Characteristics of MgIn2O4 Thin Film Transistors Enhanced by Introducing an MgO Buffer Layer

Abstract

1. Introduction

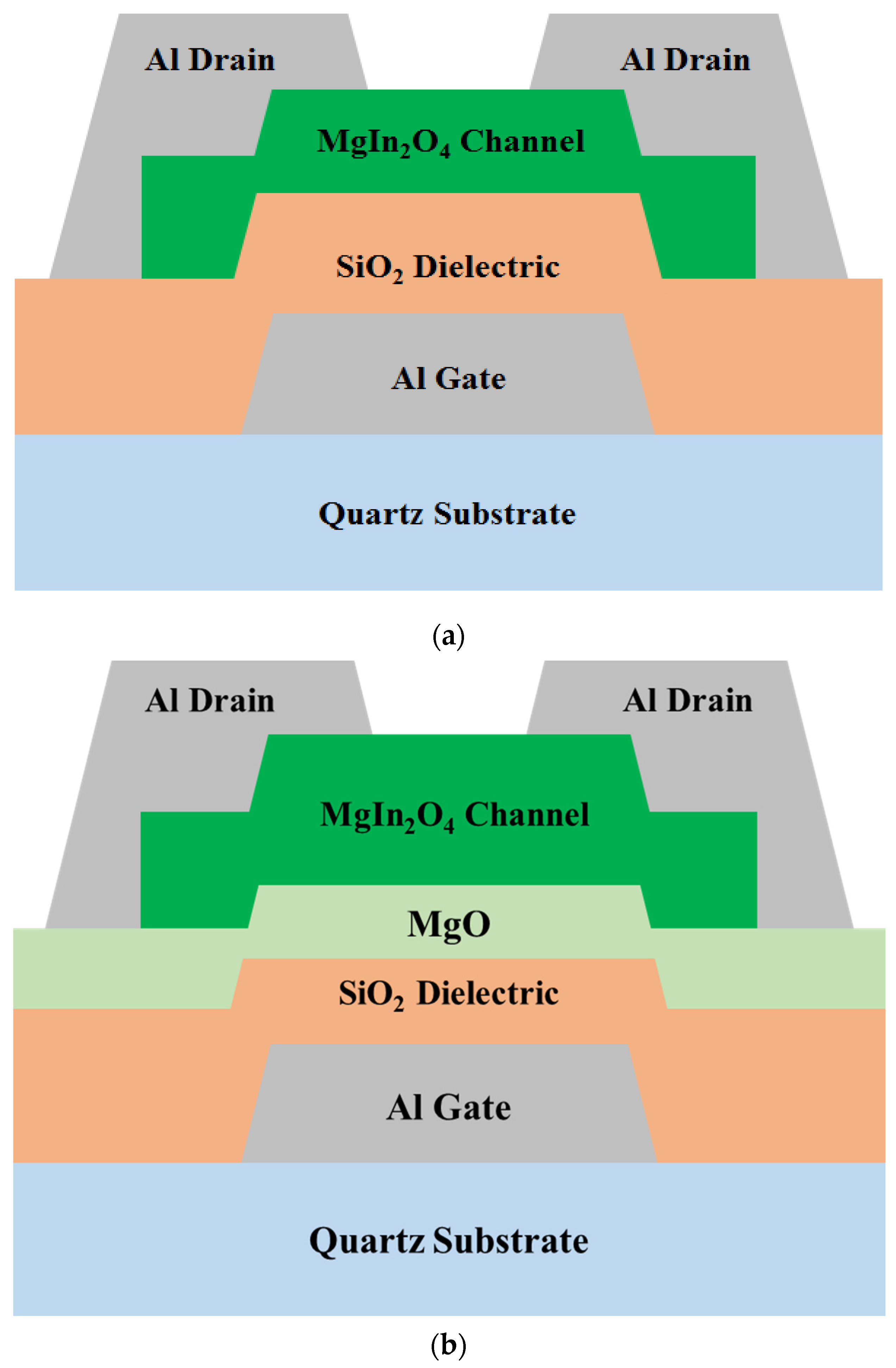

2. Materials and Methods

