Superconducting HfO2-YBa2Cu3O7−δ Nanocomposite Films Deposited Using Ink-Jet Printing of Colloidal Solutions

Abstract

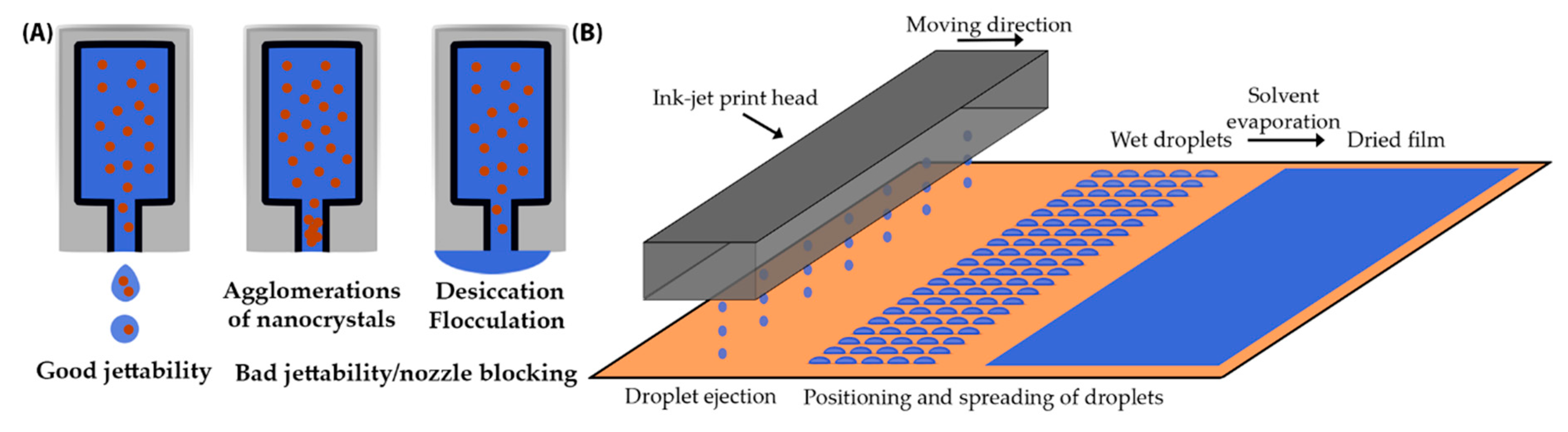

1. Introduction

2. Materials and Methods

2.1. YBCO Ink and Nano-Suspension Preparation and Characterization

2.2. Thin-Film Deposition and Thermal Treatment

2.3. Structural and Electrical Characterization

3. Results

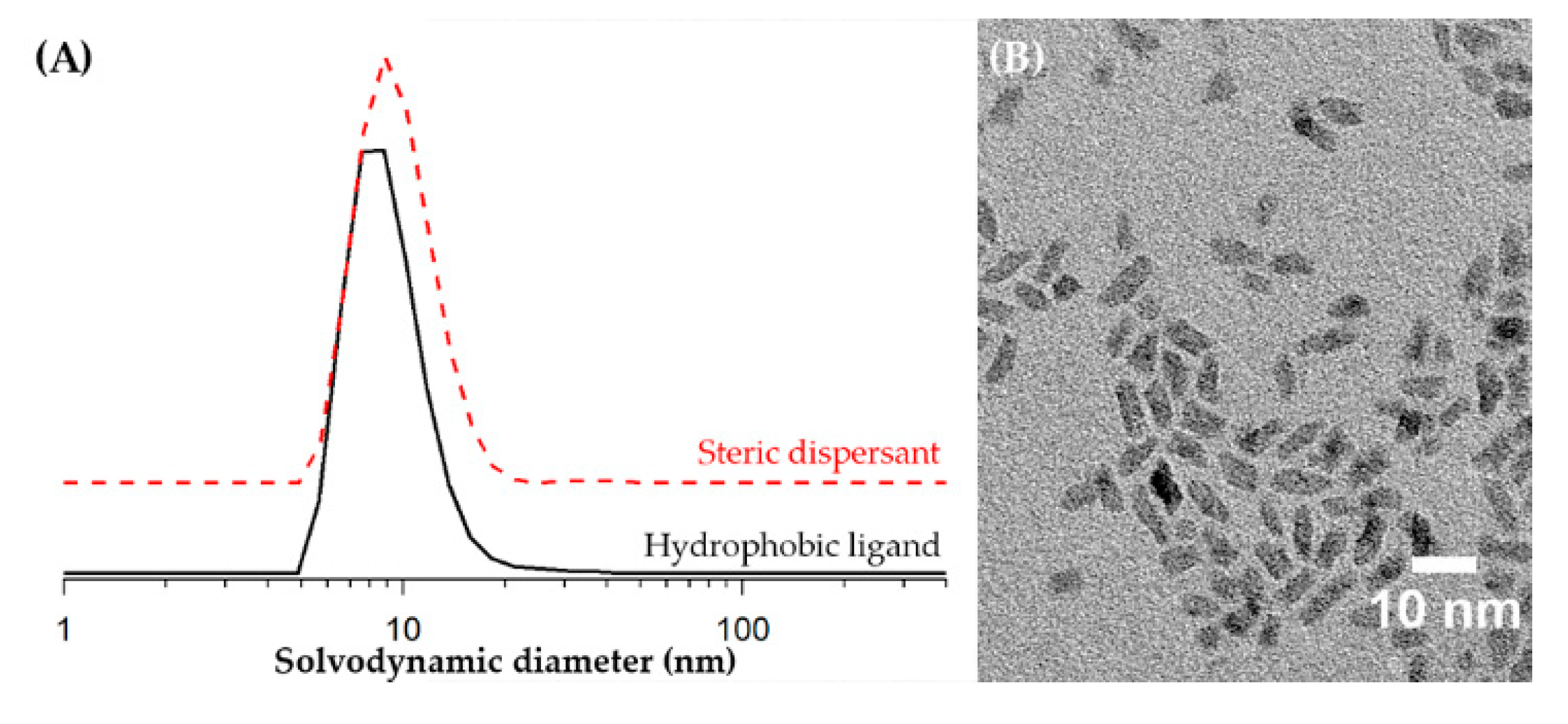

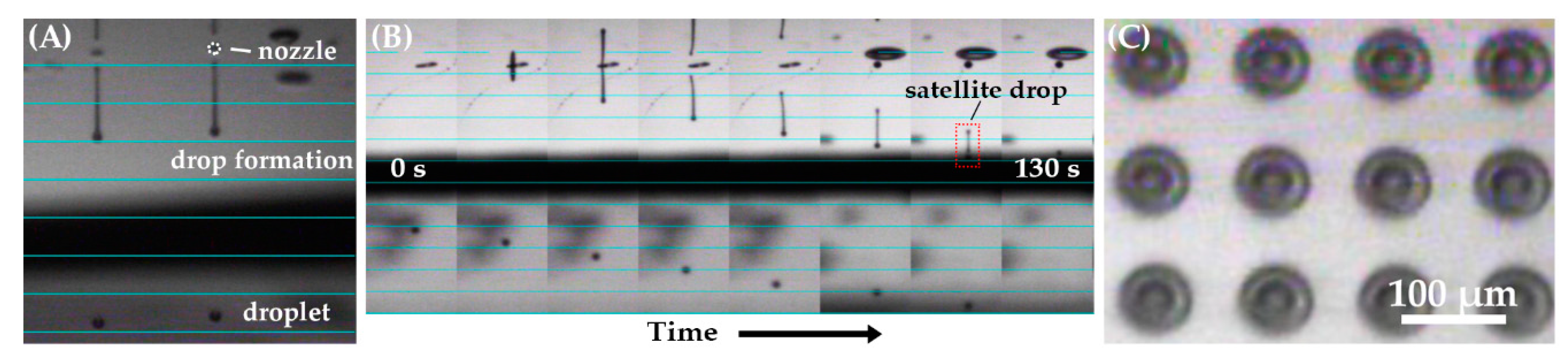

3.1. Physical Properties of the Pristine and HfO2-YBCO Inks

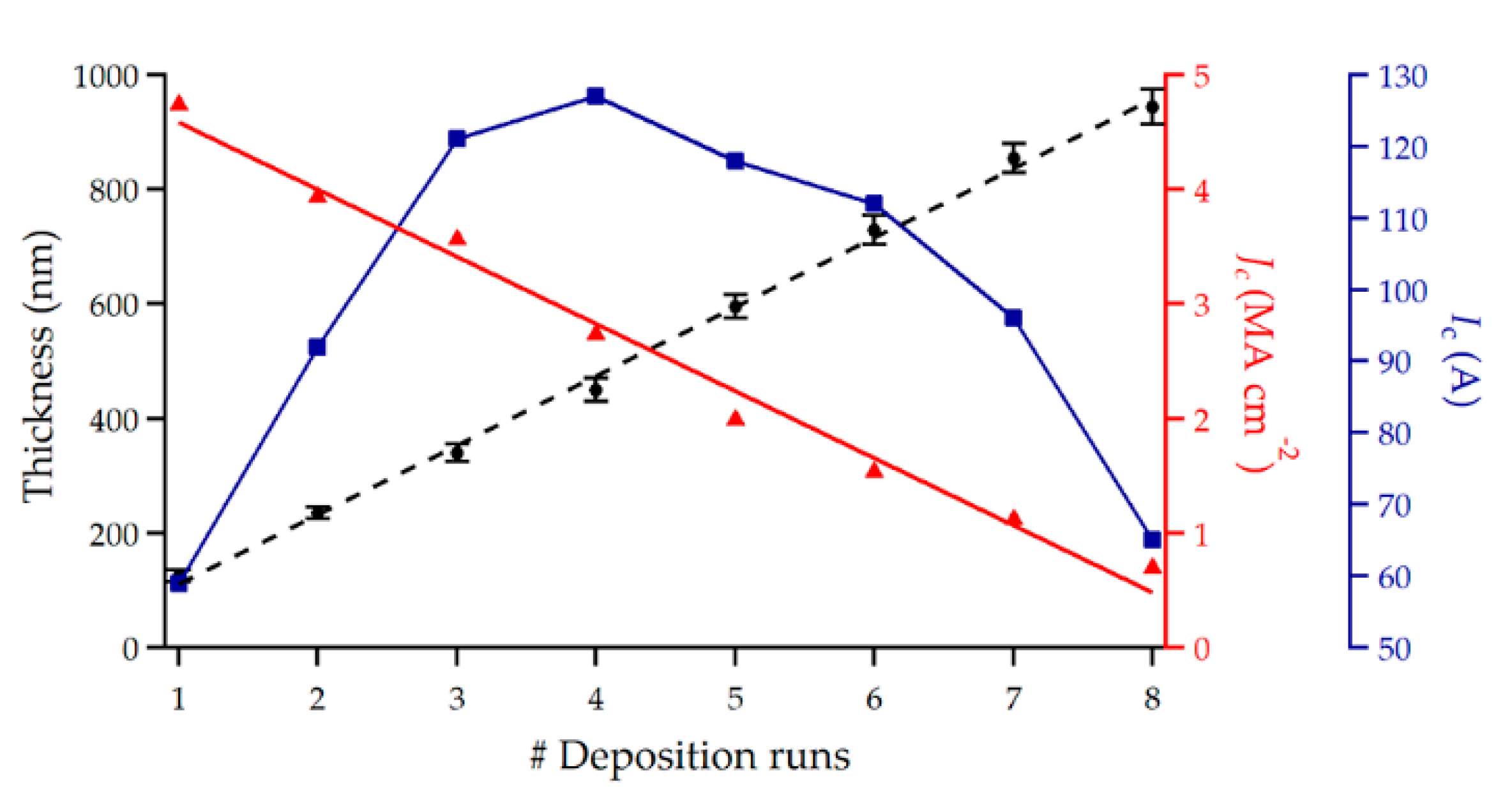

3.2. Multi-Deposition of Pristine YBCO Inks

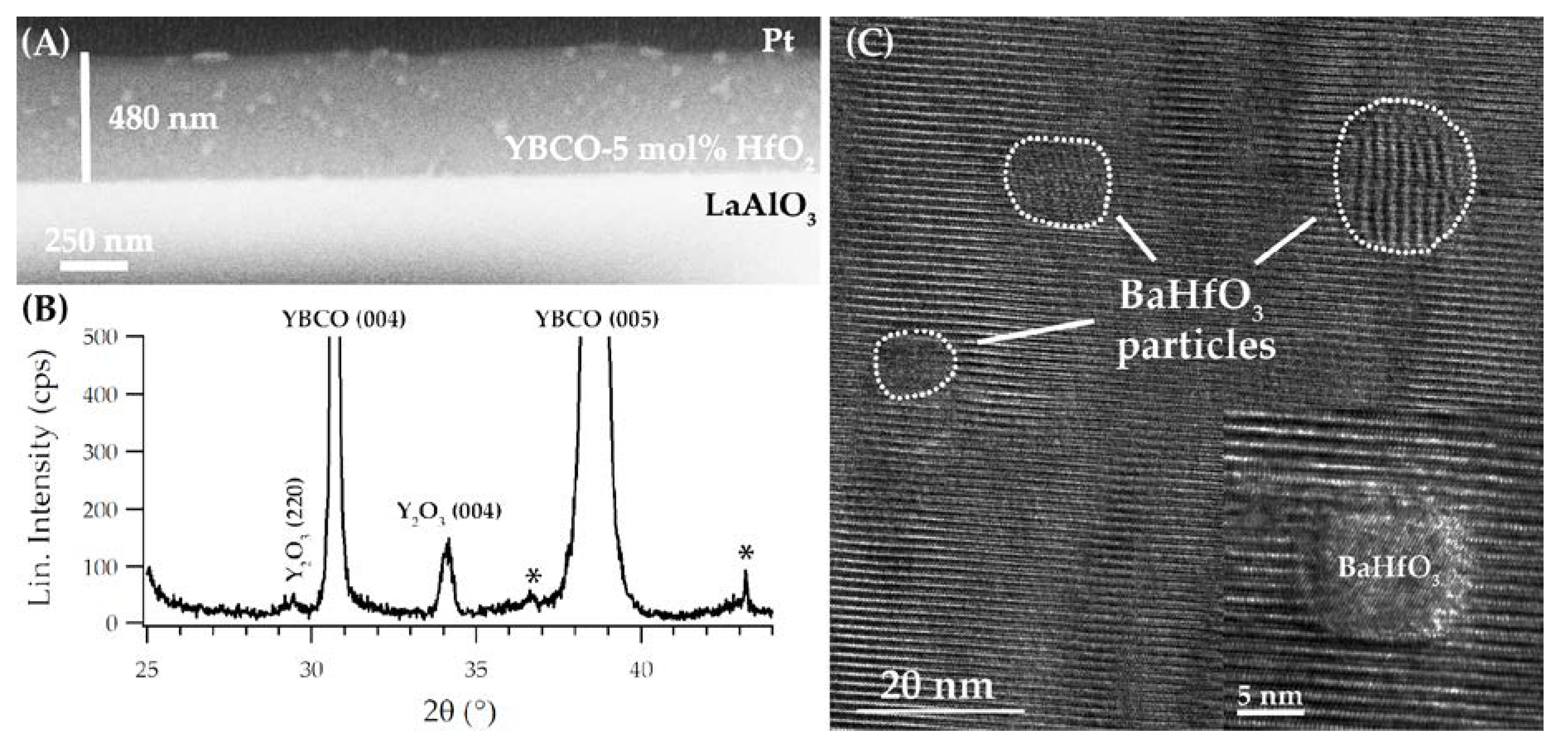

