Wear and Deformation Performance of W/Ta Multilayer Coatings on Pure Cu Prepared by Double Glow Plasma Alloying Technique

Abstract

:1. Introduction

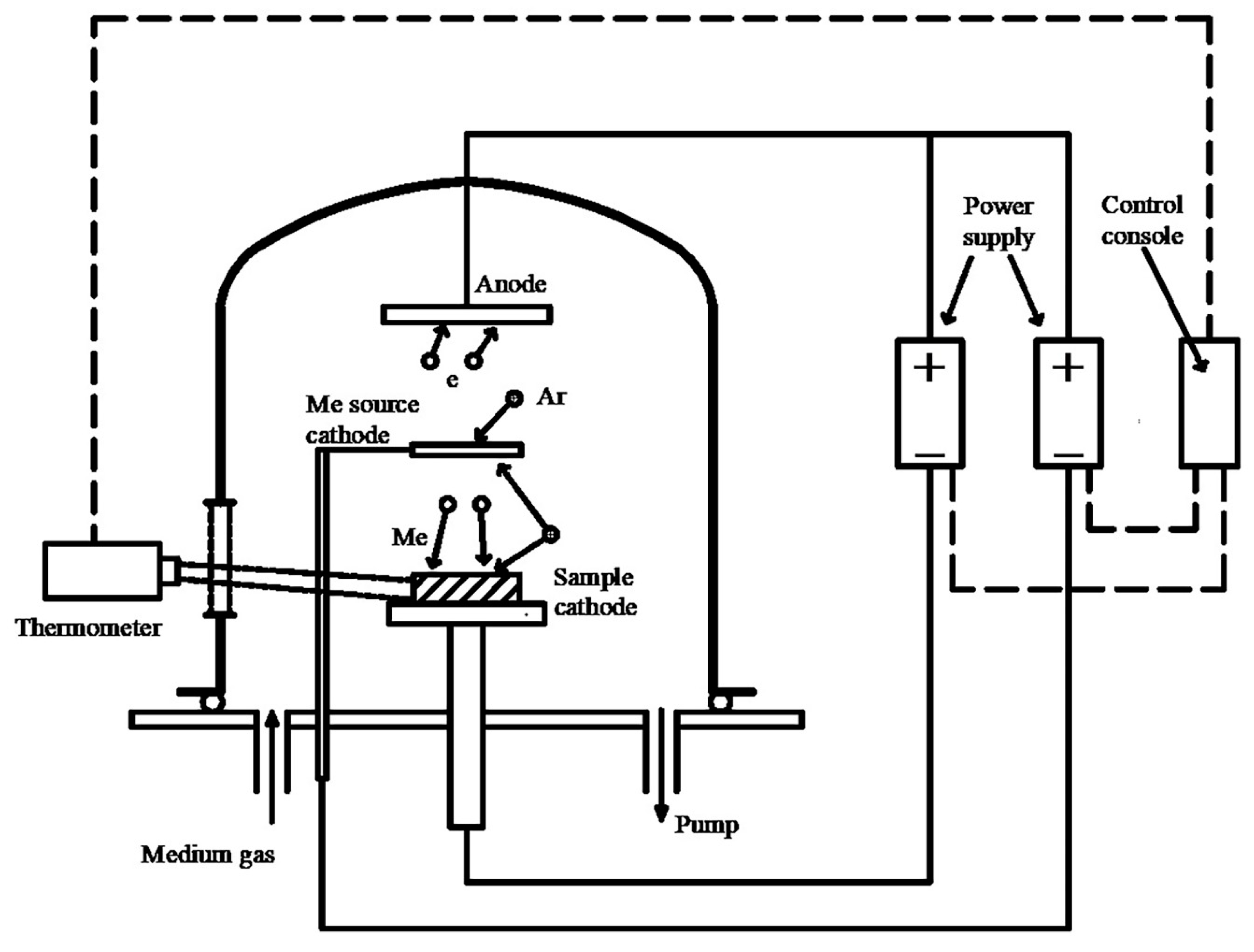

2. Materials and Methods

2.1. Coating Deposition

2.2. Mechanical Test

2.3. Wear Test

2.4. Surface Characterication

3. Results and Discussion

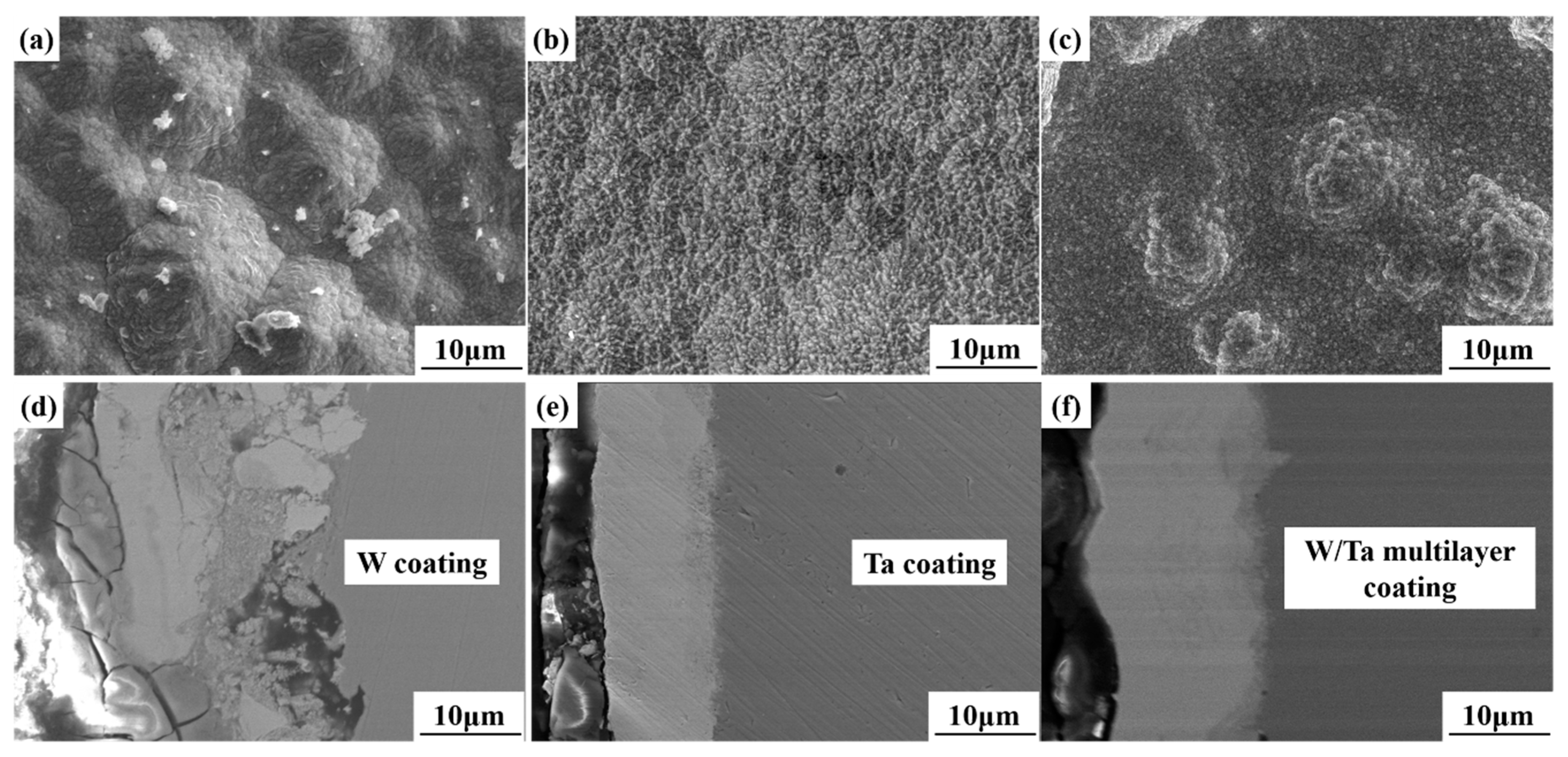

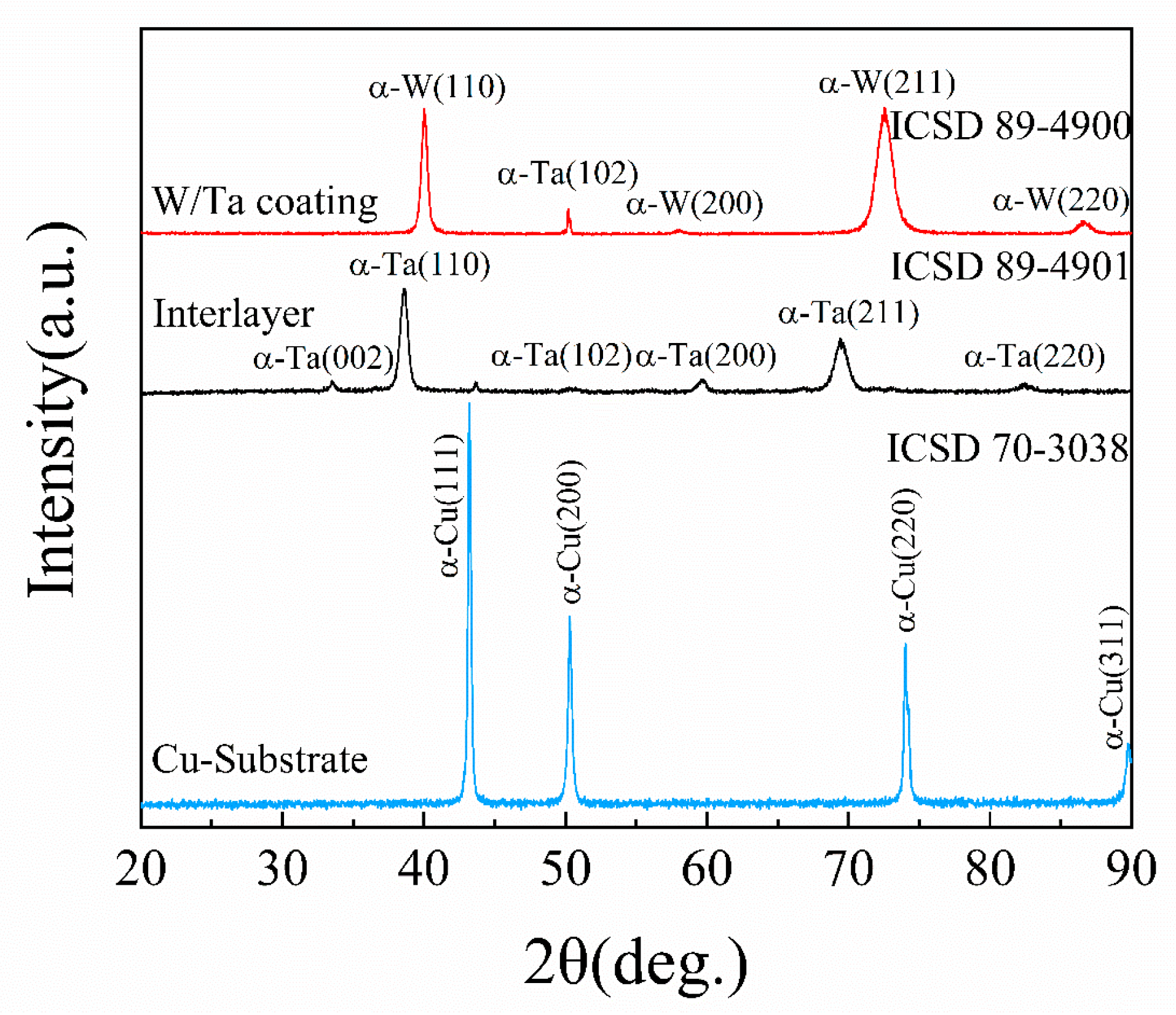

