New Low-Voltage Driving Compensating Pixel Circuit Based on High-Mobility Amorphous Indium-Zinc-Tin-Oxide Thin-Film Transistors for High-Resolution Portable Active-Matrix OLED Displays

Abstract

:1. Introduction

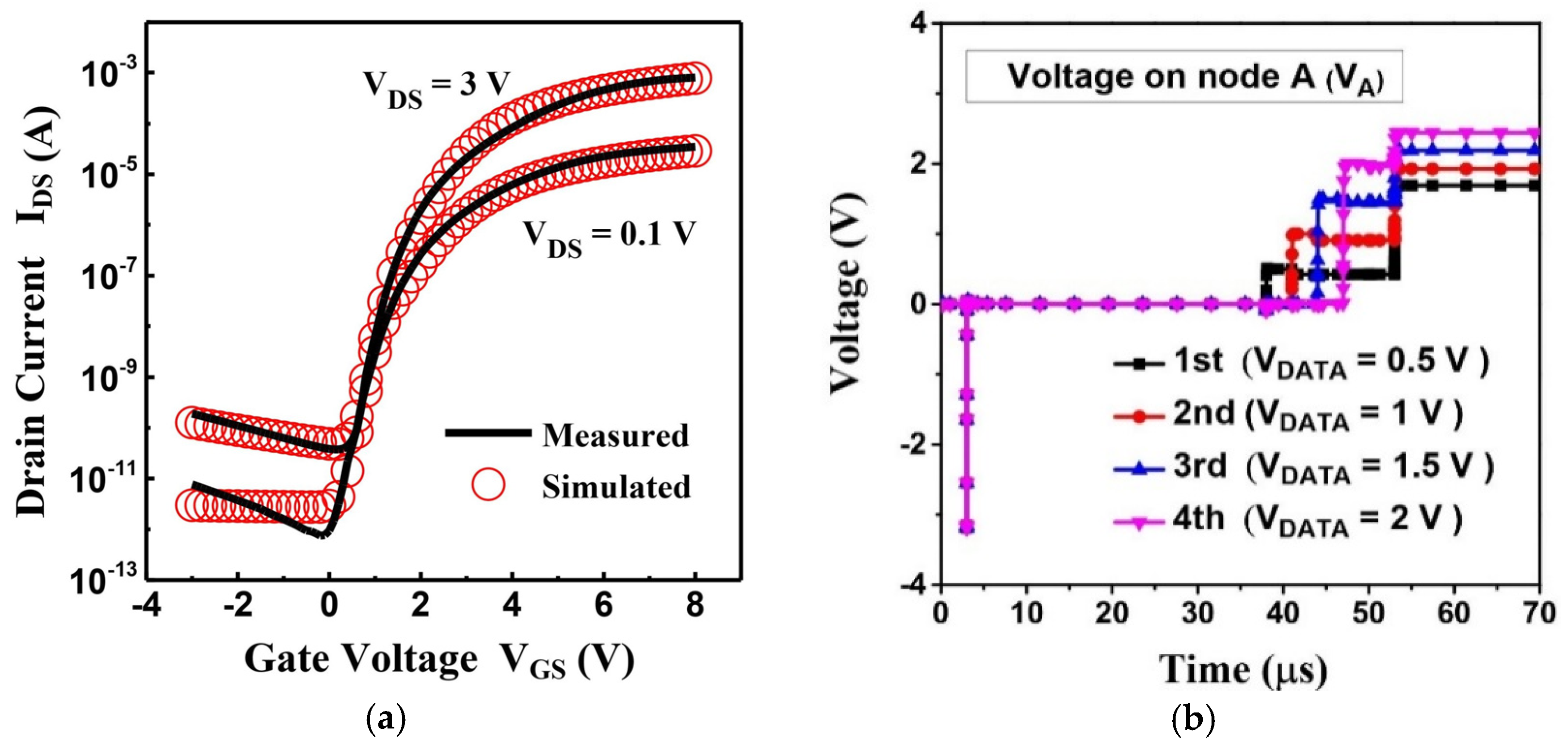

2. TFT Fabrication and Characterization

