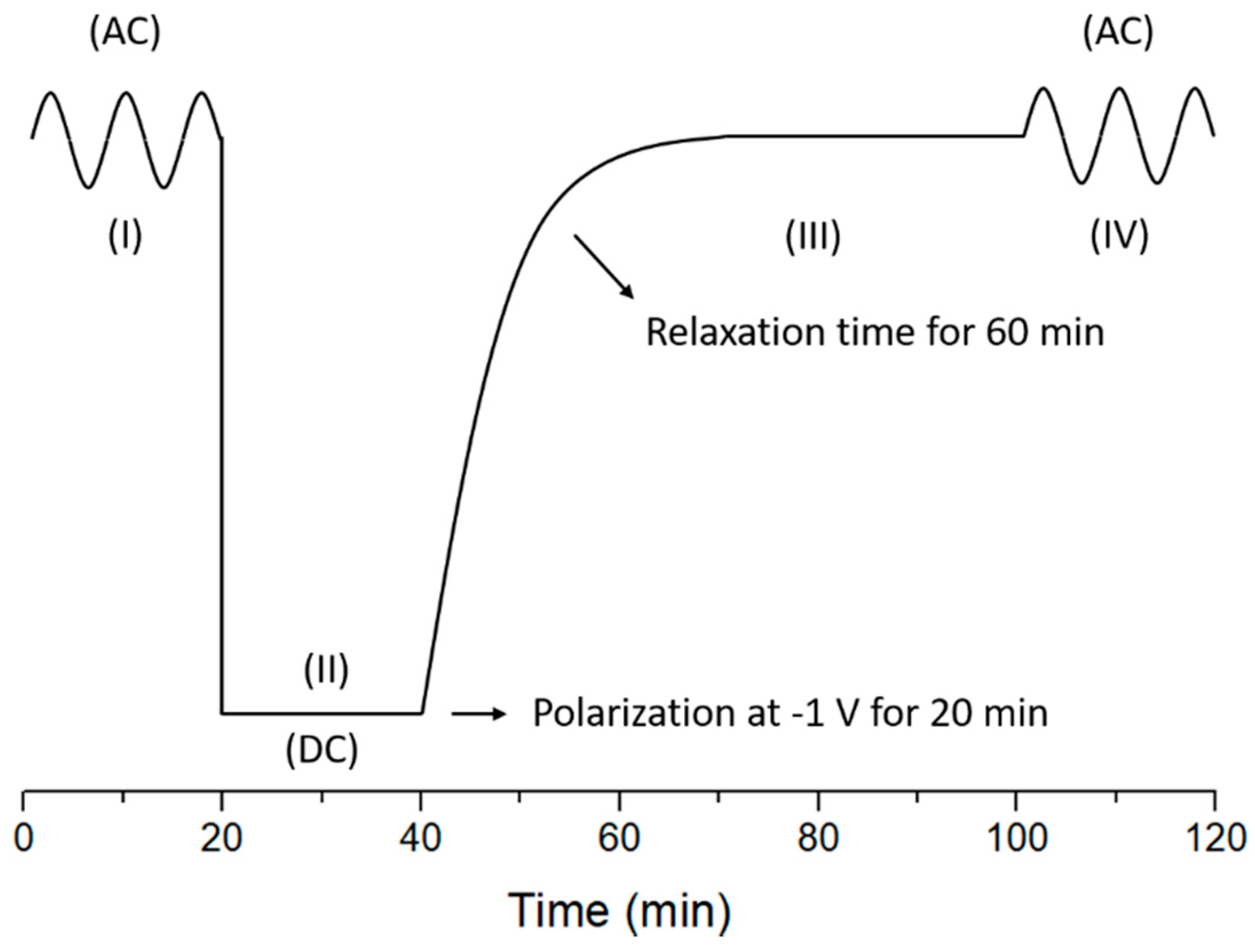

- an electrochemical impedance spectroscopy (EIS) measurement at the open circuit potential (OCP);

- constant cathodic polarization at −1 V Ag/AgCl for 20 min;

- OCP measurement for 1 h to stabilize the polarized samples.

