Effect of Cr Atom Plasma Emission Intensity on the Characteristics of Cr-DLC Films Deposited by Pulsed-DC Magnetron Sputtering

Abstract

1. Introduction

2. Experiment Details

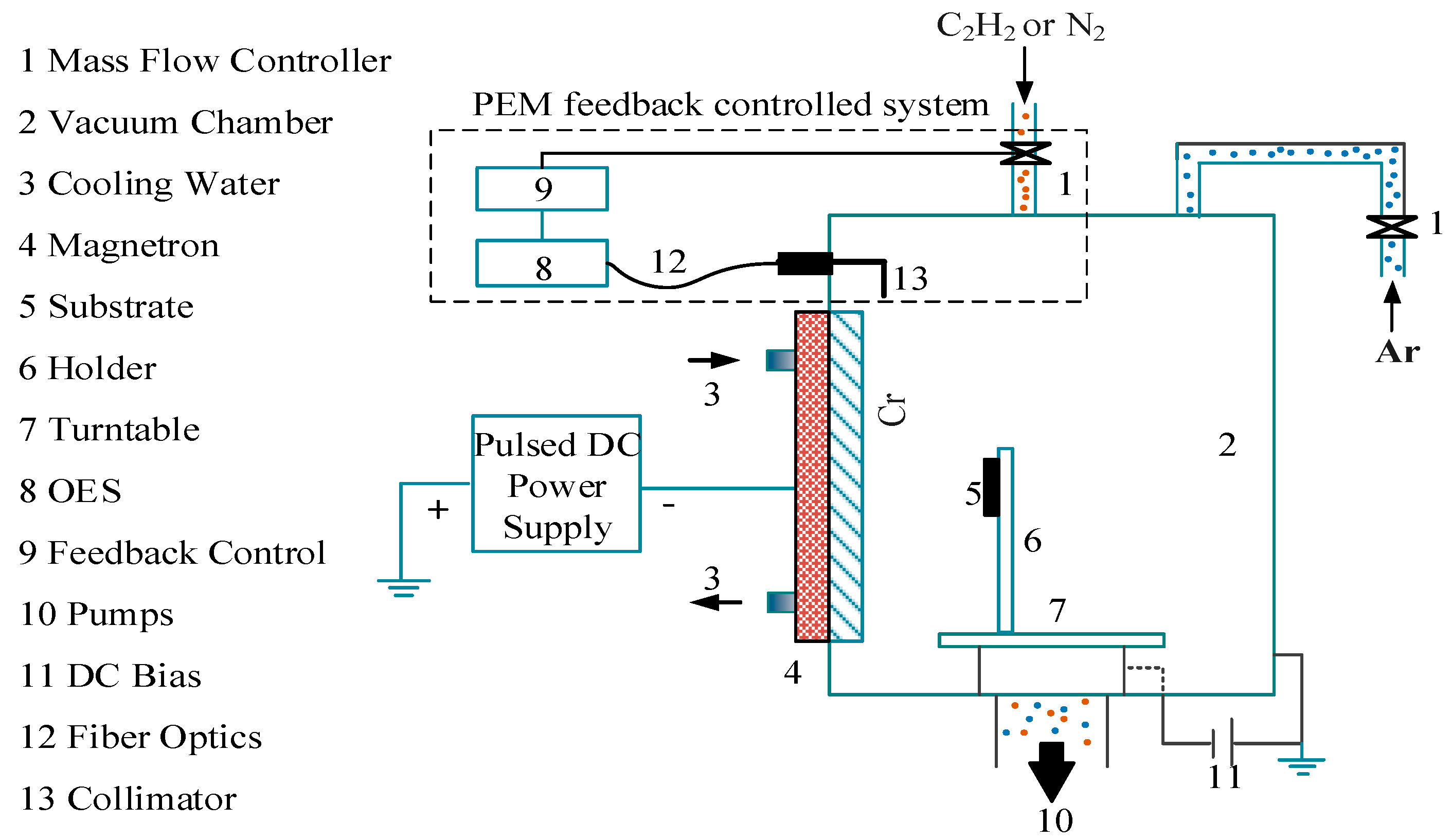

2.1. Deposition

