Microstructures and Wear Resistance of FeCoCrNi-Mo High Entropy Alloy/Diamond Composite Coatings by High Speed Laser Cladding

Abstract

1. Introduction

2. Experimental

3. Results and Discussions

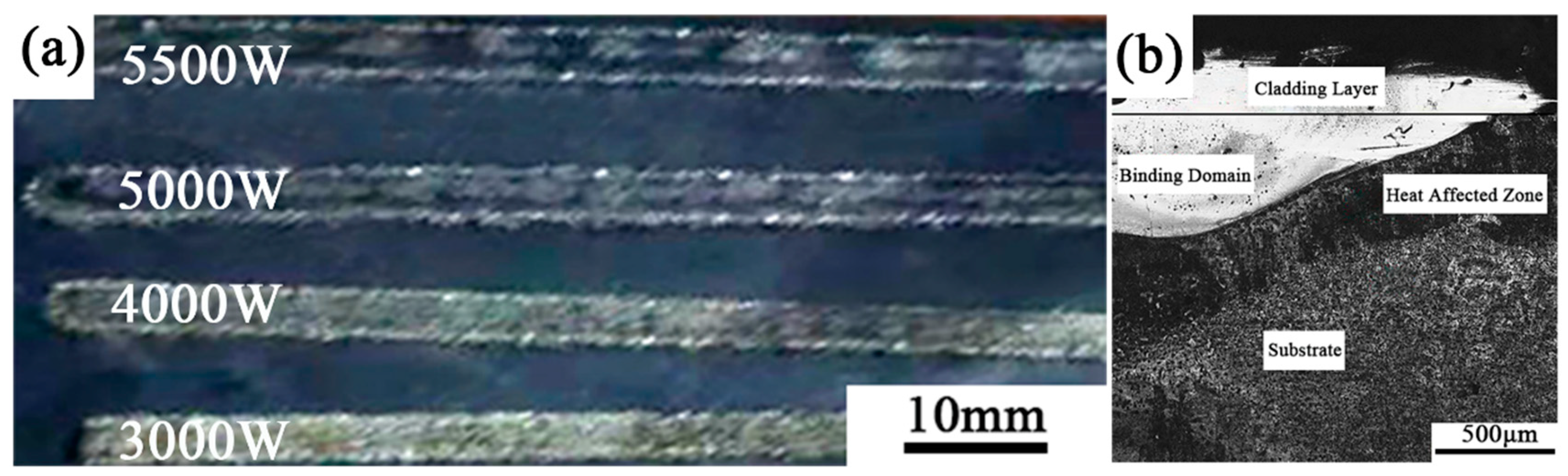

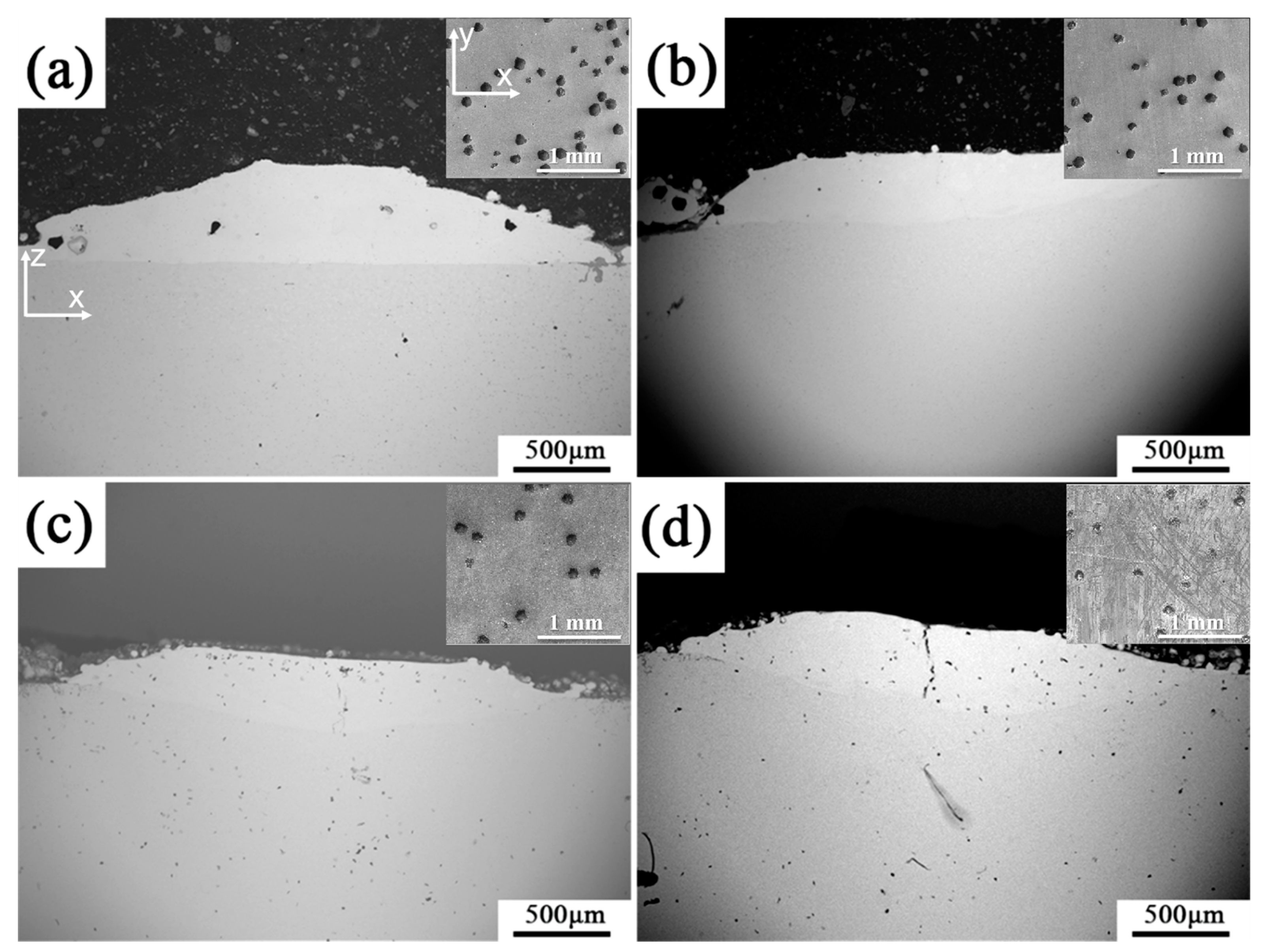

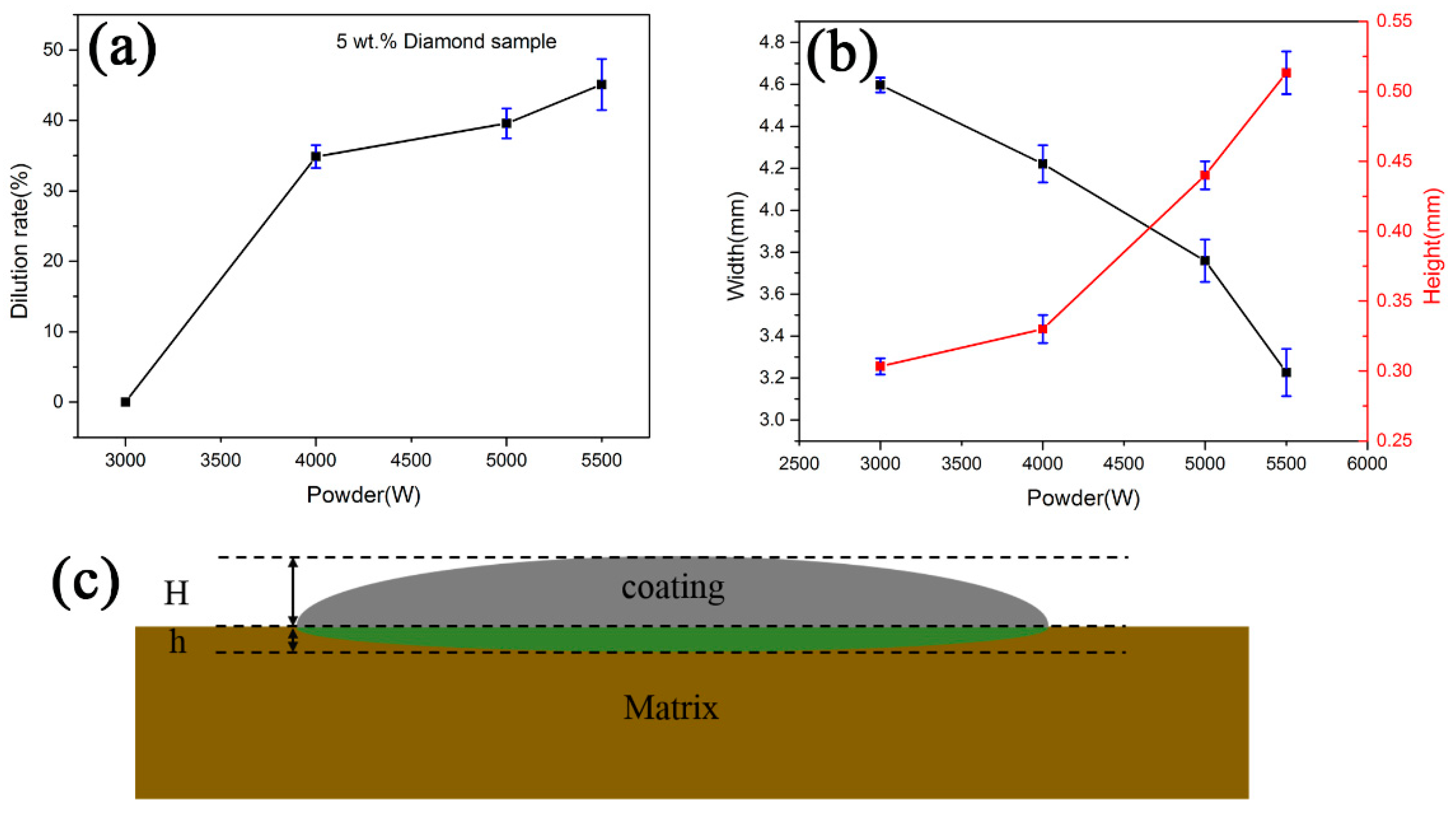

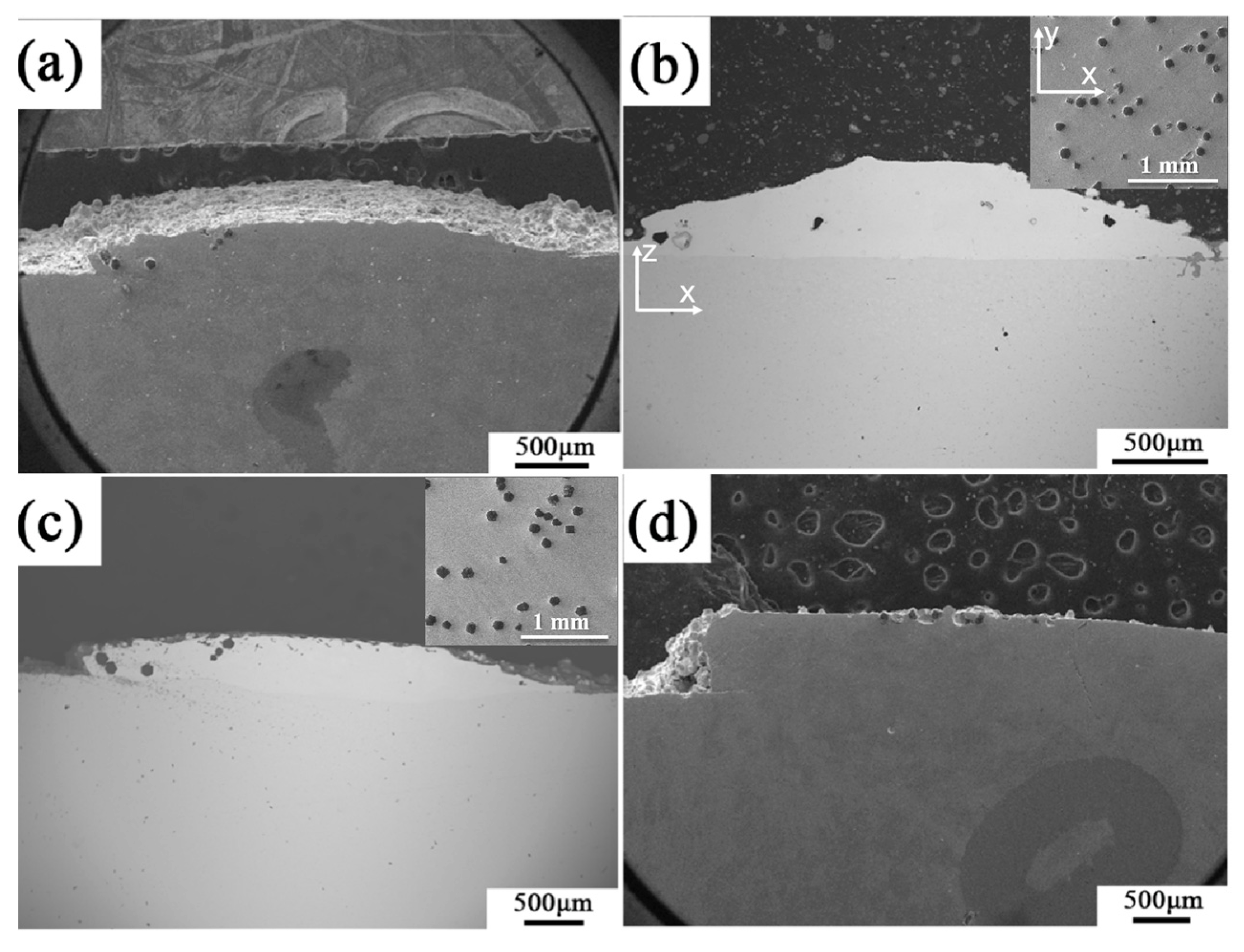

3.1. Effect of Laser Power

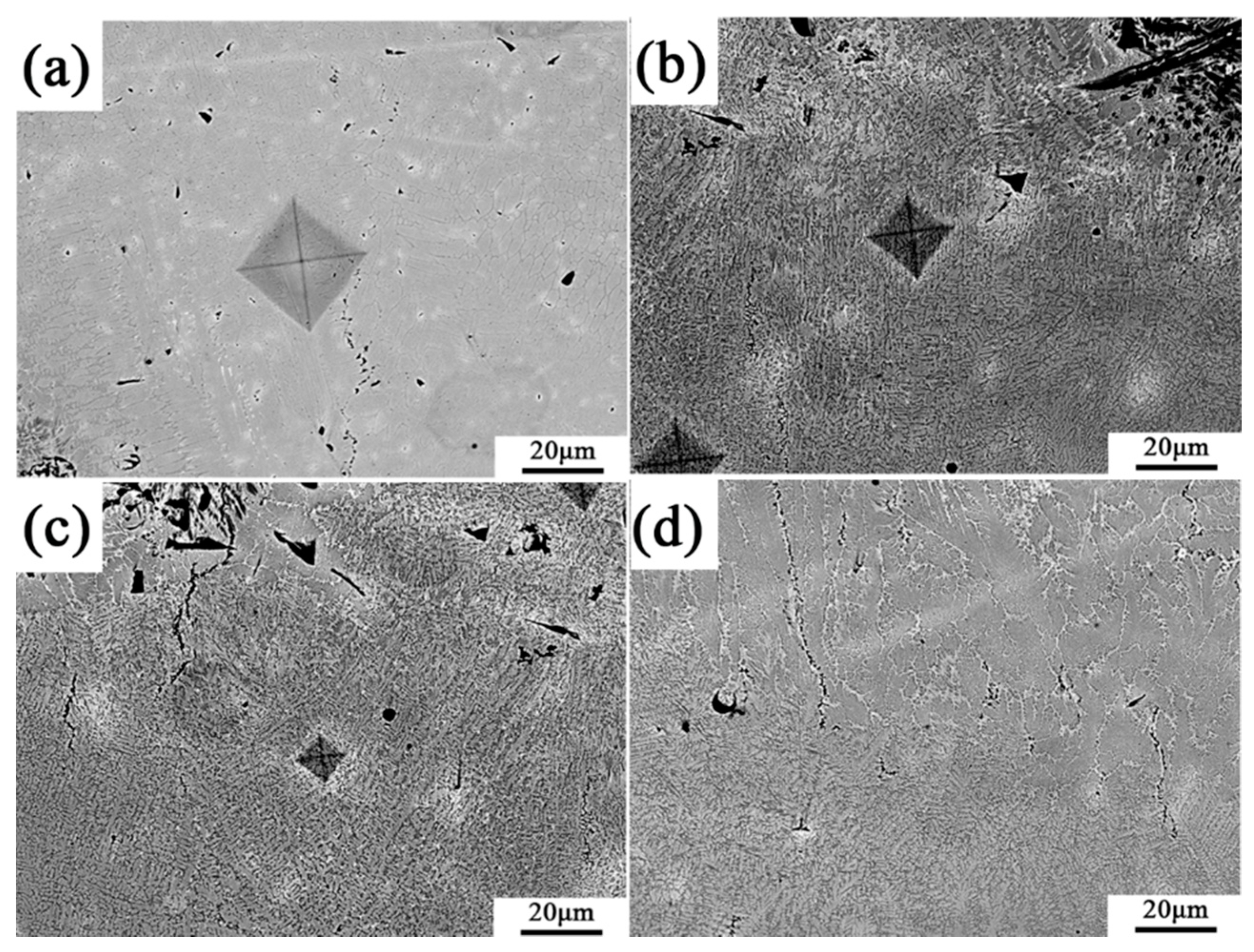

3.1.1. Microstructures

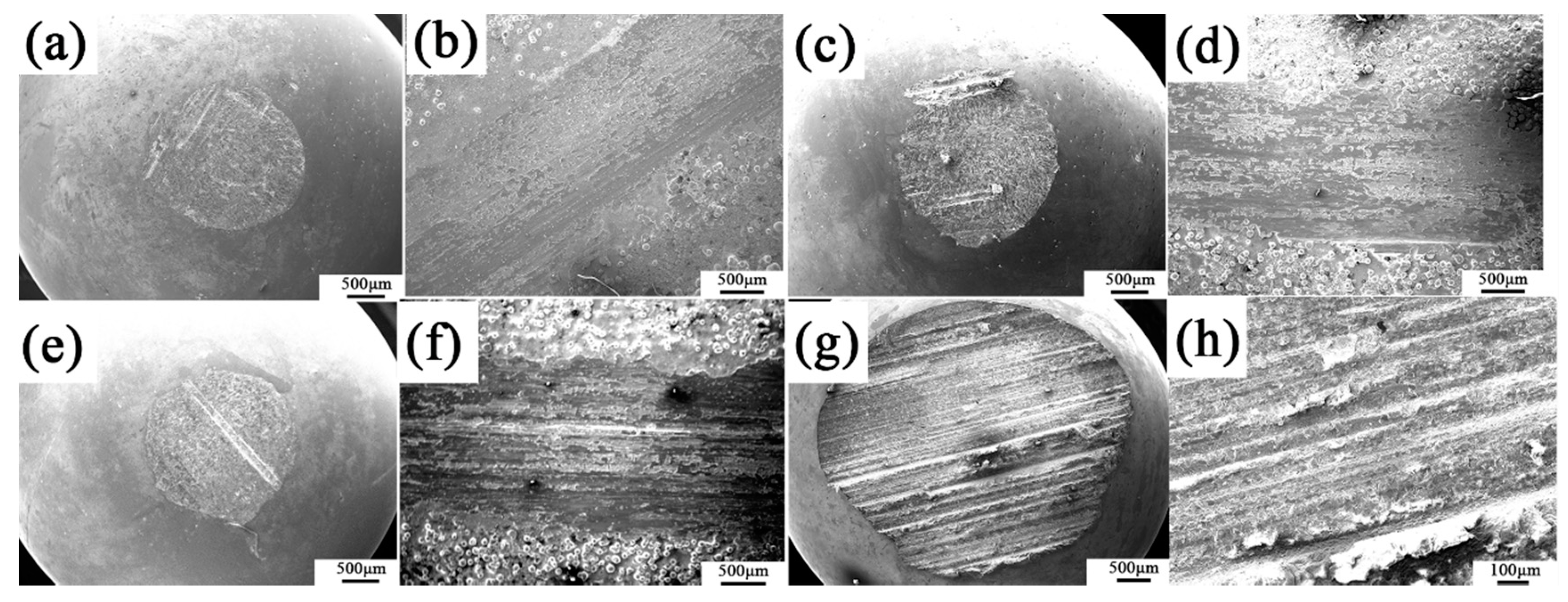

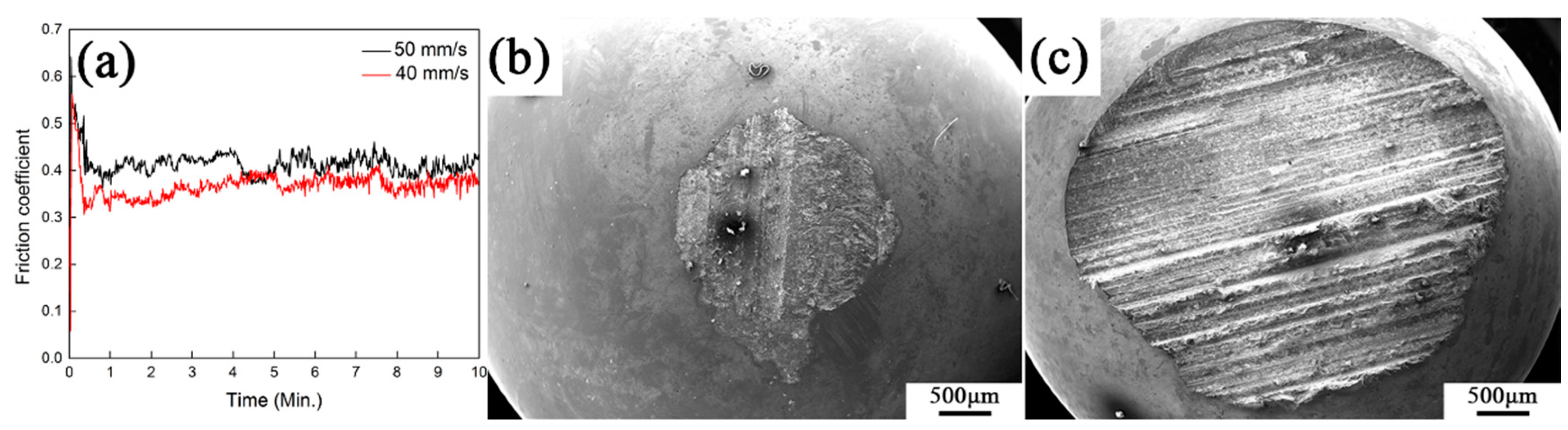

3.1.2. Mechanical Properties

3.2. Effect of Scanning Speed

