Abstract

The study proposes a model for the deposition of coatings, which takes into account the stochastic nature of the deposition process and is built considering the influence of the parallel convection and diffusion processes. The investigation has found that the dispersion of the motion direction of deposited particles in front of a substrate increases, which indicates a growth of the randomness in the trajectories of the particles being deposited. The obtained formulas indicate the fractal nature of the deposition process. During the formation of the multilayer coating structure, mismatched fractal structures of the layers overlap each other and thus the clustering effect is largely leveled out. The value of the nanolayer λ period has a significant influence on the fractal structure of the coating and the formation of feather-like hierarchical structures in it.

1. Introduction

The process of the coating deposition is very complex and undoubtedly stochastic [1,2,3,4,5,6,7]. Accordingly, the modeling of the coating deposition process is also a complex and many-sided challenge, and in some cases, a probabilistic approach is required to meet this challenge [3,4,5,6,7]. Initially, one of the key tasks for the modeling of the processes under consideration was to predict a thickness of a coating, including a coating deposited on a complex-shape surface. To meet the above challenges, physical and geometric methods were applied, which made it possible to achieve the certain prediction accuracy. In particular, the studies proposed the coating thickness uniformity model [8,9], the cosine analytical and generic computational model [10], and the inverse power law relationship between thickness and source-to-substrate distance was considered [11]. Recent studies also applied true line-of-sight models, based on the inverse square law and also taking into account the effect of shadow masks [12]. In [13], the computational level set method was also applied for tracking topographic change of a surface.

The traditional approaches to the modeling of mass transfer processes, in particular, the coating deposition processes, have significant limitations when described in micro- and mesosystems [14,15]. In connection with the above, the processes are often modeled on micro- nano- and atomic levels, due to the integration of systems with a large number of particles, the motion of which is described, in particular, by equations of molecular dynamics of Newtonian mechanics. A significant problem of these methods is the existing limitation of the maximum number of particles in a system due to the limit of computing power.

Approaches of molecular dynamics are used to model the deposition process [16]. By simulating the interaction of individual atoms, this method makes it possible to predict the morphology, thermal and electronic properties, and also internal stresses of the coating being deposited. When the above method is applied, the forces of interatomic interaction are presented in the form of classical potential forces. The configuration sets obtained in the course of the calculations using the method of molecular dynamics are distributed in accordance with a certain statistical distribution function, for example, a one corresponding to microcanonical distribution. The exact information concerning the trajectories of system particles at large time intervals is not necessary to obtain results of a macroscopic (thermodynamic) nature [17]. The principals of molecular dynamics can be applied to simulate the coating deposition process using dynamic equations and pressure and temperature boundary conditions for substrate and coating surfaces, taking into account the results of the preliminary study of stresses in the coating.

In particular, to model the coating deposition process, the Particle-in-Cell Monte Carlo simulation method [3,4], with both modeling options of simpler 2D [5] and more complex 3D [6,7,8], requiring advanced computing power, is applied. During the comparison of 2D and 3D models, it was found that the main difference between two-dimensional and three-dimensional options of modeling was consideration of the effect of propagating plasma waves that had a significant influence on the properties of particle transport in discharges limited by a magnetic field. Two-dimensional modeling provides useful qualitative information about the general trends and mechanisms of magnetron discharges, while three-dimensional modeling makes it possible to quantitatively describe the electron transfer and current–voltage characteristics [18]. Based on the results of 2D modeling using the Monte Carlo algorithm, the formation of a coating with feather-like hierarchical structure was demonstrated in [19]. The results of the study focused on the development of a columnar coating structure have proved that the average distance between columns first increases sharply and then stabilizes due to cessation of the growth and regeneration of the structure. The Monte Carlo methods were applied for 2D modeling of the process of micropore formation in a coating, given the stochastic nature of the process [20]. Approaches of computational fluid dynamics were also applied, they give a much rougher description of the process, but at the same time contribute to a noticeable reduction in the amount of calculations, thus making it possible to introduce modeling in the 3D geometry with high-scale detailing [21,22]. A more detailed analysis of various methods for modeling the coating deposition process can be found in [23]. Thus, the most accurate and complete simulation of the deposition process should take into account the stochastic nature of this process and consider the molecular level, because a coating is formed precisely at this level. Several studies [24,25,26] consider a cluster, hierarchical structure of the coating, deposited through various methods, and the influence of the deposition process parameters on the formation of such structure. However, the influence of the parameters of the nanolayer coating structure on the formation of hierarchical structures in the coating requires an additional study.