2.2. Characterization

3. Results and Discussion

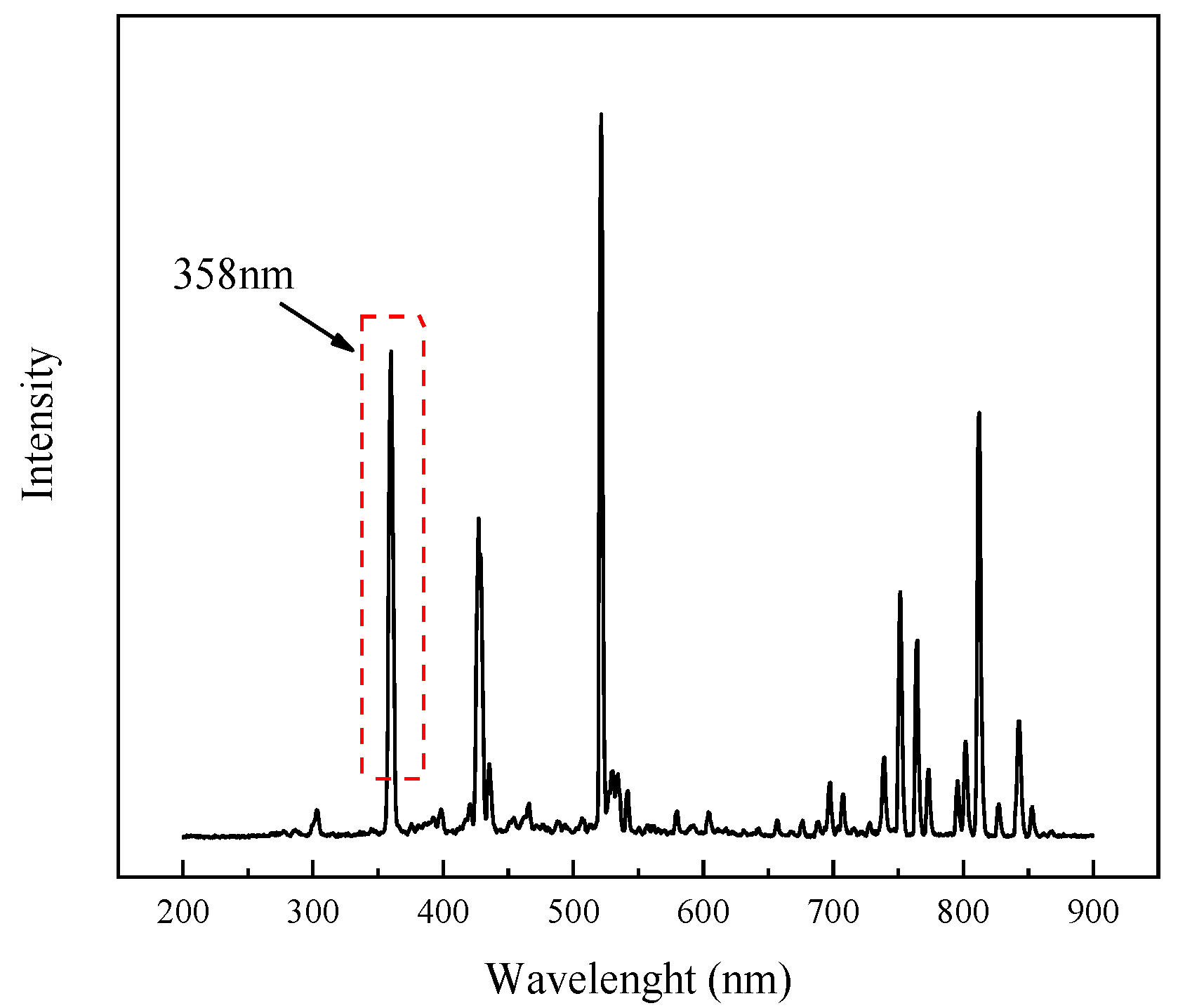

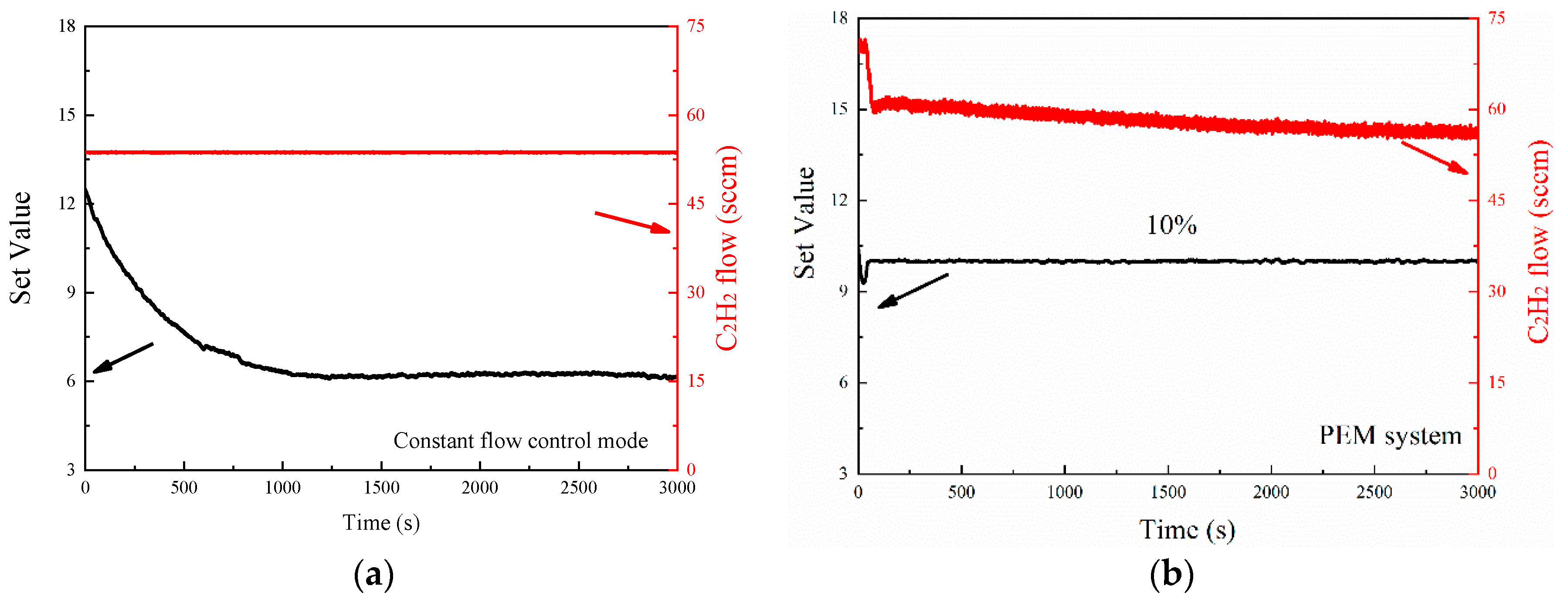

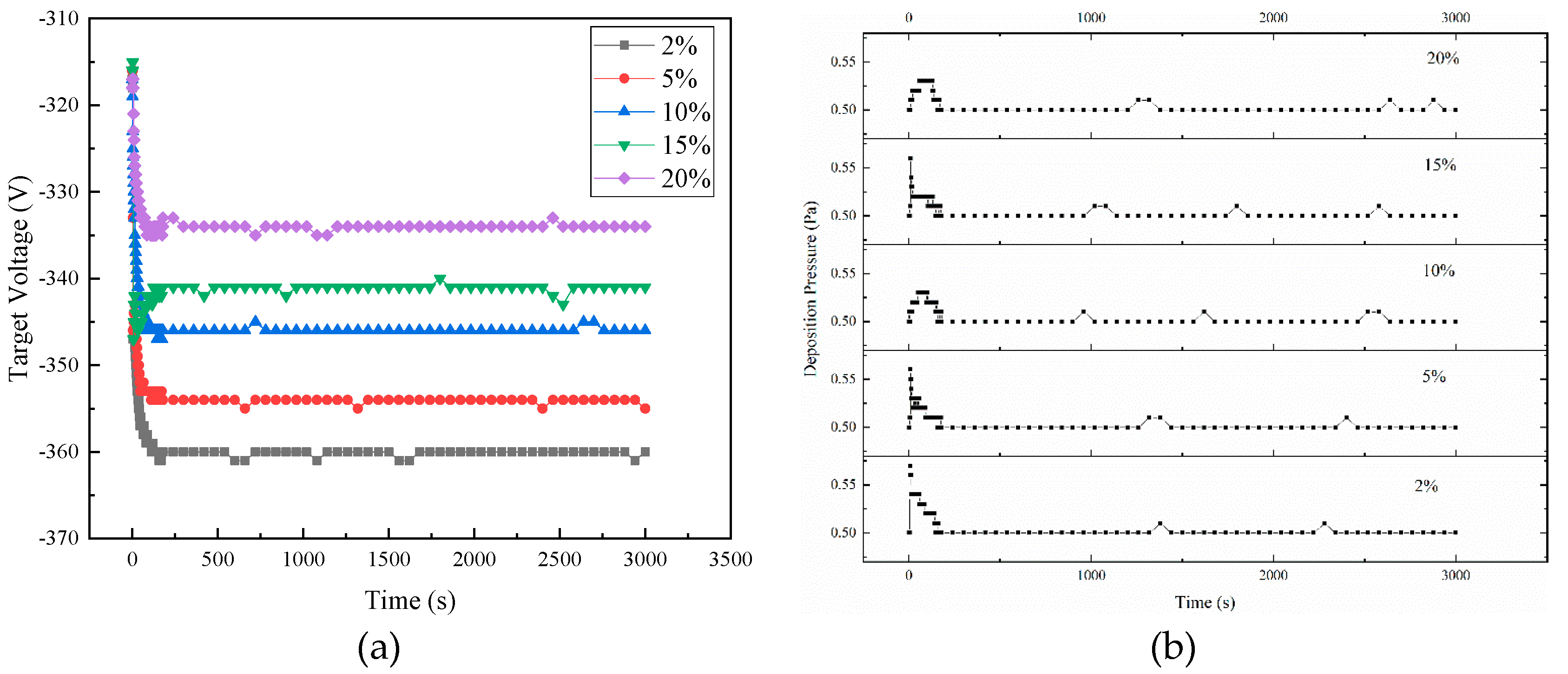

3.1. Stability Comparison: Constant Flow Control Mode vs. PEM System