3.2.1. Microstructures

3.2.2. Mechanical Properties

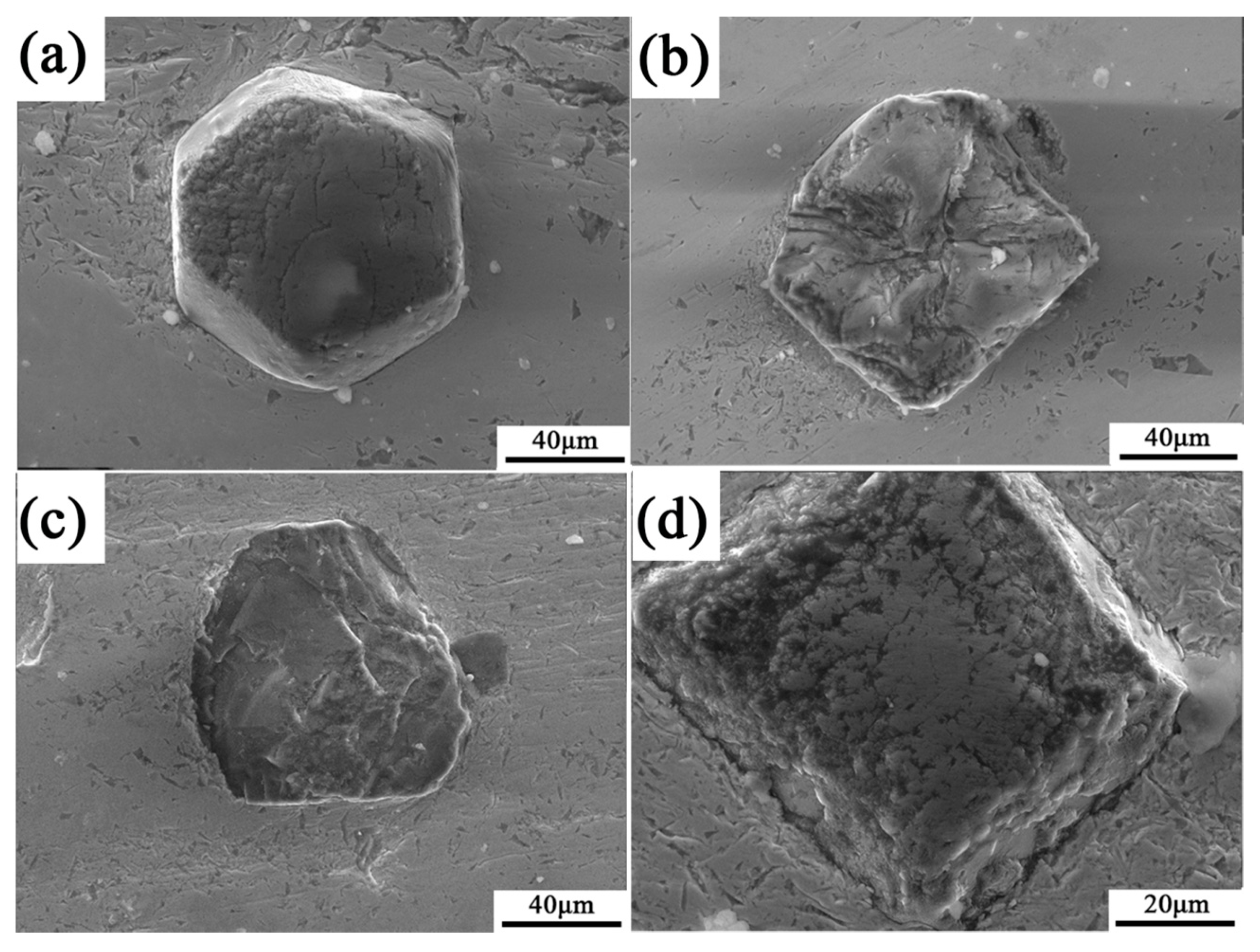

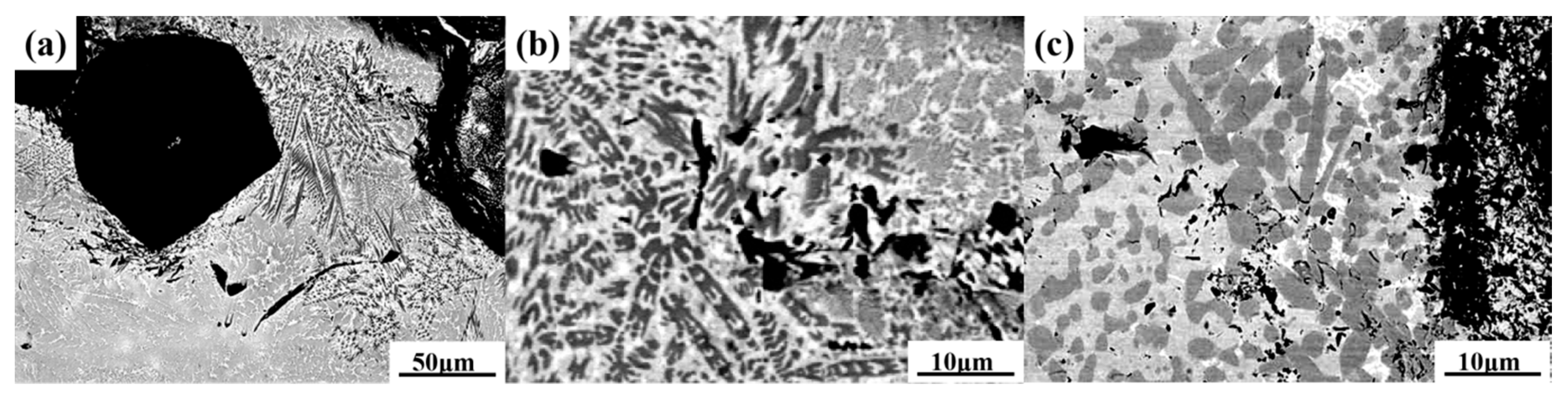

3.3. Morphology of Diamond

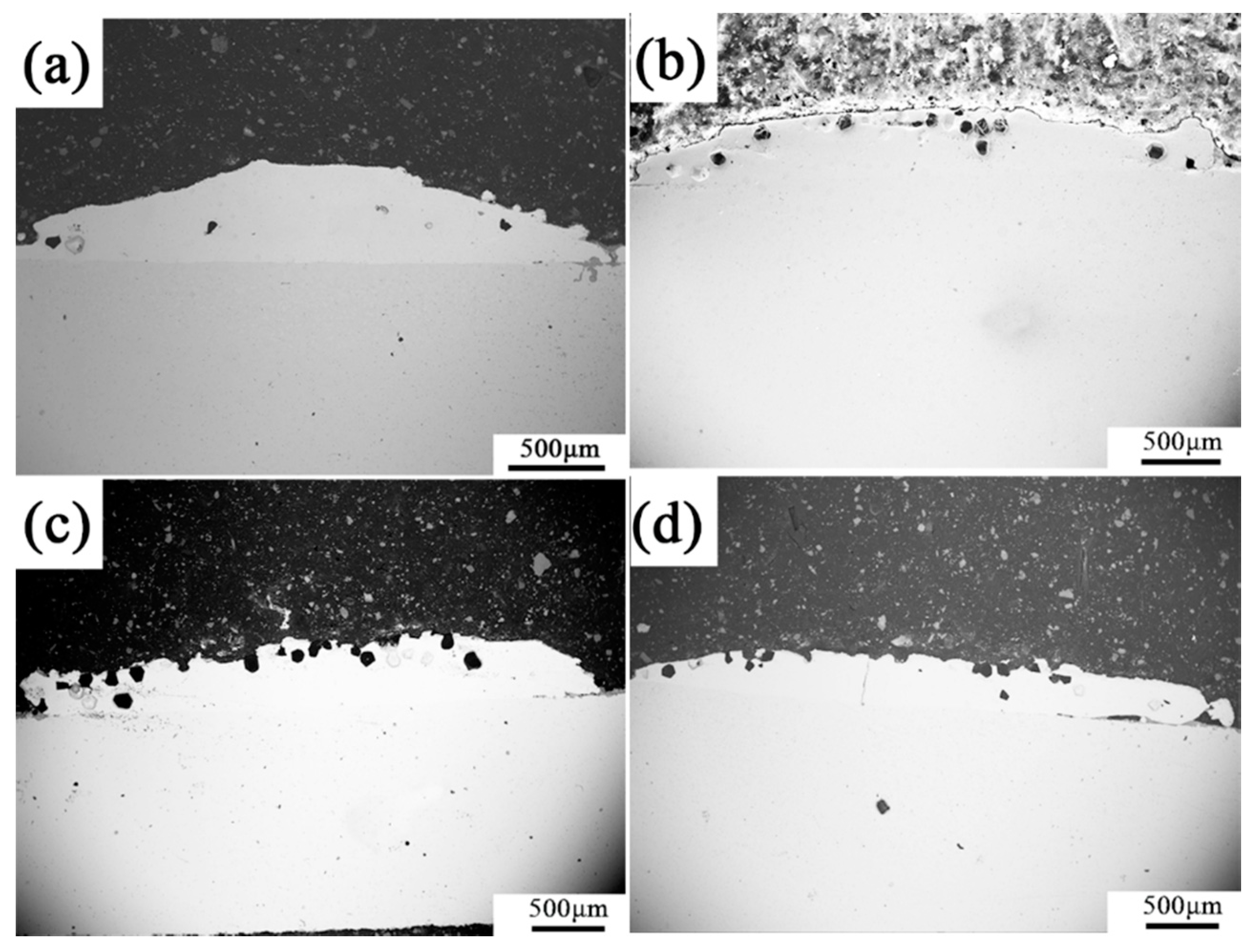

3.4. Effect of Diamond Content

3.4.1. Microstructures

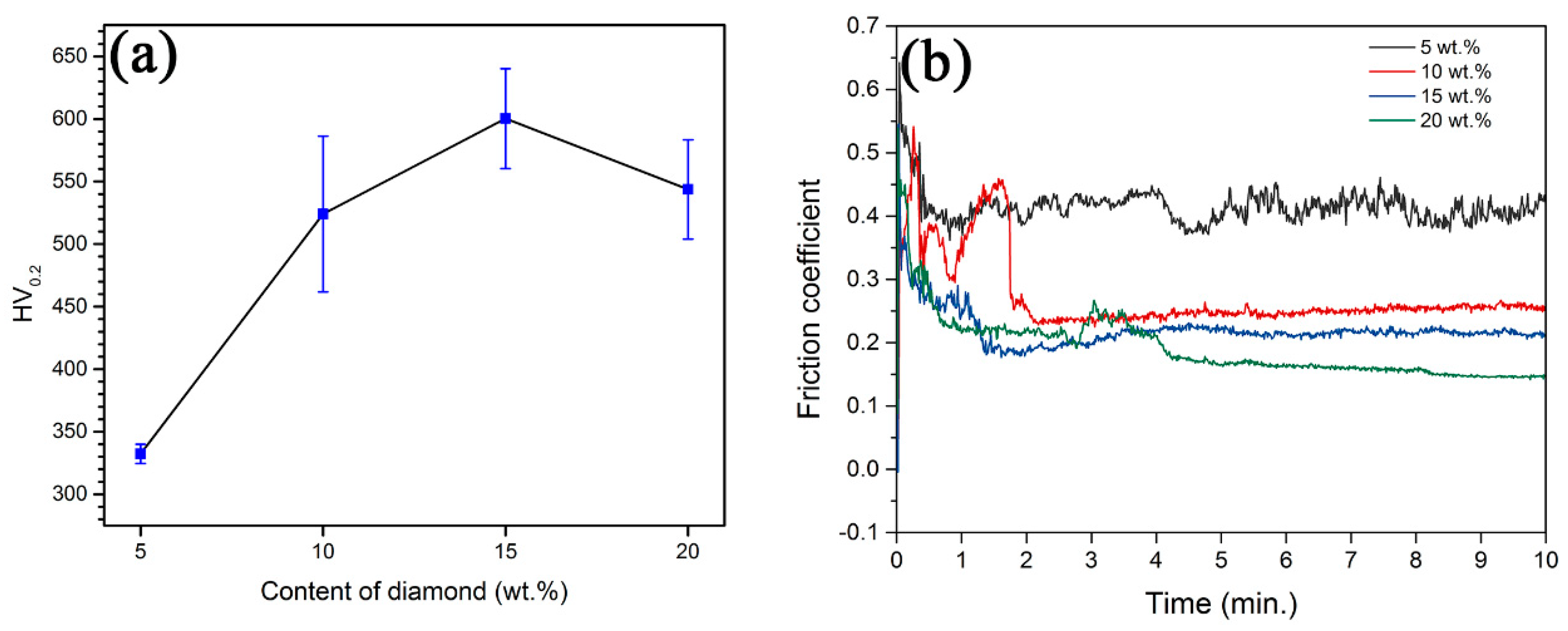

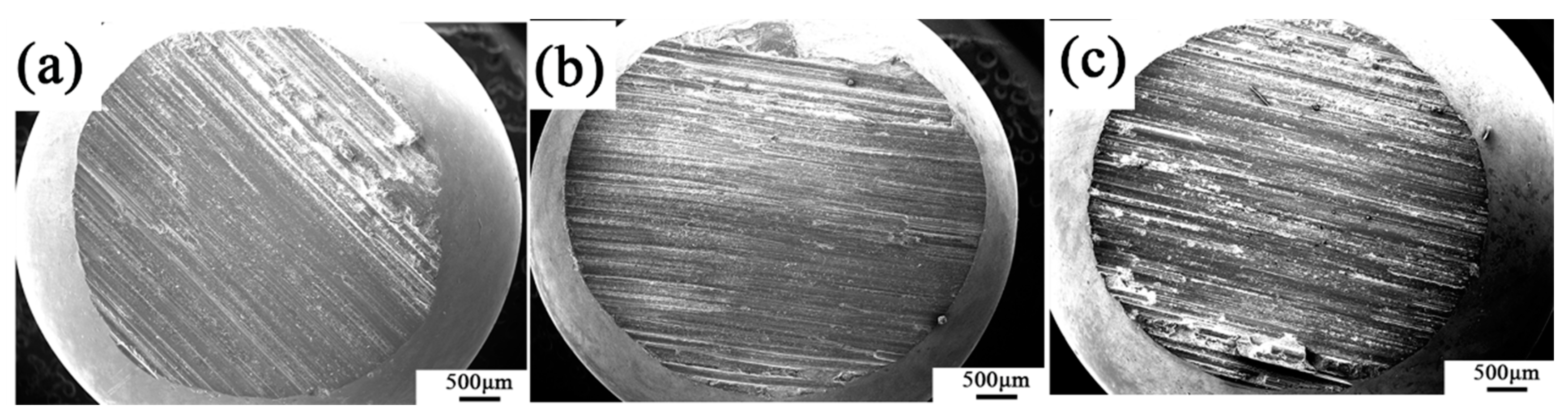

3.4.2. Mechanical Properties

4. Conclusions

- FeCoCrNi-Mo HEA/diamond composite coatings with good wear resistance were successfully prepared by high speed laser cladding technology.