3. Results and Discussion

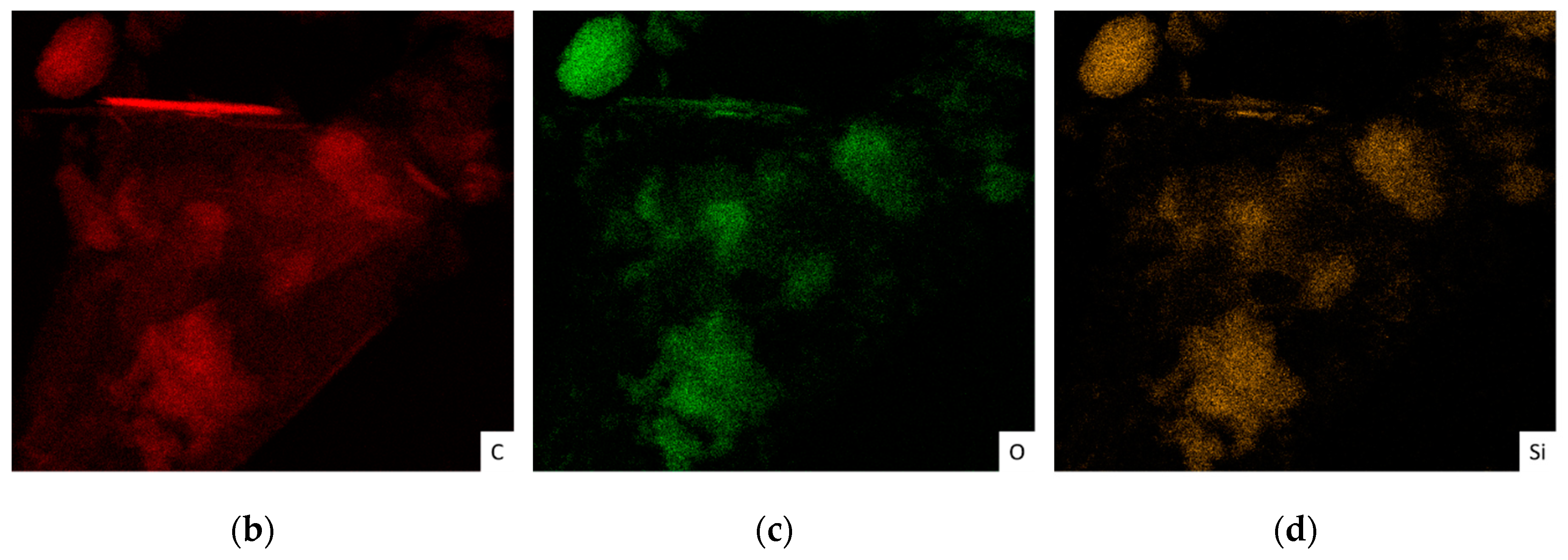

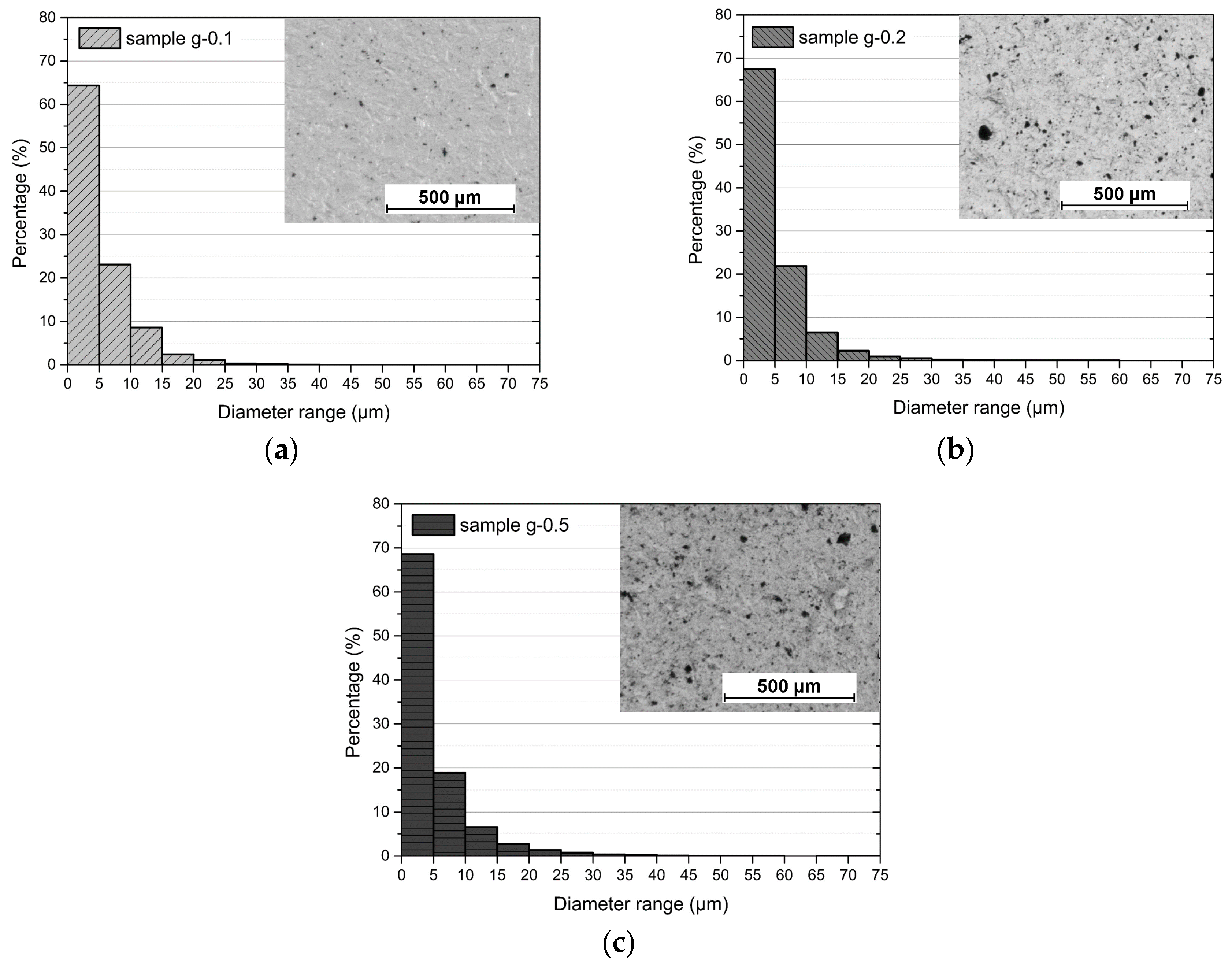

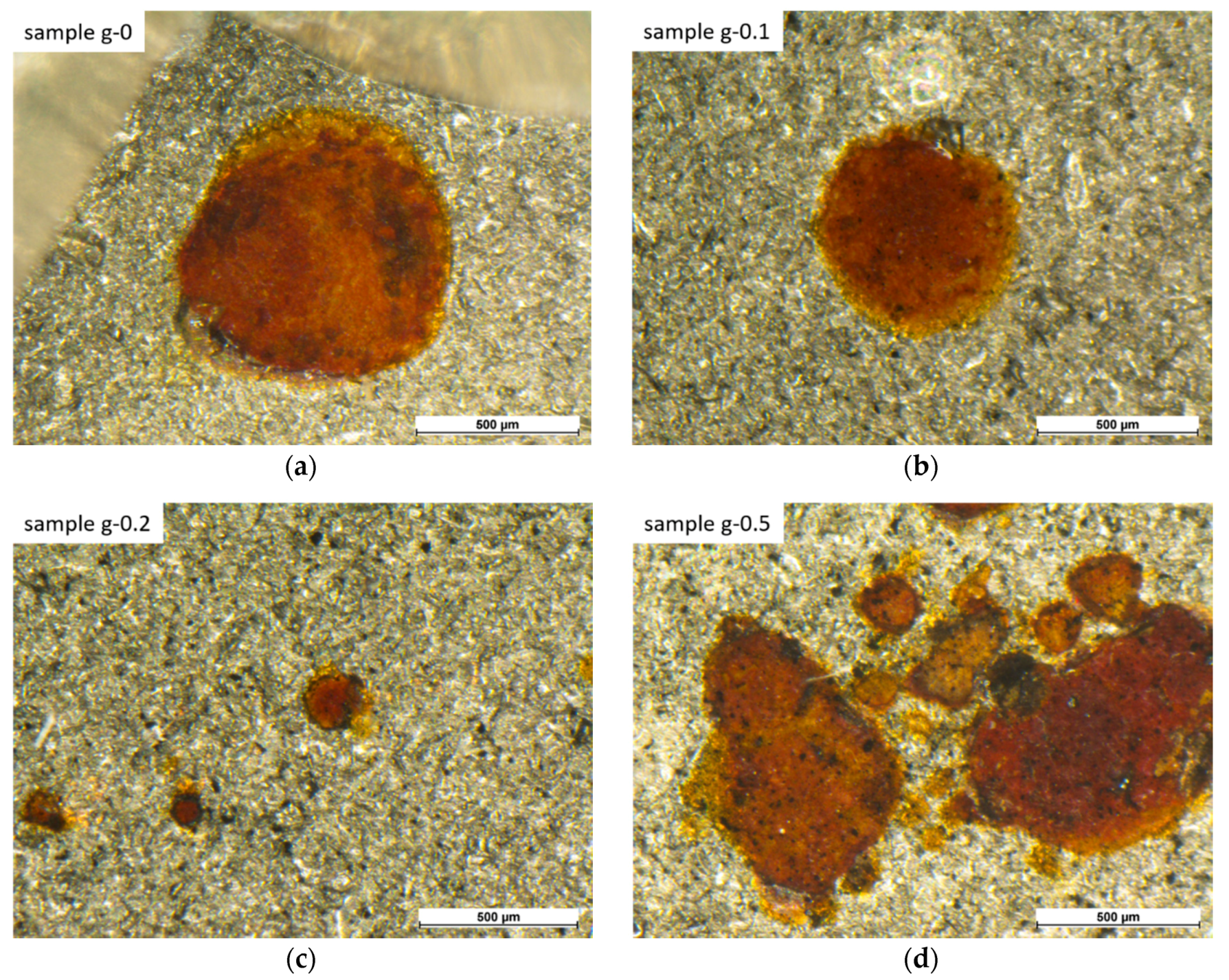

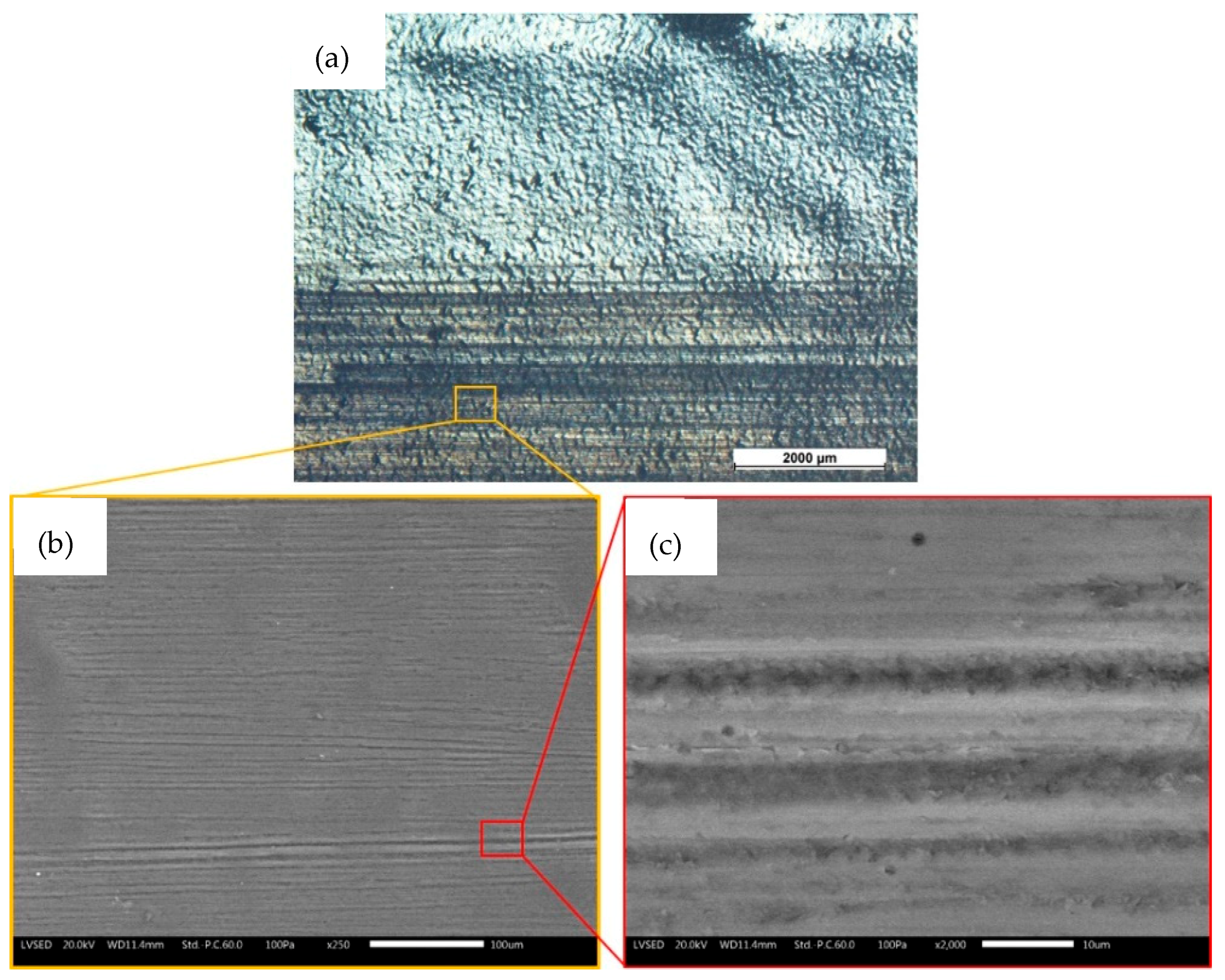

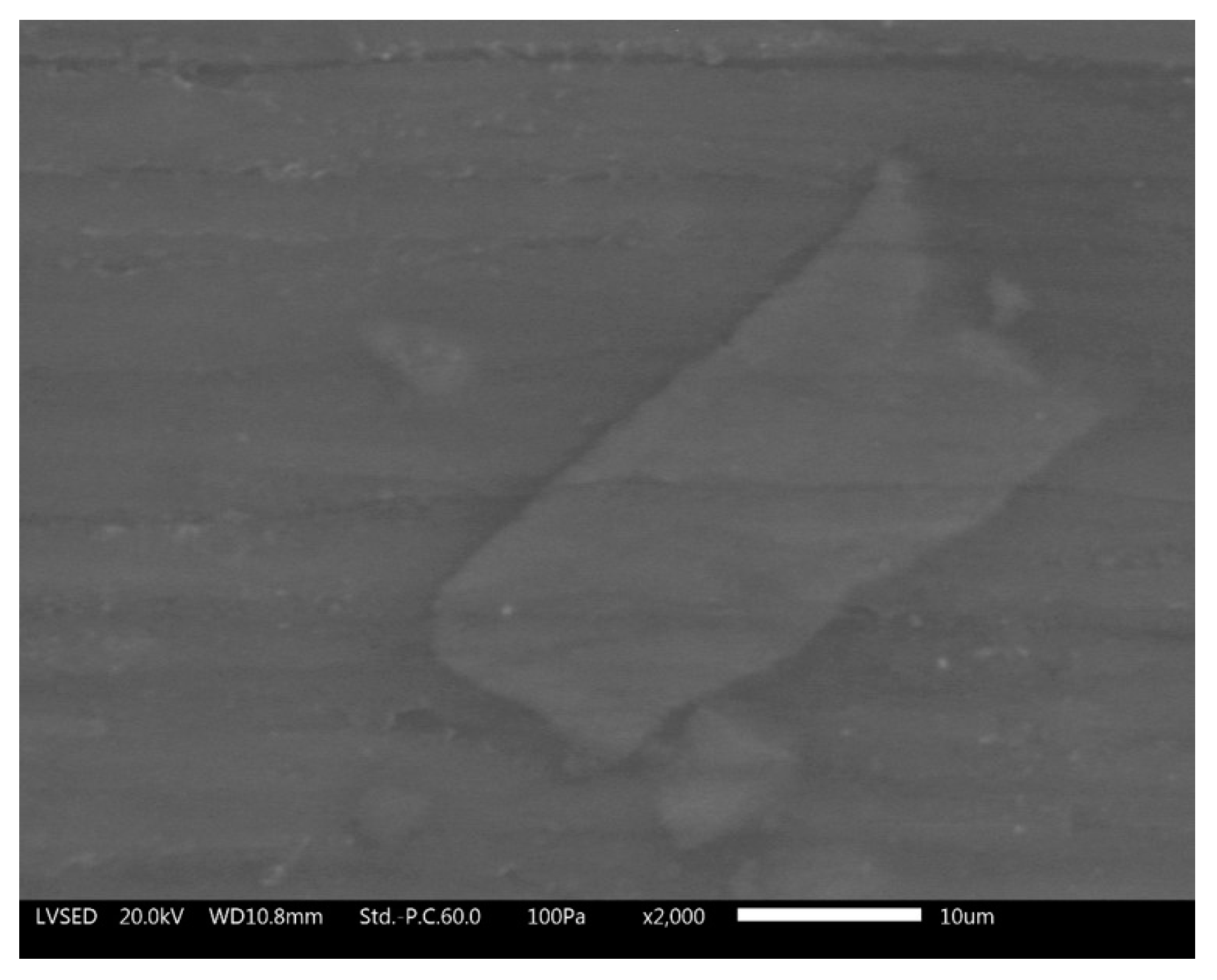

3.1. Filler Distribution

3.2. AC–DC–AC Test

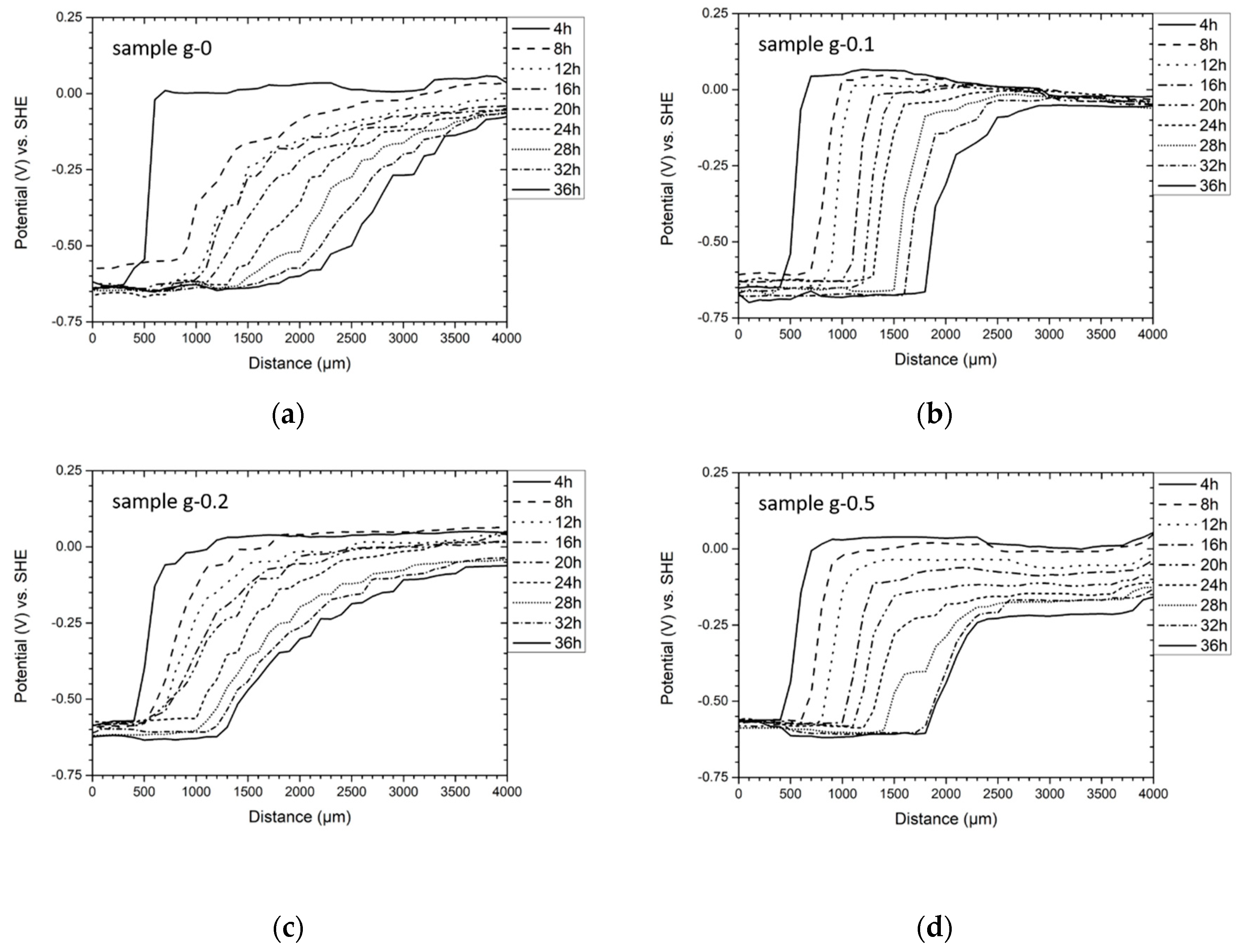

3.3. Scanning Kelvin Probe Measurements

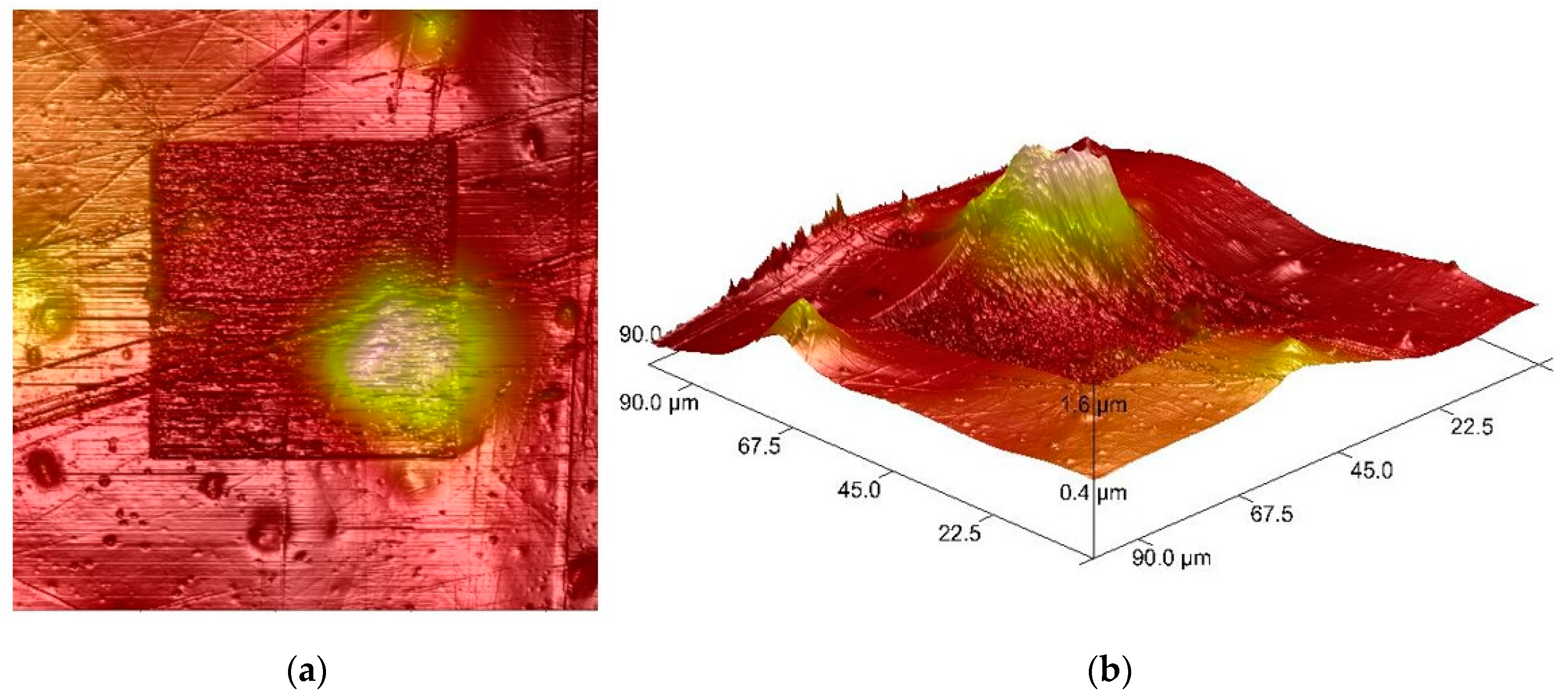

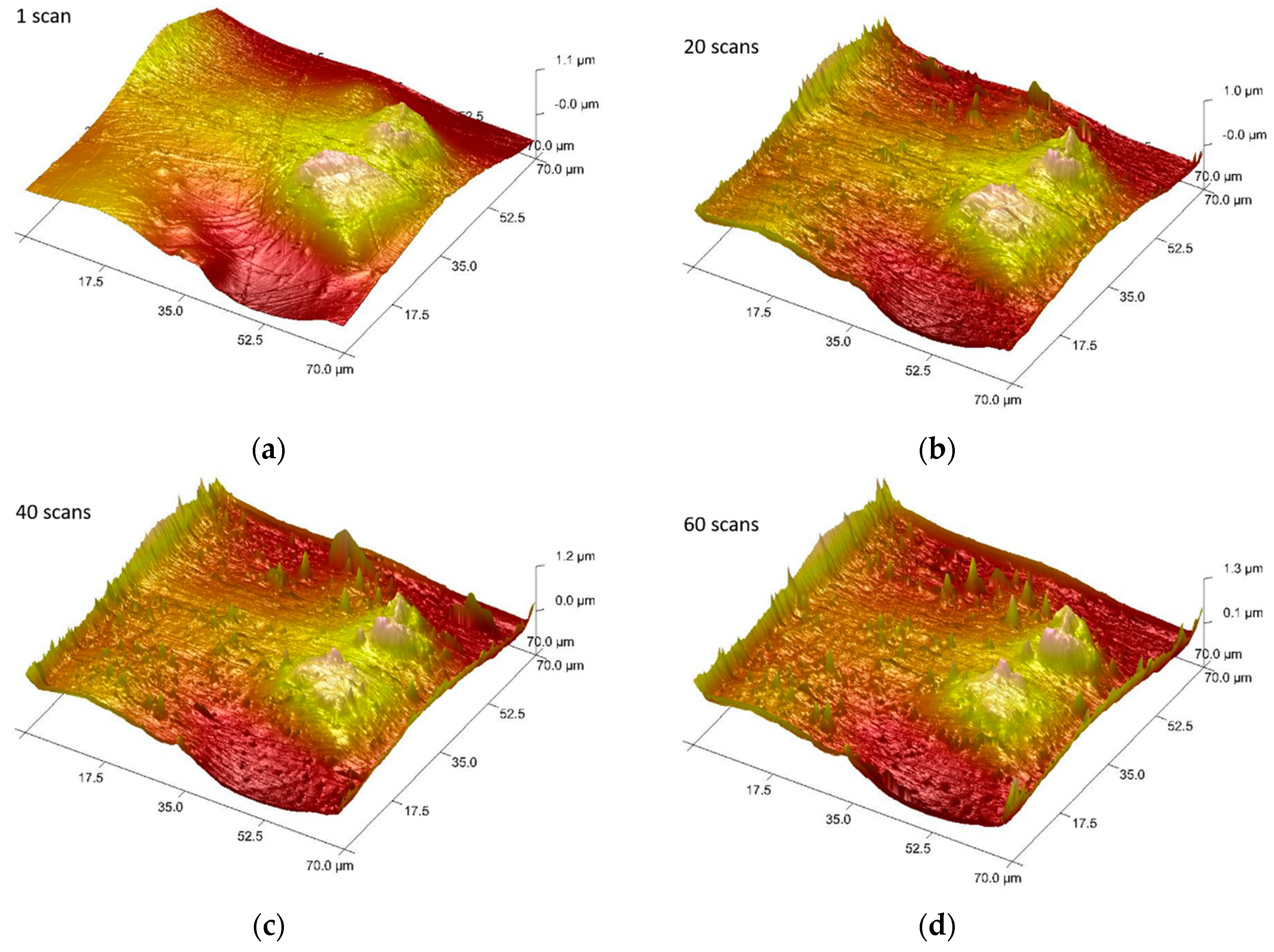

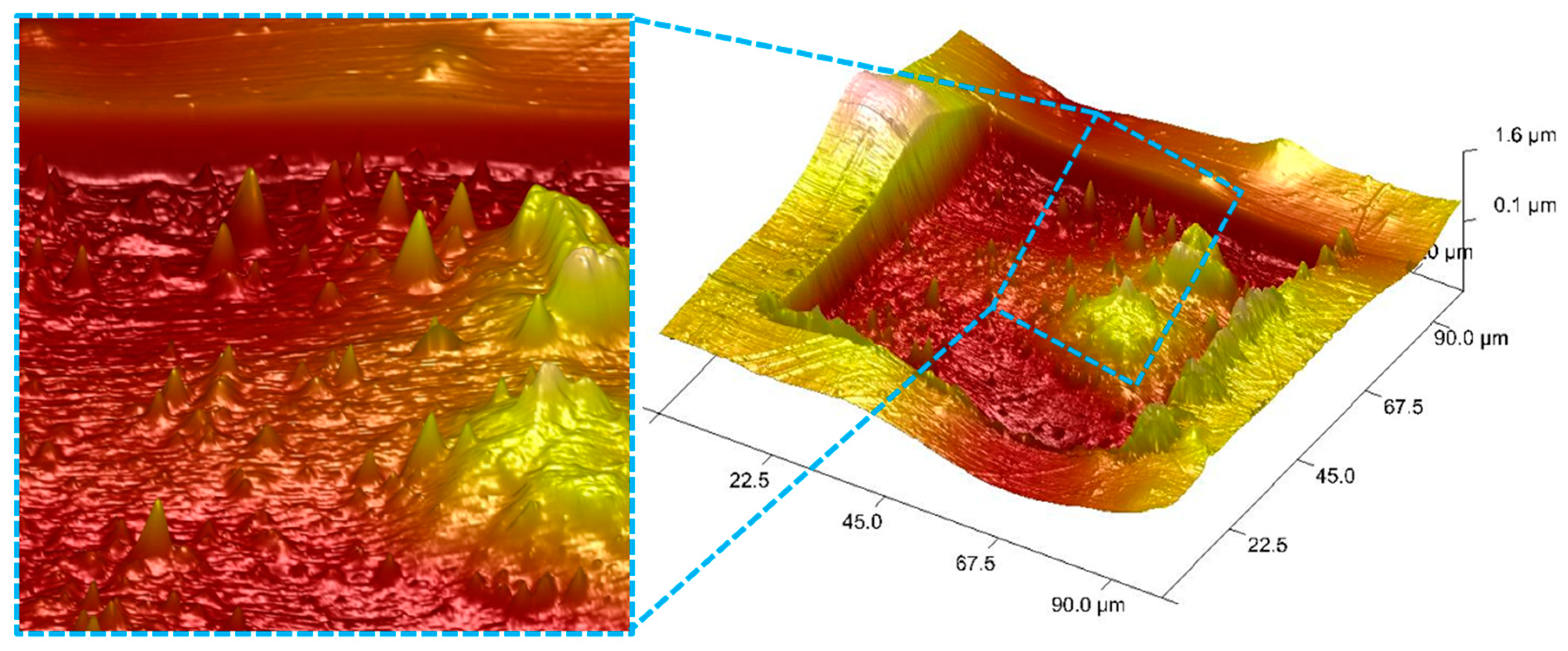

3.4. Scratching AFM Analysis

3.5. Scrub Test

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Geim, A.K.; Novoselov, K.S. The rise of graphene. Nat. Mater. 2007, 6, 183–191. [Google Scholar] [CrossRef]

- Novoselov, K.S.; Geim, A.K.; Morozov, S.V.; Jiang, D.; Dubonos, S.V.; Grigorieva, I.V. Electric Field Effect in Atomically Thin Carbon Films. Science 2004, 306, 666–669. [Google Scholar] [CrossRef]

