Applicability of Agro-Industrial By-Products in Intelligent Food Packaging

Abstract

:1. Introduction

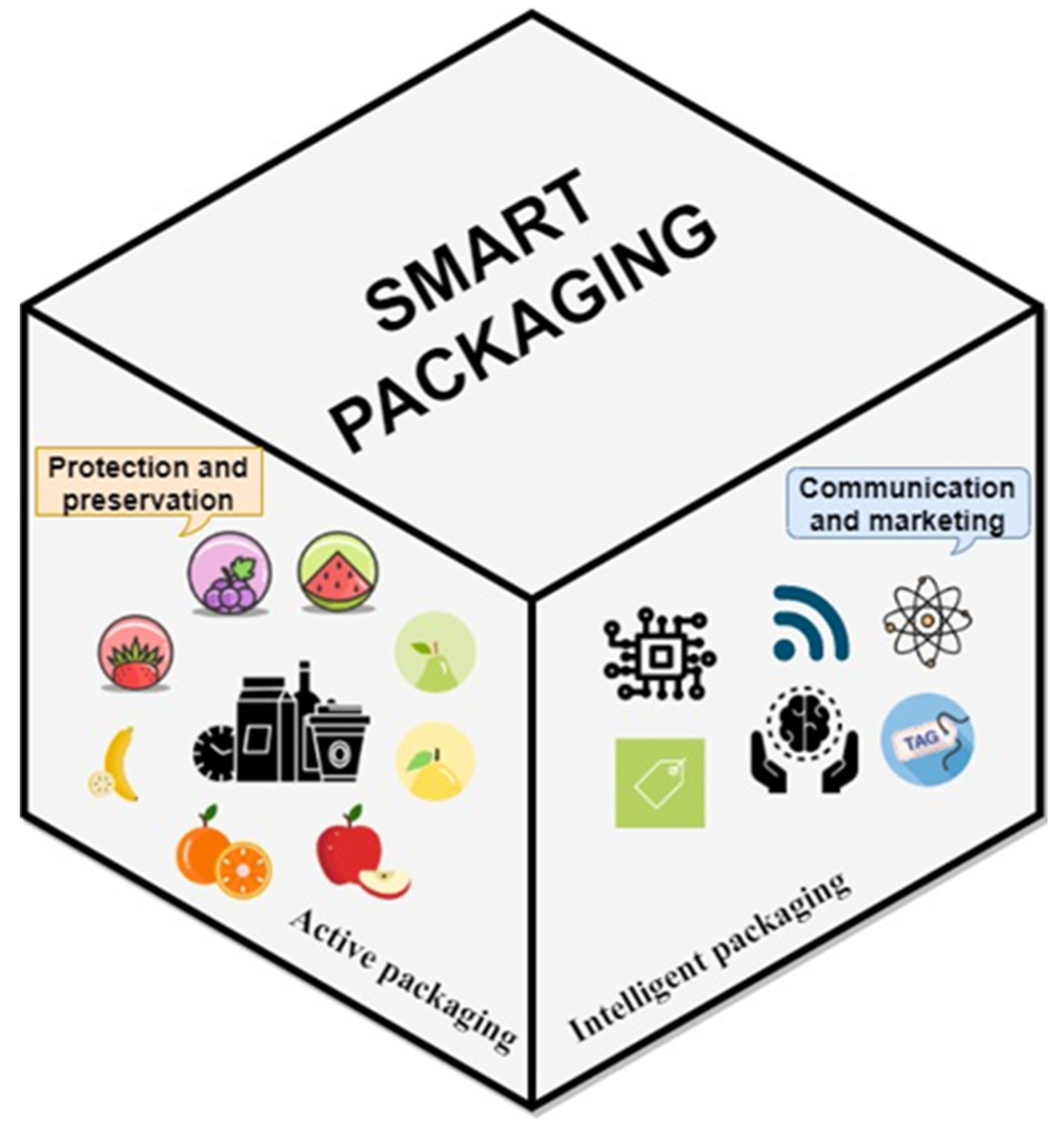

2. Concepts Definitions

3. Smart Packaging

4. Active Packaging

4.1. Nanomaterials

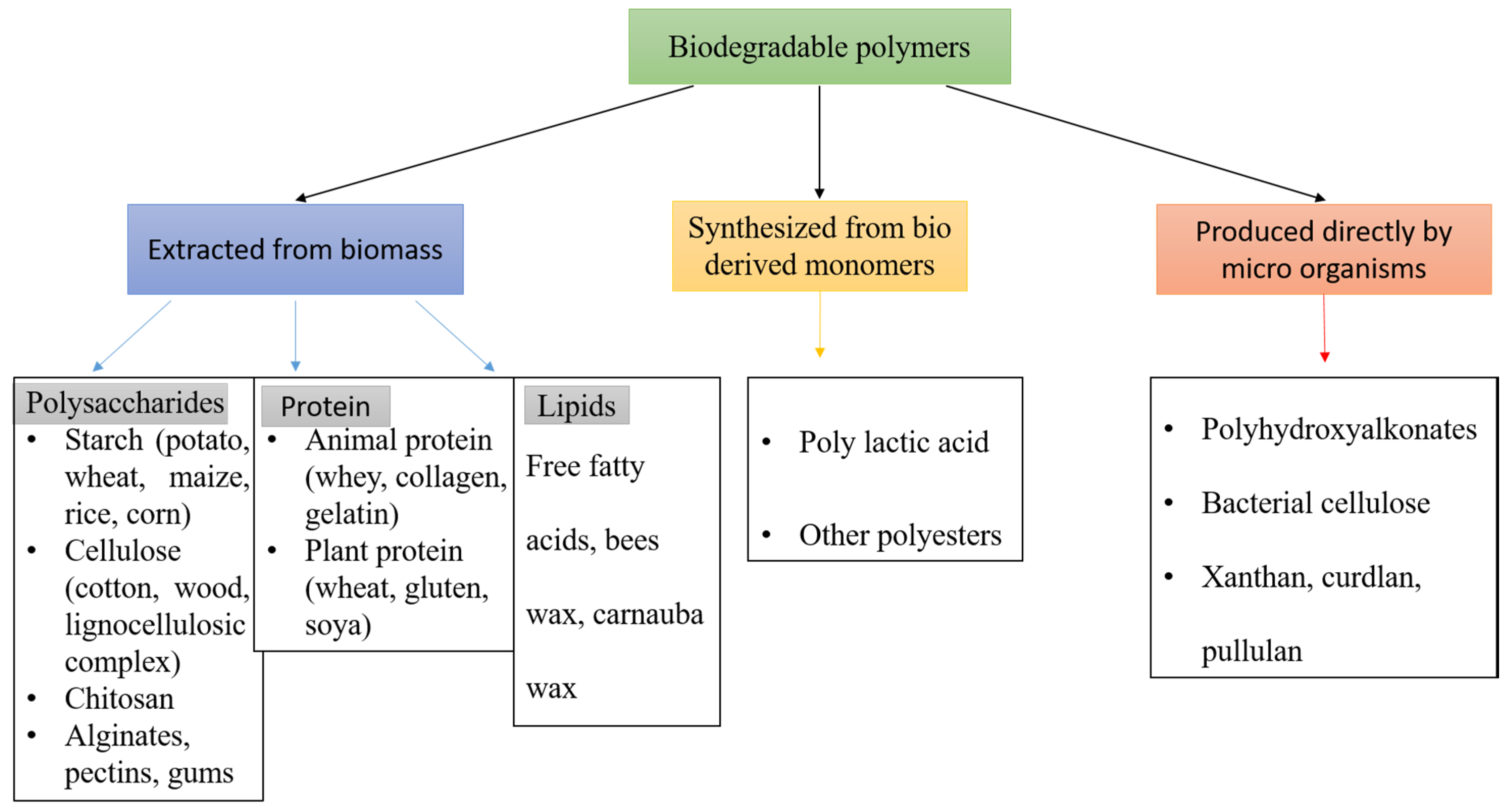

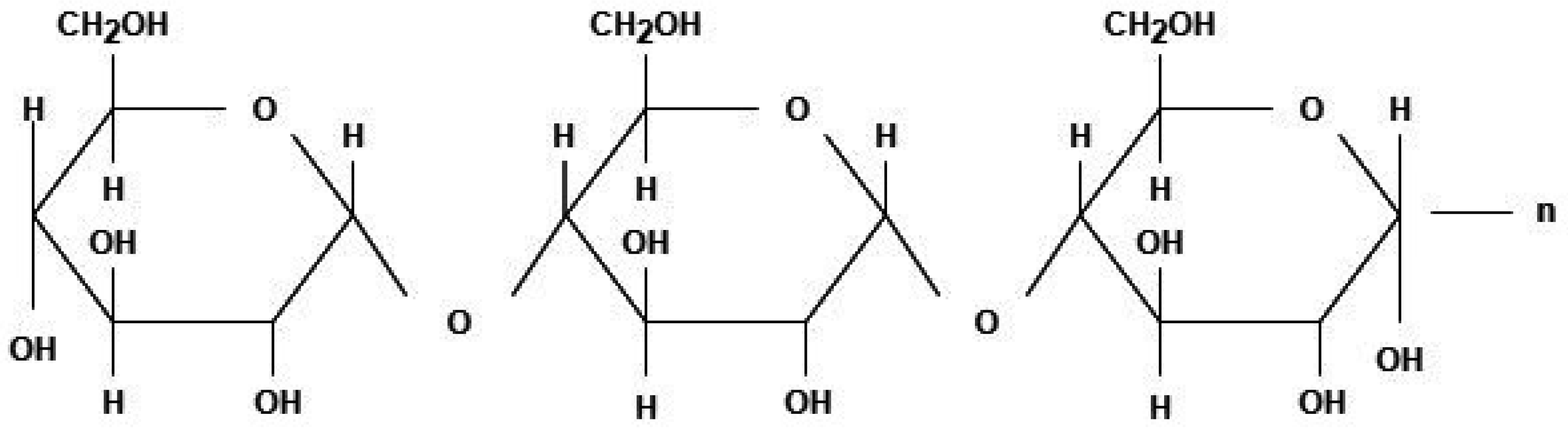

4.2. Polymers

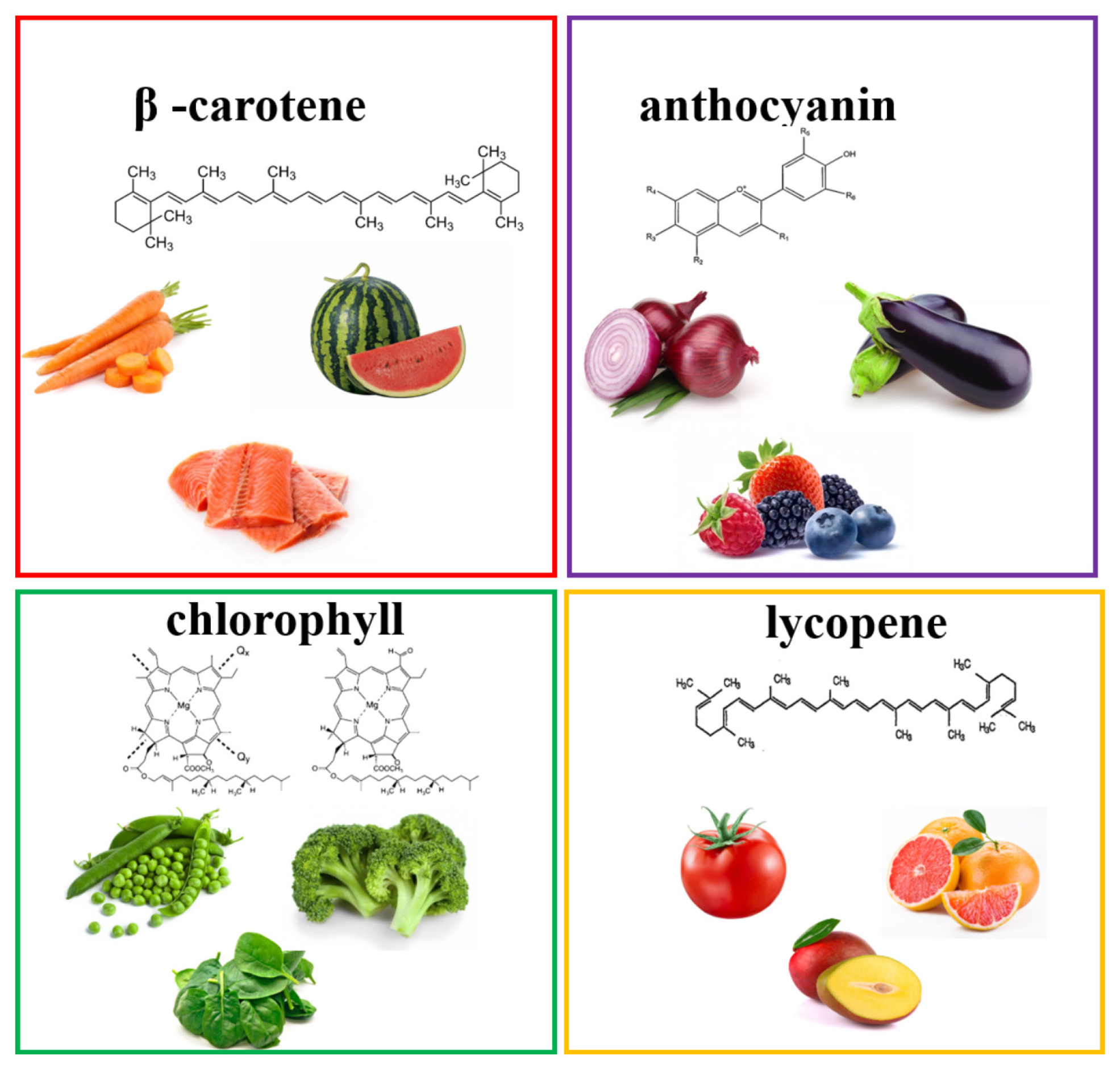

4.3. Antioxidants

5. Intelligent Packaging

5.1. Sensors Used in Food Packaging

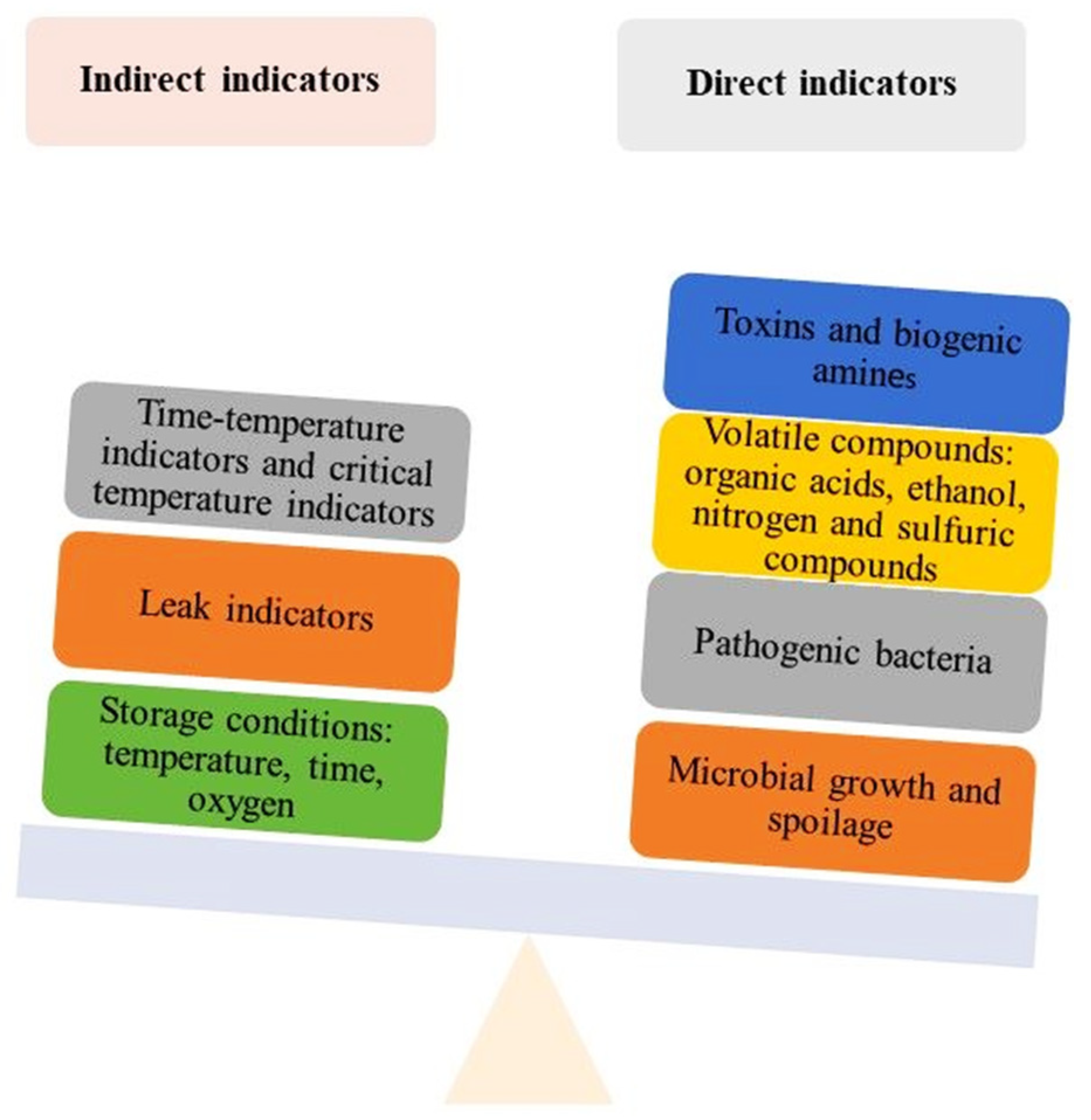

5.2. Indicators Used in Food Packaging

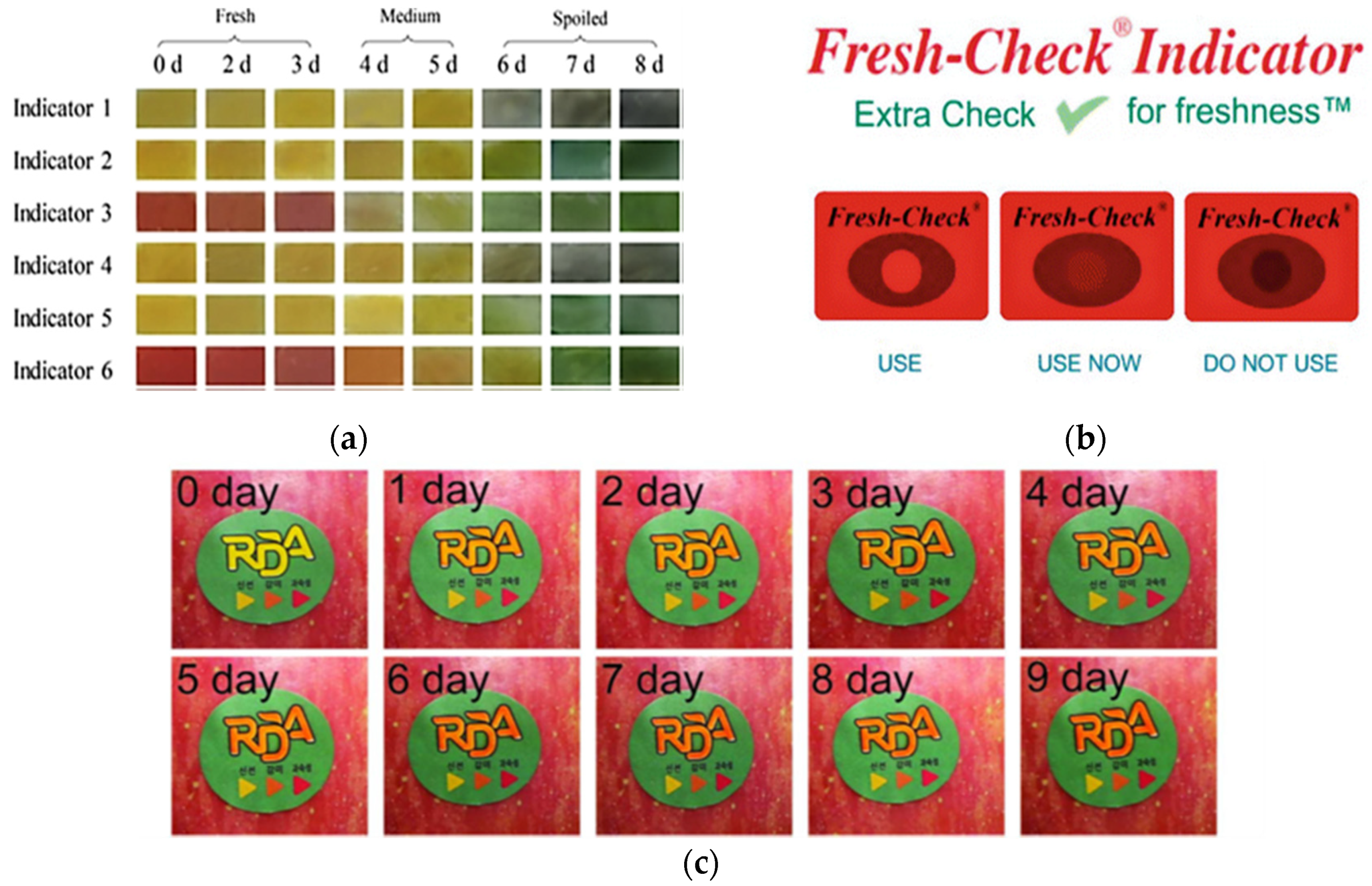

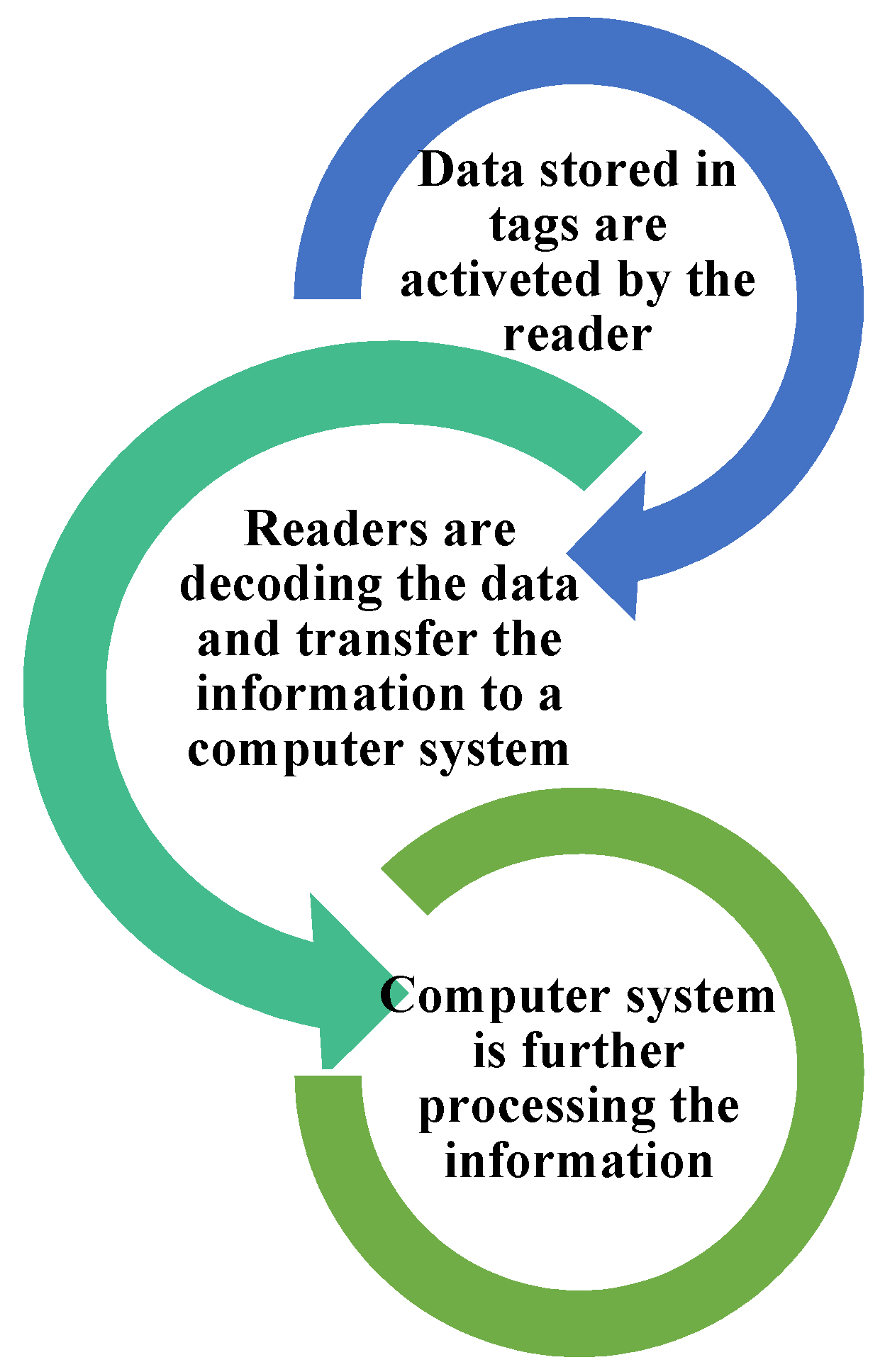

5.3. Radio Frequency Identification

6. Food Packaging Materials

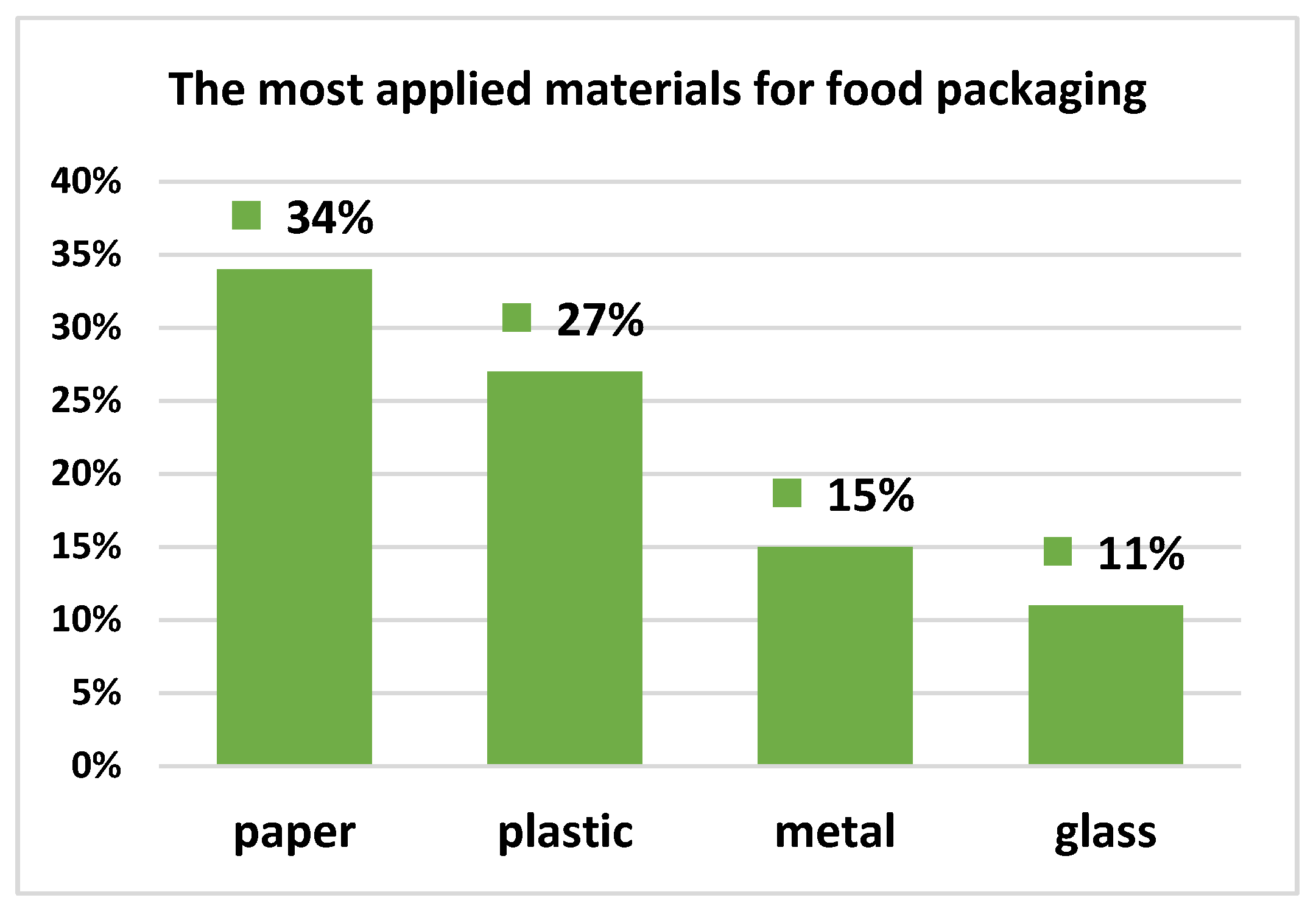

6.1. Typical Packaging Materials

6.2. Alternative Materials

7. Future Perspectives

8. Conclusions

Funding

Conflicts of Interest

References

- Robertson, G.L. History of Food Packaging. In Reference Module in Food Science; Elsevier: Brisbane, Australia, 2019. [Google Scholar]