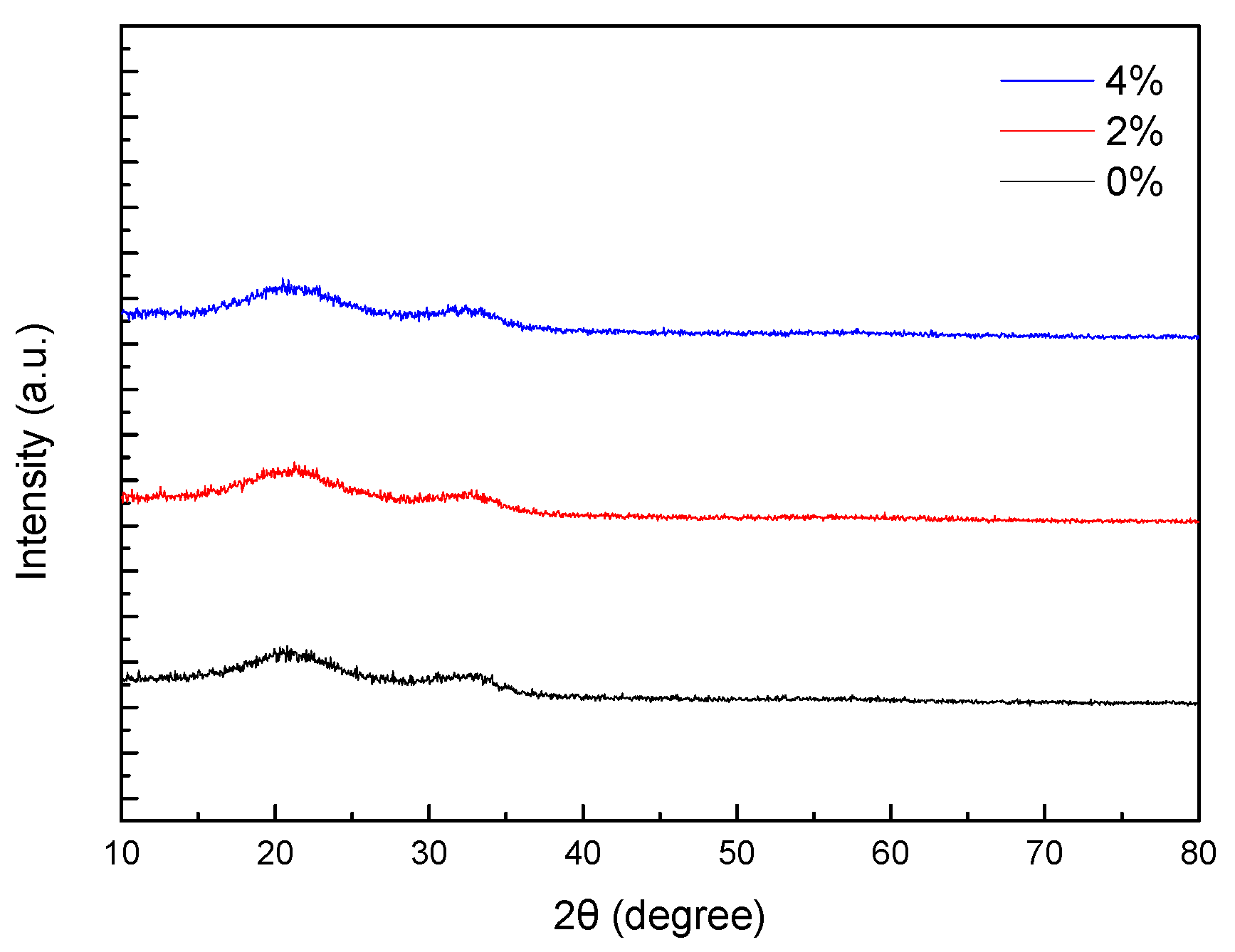

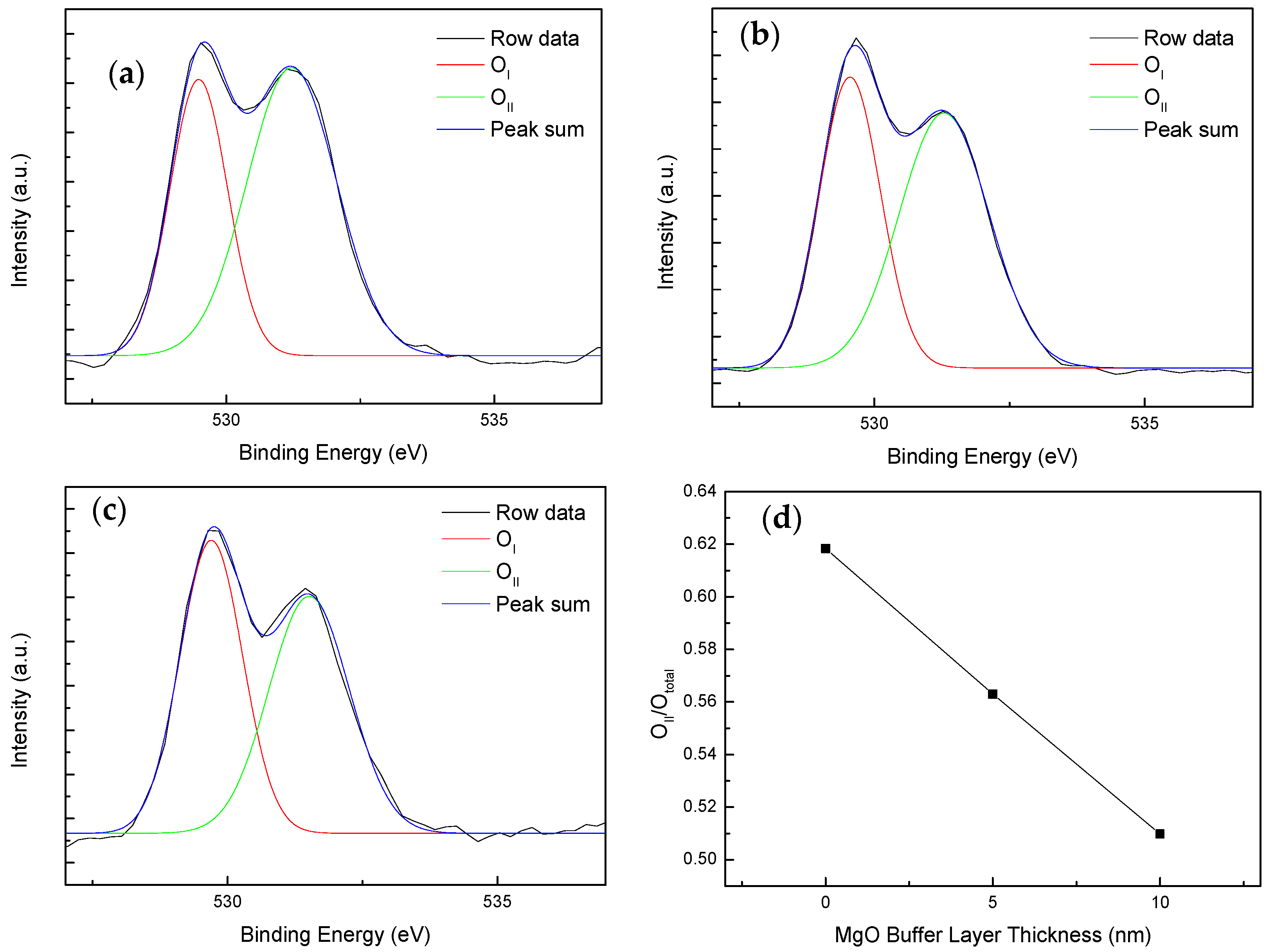

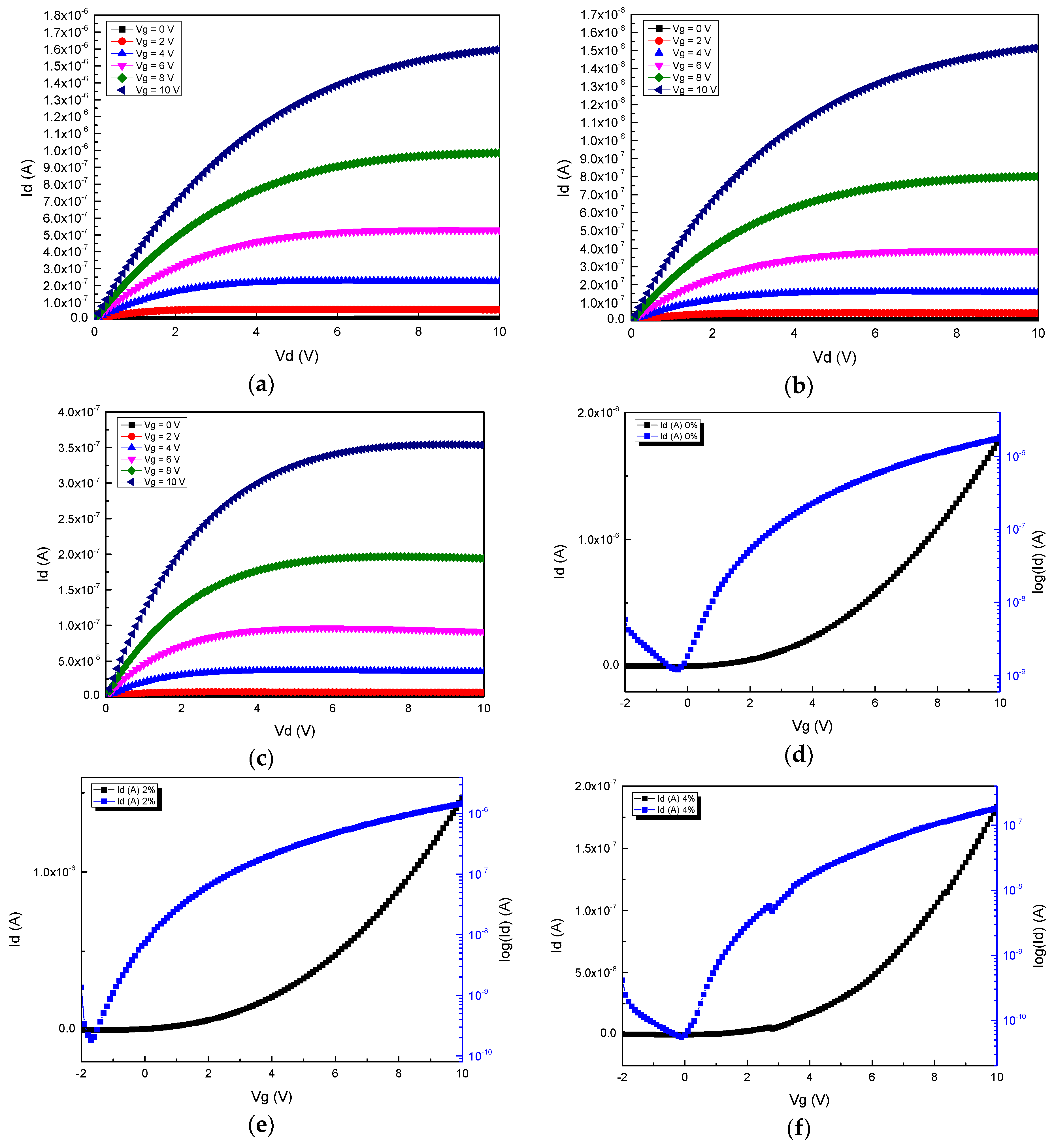

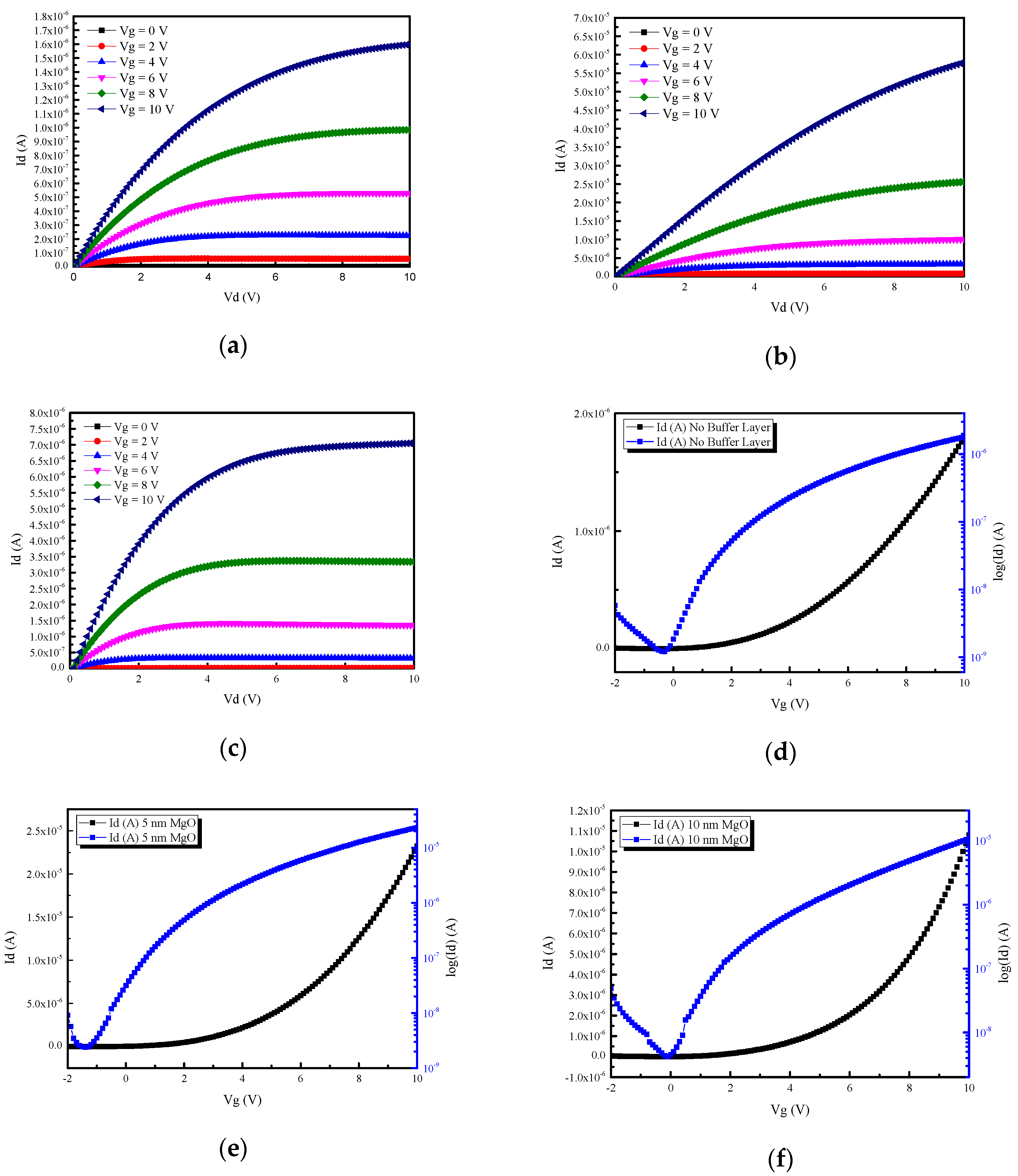

3. Results and Discussions

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Nomura, K.; Ohta, H.; Takagi, A.; Kamiya, T.; Hirano, M.; Hosono, H. Room-temperature fabrication of transparent flexible thin-film transistors using amorphous oxide semiconductors. Nature 2004, 432, 488–492. [Google Scholar] [CrossRef] [PubMed]

- Fortunato, E.M.C.; Barquinha, P.M.C.; Pimentel, A.C.M.B.G.; Gonçalves, A.M.F.; Marques, A.J.S.; Pereira, L.M.N.; Martins, R.F.P. Fully transparent ZnO thin-film transistor produced at room temperature. Adv. Mater. 2005, 17, 590–594. [Google Scholar] [CrossRef]

