Additional Tribological Effect of Laser Surface Texturing and Diamond-Like Carbon Coating for Medium Carbon Steel at Near Room Temperature

Abstract

1. Introduction

2. Materials and Methods

2.1. Preparation and Characterization

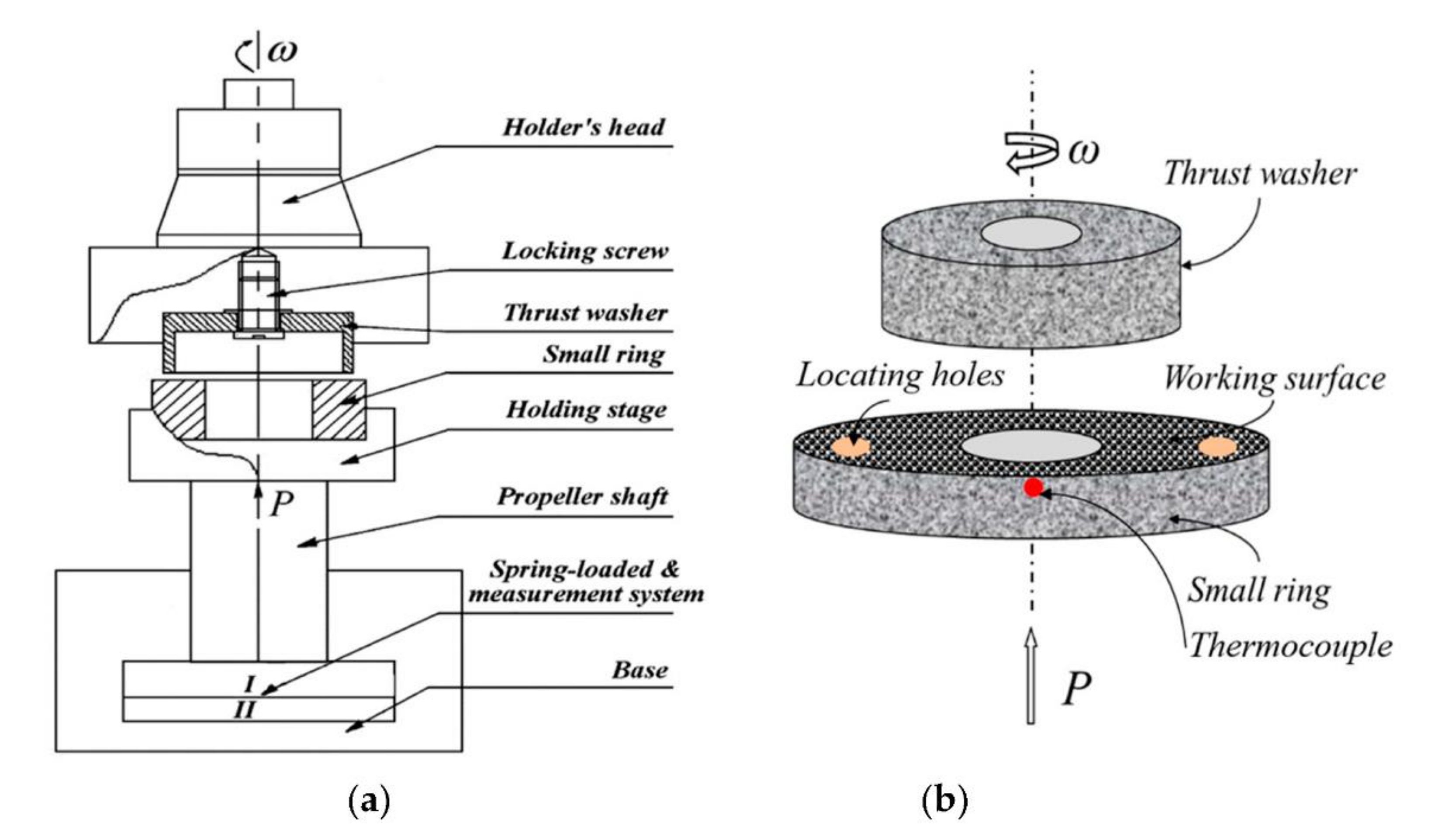

2.2. Tribological Experiments

3. Results

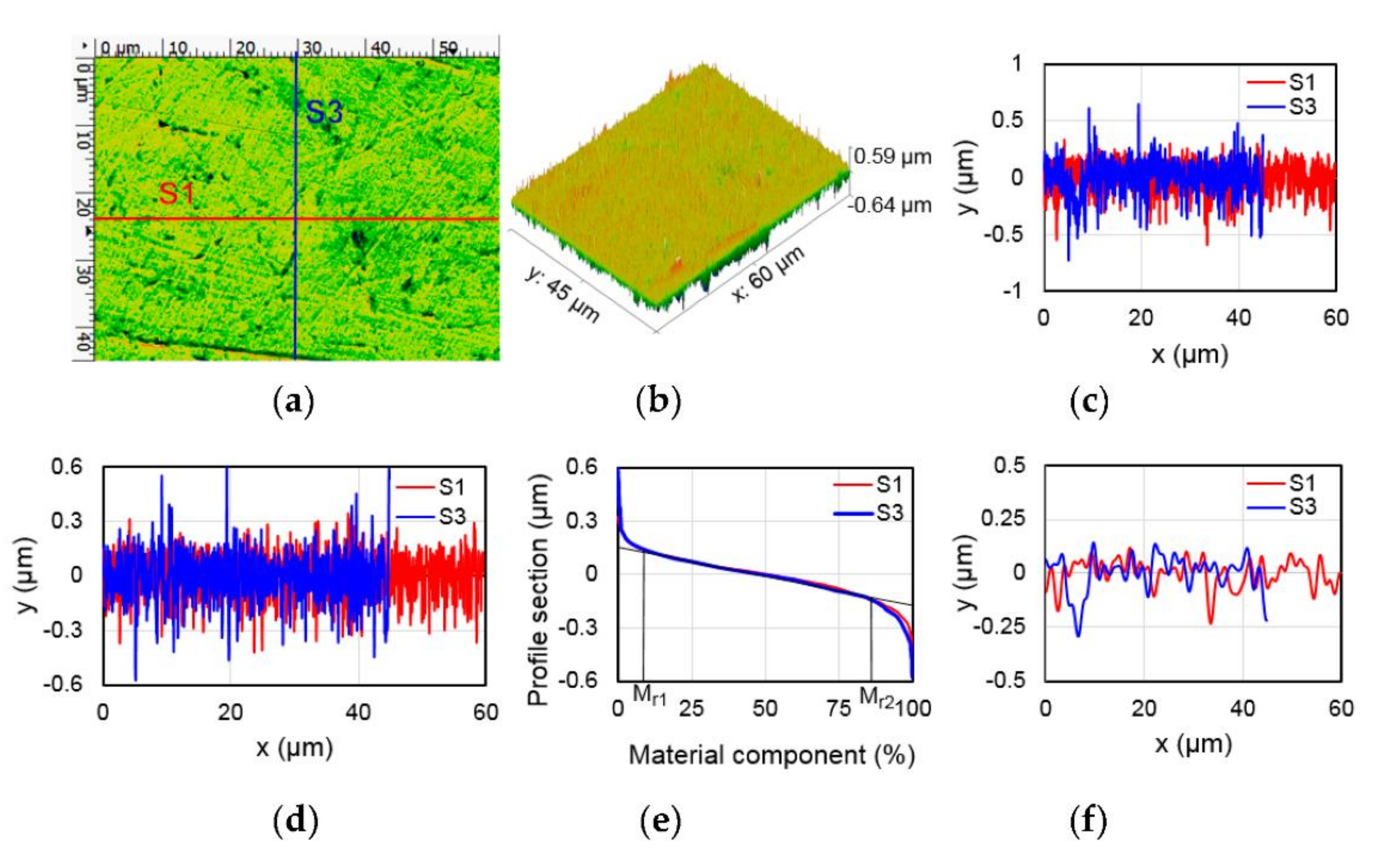

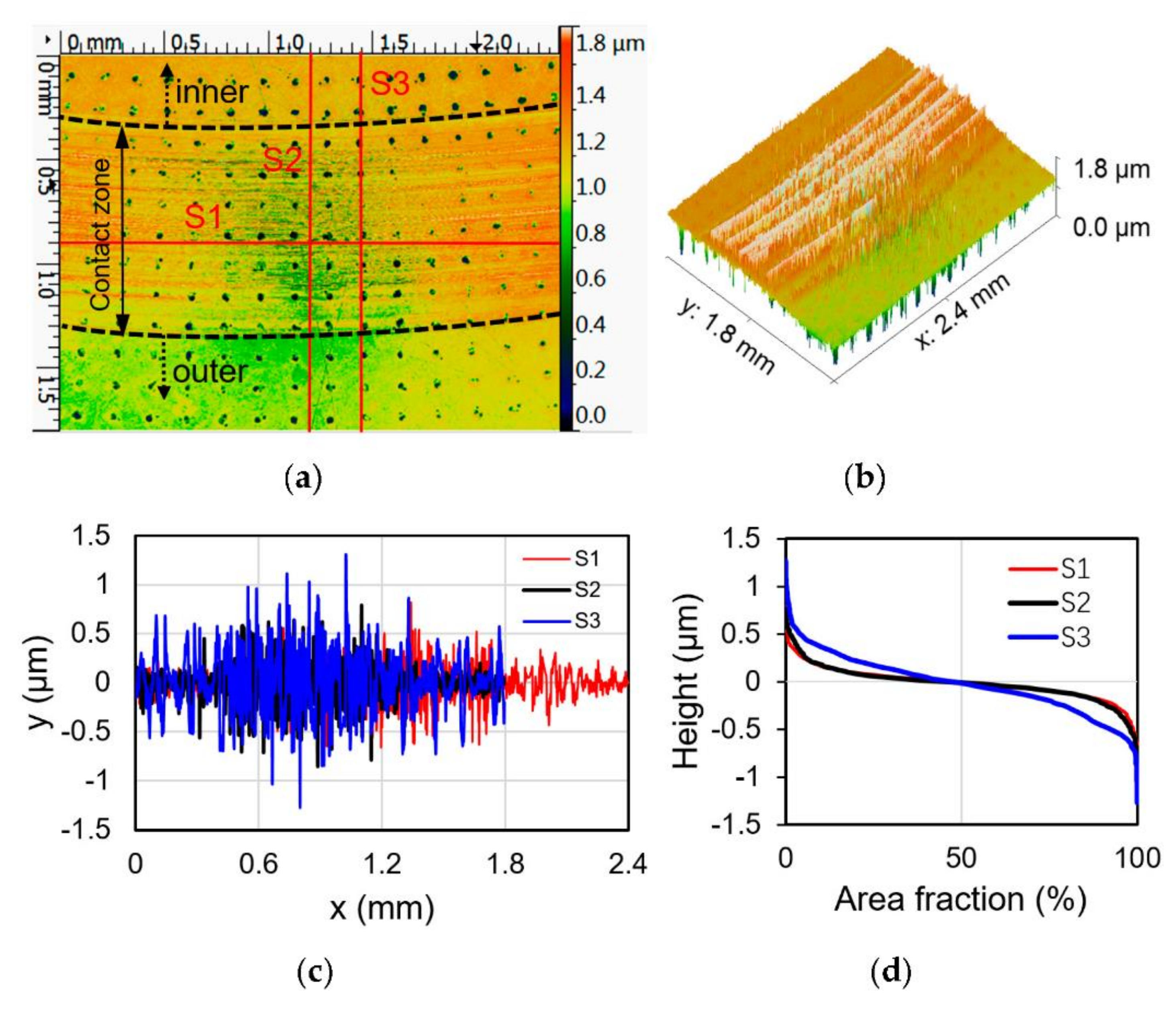

3.1. Surface Characterization

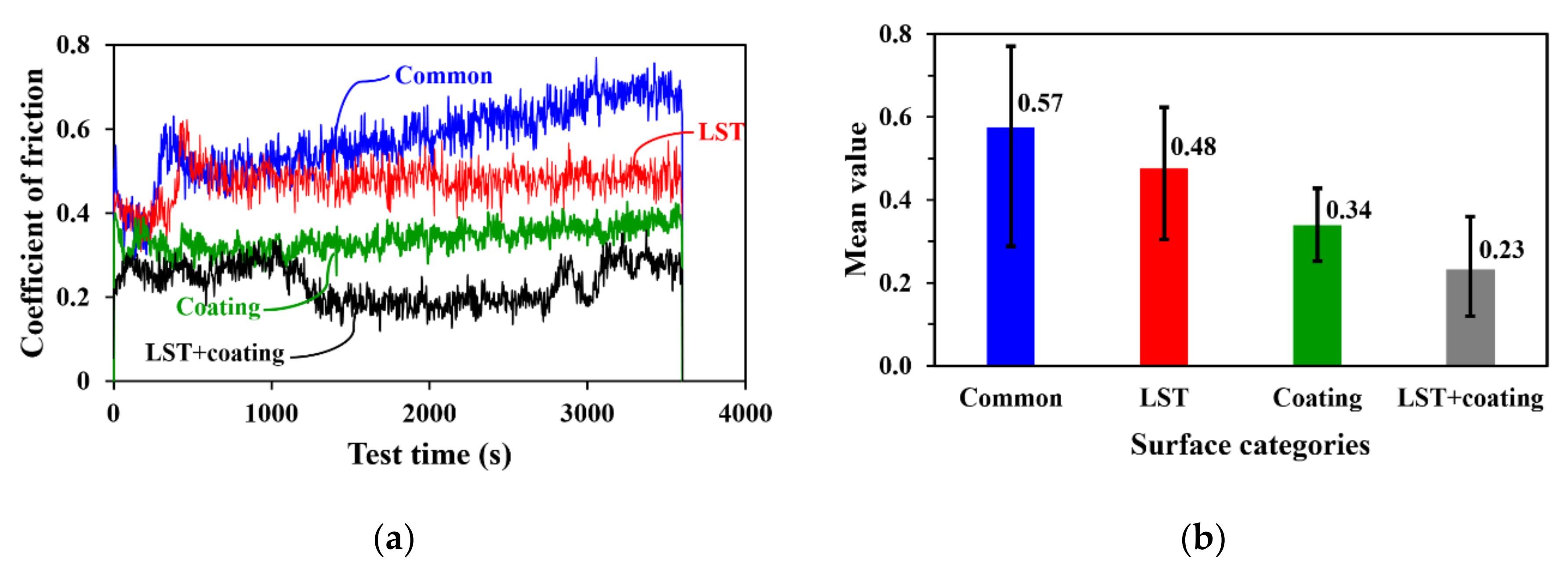

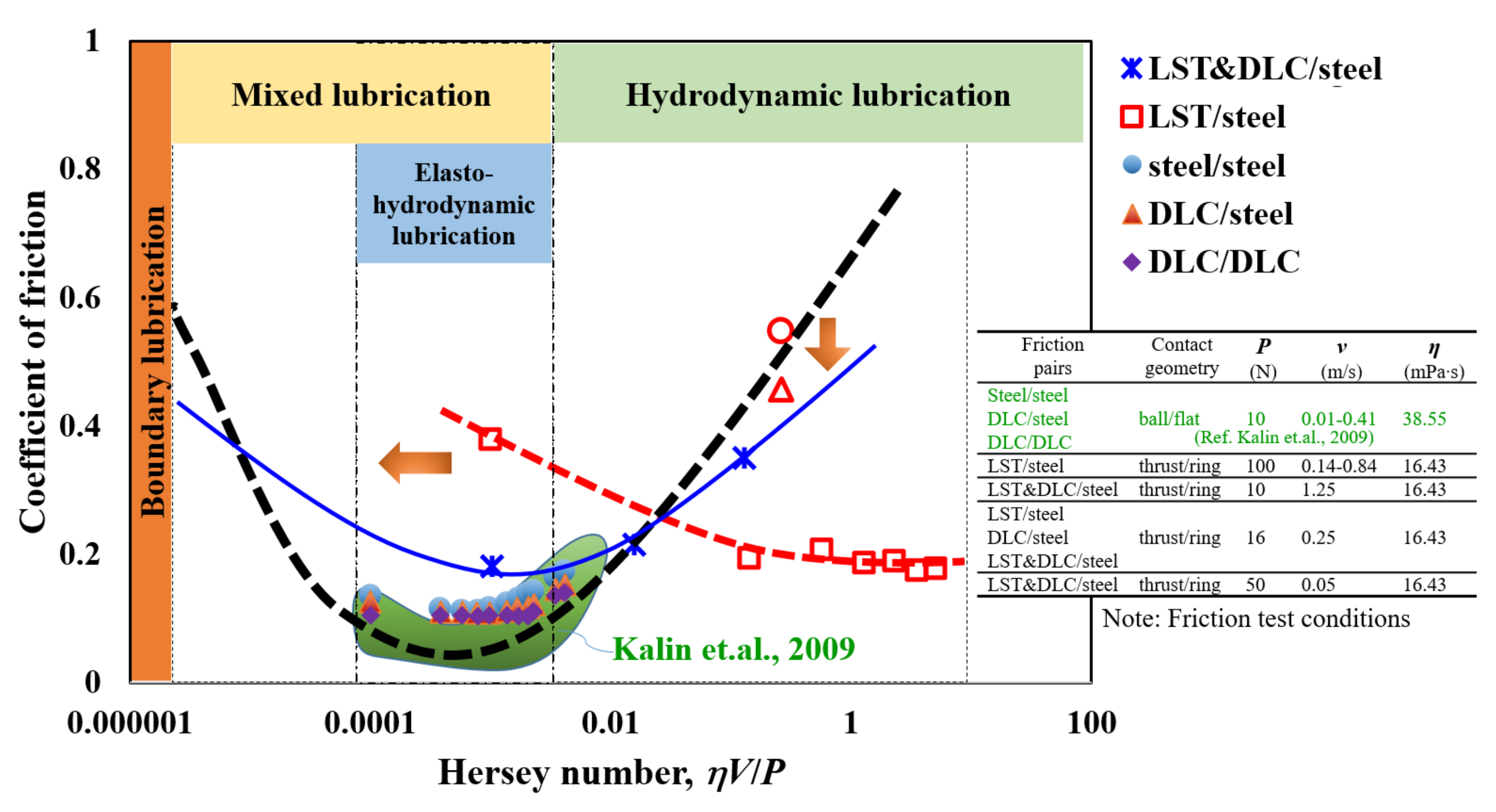

3.2. Friction Properties