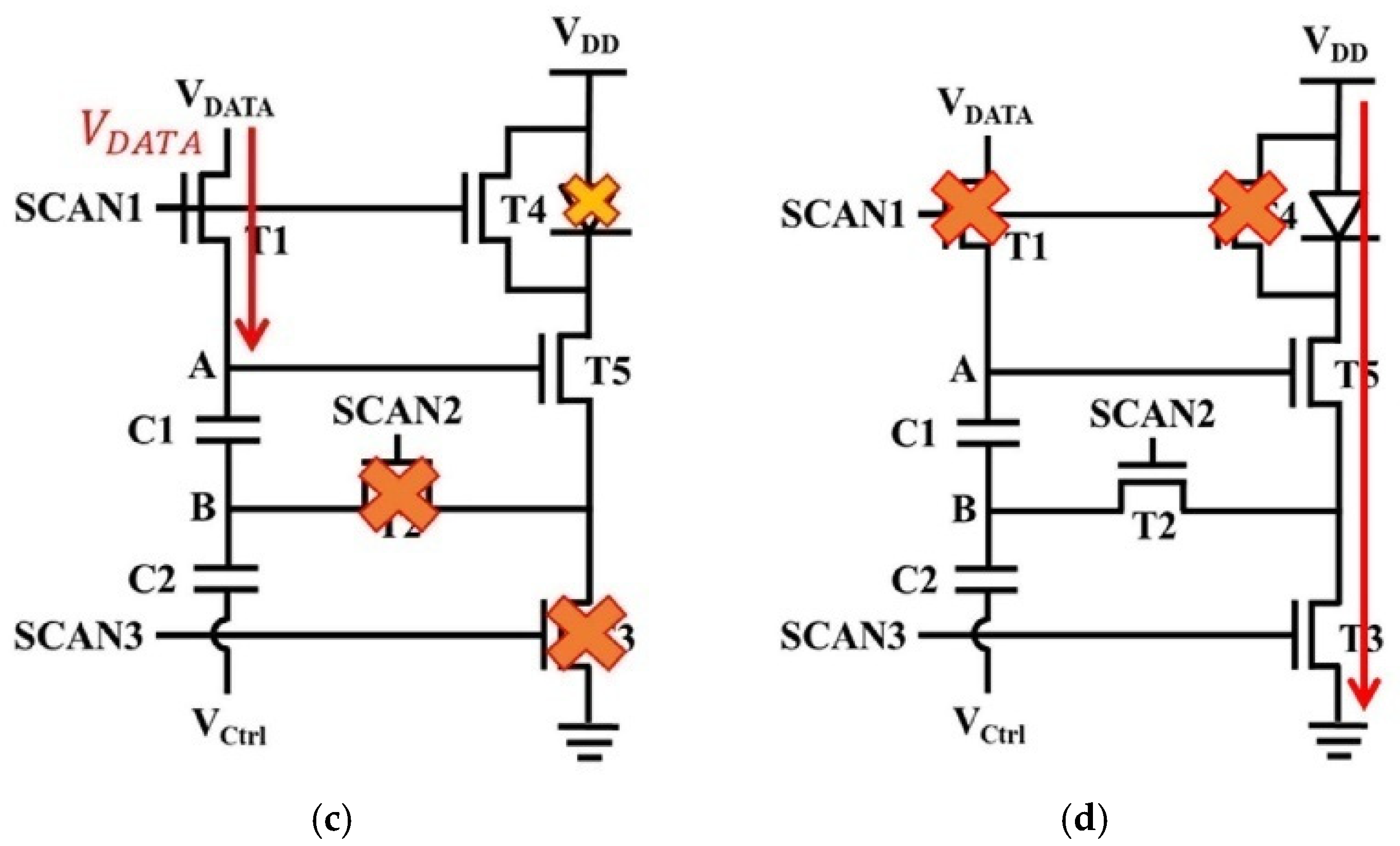

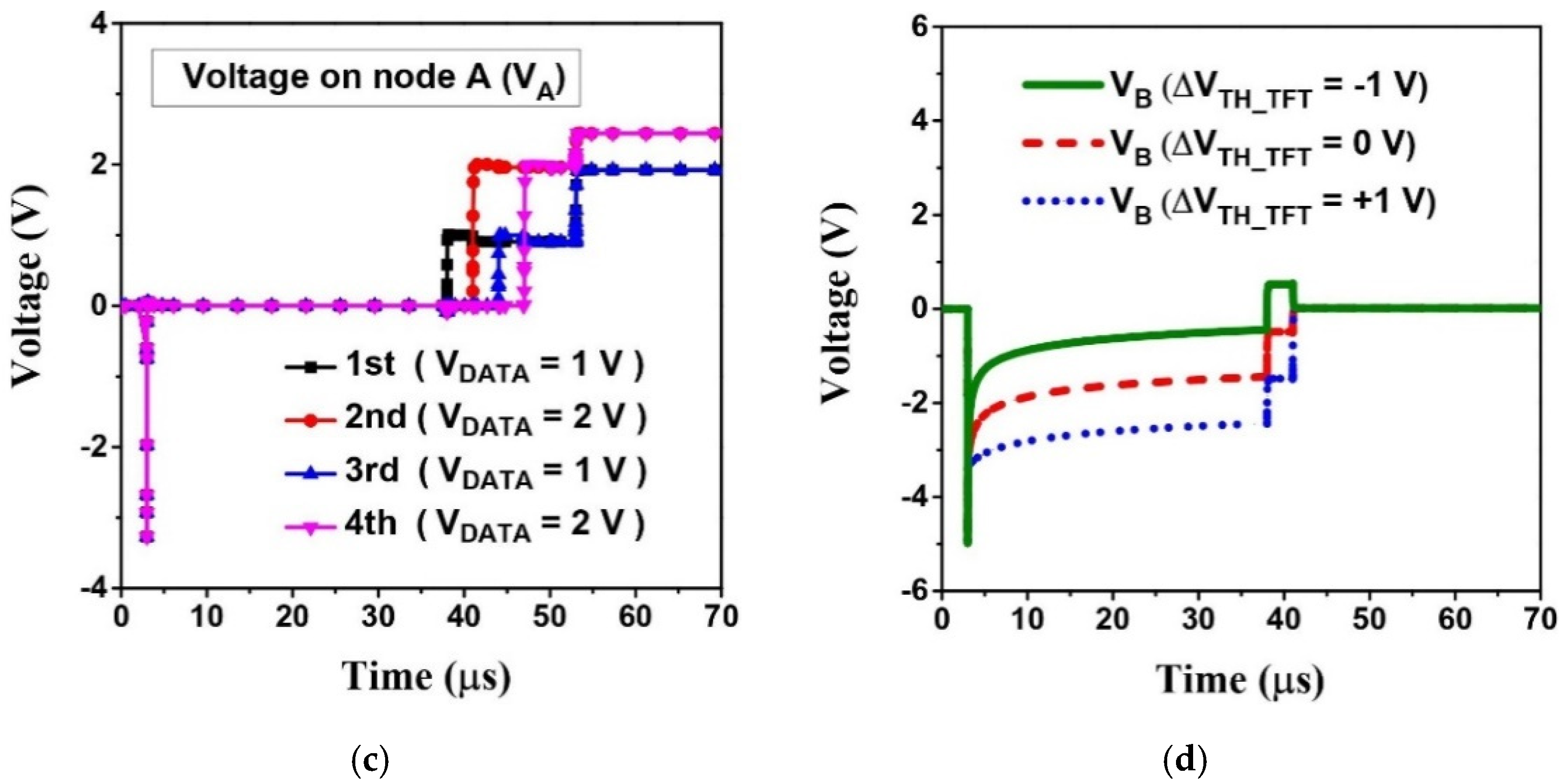

3. Proposed Pixel Circuit Operation

3.1. Reset

3.2. Compensation

3.3. Data Input

3.4. Emission

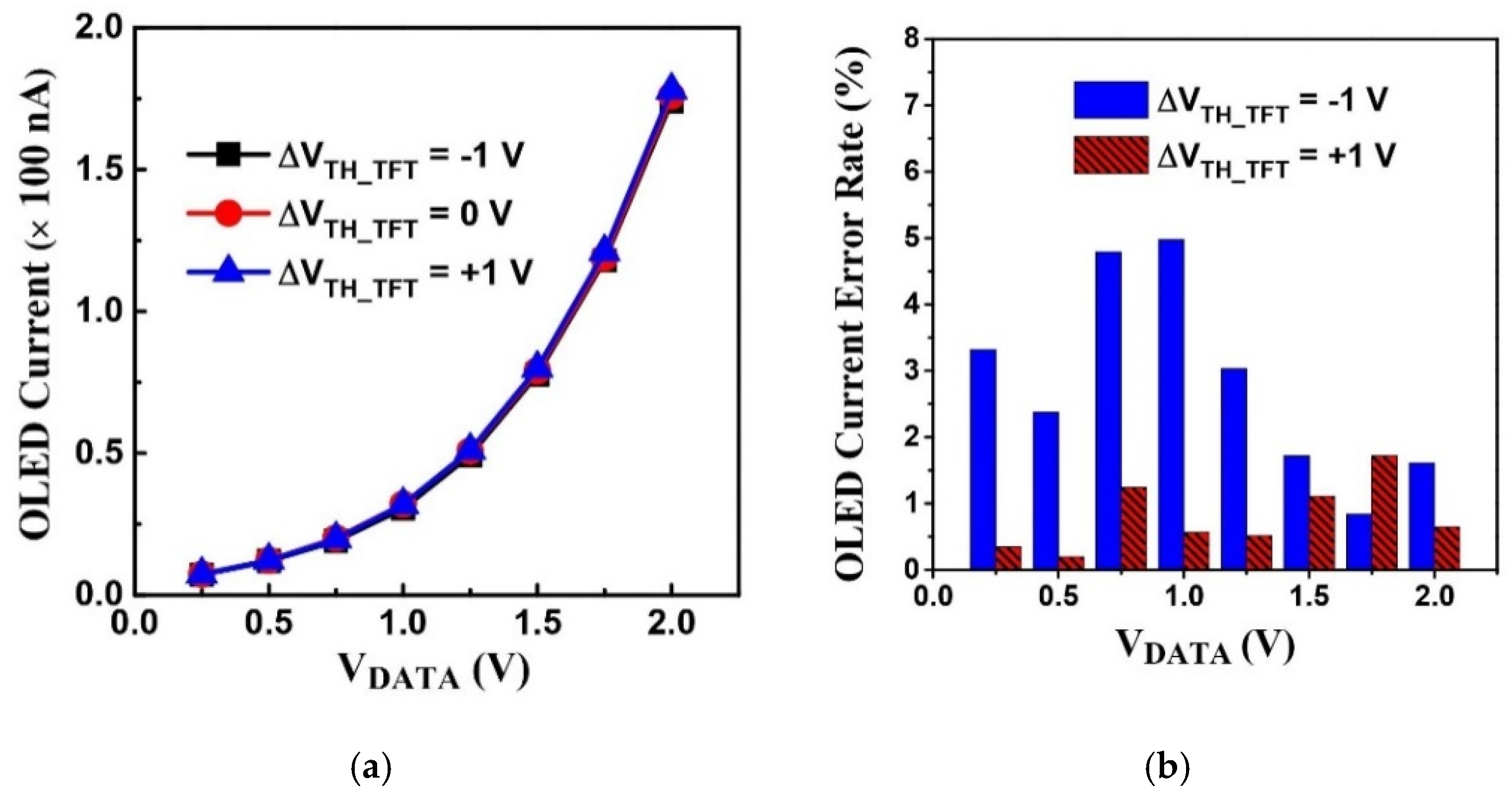

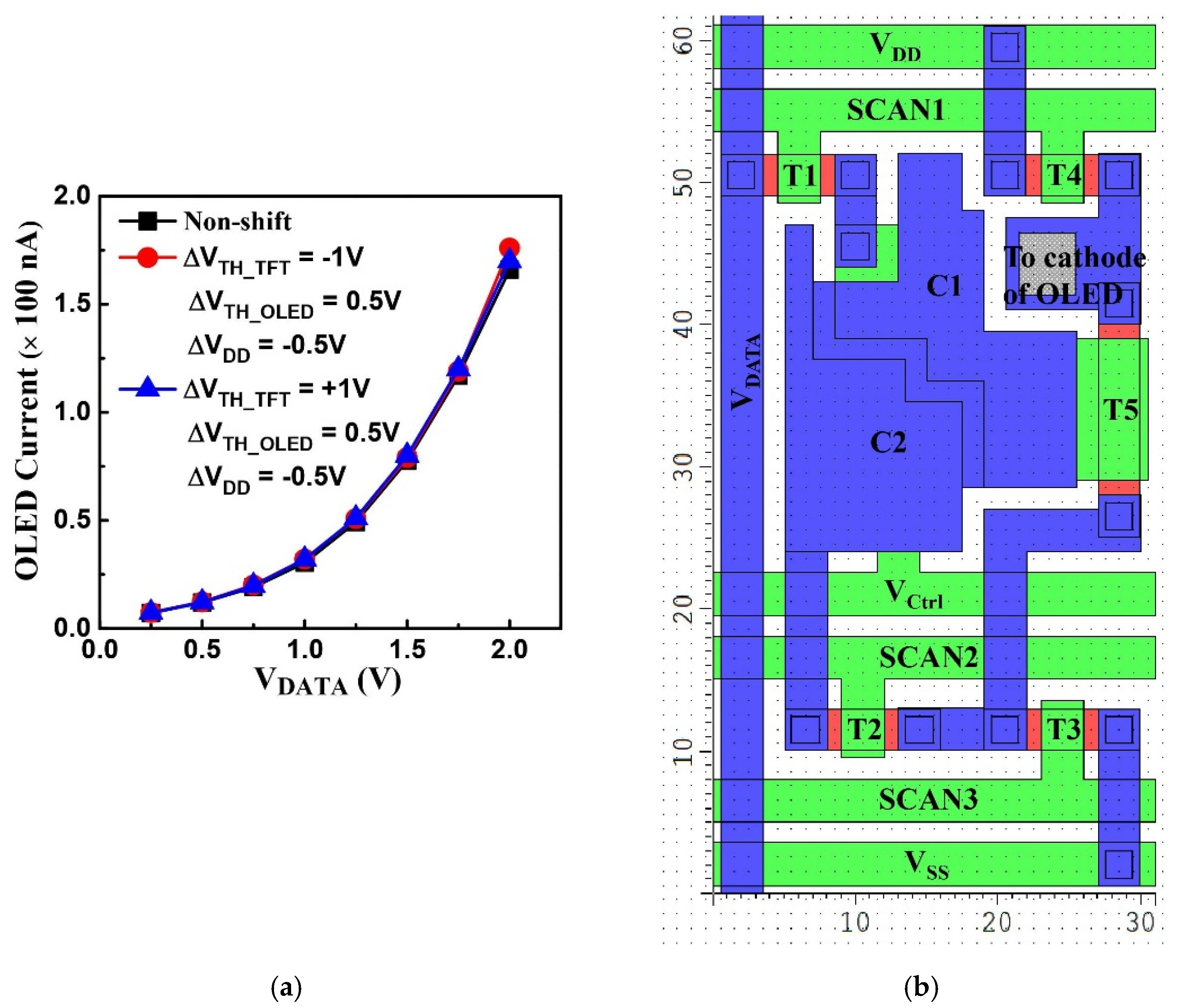

4. Results and Discussion

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Dawson, R.M.A.; Shen, Z.; Furst, D.A.; Connor, S.; Hsu, J.; Kane, M.G.; Stewart, R.G.; Ipri, A.; King, C.N.; Green, P.J.; et al. The impact of the transient response of organic light emitting diodes on the design of active matrix OLED displays. In Proceedings of the International Electron Devices Meeting 1998, Technical Digest (Cat. No.98CH36217), San Francisco, CA, USA, 6–9 December 1998; pp. 875–878. [Google Scholar]

- Wang, C.; Hu, Z.; He, X.; Liao, C.; Zhang, S. One gate diode-connected dual-gate a-IGZO TFT driven pixel circuit for active matrix organic light-emitting diode displays. IEEE Trans. Electron Devices 2016, 63, 3800–3803. [Google Scholar] [CrossRef]

- Fan, C.L.; Chen, Y.C.; Yang, C.C.; Tsai, Y.K.; Hung, B.R. Novel LTPS-TFT pixel circuit with OLED luminance compensation for 3D AMOLED displays. J. Disp. Technol. 2016, 12, 425–428. [Google Scholar] [CrossRef]