- Jang, Y.K.; Kyoung, S.S.; Ji, S.J.; Tae, S.K.; Myung, K.R.; Kyung, B.P.; Byung, W.Y.; Jung, W.Y.; Young, G.L.; Kee, C.P.; et al. Bottom-gate gallium indium zinc oxide thin-film transistor array for high-resolution AMOLED display. IEEE Electron. Device Lett. 2008, 29, 1309–1311. [Google Scholar]

- Lee, S.; Arokia, N. Subthreshold Schottky-barrier thin-film transistors with ultralow power and high intrinsic gain. Science 2016, 354, 302–304. [Google Scholar] [CrossRef] [PubMed]

- Faber, H.; Das, S.; Lin, Y.H.; Pliatsikas, N.; Zhao, K.; Kehagias, T.; Dimitrakopulos, G.; Amassian, A.; Patsalas, P.A.; Anthopoulos, T.D. Heterojunction oxide thin-film transistors with unprecedented electron mobility grown from solution. Sci. Adv. 2017, 3, e1602640. [Google Scholar] [CrossRef] [PubMed]

- Wu, C.; Li, X.; Lu, J.; Ye, Z.; Zhang, J.; Zhou, T.; Sun, R.; Chen, L.; Lu, B.; Pan, X. Characterization of amorphous Si-Zn-Sn-O thin films and applications in thin-film transistors. Appl. Phys. Lett. 2013, 103, 082109. [Google Scholar] [CrossRef]

- Noh, J.H.; Ryu, S.Y.; Jo, S.J.; Kim, C.S.; Sohn, S.W.; Rack, P.D.; Kim, D.J.; Baik, H.K. Indium oxide thin-film transistors fabricated by RF sputtering at room temperature. IEEE Electron. Device Lett. 2010, 31, 567–569. [Google Scholar]

- Kim, Y.G.; Kim, T.; Avis, C.; Lee, S.H.; Jang, J. Stable and high-performance indium oxide thin-film transistor by Ga doping. IEEE Trans. Electron. Devices 2016, 63, 1078–1084. [Google Scholar] [CrossRef]

- Luo, Y.R. Comprehensive Handbook of Chemical Bond. Energies; CRC Press: New York, NY, USA, 2007; pp. 9-65–9-70. [Google Scholar]

- Barbalace, K. “Periodic Table of Elements”. Environmental Chemistry.com 2007, 04–14. Available online: https://environmentalchemistry.com/ (accessed on 20 December 2020).

- Koide, H.; Nagao, Y.; Koumoto, K.; Takasaki, Y.; Umemura, T.; Kato, T.; Ikuhara, Y.; Ohta, H. Electric field modulation of thermopower for transparent amorphous oxide thin film transistors. Appl. Phys. Lett. 2010, 97, 182105. [Google Scholar] [CrossRef]

- Luka, G.; Krajewski, T.A.; Witkowski, B.S.; Wisz, G.; Virt, I.S.; Guziewicz, E.; Godlewski, M. Aluminum-doped zinc oxide films grown by atomic layer deposition for transparent electrode applications. J. Mater. Sci. Mater. Electron. 2011, 22, 1810–1815. [Google Scholar] [CrossRef]

- Zhan, R.; Dong, C.; Liu, P.T.; Shieh, H.P.D. Influence of channel layer and passivation layer on the stability of amorphous InGaZnO thin film transistors. Microelectron. Reliab. 2013, 53, 1879–1885. [Google Scholar] [CrossRef]

- Wu, C.H.; Chang, K.M.; Huang, S.H.; Deng, I.C.; Wu, C.J.; Chiang, W.H.; Chang, C.C. Characteristics of IGZO TFT Prepared by Atmospheric Pressure Plasma Jet Using PE-ALD Al2O3 Gate Dielectric. IEEE Electron. Device Lett. 2012, 33, 552–554. [Google Scholar] [CrossRef]

- Liu, G.X.; Liu, A.; Shan, F.K.; Meng, Y.; Shin, B.C.; Fortunato, E.; Martins, R. High-performance fully amorphous bilayer metal-oxide thin film transistors using ultra-thin solution-processed ZrOx dielectric. Appl. Phys. Lett. 2014, 105, 113509. [Google Scholar] [CrossRef]