3.3. Multi-Deposition of HfO2-YBCO Inks

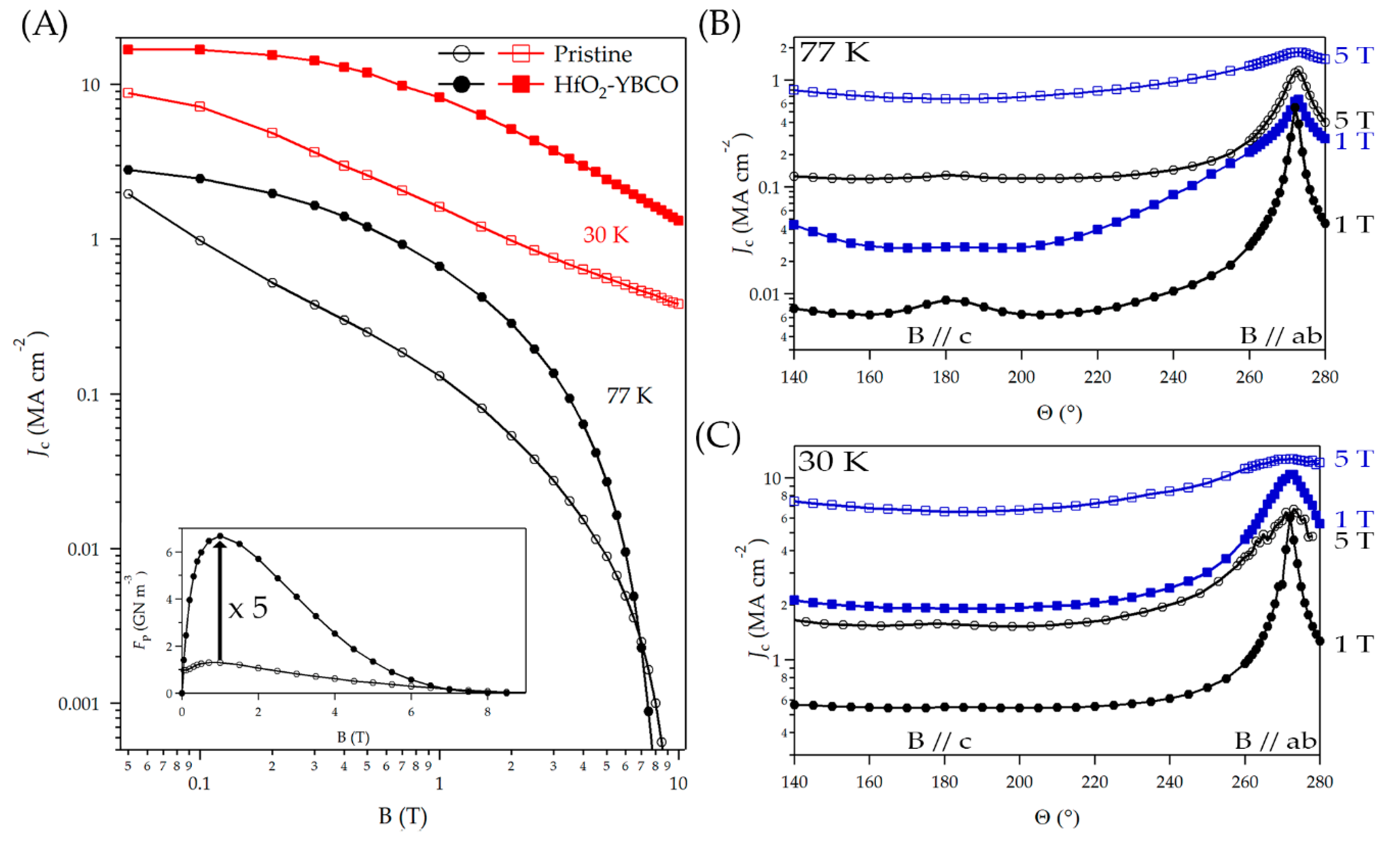

3.4. Transport Measurements of Pristine and HfO2-YBCO Films

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Obradors, X.; Puig, T. Coated conductors for power applications: Materials challenges. Supercond. Sci. Technol. 2014, 27, 044003. [Google Scholar] [CrossRef]

- Araki, T.; Hirabayashi, I. Review of a chemical approach to YBa2Cu3O7−x-coated superconductors—metalorganic deposition using trifluoroacetates. Supercond. Sci. Technol. 2003, 16, R71–R94. [Google Scholar] [CrossRef]