3.1. Microstructure and Phase Distribution

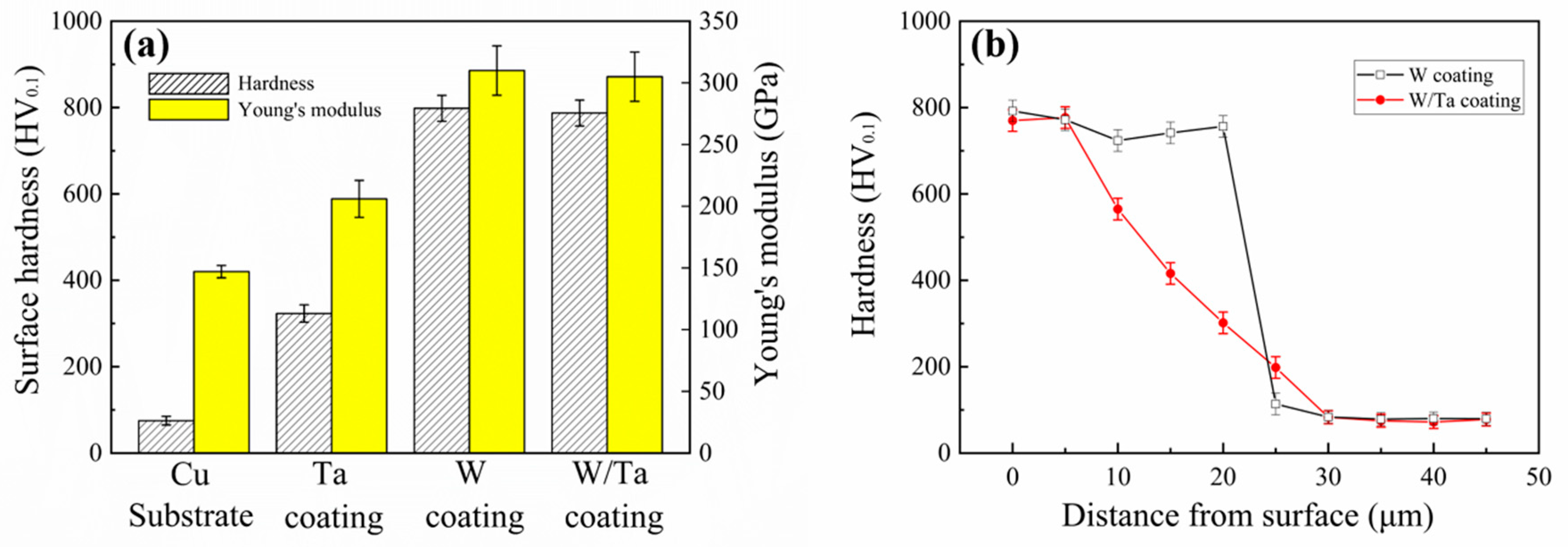

3.2. Mechanical Properties

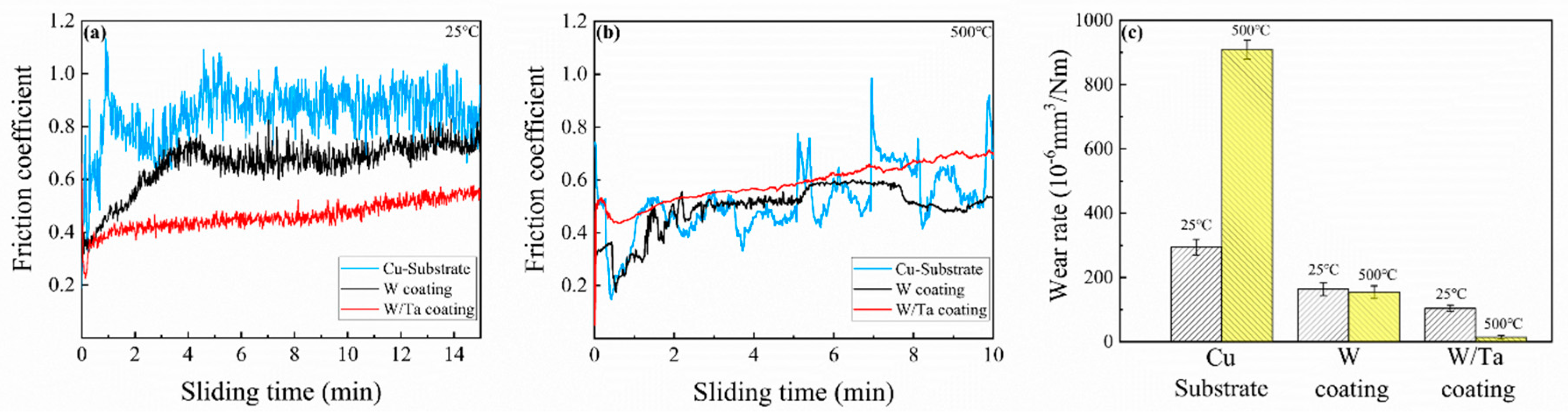

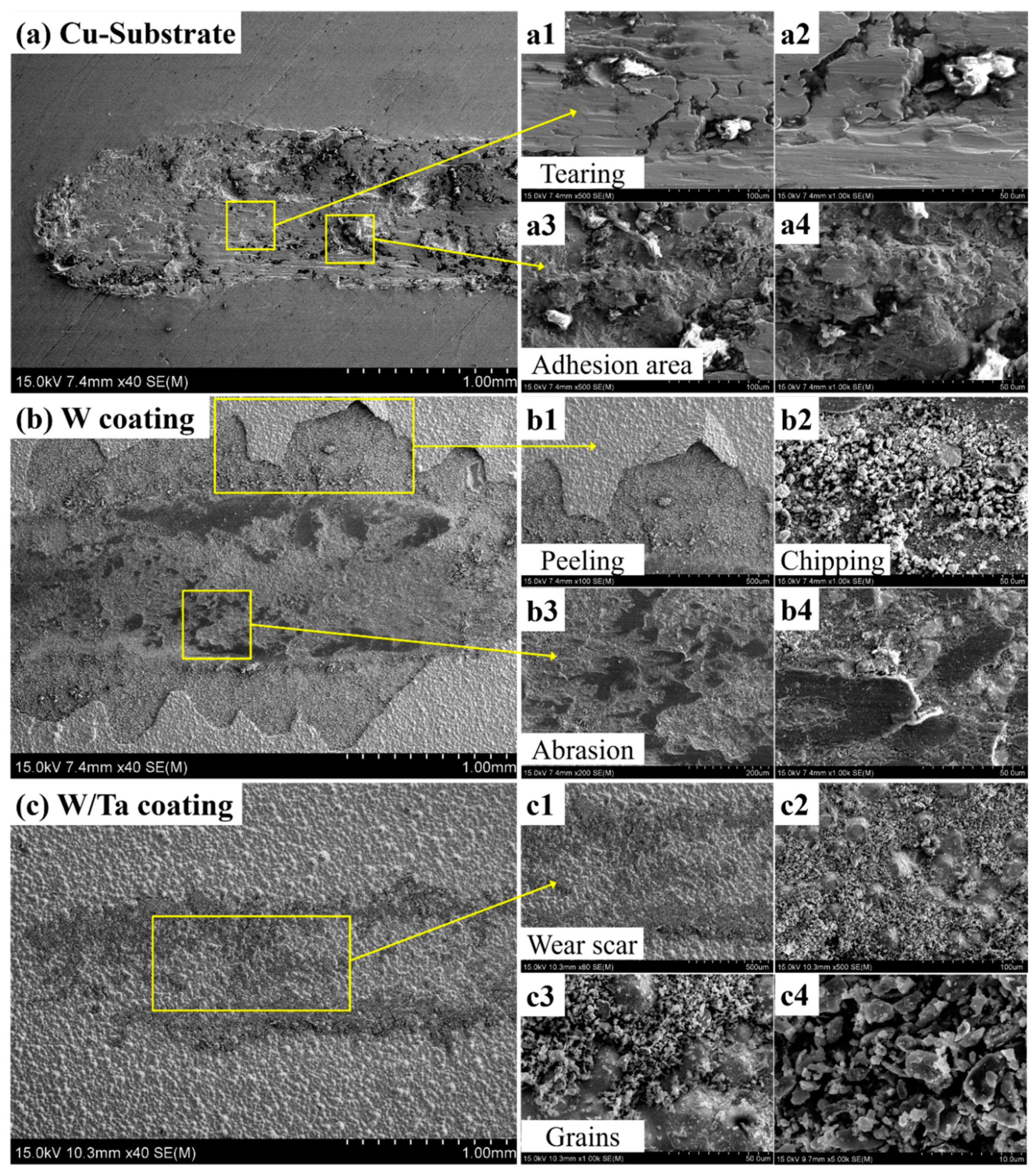

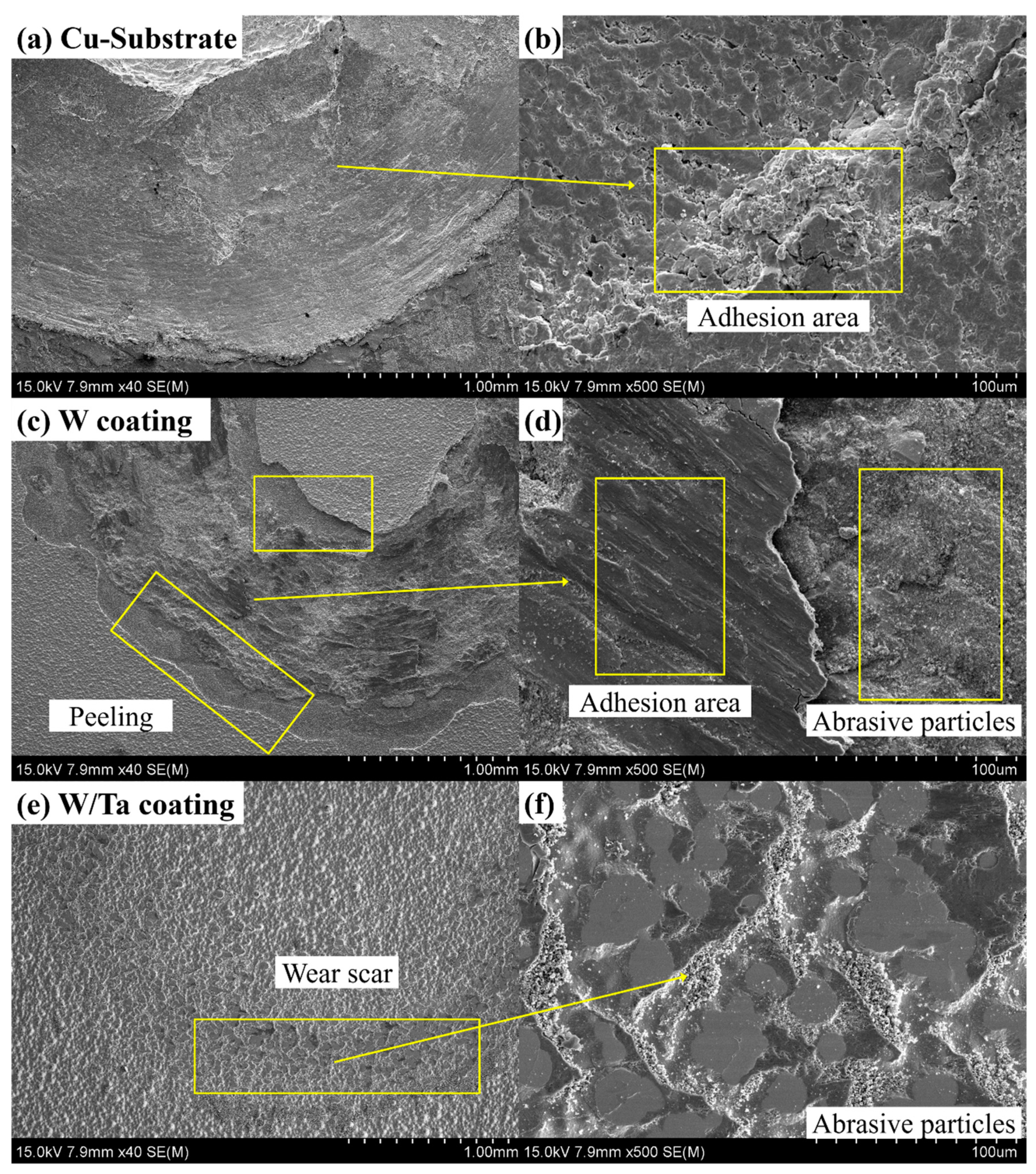

3.3. Tribological Behavior

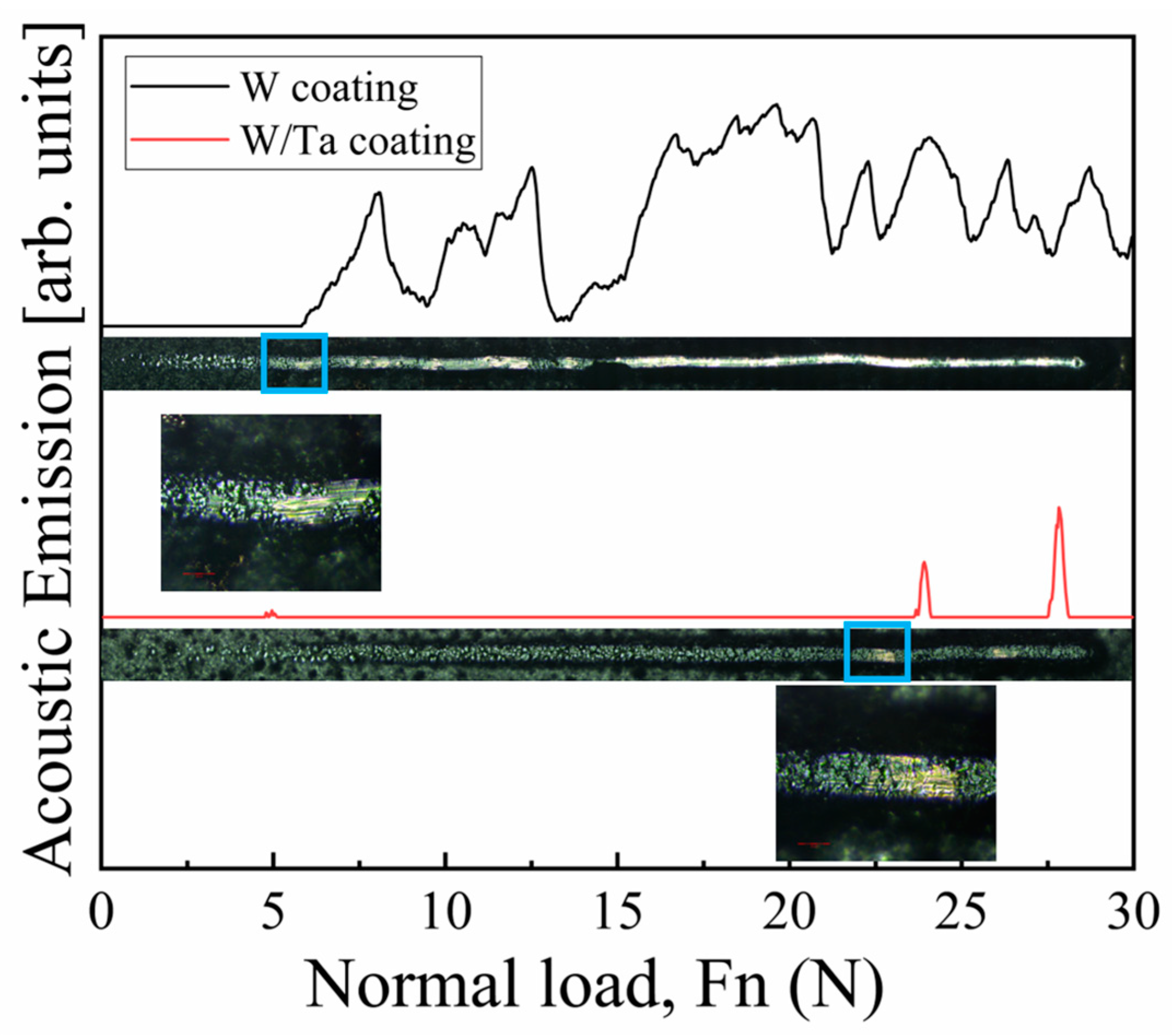

3.4. Deformation Mechanism during Scratching

4. Conclusions