- Micro-holes, cracks, and graphitization of diamond appeared and aggravated with the increase of laser power, resulting in the decrease of hardness and wear resistance. Too low a scanning speed increased the energy absorption of powder and the graphitization of diamond; too high a scanning speed resulted in the increase of un-melted HEA powders and poor bonding between HEA and the diamond.

- When the high scanning speed of 50 mm/s and relatively low laser power of 3000 W was adopted, optimal microstructures and properties were obtained. Too high a scanning speed of 60 mm/s could not realize metallurgical bonding between the HEA matrix and diamond. At high laser power and low scanning speed, the diamond graphitized and lost the crystal shape, and diffused C reacted with Cr and Mo to form carbides.

- With the increase of diamond content, the microstructures of the composite coating were obviously refined, and the wear resistance was improved. However, the high content (20 wt.%) aggravated the incompatibility of coating microstructures, resulting in microcracks. When the diamond content was 15 wt.%, optimal hardness and wear resistance were obtained.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Fang, X.; Deng, F.; Zheng, R. Advanced Superabrasives and Related Products; Zhejiang University Press: Hangzhou, China, 2011. [Google Scholar]

- Wright, D.N.; Engels, J.A. The environmental and cost benefits of using diamond wire for quarrying and processing of natural stone. Ind. Diamond Rev. 2003, 4, 16–24. [Google Scholar]

- Wang, F.; Zhang, J.; Wang, Z. Current situation and development of diamond wire saw cutting technology. Diam. Abras. Eng. 2013, 33, 36–42. [Google Scholar]

- Zhang, Z.; Liu, B. Development of Diamond Rope Saw; West-China Exploration Engineering: Changchun, China, 1995. [Google Scholar]

- Li, H.; Feng, Y.; Yang, L. Hybrid diamond rope saw. CN Patent CN203305381U, 27 Noverber 2013. [Google Scholar]

