The Use of Edible Films Based on Sodium Alginate in Meat Product Packaging: An Eco-Friendly Alternative to Conventional Plastic Materials

Abstract

1. Introduction to the World of Plastics: The Need for Alternative Materials

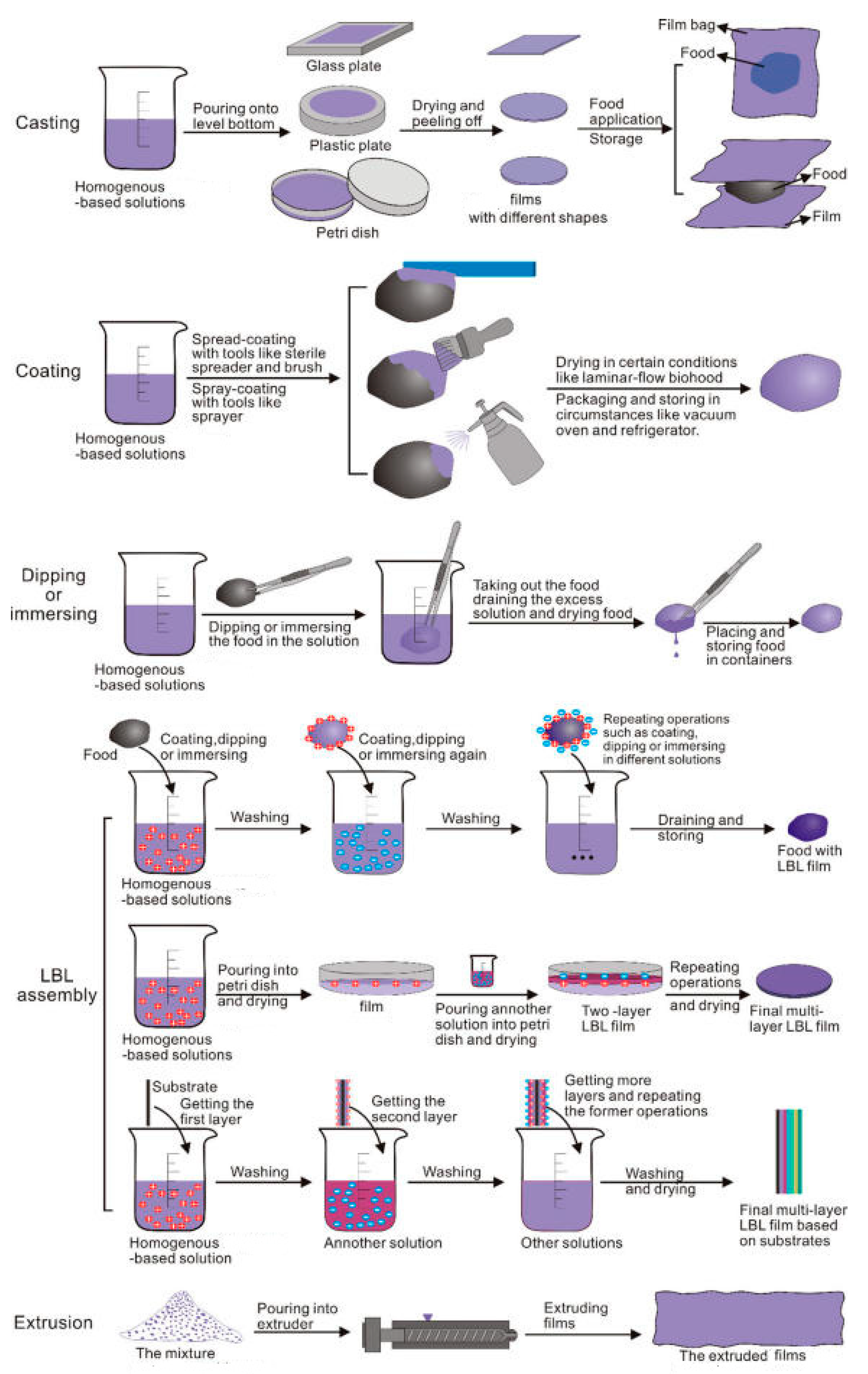

2. Films and Coatings Used in the Food Industry

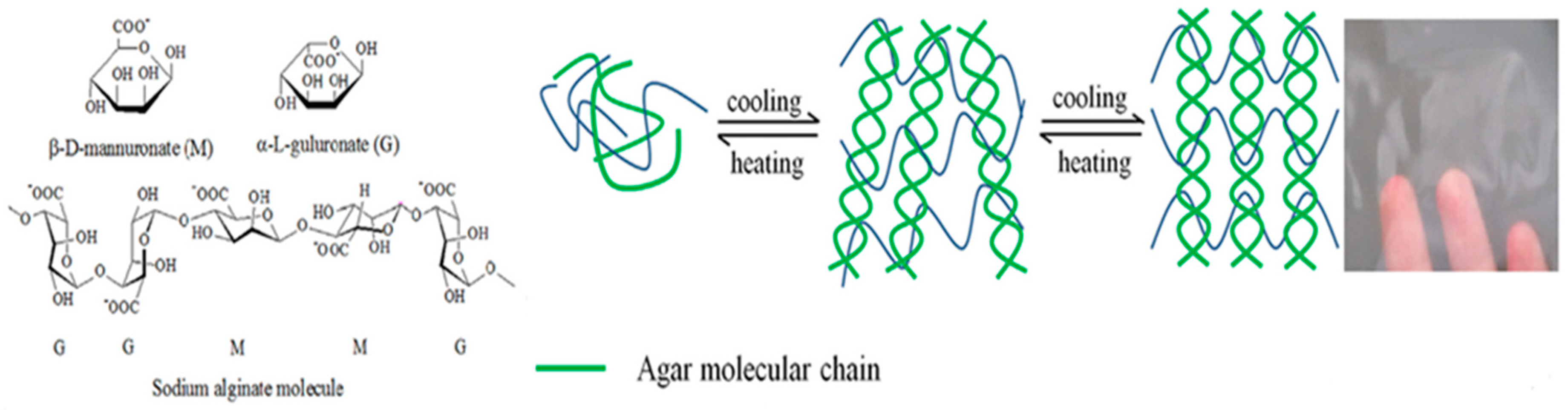

3. Sodium Alginate—a Basic Component of Bio-Based Polymer Materials

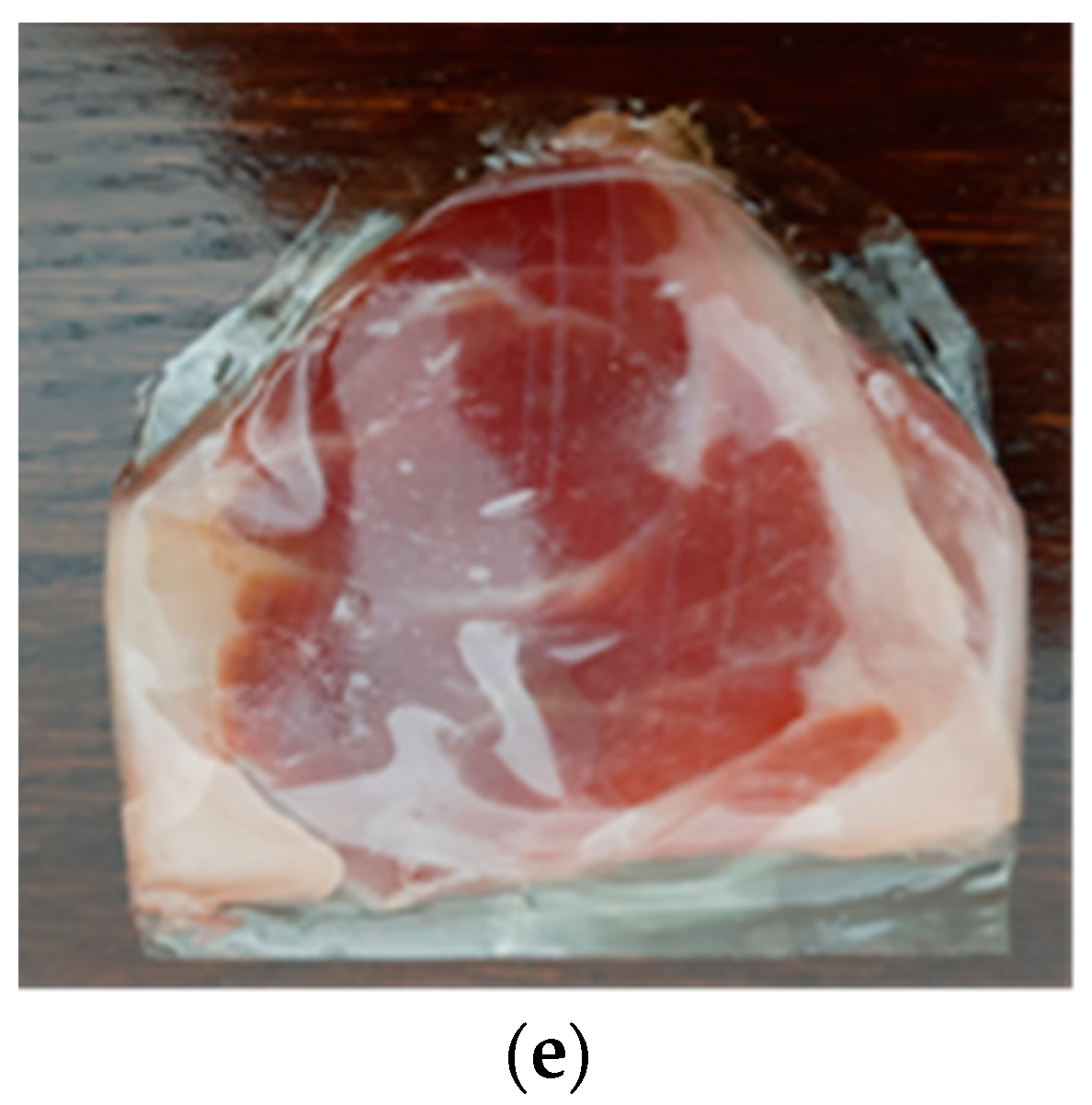

4. Sodium Alginate—a Basic Component of Packaging Materials in the Meat Industry

5. Conclusions and Future Perspectives

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Ananda, A.P.; Manukumar, H.M.; Umesha, S.; Soumya, G.; Priyanka, D.; Kumar, A.S.M.; Krishnamurthy, N.B.; Savitha, K.R. A Relook at Food Packaging for Cost Effective by Incorporation of Novel Technologies. J. Packag. Technol. Res. 2017, 1, 67–85. [Google Scholar] [CrossRef]

- Andrady, A.L. Plastics and Environmental Sustainability: Fact and Fiction; John Wiley & Sons: Hoboken, NJ, USA, 2015. [Google Scholar]

- Ellen MacArthur Foundation. The New Plastics Economy: Catalysing Action; Ellen MacArthur Foundation and World Economic Forum: Davos, Switzerland, 2017. [Google Scholar]

- Available online: https://ec.europa.eu/commission/news/first-ever-europe-wide-strategy-plastics-2018-jan-16_ro (accessed on 1 December 2019).