2. Materials and Methods

The filtered cathodic vacuum arc deposition (FCVAD) [27,28,29,30,31,32,33,34,35,36] technology was applied to deposit the Ti–TiN–(Ti,Cr,Al)N coatings. A VIT-2 unit, (IDTI RAS—MSTU STANKIN, Moscow, Russia), equipped with two arc evaporators with a pulsed magnetic field and one arc evaporator with filtering of the vapor-ion flow, was used to deposit the coatings. In addition, the system was equipped with a source of pulsed bias voltage supply to a substrate, a dynamic gas mixing system for reaction gases, a system for automatic control of pressure in the chamber and a process temperature control system, and a system for stepless adjustment of planetary gear rotation [27,28,29,30,35,36,37,38,39,40,41,42]. The nanolayer structure of the coating provides high hardness at elevated temperatures and high oxidation resistance [27,28,29,30,31,37,38]. A three-layer structure of the coating was assumed [27,28,29,30,31].

The parameters for the process of coating deposition are presented in Table 1.

Table 1.

Parameters of stages of the technological coating deposition process.

An analysis of the microstructure and nanostructure of the samples was studied using JEM 2100 (JEOL, Tokyo, Japan) high-resolution transmission electron microscope (TEM) with an accelerating voltage of 200 kV.

3. Results

3.1. Convection–Diffusion 2D Model for the Stochastic Coating Deposition Process

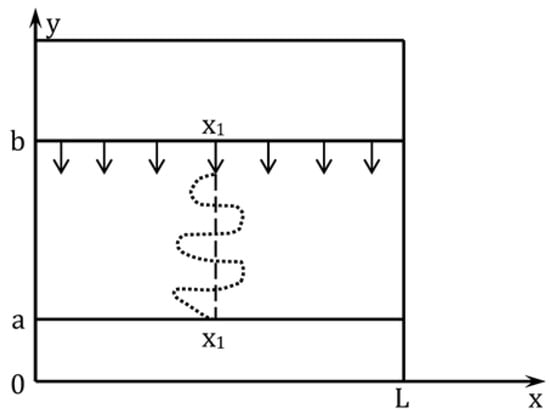

The creation of a wear resistant layer of the coating combines two parallel processes: convection and diffusion. Convection causes the rectilinear motion of particles from a cathode to the surface on which a coating is to be deposited, while diffusion gives rise to the consideration of random factors influencing particle trajectories, as a result of which the density of the substance being deposited becomes inhomogeneous, and the process represents the diffusion limited by the clustering or, alternatively, the clustering limited by the diffusion. A 2D model of the coating deposition process was considered, according to which the area where particles were deposited was plane (Figure 1). This assumption can be quite logically extended to a 3D model, because the flow of the particles moving through the fixed plane parallel to the 0XZ plane is quasi-isotropic. The typical linear size of the deposition area is about L. The particles are emitted from the line of y = b and are deposited on the line of y = a.

Figure 1.

2D model of the cross-section of the area perpendicular to the plane in which the particles emitted from the cathode in the direction of the substrate are being deposited.

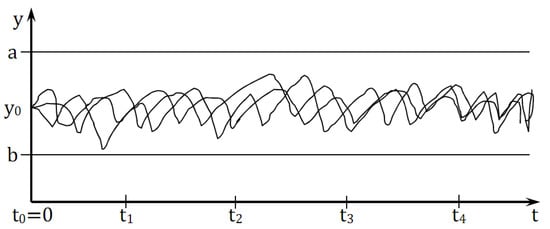

In case if no diffusion occurs, a particle leaving a point with the coordinate enters a point with the coordinate , while moving along a straight line connecting these points. In case of diffusion, a particle is moving from the point to the point along a random trajectory, and the probability of its getting into point is not equal to 1 (Figure 2). Let it be assumed that at , the particle with the coordinate begins to move along the straight line connecting it with the point with the coordinate . The one-dimensional process with for constant is first considered.

Figure 2.

Diagram reflecting random particle trajectories (random walks) moving from the point to the point .

Let at time the particle has coordinates of . The probability density f(y) and likelihood P(y) of this event are as follows:

When , the coordinate is a random time function, then its probability density can be written in the following form [43]:

where the brackets <> denote the averaging over realizations.

Let us assume that satisfies a Langevin equation of the Brownian-motion type.

where is a correlation function.

By (3), the differentiation of (2) with respect to t yields an equation for the probability density function of the particle’s position:

The Fokker-Planck-Kolmogorov differential Equation (4) should be solved with the initial condition (1). The physical meaning of the Equation (4) is in description of the stochastic processes for the motion of the coating’s deposited particle in the gas phase from the cathode to the substrate. The coefficients in the equation at are the particle transport and diffusion parameters, respectively. According to the Formulas (3) and (4), the equation terms with parameters A and F are specified by fluctuations of the field , affecting , which is a deterministic function describing the convective particle transport. If , i.e., is constant in time, then A and F are also constant in time, which corresponds to the constant diffusion coefficient F and convection A = 0. Cases when is non-stationary require a model specification.