- Duplock, E.J.; Scheffler, M.; Lindan, P.J.D. Hallmark of perfect graphene. Phys. Rev. Lett. 2004, 92, 1–4. [Google Scholar] [CrossRef]

- Xu, Z.; Zhang, J.; Shan, M.; Li, Y.; Li, B.; Niu, J.; Zhou, B.; Qian, X. Organosilane-functionalized graphene oxide for enhanced antifouling and mechanical properties of polyvinylidene fluoride ultrafiltration membranes. J. Membr. Sci. 2014, 458, 1–13. [Google Scholar] [CrossRef]

- Al-Saleh, M.H.; Sundararaj, U. Review of the mechanical properties of carbon nanofiber/polymer composites. Compos. Part A Appl. Sci. Manuf. 2011, 42, 2126–2142. [Google Scholar] [CrossRef]

- Lee, C.; Wei, X.; Kysar, J.W.; Hone, J. Measurement of the elastic properties and intrinsic strength of monolayer graphene. Science 2008, 321, 385–388. [Google Scholar] [CrossRef] [PubMed]

- Stankovich, S.; Dikin, D.A.; Dommett, G.H.B.; Kohlhaas, K.M.; Zimney, E.J.; Stach, E.A.; Piner, R.D.; Nguyen, S.T.; Ruoff, R.S. Graphene-based composite materials. Nature 2006, 442, 282–286. [Google Scholar] [CrossRef] [PubMed]