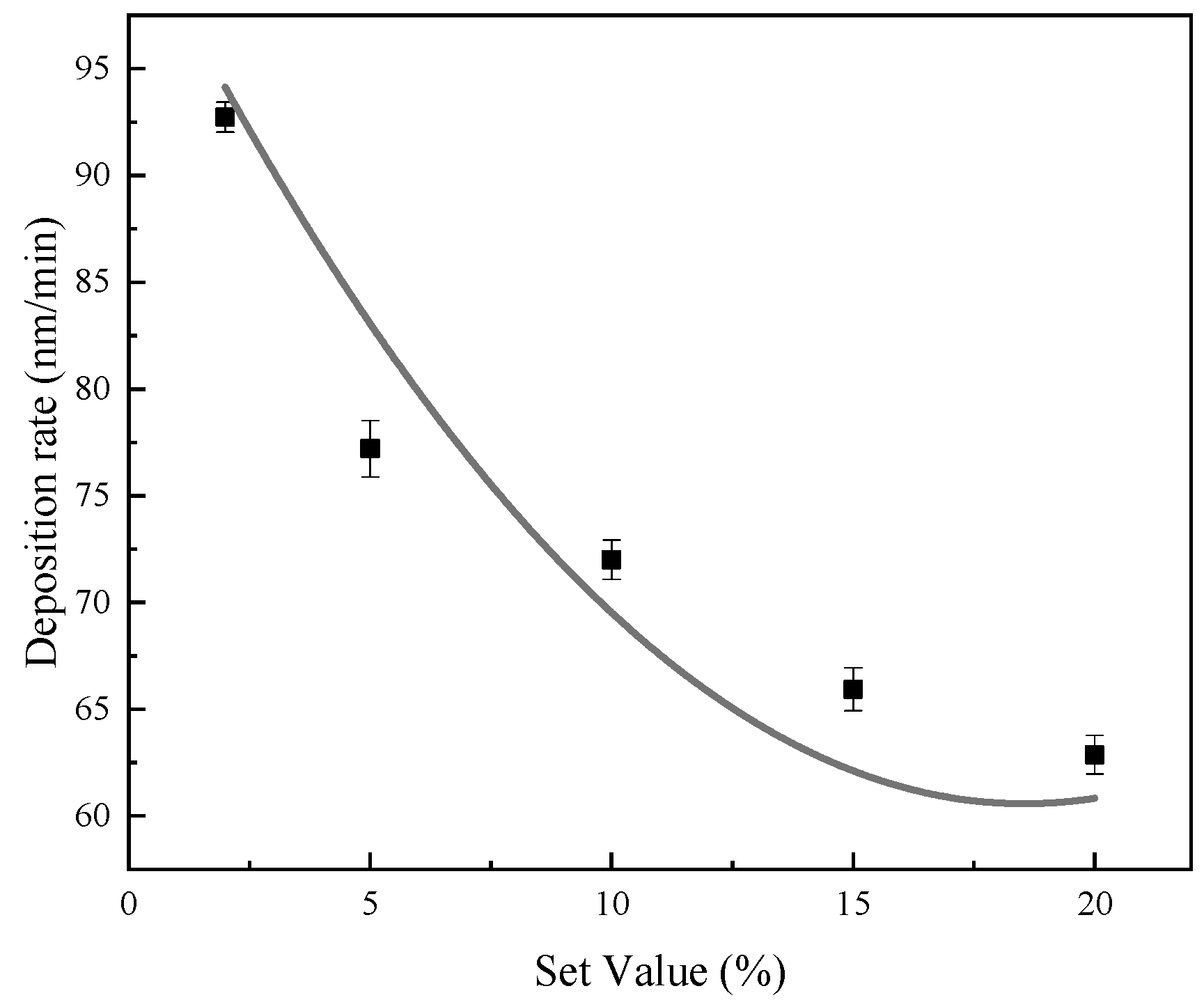

3.2. Effect of Set Values on the Composition and Deposition Rate

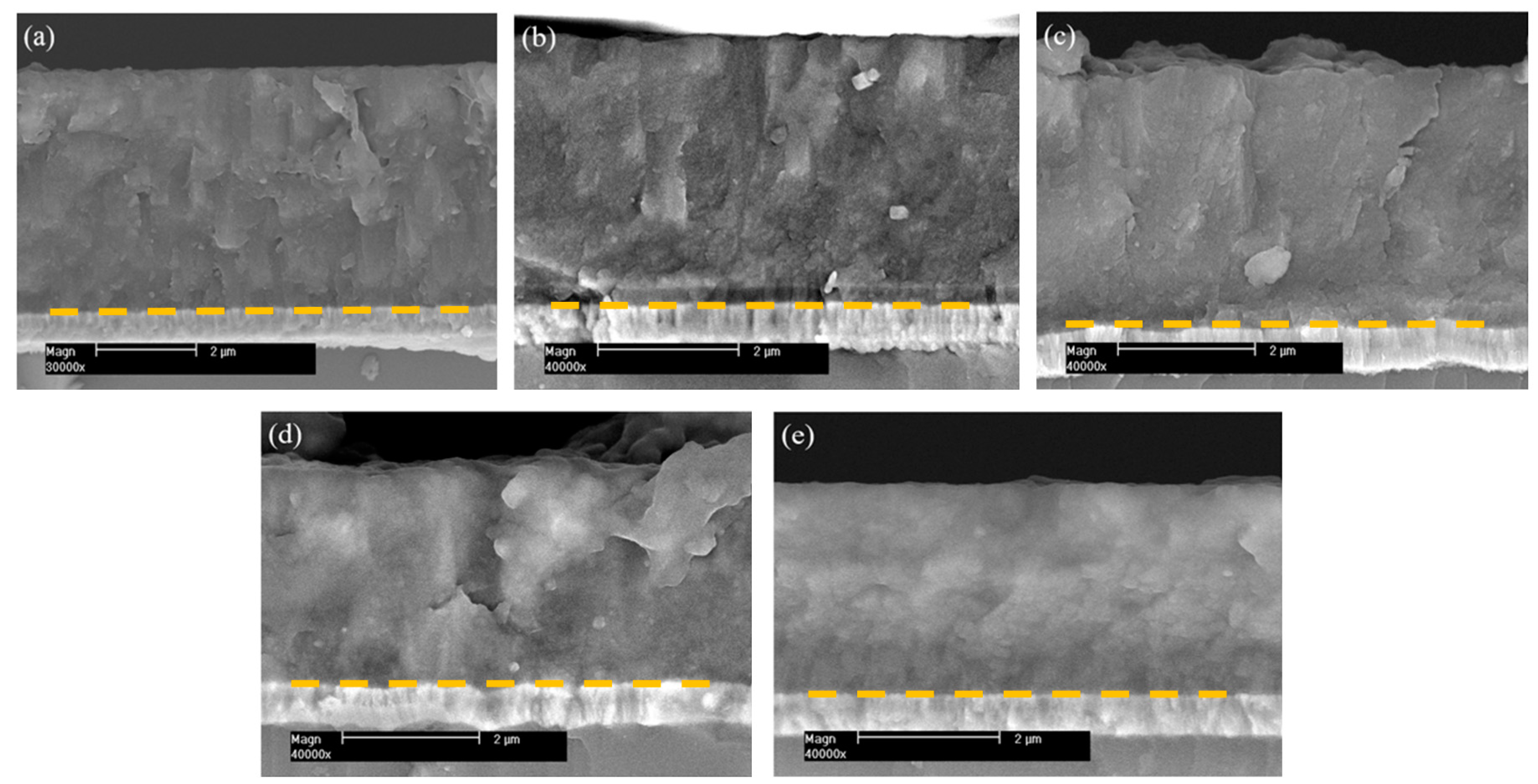

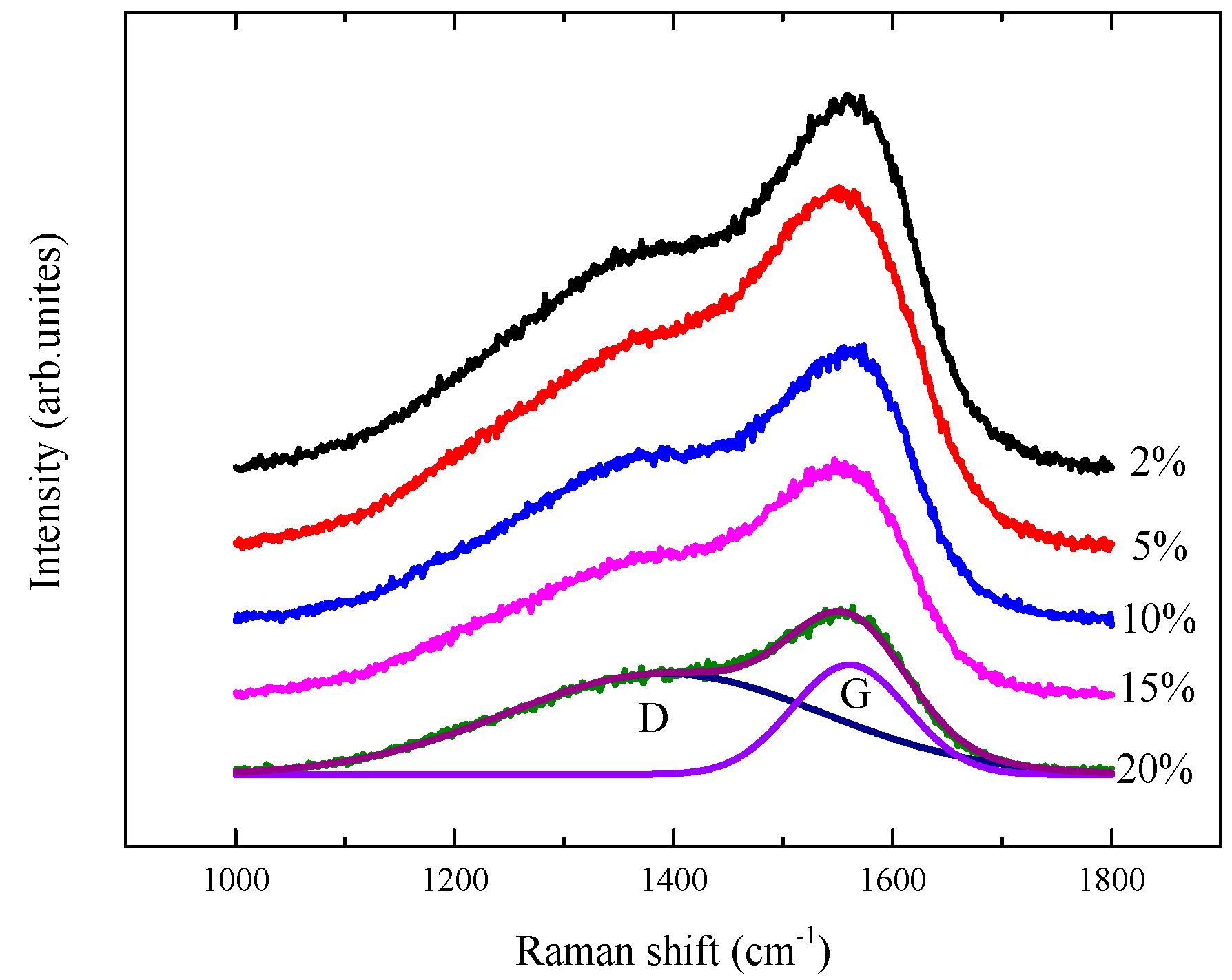

