High Temperature Oxidation and Thermal Shock Properties of La2Zr2O7 Thermal Barrier Coatings Deposited on Nickel-Based Superalloy by Laser-Cladding

Abstract

1. Introduction

2. Materials and Methods

3. Results and Discussion

3.1. Microstructure

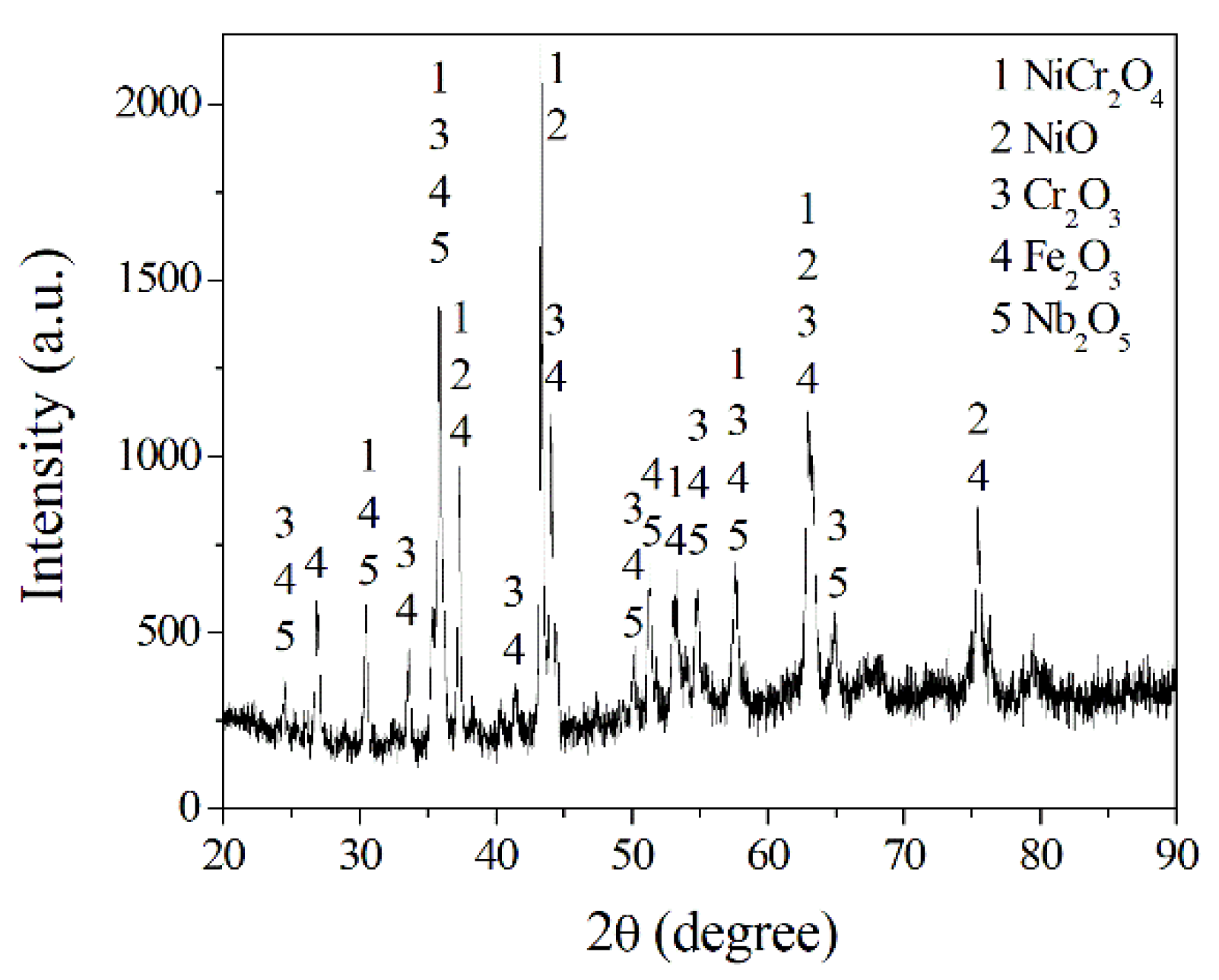

3.2. High Temperature Oxidation Properties

3.3. Thermal Shock Properties

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Thakur, A.; Gangopadhyay, S. State-of-the-art in surface integrity in machining of nickel-based superalloys. Int. J. Mach. Tool. Manu. 2016, 100, 25–54. [Google Scholar] [CrossRef]