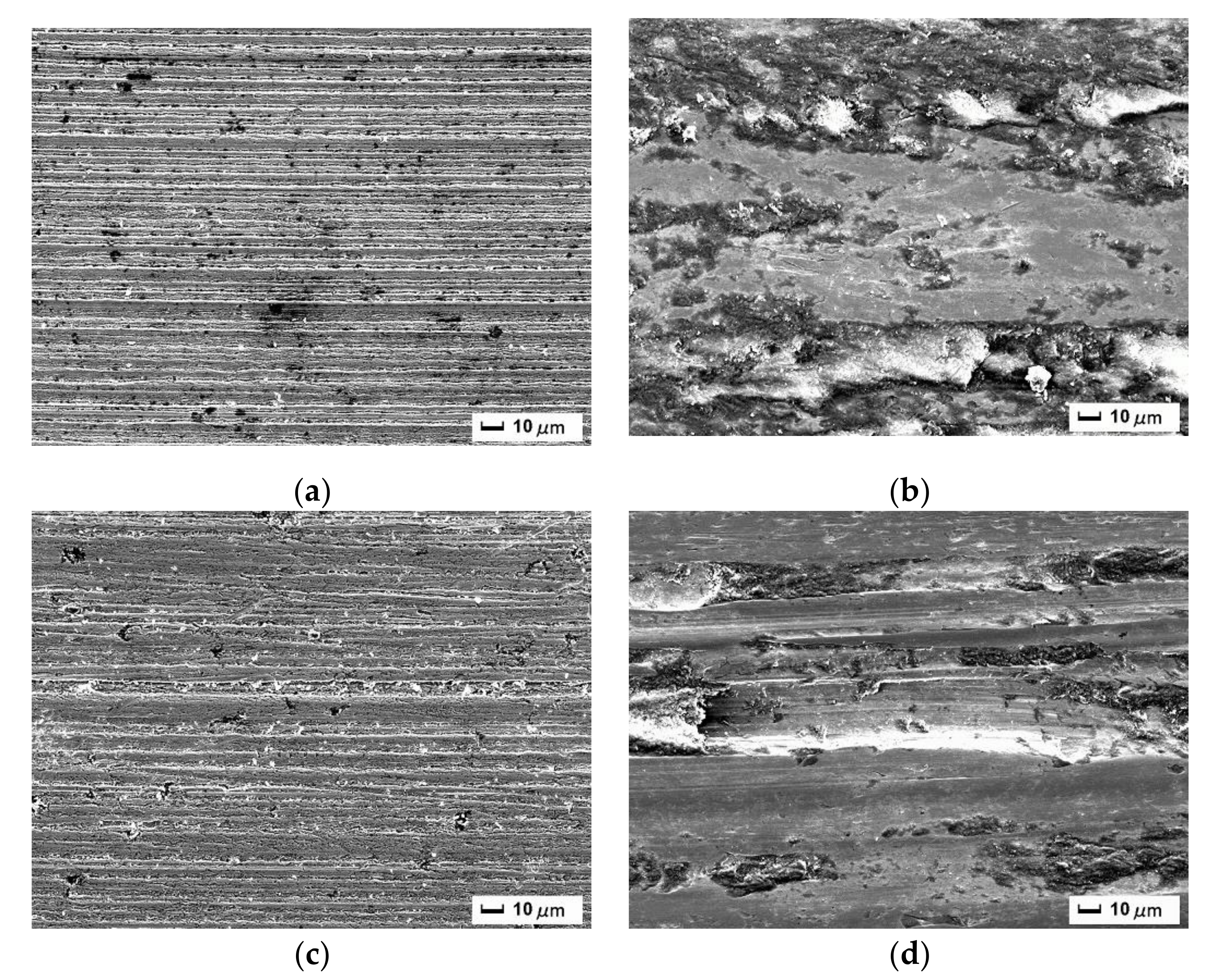

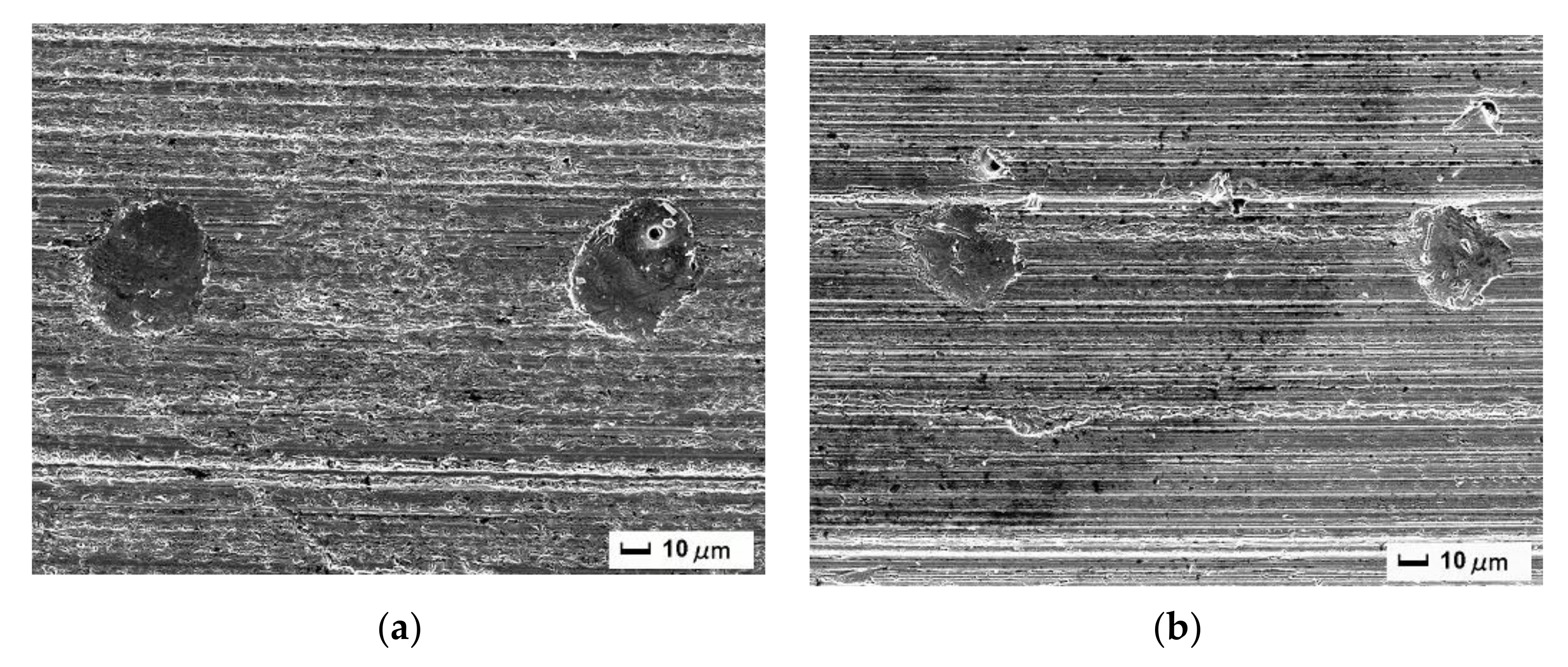

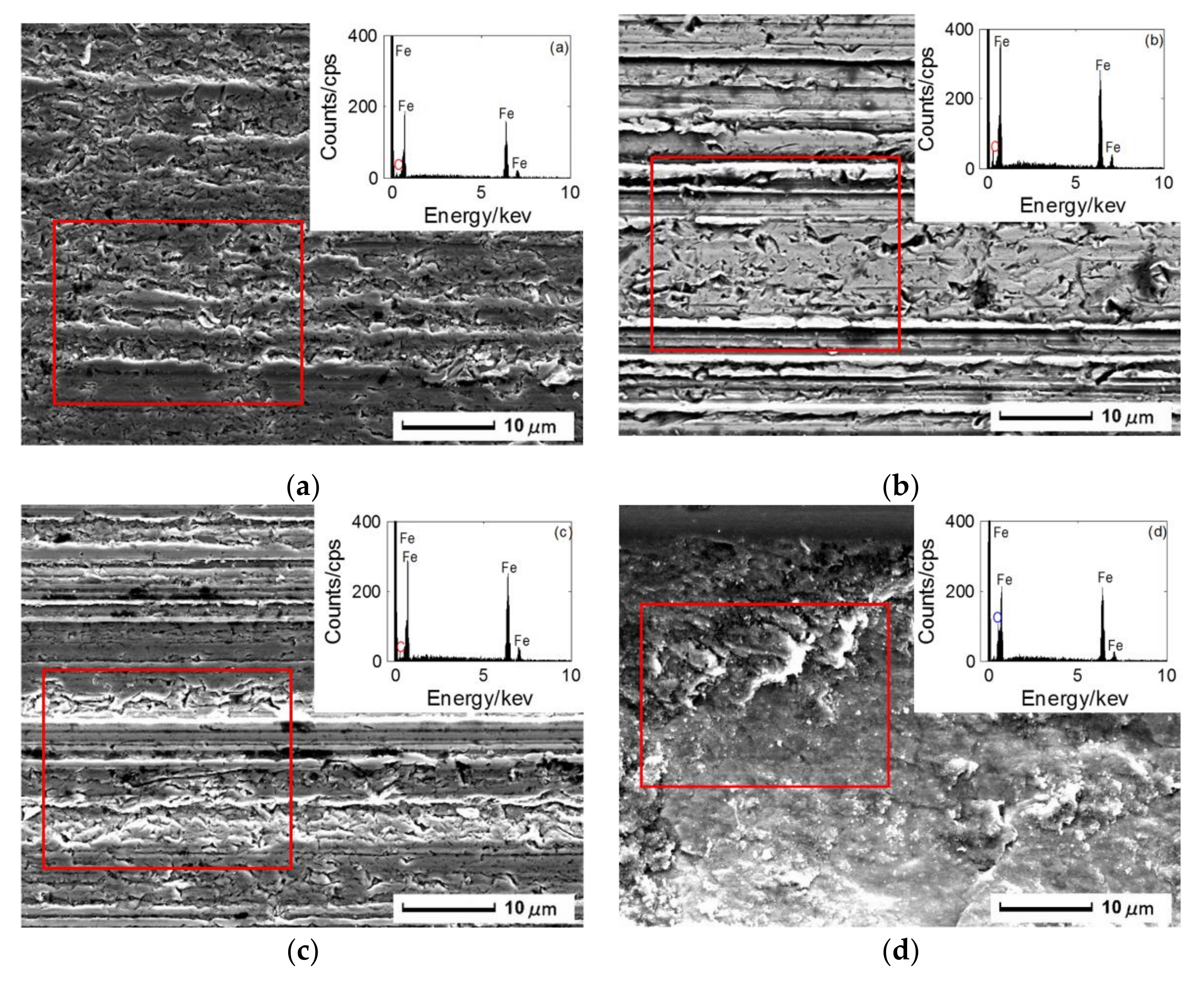

3.3. Wear Behavior

4. Discussion

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Gualtieri, E.; Borghi, A.; Calabri, L.; Pugno, N.; Valeri, S. Increasing nanohardness and reducing friction of nitride steel by laser surface texturing. Tribol. Int. 2009, 42, 699–705. [Google Scholar] [CrossRef]

- Spikes, H. Tribology research in the twenty-first century. Tribol. Int. 2001, 34, 789–799. [Google Scholar] [CrossRef]

