Effect of Magnetic Field Arrangement of Facing Targets Sputtering (FTS) System on Controlling Plasma Confinement

Abstract

:1. Introduction

2. Experimental Methods and Measurements

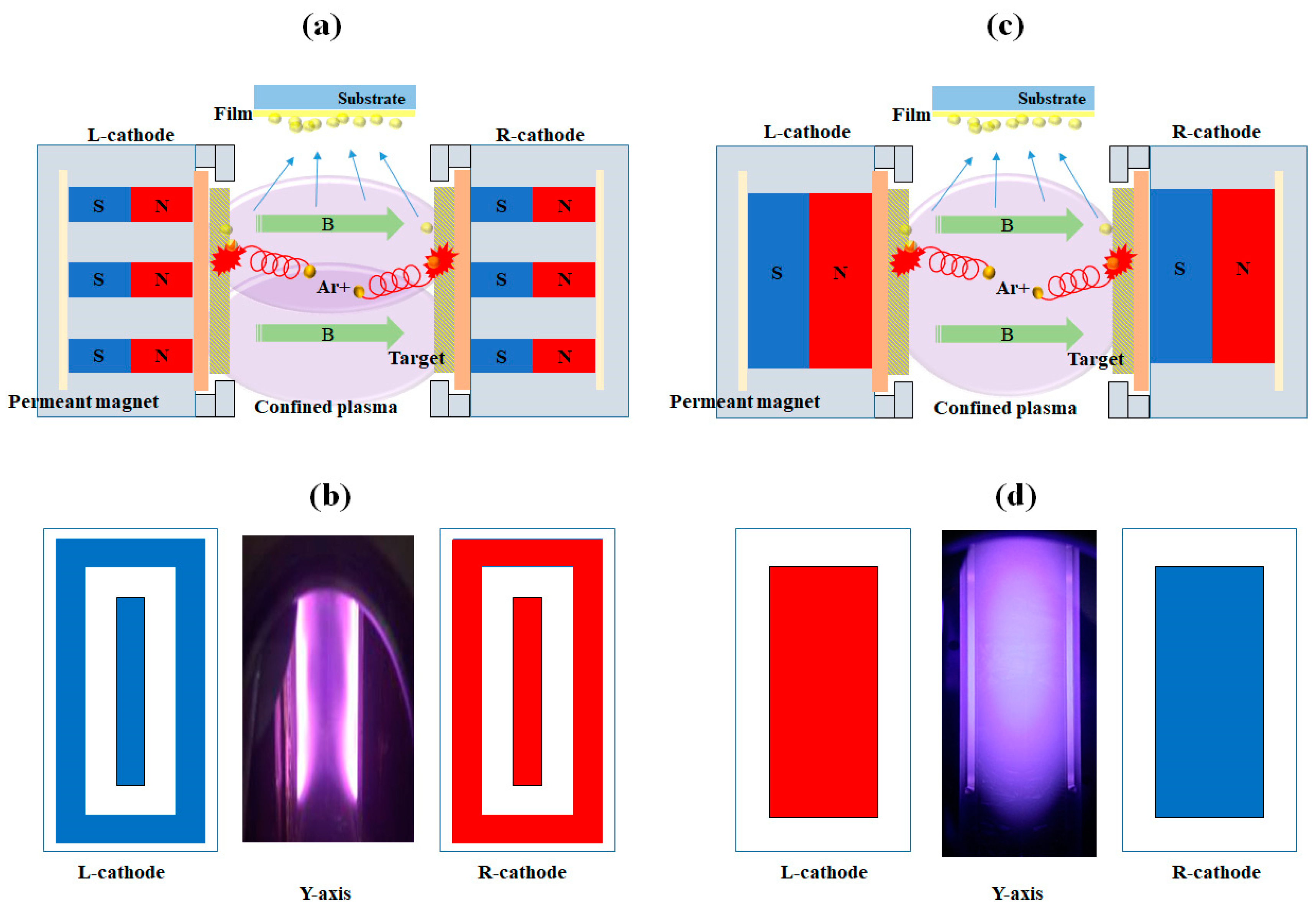

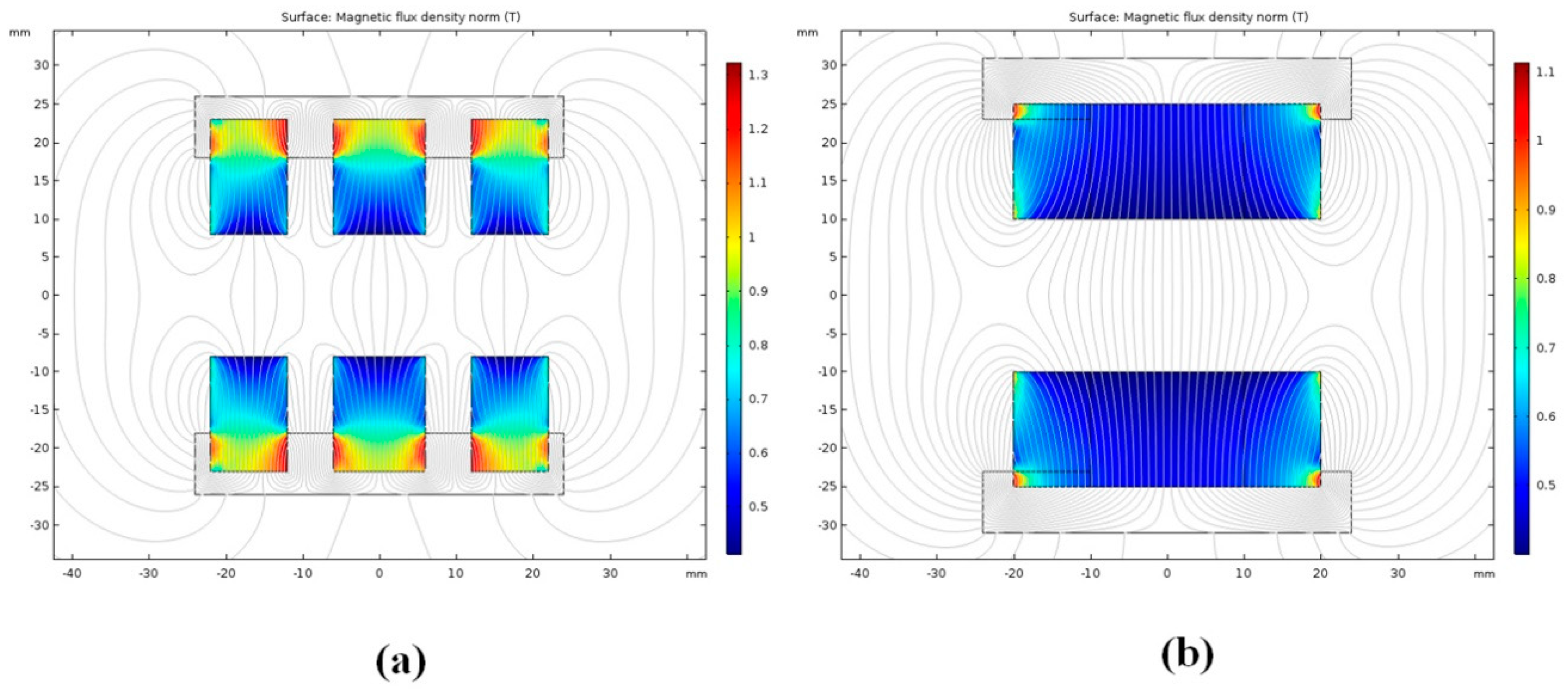

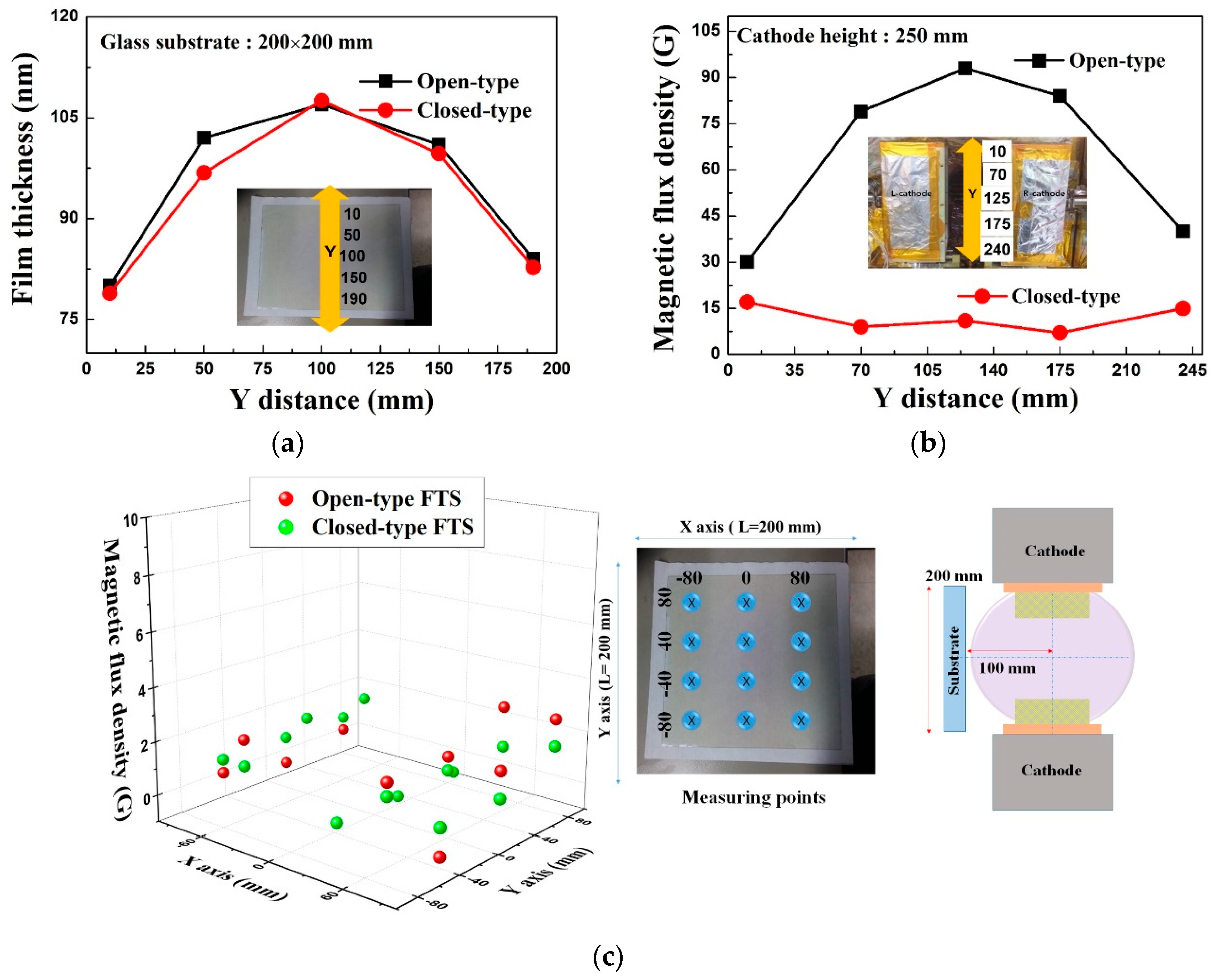

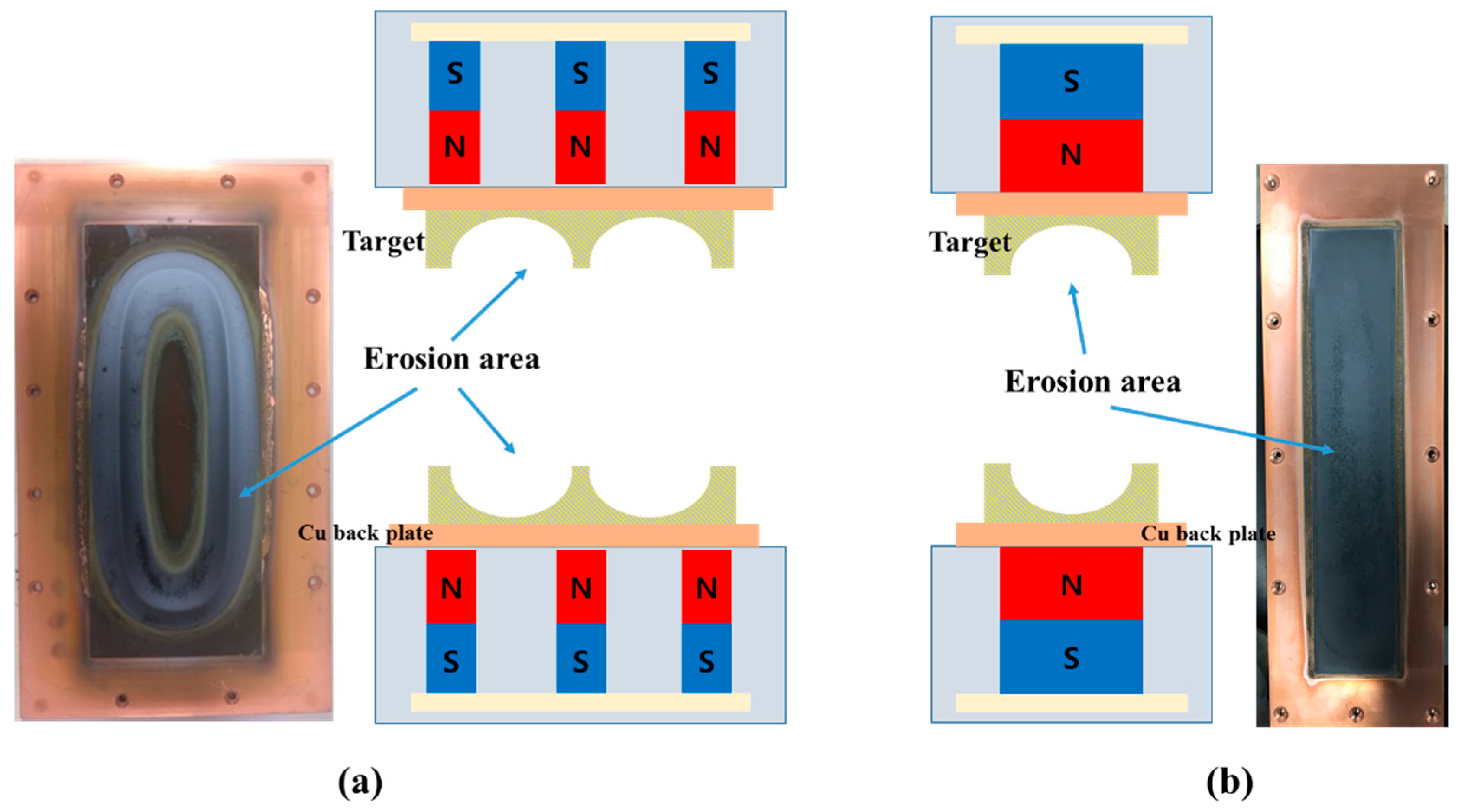

3. Results and Discussion

3.1. Magnetism Simulation

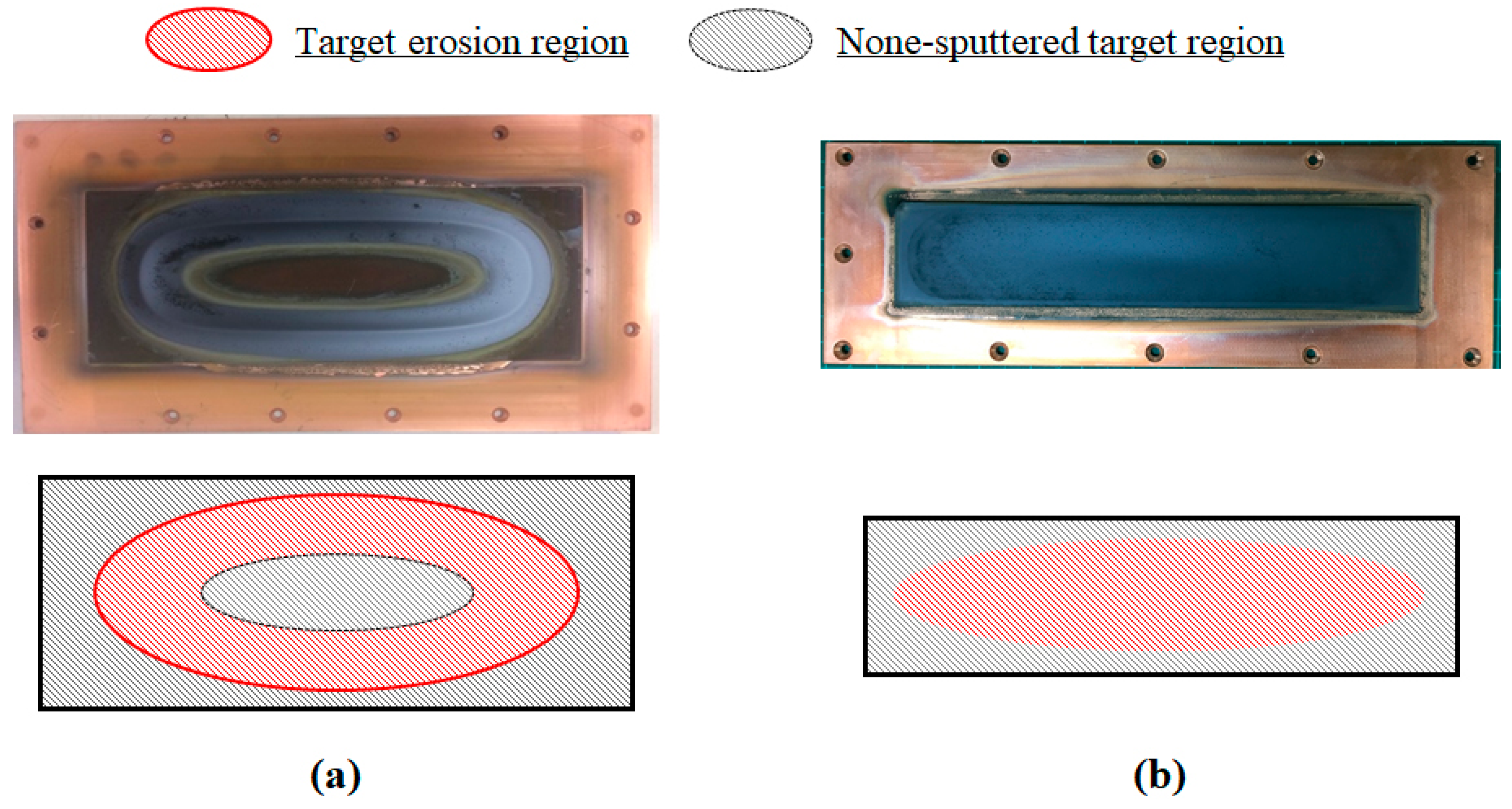

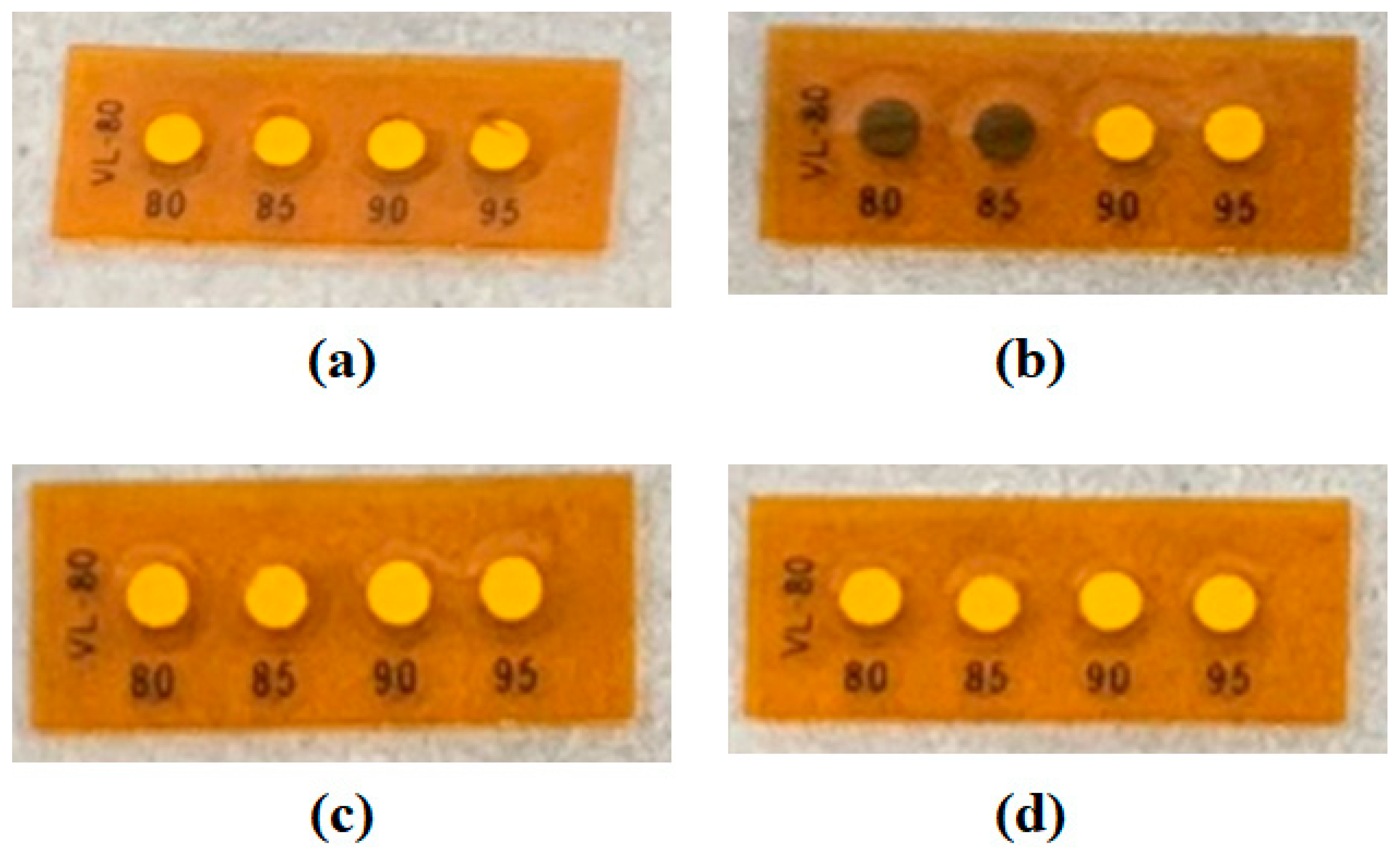

3.2. Film Uniformity and Target Erosion

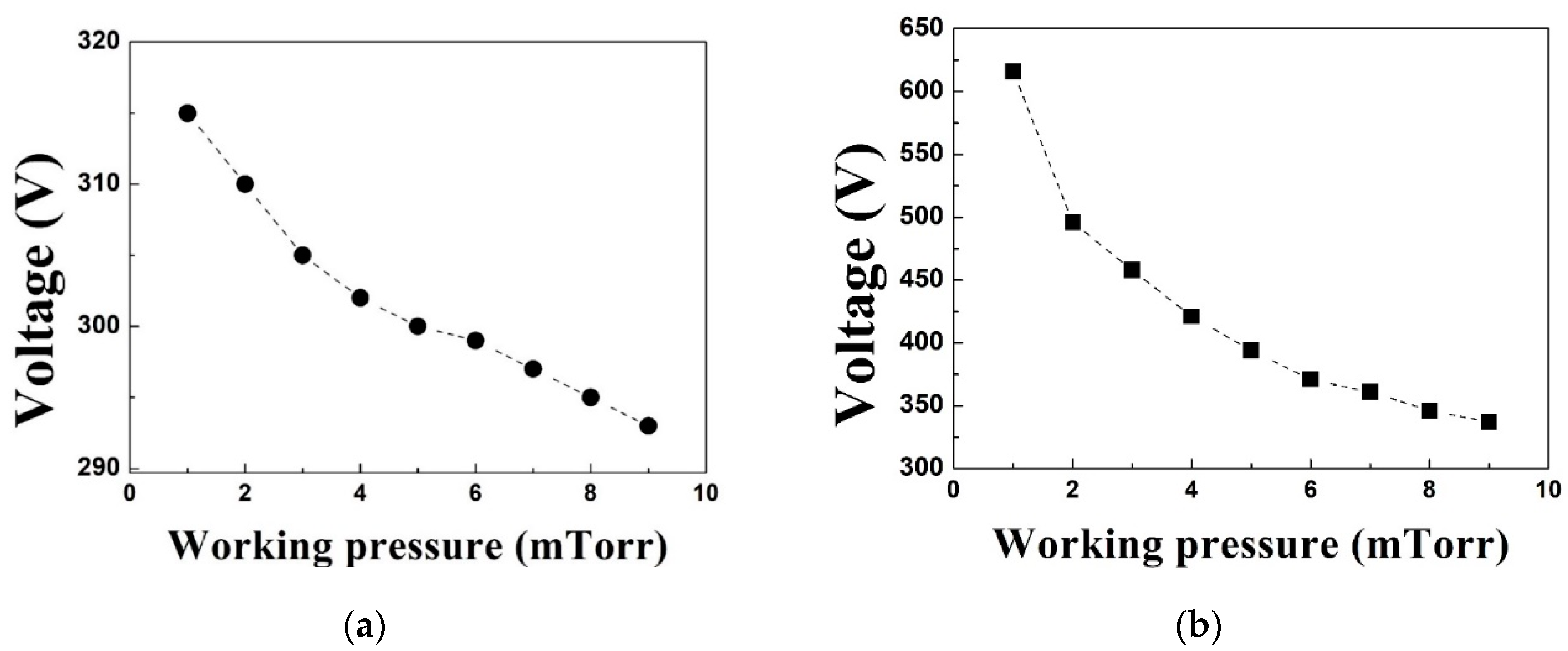

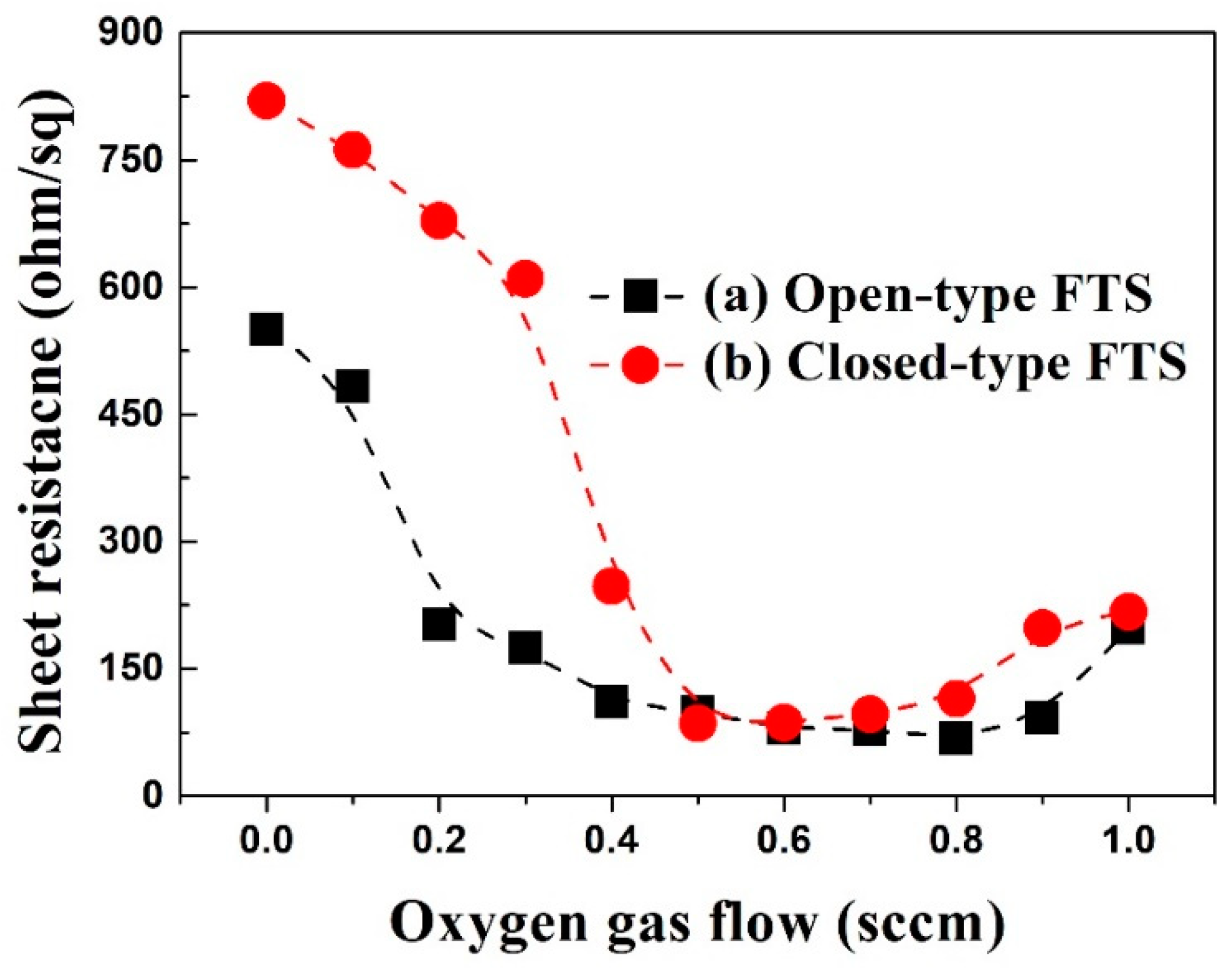