- Haward, M. Plastic pollution of the world’s seas and oceans as a contemporary challenge in ocean governance. Nat. Commun. 2018, 9, 667. [Google Scholar] [CrossRef] [PubMed]

- Available online: https://ec.europa.eu/commission/presscorner/detail/en/IP_18_5 (accessed on 1 December 2019).

- Available online: https://efsa.onlinelibrary.wiley.com/doi/epdf/10.2903/j.efsa.2017.5049 (accessed on 9 December 2019).

- Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?qid=1516265440535&uri=COM:2018:28:FIN (accessed on 1 December 2019).

- Tsang, Y.F.; Kumar, V.; Samadar, P.; Yang, Y.; Lee, J.; Ok, Y.S.; Song, H.; Kim, K.-H.; Kwon, E.E.; Jeon, Y.J. Production of bioplastic through food waste valorization. Environ. Int. 2019, 127, 625–644. [Google Scholar] [CrossRef] [PubMed]

- Hammam, A.R.A. Technological, applications, and characteristics of edible films and coatings: A review. SN Appl. Sci. 2019, 1, 632. [Google Scholar] [CrossRef]

- Vargas, M.; Pastor, C.; Chiralt, A.; McClements, D.J.; González-Martínez, C. Recent Advances in Edible Coatings for Fresh and Minimally Processed Fruits. Crit. Rev. Food Sci. Nutr. 2008, 48, 496–511. [Google Scholar] [CrossRef]

- Biji, K.B.; Ravishankar, C.N.; Mohan, C.O.; Gopal, T.K.S. Smart packaging systems for food applications: A review. J. Food Sci. Technol. 2015, 52, 6125–6135. [Google Scholar] [CrossRef]