- Holmberg, K.; Andersson, P.; Erdemir, A. Global energy consumption due to friction in passenger cars. Tribol. Int. 2012, 47, 221–234. [Google Scholar] [CrossRef]

- Rabuté, R.; Tian, T. Challenges involved in piston top ring designs for modern SI engines. J. Eng. Gas Turbines Power 2001, 123, 448–459. [Google Scholar] [CrossRef]

- Arslan, A.; Quazi, M.M.; Masjuki, H.H.; Kalam, M.A.; Varman, M.; Zulkifli, N.W.M.; Jamshaid, M.; Mandalan, S.M.; Gohar, G.A.; Gulzar, M.; et al. Wear characteristics of patterned and un-patterned tetrahedral amorphous carbon film in the presence of synthetic and bio based lubricants. Mater. Res. Express 2018, 6, 036414. [Google Scholar] [CrossRef]

- Wang, X.; Khonsari, M.; Li, S.; Dai, Q.; Wang, X. Experimental verification of textured mechanical seal designed using multi-objective optimization. Ind. Lubr. Tribol. 2019, 71, 766–771. [Google Scholar] [CrossRef]

- Trdan, U.; Hocevar, M.; Gregorcic, P. Transition from superhydrophilic to superhydrophobic state of laser textured stainless steel surface and its effect on corrosion resistance. Corros. Sci. 2017, 123, 21–26. [Google Scholar] [CrossRef]

- Etsion, I. State of the art in laser surface texturing. J. Tribol. 2005, 127, 248–253. [Google Scholar] [CrossRef]

- Etsion, I.; Sher, E. Improving fuel efficiency with laser surface textured piston rings. Tribol. Int. 2009, 42, 542–547. [Google Scholar] [CrossRef]

- Ronen, A.; Etsion, I.; Kligerman, Y. Friction-reducing surface-texturing in reciprocating automotive components. Tribol. Trans. 2001, 44, 359–366. [Google Scholar] [CrossRef]