3.3. Properties of Films

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Pereira, P.J.S.; Escrivão, M.L.; Teixeira, M.R.; Maneira, M.J.P.; Nunes, Y. Analytical model and measurements of the target erosion depth profile of balanced and unbalanced planar magnetron cathodes. Plasma Sources Sci. Technol. 2014, 23. [Google Scholar] [CrossRef]

- Hou, Q.; Buckeridge, J.; Lazauskas, T.; Mora-Fonz, D.; Sokol, A.A.; Woodley, S.M.; Catlow, C.R.A. Defect formation in In2O3 and SnO2: A new atomistic approach based on accurate lattice energies. J. Mater. Chem. C 2018, 6, 12386–12395. [Google Scholar] [CrossRef] [Green Version]

- Tien, C.-L.; Lin, H.-Y.; Chang, C.-K.; Tang, C.-J. Effect of Oxygen Flow Rate on the Optical, Electrical, and Mechanical Properties of DC Sputtering ITO Thin Films. Adv. Condens. Matter Phys. 2018, 2018. [Google Scholar] [CrossRef] [Green Version]

- Shin, H.-S.; Seo, K.-W.; Lee, J.-H.; Kim, H.-K. Effect of Target–Substrate Distance on the Properties of Hetero Facing Target Sputtered Al-Ga-Zn-O Films. Jpn. J. Appl. Phys. 2013, 52. [Google Scholar] [CrossRef] [Green Version]

- Xiao, Y.; Gao, F.; Dong, G.; Guo, T.; Liu, Q.; Ye, D.; Diao, X. Amorphous indium tin oxide films deposited on flexible substrates by facing