- A W/Ta multilayer coating was designed and deposited on the surface of pure copper by DGP surface alloying technology. As a result of the presence of α-W phase with high hardness, the surface hardness of coatings increases to ≈800 HV0.1, which is almost decuple that of the Cu substrate. Compared to the separate W coating, the W/Ta multilayer coating exhibits the preferable adhesive strength and sufficient toughness due to the existence of a transition interlayer (Ta layer), accomplishing the favorable matching of mechanical properties between the W coating and Cu substrate.

- The separate W coating was more likely to peel during the wear process due to its poor adhesive strength and toughness, and these peeling areas were easier to generate oxidative and adhesive wear. The good design of a multilayer microstructure made a critical difference in enhancing the wear resistance, leading to the lowest wear rate of 14 × 10−6 mm3/Nm, which was greatly less than the substrate or the separate W coating. Furthermore, the wear mechanism of the multilayer coating was mainly abrasive wear.

- The addition of a transition interlayer, causing the persistence stage of changing elastic–plastic deformation of the W/Ta multilayer coating to be more than that of the W coating, makes a significant contribution in affecting the deformation of the coating under stress. In addition, the extension of changing elastic–plastic deformation is salutary to the wear course, resulting in the mechanical properties of the coating presenting a linear gradient descent instead of a vertical gradient, which makes a substantial contribution in the wear stage.