- Groh, K.J.; Backhaus, T.; Carney-Almroth, B.; Geueke, B.; Inostroza, P.A.; Lennquist, A.; Leslie, H.A.; Maffini, M.; Slunge, D.; Trasande, L.; et al. Overview of known plastic packaging-associated chemicals and their hazards. Sci. Total Environ. 2019, 651, 3253–3268. [Google Scholar] [CrossRef] [PubMed]

- Dainelli, D.; Gontard, N.; Spyropoulos, D.; Zondervan-van den Beuken, E.; Tobback, P. Active and intelligent food packaging: Legal aspects and safety concerns. Trends Food Sci. Technol. 2008, 19, S103–S112. [Google Scholar] [CrossRef]

- FAO. Appropriate Food Packaging Solutions for Developing Countries; Food and Agriculture Organization of the United Nations: Rome, Italy, 2014. [Google Scholar]

- Wikström, F.; Williams, H.; Trischler, J.; Rowe, Z. The Importance of Packaging Functions for Food Waste of Different Products in Households. Sustainability 2019, 11, 2641. [Google Scholar] [CrossRef] [Green Version]

- Fuertes, G.; Soto, I.; Carrasco, R.; Vargas, M.; Sabattin, J.; Lagos, C. Intelligent Packaging Systems: Sensors and Nanosensors to Monitor Food Quality and Safety. J. Sens. 2016, 2016, 1–8. [Google Scholar] [CrossRef] [Green Version]

- Schaefer, D.; Cheung, W.M. Smart Packaging: Opportunities and Challenges. Procedia CIRP 2018, 72, 1022–1027. [Google Scholar] [CrossRef]