- Stadel, O.; Muydinov, R.Y.; Brauer, G.; Rikel, M.O.; Ehrenberg, J.; Bock, J.; Kotzyba, G.; Nast, R.; Goldacker, W.; Samoylenkov, S.V. MOCVD and MOD of YBCO and buffer layers on textured metal tapes. IEEE Trans. Appl. Supercond. 2009, 19, 3160–3163. [Google Scholar] [CrossRef]

- Chepikov, V.; Mineev, N.; Degtyarenko, P.; Lee, S.; Petrykin, V.; Ovcharov, A.; Vasiliev, A.; Kaul, A.; Amelichev, V.; Kamenev, A. Introduction of BaSnO3 and BaZrO3 artificial pinning centres into 2G HTS wires based on PLD-GdBCO films. Phase I of the industrial R&D programme at SuperOx. Supercond. Sci. Technol. 2017, 30, 124001. [Google Scholar] [CrossRef]

- Bäcker, M.; Baumann, A.; Brunkahl, O.; Erbe, M.; Schneller, T. Chemical Solution Deposition (CSD). Digit. Encycl. Appl. Phys. 2019, 1–34. [Google Scholar]

- George, J.; Smet, P.; Botterman, J.; Bliznuk, V.; Woestenborghs, W.; Van Thourhout, D.; Neyts, K.; Beeckman, J. Lanthanide-assisted deposition of strongly electro-optic PZT thin films on silicon: Toward integrated active nanophotonic devices. ACS Appl. Mater. Interfaces 2015, 7, 13350–13359. [Google Scholar] [CrossRef]

- Van Driessche, I.; Hopkins, S.; Lommens, P.; Granados, X.; Andreouli, D.; Glowacki, B.; Arabatzis, I.M.; Arin, M.; Ricart, S.; Fasaki, I. Efficient and environmentally friendly ink-jet printing of ceramic thin films. Nanosci. Nanotechnol. Lett. 2013, 5, 466–474. [Google Scholar] [CrossRef]