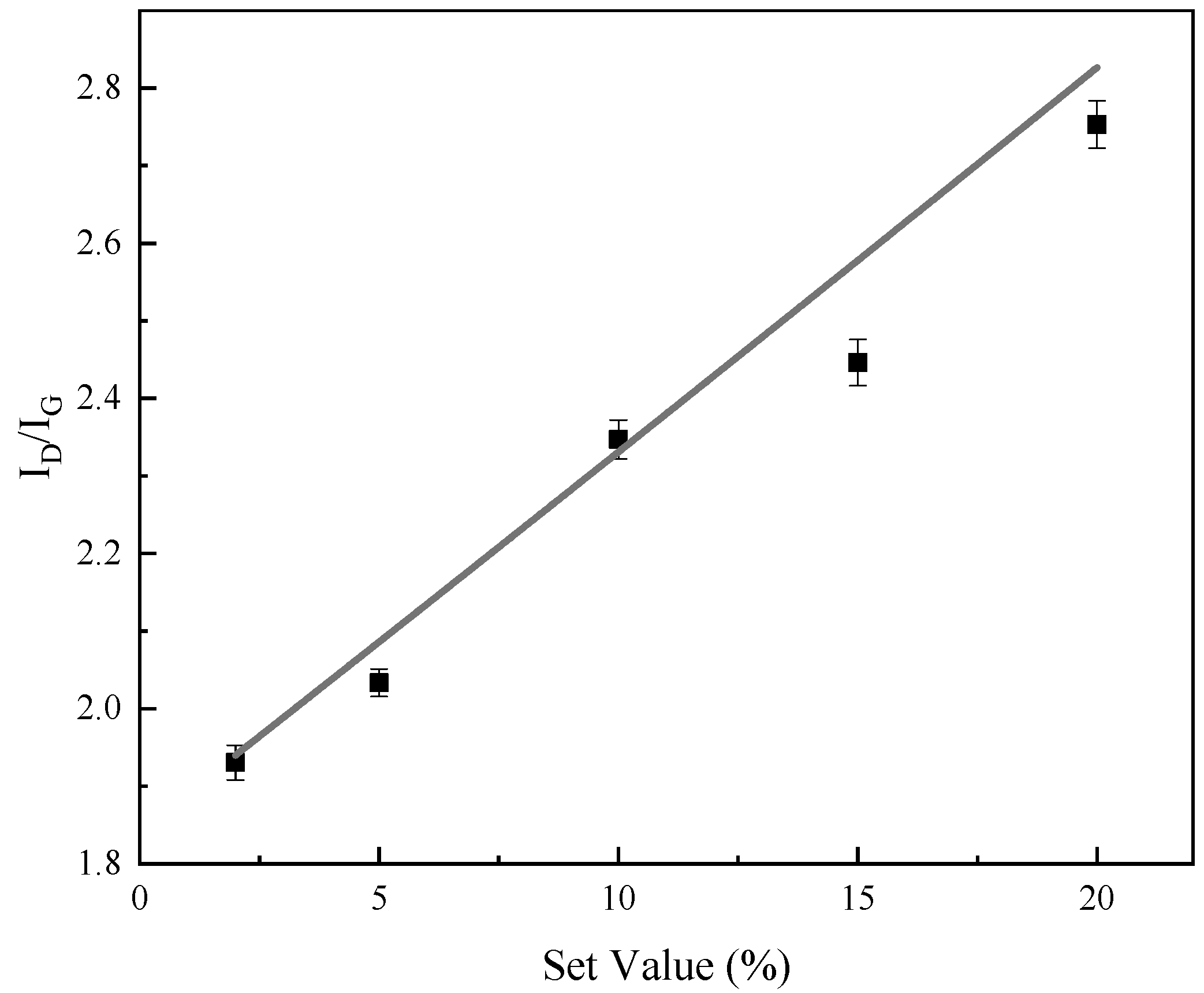

3.3. Effect of Set Values on the Microstructure

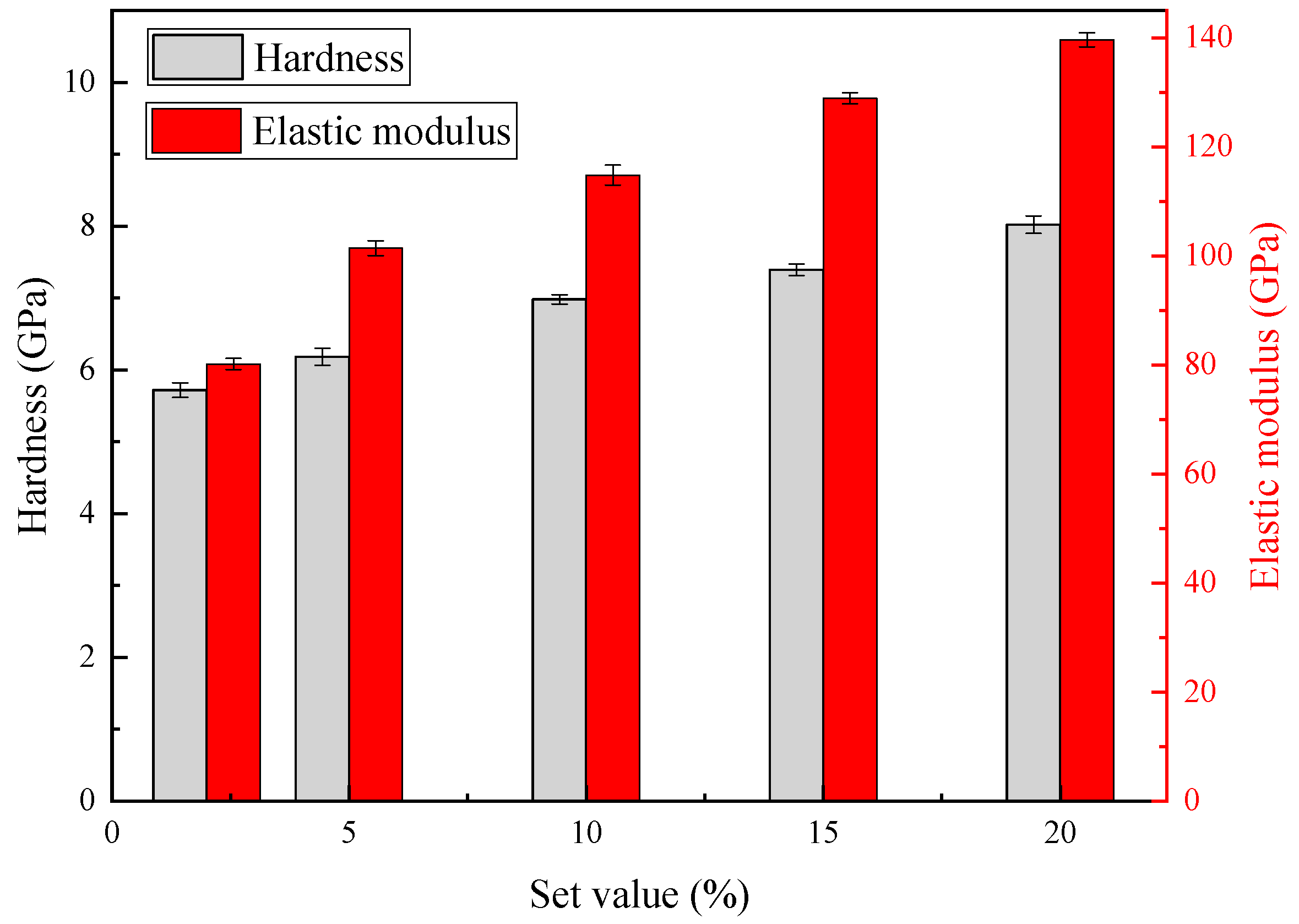

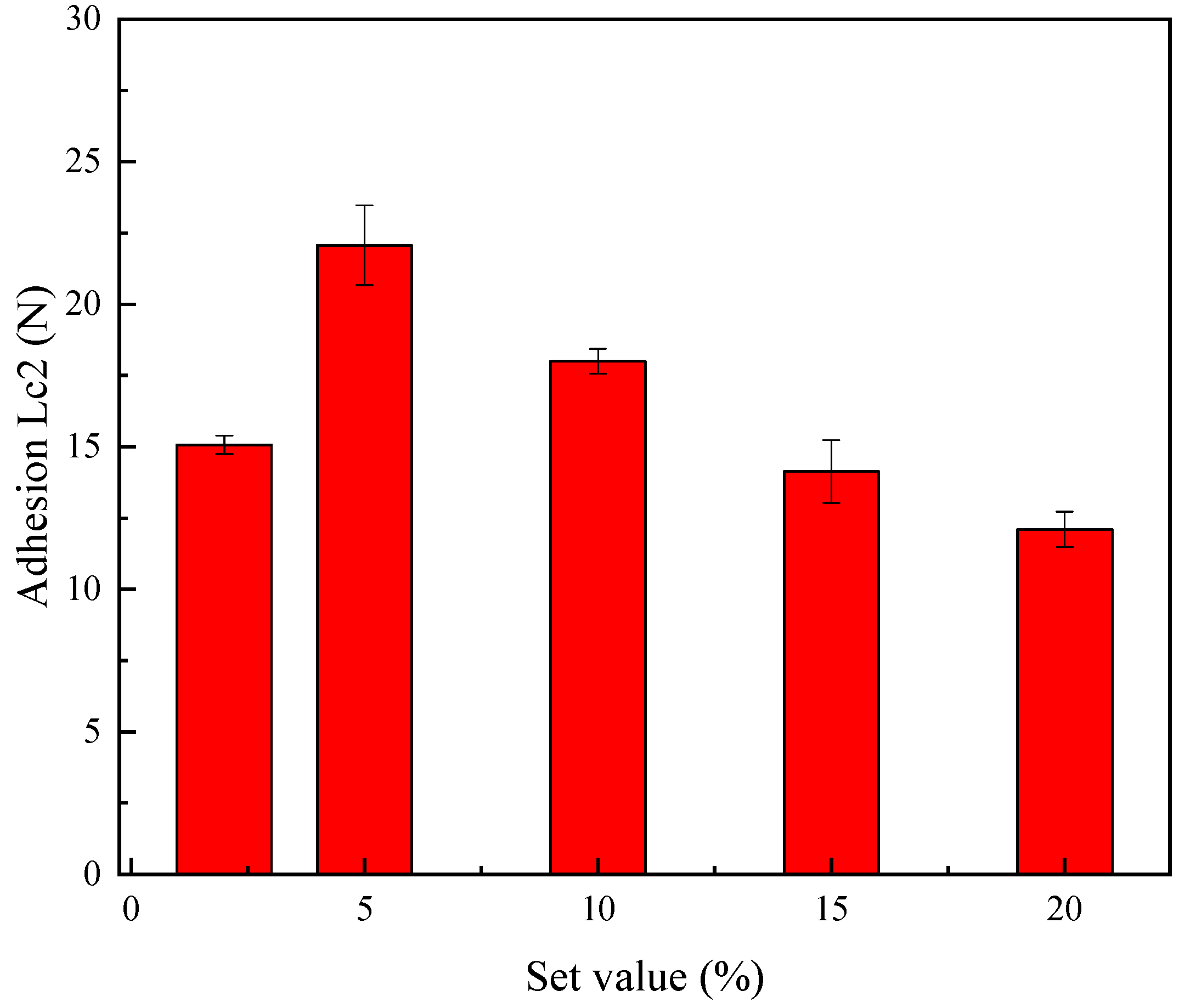

3.4. Effect of Set Values on Mechanical Properties