- Renata Dobrucka, R.C. Active and Intelligent Packaging Food—Research and Development—A Review. Pol. J. Food Nutr. Sci. 2014, 64, 7–15. [Google Scholar] [CrossRef] [Green Version]

- Robertson, G.L. Food Packaging and Shelf Life; CRC Press: Boca Raton, FL, USA, 2009. [Google Scholar]

- Yam, K.L.; Takhistov, P.T.; Miltz, J. Intelligent Packaging: Concepts and Applications. J. Food Sci. 2005, 70, R1–R10. [Google Scholar] [CrossRef]

- Madhusudan, P.; Chellukuri, N.; Shivakumar, N. Smart packaging of food for the 21st century—A review with futuristic trends, their feasibility and economics. Mater. Today Proc. 2018, 5, 21018–21022. [Google Scholar] [CrossRef]

- Restuccia, D.; Spizzirri, U.G.; Parisi, O.I.; Cirillo, G.; Curcio, M.; Iemma, F.; Puoci, F.; Vinci, G.; Picci, N. New EU regulation aspects and global market of active and intelligent packaging for food industry applications. Food Control 2010, 21, 1425–1435. [Google Scholar] [CrossRef]

- Ghoshal, G. Recent Trends in Active, Smart, and Intelligent Packaging for Food Products. In Food Packaging and Preservation; Academic Press: Cambridge, MA, USA, 2018; pp. 343–374. [Google Scholar]