The real process of the layer-by-layer formation of a coating is of stochastic nature due to the fact that the layer of particles which started their motion from a source plane does not remain planar, while the particles interact with each other and cannot simultaneously form microclusters during the deposition, with correlations formed between them. Such microconglomerates, being deposited on the substrate, will be considered as nuclei of clusters in the coating layer, which introduce randomness into the deposition process and make the coating structure heterogeneous, fractal. Depending on the mentioned random factors, the deposition time is a random variable for different particles.

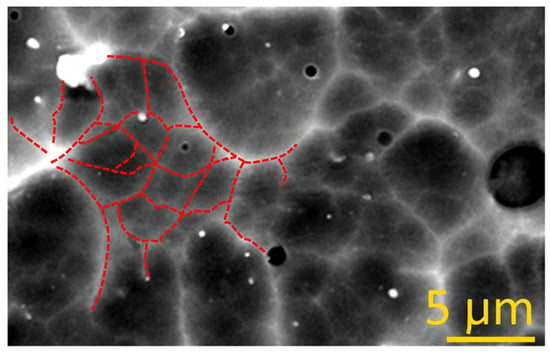

Figure 3 exhibits an initial view of the surface of the Ti–TiN–(Ti,Cr,Al)N coating with a pronounced cluster structure.

Figure 3.

Cluster structure of the surface of the Ti–TiN–(Ti,Cr,Al)N coating after deposition.

The model of a random process reaching the boundaries of its variation area makes it possible to estimate the probability of this event and the average time required for that [43]. Let denote the probability of the event that the random process will reach the boundary with the initial condition of and the boundary conditions of then satisfies the equation [43]:

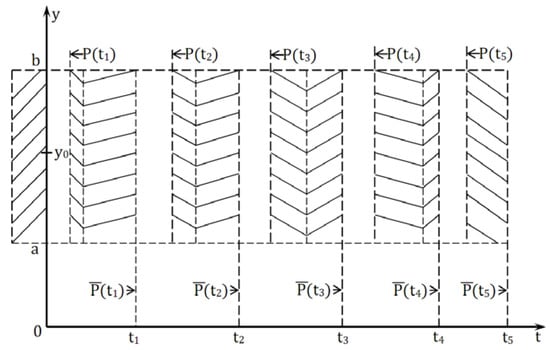

The drift coefficient and the diffusion coefficient are to be specified for every model. As is known [43], the Equation (5) can be solved only for some particular models. When the initial and boundary conditions are formulated, the probability to reach the boundary increases. Figure 4 exhibits in graphic form the probabilities —to reach the boundary and —not to reach the boundary when the normalization condition is satisfied.

Figure 4.

Graphic form depicting the probabilities —to reach the boundary and —not to reach the boundary.

At Figure 4, is the normalization condition:

Si is the area of the rectangle P(ti),

is the area of the rectangle (ti).

Thus, P(ti) describes a change in the rectangle, which area is numerically equal to the probability of reaching the boundary (of the substrate), while (ti) describes a change in the rectangle, which area is numerically equal to the probability of not reaching the boundary.

The time it takes for a particle to reach the substrate is a random variable over a set of realizations. Then to calculate the average time to reach , a formula for mathematical expectation can be used as follows:

As far as , then

Given (5), an equation for can be derived from (7), as follows:

Integration by parts:

Through adding, we get:

The boundary conditions for (13) are:

The form of solution for (13) depends on the form of the coefficients , , i.e., the form of the equation of motion. If the drift and diffusion coefficients are constant, then the source of particles coincides with the y-axis, i.e., , and the real and imaginary substrates are located symmetrically: , then

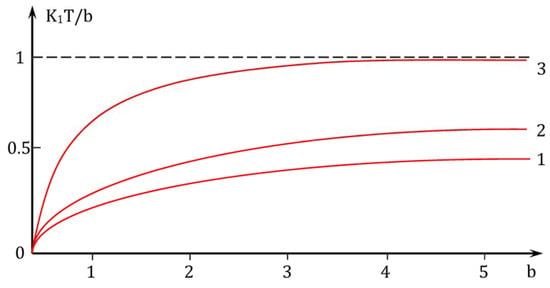

Function graph (15) is depicted in Figure 5.

Figure 5.

Dimensionless relationship for at various values of . 1: K1/K2 = 10, 2: K1/K2 = 1, 3: K1/K2 = 0.1

Figure 5 depicts the dimensionless relationship for at various values of .

b is the distance from the cathode to the substrate surface (in conventional units).

Figure 5 proves that the larger the drift coefficient is, the shorter time to deposition is, while the larger the diffusion coefficient is, the longer the time to deposition is. A model of coating synthesis during the layer-by-layer deposition of particles on a substrate was considered. Under the ideal conditions, a layer of particles emitted by a plane source is deposited on a substrate as a layer, and then the layer thickness is a deterministic function. Under the real conditions, the coating thickness is a random function, as mentioned above, and it can be represented as follows:

where is a random function of white-noise type.