- Shinkarenko, A.; Kligerman, Y.; Etsion, I. The effect of elastomer surface texturing in soft elasto-hydrodynamic lubrication. Tribol. Lett. 2009, 36, 95–103. [Google Scholar] [CrossRef]

- Antoszewski, B. Mechanical seals with sliding surface texture–model fluid flow and some aspects of the laser forming of the texture. Procedia Eng. 2012, 39, 51–62. [Google Scholar] [CrossRef]

- Shi, L.; Wang, X.; Su, X.; Huang, W.; Wang, X. Comparison of the load-carrying performance of mechanical gas seals textured with microgrooves and microdimples. J. Tribol. 2016, 138, 021701. [Google Scholar] [CrossRef]

- Lu, X.; Khonsari, M. An experimental investigation of dimple effect on the Stribeck curve of journal bearings. Tribol. Lett. 2007, 27, 169. [Google Scholar] [CrossRef]

- Brizmer, V.; Kligerman, Y. A laser surface textured journal bearing. J. Tribol. 2012, 134, 031702. [Google Scholar] [CrossRef]

- Sulaiman, M.H.; Christiansen, P.; Bay, N. The Influence of Tool Texture on Friction and Lubrication in Strip Reduction Testing. Lubricants 2017, 5, 3. [Google Scholar] [CrossRef]

- Fang, S.; Llanes, L.; Bähre, D. Wear Characterization of Cemented Carbides (WC–CoNi) Processed by Laser Surface Texturing under Abrasive Machining Conditions. Lubricants 2017, 5, 20. [Google Scholar] [CrossRef]

- Sharma, V.; Pandey, P.M. Geometrical design optimization of hybrid textured self-lubricating cutting inserts for turning 4340 hardened steel. Int. J. Adv. Manuf. Technol. 2017, 89, 1575–1589. [Google Scholar] [CrossRef]

- Arslan, A.; Masjuki, H.H.; Varman, M.; Kalam, M.A.; Quazi, M.M.; Mosarof, M.H. Effect of change in temperature on the tribological performance of micro surface textured DLC coating. J. Mater. Res. 2016, 31, 1837–1847. [Google Scholar] [CrossRef]

- Ling, T.D.; Liu, P.; Xiong, S.; Grzina, D.; Cao, J.; Wang, Q.J.; Xia, Z.C.; Talwar, R. Surface texturing of drill bits for adhesion reduction and tool life enhancement. Tribol. Lett. 2013, 52, 113–122. [Google Scholar] [CrossRef]

- Grabon, W.; Koszela, W.; Pawlus, P.; Ochwat, S. Improving tribological behaviour of piston ring–cylinder liner, frictional pair by liner surface texturing. Tribol. Int. 2013, 61, 102–108. [Google Scholar]

- Gu, C.; Meng, X.; Xie, Y.; Yang, Y. Effects of surface texturing on ring/liner friction under starved lubrication. Tribol. Int. 2016, 94, 591–605. [Google Scholar]

- Baumgart, P.; Krajnovich, D.; Nguyen, T.; Tam, A.G. A new laser texturing technique for high performance magnetic disk drives. IEEE Trans. Magn. 1995, 31, 2946–2951. [Google Scholar]

- Oka, T.; Itani, K.; Taguchi, Y.; Nagasaka, Y. Development of interferometric excitation device for micro optical diffusion sensor using laser-induced dielectrophoresis. J. Microelectromech. Syst. 2012, 21, 324–330. [Google Scholar]

- Yu, H.; Wang, X.; Zhou, F. Geometric shape effects of surface texture on the generation of hydrodynamic pressure between conformal contacting surfaces. Tribol. Lett. 2010, 37, 123–130. [Google Scholar]

- Akbarzadeh, S.; Khonsari, M. Effect of surface pattern on Stribeck curve. Tribol. Lett. 2010, 37, 477–486. [Google Scholar]

- Kovalchenko, A.; Ajayi, O.; Erdemir, A.; Fenske, G.; Etsion, I. The effect of laser surface texturing on transitions in lubrication regimes during unidirectional sliding contact. Tribol. Int. 2005, 38, 219–225. [Google Scholar]

- Kot, M.; Major, Ł.; Lackner, J.; Chronowska-Przywara, K.; Janusz, M.; Rakowski, W. Mechanical and tribological properties of carbon-based graded coatings. J. Nanomater. 2016, 51, 1–14. [Google Scholar]

- Holmberg, K.; Mathews, A. Coatings tribology: A concept, critical aspects and future directions. Thin Solid Films 1994, 253, 173–178. [Google Scholar]

- Tyagi, A.; Walia, R.; Murtaza, Q.; Pandey, S.M.; Tyagi, P.K.; Bajaj, B. A critical review of diamond like carbon coating for wear resistance applications. Int. J. Refract. Met. Hard Mater. 2019, 78, 107–122. [Google Scholar]

- Wang, J.; Ma, J.; Huang, W.; Wang, L.; He, H.; Liu, C. The investigation of the structures and tribological properties of F-DLC coatings deposited on Ti-6Al-4V alloys. Surf. Coat. Technol. 2017, 316, 22–29. [Google Scholar] [CrossRef]

- Han, X.; Zheng, J.; Hao, J.; Zhang, S. The microstructure, mechanical and tribological properties of aC: H films with self-assembled carbon nanohoops. Surf. Coat. Technol. 2017, 311, 27–34. [Google Scholar] [CrossRef]

- Charitidis, C. Nanomechanical and nanotribological properties of carbon-based thin films: A review. Int. J. Refract. Met. Hard Mater. 2010, 28, 51–70. [Google Scholar] [CrossRef]

- Arslan, A.; Masjuki, H.H.; Kalam, M.A.; Varman, M.; Mosarof, M.H.; Mufti, R.A.; Quazi, M.M.; Khuong, L.S.; Liaqat, M.; Jamshaid, M.; et al. Investigation of laser texture density and diameter on the tribological behavior of hydrogenated DLC coating with line contact configuration. Surf. Coat. Technol. 2017, 322, 31–37. [Google Scholar] [CrossRef]

- Yasumaru, N.; Miyazaki, K.; Kiuchi, J. Control of tribological properties of diamond-like carbon films with femtosecond-laser-induced nanostructuring. Appl. Surf. Sci. 2008, 254, 2364–2368. [Google Scholar] [CrossRef]

- Chouquet, C.; Gavillet, J.; Ducros, C.; Sanchette, F. Effect of DLC surface texturing on friction and wear during lubricated sliding. Mater. Chem. Phys. 2010, 123, 367–371. [Google Scholar] [CrossRef]