- Calva-Estrada, S.J.; Jiménez-Fernández, M.; Lugo-Cervantes, E. Protein-Based Films: Advances in the Development of Biomaterials Applicable to Food Packaging. Food Eng. Rev. 2019, 11, 78–92. [Google Scholar] [CrossRef]

- Crouvisier-Urion, K.; Lagorce-Tachon, A.; Lauquin, C.; Winckler, P.; Tongdeesoontorn, W.; Domenek, S.; Debeaufort, F.; Karbowiak, T. Impact of the homogenization process on the structure and antioxidant properties of chitosan-lignin composite films. Food Chem. 2017, 236, 120–126. [Google Scholar] [CrossRef]

- Majid, I.; Nayik, G.A.; Dar, S.M.; Nanda, V. Novel food packaging technologies: Innovations and future prospective. J. Saudi Soc. Agric. Sci. 2016, 17, 454–462. [Google Scholar] [CrossRef]

- Parreidt, T.S.; Müller, K.; Schmid, M. Alginate-Based Edible Films and Coatings for Food Packaging Applications. Foods 2018, 7, 170. [Google Scholar] [CrossRef]

- Kester, J.; Fennema, O. Edible films and coatings: A review. Food Technol. 1986, 48, 47. [Google Scholar]

- Contreras-Medellin, R.; Labuza, T.P. Prediction of moisture protection requirements for foods. Cereal Food World 1981, 26, 335. [Google Scholar]

- Valdés, A.; Ramos, M.; Beltrán, A.; Jiménez, A.; Garrigós, M.C. State of the Art of Antimicrobial Edible Coatings for Food Packaging Applications. Coatings 2017, 7, 56. [Google Scholar] [CrossRef]

- Kuswandi, B. Environmental friendly food nano-packaging. Environ. Chem. Lett. 2017, 15, 205–221. [Google Scholar] [CrossRef]

- Costa, M.J.; Maciel, L.C.; Teixeira, J.A.; Vicente, A.A.; Cerqueira, M.A. Use of edible films and coatings in cheese preservation: Opportunities and challenges. Food Res. Int. 2018, 107, 84–92. [Google Scholar] [CrossRef]

- Hassan, B.; Chatha, S.A.S.; Hussain, A.I.; Zia, K.M.; Akhtar, N. Recent advances on polysaccharides, lipids and protein based edible films and coatings: A review. Int. J. Boil. Macromol. 2018, 109, 1095–1107. [Google Scholar] [CrossRef]

- Dehghani, S.; Hosseini, S.V.; Regenstein, J.M. Edible films and coatings in seafood preservation: A review. Food Chem. 2017, 240, 505–513. [Google Scholar] [CrossRef]

- Galgano, F. Biodegradable packaging and edible coating for fresh-cut fruits and vegetables. Ital. J. Food Sci. 2015, 27. [Google Scholar] [CrossRef]

- Rai, M.; Ingle, A.P.; Gupta, I.; Pandit, R.; Paralikar, P.; Gade, A.; Chaud, M.V.; Dos Santos, C.A. Smart nanopackaging for the enhancement of food shelf life. Environ. Chem. Lett. 2018, 17, 277–290. [Google Scholar] [CrossRef]

- Ramos, M.; Valdés, A.; Beltrán, A.; Garrigós, M.C. Gelatin-Based Films and Coatings for Food Packaging Applications. Coatings 2016, 6, 41. [Google Scholar] [CrossRef]

- Tabassum, N.; Khan, M.A. Modified atmosphere packaging of fresh-cut papaya using alginate based edible coating: Quality evaluation and shelf life study. Sci. Hortic. 2020, 259, 108853. [Google Scholar] [CrossRef]

- Heydari, R.; Bavandi, S.; Javadian, S.R. Effect of sodium alginate coating enriched with horsemint (Mentha longifolia) essential oil on the quality of bighead carp fillets during storage at 4 °C. Food Sci. Nutr. 2015, 3, 188–194. [Google Scholar] [CrossRef] [PubMed]

- Younes, M.; Aggett, P.; Aguilar, F.; Crebelli, R.; Filipič, M.; Jose Frutos, M.; Galtier, P.; Gott, D.; Gundert-Remy, U.; Georg Kuhnle, G. Re-evaluation of Alginic Acid and its Sodium, Potassium, Ammonium and Calcium Salts (e 400–e 404) as Food Additives. EFSA J. 2017, 15, e05049. [Google Scholar]

- Fat Moradali, M.; Ghods, S.; Rehm, B. Alginate Biosynthesis and biotechnological production. Chem. Mater. Sci. 2017, 11. [Google Scholar] [CrossRef]

- Alboofetileh, M.; Rezaei, M.; Hosseini, H.; Abdollahi, M. Antimicrobial activity of alginate/clay nanocomposite films enriched with essential oils against three common foodborne pathogens. Food Control. 2014, 36, 1–7. [Google Scholar] [CrossRef]

- Hou, X.; Xue, Z.; Xia, Y.; Qin, Y.; Zhang, G.; Liu, H.; Li, K. Effect of SiO2 nanoparticle on the physical and chemical properties of eco-friendly agar/sodium alginate nanocomposite film. Int. J. Boil. Macromol. 2019, 125, 1289–1298. [Google Scholar] [CrossRef]