- Vernieuwe, K.; Feys, J.; Cuypers, D.; De Buysser, K. Ink-Jet Printing of Aqueous Inks for Single-Layer Deposition of Al-Doped ZnO Thin Films. J. Am. Ceram. Soc. 2016, 99, 1353–1359. [Google Scholar] [CrossRef]

- Obradors, X.; Puig, T.; Pomar, A.; Sandiumenge, F.; Mestres, N.; Coll, M.; Cavallaro, A.; Romà, N.; Gázquez, J.; González, J.C.; et al. Progress towards all-chemical superconducting YBa2Cu3O7-coated conductors. Supercond. Sci. Technol. 2006, 19, S13–S26. [Google Scholar] [CrossRef]

- Van Driessche, I.; Feys, J.; Vermeir, P.; Lommens, P.; Hopkins, S.C.; Granados, X.; Glowacki, B.A.; Baecker, M.; Reich, E.; Ricard, S.; et al. Ink-jet printing of YBa2Cu3O7 superconducting coatings and patterns from aqueous solutions. J. Mater. Chem. 2012, 22, 3717–3726. [Google Scholar] [CrossRef]

- Pollefeyt, G.; Rottiers, S.; Vermeir, P.; Lommens, P.; Hühne, R.; De Buysser, K.; Van Driessche, I. Feasibility study of the synthesis of YBiO3 thin films by aqueous chemical solution deposition as an alternative for CeO2 buffer layers in coated conductors. J. Mater. Chem. A 2013, 1, 3613–3619. [Google Scholar] [CrossRef]

- Puig, T.; Gutiérrez, J.; Pomar, A.; Llordés, A.; Gazquez, J.; Ricart, S.; Sandiumenge, F.; Obradors, X. Vortex pinning in chemical solution nanostructured YBCO films. Supercond. Sci. Technol. 2008, 21, 034008. [Google Scholar] [CrossRef]

- MacManus-Driscoll, J.; Foltyn, S.; Jia, Q.; Wang, H.; Serquis, A.; Civale, L.; Maiorov, B.; Hawley, M.; Maley, M.; Peterson, D. Strongly enhanced current densities in superconducting coated conductors of YBa2Cu3O7–x+BaZrO3. Nat. Mater. 2004, 3, 439–443. [Google Scholar] [CrossRef] [PubMed]

- Matsumoto, K.; Mele, P. Artificial pinning center technology to enhance vortex pinning in YBCO coated conductors. Supercond. Sci. Technol. 2010, 23, 014001. [Google Scholar] [CrossRef]

- Opherden, L.; Sieger, M.; Pahlke, P.; Hühne, R.; Schultz, L.; Meledin, A.; Van Tendeloo, G.; Nast, R.; Holzapfel, B.; Bianchetti, M. Large pinning forces and matching effects in YBa2Cu3O7−δ thin films with Ba2Y(Nb/Ta)O6 nano-precipitates. Sci. Rep. 2016, 6, 21188. [Google Scholar] [CrossRef]

- Malmivirta, M.; Rijckaert, H.; Paasonen, V.; Huhtinen, H.; Hynninen, T.; Jha, R.; Awana, V.S.; Van Driessche, I.; Paturi, P. Enhanced flux pinning in YBCO multilayer films with BCO nanodots and segmented BZO nanorods. Sci. Rep. 2017, 7, 14682. [Google Scholar] [CrossRef]

- Rizzo, F.; Augieri, A.; Kursumovic, A.; Bianchetti, M.; Opherden, L.; Sieger, M.; Hühne, R.; Hänisch, J.; Meledin, A.; Van Tendeloo, G. Pushing the limits of applicability of REBCO coated conductor films through fine chemical tuning and nanoengineering of inclusions. Nanoscale 2018, 10, 8187–8195. [Google Scholar] [CrossRef]

- Khan, M.Z.; Rivasto, E.; Tikkanen, J.; Rijckaert, H.; Malmivirta, M.; Liedke, M.O.; Butterling, M.; Wagner, A.; Huhtinen, H.; Van Driessche, I. Enhanced flux pinning isotropy by tuned nanosized defect network in superconducting YBa2Cu3O6+x films. Sci. Rep. 2019, 9, 1–12. [Google Scholar] [CrossRef]

- Coll, M.; Guzman, R.; Garcés, P.; Gazquez, J.; Rouco, V.; Palau, A.; Ye, S.; Magen, C.; Suo, H.; Castro, H.; et al. Size-controlled spontaneously segregated Ba2YTaO6 nanoparticles in YBa2Cu3O7 nanocomposites obtained by chemical solution deposition. Supercond. Sci. Technol. 2014, 27, 044008. [Google Scholar] [CrossRef]

- Horita, H.; Teranishi, R.; Yamada, K.; Kaneko, K.; Sato, Y.; Otaguro, K.; Nishiyama, T.; Izumi, T.; Awaji, S. Miniaturization of BaHfO3 nanoparticles in YBa2Cu3Oy-coated conductors using a two-step heating process in the TFA-MOD method. Supercond. Sci. Technol. 2016, 30, 025022. [Google Scholar] [CrossRef]

- Miura, M.; Maiorov, B.; Sato, M.; Kanai, M.; Kato, T.; Kato, T.; Izumi, T.; Awaji, S.; Mele, P.; Kiuchi, M.; et al. Tuning nanoparticle size for enhanced functionality in perovskite thin films deposited by metal organic deposition. NPG Asia Mater. 2017, 9, e447. [Google Scholar] [CrossRef]