- Lin, C.L.; Chen, Y.C. A novel LTPS-TFT pixel circuit compensating for TFT threshold-voltage shift and OLED degradation for AMOLED. IEEE Electron Device Lett. 2007, 28, 129–131. [Google Scholar] [CrossRef]

- Lu, H.Y.; Chang, T.C.; Tai, Y.H.; Liu, P.T.; Chi, S. A new pixel circuit compensating for brightness variation in large size and high resolution AMOLED displays. J. Disp. Technol. 2007, 3, 398–403. [Google Scholar]

- Lin, C.L.; Chang, J.H.; Lai, P.C.; Shih, L.W.; Chen, S.C.; Cheng, M.H. Pixel circuit with leakage prevention scheme for low-frame-rate AMOLED displays. IEEE J. Electron Devices Soc. 2020, 8, 235–240. [Google Scholar] [CrossRef]

- Nathan, A.; Chaji, G.R.; Ashtiani, S.J. Driving schemes for a-Si and LTPS AMOLED displays. J. Disp. Technol. 2005, 1, 267–277. [Google Scholar] [CrossRef]

- Ma, P.; Sun, J.; Zhang, G.; Liang, G.; Xin, Q.; Li, Y.; Song, A. Low–temperature fabrication of HfAlO alloy dielectric using atomic–layer deposition and its application in a low–power device. J. Alloys Compd. 2019, 792, 543–549. [Google Scholar] [CrossRef]

- Lin, C.L.; Chen, F.H.; Hung, C.C.; Chen, P.S.; Deng, M.Y.; Lu, C.M.; Huang, T.H. New a-IGZO pixel circuit composed of three transistors and one capacitor for use in high-speed-scan AMOLED displays. J. Disp. Technol. 2015, 11, 1031–1034. [Google Scholar]

- Xu, H.; Li, M.; Wang, L.; Xu, M.; Ning, H.; Peng, J. Flexible AMOLED based on oxide TFT with high mobility. SID Symp. Dig. Tech. Pap. 2017, 48, 342–344. [Google Scholar]

- Fuh, C.S.; Liu, P.T.; Huang, W.H.; Sze, S.M. Effect of annealing on defect elimination for high mobility amorphous indium-zinc-tin-oxide thin-film transistor. IEEE Electron Device Lett. 2014, 35, 1103–1105. [Google Scholar] [CrossRef]

- Song, J.H.; Kim, K.S.; Mo, Y.G.; Choi, R.; Jeong, J.K. Achieving high field-effect mobility exceeding 50 cm2/Vs in In-Zn-Sn-O thin-film transistors. IEEE Electron Device Lett. 2014, 35, 853–855. [Google Scholar] [CrossRef]

- Mude, N.N.; Bukke, R.N.; Saha, J.K.; Avis, C.; Jang, J. Highly stable, solution-processed Ga-doped IZTO thin film transistor by Ar/O2 plasma treatment. Adv. Electron. Mater. 2019, 5, 1900768. [Google Scholar] [CrossRef]

- Lestari, A.D.; Noviyana, I.; Putri, M.; Heo, Y.W.; Lee, H.Y. Effect of the active channel thickness variation in amorphous In–Zn–Sn–O thin film transistor. Nanotechnology 2019, 19, 1686–1689. [Google Scholar] [CrossRef] [PubMed]

- Li, R.; Dai, S.; Su, J.; Ma, Y.; Wang, Y.; Zhou, D.; Zhang, X. Effect of thermal annealing on the electrical characteristics of an amorphous ITZO:Li thin film transistor fabricated using the magnetron sputtering method. Mater. Sci. Semicond. Process. 2019, 96, 8–11. [Google Scholar] [CrossRef]

- Ono, S.; Miwa, K.; Maekawa, Y.; Tsujimura, T. VT compensation circuit for AM OLED displays composed of two TFTs and one capacitor. IEEE Trans. Electron Devices 2007, 54, 462–467. [Google Scholar] [CrossRef]