target sputtering at room temperature. Thin Solid Films 2014, 556, 155–159. [Google Scholar] [CrossRef]

- Kadokura, S.; Naoe, M.; Nakagawa, S. Nano-size Magnetic Crystallite Formation in Go-Cr Thin Films for Perpendicular Recording Media. IEEE Trans. Magn. 1998, 34, 1642–1644. [Google Scholar] [CrossRef]

- Noda, K.; Kadokura, S.; Naoe, M. Microstructure and noise characteristics of Co-Cr-Ta films on ultraflat glass substrates for longitudinal recording disks. J. Appl. Phys. 2000, 87, 6343–6345. [Google Scholar] [CrossRef]

- Matsushita, N.; Nakagawa, S.; Naoe, M. Preparation of Co ferrite thin films with large perpendicular and in-plane coercivities by facing targets sputtering. IEEE Trans. Magn. 1992, 28, 3108–3110. [Google Scholar] [CrossRef]

- Kim, H.-K.; Kim, S.W.; Lee, K.-S.; Kim, K.H. Direct Al cathode layer sputtering on LiF@Alq3 using facing target sputtering with a mixture of Ar and Kr. Appl. Phys. Lett. 2006, 88. [Google Scholar] [CrossRef]

- Fan, Q.H.; Chen, H.Y. Effects of magnetic field on the target erosion in the symmetrical magnets magnetron sputtering method. Thin Solid Films 1993, 229, 143–145. [Google Scholar] [CrossRef]

- Liu, C.-T.; Lai, M.-C.; Hwang, C.-C.; Tu, C.-H.; Liu, L.-Y.; Hsu, Y.-W. Enhancements of Substrate Deposition Rate and Target Erosion Profile in a DC Magnetron Sputtering System. IEEE Trans. Magn. 2009, 45, 4391–4394. [Google Scholar] [CrossRef]

- Lin, C.; Sun, D.C.; Ming, S.L.; Jiang, E.Y.; Liu, Y.G. Magnetron facing target sputtering system for fabricating single-crystal films. Thin Solid Films 1996, 279, 49–52. [Google Scholar] [CrossRef]

- Shin, H.-S.; Lee, J.-H.; Kwak, J.-S.; Lee, H.-H.; Kim, H.-K. Linear facing target sputtering of the epitaxial Ga-doped ZnO transparent contact layer on GaN-based light-emitting diodes. J. Phys. D Appl. Phys. 2013, 46, 1–6. [Google Scholar] [CrossRef]