- Cai, D.; Yusoh, K.; Song, M. The mechanical properties and morphology of a graphite oxide nanoplatelet/polyurethane composite. Nanotechnology 2009, 20, 085712. [Google Scholar] [CrossRef]

- Ansari, S.; Giannelis, E.P. Functionalized graphene sheetpoly (inylidene fluoride) conductive nanocomposites. J. Polym. Sci. Part B Polym. Phys. 2009, 47, 888–897. [Google Scholar] [CrossRef]

- Yang, Y.G.; Chen, C.M.; Wen, Y.F.; Yang, Q.H.; Wang, M.Z. Oxidized graphene and graphene based polymer composites. New Carbon Mater. 2008, 23, 193–200. [Google Scholar] [CrossRef]

- Chen, F.; Ying, J.; Wang, Y.; Du, S.; Liu, Z.; Huang, Q. Effects of graphene content on the microstructure and properties of copper matrix composites. Carbon 2016, 96, 836–842. [Google Scholar] [CrossRef]

- Tapasztó, O.; Tapasztó, L.; Lemmel, H.; Puchy, V.; Dusza, J.; Balázsi, C.; Balázsi, K. High orientation degree of graphene nanoplatelets in silicon nitride composites prepared by spark plasma sintering. Ceram. Int. 2016, 42, 1002–1006. [Google Scholar] [CrossRef]

- Liu, J.; Zhang, Z.; Lv, Y.; Yan, J.; Yun, J.; Zhao, W.; Kou, K.; Zhai, C. Synthesis and characterization of ZnO NWAs/graphene composites for enhanced optical and field emission performances. Compos. B Eng. 2016, 99, 366–372. [Google Scholar] [CrossRef]

- Kuilla, T.; Bhadra, S.; Yao, D.; Kim, N.H.; Bose, S.; Lee, J.H. Recent advances in graphene based polymer composites. Prog. Polym. Sci. 2010, 35, 1350–1375. [Google Scholar] [CrossRef]

- Papageorgiou, D.G.; Kinloch, I.A.; Young, R.J. Mechanical properties of graphene and graphene-based nanocomposites. Prog. Mater. Sci. 2017, 90, 75–127. [Google Scholar] [CrossRef]

- Atif, R.; Shyha, I.; Inam, F. Mechanical, thermal, and electrical properties of graphene-epoxy nanocomposites—A review. Polymers 2016, 8, 281. [Google Scholar] [CrossRef]