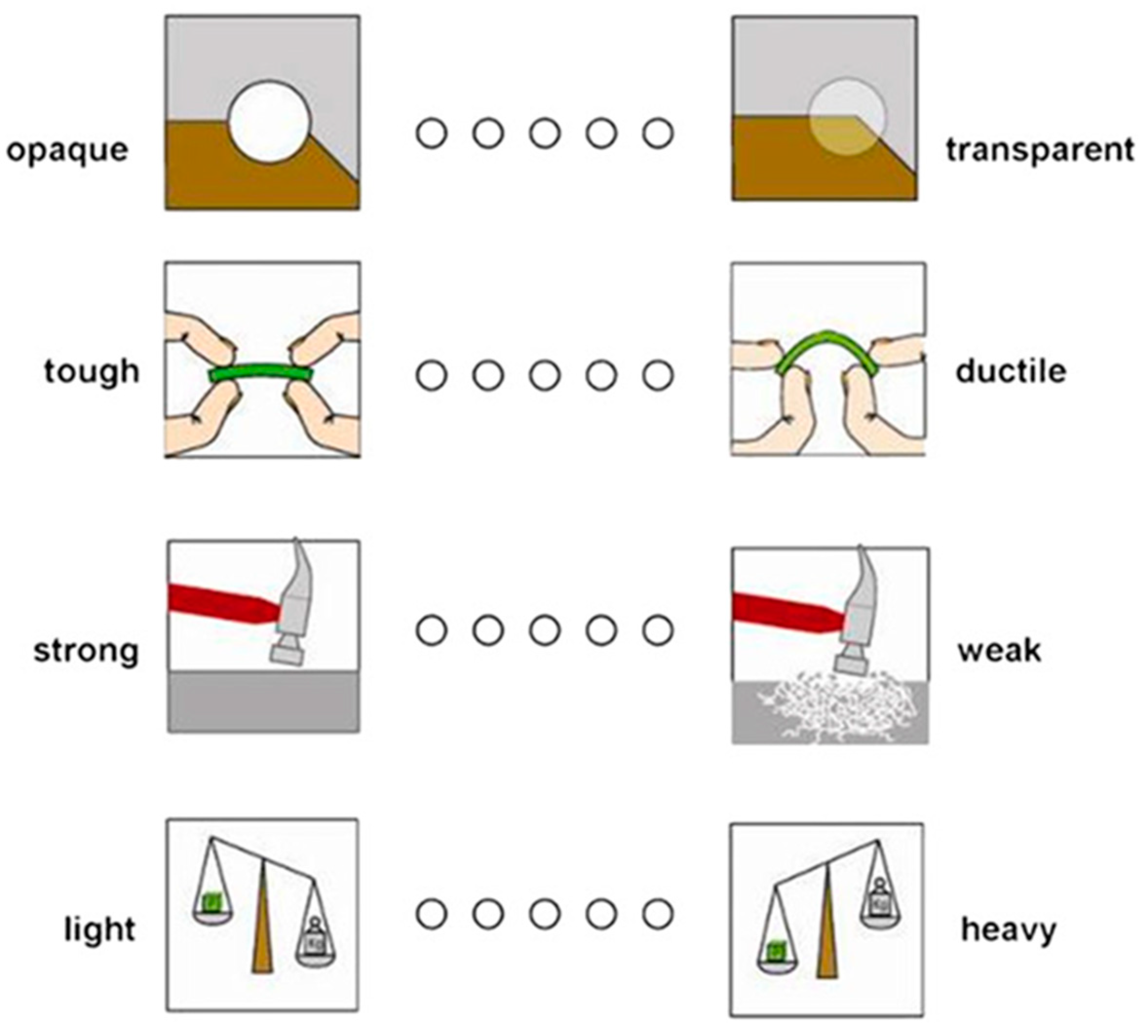

- Karana, E. Characterisation of ‘natural’ and ‘high-quality’ materials to improve perception of bio-plastics. J. Clean. Prod. 2012, 37, 316–325. [Google Scholar] [CrossRef]

- Majdinasab, M.; Hosseini, S.M.H.; Sepidname, M.; Negahdarifar, M.; Li, P. Development of a novel colorimetric sensor based on alginate beads for monitoring rainbow trout spoilage. J. Food Sci. Technol. 2018, 55, 1695–1704. [Google Scholar] [CrossRef]