After cooling down, a layer transforms, and the layer thickness at the time is a certain random process, represented in the following form:

The coating synthesis process should end when is reached. The probability that the function would reach the given thickness Q during the time t was considered. The quality of the coating is determined by the fact that its thickness in the final state should be a given constant value. The probability of reaching the boundary Q is found by the formula:

where satisfies the Equation [43]

with boundary conditions:

The initial condition is as follows:

If , i.e., a layer of the required thickness is deposited to the substrate, then the probability has the following form:

We considered Φ as the probability integral (standard Gaussian distribution function) [44].

A model of fluctuations in the direction of the deposited particle motion was considered. As a result of such fluctuation, a particle can be deposited not in the intended place, and that can lead to non-uniform density of the coating. In the plane, the position of a particle is characterized by the values of . Instead of the parameter , a parameter is introduced, defined as follows:

where is velocity of the particle motion.

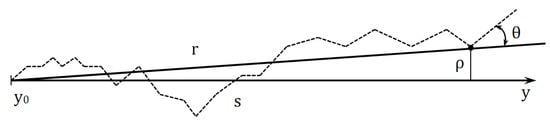

At each point, particles deviate from the rectilinear trajectories of the motion along straight lines parallel to the -axis (Figure 6).

Figure 6.

Deviation from the rectilinear trajectories of the motion along straight lines parallel to the y-axis.

The probability density satisfies the following equation [45]:

The value of B is related to the correlation function of the particle deposition rate

through the formula as follows:

The solution to the Equation (26) is being sought with the initial condition of:

and looks as follows:

where are Legendre polynomials [45].

At :

It is convenient to describe the condition for a change in the particle velocity vector through , then and the average value of the direction cosine of the velocity vector is calculated by the following formula:

The following differential equation can be derived from (24):

The solution of Equation (30) with the boundary condition of at is of the form:

At , , and in accordance with (31), that means at a sufficiently large distance from a source to a substrate, all orientations of the particle motion are equally probable. For short distances:

which follows that:

The mean square of the particle deviation ρ from the initial (rectilinear) direction along the y-axis is calculated by the following formula [46]:

It follows from (35) that when , then:

The mean square distance in a straight line to the particle being deposited is determined as follows:

The Formula (37) at is reduced to the formula for the average square of displacement of a heavy molecule in light gas, obtained by Smoluchowski [47,48,49,50]:

The fractional degree in the Formula (35) indicates that the deposition of coating particles is described by the fractal dynamics.

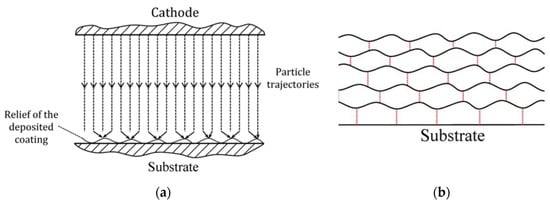

An ideal model of coating deposition represents an emission of particles from a certain conventionally planar surface of a cathode with the same velocity (temperature) along a normal to a surface (plane). The particles move along the parallel trajectories and are being layer-by-layer deposited on the surface due to the complex planetary motion of the substrate surface (Figure 7a). The process is described by the convection equation.

Figure 7.

Diagram for (a) the formation of the relief of the coating being deposited; (b) the predicted cracking for the multilayer coating.

Under the real conditions, while emitted, particles demonstrate velocity fluctuations in value and direction, and during the particle motion, the process becomes even more irregular. The cloud has density fluctuations, and diffusion of particles occurs, as a result of which the density and hence the stiffness and strength of the layer being deposited fluctuate over the surface area. Furthermore, the very surface of the substrate is in the process of the complex planetary motion (rotation). As a result, at the initial stages of the coating destruction, damages and then cracks arise in the places of the deposited coating, in which the density is lower [28,29,30,49]. In terms of mathematics, this is described by a model of Brownian motion of a particle (Equation (3)), and the probability density satisfies the Equation (4).

The analysis of the resulting model indicates that the very coating deposition process implies the formation of a fractal structure, which further contributes to the formation of stress concentration areas, which, in turn, stimulate the process of cracking. At the initial stages of the coating destruction, damages and then cracks arise in the places of the deposited coating, in which the density is lower. During the formation of the multilayer coating structure, mismatched fractal structures of the layers overlap each other, and thus the clustering effect is largely leveled out. In turn, the above reduces the likelihood of cracking in the coating structure and makes it possible to predict an increase in the performance properties of the coating [27,28,29,30,31,51,52,53] (see Figure 7b).