- Na, S.Y.; Kim, Y.M.; Yoon, D.J.; Yoon, S.M. Improvement in negative bias illumination stress stability of In-Ga-Zn-O thin film transistors using HfO2 gate insulators by controlling atomic-layer-deposition conditions. J. Phys. D Appl. Phys. 2017, 50, 495109. [Google Scholar] [CrossRef]

- Jiang, G.; Liu, A.; Liu, G.; Zhu, C.; Meng, Y.; Shin, B.; Fortunato, E.; Martins, R.; Shan, F. Solution-processed high-κ magnesium oxide dielectrics for low-voltage oxide thin-film transistors. Appl. Phys. Lett. 2016, 109, 183508. [Google Scholar] [CrossRef]

- Lee, J.H.; Kim, H.S.; Kim, S.H.; Jang, N.W.; Yun, Y. Characterization of magnesium oxide gate insulators grown using RF sputtering for ZnO thin-film transistors. Curr. Appl. Phys. 2014, 14, 794–797. [Google Scholar] [CrossRef]

- Huang, H.Q.; Liu, F.J.; Sun, J.; Zhao, J.W.; Hu, Z.F.; Li, Z.J.; Zhang, X.Q.; Wang, Y.S. Effect of MgO buffer layer thickness on the electrical properties of MgZnO thin film transistors fabricated by plasma assisted molecular beam epitaxy. Appl. Surf. Sci. 2011, 257, 10721–10724. [Google Scholar] [CrossRef]

- Dai, S.; Wang, T.; Li, R.; Wang, Q.; Ma, Y.; Tian, L.; Su, J.; Wang, Y.; Zhou, D.; Zhang, X.; et al. Preparation and electrical properties of N-doped ZnSnO thin film transistors. J. Alloys Compd. 2018, 745, 256–261. [Google Scholar] [CrossRef]

- Dali, S.E.; Chockalingam, M.J. Combustion synthesis of magnesium indate, MgIn2O4. Mater. Chem. Phys. 2001, 70, 73–77. [Google Scholar] [CrossRef]

- Jeon, H.J.; Maeng, W.J.; Park, J.S. Effect of Al concentration on the electrical characteristics of solution-processed Al doped ZnSnO thin film transistors. Ceram. Int. 2014, 40, 8769–8774. [Google Scholar] [CrossRef]

- Lee, K.H.; Ok, K.C.; Kim, H.; Park, J.S. The influence of oxygen partial pressure on the performance and stability of Ge-doped InGaO thin film transistors. Ceram. Int. 2014, 40, 3215–3220. [Google Scholar] [CrossRef]

- Liu, L.C.; Chen, J.S.; Jeng, J.S. Role of oxygen vacancies on the bias illumination stress stability of solution-processed zinc tin oxide thin film transistors. Appl. Phys. Lett. 2014, 105, 023509. [Google Scholar] [CrossRef]

- Li, J.; Huang, C.X.; Zhang, J.H.; Zhu, W.Q.; Jiang, X.Y.; Zhang, Z.L. Characterization of novel BaZnSnO thin films by solution process and applications in thin film transistors. Mater. Res. Bull. 2015, 68, 22–26. [Google Scholar] [CrossRef]

- Choi, S.; Kim, J.Y.; Kang, H.; Ko, D.; Rhee, J.; Choi, S.J.; Kim, D.M.; Kim, D.H. Effect of oxygen content on current stress-induced instability in bottom-gate amorphous InGaZnO thin-film transistors. Materials 2019, 12, 3149. [Google Scholar] [CrossRef] [PubMed]

- Yao, J.; Xu, N.; Deng, S.; Chen, J.; She, J.; Shieh, H.P.D.; Liu, P.T.; Haung, Y.P. Electrical and photosensitive characteristics of a-IGZO TFTs related to oxygen vacancy. IEEE Trans. Electron. Devices 2011, 58, 1121–1126. [Google Scholar]