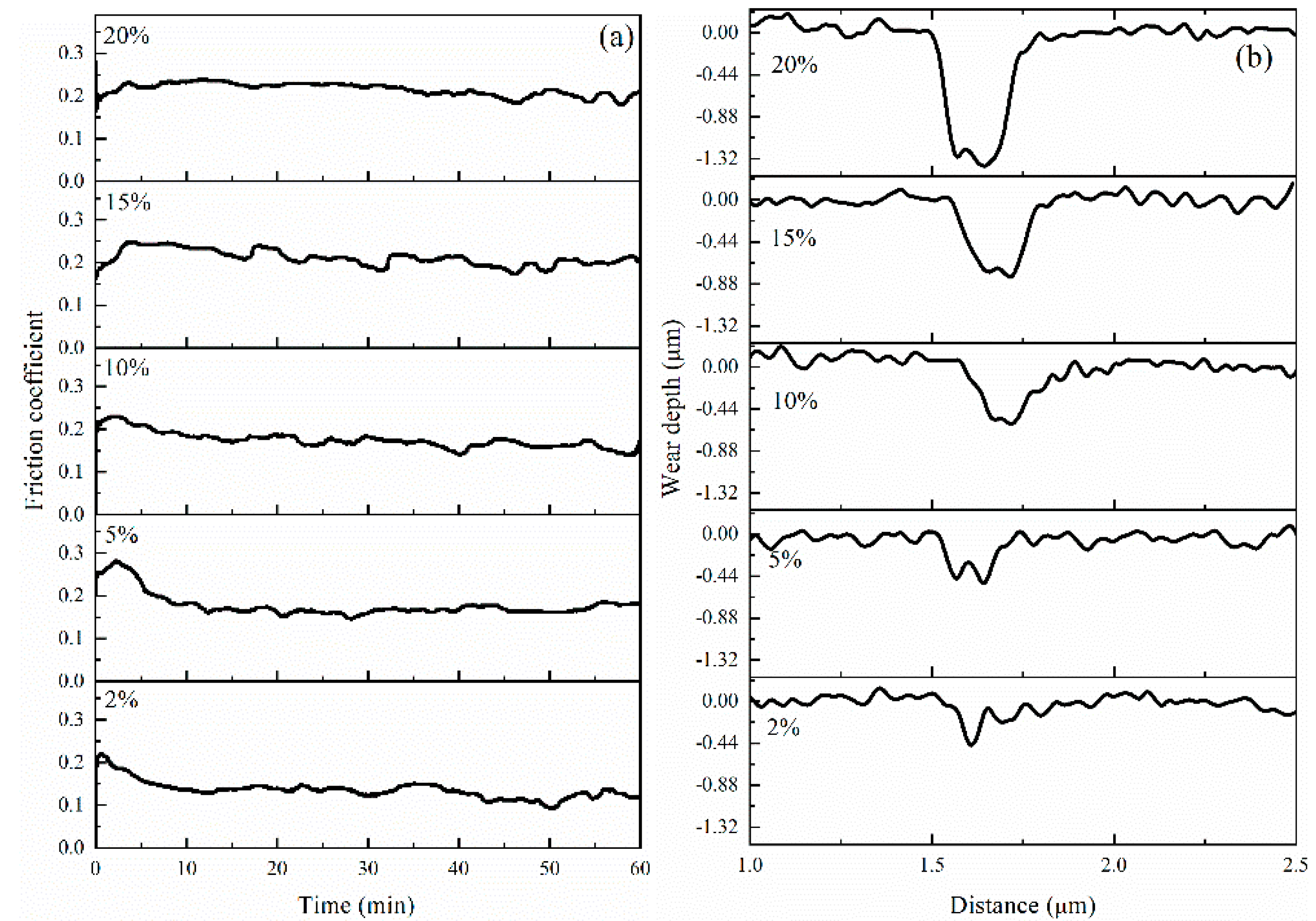

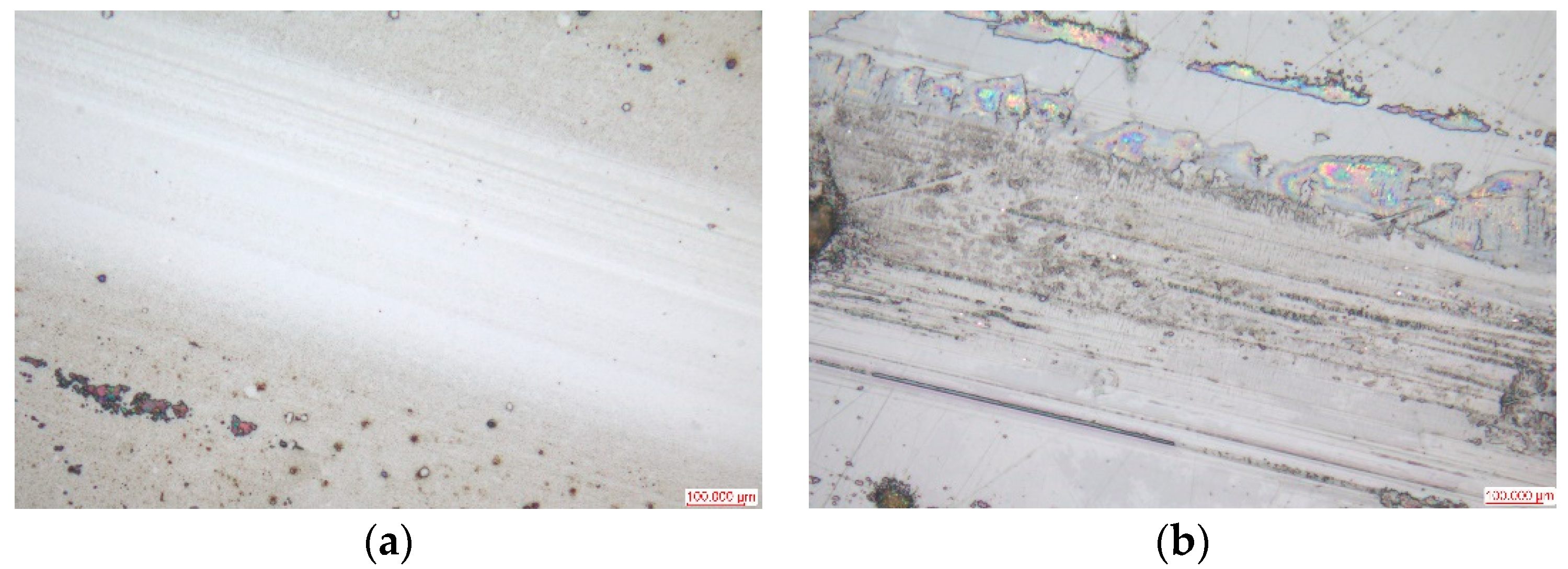

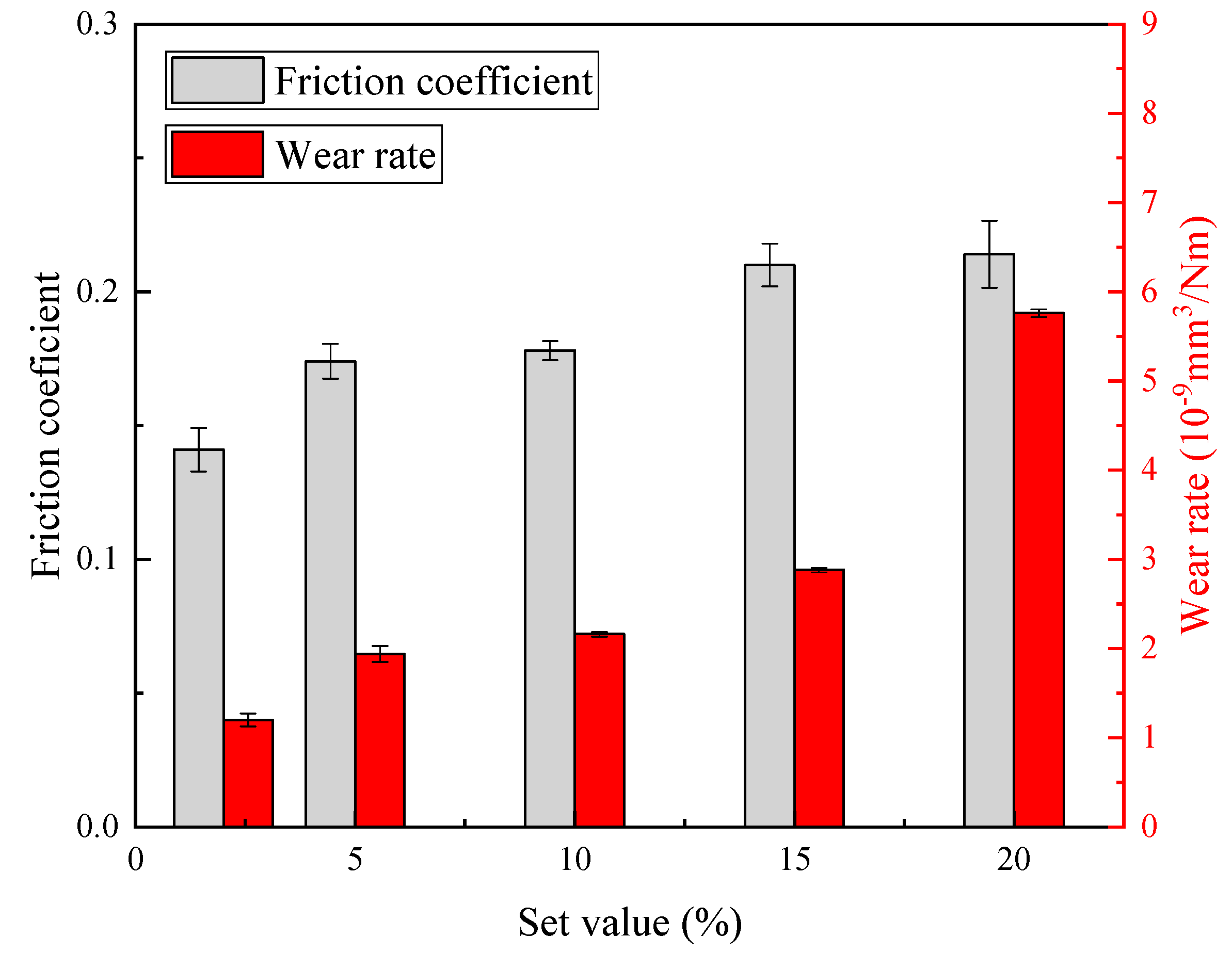

3.5. Effect of Set Values on Tribological Performance

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Sun, L.; Zuo, X.; Guo, P.; Li, X.; Ke, P.; Wang, A. Role of deposition temperature on the mechanical and tribological properties of Cu and Cr co-doped diamond-like carbon films. Thin Solid Films 2019, 678, 16–25. [Google Scholar] [CrossRef]