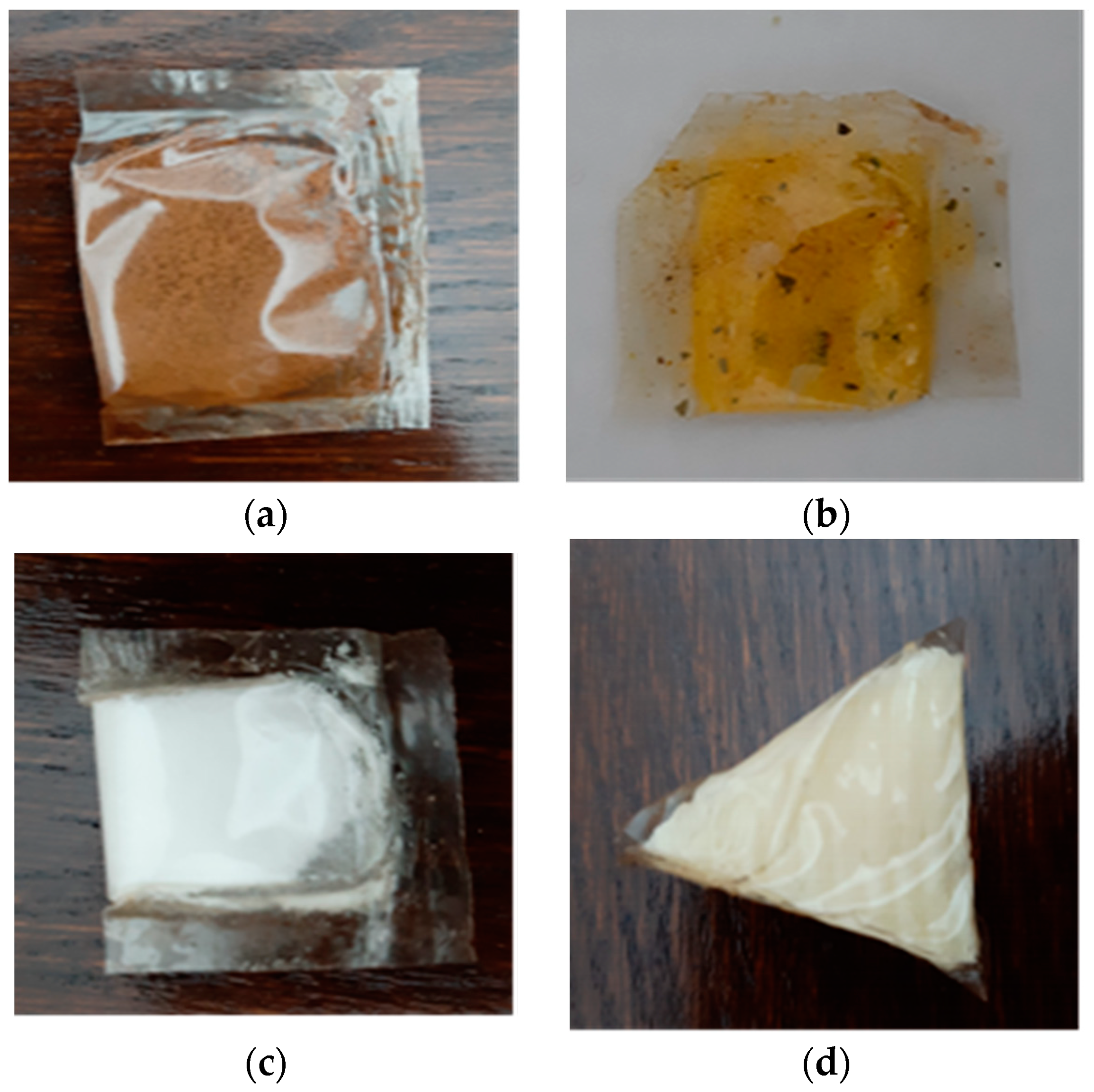

- Puscaselu, R.; Gutt, G.; Amariei, S. Gheorghe Biopolymer-Based Films Enriched with Stevia rebaudiana Used for the Development of Edible and Soluble Packaging. Coatings 2019, 9, 360. [Google Scholar] [CrossRef]

- Rowson, J.; Sangrar, A.; Rodriguez-Falcon, E.; Bell, A.; Walton, K.; Yoxall, A.; Kamat, S. Rating accesability of packaging: A medical packaging example. Packag. Technol. Sci. 2016, 29, 607. [Google Scholar] [CrossRef]

- Septianto, F.; Lee, M.S. Emotional responses to plastic waste: Matching image and message framing in encouraging consumers to reduce plastic consumption. Australas. Mark. J. (AMJ) 2019. [Google Scholar] [CrossRef]

- Wróblewska-Krepsztul, J.; Rydzkowski, T.; Michalska-Pożoga, I.; Thakur, V.K. Biopolymers for Biomedical and Pharmaceutical Applications: Recent Advances and Overview of Alginate Electrospinning. Nanomaterials 2019, 9, 404. [Google Scholar] [CrossRef] [PubMed]

- Mdhavan, S. A review on Hydrocolloids—Agar and Alginate. Int. J. Pharm. Sci. Res. 2015, 7, 704–707. [Google Scholar]

- Langer, R.; Vacanti, J.P. Tissue engineering. Science 1993, 260, 920–926. [Google Scholar] [CrossRef] [PubMed]

- Deepthi, S.; Jayakumar, R. Alginate nanobeads interspersed fibrin network as in situ forming hydrogel for soft tissue engineering. Bioact. Mater. 2017, 3, 194–200. [Google Scholar] [CrossRef] [PubMed]

- Rinaudo, M. Biomaterials based on a natural polysaccharide: Alginate. TIP 2014, 17, 92–96. [Google Scholar] [CrossRef]

- Galus, S. Development of edible coatings in the preservation of fruits and vegetables. In Polymers for Agri-Food Applications; Springer: Berlin, Germany, 2019; pp. 377–390. [Google Scholar]

- Salvia-Trujillo, L.; Rojas-Graü, M.A.; Soliva-Fortuny, R.; Martín-Belloso, O. Use of antimicrobial nanoemulsions as edible coatings: Impact on safety and quality attributes of fresh-cut Fuji apples. Postharvest Boil. Technol. 2015, 105, 8–16. [Google Scholar] [CrossRef]

- Appendini, P.; Hotchkiss, J.H. Review of antimicrobial food packaging. Innov. Food Sci. Emerg. Technol. 2002, 3, 113–126. [Google Scholar] [CrossRef]

- Cagri, A.; Ustunol, Z.; Ryser, E.T. Antimicrobial Edible Films and Coatings. J. Food Prot. 2004, 67, 833–848. [Google Scholar] [CrossRef]

- Chiabrando, V.; Giacalone, G. Effects of alginate edible coating on quality and antioxidant properties in sweet cherry during postharvest storage. Ital. J. Food Sci. 2015, 27, 173–180. [Google Scholar]

- Tavassoli-Kafrani, E.; Shekarchizadeh, H.; Masoudpour-Behabadi, M. Development of edible films and coatings from alginates and carrrageenans. Carbohydr. Polym. 2016, 37, 360–374. [Google Scholar] [CrossRef] [PubMed]

- Maftoonazad, N.; Ramaswamy, H.S.; Marcotte, M. Shelf-life extension of peaches through sodium alginate and methyl cellulose edible coatings. Int. J. Food Sci. Technol. 2008, 43, 951–957. [Google Scholar] [CrossRef]

- Wang, L.F.; Rhim, J.W. Preparation and application og agar/alginate/collagen ternary blend functional food packaging films. Int. J. Biol. Macromol. 2015, 80, 460–468. [Google Scholar] [CrossRef] [PubMed]

- Kotikalapudi, B.; Low, N.; Nickerson, M.; Korber, D. In vitro characterization of probiotic survival, adherence and antimicrobial resistance: Candidate selection for encapsulation in a pea protein isolate-alginate delivery system. Int. J. Probiotics Prebiotics 2010, 5, 1–12. [Google Scholar]

- Paula, G.; Benevides, N.; Cunha, A.; de Oliveira, A.V.; Pinto, A.; Morais, J.; Azeredo, H. Development and characterization of edible films from mixtures of k-carrageenan, i-carrageenan, and alginate. Food Hydrocoll. 2015, 47, 140–145. [Google Scholar] [CrossRef]

- Repossi, A.; Farabegoli, F.; Gazzotti, T.; Zironi, E.; Pagliuca, G. Bisphenol A in Edible Part of Seafood. Ital. J. Food Saf. 2016, 5, 98–105. [Google Scholar] [CrossRef]

- Wang, H.; Qian, J.; Ding, F. Emerging Chitosan-Based Films for Food Packaging Applications. J. Agric. Food Chem. 2018, 66, 395–413. [Google Scholar] [CrossRef]

- Huber, K.; Embuscado, E. Edible Films and Coatings for Food Applications; Springer: New York, NY, USA, 2009; pp. 245–268. ISBN 978-0-387-92823-4. [Google Scholar]

- Parreidt, T.S.; Schmid, M.; Müller, K. Effect of Dipping and Vacuum Impregnation Coating Techniques with Alginate Based Coating on Physical Quality Parameters of Cantaloupe Melon. J. Food Sci. 2018, 83, 929–936. [Google Scholar] [CrossRef]