- Wang, T.F.; Di, X.J.; Li, C.N.; Wang, J.M.; Wang, D.P. Effect of δ phase on microstructure and hardness of heat-affected zone in TIG-welded GH4169 superalloy. Acta Metall. Sinica 2019, 32, 1041–1052. [Google Scholar] [CrossRef]

- Levi, C.G. Emerging materials and processes for thermal barrier systems. Curr. Opin. Solid State Mater. Sci. 2004, 8, 77–91. [Google Scholar] [CrossRef]

- Cao, X.Q.; Vassen, R.; Stoever, D. Ceramic materials for thermal barrier coatings. J. Eur. Ceram. Soc. 2004, 24, 1–10. [Google Scholar] [CrossRef]

- Doleker, K.M.; Ozgurluk, Y.; Karaoglanli, A.C. Isothermal oxidation and thermal cyclic behaviors of YSZ and double-layered YSZ/La2Zr2O7 thermal barrier coatings (TBCs). Surf. Coat. Technol. 2018, 351, 78–88. [Google Scholar] [CrossRef]

- Satpathy, R.K.; Mishra, B.R.; Mallick, B.; Mishra, B.K. Synthesis and application of nano-structured bi-layer YSZ-LZ thermal barrier coating. Defence Sci. J. 2019, 69, 185–194. [Google Scholar] [CrossRef]

- Wang, Y.; Wang, L.; Liu, S.Y.; Liu, Y.; Wang, C.H.; Zou, Z.W. Nanostructured La2Zr2O7(LZ)/8YSZ double ceramic layer thermal barrier coatings fabricated by thermal spraying. China Surf. Eng. 2016, 29, 16–24. (In Chinese) [Google Scholar]

- Bobzin, K.N.; Bagcivan, N.; Brogelmann, T.; Yildirim, B. Influence of temperature on phase stability and thermal conductivity of single- and double-ceramic-layer EB-PVD TBC top coats consisting of 7YSZ, Gd2Zr2O7 and La2Zr2O7. Surf. Coat. Technol. 2013, 237, 56–64. [Google Scholar] [CrossRef]

- Liu, L.T.; Li, Z.X.; Zong, Y.Y.; Hu, Z.; Li, J.T. Influence of laser treatment on the microstructure and properties of YSZ thermal barrier coatings. Rare Metal Mater. Eng. 2018, 47, 1238–1242. (In Chinese) [Google Scholar]

- Xu, S.Q.; Zhu, C.; Zhang, Y. Effects of laser remelting and oxidation on NiCrAlY/8Y2O3-ZrO2 thermal barrier coatings. J. Therm. Spray Technol. 2018, 27, 412–422. [Google Scholar] [CrossRef]

- Soleimanipour, Z.; Baghshahi, S.; Shoja-razavi, R.; Salehi, M. Hot corrosion behavior of Al2O3 laser clad plasma barrier coatings sprayed YSZ thermal barrier coatings. Ceram. Int. 2016, 42, 17698–17705. [Google Scholar] [CrossRef]

- Zhou, S.F.; Lei, J.B.; Xiong, Z.; Guo, J.B.; Gu, Z.J.; Dai, X.Q.; Yan, C.; Pan, H.B. Characteristics and properties of cryomilling-induced columnar growth in NiCrAlY coatings on Ni-based superalloy by laser induction hybrid cladding. J. Mater. Res. 2016, 31, 1338–1347. [Google Scholar] [CrossRef]