- Cayado, P.; De Keukeleere, K.; Garzón, A.; Perez-Mirabet, L.; Meledin, A.; De Roo, J.; Vallés, F.; Mundet, B.; Rijckaert, H.; Pollefeyt, G.; et al. Epitaxial YBa2Cu3O7−x nanocomposite thin films from colloidal solutions. Supercond. Sci. Technol. 2015, 28, 124007. [Google Scholar] [CrossRef]

- De Keukeleere, K.; Cayado, P.; Meledin, A.; Vallès, F.; De Roo, J.; Rijckaert, H.; Pollefeyt, G.; Bruneel, E.; Palau, A.; Coll, M.; et al. Superconducting YBa2Cu3O7−δ Nanocomposites Using Preformed ZrO2 Nanocrystals: Growth Mechanisms and Vortex Pinning Properties. Adv. Electron. Mater. 2016, 2, 1600161. [Google Scholar] [CrossRef]

- Rijckaert, H.; Pollefeyt, G.; Sieger, M.; Hänisch, J.; Bennewitz, J.; De Keukeleere, K.; De Roo, J.; Hühne, R.; Bäcker, M.; Paturi, P.; et al. Optimizing Nanocomposites through Nanocrystal Surface Chemistry: Superconducting YBa2Cu3O7 Thin Films via Low-Fluorine Metal Organic Deposition and Preformed Metal Oxide Nanocrystals. Chem. Mater. 2017, 29, 6104–6113. [Google Scholar] [CrossRef]

- Rijckaert, H.; De Roo, J.; Van Zele, M.; Banerjee, S.; Huhtinen, H.; Paturi, P.; Bennewitz, J.; Billinge, S.; Bäcker, M.; De Buysser, K. Pair Distribution Function Analysis of ZrO2 Nanocrystals and Insights in the Formation of ZrO2-YBa2Cu3O7 Nanocomposites. Materials 2018, 11, 1066. [Google Scholar] [CrossRef]

- Gutierrez, J.; Llordes, A.; Gazquez, J.; Gibert, M.; Roma, N.; Ricart, S.; Pomar, A.; Sandiumenge, F.; Mestres, N.; Puig, T. Strong isotropic flux pinning in solution-derived YBa2Cu3O7−x nanocomposite superconductor films. Nat. Mater. 2007, 6, 367–373. [Google Scholar] [CrossRef] [PubMed]

- Aye, M.M.; Khan, M.Z.; Rivasto, E.; Tikkanen, J.; Huhtinen, H.; Paturi, P. Role of columnar defect size in angular dependent flux pinning properties of YBCO thin films. IEEE Trans. Appl. Supercond. 2019, 29, 1–5. [Google Scholar] [CrossRef]

- Rijckaert, H.; De Roo, J.; Roeleveld, K.; Pollefeyt, G.; Bennewitz, J.; Bäcker, M.; Lynen, F.; De Keukeleere, K.; Van Driessche, I. Microwave-assisted YBa2Cu3O7 precursors: A fast and reliable method towards chemical precursors for superconducting films. J. Am. Ceram. Soc. 2017, 100, 2407–2418. [Google Scholar] [CrossRef]

- Abbel, R.; Galagan, Y.; Groen, P. Roll-to-Roll Fabrication of Solution Processed Electronics. Adv. Eng. Mater. 2018, 20, 1701190. [Google Scholar] [CrossRef]

- Sumption, M.; Collings, E.; Barnes, P. AC loss in striped (filamentary) YBCO coated conductors leading to designs for high frequencies and field-sweep amplitudes. Supercond. Sci. Technol. 2004, 18, 122. [Google Scholar] [CrossRef]

- Nast, R.; Vojenčiak, M.; Demencik, E.; Kario, A.; Ringsdorf, B.; Jung, A.; Runtsch, B.; Grilli, F.; Goldacker, W. Influence of laser striations on the properties of coated conductors. J. Phys. Conf. Ser. 2014, 507, 022023. [Google Scholar] [CrossRef]

- Hopkins, S.; Joseph, D.; Mitchell-Williams, T.; Calleja, A.; Vlad, V.; Vilardell, M.; Ricart, S.; Granados, X.; Puig, T.; Obradors, X. Inkjet printing of multifilamentary YBCO for low AC loss coated conductors. J. Phys. Conf. Ser. 2014, 507, 022010. [Google Scholar] [CrossRef]

- Van Driessche, I.; Feys, J.; Hopkins, S.C.; Lommens, P.; Granados, X.; Glowacki, B.A.; Ricart, S.; Holzapfel, B.; Vilardell, M.; Kirchner, A.; et al. Chemical solution deposition using ink-jet printing for YBCO coated conductors. Supercond. Sci. Technol. 2012, 25, 065017. [Google Scholar] [CrossRef]

- Pop, C.; Villarejo, B.; Pino, F.; Mundet, B.; Ricart, S.; de Palau, M.; Puig, T.; Obradors, X. Growth of all-chemical high critical current YBa2Cu3O7−δ thick films and coated conductors. Supercond. Sci. Technol. 2018, 32, 015004. [Google Scholar] [CrossRef]

- Obradors, X.; Puig, T.; Li, Z.; Pop, C.; Mundet, B.; Chamorro, N.; Valles, F.; Bau, M.C.; Ricart, S.; Villarejo, B. Epitaxial YBa2Cu3O7−x nanocomposite films and coated conductors from BaMO3 (M = Zr, Hf) colloidal solutions. Supercond. Sci. Technol. 2018, 31, 044001. [Google Scholar] [CrossRef]