- Murphy, M.J.; Cameron, D.C.; Karim, M.Z.; Hashmi, M.S.J. Magnetic fields in magnetron sputtering systems. Surf. Coat. Technol. 1993, 57, 1–5. [Google Scholar] [CrossRef]

- Hollerweger, R.; Holec, D.; Paulitsch, J.; Rachbauer, R.; Polcik, P.; Mayrhofer, P.H. Magnetic field strength influence on the reactive magnetron sputter deposition of Ta2O5. J. Phys. D Appl. Phys. 2013, 46. [Google Scholar] [CrossRef] [Green Version]

- Noda, K.; Hirata, T.; Takashi, K.; Naoe, M. Novel facing targets sputtering apparatus with uniform magnetic field and plasma-free substrates. Vacuum 1998, 51, 687–690. [Google Scholar] [CrossRef]

- Hoshi, Y.; Naoe, M.; Yamanka, S. High Rate Deposition of Iron Films by Sputtering from Two Facing Targets. Jpn. J. Appl. Phys. 1977, 16, 1715–1716. [Google Scholar] [CrossRef]

- Kageyama, J.; Yoshimoto, M.; Matsuda, A.; Akao, Y.; Shidojim, E. Numerical simulation of plasma confinement in DC magnetron sputtering under different magnetic fields and anode structures. Jpn. J. Appl. Phys. 2014, 53. [Google Scholar] [CrossRef]

- Guo, T.; Dong, G.; Liu, Q.; Wang, M.; Wang, M.; Gao, F.; Chen, Q.; Yan, H.; Diao, X. Optimization of oxygen and pressure of ZnO: Al films deposited on PMMA substrates by facing target sputtering. Superlattices Microstruct. 2013, 64, 552–562. [Google Scholar] [CrossRef]

- Kim, H.-K.; Moon, J.-M. Sputtering of Aluminum Cathodes on OLEDs Using Linear Facing Target Sputtering with Ladder-Type Magnet Arrays. J. Electrochem. Soc. 2008, 155, J187–J192. [Google Scholar] [CrossRef]

- Liebrerman, M.A.; Lichtenberg, A.J. Principles of Plasma Discharges and Materials Processing, 2nd ed.; John Wiley & Sons Inc.: Hoboken, NJ, USA, 2005. [Google Scholar]

- Westwood, W.D.; Maniv, S.; Scanlon, P.J. The current-voltage characteristic of magnetron sputtering systems. J. Appl. Phys. 1983, 54, 6841–6846. [Google Scholar] [CrossRef]

- Ghorannevis, Z.; Akbarnejad, E.; Ghoranneviss, M. Structural and morphological properties of ITO thin films grown by magnetron sputtering. J. Theor. Appl. Phys. 2015, 9, 285–290. [Google Scholar] [CrossRef] [Green Version]

- Morikawa, H.; Fujita, M. Crystallization and decrease in resistivity on heat treatment of amorphous indium tin oxide thin films prepared by dc magnetron sputtering. Thin Solid Films 1999, 339, 309–313. [Google Scholar] [CrossRef]

- Shigesato, Y.; Panie, D.C. A microstructural study of low resistivity tin-doped indium oxide prepared by dc magnetron sputtering. Thin Solid Films 1994, 238, 44–50. [Google Scholar] [CrossRef]

- Hosono, H.; Ueda, K. Transparent Conductive Oxides. In Springer Handbook of Electronic and Photonic Materials, 2nd ed.; Kasap, S., Capper, P., Eds.; Springer: New York, NY, USA, 2017; pp. 1391–1403. [Google Scholar]

- Shigesato, Y.; Koshi-ishi, R.; Kawashima, T.; Ohsako, J. Early stages of ITO deposition on glass or polymer substrates. Vacuum 2000, 59, 614–621. [Google Scholar] [CrossRef]

- Lines, V.; Bivour, M.; Iwata, H.; Ortner, K. Comparison of low damage sputter deposition techniques to enable the application of very thin a-Si passivation films. AIP Conf. Proc. 2019, 2147. [Google Scholar] [CrossRef]

- Song, P.K.; Akao, H.; Kamei, M.; Shigesato, Y.; Yasui, I. Preparation and Crystallization of Tin-doped and Undoped Amorphous Indium Oxide Films Deposited by Sputtering. Jpn. J. Appl. Phys. 1999, 38, 5224–5226. [Google Scholar] [CrossRef]

- Ahmed, N.M.; Sabah, F.A.; Abdulgafour, H.I.; Alsadig, A.; Sulieman, A.; Alkhoaryef, M. The effect of post annealing temperature on grain size of indium-tin-oxide for optical and electrical properties improvement. Results Phys. 2019, 13. [Google Scholar] [CrossRef]

- Chen, A.; Zhu, K.; Zhong, H.; Shao, Q.; Ge, G. A new investigation of oxygen flow influence on ITO thin films by magnetron sputtering. Sol. Energy Mater. Sol. Cells 2014, 120, 157–162. [Google Scholar] [CrossRef] [Green Version]

- Li, S.; Qiao, X.; Chen, J. Effects of oxygen flow on the properties of indium tin oxide films. Mater. Chem. Phys. 2006, 98, 144–147. [Google Scholar] [CrossRef]

- Tahar, R.B.H.; Ban, T.; Ohya, Y.; Takahashi, Y. Tin doped indium oxide thin films: Electrical properties. J. Appl. Phys. 1998, 83, 2631–2645. [Google Scholar] [CrossRef]

- Meng, L.-J.; Maçarico, A.; Martins, R. Study of annealed indium tin oxide films prepared by rf reactive magnetron sputtering. Vacuum 1995, 6, 673–680. [Google Scholar] [CrossRef]