- Skurtys, O.; Acevedo, C.; Pedreschi, F.; Enrione, J.; Osorio, F.; Aguilera, J.M. Food hydrocolloid edible films and coatings. In Food Hydrocolloids Characteristics, Properties and Structures; Hollingworth, C.S., Ed.; Nova Science Publishers, Inc.: New York, NY, USA, 2010; pp. 41–80. [Google Scholar]

- Troy, D.; Kerry, J. Consumer perception and the role of science in the meat industry. Meat Sci. 2010, 86, 214–226. [Google Scholar] [CrossRef]

- Haile, D.; De Smet, S.; Claeys, E.; Vossen, E. Effect of light, packaging condition and dark storage durations on colour and lipid oxidative stability of cooked ham. J. Food Sci. Technol. 2013, 50, 239–247. [Google Scholar] [CrossRef]

- Sánchez-Ortega, I.; García-Almendárez, B.E.; Santos-López, E.M.; Amaro-Reyes, A.; Barboza-Corona, J.E.; Regalado, C. Antimicrobial Edible Films and Coatings for Meat and Meat Products Preservation. Sci. World J. 2014, 2014, 1–18. [Google Scholar] [CrossRef] [PubMed]

- Cutter, C.N. Opportunities for bio-based packaging technologies to improve the quality and safety of fresh and further processed muscle foods. Meat Sci. 2006, 74, 131–142. [Google Scholar] [CrossRef] [PubMed]

- Malhotra, B.; Keshwani, A.; Kharkwal, H. Antimicrobial food packaging: Potential and pitfalls. Front. Microbiol. 2015, 6, 1–9. [Google Scholar] [CrossRef] [PubMed]

- Ksoudaa, G.; Sellimia, S.; Merlierb, F.; Falcimaigne, A.; Thomassetb, B.; Nasria, M.; Hajjia, M. Composition, antibacterial and antioxidant activities of Pimpinella saxifrage essential oil and application to cheese preservation as coating additive. Food Chem. 2019, 288, 47–56. [Google Scholar] [CrossRef]

- Kapetanakoua, A.; Nestoraa, S.; Evagelioub, V.; Skandamisa, P. Sodium alginate–cinnamon essential oil coated apples and pears: Variability of Aspergillus carbonarius growth and ochratoxin A production. Food Res. Int. 2019, 119, 876–885. [Google Scholar] [CrossRef]

- Peretto, G.; Du, W.-X.; Avena-Bustillos, R.J.; Berrios, J.D.J.; Sambo, P.; McHugh, T.H. Optimization of Antimicrobial and Physical Properties of Alginate Coatings Containing Carvacrol and Methyl Cinnamate for Strawberry Application. J. Agric. Food Chem. 2014, 62, 984–990. [Google Scholar] [CrossRef]

- Raybaudi-Massilia, R.M.; Rojas-Graü, M.A.; Mosqueda-Melgar, J.; Martín-Belloso, O. Comparative Study on Essential Oils Incorporated into an Alginate-Based Edible Coating To Assure the Safety and Quality of Fresh-Cut Fuji Apples. J. Food Prot. 2008, 71, 1150–1161. [Google Scholar] [CrossRef]

- Guerreiro, A.C.; Gago, C.M.; Faleiro, M.L.; Miguel, M.G.; Antunes, M.D. The effect of alginate-based edible coatings enriched with essential oils constituents on Arbutus unedo L. fresh fruit storage. Postharvest Boil. Technol. 2015, 100, 226–233. [Google Scholar] [CrossRef]

- Zhang, Y.; Ma, Q.; Critzer, F.; Davidson, P.M.; Zhong, Q. Effect of alginate coatings with cinnamon bark oil and soybean oil on quality and microbiological safety of cantaloupe. Int. J. Food Microbiol. 2015, 215, 25–30. [Google Scholar] [CrossRef]

- Azarakhsh, N.; Osman, A.; Ghazali, H.M.; Tan, C.P.; Adzahan, N.M. Lemongrass essential oil incorporated into alginate-based edible coating for shelf-life extension and quality retention of fresh-cut pineapple. Postharvest Boil. Technol. 2014, 88, 1–7. [Google Scholar] [CrossRef]

- Raybaudimassilia, R.; Mosquedamelgar, J.; Martin-Belloso, O. Edible alginate-based coating as carrier of antimicrobials to improve shelf-life and safety of fresh-cut melon. Int. J. Food Microbiol. 2008, 121, 313–327. [Google Scholar] [CrossRef] [PubMed]

- Ye, M.; Neetoo, H.; Chen, H. Control of Listeria monocytogenes on ham steaks by antimicrobials incorporated into chitosan-coated plastic films. Food Microbiol. 2008, 25, 260–268. [Google Scholar] [CrossRef] [PubMed]

- Mohebi, E.; Marquez, L. Intelligent packaging in meat industry: An overview of existing solutions. J. Food Sci. Technol. 2015, 52, 3947–3964. [Google Scholar] [CrossRef] [PubMed]

- Gaikwad, K.; Singh, S.; Ajji, A. Moisture absorbers for food packaging applications. Environ. Chem. Lett. 2019, 17, 609–628. [Google Scholar] [CrossRef]

- Toldra, F. Meat Biotechnology; Springer: New York, NY, USA, 2008; pp. 425–452. ISBN 978-0-387-79381-8. [Google Scholar]

- Park, Y.W.; Kim, S.M.; Lee, J.Y.; Jang, W. Application of biosensors in smart packaging. Mol. Cell. Toxicol. 2015, 11, 277–285. [Google Scholar] [CrossRef]

- Takma, D.K.; Korel, F. Active packaging films as a carrier of black cumin essential oil: Development and effect on quality and shelf-life of chicken breast meat. Food Packag. Shelf Life 2019, 19, 210–217. [Google Scholar] [CrossRef]

- Abdallah, M.R.; Mohamed, M.A.; Mohamed, H.; Emara, M.T. Application of alginate and gelatin-based edible coating materials as alternatives to traditional coating for improving the quality of pastirma. Food Sci. Biotechnol. 2018, 27, 1589–1597. [Google Scholar] [CrossRef]

- Król, Ż.; Kulig, D.; Marycz, K.; Zimoch-Korzycka, A.; Jarmoluk, A. The Effects of Using Sodium Alginate Hydrosols Treated with Direct Electric Current as Coatings for Sausages. Polymers 2017, 9, 602. [Google Scholar] [CrossRef]

- Shahbazi, Y.; Shavisi, N. Effects of sodium alginate coating containing Mentha spicata essential oil and cellulose nanoparticles on extending the shelf life of raw silver carp (Hypophthalmichthys molitrix) fillets. Food Sci. Biotechnol. 2019, 28, 433–440. [Google Scholar] [CrossRef]