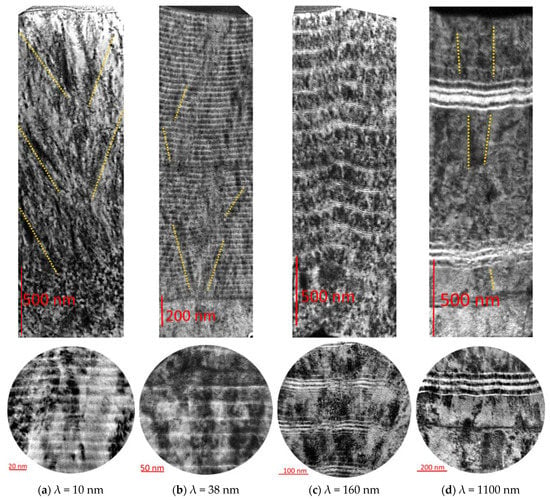

3.2. Influence of the Nanolayer Period λ on the Cluster and Hierarchical Coating Structure

The study was focused on the influence of such an important coating parameter as the nanolayer period λ on a cluster and hierarchical structure using an example of the Ti–TiN–(Ti,Cr,Al)N coating with a nanostructured wear-resistant layer (Figure 8). For a coating with λ = 10 nm (Figure 8a), there is a formation of hierarchical feather-like structures, modeled and described, in particular, in [19,20,24,25,26] for various techniques of the coating deposition. While a coating is being deposited, there in an obvious increase in the cluster size. The studies conducted earlier [52,54,55] also detected an increase in grain size. With an increase in the nanolayer period up to λ = 38 nm (Figure 8b), the feather-like structure becomes less pronounced, and at λ = 160 nm (Figure 8c), no grain growth is detected with an increase in the coating thickness, while the deposition of a coating begins “from scratch” within each nanolayer period. No feather-like structure was also detected for a coating with an extremely long nanolayer period (λ = 1100 nm, Figure 8d). A column structure, without any noticeable increase in crystal size, is formed inside a nanolayer.

Figure 8.

Formation of the cluster structure of the Ti–TiN–(Ti,Cr,Al)N coatings depending on the nanolayer period λ. (a) λ = 10 nm; (b) λ = 38 nm; (c) λ = 160 nm; (d) λ = 1100 nm.

4. Conclusions

- The obtained formulas prove that due to diffusion, particles can participate in collisions with other particles during the motion, and as a result, the velocity decreases and a particle enters a substrate at an angle, which may lead to a coating inhomogeneity over the area and the appearance of the surface microrelief, which also worsens the resistance and reliability of the coating. The Equation (16) is stochastic for various deposition trajectories.

- The Formula (32) indicates that if the distance from a cathode to a substrate is large enough, then there are a lot of particle in front of the substrate, and those particles move perpendicular to the initial direction of the motion (parallel to the substrate). The Formula (34) suggests that the dispersion of the motion direction in front of the substrate increases, which indicates an increase in randomness in the trajectories of the particles being deposited. The Formula (36) proves the fractal nature of the process of particle deposition on a substrate.

- During the formation of the multilayer coating structure, mismatched fractal structures of the layers overlap each other and thus the clustering effect is largely leveled out (averaged). In turn, the above reduces the likelihood of cracking in the coating structure and makes it possible to predict an increase in the performance properties of the products with such coatings.

- The nanolayer period λ has a significant influence on the fractal structure of the coating. When λ is low (less than 38 nm), with an increase in the coating structure, a pronounced feather-like structure is formed, and grains grow. With an increase in λ up to 160 nm and higher, no feather-like structure is formed, and no grain growth is detected during the coating deposition.

Author Contributions

Conceptualization, A.V. and S.G.; methodology, A.V. and A.C.; formal analysis, F.M. and G.O.; investigation, F.M., N.S., J.B., and N.A.; resources, S.G.; data curation, A.V., J.B., and A.C.; writing—original draft preparation, A.V. and A.C.; writing—review and editing, A.V.; project administration, A.V. and S.G.; funding acquisition, S.G. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by Ministry of Science and Higher Education of the Russian Federation, Grant No. 0707-2020-0025.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Ghafouri-Azar, R.; Mostaghimi, J.; Chandra, S.; Charmchi, M. A stochastic model to simulate the formation of a thermal spray coating. J. Therm. Spray Technol. 2003, 12, 53–69. [Google Scholar] [CrossRef]

- Grujicic, M.; Lai, S.G. Multi-length scale modeling of chemical vapor deposition of titanium nitride coatings. J. Mater. Sci. 2001, 36, 2937–2953. [Google Scholar] [CrossRef]

- Birdsall, C.K. Particle-in-Cell charged-particle simulations, plus Monte Carlo collisions with neutral atoms, PIC-MCC. IEEE Trans. Plasma Sci. 1991, 19, 65–85. [Google Scholar] [CrossRef]

- Kwok, D.T.K.; Cornet, C. Numerical simulation of metal plasma immersion ion implantation (MePIIID) on a sharp cone and a fine tip by a multiple-grid particle-in-cell (PIC) method. IEEE Trans. Plasma Sci. 2006, 34, 2434–2442. [Google Scholar] [CrossRef]