- Renna, G.; Leo, P.; Cerri, E.; Zanon, G.P. Thermal shock behavior of CoCrAlTaY coatings on a Ni-base superalloy. Metall. Ital. 2015, 7–8, 33–41. [Google Scholar]

- Pereira, J.C.; Zambrano, J.C.; Tobar, M.J.; Yanez, A.; Amigo, V. High temperature oxidation behavior of laser cladding MCrAlY coatings on austenitic stainless steel. Surf. Coat. Technol. 2015, 270, 243–248. [Google Scholar] [CrossRef]

- Wang, H.Y.; Zuo, D.W.; Chen, X.F.; Yu, S.X.; Gu, Y.Z. Microstructure and oxidation behaviors of nano-particles strengthened NiCoCrAlY cladded coatings on superalloys. Chin. J. Mech. Eng. 2010, 23, 297–304. [Google Scholar] [CrossRef]

- Chen, G.F.; Feng, Z.C.; Liang, Y. Formation mechanism of laser-clad gradient thermal barrier coatings. T. Nonferr. Metal. Soc. 2000, 10, 92–93. [Google Scholar]

- Soleimanipour, Z.; Baghshahi, S.; Shoja-razavi, R. Improving the thermal shock resistance of thermal barrier coatings through formation of an in situ YSZ/Al2O3 composite via laser cladding. J. Mater. Eng. Perform. 2017, 26, 1890–1899. [Google Scholar] [CrossRef]

- Zhou, S.F.; Dai, X.Q.; Xiong, Z.; Zhang, T.Y. Functionally graded YSZ/NiCrAlY coating prepared by laser induction hybrid rapid cladding. Chin. J. Laser. 2013, 40, 0403004-1–0403004-6. (In Chinese) [Google Scholar]

- Ouyang, J.H.; Nowotny, S.; Richter, A.; Beyer, E. Characterization of laser clad yttria partially-stabilized ZrO2 ceramic layers on steel 16MnCr5. Surf. Coat. Technol. 2001, 137, 12–20. [Google Scholar] [CrossRef]

- Vandehaar, E.; Malian, P.A.; Baldwin, M. Laser cladding of thermal barrier coatings. Surf. Eng. 1988, 4, 159–172. [Google Scholar] [CrossRef]

- Zheng, H.Z.; Li, B.T.; Tan, Y.; Li, G.F.; Shu, X.Y.; Peng, P. Derivative effect of laser cladding on interface stability of YSZ@Ni coating on GH4169 alloy: An experimental and theoretical study. Appl. Surf. Sci. 2018, 427, 1105–1113. [Google Scholar] [CrossRef]

- Ouyang, J.H.; Nowotny, S.; Richter, A.; Beyer, E. Laser cladding of yttria partially stabilized ZrO2 (YPSZ) ceramic coatings on aluminum alloys. Ceram. Int. 2001, 27, 15–24. [Google Scholar] [CrossRef]

- Pei, Y.T.; Ouyang, J.H.; Lei, T.C.; Zhou, Y. Laser clad ZrO2-Y2O3 ceramic Ni-base alloy composite coatings. Ceram. Int. 1995, 21, 131–136. [Google Scholar] [CrossRef]

- Karaoglanli, A.C.; Doleker, K.M.; Ozgurluk, Y. Interface failure behavior of yttria stabilized zirconia (YSZ), La2Zr2O7, Gd2Zr2O7, YSZ/La2Zr2O7 and YSZ/Gd2Zr2O7 thermal barrier coatings (TBCs) in thermal cyclic exposure. Mater. Charact. 2020, 159, 110072. [Google Scholar] [CrossRef]

- Wang, R.; Dong, T.S.; Di, Y.L.; Wang, H.D.; Li, G.L.; Liu, L. High temperature oxidation resistance and thermal growth oxides formation and growth mechanism of double-layer thermal barrier coatings. J. Alloys Compd. 2019, 798, 773–783. [Google Scholar] [CrossRef]