- Xiao, B.; Wang, S.; Wang, Y.A.N.; Jiang, G.; Zhang, Y.; Chen, H.; Liang, M.; Long, G.; Chen, X. Effective Thermal Conductivity of Porous Media with Roughened Surfaces by Fractal-Monte Carlo Simulations. Fractals 2020, 28, 2050029. [Google Scholar] [CrossRef]

- Mesko, B. The Real Era of the Art of Medicine Begins with Artificial Intelligence. J. Med. Internet Res. 2019, 21, 5. [Google Scholar] [CrossRef] [PubMed]

- Wang, C.H.; Zhu, X.F.; Hong, J.C.; Zheng, D.D. Artificial Intelligence in Radiotherapy Treatment Planning: Present and Future. Technol. Cancer Res. Treat. 2019, 18, 11. [Google Scholar] [CrossRef] [PubMed]

- McClements, D.J. Future foods: A manifesto for research priorities in structural design of foods. Food Funct. 2020, 11, 1933–1945. [Google Scholar] [CrossRef] [PubMed]

- Viejo, C.G.; Torrico, D.D.; Dunshea, F.R.; Fuentes, S. Emerging Technologies Based on Artificial Intelligence to Assess the Quality and Consumer Preference of Beverages. Beverages 2019, 5, 62. [Google Scholar] [CrossRef] [Green Version]