- Bultinck, E.; Bogaerts, A. Particle-in-cell/monte carlo collisions treatment of an Ar/O2 magnetron discharge used for the reactive sputter deposition of TiOx films. New J. Phys. 2009, 11, 103010. [Google Scholar] [CrossRef]

- Siemers, M.; Pflug, A.; Melzig, T.; Gehrke, K.; Weimar, A.; Szyszka, B. Model based investigation of Ar+ ion damage in DC magnetron sputtering. Surf. Coat. Technol. 2014, 241, 50–53. [Google Scholar] [CrossRef]

- Cansizoglu, H.; Yurukcu, M.; Cansizoglu, M.F.; Karabacak, T. Investigation of physical vapor deposition techniques of conformal shell coating for core/shell structures by Monte Carlo simulations. Thin Solid Film. 2015, 583, 122–128. [Google Scholar] [CrossRef]

- Fancey, K.S. A coating thickness uniformity model for physical vapour deposition systems: Overview. Surf. Coat. Technol. 1995, 71, 16–29. [Google Scholar] [CrossRef]

- Fancey, K.S. A coating thickness uniformity model for physical vapour deposition systems: Further analysis and development. Surf. Coat. Technol. 1998, 105, 76–83. [Google Scholar] [CrossRef]

- Fuke, I.; Prabhu, V.; Baek, S. Computational model for predicting coating thickness in electron beam physical vapor deposition. J. Manuf. Process. 2005, 7, 140–152. [Google Scholar] [CrossRef]

- James, A.S.; Matthews, A. A simple model for the prediction of coating thickness uniformity from limited measured data. Surf. Coat. Technol. 1993, 61, 282–286. [Google Scholar] [CrossRef]

- De Matos Loureiro da Silva Pereira, V.E.; Nicholls, J.R.; Newton, R. Modelling the EB-PVD thermal barrier coating process: Component clusters and shadow masks. Surf. Coat. Technol. 2017, 311, 307–313. [Google Scholar] [CrossRef][Green Version]

- Baek, S.; Prabhu, V. Technical paper: Simulation model for an EB-PVD coating structure using the level set method. J. Manuf. Process. 2009, 11, 1–7. [Google Scholar] [CrossRef]

- Frenkel, D.; Smit, B. Understanding Molecular Simulation, 2nd ed.; Academic Press: Cambridge, MA, USA, 2002; p. 638. [Google Scholar]

- Moarrefzadeh, A. Simulation and modeling of physical vapor deposition (PVD) process. WSEAS Trans. Appl. Theor. Mech. 2012, 7, 106–111. [Google Scholar]

- Westkämper, E.; Klein, P.; Gottwald, B.; Sommadossi, S.; Baumann, P.; Gemmler, A. A contribution of Molecular Dynamics simulation to sophisticated engineering of coating processes applied to PVD DC sputter deposition. Surf. Coat. Technol. 2005, 200, 872–875. [Google Scholar] [CrossRef]

- Aksenova, E.V.; Kshevetskiy, M.S. Computational Methods for Studying Molecular Dynamics; St. Petersburg State University Publishing House: Petersburg, Russia, 2009; p. 50. [Google Scholar]

- Pflug, A.; Siemers, M.; Melzig, T.; Schäfer, L.; Bräuer, G. Simulation of linear magnetron discharges in 2D and 3D. Surf. Coat. Technol. 2014, 260, 411–416. [Google Scholar] [CrossRef]

- Liu, M.-J.; Zhang, M.; Zhang, X.-F.; Li, G.-R.; Zhang, Q.; Li, C.-X.; Li, C.-J.; Yang, G.-J. Transport and deposition behaviors of vapor coating materials in plasma spray-physical vapor deposition. Appl. Surf. Sci. 2019, 486, 80–92. [Google Scholar] [CrossRef]

- Yoshiya, M.; Wada, K.; Jang, B.K.; Matsubara, H. Computer simulation of nano-pore formation in EB-PVD thermal barrier coatings. Surf. Coat. Technol. 2004, 187, 399–407. [Google Scholar] [CrossRef]

- Gidalevich, E.; Goldsmith, S.; Boxman, R.L. Modeling of nonstationary vacuum arc plasma jet interaction with a neutral background gas. J. Appl. Phys. 2001, 90, 4355–4360. [Google Scholar] [CrossRef]

- Kubečka, M.; Obrusník, A.; Zikán, P.; Jílekjr, M.; Vencels, J.; Bonaventura, Z. Predictive simulation of antenna effect in PVD processes using fluid models. Surf. Coat. Technol. 2019, 379, 125045. [Google Scholar] [CrossRef]

- Pinto, G.; Silva, F.; Porteiro, J.; Míguez, J.; Baptista, A. Numerical simulation applied to PVD reactors: An overview. Coatings 2018, 8, 410. [Google Scholar] [CrossRef]