- Yousefi, N.; Gudarzi, M.M.; Zheng, Q.; Lin, X.; Shen, X.; Jia, J.; Sharif, F.; Kim, J.K. Highly aligned, ultralarge-size reduced graphene oxide/polyurethane nanocomposites: Mechanical properties and moisture permeability. Compos. Part A Appl. Sci. Manuf. 2013, 49, 42–50. [Google Scholar] [CrossRef]

- Jing, Q.; Liu, W.; Pan, Y.; Silberschmidt, V.V.; Li, L.; Dong, Z.L. Chemical functionalization of graphene oxide for improving mechanical and thermal properties of polyurethane composites. Mater. Des. 2015, 85, 808–814. [Google Scholar] [CrossRef]

- Yu, B.; Wang, X.; Xing, W.; Yang, H.; Song, L.; Hu, Y. UV-Curable Functionalized Graphene Oxide/Polyurethane Acrylate Nanocomposite Coatings with Enhanced Thermal Stability and Mechanical Properties. Ind. Eng. Chem. Res. 2012, 51, 14629–14636. [Google Scholar] [CrossRef]

- Shi, Y.; Qian, X.; Zhou, K.; Tang, Q.; Jiang, S.; Wang, B.; Wang, B.; Yu, B.; Hu, Y.; Yuen, R.K.K. CuO/Graphene Nanohybrids: Preparation and Enhancement on Thermal Stability and Smoke Suppression of Polypropylene. Ind. Eng. Chem. Res. 2013, 52, 13654–13660. [Google Scholar] [CrossRef]

- Zhuo, D.; Wang, R.; Wu, L.; Guo, Y.; Ma, L.; Weng, Z.; Qi, J. Flame Retardancy Effects of Graphene Nanoplatelet/Carbon Nanotube Hybrid Membranes on Carbon Fiber Reinforced Epoxy Composites. J. Nanomater. 2013, 7, 1–7. [Google Scholar] [CrossRef]

- Wang, X.; Song, L.; Yang, H.; Lu, H.; Hu, Y. Synergistic Effect of Graphene on Antidripping and Fire Resistance of Intumescent Flame Retardant Poly (butylene succinate) Composites. Ind. Eng. Chem. Res. 2011, 50, 5376–5383. [Google Scholar] [CrossRef]

- Gong, L.; Kinloch, I.A.; Young, R.J.; Riaz, I.; Jalil, R.; Novoselov, K.S. Interfacial stress transfer in a graphene monolayer nanocomposite. Adv. Mater. 2012, 22, 2694–2697. [Google Scholar] [CrossRef] [PubMed]

- Young, R.J.; Kinloch, I.A.; Gong, L.; Novoselov, K.S. The mechanics of graphene nanocomposites: A review. Compos. Sci. Technol. 2012, 72, 1459–1476. [Google Scholar] [CrossRef]

- Anandan, S.; Narasinga Rao, T.; Sathish, M.; Rangappa, D.; Honma, I.; Miyauchi, M. Superhydrophilic Graphene-Loaded TiO2 Thin Film for Self-Cleaning Applications. ACS Appl. Mater. Interfaces 2012, 5, 207–212. [Google Scholar] [CrossRef]

- Jin, J.; Wang, X.; Song, M. Graphene-Based Nanostructured Hybrid Materials for Conductive and Superhydrophobic Functional Coatings. J. Nanosci. Nanotechnol. 2011, 11, 7715–7722. [Google Scholar] [CrossRef] [PubMed]

- Ramezanzadeh, B.; Ghasemi, E.; Mahdavian, M.; Changizi, E.; Mohamadzadeh Moghadam, M.H. Covalently-grafted graphene oxide nanosheets to improve barrier and corrosion protection properties of polyurethane coatings. Carbon 2015, 93, 555–573. [Google Scholar] [CrossRef]

- Chang, K.C.; Hsu, M.H.; Lu, H.I.; Lai, M.C.; Liu, P.J.; Hsu, C.H.; Ji, W.F.; Chuang, T.L.; Wei, Y.; Yeh, J.M.; et al. Room-temperature cured hydrophobic epoxy/graphene composites as corrosion inhibitor for cold-rolled steel. Carbon 2014, 66, 144–153. [Google Scholar] [CrossRef]

- Ramezanzadeh, B.; Niroumandrad, S.; Ahmadi, A.; Mahdavian, M.; Mohamadzadeh Moghadam, M.H. Enhancement of barrier and corrosion protection performance of an epoxy coating through wet transfer of amino functionalized graphene oxide. Corros. Sci. 2016, 103, 283–304. [Google Scholar] [CrossRef]

- Othman, N.H.; Ismail, M.C.; Mustapha, M.; Sallih, N.; Kee, K.E.; Jaal, R.A. Graphene-based polymer nanocomposites as barrier coatings for corrosion protection. Prog. Org. Coat. 2019, 135, 82–99. [Google Scholar] [CrossRef]

- Ray, S.C. Application and Uses of Graphene, 1st ed.; Elsevier: Amsterdam, The Netherlands, 2015; pp. 1–92. [Google Scholar]

- Kamal, M.R.; Uribe-Calderon, J. Nanoparticles and Polymer Nanocomposites, Graphite, Graphene, and Their Polymer Nanocomposites, 1st ed.; CRC Press: Boca Raton, FL, USA, 2013; pp. 353–392. [Google Scholar]

- Huang, H.D.; Ren, P.G.; Chen, J.; Zhang, W.Q.; Ji, X.; Li, Z.M. High barrier graphene oxide nanosheet/poly(vinyl alcohol) nanocomposite films. J. Membr. Sci. 2012, 409–410, 156–163. [Google Scholar] [CrossRef]

- Kalaitzidou, K.; Fukushima, H.; Drzal, L.T. Multifunctional polypropylene composites produced by incorporation of exfoliated graphite nanoplatelets. Carbon 2007, 45, 1446–1452. [Google Scholar] [CrossRef]

- Yang, S.Y.; Lin, W.N.; Huang, Y.L.; Tien, H.W.; Wang, J.Y.; Ma, C.C.M.; Li, S.M.; Wang, Y.S. Synergetic effects of graphene platelets and carbon nanotubes on the mechanical and thermal properties of epoxy composites. Carbon 2011, 49, 793–803. [Google Scholar] [CrossRef]

- Wang, X.; Xing, W.; Zhang, P.; Song, L.; Yang, H.; Hu, Y. Covalent functionalization of graphene with organosilane and its use as a reinforcement in epoxy composites. Compos. Sci. Technol. 2012, 72, 737–743. [Google Scholar] [CrossRef]

- Rossi, S.; Calovi, M. Addition of graphene oxide plates in cataphoretic deposited organic coatings. Prog. Org. Coat. 2018, 424, 40–47. [Google Scholar] [CrossRef]

- Pourhashem, S.; Vaezi, M.R.; Rashidi, A.; Bagherzadeh, M.R. Distinctive roles of silane coupling agents on the corrosion inhibition performance of graphene oxide in epoxy coatings. Prog. Org. Coat. 2017, 111, 47–56. [Google Scholar] [CrossRef]

- Pourhashem, S.; Rashidi, A.; Vaezi, M.R.; Bagherzadeh, M.R. Excellent corrosion protection performance of epoxy composite coatings filled with aminosilane functionalized graphene oxide. Surf. Coat. Technol. 2017, 317, 1–9. [Google Scholar] [CrossRef]

- Mo, M.; Zhao, W.; Chen, Z.; Yu, Q.; Zeng, Z.; Wu, X.; Xue, Q. Excellent tribological and anti-corrosion performance of polyurethane composite coatings reinforced with functionalized graphene and graphene oxide nanosheets. RSC Adv. 2015, 5, 56486–56497. [Google Scholar] [CrossRef]

- Mo, M.; Zhao, W.; Chen, Z.; Liu, E.; Xue, Q. Corrosion inhibition of functional graphene reinforced polyurethane nanocomposite coatings with regular textures. RSC Adv. 2016, 6, 7780–7790. [Google Scholar] [CrossRef]

- Ramezanzadeh, B.; Bahlakeh, G.; Mohamadzadeh Moghadam, M.H.; Miraftab, R. Impact of size-controlled p-phenylenediamine (PPDA)-functionalized graphene oxide nanosheets on the GO-PPDA/Epoxy anti-corrosion, interfacial interactions and mechanical properties enhancement: Experimental and quantum mechanics investigations. Chem. Eng. J. 2018, 335, 737–755. [Google Scholar] [CrossRef]