- Lu, H.; Bi, X.; Zhang, S.; Zhou, H. Ultraviolet detecting properties of amorphous MgInO thin film phototransistors. Semicond. Sci. Technol. 2015, 30, 125010. [Google Scholar] [CrossRef]

- Lu, H.; Zhou, X.; Liang, T.; Zhang, L.; Zhang, S. Oxide thin-film transistors with IMO and IGZO stacked active layers for UV detection. IEEE J. Electron. Devices Soc. 2017, 5, 504–508. [Google Scholar] [CrossRef]

- Chen, A.H.; Cao, H.T.; Zhang, H.Z.; Liang, L.Y.; Liu, Z.M.; Yu, Z.; Wan, Q. Influence of the channel layer thickness on electrical properties of indium zinc oxide thin-film transistor. Microelectron. Eng. 2010, 87, 2019–2023. [Google Scholar] [CrossRef]

- Yang, Z.; Yang, J.; Meng, T.; Qu, M.; Zhang, Q. Influence of channel layer thickness on the stability of amorphous indium zinc oxide thin film transistors. Mater. Lett. 2016, 166, 46–50. [Google Scholar] [CrossRef]

| Element | MIO without MgO Layer | MIO with 5 nm MgO | MgO Buffer Layer |

|---|---|---|---|

| Mg | 11.39% | 11.44% | 26.84% |

| In | 41.84% | 31.44% | N/A |

| O | 46.76% | 57.12% | 73.16% |

| Mg/In | 0.27 | 0.36 | N/A |

| MIO TFT | Oxygen Partial Pressure | MIO Thickness (nm) | VT (V) | μE (cm2/V∙s) | On/Off Ratio | SS (V/dec) | Nit (cm−2) |

|---|---|---|---|---|---|---|---|

| T1 | 0% | 50 | 0.97 | 0.34 | 1.49 × 103 | 1.01 | 1.72 × 1012 |

| T2 | 2% | 50 | 1.15 | 0.29 | 8.06 × 103 | 0.77 | 1.28 × 1012 |

| T3 | 4% | 50 | 2.34 | 0.02 | 3.35 × 103 | 0.70 | 1.17 × 1012 |

| T4 | 2% | 30 | 1.54 | 0.23 | 5.88 × 104 | 0.61 | N/A |

| T5 | 2% | 20 | 1.69 | 0.23 | 2.15 × 104 | 0.59 | N/A |

| T6 | 2% | 10 | 2.52 | 0.06 | 1.52 × 104 | 0.46 | N/A |

| MgO Thickness (nm) | VT (V) | μE (cm2/V∙s) | On/Off Ratio | SS (V/dec) | Nit (cm−2) |

|---|---|---|---|---|---|

| 0 | 0.97 | 0.34 | 1.49 × 103 | 1.01 | 1.72 × 1012 |

| 5 | 2.01 | 4.81 | 9.68 × 103 | 0.76 | 1.27 × 1012 |

| 10 | 3.06 | 3.32 | 2.58 × 103 | 0.69 | 1.14 × 1012 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, W.-D.; Chang, S.-P.; Huang, W.-L. Characteristics of MgIn2O4 Thin Film Transistors Enhanced by Introducing an MgO Buffer Layer. Coatings 2020, 10, 1261. https://doi.org/10.3390/coatings10121261

Chen W-D, Chang S-P, Huang W-L. Characteristics of MgIn2O4 Thin Film Transistors Enhanced by Introducing an MgO Buffer Layer. Coatings. 2020; 10(12):1261. https://doi.org/10.3390/coatings10121261

Chicago/Turabian StyleChen, Wei-De, Sheng-Po Chang, and Wei-Lun Huang. 2020. "Characteristics of MgIn2O4 Thin Film Transistors Enhanced by Introducing an MgO Buffer Layer" Coatings 10, no. 12: 1261. https://doi.org/10.3390/coatings10121261

APA StyleChen, W.-D., Chang, S.-P., & Huang, W.-L. (2020). Characteristics of MgIn2O4 Thin Film Transistors Enhanced by Introducing an MgO Buffer Layer. Coatings, 10(12), 1261. https://doi.org/10.3390/coatings10121261