- Zhou, Y.; Guo, P.; Sun, L.L.; Liu, L.L.; Xu, X.W.; Li, W.X.; Lee, K.R.; Wang, A.Y. Microstructure and property evolution of diamond-like carbon films co-doped by Al and Ti with different ratios. Surf. Coat. Technol. 2019, 361, 83–90. [Google Scholar] [CrossRef]

- Savchenko, D.; Vorlíček, V.; Prokhorov, A.; Kalabukhova, E.; Lančok, J.; Jelínek, M. Raman and EPR spectroscopic studies of chromium-doped diamond-like carbon films. Diam. Relat. Mater. 2018, 83, 30–37. [Google Scholar] [CrossRef]

- Sun, L.L.; Zuo, X.; Guo, P.; Li, X.W.; Ke, P.L.; Wang, A.Y. Structural properties of hydrogenated Al-doped diamond-like carbon films fabricated by a hybrid plasma system. Thin solid Films 2019, 678, 16–25. [Google Scholar] [CrossRef]

- Zhou, Y.F.; Li, L.L.; Shao, W.; Chen, Z.H.; Wang, S.F.; Xing, X.L.; Yang, Q.X. Mechanical and tribological behaviors of Ti-DLC films deposited on 304 stainless steel: Exploration with Ti doping from micro to macro. Diam. Relat. Mater. 2020, 107, 107870. [Google Scholar] [CrossRef]

- Singh, V.; Palshin, V.; Tittsworth, R.; Meletis, E. Local structure of composite Cr-containing diamond-like carbon thin films. Carbon 2006, 44, 1280–1286. [Google Scholar] [CrossRef]

- Xu, X.W.; Zhou, Y.; Liu, L.L.; Guo, P.; Li, W.X.; Lee, K.R.; Cui, P.; Wang, A.Y. Corrosion behavior of diamond-like carbon film induced by Al/Ti co-doping. Appl. Surf. Sci. 2020, 590, 144877. [Google Scholar] [CrossRef]

- Zhou, S.; Liu, L.; Ma, L.; Wang, Y.; Liu, Z. Influence of CH4 Flow Rate on Microstructure and Properties of Ti-C: H Films Deposited by DC Reactive Magnetron Sputtering. Tribol. Trans. 2017, 60, 852–860. [Google Scholar] [CrossRef]

- Santiago, J.A.; Martine, I.F.; Lopez, J.C.S.; Rojas, T.C.; Wennberg, A.; Gonzalez, V.B.; Aldareguia, J.M.; Monclus, M.A.; Arrabal, R.G. Tribomechanical properites of hard Cr-doped DLC coatings deposited by low-frequency HiPIMS. Surf. Coat. Technol. 2020, 382, 124899. [Google Scholar] [CrossRef]

- Shimizu, T.; Villamayor, M.; Lundin, D.; Helmersson, U. Process stabilization by peak current regulation in reactive high-power impulse magnetron sputtering of hafnium nitride. J. Phys. D Appl. Phys. 2016, 49, 065202. [Google Scholar] [CrossRef]

- Audronis, M.; Bellido-Gonzalez, V.; Daniel, B. Control of reactive high power impulse magnetron sputtering processes. Surf. Coat. Technol. 2010, 204, 2159–2164. [Google Scholar] [CrossRef]

- Aubry, E.; Liu, T.; Dekens, A.; Perry, F.; Mangin, S.; Hauet, T.; Billard, A. Synthesis of iron oxide films by reactive magnetron sputtering assisted by plasma emission monitoring. Mater. Chem. Phys. 2019, 223, 360–365. [Google Scholar] [CrossRef]

- Coddet, P.; Pera, M.; Billard, A. Reactive co-sputter deposition of YSZ coatings using plasma emission monitoring. Surf. Coat. Technol. 2011, 205, 3987–3991. [Google Scholar] [CrossRef]

- Wu, W.Y.; Hsiao, B.H.; Chen, P.-H.; Chen, W.-C.; Ho, C.-T.; Chang, C.-L. CrNx films prepared using feedback-controlled high power impulse magnetron sputter deposition. J. Vac. Sci. Technol. A Vac. Surf. Films 2014, 32, 02B115. [Google Scholar] [CrossRef]

- Ohno, S.; Takasawa, N.; Sato, Y.; Yoshikawa, M.; Suzuki, K.; Frach, P.; Shigesato, Y. Photocatalytic TiO2 films deposited by reactive magnetron sputtering with unipolar pulsing and plasma emission control systems. Thin Solid Films 2006, 496, 126–130. [Google Scholar] [CrossRef]

- Hirohata, K.; Nishi, Y.; Tsukamoto, N.; Oka, N.; Sato, Y.; Yamamoto, I.; Shigesato, Y. Al-doped ZnO (AZO) films deposited by reactive sputtering with unipolar-pulsing and plasma-emission control systems. Thin Solid Films 2010, 518, 2980–2983. [Google Scholar] [CrossRef]

- Jiang, X.; Yang, F.-C.; Lee, J.-W.; Chang, C.-L. Effect of an optical emission spectrometer feedback-controlled method on the characterizations of nc-TiC/aC: H coated by high power impulse magnetron sputtering. Diam. Relat. Mater. 2017, 73, 19–24. [Google Scholar] [CrossRef]

- Chang, C.L.; Yang, F.C. Synthesis and characteristics of nc-WC/a-C:H thin films deposited via a reactive HIPIMS process using optical emission spectrometry feedback control. Surf. Coat. Technol. 2018, 350, 1120–1127. [Google Scholar] [CrossRef]

- Purandare, Y.P.; Ehiasarian, A.P.; Eh Hovsepian, P. Target poisoning during CrN deposition by mixed high power impulse magnetron sputtering and unbalanced magnetron sputtering technique. J. Vac. Sci. Technol. A Vac. Surf. Films 2016, 34, 041502. [Google Scholar] [CrossRef]

- Layes, V.; Corbella, C.; Monjé, S.; der Gathen, V.S.; von Keudell, A.; de los Arcos, T. Connection between target poisoning and current waveforms in reactive high-power impulse magnetron sputtering of chromium. Plasma Sour. Sci. Technol. 2018, 27, 084004. [Google Scholar] [CrossRef]

- Guo, T.; Kong, C.C.; Li, X.W.; Guo, P.; Wang, Z.Y.; Wang, A.Y. Microstructure and mechanical properties of Ti/Al co-doped DLC films: Dependence on sputtering current, source gas, and substrate bias. Appl. Surf. Sci. 2017, 410, 51–59. [Google Scholar] [CrossRef]

- Huang, L.; Yuan, J.T.; Li, C. Influence of titanium concentration on mechanical properties and wear resistance to Ti6Al4V of Ti-C: H on cemented carbide. Vacuum 2017, 138, 1–7. [Google Scholar] [CrossRef]

- Wu, Z.Z.; Tian, X.B.; Gui, G.; Gong, C.Z.; Yang, S.Q.; Chu, P.K. Microstructure and surface properties of chromium-doped diamond -like carbon thin films fabricated by high power pylsed magnetron sputtering. Appl. Surf. Sci. 2013, 276, 31–36. [Google Scholar] [CrossRef]

- Tillmann, W.; Dias, N.F.; Stangier, D. Tribo-mechanical properties of CrC/a-C thin films sequentially deposited by HiPIMS and mfMS. Surf. Coat. Technol. 2018, 335, 173–180. [Google Scholar] [CrossRef]