- Bazargani-Gilani, B. Activating sodium alginate-based edible coating using a dietary supplement for increasing the shelf life of rainbow trout fillet during refrigerated storage. J. Food Saf. 2018, 38, e12395. [Google Scholar] [CrossRef]

- Alboofetileh, M.; Rezaei, M.; Hosseini, H.; Abdollahi, M. Efficacy of activated alginate-based nanocomposite films to control Listeria monocytogenes and spoilage flora in rainbow trout slice. J. Food Sci. Technol. 2016, 53, 521–530. [Google Scholar] [CrossRef] [PubMed]

- Vital, A.C.P.; Guerrero, A.; Monteschio, J.D.O.; Valero, M.V.; Carvalho, C.B.; Filho, B.A.D.A.; Madrona, G.S.; Prado, I.N.D. Effect of Edible and Active Coating (with Rosemary and Oregano Essential Oils) on Beef Characteristics and Consumer Acceptability. PLoS ONE 2016, 11, e0160535. [Google Scholar] [CrossRef] [PubMed]

- Jalali, N.; Ariiai, P.; Fattahi, E. Effect of alginate/carboxyl methyl cellulose composite coating incorporated with clove essential oil on the quality of silver carp fillet and Escherichia coli O157:H7 inhibition during refrigerated storage. J. Food Sci. Technol. 2015, 53, 757–765. [Google Scholar] [CrossRef] [PubMed]

- Raeisi, M.; Tabaraei, A.; Hashemi, M.; Behnampour, N. Effect of sodium alginate coating incorporated with nisin, Cinnamomum zeylanicum, and rosemary essential oils on microbial quality of chicken meat and fate of Listeria monocytogenes during refrigeration. Int. J. Food Microbiol. 2016, 238, 139–145. [Google Scholar] [CrossRef] [PubMed]

- Oussalah, M.; Caillet, S.; Salmieri, S.; Saucier, L.; Lacroix, M. Antimicrobial effects of alginate-based film containing essential oils of Listeria monocytogenes and Salmonella thyphimurium present in bologna and ham. J. Food Prot. 2007, 70, 901–908. [Google Scholar] [CrossRef] [PubMed]

- Kazemi, S.M.; Rezaei, M. Antimicrobial Effectiveness of Gelatin-Alginate Film Containing Oregano Essential Oil for Fish Preservation. J. Food Saf. 2015, 35, 482–490. [Google Scholar] [CrossRef]

- Oussalah, M.; Caillet, S.; Salmiéri, S.; Saucier, L.; Lacroix, M. Antimicrobial Effects of Alginate-Based Film Containing Essential Oils for the Preservation of Whole Beef Muscle. J. Food Prot. 2006, 69, 2364–2369. [Google Scholar] [CrossRef]

- Lu, F.; Ding, Y.; Ye, X.; Liu, D. Cinnamon and nisin in alginate–calcium coating maintaing quality of fresh northern snakehead fish fillets. LWT-Food Sci. Technol. 2010, 43, 1331–1335. [Google Scholar] [CrossRef]

- Sharifi, F.; Khanzadi, S.; Hashemi, M.; Azizzadeh, M. Control of Listeria Monocytogenes and Escherichia coli O157:H7 Inoculated on Fish Fillets Using Alginate Coating Containing Lactoperoxidase System and Zataria multiflora Boiss Essential Oil. J. Aquat. Food Prod. Technol. 2017, 26, 1014–1021. [Google Scholar] [CrossRef]

- Deng, X.; Srinivasan, R. When Do Transparent Packages Increase (or Decrease) Food Consumption? J. Mark. 2013, 77, 104–117. [Google Scholar] [CrossRef]

- Silberbauer, A.; Schmid, M. Packaging Concepts for Ready-to-Eat Food: Recent Progress. J. Packag. Technol. Res. 2017, 1, 113–126. [Google Scholar] [CrossRef]

| AGAR | STARCH | CHITOSAN | SODIUM ALGINATE | CARRAGEENAN | |

|---|---|---|---|---|---|

| AGAR | + low costs - brittle, rigid, gloss-free films, with high solubility, low tensile strength and elasticity | + decreases color intensity, increases transparency and gloss; antibacterial properties | - low tensile strength | - increases hydration capacity and vapor permeability | |

| STARCH | + homogeneous microstructure, good barrier and mechanical properties | + increases mechanical strength, decreases vapor permeability and solubility; antibacterial effect | + high water-holding capacity | + improved mechanical properties - increases oxygen permeability | |

| CHITOSAN | + improved mechanical properties | - reduced mechanical properties; low gloss and transparency | + allows compound encapsulation - low mechanical performance | + allows the encapsulation of controlled-release compounds - increases hydration capacity and solubility | |

| SODIUM ALGINATE | + homogeneous, flexible, and fine films | - high solubility, more brittle films | + allows encapsulation of compounds | + vapor permeability decreases - low mechanical properties | |

| CARRAGE-ENAN | + reduces hydration capacity; more flexible and elastic films - reduces transparency | + low cost - low flexibility and elasticity, high solubility | + encapsulation of compounds | - low elongation at break |

| Food | Essential Oils Added | Results | References |

|---|---|---|---|

| Cheese | Pimpinella saxifrage | The addition of PSEO (1%–3%) in sodium alginate coating (2% sodium alginate+15% glycerol) was effective in reducing the weight loss, preserving pH and color and improving the oxidative and bacterial stability of the coated cheese. | [63] |

| Apples and pears | Cinnamon | Inhibition of growth and toxin production of Aspergillus carbonarius growth and ochratoxin A production. | [64] |

| Bighead carp fillets | Horsemint (Mentha longifolia) | Samples treated showed significantly lower lipid oxidation during the storage period and reduced degree of microbial deterioration. Antioxidant and antibacterial effects of sodium alginate coating and horsemint were more pronounced when a horsemint was used at 1% concentration. | [28] |

| Fresh-cut papaya | Thyme (Thymus vulgaris) and oregano (Origanum vulgare) | Retarded the degradation rate of physicochemical properties, improved microbiological food safety and had the highest sensory evaluation scores for fresh-cut papaya stored for 12 days at 4 °C. | [27] |