- Yu, Y.-H.; Lin, Y.-Y.; Lin, C.-H.; Chan, C.-C.; Huang, Y.-C. High-performance polystyrene/graphene-based nanocomposites with excellent anti-corrosion properties. Polym. Chem. 2014, 5, 535–550. [Google Scholar] [CrossRef]

- Calovi, M.; Callone, E.; Ceccato, R.; Deflorian, F.; Rossi, S.; Dirè, S. Effect of the organic functional group on the grafting ability of trialkoxysilanes onto graphene oxide: A combined NMR, XRD and ESR study. Materials 2019, 12, 3828. [Google Scholar] [CrossRef] [PubMed]

- Calovi, M.; Dirè, S.; Ceccato, R.; Deflorian, F.; Rossi, S. Corrosion protection properties of functionalized graphene—Acrylate coatings produced by cataphoretic deposition. Prog. Org. Coat. 2019, 136. [Google Scholar] [CrossRef]

- Calovi, M.; Rossi, S.; Deflorian, F.; Dirè, S.; Ceccato, R. Effect of functionalized graphene oxide concentration on the corrosion resistance properties provided by cataphoretic acrylic coatings. Mat. Chem. Phys. 2020, 239, 121984–121996. [Google Scholar] [CrossRef]

- Almeida, E.; Alves, I.; Brites, C.; Fedrizzi, L. Cataphoretic and autophoretic automotive primers A comparative study. Prog. Org. Coat. 2003, 46, 8–20. [Google Scholar] [CrossRef]

- Rossi, S.; Calovi, M.; Fedel, M. Corrosion protection of aluminum foams by cataphoretic deposition of organic coatings. Prog. Org. Coat. 2017, 109, 144–151. [Google Scholar] [CrossRef]

- Ramdé, T.; Ecco, L.G.; Rossi, S. Visual appearance durability as function of natural and accelerated ageing of electrophoretic styrene-acrylic coatings: Influence of yellow pigment concentration. Prog. Org. Coat. 2017, 103, 23–32. [Google Scholar] [CrossRef]

- Deflorian, F.; Rossi, S.; Prosseda, S. Improvement of corrosion protection system for aluminium body bus used in public transportation. Mater. Des. 2006, 27, 758–769. [Google Scholar] [CrossRef]

- Fedrizzi, L.; Rodriguez, F.J.; Rossi, S.; Deflorian, F. Corrosion study of industrial painting cycles for garden furniture. Prog. Org. Coat. 2003, 46, 62–73. [Google Scholar] [CrossRef]

- Zadeh, M.A.; van der Zwaag, S.; García, S.J. Assessment of healed scratches in intrinsic healing coatings by AC/DC/AC accelerated electrochemical procedure. Surf. Coat. Technol. 2016, 303, 396–405. [Google Scholar] [CrossRef]

- Khun, N.W.; Frankel, G.S. Effects of surface roughness texture and polymerdegradation on cathodic delamination of epoxy coated steel samples. Corros. Sci. 2013, 67, 152–160. [Google Scholar] [CrossRef]

- Leng, A.; Streckel, H.; Stratmann, M. The delamination of polymeric coatingsfrom steel. Part 1: Calibration of the Kelvin probe and basic delaminationmechanism. Corros. Sci. 1999, 41, 547–578. [Google Scholar] [CrossRef]

- Frankel, G.S.; Stratmann, M.; Rohwerder, M.; Michalik, A.; Maier, B.; Dora, J.; Wicinski, M. Potential control under thin aqueous layers using a Kelvin probe. Corros. Sci. 2007, 49, 2021–2036. [Google Scholar] [CrossRef]

- Khun, N.W.; Frankel, G.S. Cathodic delamination of polyurethane/multiwalled carbon nanotubecomposite coatings from steel substrates. Prog. Org. Coat. 2016, 99, 55–60. [Google Scholar] [CrossRef]

- Paints and Varnishes—Determination of Wet-Scrub Resistance and Cleanability of Coatings; BS EN ISO 11998:2006; BSI British Standards: London, UK, 2006; pp. 1–11.

- Da Silva Lopes, T.; Lopes, T.; Martins, D.; Carneiro, C.; Machado, J.; Mendes, A. Accelerated aging of anticorrosive coatings: Two-stage approach to the AC/DC/AC electrochemical method. Prog. Org. Coat. 2020, 138, 105365. [Google Scholar] [CrossRef]

- Allahar, K.N.; Upadhyay, V.; Bierwagen, G.P. Characterizing the Relaxation of the Open-Circuit Potential During an AC-DC-AC Accelerated Test. Corrosion 2010, 66, 095001–095011. [Google Scholar] [CrossRef]

- García, S.J.; Suay, J. Optimization of deposition voltage of cataphoretic automotive primers assessed by EIS and AC/DC/AC. Prog. Org. Coat. 2009, 66, 306–313. [Google Scholar] [CrossRef]

- Qian, X.; Song, L.; Yu, B.; Yang, W.; Wang, B.; Hu, Y.; Yuen, R.K.K. One-pot surface functionalization and reduction of graphene oxide with long-chain molecules: Preparation and its enhancement on the thermal and mechanical properties of polyuria. Chem. Eng. J. 2014, 236, 233–241. [Google Scholar] [CrossRef]

- Nazarov, A.; Olivier, M.G.; Thierry, D. SKP and FT-IR microscopy study of the paint corrosion de-adhesion from the surface of galvanized steel. Prog. Org. Coat. 2012, 74, 356–364. [Google Scholar] [CrossRef]

- Glover, C.F.; Richards, C.A.J.; Williams, G.; McMurray, H.N. Evaluation of multi-layered graphene nano-platelet composite coatings for corrosion control part II—Cathodic delamination kinetics. Corros. Sci. 2018, 136, 304–310. [Google Scholar] [CrossRef]

- Leng, A.; Streckel, H.; Stratmann, M. The delamination of polymeric coatings from steel. Part 2: First stage of delamination effect of type and concentration of cations on delamination, chemical analysis of the interface. Corros. Sci. 1999, 41, 579–597. [Google Scholar] [CrossRef]

- Wielant, J.; Ponser, R.; Grundmeier, G.; Terryn, H. Cathodic delamination ofpolyurethane films on oxide covered steel-combined adhesion and interfaceelectrochemical studies. Corros. Sci. 2009, 51, 1664–1670. [Google Scholar] [CrossRef]

- Stratmann, M.; Leng, A.; Furbeth, W.; Streckel, H.; Gehmecker, H.; Grobe-Brinkhaus, K.H. The scanning Kelvin probe; a new technique for the in situanalysis of the delamination of organic coatings. Prog. Org. Coat. 1996, 27, 261–267. [Google Scholar] [CrossRef]

- Linossier, I.; Gaillard, M.; Romand, M. A spectroscopic technique for studies ofwater transport along the interface and hydrolytic stability ofpolymer/substrate systems. J. Adhes. 1999, 70, 221–239. [Google Scholar] [CrossRef]

- Kinloch, A.J. The science of adhesion. Part 2: Mechanics and mechanisms of adhesion. J. Mater. Sci. 1982, 17, 617–651. [Google Scholar] [CrossRef]

- Tong, L.B.; Zhang, J.B.; Xu, C.; Wang, X.; Song, S.Y.; Jiang, Z.H.; Kamado, S.; Cheng, L.R.; Zhang, H.J. Enhanced corrosion and wear resistances by graphene oxide coating on the surface of Mg-Zn-Ca alloy. Carbon 2016, 109, 340–351. [Google Scholar] [CrossRef]

- Feng, J.; Wang, X.; Guo, P.; Wang, Y.; Luo, X. Mechanical Properties and Wear Resistance of Sulfonated Graphene/Waterborne Polyurethane Composites Prepared by In Situ Method. Polymers 2018, 10, 75. [Google Scholar] [CrossRef]

- Wang, L.; Liu, S.; Guo, J.; Zhang, Q.; Zhou, F.; Wang, Y.; Chu, R. Study on the wear resistance of graphene modified nanostructured Al2O3/TiO2 coatings. Appl. Surf. Sci. 2019, 492, 272–279. [Google Scholar] [CrossRef]