- Weng, F.; Huang, G.; Huang, H. Study on sawing forces of sintered diamond wire-saw in granite cutting. Diam. Abras. Eng. 2007, 01, 25–27. [Google Scholar]

- Huang, X. Design of Deep-Water Diamond Wire Saw Machine and Research on Life Prediction of Beaded Wire. Master’s Thesis, Harbin Engineering University, Harbin, China, 2016. [Google Scholar]

- Wang, C.; Liu, H.; Zhang, X. Effect of laser power and heat treatment process on microstructure and property of multi-pass Ni based alloy laser cladding coating. In Proceedings of the SPIE-The International Society for Optical Engineering, Beijing, China, 16 November 2010. [Google Scholar] [CrossRef]

- Toyserkani, E.; Khajepour, A.; Corbin, S. Laser Cladding; CRC Press: Boca Raton, FL, USA, 2005. [Google Scholar]

- Sun, H.H.; Guo, M.H.; Meng, F.L. Studies on hard faced overlay of diamond grits reinforced Ni-based alloy fabricated by laser cladding. Trans. Indian Inst. Met. 2016, 69, 1369–1376. [Google Scholar] [CrossRef]

- Rommel, D.; Scherm, F.; Kuttner, C. Laser cladding of diamond tools: Interfacial reactions of diamond and molten metal. Surf. Coat. Technol. 2016, 291, 62–69. [Google Scholar] [CrossRef]