Author Contributions

Funding

Conflicts of Interest

References

- Linke, J. Plasma facing materials and components for future fusion devices-development, characterization and performance under fusion specific loading conditions. Phys. Scr. 2006, T123, 45–53. [Google Scholar] [CrossRef]

- Bolt, H.; Barabash, V.; Federici, G.; Linke, J.; Loarte, A.; Roth, J.; Sato, K. Plasma facing and high heat flux materials-needs for ITER and beyond. J. Nucl. Mater. 2002, 307, 43–52. [Google Scholar] [CrossRef]

- Huang, Y.; Du, J.L.; Wang, Z. Progress in research on the alloying of binary immiscible metals. Acta Metall. Sin. 2020, 56, 801–820. [Google Scholar]

- Lu, G.H.; Zhou, H.B.; Becquart, C.S. A review of modelling and simulation of hydrogen behaviour in tungsten at different scales. Nucl. Fusion. 2014, 54, 086001. [Google Scholar] [CrossRef]

- Meng, Y.F.; Zhang, J.P.; Duan, C.Y.; Chen, C.; Feng, X.M.; Shen, Y.F. Microstructures and properties of W-Cu functionally graded composite coatings on copper substrate via high-energy mechanical alloying method. Adv. Powder Technol. 2015, 26, 392–400. [Google Scholar] [CrossRef]

- Philipps, V. Tungsten as material for plasma-facing components in fusion devices. J. Nucl. Mater. 2011, 415, S2–S9. [Google Scholar] [CrossRef]

- Wen, S.P.; Zong, R.L.; Zeng, F.; Gao, Y.; Pan, F. Evaluating modulus and hardness enhancement in evaporated Cu/W multilayers. Acta Mater. 2007, 55, 345–351. [Google Scholar] [CrossRef]

- Liu, Y.H.; Zhang, Y.C.; Liu, Q.Z.; Li, X.L.; Jiang, F. Electro-deposition metallic tungsten coatings in a Na2WO4-WO3 melt on copper based alloy substrate. Fusion Eng. Des. 2012, 87, 1861–1865. [Google Scholar] [CrossRef]

- Monclús, M.A.; Karlik, M.; Callisti, M.; Frutos, E.; Llroca, J.; Pplcar, T.; Molina-Aldareguía, J.M. Microstructure and mechanical properties of physical vapor deposited Cu/W nanoscale multilayers: Influence of layer thickness and temperature. Thin Solid Film. 2014, 571, 275–282. [Google Scholar] [CrossRef] [Green Version]

- Wang, T.G.; Chen, J.L.; Chen, Y.; Wu, Y.C. Thermal properties of VPS-W coatings on CuCrZr alloy with Ti bonding layer. J. Nucl. Mater. 2007, 363, 1294–1298. [Google Scholar] [CrossRef]

- Zhang, J.; Huang, Y.; Wang, Z.; Liu, Y.C. Thermodynamic mechanism for direct alloying of immiscible tungsten and copper at a critical temperature range. J. Alloys Compd. 2018, 774, 939–947. [Google Scholar] [CrossRef]

- Qiu, Z.K.; Zhang, P.Z.; Wei, D.B.; Wei, X.F.; Chen, X.H. A study on tribological behavior of double-glow plasma surface alloying W-Mo coating on gear steel. Surf. Coat. Technol. 2015, 278, 92–98. [Google Scholar] [CrossRef]

- Yi, J.W.; Miao, Q.; Liang, W.P.; Ding, Z.; Qi, Y.; Lin, H.; Huang, C.J. A study for pre-processing of Nb diffusion in Nb-N layer by double-glow plasma alloying. J. Alloys Compd. 2020, 820, 153121. [Google Scholar] [CrossRef]

- Li, J.X.; Chen, Y.H.; Bai, Z.J.; Zhao, B.J.; Jiang, L. Oxidation behavior of multi-component Ta-W-Al-Ti alloy at 1173K. Rare Met. 2020, 39, 1–9. [Google Scholar]

- Dias, M.; Guerreiro, F.; Correia, J.B.; Galatanu, A.; Rosiński, M.; Monge, M.A.; Munoz, A.; Alves, E.; Carvalho, P.A. Consolidation of W-Ta composites: Hot isostatic pressing and spark and pulse plasma sintering. Fusion Eng. Des. 2015, 98, 1950–1955. [Google Scholar] [CrossRef] [Green Version]

- Liu, X.; Zhang, F.; Tao, S.Y.; Cao, Y.Z.; Xu, Z.Y.; Liu, Y.; Noda, N. Research and development of plasma sprayed tungsten coating on graphite and copper substrates. J. Nucl. Mater. 2007, 363, 1299–1303. [Google Scholar] [CrossRef]