- Wang, X.; Qi, X.; Lin, Z.; Battocchi, D. Graphene Reinforced Composites as Protective Coatings for Oil and Gas Pipelines. Nanomaterials 2018, 8, 1005. [Google Scholar] [CrossRef]

- Adhikari, S.; Frankel, G.S.; Bammel, B.D.; Zimmerman, J. AFM Scratching for Adhesion Studies of Thin Polymer Coatings on Steel. J. Adhes. Sci. Technol. 2012, 26, 1591–1609. [Google Scholar] [CrossRef]

- Khun, N.W.; Frankel, G.S.; Zimmerman, J. Investigation of Surface Morphology, Wear Resistance, and Adhesiveness of AA6061-T6 Treated in a Hexafluorozirconic Acid-Based Solution. Corrosion 2013, 69, 259–267. [Google Scholar] [CrossRef]

- Seong, J.; Frankel, G.S. Assessment of Coating Adhesion Degradation by Atomic Force Microscopy Scratching. Corrosion 2012, 68. [Google Scholar] [CrossRef]

- Wang, X.; Tang, F.; Qi, X.; Lin, Z. Mechanical, electrochemical, and durability behavior of graphene nano-platelet loaded epoxy-resin composite coatings. Compos. Part B 2019, 176, 107103. [Google Scholar] [CrossRef]

- Kalea, M.B.; Luo, Z.; Zhang, X.; Dhamodharan, D.; Divakaran, N.; Mubarak, S.; Wu, L.; Xu, Y. Waterborne polyurethane/graphene oxide-silica nanocomposites with improved mechanical and thermal properties for leather coatings using screen printing. Polymer 2019, 170, 43–53. [Google Scholar] [CrossRef]

- Wu, L.; Wu, R.; Hou, L.; Zhang, J.; Zhang, M. Microstructure, mechanical properties and wear performance of AZ31 matrix composites reinforced by graphene nanoplatelets(GNPs). J. Alloys Compd. 2018, 750, 530–536. [Google Scholar] [CrossRef]

- Kirsch, S.; Pfau, A.; Frechen, T.; Schrof, W.; Pfohler, P.; Francke, D. Scrub resistance of highly pigmented paints: A study on abrasion mechanisms of different scrub techniques. Prog. Org. Coat. 2001, 43, 99–110. [Google Scholar] [CrossRef]

- Lopez, A.B.; De la Cal, J.C.; Asua, J.M. From fractal polymer dispersions to mechanically resistant waterborne superhydrophobic coatings. Polymer 2017, 124, 12–19. [Google Scholar] [CrossRef]

- Kaew-on, N.; Katemake, P.; Prasongsuk, S. Primer formulations with antibacterial properties for murals. Prog. Org. Coat. 2020, 138, 105395. [Google Scholar] [CrossRef]

- Kok, K.; Young, T.M. Evaluation of insect residue resistant coatings—Correlation of a screening method with a conventional assessment technique. Prog. Org. Coat. 2014, 77, 1382–1390. [Google Scholar] [CrossRef]

- Féat, A.; Federle, W.; Kamperman, M.; Murray, M.; Van der Gucht, J.; Taylor, P. Slippery paints: Eco-friendly coatings that cause ants to slip. Prog. Org. Coat. 2019, 135, 331–344. [Google Scholar] [CrossRef]

- De Oliveira, M.P.; Reggiani Silva, C.; Muller Guerrini, L. Effect of itaconic acid on the wet scrub resistance of highly pigmented paints for architectural coatings. J. Coat. Technol. Res. 2011, 8, 439–447. [Google Scholar] [CrossRef]

- Zhang, J.; Lan, P.; Li, J.; Xu, H.; Wang, Q.; Zhang, X.; Zheng, L.; Lu, Y.; Dai, N.; Song, W. Sol–gel derived near-UV and visible antireflection coatings from hybridized hollow silica nanospheres. J. Sol-Gel Sci. Technol. 2014, 71, 267–275. [Google Scholar] [CrossRef]

- Khanjani, J.; Hanifpour, A.; Pazokifard, S.; Zohuriaan-Mehr, M.J. Waterborne acrylic-styrene/PDMS coatings formulated by different particle sizes of PDMS emulsions for outdoor applications. Prog. Org. Coat. 2020, 141, 105267. [Google Scholar] [CrossRef]

- Rossi, S.; Deflorian, F.; Fontanari, L.; Cambruzzi, A.; Bonora, P.L. Electrochemical measurements to evaluate the damage due to abrasion on organic protective system. Prog. Org. Coat. 2005, 52, 288–297. [Google Scholar] [CrossRef]

- Akbarinezhad, E.; Bahremandi, M.; Faridi, H.R.; Rezaei, F. Another approach for ranking and evaluating organic paint coatings via electrochemical impedance spectroscopy. Corros. Sci. 2009, 51, 356–363. [Google Scholar] [CrossRef]

- Amirudin, D.T.A.; Amirudin, A.; Thierry, D. Application of electrochemical impedance spectroscopy to study the degradation of polymer-coated metals. Prog. Org. Coat. 1995, 26, 1–28. [Google Scholar] [CrossRef]

| Bath | fGO Concentration (wt.%) | Sample Nomenclature |

|---|---|---|

| Clear coat | 0.0 | g-0 |

| 0.1 | g-0.1 | |

| 0.2 | g-0.2 | |

| 0.5 | g-0.5 |

| Diameter Range (µm) | Sample g-0.1 | Sample g-0.2 | Sample g-0.5 |

|---|---|---|---|

| Percentage (%) | |||

| 0–5 | 66.41 | 67.51 | 68.63 |

| 5–10 | 23.09 | 21.86 | 18.88 |

| 10–15 | 8.59 | 6.49 | 6.53 |

| 15–20 | 2.43 | 2.25 | 2.75 |

| 20–25 | 1.06 | 0.92 | 1.39 |

| 25–30 | 0.28 | 0.51 | 0.77 |

| 30–35 | 0.16 | 0.19 | 0.38 |

| 35–40 | 0.04 | 0.09 | 0.33 |

| 40–45 | - | 0.06 | 0.12 |

| 45–50 | - | 0.07 | 0.07 |

| 50–55 | - | 0.01 | 0.07 |

| 55–60 | - | 0.03 | 0.06 |

| 60–65 | - | - | - |

| 65–70 | - | - | 0.01 |

| 70–75 | - | - | 0.01 |

| Sample | Coating Thickness (µm) | Largest Filler Agglomeration Range (µm) |

|---|---|---|

| g-0 | 30.4 ± 2.5 | 0 |

| g-0.1 | 26.4 ± 1.3 | 35–40 |

| g-0.2 | 25.4 ± 1.0 | 55–60 |

| g-0.5 | 17.8 ± 0.9 | 70–75 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Calovi, M.; Rossi, S.; Deflorian, F.; Dirè, S.; Ceccato, R.; Guo, X.; Frankel, G.S. Effects of Graphene-Based Fillers on Cathodic Delamination and Abrasion Resistance of Cataphoretic Organic Coatings. Coatings 2020, 10, 602. https://doi.org/10.3390/coatings10060602

Calovi M, Rossi S, Deflorian F, Dirè S, Ceccato R, Guo X, Frankel GS. Effects of Graphene-Based Fillers on Cathodic Delamination and Abrasion Resistance of Cataphoretic Organic Coatings. Coatings. 2020; 10(6):602. https://doi.org/10.3390/coatings10060602

Chicago/Turabian StyleCalovi, Massimo, Stefano Rossi, Flavio Deflorian, Sandra Dirè, Riccardo Ceccato, Xiaolei Guo, and Gerald S. Frankel. 2020. "Effects of Graphene-Based Fillers on Cathodic Delamination and Abrasion Resistance of Cataphoretic Organic Coatings" Coatings 10, no. 6: 602. https://doi.org/10.3390/coatings10060602

APA StyleCalovi, M., Rossi, S., Deflorian, F., Dirè, S., Ceccato, R., Guo, X., & Frankel, G. S. (2020). Effects of Graphene-Based Fillers on Cathodic Delamination and Abrasion Resistance of Cataphoretic Organic Coatings. Coatings, 10(6), 602. https://doi.org/10.3390/coatings10060602