- Kalpana, S.; Priyadarshini, S.R.; Maria Leena, M.; Moses, J.A.; Anandharamakrishnan, C. Intelligent packaging: Trends and applications in food systems. Trends Food Sci. Technol. 2019, 93, 145–157. [Google Scholar] [CrossRef]

- Majid, I.; Thakur, M.; Nanda, V. Innovative and Safe Packaging Technologies for Food and Beverages: Updated Review. In Innovations in Technologies for Fermented Food and Beverage Industries; Springer: Cham, Switzerland, 2018; pp. 257–287. [Google Scholar]

- Opara, U.L.; Mditshwa, A. A review on the role of packaging in securing food system: Adding value to food products and reducing losses and waste. Afr. J. Agric. Res. 2013. [Google Scholar] [CrossRef]

- Ortega-Rivas, E. Non-Thermal Food Engineering Operations; Springer: Chihuahua, Mexico, 2012. [Google Scholar]

- Commission, T.E. On materials and articles intended to come into contact with food and repealing Directives 80/590/EEC and 89/109/EEC. In Proceedings of the Regulation (EC) No 1935/2004 of the European Parliament and of the Council, Strasbourg, France, 27 October 2004. [Google Scholar]

- Vanderroost, M.; Ragaert, P.; Devlieghere, F.; De Meulenaer, B. Intelligent food packaging: The next generation. Trends Food Sci. Technol. 2014, 39, 47–62. [Google Scholar] [CrossRef]

- Commission, E. Guidance to the commission regulation (EC) No 450/2009 of 29 May 2009 on active and intelligent materials and articles intended to come into contact with food. Off. J. Eur. Union 2009. [Google Scholar]

- Ghaani, M.; Cozzolino, C.A.; Castelli, G.; Farris, S. An overview of the intelligent packaging technologies in the food sector. Trends in Food Sci. Technol. 2016, 51, 1–11. [Google Scholar] [CrossRef] [Green Version]

- Vilas, C.; Mauricio-Iglesias, M.; García, M.R. Model-based design of smart active packaging systems with antimicrobial activity. Food Packag. Shelf Life 2020, 24. [Google Scholar] [CrossRef]

- Realini, C.E.; Marcos, B. Active and intelligent packaging systems for a modern society. Meat Sci 2014, 98, 404–419. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Fang, Z.; Zhao, Y.; Warner, R.D.; Johnson, S.K. Active and intelligent packaging in meat industry. Trends Food Sci. Technol. 2017, 61, 60–71. [Google Scholar] [CrossRef]

- Ramos, M.; Valdés, A.; Mellinas, A.; Garrigós, M. New Trends in Beverage Packaging Systems: A Review. Beverages 2015, 1, 248–272. [Google Scholar] [CrossRef]

- Galić, K.; Ščetar, M.; Kurek, M. The benefits of processing and packaging. Trends Food Sci. Technol. 2011, 22, 127–137. [Google Scholar] [CrossRef]

- Gnanaraj, J.; Welt, B.A.; Otwell, W.S.; Kristinsson, H.G. Influence of Oxygen Transmission Rate of Packaging Film on Outgrowth of Anaerobic Bacterial Spores. J. Aquat. Food Prod. Technol. 2005, 14, 51–69. [Google Scholar] [CrossRef]

- Holley, R.A.; Patel, D. Improvement in shelf-life and safety of perishable foods by plant essential oils and smoke antimicrobials. Food Microbiol. 2005, 22, 273–292. [Google Scholar] [CrossRef]

- Latos-Brozio, M.; Masek, A. The application of natural food colorants as indicator substances in intelligent biodegradable packaging materials. Food Chem. Toxicol. 2020, 135, 110975. [Google Scholar] [CrossRef]

- Yucel, U. Intelligent Packaging. In Reference Module in Food Science; Elsevier: Amsterdam, The Netherlands, 2016. [Google Scholar] [CrossRef]

- Jung H, H.; Colin H, L.H.; Rodrigues, E.T. Intelligent Packaging; Academic Press: Cambridge, MA, USA, 2005. [Google Scholar]

- Brody, A.L. Packages that heat and cool themselves. Food Technol Chic. 2002, 56, 80–82. [Google Scholar]

- YAM, K.L. The Wiley Encyclopedia of Packaging Technology; John Wiley & Sons: Hoboken, NJ, USA, 2009. [Google Scholar]

- Vodnar, D.C.; Mitrea, L.; Călinoiu, L.F.; Szabo, K.; Ştefănescu, B.E. Removal of bacteria, viruses, and other microbial entities by means of nanoparticles. In Advanced Nanostructures for Environmental Health; Baia, L., Pap, Z., Hernadi, K., Baia, M., Eds.; Elsevier: Amsterdam, The Netherlands, 2020; pp. 465–491. [Google Scholar]

- Rai, M.; Ingle, A.P.; Gupta, I.; Pandit, R.; Paralikar, P.; Gade, A.; Chaud, M.V.; dos Santos, C.A. Smart nanopackaging for the enhancement of food shelf life. Environ. Chem. Lett. 2018, 17, 277–290. [Google Scholar] [CrossRef]

- Huayhongthong, S.; Khuntayaporn, P.; Thirapanmethee, K.; Wanapaisan, P.; Chomnawang, M.T. Raman spectroscopic analysis of food-borne microorganisms. LWT 2019, 114, 108419. [Google Scholar] [CrossRef]

- Pal, M. Nanotechnology: A New Approach in Food Packaging. J. Food Microbiol. Saf. Hyg. 2017, 2. [Google Scholar] [CrossRef]

- Al-Tayyar, N.A.; Youssef, A.M.; Al-Hindi, R. Antimicrobial food packaging based on sustainable Bio-based materials for reducing foodborne Pathogens: A review. Food Chem. 2020, 310, 125915. [Google Scholar] [CrossRef] [PubMed]

- Martau, G.A.; Mihai, M.; Vodnar, D.C. The Use of Chitosan, Alginate, and Pectin in the Biomedical and Food Sector-Biocompatibility, Bioadhesiveness, and Biodegradability. Polymers 2019, 11, 1837. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Lalit, R.; Mayank, P.; Ankur, K. Natural Fibers and Biopolymers Characterization: A Future Potential Composite Material. Stroj. Cas. J. Mech. Eng. 2018, 68, 33–50. [Google Scholar] [CrossRef] [Green Version]

- Youssef, A.M.; Assem, F.M.; Abdel-Aziz, M.E.; Elaaser, M.; Ibrahim, O.A.; Mahmoud, M.; Abd El-Salam, M.H. Development of bionanocomposite materials and its use in coating of Ras cheese. Food Chem. 2019, 270, 467–475. [Google Scholar] [CrossRef]

- Venkatasubbu, G.D.; Baskar, R.; Anusuya, T.; Seshan, C.A.; Chelliah, R. Toxicity mechanism of titanium dioxide and zinc oxide nanoparticles against food pathogens. Colloids Surf. B Biointerfaces 2016, 148, 600–606. [Google Scholar] [CrossRef]

- Grillo, G.; Boffa, L.; Binello, A.; Mantegna, S.; Cravotto, G.; Chemat, F.; Dizhbite, T.; Lauberte, L.; Telysheva, G. Cocoa bean shell waste valorisation; extraction from lab to pilot-scale cavitational reactors. Food Res. Int. 2019, 115, 200–208. [Google Scholar] [CrossRef]

- Vidanarachchi, J.K.; Ranadheera, C.S.; Wijerathne, T.D.; Udayangani, R.M.C.; Himali, S.M.C.; Pickova, J. Applications of Seafood By-Products in the Food Industry and Human Nutrition; Kim, S.K., Ed.; Springer: New York, NY, USA, 2014. [Google Scholar]

- Salazar-Leyva, J.A.; Lizardi-Mendoza, J.; Ramirez-Suarez, J.C.; Valenzuela-Soto, E.M.; Ezquerra-Brauer, J.M.; Castillo-Yanez, F.J.; Pacheco-Aguilar, R. Acidic proteases from Monterey sardine (Sardinops sagax caerulea) immobilized on shrimp waste chitin and chitosan supports: Searching for a by-product catalytic system. Appl. Biochem. Biotechnol. 2013, 171, 795–805. [Google Scholar] [CrossRef]

- Fleury, N.; Lahaye, M. Studies on by-products from the industrial extraction of alginate. J. Appl. Phycol. 1993, 5, 63–69. [Google Scholar] [CrossRef]

- Masmoudi, M.; Besbes, S.; Abbes, F.; Robert, C.; Paquot, M.; Blecker, C.; Attia, H. Pectin Extraction from Lemon By-Product with Acidified Date Juice: Effect of Extraction Conditions on Chemical Composition of Pectins. Food Bioprocess Technol. 2010, 5, 687–695. [Google Scholar] [CrossRef]