- Kim, Y.; Kim, Y.; Lee, H. A novel a-InGaZnO TFT pixel circuit for AMOLED display with the enhanced reliability and aperture ratio. J. Disp. Technol. 2014, 10, 80–83. [Google Scholar] [CrossRef]

- Kim, D.; Kim, Y.; Lee, S.; Kang, M.S.; Kim, D.H.; Lee, H. High resolution a-IGZO TFT pixel circuit for compensating threshold voltage shifts and OLED degradations. IEEE J. Electron Devices Soc. 2017, 5, 372–377. [Google Scholar] [CrossRef]

- Lin, C.L.; Liu, Y.T.; Lee, C.E.; Chen, P.S.; Chu, T.C.; Hung, C.C. a-InGaZnO active-matrix organic LED pixel periodically detecting thin-film transistor threshold voltage once for multiple frames. IEEE Electron Device Lett. 2015, 36, 1166–1168. [Google Scholar] [CrossRef]

- Lai, P.C.; Lin, C.L.; Kanicki, J. Novel top-anode OLED/a-IGZO TFTs pixel circuit for 8K4K AM-OLEDs. IEEE Trans. Electron Devices 2019, 66, 436–444. [Google Scholar] [CrossRef]

- Sze, S.M. Physics of Semiconductor Devices; Wiley: New York, NY, USA; National Taiwan University Press: Taibei, Taiwan, 2018; pp. 186–192. [Google Scholar]

- In, H.J.; Kwon, O.K. External compensation of nonuniform electrical characteristics of thin-film transistors and degradation of OLED devices in AMOLED displays. IEEE Electron Device Lett. 2009, 30, 377–379. [Google Scholar]

| Reference | Driving Voltage (VDD & VSS) | VTH_DTFT Variation Error Rate | OLED Compensation | Eliminate in I-R Drop of VDD |

|---|---|---|---|---|

| This study | VDD = 4.5 V VSS = 0 V | 4.97% (ΔVTH = ±1 V) | O | O |

| [17] | VDD = 15 V VSS = 0 V | 7% (ΔVTH = ±2 V) | X | O |

| [18] | VDD = 15 ~ −5 V VSS = 0 V | 9.4% (ΔVTH = ±2 V) | O | O |

| [19] | VDD = 9.75 V VSS = −7 V | 4.14% (ΔVTH = +1 V) | O | O |

| [20] | VDD = 13 V VSS = −7 V | 4.42% (ΔVTH = ±2 V) | O | O |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fan, C.-L.; Tsao, H.-Y.; Chen, C.-Y.; Chou, P.-C.; Lin, W.-Y. New Low-Voltage Driving Compensating Pixel Circuit Based on High-Mobility Amorphous Indium-Zinc-Tin-Oxide Thin-Film Transistors for High-Resolution Portable Active-Matrix OLED Displays. Coatings 2020, 10, 1004. https://doi.org/10.3390/coatings10101004

Fan C-L, Tsao H-Y, Chen C-Y, Chou P-C, Lin W-Y. New Low-Voltage Driving Compensating Pixel Circuit Based on High-Mobility Amorphous Indium-Zinc-Tin-Oxide Thin-Film Transistors for High-Resolution Portable Active-Matrix OLED Displays. Coatings. 2020; 10(10):1004. https://doi.org/10.3390/coatings10101004

Chicago/Turabian StyleFan, Ching-Lin, Hou-Yen Tsao, Chun-Yuan Chen, Pei-Chieh Chou, and Wei-Yu Lin. 2020. "New Low-Voltage Driving Compensating Pixel Circuit Based on High-Mobility Amorphous Indium-Zinc-Tin-Oxide Thin-Film Transistors for High-Resolution Portable Active-Matrix OLED Displays" Coatings 10, no. 10: 1004. https://doi.org/10.3390/coatings10101004

APA StyleFan, C.-L., Tsao, H.-Y., Chen, C.-Y., Chou, P.-C., & Lin, W.-Y. (2020). New Low-Voltage Driving Compensating Pixel Circuit Based on High-Mobility Amorphous Indium-Zinc-Tin-Oxide Thin-Film Transistors for High-Resolution Portable Active-Matrix OLED Displays. Coatings, 10(10), 1004. https://doi.org/10.3390/coatings10101004