- Zhang, X.F.; Zhou, K.S.; Deng, C.M.; Liu, M.; Deng, Z.Q.; Deng, C.G.; Song, J.B. Gas-deposition mechanisms of 7YSZ coating based on plasma spray-physical vapor deposition. J. Eur. Ceram. Soc. 2016, 36, 697–703. [Google Scholar] [CrossRef]

- Li, J.; Li, C.-X.; Chen, Q.-Y.; Gao, J.-T.; Wang, J.; Yang, G.-J.; Li, C.-J. Super-Hydrophobic surface prepared by lanthanide oxide ceramic deposition through PS-PVD process. J. Therm. Spray Technol. 2017, 26, 398–408. [Google Scholar] [CrossRef]

- Hass, D.D.; Yang, Y.Y.; Wadley, H.N.G. Pore evolution during high pressure atomic vapor deposition. J. Porous Mater. 2010, 17, 27–38. [Google Scholar] [CrossRef]

- Vereshchaka, A.A.; Vereshchaka, A.S.; Mgaloblishvili, O.; Morgan, M.N.; Batako, A.D. Nano-scale multilayered-composite coatings for the cutting tools. Int. J. Adv. Manuf. Tech. 2014, 72, 303–317. [Google Scholar] [CrossRef]

- Vereschaka, A.; Tabakov, V.; Grigoriev, S.; Sitnikov, N.; Oganyan, G.; Andreev, N.; Milovich, F. Investigation of wear dynamics for cutting tools with multilayer composite nanostructured coatings in turning constructional steel. Wear 2019, 420–421, 17–37. [Google Scholar] [CrossRef]

- Vereschaka, A.; Tabakov, V.; Grigoriev, S.; Sitnikov, N.; Milovich, F.; Andreev, N.; Bublikov, J. Investigation of wear mechanisms for the rake face of a cutting tool with a multilayer composite nanostructured Cr–CrN–(Ti,Cr,Al,Si)N coating in high-speed steel turning. Wear 2019, 438–439, 203069. [Google Scholar] [CrossRef]

- Vereshchaka, A.S.; Vereshchaka, A.A.; Kirillov, A.K. Ecologically friendly dry machining by cutting tool from layered composition ceramic with nano-scale multilayered coatings. Key Eng. Mater. 2012, 496, 67–74. [Google Scholar] [CrossRef]

- Vereschaka, A.; Tabakov, V.; Grigoriev, S.; Aksenenko, A.; Sitnikov, N.; Oganyan, G.; Seleznev, A.; Shevchenko, S. Effect of adhesion and the wear-resistant layer thickness ratio on mechanical and performance properties of ZrN–(Zr,Al,Si)N coatings. Surf. Coat. Technol. 2019, 357, 218–234. [Google Scholar] [CrossRef]

- Volosova, M.A.; Grigor’ev, S.N.; Kuzin, V.V. Effect of titanium nitride coating on stress structural inhomogeneity in oxide-carbide ceramic. Part 4. Action of heat flow. Refract. Ind. Ceram. 2015, 56, 91–96. [Google Scholar] [CrossRef]

- Metel, A.; Bolbukov, V.; Volosova, M.; Grigoriev, S.; Melnik, Y. Equipment for Deposition of thin metallic films bombarded by fast argon atoms. Instrum. Exp. Tech. 2014, 57, 345–351. [Google Scholar] [CrossRef]

- Metel, A.S.; Grigoriev, S.N.; Melnik, Y.A.; Bolbukov, V.P. Characteristics of a fast neutral atom source with electrons injected into the source through its emissive grid from the vacuum chamber. Instrum. Exp. Tech. 2012, 55, 288–293. [Google Scholar] [CrossRef]

- Metel, A.; Bolbukov, V.; Volosova, M.; Grigoriev, S.; Melnik, Y. Source of metal atoms and fast gas molecules for coating deposition on complex shaped dielectric products. Surf. Coat. Technol. 2013, 225, 34–39. [Google Scholar] [CrossRef]

- Grigoriev, S.N.; Sobol, O.V.; Beresnev, V.M.; Serdyuk, I.V.; Pogrebnyak, A.D.; Kolesnikov, D.A.; Nemchenko, U.S. Tribological characteristics of (TiZrHfVNbTa) N coatings applied using the vacuum arc deposition method. J. Frict. Wear 2014, 35, 359–364. [Google Scholar] [CrossRef]

- Vereschaka, A.A.; Grigoriev, S.N.; Vereschaka, A.S.; Popov, A.Y.; Batako, A.D. Nano-scale multilayered composite coatings for cutting tools operating under heavy cutting conditions. Procedia CIRP 2014, 14, 239–244. [Google Scholar] [CrossRef]

- Vereschaka, A.A.; Volosova, M.A.; Grigoriev, S.N.; Vereschaka, A.S. Development of wear-resistant complex for high-speed steel tool when using process of combined cathodic vacuum arc deposition. Procedia CIRP 2013, 9, 8–12. [Google Scholar] [CrossRef]