- Kazemi, M.; Khodaiyan, F.; Labbafi, M.; Hosseini, S.S. Ultrasonic and heating extraction of pistachio by-product pectin: Physicochemical, structural characterization and functional measurement. J. Food Meas. Charact. 2019, 14, 679–693. [Google Scholar] [CrossRef]

- Lalnunthari, C.; Devi, L.M.; Badwaik, L.S. Extraction of protein and pectin from pumpkin industry by-products and their utilization for developing edible film. J. Food Sci. Technol. 2019, 57, 1807–1816. [Google Scholar] [CrossRef] [PubMed]

- Riaz, A.; Lei, S.; Akhtar, H.M.S.; Wan, P.; Chen, D.; Jabbar, S.; Abid, M.; Hashim, M.M.; Zeng, X. Preparation and characterization of chitosan-based antimicrobial active food packaging film incorporated with apple peel polyphenols. Int. J. Biol. Macromol. 2018, 114, 547–555. [Google Scholar] [CrossRef] [PubMed]

- Bi, F.; Zhang, X.; Bai, R.; Liu, Y.; Liu, J.; Liu, J. Preparation and characterization of antioxidant and antimicrobial packaging films based on chitosan and proanthocyanidins. Int. J. Biol. Macromol. 2019, 134, 11–19. [Google Scholar] [CrossRef] [PubMed]

- Sogut, E.; Seydim, A.C. The effects of Chitosan and grape seed extract-based edible films on the quality of vacuum packaged chicken breast fillets. Food Packag. Shelf Life 2018, 18, 13–20. [Google Scholar] [CrossRef]

- Priyadarshi, R.; Sauraj; Kumar, B.; Deeba, F.; Kulshreshtha, A.; Negi, Y.S. Chitosan films incorporated with Apricot (Prunus armeniaca) kernel essential oil as active food packaging material. Food Hydrocoll. 2018, 85, 158–166. [Google Scholar] [CrossRef]

- Davoodi, M.; Kavoosi, G.; Shakeri, R. Preparation and characterization of potato starch-thymol dispersion and film as potential antioxidant and antibacterial materials. Int. J. Biol. Macromol. 2017, 104, 173–179. [Google Scholar] [CrossRef]

- Ma, X.F.; Yu, J.G.; Wan, J.J. Urea and ethanolamine as a mixed plasticizer for thermoplastic starch. Carbohydr. Polym. 2006, 64, 267–273. [Google Scholar] [CrossRef]

- Assis, R.Q.; Pagno, C.H.; Costa, T.M.H.; Flôres, S.H.; Rios, A.d.O. Synthesis of biodegradable films based on cassava starch containing free and nanoencapsulated β-carotene. Packag. Technol. Sci. 2018, 31, 157–166. [Google Scholar] [CrossRef]

- Yong, H.; Wang, X.; Bai, R.; Miao, Z.; Zhang, X.; Liu, J. Development of antioxidant and intelligent pH-sensing packaging films by incorporating purple-fleshed sweet potato extract into chitosan matrix. Food Hydrocoll. 2019, 90, 216–224. [Google Scholar] [CrossRef]

- Ma, G.; Chen, Y. Polyphenol supplementation benefits human health via gut microbiota: A systematic review via meta-analysis. J. Funct. Foods 2020, 66. [Google Scholar] [CrossRef]

- Moorthy, M.; Chaiyakunapruk, N.; Jacob, S.A.; Palanisamy, U.D. Prebiotic potential of polyphenols, its effect on gut microbiota and anthropometric/clinical markers: A systematic review of randomised controlled trials. Trends Food Sci. Technol. 2020. [Google Scholar] [CrossRef]

- Dzah, C.S.; Duan, Y.; Zhang, H.; Serwah Boateng, N.A.; Ma, H. Latest developments in polyphenol recovery and purification from plant by-products: A review. Trends Food Sci. Technol. 2020, 99, 375–388. [Google Scholar] [CrossRef]

- Calinoiu, L.F.; Vodnar, D.C. Thermal Processing for the Release of Phenolic Compounds from Wheat and Oat Bran. Biomolecules 2019, 10, 21. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Castro-Barquero, S.; Shahbaz, M.; Estruch, R.; Casas, R. Cardiovascular Protection by Dietary Polyphenols. In Reference Module in Food Science; Elsevier: Amsterdam, The Netherlands, 2019. [Google Scholar]

- Mendonca, R.D.; Carvalho, N.C.; Martin-Moreno, J.M.; Pimenta, A.M.; Lopes, A.C.S.; Gea, A.; Martinez-Gonzalez, M.A.; Bes-Rastrollo, M. Total polyphenol intake, polyphenol subtypes and incidence of cardiovascular disease: The SUN cohort study. Nutr. Metab. Cardiovasc. Dis. 2019, 29, 69–78. [Google Scholar] [CrossRef] [PubMed]

- Sanches-Silva, A.; Testai, L.; Nabavi, S.F.; Battino, M.; Pandima Devi, K.; Tejada, S.; Sureda, A.; Xu, S.; Yousefi, B.; Majidinia, M.; et al. Therapeutic potential of polyphenols in cardiovascular diseases: Regulation of mTOR signaling pathway. Pharmacol. Res. 2020, 152, 104626. [Google Scholar] [CrossRef]

- Burgos-Edwards, A.; Martín-Pérez, L.; Jiménez-Aspee, F.; Theoduloz, C.; Schmeda-Hirschmann, G.; Larrosa, M. Anti-inflammatory effect of polyphenols from Chilean currants (Ribes magellanicum and R. punctatum) after in vitro gastrointestinal digestion on Caco-2 cells. J. Funct. Foods 2019, 59, 329–336. [Google Scholar] [CrossRef]

- Dzah, C.S.; Duan, Y.; Zhang, H.; Wen, C.; Zhang, J.; Chen, G.; Ma, H. The effects of ultrasound assisted extraction on yield, antioxidant, anticancer and antimicrobial activity of polyphenol extracts: A review. Food Biosci. 2020, 35, 100547. [Google Scholar] [CrossRef]

- Hoskin, R.T.; Xiong, J.; Esposito, D.A.; Lila, M.A. Blueberry polyphenol-protein food ingredients: The impact of spray drying on the in vitro antioxidant activity, anti-inflammatory markers, glucose metabolism and fibroblast migration. Food Chem. 2019, 280, 187–194. [Google Scholar] [CrossRef]

- Khouya, T.; Ramchoun, M.; Amrani, S.; Harnafi, H.; Rouis, M.; Couchie, D.; Simmet, T.; Alem, C. Anti-inflammatory and anticoagulant effects of polyphenol-rich extracts from Thymus atlanticus: An in vitro and in vivo study. J. Ethnopharmacol. 2020, 252, 112475. [Google Scholar] [CrossRef]

- Le Sage, F.; Meilhac, O.; Gonthier, M.P. Anti-inflammatory and antioxidant effects of polyphenols extracted from Antirhea borbonica medicinal plant on adipocytes exposed to Porphyromonas gingivalis and Escherichia coli lipopolysaccharides. Pharmacol. Res. 2017, 119, 303–312. [Google Scholar] [CrossRef] [PubMed]

- Sajadimajd, S.; Bahramsoltani, R.; Iranpanah, A.; Kumar Patra, J.; Das, G.; Gouda, S.; Rahimi, R.; Rezaeiamiri, E.; Cao, H.; Giampieri, F.; et al. Advances on Natural Polyphenols as Anticancer Agents for Skin Cancer. Pharmacol. Res. 2020, 151, 104584. [Google Scholar] [CrossRef] [PubMed]

- Zhang, H.; Tsao, R. Dietary polyphenols, oxidative stress and antioxidant and anti-inflammatory effects. Curr. Opin. Food Sci. 2016, 8, 33–42. [Google Scholar] [CrossRef]

- Han, J.-W.; Ruiz-Garcia, L.; Qian, J.-P.; Yang, X.-T. Food Packaging: A Comprehensive Review and Future Trends. Compr. Rev. Food Sci. Food Saf. 2018, 17, 860–877. [Google Scholar] [CrossRef] [Green Version]

- Dobrucka, R.; Przekop, R. New perspectives in active and intelligent food packaging. J. Food Process. Preserv. 2019, 43. [Google Scholar] [CrossRef]

- Yam, K.L.; Lee, D.S. Emerging food packaging technologies: An overview. In Emerging Food Packaging Technologies; Yam, K.L., Lee, D.S., Eds.; Woodhead Publishing: Cambridge, MA, USA, 2012. [Google Scholar]