- Ding, Q.; Wang, L.; Hu, L.; Hu, T.Y. The pairing-dependent effects of laser surface texturing on micro tribological behavior of amorphous carbon film. Wear 2012, 274–275, 43–49. [Google Scholar] [CrossRef]

- Shamsul Baharin, A.F.; Ghazali, M.J.A.; Wahab, J. Laser surface texturing and its contribution to friction and wear reduction: A brief review. Ind. Lubr. Tribol. 2016, 68, 57–66. [Google Scholar] [CrossRef]

- Fu, Y.; Liu, Q.; Ye, Y.; Hua, X.; Kang, Z.; Hao, F. Research on Laser Surface Micro Texturing Processing of Single Pulse Intervals. Chin. J. Lasers 2015, 42, 1203005. [Google Scholar]

- Fu, Y.; Pan, G.; Hua, X.; Fu, H.; Gao, X. Study on the laser micro-manufacturing equipment of special micro-manufacturing technology. In Proceedings of the 2011 Second International Conference on Digital Manufacturing & Automation, Zhangjiajie, China, 5–7 August 2011; pp. 1176–1179. [Google Scholar]

- Dutta Majumdar, J.I. Laser material processing. Int. Mater. Rev. 2011, 56, 341–388. [Google Scholar] [CrossRef]

- Hu, T.; Hu, L.; Ding, Q. Effective solution for the tribological problems of Ti-6Al-4V: Combination of laser surface texturing and solid lubricant film. Surf. Coat. Technol. 2012, 206, 5060–5066. [Google Scholar] [CrossRef]

- Moore, A.J.W.; Tegart, W.J.M.; Bowden, F.P. Relation between friction and hardness. Proc. R. Soc. Lond. Ser. A Math. Phys. Sci. 1952, 212, 452–458. [Google Scholar]

- Sahoo, P.; Ali, S.M. Elastic-plastic adhesive contact of rough surfaces with soft coatings. Tribol. Online 2008, 3, 216–221. [Google Scholar] [CrossRef]

- Vandevelde, T.C.S.; Vandierendonck, K.; Van Stappen, M.; Du Mong, W.; Perremans, P. Cutting applications of DLC, hard carbon and diamond films. Surf. Coat. Technol. 1999, 113, 80–85. [Google Scholar] [CrossRef]

- Habig, K.H. Fundamentals of the tribological behaviour of diamond, diamond-like carbon and cubic boron nitride coatings. Surf. Coat. Technol. 1995, 76, 540–547. [Google Scholar] [CrossRef]

- Andersson, J.; Erck, R.A.; Erdemir, A. Friction of diamond-like carbon films in different atmospheres. Wear 2003, 254, 1070–1075. [Google Scholar] [CrossRef]

- Horng, J.H. Contact analysis of rough surfaces under transition conditions in sliding line lubrication. Wear 1998, 219, 205–212. [Google Scholar] [CrossRef]

- Jianglong, L.; Zhirong, Z. A study of morphologies of residual austenite after laser transformation hardening. Mater. Mech. Eng. 1989, 13, 35–38. (In Chinese) [Google Scholar]

- Ling, Z. The microstructure and the wear resistance of 45-steel after laser transformation hardening. J. Chongqing Jiaotong Inst. 1992, 11, 103–107. (In Chinese) [Google Scholar]

- Jiandong, H.; Zhang, L. The observation on the lath martensite in the laser processing areas by TEM. J. Chin. Electron. Microsc. Soc. 1986, 5, 72–76. (In Chinese) [Google Scholar]

- We, F.; Zhiqin, Y. Study on laser transformation hardening of metal surface. Heat Treat. Met. 1982, 25, 12–20. (In Chinese) [Google Scholar]

- Grabon, W.A. A new approach to the description of height distribution of plateau honed cylinder liner surface texture during the initial stage of wear. Wear 2018, 408, 34–42. [Google Scholar] [CrossRef]

- Moriguchi, H.; Ohara, H.; Tsujioka, M. History and applications of diamond-like carbon manufacturing processes. Sei Tech. Rev. 2016, 82, 52–58. [Google Scholar]

- Kalin, M.; Velkavrh, I.; Vižintin, J. The Stribeck curve and lubrication design for non-fully wetted surfaces. Wear 2009, 267, 1232–1240. [Google Scholar] [CrossRef]

- Podgornik, B.; Jacobson, S.; Hogmark, S. DLC coating of boundary lubricated components—Advantages of coating one of the contact surfaces rather than both or none. Tribol. Int. 2003, 36, 843–849. [Google Scholar] [CrossRef]

- Topolovec-Miklozic, K.; Lockwood, F.; Spikes, H. Behaviour of boundary lubricating additives on DLC coatings. Wear 2008, 265, 1893–1901. [Google Scholar] [CrossRef]

- Kovaci, H.; Yetim, A.F.; Baran, O.; Celik, A. Tribological behavior of DLC films and duplex ceramic coatings under different sliding conditions. Ceram. Int. 2018, 44, 7151–7158. [Google Scholar] [CrossRef]

- Peng, R.; Zhang, P.; Tian, Z.; Zhu, D.; Chen, C.; Yin, B.; Hua, X. Effect of textured DLC coatings on tribological properties of titanium alloy under grease lubrication. Mater. Res. Express 2020, 7, 066408. [Google Scholar] [CrossRef]

- Amanov, A.; Watabe, T.; Tsuboi, R.; Sasaki, S. Improvement in the tribological characteristics of Si-DLC coating by laser surface texturing under oil-lubricated point contacts at various temperatures. Surf. Coat. Technol. 2013, 232, 549–560. [Google Scholar] [CrossRef]

- Shum, P.W.; Zhou, Z.F.; Li, K.Y. To increase the hydrophobicity, non-stickiness and wear resistance of DLC surface by surface texturing using a laser ablation process. Tribol. Int. 2014, 78, 1–6. [Google Scholar] [CrossRef]

- Arslan, A.; Masjuki, H.H.; Varman, M.; Kalam, M.A.; Quazi, M.M.; Al Mahmud, K.A.H.; Gulzar, M.; Habibullah, M. Effects of texture diameter and depth on the tribological performance of DLC coating under lubricated sliding condition. Appl. Surf. Sci. 2015, 356, 1135–1149. [Google Scholar] [CrossRef]