- Parchuri, P.; Kotegawa, S.; Yamamoto, H.; Ito, K.; Mori, A.; Hokamoto, K. Benefits of intermediate-layer formation at the interface of Nb/Cu and Ta/Cu explosive clads. Mater. Des. 2019, 166, 107610. [Google Scholar] [CrossRef]

- Peng, X.M.; Xia, C.Q.; Zhou, L.; Huang, L.; Li, D.F.; Wu, A.R. Study of arc ion plated Ta-W coating on a titanium alloy. Surf. Coat. Technol. 2018, 349, 622–635. [Google Scholar] [CrossRef]

- Li, X.B.; Zhang, P. Phase stability of Ta-W alloys. Acta Metall. Sin Eng. Lett. 2010, 23, 215–222. [Google Scholar]

- Gong, H.R.; Liu, B.X. Interface stability and solid-state amorphization in an immiscible Cu-Ta system. Appl. Phys. Lett. 2003, 83, 4515. [Google Scholar] [CrossRef]

- Zhang, J.; Huang, Y.; Liu, Y.C.; Wang, Z.M. Direct diffusion bonding of immiscible tungsten and copper at temperature close to Copper’s melting point. Mater. Des. 2018, 137, 473–480. [Google Scholar] [CrossRef]

- Kabir, M.S.; Munroe, P.; Zhou, Z.F.; Xie, Z.H. Scratch adhesion and tribological behaviour of graded Cr/CrN/CrTiN coatings synthesized by closed-field unbalanced magnetron sputtering. Wear 2017, 380, 163–175. [Google Scholar] [CrossRef]

- Kovářík, O.; Haušild, P.; Siegl, J.; Chráska, T.; Matějíček, J.; Pala, Z.; Boulos, M. The influence of substrate temperature on properties of APS and VPS W coatings. Surf. Coat. Technol. 2015, 268, 7–14. [Google Scholar] [CrossRef]

- Qiu, J.W.; Fu, Z.F.; Liu, B.; Liu, Y.; Yan, J.H.; Pan, D.; Zhang, W.D.; Baked, I. Effects of niobium particles on the wear behavior of powder metallurgical γ-TiAl alloy in different environments. Wear 2019, 434, 202964. [Google Scholar] [CrossRef]

- Gao, S.; He, B.; Zhou, L.Z.; Hou, J.S. Effects of Ta on the high temperature oxidation behavior of IN617 alloy in air. Corros. Sci. 2020, 170, 108682. [Google Scholar] [CrossRef]

- Xu, N.; Han, W.Z.; Wang, Y.C.; Li, J.; Shan, Z.W. Nanoscratching of copper surface by CeO2. Acta Mater. 2017, 124, 343–350. [Google Scholar] [CrossRef]

- Bhushan, B. Modern Tribology Handbook; CRC Press: Boka Raton, FL, USA, 2001. [Google Scholar]

- Wang, Y.G.; Chen, Y.; Zhao, D.; Lu, X.L.; Liu, W.W.; Qi, F.; Chen, Y. Deformation mechanism of CrN/nitriding coated steel in wear and nano-scratch experiments under heavy loading conditions. Appl. Surf. Sci. 2018, 447, 100–106. [Google Scholar] [CrossRef]

| Process Parameters and Their Corresponding Values | ||

|---|---|---|

| Target | Ta (99.95%) | W (99.95%) |

| Temperature (K) | 1123 | 1123 |

| Time (h) | 3 | 3 |

| Working pressure (Pa) | 38 | 40 |

| Distance between the source and substrate (mm) | 15 | 18 |

| Voltage of the target (V) | 800–850 | 850–900 |

| Voltage of the substrate (V) | 500–520 | 450–500 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dang, B.; Tian, T.; Yang, K.; Ding, F.; Li, F.; Wei, D.; Zhang, P. Wear and Deformation Performance of W/Ta Multilayer Coatings on Pure Cu Prepared by Double Glow Plasma Alloying Technique. Coatings 2020, 10, 926. https://doi.org/10.3390/coatings10100926

Dang B, Tian T, Yang K, Ding F, Li F, Wei D, Zhang P. Wear and Deformation Performance of W/Ta Multilayer Coatings on Pure Cu Prepared by Double Glow Plasma Alloying Technique. Coatings. 2020; 10(10):926. https://doi.org/10.3390/coatings10100926

Chicago/Turabian StyleDang, Bo, Tian Tian, Kai Yang, Feng Ding, Fengkun Li, Dongbo Wei, and Pingze Zhang. 2020. "Wear and Deformation Performance of W/Ta Multilayer Coatings on Pure Cu Prepared by Double Glow Plasma Alloying Technique" Coatings 10, no. 10: 926. https://doi.org/10.3390/coatings10100926

APA StyleDang, B., Tian, T., Yang, K., Ding, F., Li, F., Wei, D., & Zhang, P. (2020). Wear and Deformation Performance of W/Ta Multilayer Coatings on Pure Cu Prepared by Double Glow Plasma Alloying Technique. Coatings, 10(10), 926. https://doi.org/10.3390/coatings10100926