- Chen, H.; Zhang, M.; Bhandari, B.; Yang, C. Development of a novel colorimetric food package label for monitoring lean pork freshness. LWT 2019, 99, 43–49. [Google Scholar] [CrossRef] [Green Version]

- Kuswandi, B.; Wicaksono, Y.; Abdullah, A.; Heng, L.Y.; Ahmad, M. Smart packaging: Sensors for monitoring of food quality and safety. Sens. Food Qual. Saf. 2011, 5, 137–146. [Google Scholar] [CrossRef]

- Kim, Y.H.; Yang, Y.J.; Kim, J.S.; Choi, D.S.; Park, S.H.; Jin, S.Y.; Park, J.S. Non-destructive monitoring of apple ripeness using an aldehyde sensitive colorimetric sensor. Food Chem. 2018, 267, 149–156. [Google Scholar] [CrossRef]

- Kerry, J.P.; O’Grady, M.N.; Hogan, S.A. Past, current and potential utilisation of active and intelligent packaging systems for meat and muscle-based products: A review. Meat Sci. 2006, 74, 113–130. [Google Scholar] [CrossRef]

- Mahalik, N.; Kim, K. The Role of Information Technology Developments in Food Supply Chain Integration and Monitoring. In Innovation and Future Trends in Food Manufacturing and Supply Chain Technologies; Leadley, C.E., Ed.; Woodhead Publishing: Cambridge, MA, USA, 2016; pp. 21–37. [Google Scholar]

- Turner, A.P. Biosensors: Sense and sensibility. Chem. Soc. Rev. 2013, 42, 3184–3196. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Flex Alert Company Ltd. Available online: https://flex-alert.com/ (accessed on 26 March 2020).

- Biji, K.B.; Ravishankar, C.N.; Mohan, C.O.; Srinivasa Gopal, T.K. Smart packaging systems for food applications: A review. J. Food Sci. Technol. 2015, 52, 6125–6135. [Google Scholar] [CrossRef] [PubMed]

- Galanakis, C.M. Food Quality and Shelf Life; Elsevier Science: Amsterdam, The Netherland, 2019. [Google Scholar]

- Yahia, E. Postharvest Technology of Perishable Horticultural Commodities; Woodhead Publishing: Cambridge, MA, USA, 2019. [Google Scholar]

- Mitsubishi Gas Chemical. Available online: https://www.mgc.co.jp/eng/products/sc/rpsystem/metal/indicator.html (accessed on 4 April 2020).

- Peng, S.-L.; Pal, S.; Huang, L. Principles of Internet of Things (IoT) Ecosystem: Insight Paradigm; Springer: Cham, Switzerland, 2020. [Google Scholar]

- Dutra Resem Brizio, A.P. Use of Indicators in Intelligent Food Packaging. In Reference Module in Food Science; Elsevier: Amsterdam, The Netherland, 2016. [Google Scholar] [CrossRef]

- DSM Invests in Food Freshness Device Company. Available online: https://www.dsm.com/markets/foodandbeverages/fr_FR/home.html (accessed on 6 April 2020).

- Timestrip® Cold Chain Products for Food. Available online: https://timestrip.com/ (accessed on 6 April 2020).

- 3M™ MonitorMark™ Time Temperature Indicators. Available online: https://www.3m.com/ (accessed on 7 April 2020).

- Kour, H.; Wani, N.A.T.; Anisa Malik, R.K.; Chauhan, H.; Gupta, P.; Bhat, A.; Singh, J. Advances in food packaging—A review. Stewart Postharvest Rev. 2013, 9, 1–7. [Google Scholar] [CrossRef]

- Brizio, A.P.D.R.; Prentice, C. Use of smart photochromic indicator for dynamic monitoring of the shelf life of chilled chicken based products. Meat Sci. 2014, 96, 1219–1226. [Google Scholar] [CrossRef] [PubMed]

- OnVu time-temperature indicator (TTI) system. Available online: https://www.aiche.org/ (accessed on 7 April 2020).

- Baptista, R.C.; Rodrigues, H.; Sant’Ana, A.S. Consumption, knowledge, and food safety practices of Brazilian seafood consumers. Food Res. Int. 2020, 132, 109084. [Google Scholar] [CrossRef] [PubMed]

- TTI Label. Available online: http://vitsab.com/en/startpage/ (accessed on 8 April 2020).

- U.S. Food & Drug Administration. Steam Activated Heat Sensitive Indicators. Available online: https://www.fda.gov/ (accessed on 8 April 2020).

- Karst, T. Evigence Sensors Seeking Quality, Food Safety Uses in Fresh Produce. Available online: https://www.thepacker.com/ (accessed on 9 April 2020).

- Time Temperature Indicators. Available online: https://evigence.com/ (accessed on 9 April 2020).

- Fresh-Check® Indicator Temperature IntelligenceTM. Available online: http://fresh-check.com/ (accessed on 7 April 2020).

- Thermostrip® DL. Available online: https://www.hallcrest.com/ (accessed on 9 April 2020).

- Abad, E.; Palacio, F.; Nuin, M.; de Zarate, A.G.; Juarros, A.; Gomez, J.M.; Marco, S. RFID smart tag for traceability and cold chain monitoring of foods: Demonstration in an intercontinental fresh fish logistic chain. J. Food Eng. 2009, 93, 394–399. [Google Scholar] [CrossRef]

- Munteanu, S.B.; Vasile, C. Vegetable Additives in Food Packaging Polymeric Materials. Polymers 2019, 12, 28. [Google Scholar] [CrossRef] [Green Version]

- Gholami, R.; Ahmadi, E.; Ahmadi, S. Investigating the effect of chitosan, nanopackaging, and modified atmosphere packaging on physical, chemical, and mechanical properties of button mushroom during storage. Food Sci. Nutr. 2020, 8, 224–236. [Google Scholar] [CrossRef] [Green Version]

- Zhang, W.; Li, X.; Jiang, W. Development of antioxidant chitosan film with banana peels extract and its application as coating in maintaining the storage quality of apple. Int. J. Biol. Macromol. 2019. [Google Scholar] [CrossRef]

- Zhao, Y.; Saldaña, M.D.A. Use of potato by-products and gallic acid for development of bioactive film packaging by subcritical water technology. J. Supercrit. Fluids 2019, 143, 97–106. [Google Scholar] [CrossRef]

- Torres-León, C.; Rojas, R.; Contreras-Esquivel, J.C.; Serna-Cock, L.; Belmares-Cerda, R.E.; Aguilar, C.N. Mango seed: Functional and nutritional properties. Trends Food Sci. Technol. 2016, 55, 109–117. [Google Scholar] [CrossRef]

- Torres-León, C.; Vicente, A.A.; Flores-López, M.L.; Rojas, R.; Serna-Cock, L.; Alvarez-Pérez, O.B.; Aguilar, C.N. Edible films and coatings based on mango (var. Ataulfo) by-products to improve gas transfer rate of peach. LWT 2018, 97, 624–631. [Google Scholar] [CrossRef] [Green Version]

- Dufresne, A. Nanocellulose: From Nature to High Performance Tailored Materials, 2nd ed.; Walter de Gruyter GmbH & Co KG: Berlin, Germany, 2018. [Google Scholar]

- Cerqueira, F.M.; Photenhauer, A.L.; Pollet, R.M.; Brown, H.A.; Koropatkin, N.M. Starch Digestion by Gut Bacteria: Crowdsourcing for Carbs. Trends Microbiol. 2020, 28, 95–108. [Google Scholar] [CrossRef] [PubMed]

- Sadeghizadeh-Yazdi, J.; Habibi, M.; Kamali, A.A.; Banaei, M. Application of Edible and Biodegradable Starch-Based Films in Food Packaging: A Systematic Review and Meta-Analysis. Curr. Res. Nutr. Food Sci. J. 2019, 7, 624–637. [Google Scholar] [CrossRef]

- Rodriguez-Amaya, D.B. Update on natural food pigments–A mini-review on carotenoids, anthocyanins, and betalains. Food Res. Int. 2019, 124, 200–205. [Google Scholar] [CrossRef] [PubMed]

- Szabo, K.; Teleky, B.-E.; Mitrea, L.; Călinoiu, L.-F.; Martău, G.-A.; Simon, E.; Varvara, R.-A.; Vodnar, D.C. Active Packaging—Poly(Vinyl Alcohol) Films Enriched with Tomato By-Products Extract. Coatings 2020, 10, 141. [Google Scholar] [CrossRef] [Green Version]

- Stoll, L.; Rech, R.; Flores, S.H.; Nachtigall, S.M.B.; de Oliveira Rios, A. Poly(acid lactic) films with carotenoids extracts: Release study and effect on sunflower oil preservation. Food Chem. 2019, 281, 213–221. [Google Scholar] [CrossRef]