| Fresh-cut apple | Lemongrass | Inactivation of Escherichia coli. | [45] |

| Strawberry | Carvacrol | Carvacrol was effective against both Escherichia coli and Botrytis cinerea. | [65] |

| Fresh-cut apples | Cinnamon, clove, and lemongrass | The coatings applied on apple pieces maintained the physicochemical characteristics of the apple pieces for more than 30 days, decreased the respiration rate, reduced the Escherichia coli population by about 1.23 log CFU/g at day 0, and extended the microbiological shelf life by at least 30 days. | [66] |

| Strawberry | Citral and eugenol | Alginate edible with essential oils added improved the coatings in most cases, better preserved sensory and nutritional attributes, and reduced microbial spoilage. | [67] |

| Fresh-cut cantaloupes | Cinnamon bark oil and soybean oil | Cocktails of Salmonella enterica, Escherichia coli O157:H7, or Listeria monocytogenes inoculated onto cantaloupes were reduced to the detection limit and completely inhibited during 15 day storage with the coating treatment. | [68] |

| Fresh-cut pineapple | Lemongrass | The results indicate that an alginate-based edible coating formulation incorporated with 0.3% (w/v) lemongrass has potential to extend the shelf life and maintain quality of fresh-cut pineapple. | [69] |

| Fresh-cut melon | Cinnamon, palmarosa, and lemongrass | Palmarosa oil incorporated at 0.3% into the coating was shown to be a promising preservation alternative for fresh-cut melon, since it had a good acceptation by panelists, maintained the fruit quality parameters, inhibited the native flora growth, and reduced Salmonella enteritidis population. | [70] |

| Food | Film | Results | References |

|---|---|---|---|

| Chicken breast meat | Alginate-based film with black cumin | Indicated antimicrobial activity against Escherichia coli, less variation in pH, lower color changes for chicken breast meats over 5 days of storage at 4 °C. | [76] |

| Pastirma | Sodium-alginate- and gelatin-based coatings | The color of pastirma was preserved after coating with gelatin or alginate, which will make the dry cured meat more attractive to consumers. | [77] |

| Sausages | Sodium alginate | Enterobacteriaceae microorganisms were inhibited by about 2 log CFU/cm2 on sausage samples covered with experimental sodium alginate coatings. | [78] |

| Raw silver carp (Hypophthalmichthys molitrix) fillets | Sodium alginate coating containing Mentha spicata essential oil and cellulose nanoparticles | Retarded the growth of mesophilic and psychrotrophic bacterial population for up to 7 days and enhanced the shelf life of minced beef meat compared to the control; the shelf life of silver carp fillets using coatings was significantly improved for up to 14 days compared to the control group. | [79] |

| Refrigerated trout (Oncorhynchus mykiss) fillets | Sodium-alginate-based films with resveratrol | Enhanced the shelf life and exhibited strong antioxidant activities at very low concentrations; it also led to stable and unchanged sensory properties such as odor, color, flavor, and general acceptability. | [80] |

| Fish fillet | Alginate-based nanocomposite films with marjoram, clove, cinnamon, coriander, caraway, and cumin | Inhibited the growth of Listeria monocytogenes in the following order: marjoram > clove > cinnamon > coriander > caraway > cumin essential oils. | [81] |

| Beef steaks | Alginate-based films with rosemary and oregano essential oils | The edible coatings decreased lipid oxidation of the meat compared to the control; significantly decreased color losses, water losses, and shear force compared to the control; and had a significant effect on consumer perception of odor, flavor, and overall acceptance of the beef. | [82] |

| Carp fillet | Alginate/carboxyl methyl cellulose composite coating incorporated with clove essential oil | Maintained silver fillet shelf life up to 16 days without any significant loss of texture, odor, color, or overall acceptability, and had lower bacterial count, TVB-N, and lipid oxidation rate in comparison to control. | [83] |

| Chicken meat | Sodium alginate coating incorporated with nisin, Cinnamomum zeylanicum, and rosemary essential oils | Longer storage of chicken breast at refrigerated temperatures (4 °C); reduced the degradation of bioactive compounds and maintained the nutritional quality. | [84] |

| Baked ham and bologna sliced | Alginate films and essential oils of oregano, cinnamon, savory | Reductions populations of Salmonella enterica and Listeria monocytogenes in bologna and baked ham slices when applying alginate films with cinnamon essential oil. | [85] |

| Fish fillet | Gelatin–alginate film containing oregano essential oil | Study showed that film was an effective antimicrobial suitable for potential food packaging applications; use of the OEO blend film delayed bacterial growth over 15 days of storage. | [86] |

| Beef muscle | Sodium alginate and oregano, cinnamon, savory oils | After 5 days of storage, films containing oregano or cinnamon essential oils were the most effective against Salmonella typhimurium. | [87] |

| Fish fillets | Alginate–calcium coating with cinnamon and nisin | Cinnamon in alginate–calcium coating treatments could efficiently maintain quality during storage, but colors of fish fillets were evidently changed due to the color of cinnamon. | [88] |

| Rainbow trout fillets | Alginate coating containing lactoperoxidase system and Zataria multiflora Boiss essential oil | Alginate coating, when used with no antimicrobial agent, had a supportive effect on the growth of Listeria monocytogenes and Escherichia coli O157:H7 pathogenic bacteria. | [89] |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gheorghita, R.; Gutt, G.; Amariei, S. The Use of Edible Films Based on Sodium Alginate in Meat Product Packaging: An Eco-Friendly Alternative to Conventional Plastic Materials. Coatings 2020, 10, 166. https://doi.org/10.3390/coatings10020166

Gheorghita R, Gutt G, Amariei S. The Use of Edible Films Based on Sodium Alginate in Meat Product Packaging: An Eco-Friendly Alternative to Conventional Plastic Materials. Coatings. 2020; 10(2):166. https://doi.org/10.3390/coatings10020166

Chicago/Turabian StyleGheorghita (Puscaselu), Roxana, Gheorghe Gutt, and Sonia Amariei. 2020. "The Use of Edible Films Based on Sodium Alginate in Meat Product Packaging: An Eco-Friendly Alternative to Conventional Plastic Materials" Coatings 10, no. 2: 166. https://doi.org/10.3390/coatings10020166

APA StyleGheorghita, R., Gutt, G., & Amariei, S. (2020). The Use of Edible Films Based on Sodium Alginate in Meat Product Packaging: An Eco-Friendly Alternative to Conventional Plastic Materials. Coatings, 10(2), 166. https://doi.org/10.3390/coatings10020166