- Rijckaert, H.; Van Driessche, I. Superconducting YBa2Cu3O7−δ Nanocomposite Films Using Preformed ZrO2 Nanocrystals via Chemical Solution Deposition. In Superconductivity: From Materials Science to Practical Applications; Mele, P., Prassides, K., Tarantini, C., Palau, A., Badica, P., Jha, A.K., Endo, T., Eds.; Springer International Publishing: Cham, Germany, 2020; pp. 133–167. [Google Scholar]

- Tang, J.; Fabbri, J.; Robinson, R.D.; Zhu, Y.; Herman, I.P.; Steigerwald, M.L.; Brus, L.E. Solid-Solution Nanoparticles: Use of a Nonhydrolytic Sol-Gel Synthesis To Prepare HfO2 and HfxZr1−xO2 Nanocrystals. Chem. Mater. 2004, 16, 1336–1342. [Google Scholar] [CrossRef]

- De Keukeleere, K.; Coucke, S.; De Canck, E.; Van Der Voort, P.; Delpech, F.; Coppel, Y.; Hens, Z.; Van Driessche, I.; Owen, J.S.; De Roo, J. Stabilization of Colloidal Ti, Zr, and Hf Oxide Nanocrystals by Protonated Tri-n-octylphosphine Oxide (TOPO) and Its Decomposition Products. Chem. Mater. 2017, 29, 10233–10242. [Google Scholar] [CrossRef]

- Rijckaert, H.; Hänisch, J.; Pollefeyt, G.; Bäcker, M.; Van Driessche, I. Influence of Ba2+ consumption and intermediate dwelling during processing of YBa2Cu3O7 nanocomposite films. J. Am. Ceram. Soc. 2019, 102, 3870–3878. [Google Scholar] [CrossRef]

- Van Zele, M.; Watté, J.; Hasselmeyer, J.; Rijckaert, H.; Vercammen, Y.; Verstuyft, S.; Deduytsche, D.; Debecker, D.; Poleunis, C.; Van Driessche, I. Thickness Characterization Toolbox for Transparent Protective Coatings on Polymer Substrates. Materials 2018, 11, 1101. [Google Scholar] [CrossRef]

- Derby, B. Inkjet printing of functional and structural materials: Fluid property requirements, feature stability, and resolution. Annu. Rev. Mater. Res. 2010, 40, 395–414. [Google Scholar] [CrossRef]

- De Roo, J.; Coucke, S.; Rijckaert, H.; De Keukeleere, K.; Sinnaeve, D.; Hens, Z.; Martins, J.C.; Van Driessche, I. Amino Acid-Based Stabilization of Oxide Nanocrystals in Polar Media: From Insight in Ligand Exchange to Solution 1H NMR Probing of Short-Chained Adsorbates. Langmuir 2016, 32, 1962–1970. [Google Scholar] [CrossRef] [PubMed]

- De Keukeleere, K.; Pollefeyt, G.; Feys, J.; De Roo, J.; Rijckaert, H.; Lommens, P.; Van Driessche, I. Chemical solution deposition of functional ceramic coatings using ink-jet printing. Pure Appl. Chem. 2015, 87, 231–238. [Google Scholar] [CrossRef]

- Hengstberger, F.; Eisterer, M.; Weber, H. Thickness dependence of the critical current density in superconducting films: A geometrical approach. Appl. Phys. Lett. 2010, 96, 022508. [Google Scholar] [CrossRef]

- Smith, J.; Cima, M.; Sonnenberg, N. High critical current density thick MOD-derived YBCO films. IEEE Trans. Appl. Supercond. 1999, 9, 1531–1534. [Google Scholar] [CrossRef]

- Boubeche, M.; Cai, C.; Jian, H.; Li, M.; Yang, W.; Liu, Z.; Bai, C. Thick REBaCuO superconducting films through single-coating of low-fluorine metallorganic solution. Cryogenics 2016, 79, 49–52. [Google Scholar] [CrossRef]

- Kim, S.; Gurevich, A.; Song, X.; Li, X.; Zhang, W.; Kodenkandath, T.; Rupich, M.; Holesinger, T.; Larbalestier, D. Mechanisms of weak thickness dependence of the critical current density in strong-pinning ex situ metal–organic-deposition-route YBa2Cu3O7−x coated conductors. Supercond. Sci. Technol. 2006, 19, 968. [Google Scholar] [CrossRef]

- Vilardell, M.; Granados, X.; Ricart, S.; Van Driessche, I.; Palau, A.; Puig, T.; Obradors, X. Flexible manufacturing of functional ceramic coatings by inkjet printing. Thin Solid Film. 2013, 548, 489–497. [Google Scholar] [CrossRef]

- Llordés, A.; Palau, A.; Gázquez, J.; Coll, M.; Vlad, R.; Pomar, A.; Arbiol, J.; Guzmán, R.; Ye, S.; Rouco, V.; et al. Nanoscale strain-induced pair suppression as a vortex-pinning mechanism in high-temperature superconductors. Nat. Mater. 2012, 11, 329–336. [Google Scholar] [CrossRef]

- Erbe, M.; Hänisch, J.; Hühne, R.; Freudenberg, T.; Kirchner, A.; Molina-Luna, L.; Damm, C.; Van Tendeloo, G.; Kaskel, S.; Schultz, L. BaHfO3 artificial pinning centres in TFA-MOD-derived YBCO and GdBCO thin films. Supercond. Sci. Technol. 2015, 28, 114002. [Google Scholar] [CrossRef]

- Kang, H.M.; Baek, S.-H.; Song, J.H.; Cho, Y.S.; Choi, J.-W. Full Range Dielectric Characteristics of Calcium Copper Titanate Thin Films Prepared by Continuous Composition-Spread Sputtering. ACS Comb. Sci. 2014, 16, 478–484. [Google Scholar] [CrossRef]