- Xu, Y.; Li, L.; Chu, P. Deposition of diamond-like carbon films on interior surface of long and slender quartz glass tube by enhanced glow discharge plasma immersion ion implantation. Surf. Coat. Technol. 2015, 265, 218–221. [Google Scholar] [CrossRef]

- Chen, J.; Li, Y.; Huang, L.; Li, C.; Shi, G. High-yield preparation of graphene oxide from small graphite flakes via an improved Hummers method with a simple purification process. Carbon 2015, 81, 826–834. [Google Scholar] [CrossRef]

- Duraia, E.-S.M.; Fahami, A.; Beall, G.W. Modifications of graphite and multiwall carbon nanotubes in the presence of urea. J. Electron. Mater. 2018, 47, 1176–1182. [Google Scholar] [CrossRef]

- Beeman, D.; Silverman, J.; Lynds, R.; Anderson, M. Modeling studies of amorphous carbon. Phys. Rev. B 1984, 30, 870. [Google Scholar] [CrossRef]

- Tucker, M.D.; Ganesan, R.; Mcculloch, D.G.; Partridge, J.G.; Stueber, M.; Ulrich, S.; Bilek, M.M.M.; Mckenzie, D.R.; Marks, N.A. Mixed-mode high-power impulse magnetron sputter deposition of tetrahedral amorphous carbon with pulse-length control of ionization. J. Appl. Phys. 2016, 119, 155303. [Google Scholar] [CrossRef]

- Mbiombi, W.; Mathe, B.; Wamwangi, D.; Erasmus, R.; Every, A.; Billing, D.G. Optoelectronic and mechanical properties of PVD diamond-like carbon films. Mater. Today Proc. 2018, 5, 27307–27315. [Google Scholar] [CrossRef]

- Bin, L.Q.; Zhang, B.; Zhou, Y.; Zhang, J.Y. Improving the internal stress and wear resistance of DLC film by low content Ti doping. Solid State Sci. 2013, 20, 17–22. [Google Scholar]

- Yang, W.; Guo, Y.; Xu, D.; Li, J.; Wang, P.; Ke, P.; Wang, A. Microstructure and properties of (Cr:N)-DLC films deposited by a hybrid beam technique. Surf. Coat. Technol. 2015, 261, 398–403. [Google Scholar] [CrossRef]

- Dai, W.; Wu, G.S.; Wang, A.Y. Structure and elastic recovery of Cr-C:H films deposited by a reactive magnetron sputtering technique. Appl. Surf. Sci. 2010, 257, 244–248. [Google Scholar] [CrossRef]

- Hsu, J.S.; Tzeng, S.S.; Wu, Y.J. Influence of hydrogen on the mechanical properties and microstructure of DLC films synthesized by r.f.-PECVD. Vacum 2009, 83, 622–624. [Google Scholar] [CrossRef]

- Gou, W.; Chu, X.P.; Li, G.Q. Structure and properties of Cr-Containing hydrogenated amorphous carbon films synthesized by Filtered cathodic vacuum. Plasma Process. Polym. 2007, 4, S269–S272. [Google Scholar] [CrossRef]

- Robertson, J. Diamond-like amorphous carbon. Mater. Sci. Eng. R Rep. 2002, 37, 129–281. [Google Scholar] [CrossRef]

- Tay, B.; Cheng, Y.; Ding, X.; Lau, S.; Shi, X.; You, G.; Sheeja, D. Hard carbon nanocomposite films with low stress. Diam. Relat. Mater. 2001, 10, 1082–1087. [Google Scholar] [CrossRef]

- Choi, J.; Ahn, H.; Lee, S.; Lee, K. Stress reduction behavior in metal-incorporated amorphous carbon films: First-principles approach. J. Phys. Conf. Ser. IOP Publ. 2006, 29, 155–158. [Google Scholar] [CrossRef]

- Wang, A.Y.; Lee, K.-R.; Ahn, J.P.; Han, J.H. Structure and mechanical properties of W incorporated diamond-like carbon films prepared by a hybrid ion beam deposition technique. Carbon 2006, 44, 1826–1832. [Google Scholar] [CrossRef]

- Dai, W.; Wu, G.; Wang, A. Preparation, characterization and properties of Cr-incorporated DLC films on magnesium alloy. Diam. Relat. Mater. 2010, 19, 1307–1315. [Google Scholar] [CrossRef]

- Gassner, G.; Patscheider, J.; Mayrhofer, P.H.; Šturm, S.; Scheu, C.; Mitterer, C. Tribological properties of nanocomposite CrC x/aC: H thin films. Tribol. Lett. 2007, 27, 97–104. [Google Scholar] [CrossRef]

- Michau, A.; Maury, F.; Schuster, F.; Boichot, R.; Pons, M. Evidence for a Cr metastable phase as a tracer in DLI-MOCVD chromium hard coatings usable in high temperature environment. Appl. Surf. Sci. 2017, 422, 198–206. [Google Scholar] [CrossRef]

- Dai, W.; Liu, J.; Geng, D.; Guo, P.; Zheng, J.; Wang, Q. Microstructure and property of diamond-like carbon films with Al and Cr co-doping deposited using a hybrid beams system. Appl. Surf. Sci. 2016, 388, 503–509. [Google Scholar] [CrossRef]

- Gayathri, S.; Kumar, N.; Krishnan, R.; Ravindran, T.; Dash, S.; Tyagi, A.; Sridharan, M. Influence of Cr content on the micro-structural and tribological properties of PLD grown nanocomposite DLC-Cr thin films. Mater. Chem. Phys. 2015, 167, 194–200. [Google Scholar] [CrossRef]

- Xiao, Y.; Shi, W.; Luo, J.; Liao, Y. The tribological performance of TiN, WC/C and DLC coatings measured by the four-ball test. Ceram. Int. 2014, 40, 6919–6925. [Google Scholar] [CrossRef]

| Parameter | Value |

|---|---|

| Target-Substrate Distance (mm) | 85 |

| Ar Gas Pressure (Pa) | 0.5 |

| Bias Voltage (V) | −75 |

| Set Value (%) | 2/5/10/15/20 |

| Pulse Frequency (kHz) | 40 |

| Duty Ratio (%) | 80 |

| Pulse Current (A) | 5 |

| Average power (kW) | 1.44/1.42/1.38/1.36/1.33 (stable deposition state) |

| Deposition Time (min) | 50 |

| Set Value | Element Composition (at.%) | ||

|---|---|---|---|

| C | Cr | O | |

| 2% | 97.59 | 1.96 | 0.45 |

| 5% | 93.88 | 5.78 | 0.34 |

| 10% | 89.87 | 9.26 | 0.87 |

| 15% | 86.11 | 13.61 | 0.28 |

| 20% | 82.34 | 17.21 | 0.45 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, G.; Xu, Y.; Xia, Y. Effect of Cr Atom Plasma Emission Intensity on the Characteristics of Cr-DLC Films Deposited by Pulsed-DC Magnetron Sputtering. Coatings 2020, 10, 608. https://doi.org/10.3390/coatings10070608

Li G, Xu Y, Xia Y. Effect of Cr Atom Plasma Emission Intensity on the Characteristics of Cr-DLC Films Deposited by Pulsed-DC Magnetron Sputtering. Coatings. 2020; 10(7):608. https://doi.org/10.3390/coatings10070608

Chicago/Turabian StyleLi, Guang, Yi Xu, and Yuan Xia. 2020. "Effect of Cr Atom Plasma Emission Intensity on the Characteristics of Cr-DLC Films Deposited by Pulsed-DC Magnetron Sputtering" Coatings 10, no. 7: 608. https://doi.org/10.3390/coatings10070608

APA StyleLi, G., Xu, Y., & Xia, Y. (2020). Effect of Cr Atom Plasma Emission Intensity on the Characteristics of Cr-DLC Films Deposited by Pulsed-DC Magnetron Sputtering. Coatings, 10(7), 608. https://doi.org/10.3390/coatings10070608