- Iravani, M.; Khajepour, A.; Corbin, S. Pre-placed laser cladding of metal matrix diamond composite on mild steel. Surf. Coat. Technol. 2012, 206, 2089–2097. [Google Scholar] [CrossRef]

- Yan, X.H.; Li, J.S.; Zhang, W.R. A brief review of high-entropy films. Mater. Chem. Phys. 2017, 210, 12–19. [Google Scholar] [CrossRef]

- Vaidya, M.; Pradeep, K.G.; Murty, B.S. Bulk tracer diffusion in CoCrFeNi and CoCrFeMnNi high entropy alloys. Acta Mater. 2018, 146, 211–224. [Google Scholar] [CrossRef]

- Verma, A.; Tarate, P.; Abhyankar, A.C. High temperature wear in CoCrFeNiCux high entropy alloys: The role of Cu. Scr. Mater. 2019, 161, 28–31. [Google Scholar] [CrossRef]

- Zhang, W.; Zhang, M.; Peng, Y. Effect of Ti/Ni coating of diamond particles on microstructure and properties of high-entropy alloy/diamond composites. Entropy 2019, 21, 164. [Google Scholar] [CrossRef]

- Huang, F. An investigation on microstructure and properties of Ni-based alloy by laser cladding and laser cladding forming. Ph.D. Thesis, Jilin University, Changchun, China, 2011. [Google Scholar]

- Zou, Q. Analysis of structures and surface states of nanodiamond and its treated methods. Master’s Thesis, Yanshan University, Qinhuangdao, China, 2004. [Google Scholar]

- Zhang, W.; Zhang, M.; Peng, Y. Interfacial structures and mechanical properties of a high entropy alloy-diamond composite. Int. J. Refract. Met. Hard Mater 2020, 86, 105109. [Google Scholar] [CrossRef]

- Li, Z. Interstitial equiatomic CoCrFeMnNi high-entropy alloys: carbon content, microstructure, and compositional homogeneity effects on deformation behavior. Acta Mater. 2019, 164, 400–412. [Google Scholar] [CrossRef]

- Liu, W.H.; Lu, Z.P.; He, J.Y.; Luan, J.H.; Wang, Z.J.; Liu, B.; Liu, Y.; Chen, M.W.; Liu, C.T. Ductile CoCrFeNiMox high entropy alloys strengthened by hard intermetallic phases. Acta Mater. 2016, 116, 332–342. [Google Scholar] [CrossRef]

- Peng, Y.; Zhang, W.; Mei, X. Microstructures and mechanical properties of FeCoCrNi-Mo High entropy alloys prepared by spark plasma sintering and vacuum hot-pressed sintering. Mater. Today Commun. 2020, 24, 101009. [Google Scholar] [CrossRef]

- Zhang, M.; Peng, Y.; Zhang, W. Gradient distribution of microstructures and mechanical properties in a FeCoCrNiMo high-entropy alloy during spark plasma sintering. Metals 2019, 9, 351. [Google Scholar] [CrossRef]

- Takeuchi, A.; Inoue, A. Classification of bulk metallic glasses by atomic size difference, heat of mixing and period of constituent elements and its application to characterization of the main alloying element. Mater. Trans. 2005, 46, 2817–2829. [Google Scholar] [CrossRef]

| Scanning Speed (mm/s) | Width (mm) | Height (mm) | Dilution Ratio (%) |

|---|---|---|---|

| 60 | 4.02 | 0.32 | 0 |

| 50 | 3.88 | 0.33 | <10 |

| 40 | 2.77 | 0.34 | 28.24 |

| 30 | 2.31 | 0.33 | 43.58 |

| Laser Power (W) | Scanning Speed (mm/s) | Grinding Effect |

|---|---|---|

| 5500 | 50 | Bad |

| 5000 | 50 | Bad |

| 4000 | 50 | Bad |

| 3000 | 50 | Good |

| 3000 | 40 | Bad |

| 3000 | 30 | Bad |

| 3000 | 60 | Bad |

| Phase | Fe | Co | Cr | Ni | Mo | C |

|---|---|---|---|---|---|---|

| Black phase | 12.01 | 8.27 | 30.15 | 5.41 | 2.65 | 41.50 |

| Light grey phase | 19.53 | 18.50 | 22.48 | 23.90 | 4.65 | 21.34 |

| Dark grey phase | 17.71 | 19.58 | 5.70 | 28.84 | 6.88 | 23.36 |

| White phase | 10.23 | 17.92 | 8.96 | 11.65 | 9.87 | 39.90 |

| Element | Fe | Co | Cr | Ni | Mo |

|---|---|---|---|---|---|

| C | −50 | −42 | −61 | −39 | −67 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, H.; Zhang, W.; Peng, Y.; Zhang, M.; Liu, S.; Liu, Y. Microstructures and Wear Resistance of FeCoCrNi-Mo High Entropy Alloy/Diamond Composite Coatings by High Speed Laser Cladding. Coatings 2020, 10, 300. https://doi.org/10.3390/coatings10030300

Wang H, Zhang W, Peng Y, Zhang M, Liu S, Liu Y. Microstructures and Wear Resistance of FeCoCrNi-Mo High Entropy Alloy/Diamond Composite Coatings by High Speed Laser Cladding. Coatings. 2020; 10(3):300. https://doi.org/10.3390/coatings10030300

Chicago/Turabian StyleWang, Haijiang, Wei Zhang, Yingbo Peng, Mingyang Zhang, Shuyu Liu, and Yong Liu. 2020. "Microstructures and Wear Resistance of FeCoCrNi-Mo High Entropy Alloy/Diamond Composite Coatings by High Speed Laser Cladding" Coatings 10, no. 3: 300. https://doi.org/10.3390/coatings10030300

APA StyleWang, H., Zhang, W., Peng, Y., Zhang, M., Liu, S., & Liu, Y. (2020). Microstructures and Wear Resistance of FeCoCrNi-Mo High Entropy Alloy/Diamond Composite Coatings by High Speed Laser Cladding. Coatings, 10(3), 300. https://doi.org/10.3390/coatings10030300