- He, D.; Zheng, S.; Pu, J.; Zhang, G.; Hu, L. Improving tribological properties of titanium alloys by combining laser surface texturing and diamond-like carbon film. Tribol. Int. 2015, 82, 20–27. [Google Scholar] [CrossRef]

- Gu, D.; Hagedorn, Y.C.; Meiners, W.; Meng, G.; Batista, R.J.S.; Wissenbach, K.; Poprawe, R. Densification behavior, microstructure evolution, and wear performance of selective laser melting processed commercially pure titanium. Acta Mater. 2012, 60, 3849–3860. [Google Scholar] [CrossRef]

- Suh, N.P. An overview of the delamination theory of wear. Wear 1977, 44, 1–16. [Google Scholar] [CrossRef]

- Dufils, J.; Faverjon, F.; Heau, C.; Donnet, C.; Benayoun, S.; Valette, S. Combination of laser surface texturing and DLC coating on PEEK for enhanced tribological properties. Surf. Coat. Technol. 2017, 329, 29–41. [Google Scholar] [CrossRef]

- Aghababaei, R. On the origins of third-body particle formation during adhesive wear. Wear 2019, 426–427, 1076–1081. [Google Scholar] [CrossRef]

- Wang, C.T.; Hakala, T.J.; Laukkanen, A.; Ronkainen, H.; Holmberg, K.; Gao, N.; Wood, R.J.; Langdon, T.G. An investigation into the effect of substrate on the load-bearing capacity of thin hard coatings. J. Mater. Sci. 2016, 51, 4390–4398. [Google Scholar] [CrossRef]

- Bhaskaran, H.; Gotsmann, B.; Sebastian, A.; Drechsler, U.; Lantz, M.A.; Despont, M.; Jaroenapibal, P.; Carpick, R.W.; Chen, Y.; Sridharan, K. Ultralow nanoscale wear through atom-by-atom attrition in silicon-containing diamond-like carbon. Nat. Nanotechnol. 2010, 5, 181–185. [Google Scholar] [CrossRef]

| Type | Material | Technology | Parameters | Note |

|---|---|---|---|---|

| Smooth | 45# steel * | Quenching; Finishing | Ra < 0.56 μm (L = 120 μm) HRC 40~43 | * parallel to 10455 of ASTM |

| LST | 45#steel; Gas: N2 | Laser: 512 nm; Nd3+:YAG; 50 Watts; 14 Ampere | Space: 150 μm × 150 μm; Diameter: 60 μm; Depth: 10~15 μm; Ra < 0.8 μm (L = 120 μm) HRC 45~48 | TEM00; Q-switch; Frequency: 6.4 kHz; Pressure: 0.15 Mpa |

| Coating | 45#steel; Target: carbon (TK8869) | Coater: K575; Current: 120 mA; Power: 110 W; Time:12 min | Thickness < 0.12 μm; Ra < 0.2 μm (L = 120 μm) HV 1800~2000 | Argon: 40 mL/L, 99.99%; Delay: 4 min; No. cycles: 6 |

| LST + coating | 45# steel | Same as above | Ra < 0.5 μm (L = 120 μm) | Same as above |

| Conditions | Speed (m/s) | Load (N) | Temperature (°C) | Humidity (%) | Viscosity (mm2/s) |

|---|---|---|---|---|---|

| (PV)1 | 1.25 | 10 | 8~10 | 45 ± 3% | 14.21 |

| (PV)2 | 0.25 | 16 | 8~10 | 45 ± 3% | 14.21 |

| (PV)3 | 0.05 | 50 | 8~10 | 45 ± 3% | 14.21 |

| Parameters | Smooth | Textured | Coated | Textured + Coated |

|---|---|---|---|---|

| Rt (μm) | 12.45 | 11.51 | 4.32 | 9.45 |

| Ra (μm) | 0.553 | 0.705 | 0.126 | 0.404 |

| Rq (μm) | 0.700 | 1.130 | 0.177 | 0.593 |

| Rpk (μm) | 0.592 | 0.728 | 0.154 | 1.287 |

| Rvk (μm) | 0.945 | 3.321 | 0.329 | 0.487 |

| V1 (nm) | 21.29 | 17.36 | 5.75 | 56.4 |

| V2 (nm) | 82.47 | 375.49 | 22.36 | 26.38 |

| Mr1 (%) | 7.19 | 4.76 | 7.47 | 8.76 |

| Mr2 (%) | 82.56 | 77.38 | 86.42 | 89.17 |

| Working Condition | Wear Intensity Iw, × 10−6 (mg/N·m) | |||||

|---|---|---|---|---|---|---|

| Smooth | Textured | Coated | Textured + Coated | |||

| Lubrication | 2.8861 | −3.2401 | 0.0476 | 0.9277 | 0.5542 | −0.8515 |

| Starvation | 0.0959 | −3.2742 | −3.5881 | 2.4829 | - | - |

| Note | (PV)2 | (PV)2 | (PV)2 | (PV)2 | (PV)3 | (PV)1 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, Y.; Fu, H.; Wang, X.; Liang, H.; Puoza, J.C.; Ji, J.; Hua, X.; Xu, X.; Fu, Y. Additional Tribological Effect of Laser Surface Texturing and Diamond-Like Carbon Coating for Medium Carbon Steel at Near Room Temperature. Coatings 2020, 10, 929. https://doi.org/10.3390/coatings10100929

Zhang Y, Fu H, Wang X, Liang H, Puoza JC, Ji J, Hua X, Xu X, Fu Y. Additional Tribological Effect of Laser Surface Texturing and Diamond-Like Carbon Coating for Medium Carbon Steel at Near Room Temperature. Coatings. 2020; 10(10):929. https://doi.org/10.3390/coatings10100929

Chicago/Turabian StyleZhang, Yanhu, Hao Fu, Xinwei Wang, Hongyu Liang, Julius Caesar Puoza, Jinghu Ji, Xijun Hua, Xiaojing Xu, and Yonghong Fu. 2020. "Additional Tribological Effect of Laser Surface Texturing and Diamond-Like Carbon Coating for Medium Carbon Steel at Near Room Temperature" Coatings 10, no. 10: 929. https://doi.org/10.3390/coatings10100929

APA StyleZhang, Y., Fu, H., Wang, X., Liang, H., Puoza, J. C., Ji, J., Hua, X., Xu, X., & Fu, Y. (2020). Additional Tribological Effect of Laser Surface Texturing and Diamond-Like Carbon Coating for Medium Carbon Steel at Near Room Temperature. Coatings, 10(10), 929. https://doi.org/10.3390/coatings10100929