- Grigoriev, S.; Melnik, Y.; Metel, A. Broad fast neutral molecule beam sources for industrial-scale beam-assisted deposition. Surf. Coat. Technol. 2002, 156, 44–49. [Google Scholar] [CrossRef]

- Grigoriev, S.N.; Melnik, Y.A.; Metel, A.S.; Panin, V.V. Broad beam source of fast atoms produced as a result of charge exchange collisions of ions accelerated between two plasmas. Instrum. Exp. Tech. 2009, 52, 602–608. [Google Scholar] [CrossRef]

- Metel, A.S.; Grigoriev, S.N.; Melnik, Y.; Bolbukov, V.P. Broad beam sources of fast molecules with segmented cold cathodes and emissive grids. Instrum. Exp. Tech. 2012, 55, 122–130. [Google Scholar] [CrossRef]

- Metel, A.S.; Grigoriev, S.N.; Melnik, Y.A.; Prudnikov, V.V. Glow discharge with electrostatic confinement of electrons in a chamber bombarded by fast electrons. Plasma Phys. Rep. 2011, 37, 628–637. [Google Scholar] [CrossRef]

- Miklashevich, I.A.; Chigarev, A.V.; Korsunsky, A.M. Variational determination of the crack trajectory in inhomogeneous media. Int. J. Fract. 2001, 111, L29–L34. [Google Scholar] [CrossRef]

- Brownlee, K.A. Statistical Theory and Methodology in Science and Engineering; Wiley: New York, NY, USA, 1965. [Google Scholar]

- Miklashevich, I.A.; Chigarev, A.V. Equation of the crack front with allowance for the metric properties of the material. Russ. Phys. J. 2002, 45, 1159–1164. [Google Scholar] [CrossRef]

- Lévy, P. Processus Stochastiques et Movement Brownien; Villars, G., Ed.; Academic Press: Cambridge, MA, USA, 1965. [Google Scholar]

- Chigarev, A.; Polenov, V.; Shirvel, P. Simulation of tsunami effect by seismic wave propagation in hypoplastic medium at vicinity of free boundary. Univ. J. Mech. Eng. 2018, 6, 9–20. [Google Scholar] [CrossRef]

- Polenov, V.S.; Chigarev, A.V. Propagation of waves in an inhomogeneous viscoelastic medium with initial stresses. Pmm J. Appl. Math. Mech. 1994, 58, 563–568. [Google Scholar] [CrossRef]

- Chigarev, A.; Chigarev, J. Expansion of wave rays and fronts in media with inhomogeneous structure. Univers. J. Mech. Eng. 2018, 6, 76–95. [Google Scholar] [CrossRef][Green Version]

- Zhao, C.; Yang, C. Nonlinear Smoluchowski velocity for electroosmosis of power-law fluids over a surface with arbitrary zeta potentials. Electrophoresis 2010, 31, 973–979. [Google Scholar] [CrossRef]

- Norris, J.R. Smoluchowski’s coagulation equation: Uniqueness, nonuniqueness and a hydrodynamic limit for the stochastic coalescent. Ann. Appl. Probab. 1999, 9, 78–109. [Google Scholar] [CrossRef]

- Vereschaka, A.; Tabakov, V.; Grigoriev, S.; Sitnikov, N.; Andreev, N.; Milovich, F. Investigation of wear and diffusion processes on rake faces of carbide inserts with Ti–TiN–(Ti,Al,Si)N composite nanostructured coating. Wear 2018, 416–417, 72–80. [Google Scholar] [CrossRef]

- Vereschaka, A.; Tabakov, V.; Grigoriev, S.; Sitnikov, N.; Milovich, F.; Andreev, N.; Sotova, C.; Kutina, N. Investigation of the influence of the thickness of nanolayers in wear-resistant layers of Ti–TiN–(Ti,Cr,Al)N coating on destruction in the cutting and wear of carbide cutting tools. Surf. Coat. Technol. 2020, 385, 125402. [Google Scholar] [CrossRef]

- Vereschaka, A.; Aksenenko, A.; Sitnikov, N.; Migranov, M.; Shevchenko, S.; Sotova, C.; Batako, A.; Andreev, N. Effect of adhesion and tribological properties of modified composite nano-structured multi-layer nitride coatings on WC-Co tools life. Tribol. Int. 2018, 128, 313–327. [Google Scholar] [CrossRef]

- Vereschaka, A.; Grigoriev, S.; Sitnikov, N.; Milovich, F.; Aksenenko, A.; Andreev, N. Investigation of performance and cutting properties of carbide tool with nanostructured multilayer Zr–ZrN–(Zr0.5,Cr0.3,Al0.2)N coating. Int. J. Adv. Manuf. Technol. 2019, 102, 2953–2965. [Google Scholar] [CrossRef]

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).