- Jung, J.; Yim, H.; Parmar, N.S.; Lee, J.-S.; Choi, J.-W. Continuous Composition Spread and Electrochemical Studies of Low Cobalt Content Li (Ni,Mn,Co)O2 Cathode Materials. Coatings 2019, 9, 366. [Google Scholar] [CrossRef]

- Von Wenckstern, H.; Zhang, Z.; Schmidt, F.; Lenzner, J.; Hochmuth, H.; Grundmann, M. Continuous composition spread using pulsed-laser deposition with a single segmented target. CrystEngComm 2013, 15, 10020–10027. [Google Scholar] [CrossRef]

- Mohammadi, F. Design and electrification of an electric vehicle using lithium-ion batteries. In Proceedings of the 3rd International Conference on Electrical Engineering, Tehran, Iran, 7 September 2018; pp. 2–3. [Google Scholar]

- Billet, J.; Dujardin, W.; De Keukeleere, K.; De Buysser, K.; De Roo, J.; Van Driessche, I. Size Tunable Synthesis and Surface Chemistry of Metastable TiO2-Bronze Nanocrystals. Chem. Mater. 2018, 30, 4298–4306. [Google Scholar] [CrossRef]

- Cayado, P.; Rijckaert, H.; Erbe, M.; Langer, M.; Jung, A.; Hänisch, J.; Holzapfel, B. CSD-Grown Y1−xGdxBa2Cu3O7−δ-BaHfO3 Nanocomposite Films on Ni5W and IBAD Technical Substrates. Nanomaterials 2020, 10, 21. [Google Scholar] [CrossRef]

| Type of YBCO Ink | Density ρ | Viscosity η | Surface Tension γ | Contact Angle θC | Oh−1 |

|---|---|---|---|---|---|

| (kg∙m−3) | (Pa∙s) | (N∙m−1) | (°) | ||

| Pristine | 918 | 6.4 × 10−3 | 2.21 × 10−2 | 14.1 | 3.23 |

| 5 mol% HfO2 | 946 | 6.4 × 10−3 | 2.34 × 10−2 | 14.6 | 3.37 |

| 10 mol% HfO2- | 961 | 6.4 × 10−3 | 2.44 × 10−2 | 15.0 | 3.47 |

| Type of YBCO Film | Thickness | Critical Current Densities |

|---|---|---|

| (nm) | (MA∙cm−2) | |

| Pristine YBCO film in this work | 450 | 2.7 |

| Trifluoroacetic based pristine YBCO film [48] | 400 | 2.7 |

| Low-fluorine based pristine YBCO film [34] | 600–1200 | 2.0–2.7 |

| Preparation Route of Pristine and Nanocomposite YBCO Film | Critical Current Density (Jc, MA∙cm−2) | Maximum Pinning Force Density (Fp,max, GN∙m−3) | Factor | ||

|---|---|---|---|---|---|

| Pristine | Nanocomposite | Pristine | Nanocomposite | ||

| Trifluoroacetic route with ZrO2 nanocrystals and a seed layer [23]. | 4.0 | 5.0 | 2.0 | 6.0 | 3.0 |

| Propionate route with ZrO2 nanocrystals and an adjusted thermal two-step process [39]. | 5.5 | 5.8 | 3.0 | 7.3 | 2.4 |

| Propionate route with HfO2 nanocrystals in this work. | 2.7 | 3.1 | 1.3 | 6.8 | 5.2 |

| Propionate route with ZrO2 nanocrystals with a careful ligand choice [24]. | 4.7 | 5.2 | 1.6 | 5.5 | 3.5 |

| Trifluoroacetic route with self-assembled BaHfO3 particles [50]. | 3.5 | 4.5 | 1.2 | 2.1 | 1.8 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rijckaert, H.; Cayado, P.; Nast, R.; Diez Sierra, J.; Erbe, M.; López Dominguez, P.; Hänisch, J.; De Buysser, K.; Holzapfel, B.; Van Driessche, I. Superconducting HfO2-YBa2Cu3O7−δ Nanocomposite Films Deposited Using Ink-Jet Printing of Colloidal Solutions. Coatings 2020, 10, 17. https://doi.org/10.3390/coatings10010017

Rijckaert H, Cayado P, Nast R, Diez Sierra J, Erbe M, López Dominguez P, Hänisch J, De Buysser K, Holzapfel B, Van Driessche I. Superconducting HfO2-YBa2Cu3O7−δ Nanocomposite Films Deposited Using Ink-Jet Printing of Colloidal Solutions. Coatings. 2020; 10(1):17. https://doi.org/10.3390/coatings10010017

Chicago/Turabian StyleRijckaert, Hannes, Pablo Cayado, Rainer Nast, Javier Diez Sierra, Manuela Erbe, Pedro López Dominguez, Jens Hänisch, Klaartje De Buysser, Bernhard Holzapfel, and Isabel Van Driessche. 2020. "Superconducting HfO2-YBa2Cu3O7−δ Nanocomposite Films Deposited Using Ink-Jet Printing of Colloidal Solutions" Coatings 10, no. 1: 17. https://doi.org/10.3390/coatings10010017

APA StyleRijckaert, H., Cayado, P., Nast, R., Diez Sierra, J., Erbe, M., López Dominguez, P., Hänisch, J., De Buysser, K., Holzapfel, B., & Van Driessche, I. (2020). Superconducting HfO2-YBa2Cu3O7−δ Nanocomposite Films Deposited Using Ink-Jet Printing of Colloidal Solutions. Coatings, 10(1), 17. https://doi.org/10.3390/coatings10010017