- Gupta, L.; Mansingh, A.; Srivastava, P.K. Band GAP Narrowing and the band structure of tindoped indium oxide films. Thin Solid Films 1989, 176, 33–44. [Google Scholar] [CrossRef]

- Cho, S.H.; Park, J.H.; Lee, S.C.; Cho, W.S.; Lee, J.H.; Yon, H.H.; Song, P.K. Effects of O2 addition on microstructure and electrical property for ITO films deposited with several kinds of ITO targets. J. Phys. Chem. Solids 2008, 69, 1334–1337. [Google Scholar] [CrossRef]

- Kim, C.E.; Moon, P.; Kim, S.; Myoung, J.-M.; Jang, H.W.; Bang, J.; Yun, I. Effect of carrier concentration on optical bandgap shift in ZnO: Ga thin films. Thin Solid Films 2010, 518, 6304–6307. [Google Scholar] [CrossRef]

| Parameters | Conditions | |

|---|---|---|

| Open-Type FTS (OFTS) | Closed-Type FTS (CFTS) | |

| Target material | ITO (In2O3: 90%, SnO2: 10%) | |

| Target size | 250 × 100 mm | 250 × 50 mm |

| Base pressure | 5 × 10−6 Torr | |

| Working pressure | 0.5–5 mTorr | |

| Working gas | Ar: 9–10 sccm, O2: 0–1sccm | |

| DC power (5kW) | 500 W | |

| Distance from the target to the substrate (DT-S) | 100 mm | |

| Distance from the target to the target (DT-T) | 100 mm | |

| Film thickness | 100 nm | |

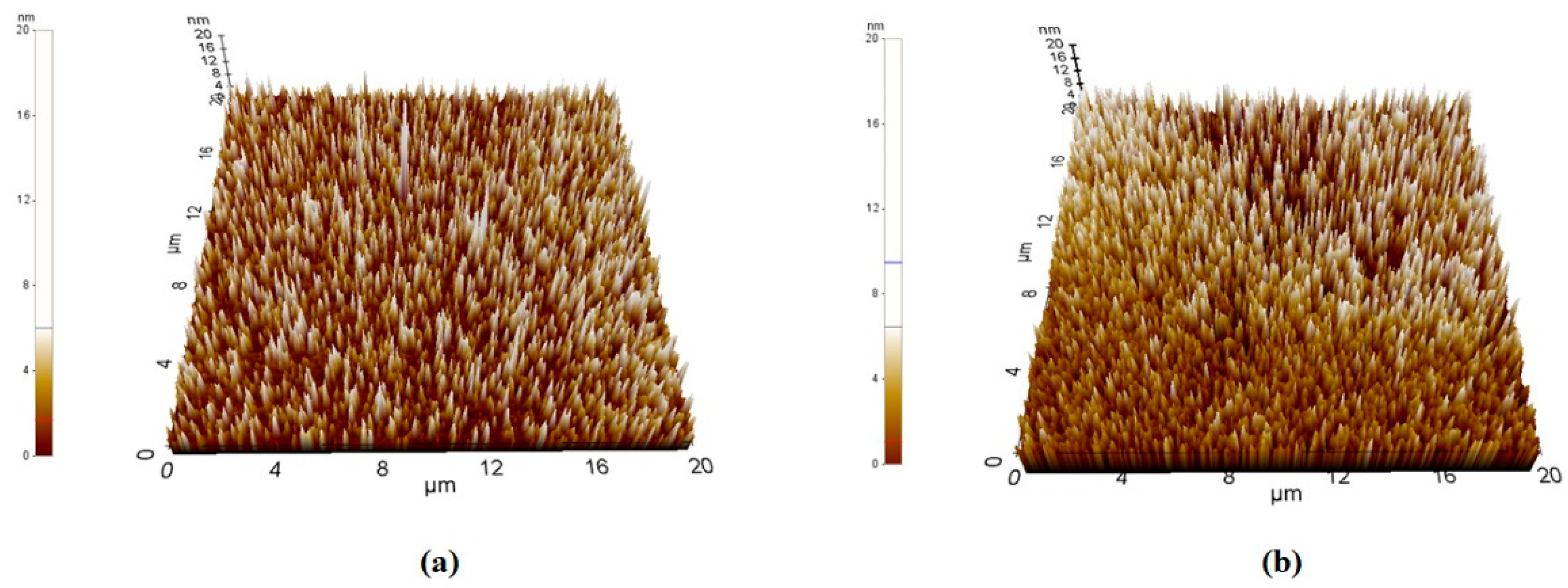

| Magnetic Type | Ra (nm) | RMS (nm) |

|---|---|---|

| Open-type FTS(1) | 2.006 | 2.575 |

| Closed-type FTS(2) | 1.565 | 2.151 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kim, S.; Kim, K.H. Effect of Magnetic Field Arrangement of Facing Targets Sputtering (FTS) System on Controlling Plasma Confinement. Coatings 2020, 10, 321. https://doi.org/10.3390/coatings10040321

Kim S, Kim KH. Effect of Magnetic Field Arrangement of Facing Targets Sputtering (FTS) System on Controlling Plasma Confinement. Coatings. 2020; 10(4):321. https://doi.org/10.3390/coatings10040321

Chicago/Turabian StyleKim, Sangmo, and Kyung Hwan Kim. 2020. "Effect of Magnetic Field Arrangement of Facing Targets Sputtering (FTS) System on Controlling Plasma Confinement" Coatings 10, no. 4: 321. https://doi.org/10.3390/coatings10040321

APA StyleKim, S., & Kim, K. H. (2020). Effect of Magnetic Field Arrangement of Facing Targets Sputtering (FTS) System on Controlling Plasma Confinement. Coatings, 10(4), 321. https://doi.org/10.3390/coatings10040321