- Jesuraj, S.A.; Kuppusami, P.; Kumar, S.A.; Panda, P.; Udaiyappan, S. Investigation on the effect of deposition temperature on structural and nanomechanical properties of electron beam evaporated lanthanum zirconate coatings. Mater. Chem. Phys. 2019, 236, 121789. [Google Scholar] [CrossRef]

- Huang, B.Z. Research on high temperature properties of laser remelting plasma sprayed ZrO2-8%Y2O3 thermal barrier coatings on GH4169 alloy. Master’s Thesis, Nanjing University of Aeronautics and Astronautics, Nanjing, China, 2017. (In Chinese). [Google Scholar]

- Zhou, H.F.; Yi, D.Q.; Yu, Z.M.; Xiao, L.R. Preparation and thermophysical properties of CeO2 doped La2Zr2O7 ceramic for thermal barrier coatings. J. Alloys Compd. 2006, 438, 217–221. [Google Scholar] [CrossRef]

- Zhang, L.P.; Goncalves, A.A.S.; Jaroniec, M. Identification of preferentially exposed crystal facets by X-ray diffraction. RSC Adv. 2020, 10, 5585–5589. [Google Scholar] [CrossRef]

- Guo, X.Y.; Wu, L.M.; Zhang, Y.; Jung, Y.G.; Li, L.; Knapp, J.; Zhang, J. First principles study of nanoscale mechanism of oxygen adsorption on lanthanum zirconate surfaces. Physica E 2016, 83, 36–40. [Google Scholar] [CrossRef]

- Qu, H.X.; Kou, S.Z.; Pu, Y.L.; Guo, X.F. Effect of cooling rate on microstructure and mechanical properties of as-cast GH4169 alloy. Foundry Technol. 2016, 37, 481–484. (In Chinese) [Google Scholar]

- Labrincha, J.A.; Frade, J.R.; Marques, F.M.B. Protonic conduction in La2Zr2O7-based pyrochlore materials. Solid State Ionics. 1997, 99, 33–40. [Google Scholar] [CrossRef]

- Zhang, J.; Guo, X.Y.; Jung, Y.G.; Li, L.; Knapp, J. Lanthanum zirconate based thermal barrier coatings: A review. Surf. Coat. Technol. 2017, 323, 18–29. [Google Scholar] [CrossRef]

- Yu, Z.F.; Liu, L.; Liu, R.; Cao, M.; Fan, L.; Li, Y.; Geng, S.J.; Wang, F.H. Corrosion behavior of GH4169 alloy under alternating oxidation at 900 °C and solution immersion. Materials 2019, 12, 1503. [Google Scholar] [CrossRef] [PubMed]

- Wang, D.X.; Tian, Z.J.; Shen, L.D.; Huang, Y.H. Research progress in preparation technology of thick thermal barrier coating. Mater. Prot. 2013, 46, 60–63. (In Chinese) [Google Scholar]

- Wagner, C. Beitrag zur theorie des anlaufvorgangs. Z. Phys. Chem. 1933, 21, 25–41. (In German) [Google Scholar] [CrossRef]

- Liu, M.T. Preparation and properties of MoSi2-CoNiCrAlY nano-composite coating on GH4169 alloy by plasma spraying. Master’s Thesis, South China University of Technology, Guangzhou, China, 2013; pp. 63–64. (In Chinese). [Google Scholar]