- Mitrea, L.; Calinoiu, L.F.; Martau, G.A.; Szabo, K.; Teleky, B.E.; Muresan, V.; Rusu, A.V.; Socol, C.T.; Vodnar, D.C. Poly(vinyl alcohol)-Based Biofilms Plasticized with Polyols and Colored with Pigments Extracted from Tomato By-Products. Polymers 2020, 12, 532. [Google Scholar] [CrossRef] [Green Version]

- Maciel, V.B.V.; Yoshida, C.M.P.; Franco, T.T. Development of a prototype of a colourimetric temperature indicator for monitoring food quality. J. Food Eng. 2012, 111, 21–27. [Google Scholar] [CrossRef] [Green Version]

- Giovannucci, E. A review of epidemiologic studies of tomatoes, lycopene, and prostate cancer. Exp. Biol. Med. 2002, 227, 852–859. [Google Scholar] [CrossRef]

- Assis, R.Q.; Rios, P.D.A.; de Oliveira Rios, A.; Olivera, F.C. Biodegradable packaging of cellulose acetate incorporated with norbixin, lycopene or zeaxanthin. Ind. Crops Prod. 2020, 147. [Google Scholar] [CrossRef]

- Szabo, K.; Catoi, A.F.; Vodnar, D.C. Bioactive Compounds Extracted from Tomato Processing by-Products as a Source of Valuable Nutrients. Plant Foods Hum. Nutr. 2018, 73, 268–277. [Google Scholar] [CrossRef] [PubMed]

- Baranska, M.; Schutze, W.; Schulz, H. Determination of lycopene and beta-carotene content in tomato fruits and related products: Comparison of FT-Raman, ATR-IR, and NIR spectroscopy. Anal. Chem. 2006, 78, 8456–8461. [Google Scholar] [CrossRef] [PubMed]

- Cerruti, P.; Malinconico, M.; Rychly, J.; Matisova-Rychla, L.; Carfagna, C. Effect of natural antioxidants on the stability of polypropylene films. Polym. Degrad. Stab. 2009, 94, 2095–2100. [Google Scholar] [CrossRef]

- Calinoiu, L.F.; Farcas, A.; Socaci, S.; Vodnar, D.C. Innovative Sources; Academic Press Ltd-Elsevier Science Ltd.: London, UK, 2019; pp. 235–265. [Google Scholar]

- Calinoiu, L.F.; Vodnar, D.C. Whole Grains and Phenolic Acids: A Review on Bioactivity, Functionality, Health Benefits and Bioavailability. Nutrients 2018, 10, 1615. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Vandermeer, C.; Olejar, K.J.; Ricci, A.; Swift, S.; Versari, A.; Kilmartin, P.A. Effect of heat on grape marc extract. Int. J. Nanotechnol. 2018, 15, 792–797. [Google Scholar] [CrossRef]

- Andrade, M.A.; Lima, V.; Sanches Silva, A.; Vilarinho, F.; Castilho, M.C.; Khwaldia, K.; Ramos, F. Pomegranate and grape by-products and their active compounds: Are they a valuable source for food applications? Trends Food Sci. Technol. 2019, 86, 68–84. [Google Scholar] [CrossRef]

| Innovative Packaging | Definitions | Reference |

|---|---|---|

| Active packaging |

| [23] |

| [24] | |

| ||

| Intelligent packaging |

| [23] |

| [25] | |

| [19] | |

| [3] | |

| [26] | |

| Smart packaging |

| [27] |

| [24] | |

| [21] |

| Intrinsic Factors | Extrinsic Factors | Reference |

|---|---|---|

| Water activity | Time–temperature profile | [9] |

| pH value | Temperature control | [31] |

| Redox potential | Relative humidity | [13] |

| Available oxygen | Exposure to light | [32] |

| Nutrients | Microbial environment | [32] |

| Natural microflora | Environment in packaging | [9,13] |

| Biochemical products | Heat treatment | [13] |

| Preservative | Purchaser handling | [13] |

| Type | Trade Name | Manufacturer | Information | Reference |

|---|---|---|---|---|

| Gas indicators | O2 Sense | Freshpoint Lab |

| [24,87,88] |

| Novas | Insignia Technologies Ltd. |

| [24,87] | |

| Ageless Eye | Mitsubishi Gas Chemical Inc. |

| [88,89,90,91] | |

| Freshness indicator | Freshtag | COX Technologies |

| [24,92] |

| Sensorq | DSM NV and Food Quality Sensor International |

| [87,93] | |

| Time-temperature | Timestrip | Timestrip UK Ltd. |

| [87,94] |

| Monitormark | 3M |

| [19,87,95,96] | |

| Time–temperature indicators | Onvu | Ciba Specialty Chemicals and FreshPoint |

| [97,98] |

| L5-8 Smart TTI Seafood Label | Vitsab |

| [24,99,100] | |

| Cook-Chex | Pymah Corp |

| [87,101] | |

| Evigence sensors | EVIGENCE SENSORS |

| [102,103] | |

| Time–temperature indicator/freshness indicator | Fresh-Check | Temptime Corp |

| [19,104] |

| Disinfection Indicator | Thermostrip DL | LCR HALLCREST LLC |

| [105] |

| Advantage | Disadvantage | References | |

|---|---|---|---|

| Typical Packaging Materials | |||

| Glass | Inorganic and chemically inert; | High manufacturing temperatures; Big energy consumption at manufacturing; High net mass; Breaks easily and it is nonbiodegradable. | [1,13] |

| Transparent, recyclable and it does not pollute; | |||

| Easy to model; | |||

| It can be sterilized at high temperatures; | |||

| It offers protection against water and gas vapor; | |||

| It does not deteriorate by oxidation or other forms; | |||

| It does not react with food or the environment. | |||

| Metals (steel, tin, chromium, and aluminum) | It is a barrier to gasses and humidity; | Has high costs of manufacturing; Energy intensive; | [1,13] |

| It can be sterilized and it is recyclable; | |||

| Covers a larger area of the food industry; | |||

| Low toxicity; | |||

| Good mechanical strength and resistance to working. | |||

| Paper and cardboard | Low costs, low weight, recyclable, and biodegradable; | Barriers to moisture and vapor are weak; Shock protection is low. | [1,13] |

| The resulting wastes can be reused for energy recovery; | |||

| It has good printing properties. | |||

| Plastic | Economically efficient; | Replaces glass, metal, and paper packaging; Pollute the soil; It is not degradable and harms marine life; The debris cannot be eliminated and can be ingested from seafood. | [1,13] |

| Good mechanical properties and a barrier to gasses and humidity; | |||

| It is flexible, transparent, or can be colored. | |||

| Alternative Packaging Materials | |||

| Chitosan-based biofilms | Non-toxic and biodegradable; | Restricted scope. | [13,107,108,109] |

| Environmental friendly; | |||

| Antimicrobial and bacteriostatic proprieties; | |||

| Preserve the taste; | |||

| Improve physical, mechanical, and chemical properties; | |||

| Maintain tissue firmness; inhibit the increase of respiration rate. | |||

| Starch-based biofilms | Frequency in nature, renewable; | High water solubility; Insufficient water barrier properties; Weak mechanical properties; Reduced plasticity. | [1,59,107,110] |

| Environmentally friendly; | |||

| Low cost, non-toxic; | |||

| Biodegradable; | |||

| Suitable for foods with low humidity (confectionery and biscuit trays). | |||

| Films and coatings based on mango by-product | Good properties of permeability; | Low surface tension. | [111,112] |

| Color stability; | |||

| Antioxidant activity; | |||

| Hydrophobicity; | |||

| Decreases in manufacturing cost. | |||

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nemes, S.A.; Szabo, K.; Vodnar, D.C. Applicability of Agro-Industrial By-Products in Intelligent Food Packaging. Coatings 2020, 10, 550. https://doi.org/10.3390/coatings10060550

Nemes SA, Szabo K, Vodnar DC. Applicability of Agro-Industrial By-Products in Intelligent Food Packaging. Coatings. 2020; 10(6):550. https://doi.org/10.3390/coatings10060550

Chicago/Turabian StyleNemes, Silvia Amalia, Katalin Szabo, and Dan Cristian Vodnar. 2020. "Applicability of Agro-Industrial By-Products in Intelligent Food Packaging" Coatings 10, no. 6: 550. https://doi.org/10.3390/coatings10060550

APA StyleNemes, S. A., Szabo, K., & Vodnar, D. C. (2020). Applicability of Agro-Industrial By-Products in Intelligent Food Packaging. Coatings, 10(6), 550. https://doi.org/10.3390/coatings10060550