- Li, M.S. High Temperature Corrosion of Metals; Metallurgical Industry Press: Beijing, China, 2001; p. 263. (In Chinese) [Google Scholar]

| Element | Cr | Ni | Nb | Al | Co | Ti | Fe |

|---|---|---|---|---|---|---|---|

| % | 18.8 | 52.7 | 5.3 | 0.5 | 0.02 | 0.9 | Bal. |

| Element | O | Ni | Nb | Cr | Fe | Ti | Co | Al |

|---|---|---|---|---|---|---|---|---|

| Spot1 | 38.7 | 32.8 | 16.0 | 7.4 | 5.1 | 0 | 0 | 0 |

| Spot2 | 55.1 | 31.8 | 9.8 | 1.9 | 1.4 | 0 | 0 | 0 |

| Spot3 | 52.1 | 32.9 | 8.5 | 4.4 | 2.1 | 0 | 0 | 0 |

| Spot4 | 30.9 | 21.7 | 8.4 | 30.7 | 7.4 | 0.9 | 0 | 0 |

| Spot5 | 53.7 | 34.2 | 7.9 | 2.9 | 1.3 | 0 | 0 | 0 |

| Area B | 62.1 | 18.2 | 6.9 | 1.8 | 6.3 | 0.8 | 0.3 | 3.6 |

| Area C | 0 | 22.9 | 25.0 | 33.9 | 12.4 | 2.6 | 0.1 | 3.1 |

| Element | O | Zr | La | Ni | Nb | Cr | Ti | Fe | Al | Co |

|---|---|---|---|---|---|---|---|---|---|---|

| Spot1 | 65.9 | 2.1 | 0.3 | 1.6 | 11.9 | 15.9 | 1.1 | 1.3 | 0 | 0 |

| Spot2 | 57.2 | 1.8 | 1.0 | 5.8 | 18.7 | 12.1 | 0 | 3.0 | 0.4 | 0 |

| Spot3 | 63.7 | 1.7 | 0.1 | 3.5 | 1.6 | 22.6 | 0.3 | 6.5 | 0 | 0 |

| Spot4 | 66.8 | 1.6 | 0.2 | 1.7 | 9.6 | 12.5 | 2.7 | 3.4 | 1.5 | 0 |

| Spot5 | 72.0 | 1.5 | 0.1 | 4.5 | 10.0 | 7.9 | 1.7 | 2.3 | 0 | 0 |

| Area D | 49.1 | 10.8 | 0.4 | 15.4 | 4.2 | 3.6 | 1.0 | 6.7 | 8.6 | 0.2 |

| Area E | 0 | 0 | 0 | 56.9 | 7.2 | 15.8 | 0.5 | 17.7 | 1.8 | 0.1 |

| Samples | Oxidation Index n | Oxidation Rate Constant K |

|---|---|---|

| La2Zr2O7 coating | 1.53 | 0.47 |

| GH4169 substrate | 1.31 | 0.48 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Huang, K.; Li, W.; Pan, K.; Lin, X.; Wang, A. High Temperature Oxidation and Thermal Shock Properties of La2Zr2O7 Thermal Barrier Coatings Deposited on Nickel-Based Superalloy by Laser-Cladding. Coatings 2020, 10, 370. https://doi.org/10.3390/coatings10040370

Huang K, Li W, Pan K, Lin X, Wang A. High Temperature Oxidation and Thermal Shock Properties of La2Zr2O7 Thermal Barrier Coatings Deposited on Nickel-Based Superalloy by Laser-Cladding. Coatings. 2020; 10(4):370. https://doi.org/10.3390/coatings10040370

Chicago/Turabian StyleHuang, Kaijin, Wei Li, Kai Pan, Xin Lin, and Aihua Wang. 2020. "High Temperature Oxidation and Thermal Shock Properties of La2Zr2O7 Thermal Barrier Coatings Deposited on Nickel-Based Superalloy by Laser-Cladding" Coatings 10, no. 4: 370. https://doi.org/10.3390/coatings10040370

APA StyleHuang, K., Li, W., Pan, K., Lin, X., & Wang, A. (2020). High Temperature Oxidation and Thermal Shock Properties of La2Zr2O7 Thermal Barrier Coatings Deposited on Nickel-Based Superalloy by Laser-Cladding. Coatings, 10(4), 370. https://doi.org/10.3390/coatings10040370