A Comprehensive Review on Significance and Advancements of Antimicrobial Agents in Biodegradable Food Packaging

Abstract

1. Introduction

2. Classification of Antimicrobial Agents

3. Types of Antimicrobial Agent

3.1. Natural Antimicrobial Agent

3.2. Plant-Based Antimicrobial Agent

3.3. Animal and Microbe-Based Antimicrobial Agent

3.4. Chemical Antimicrobial Agent

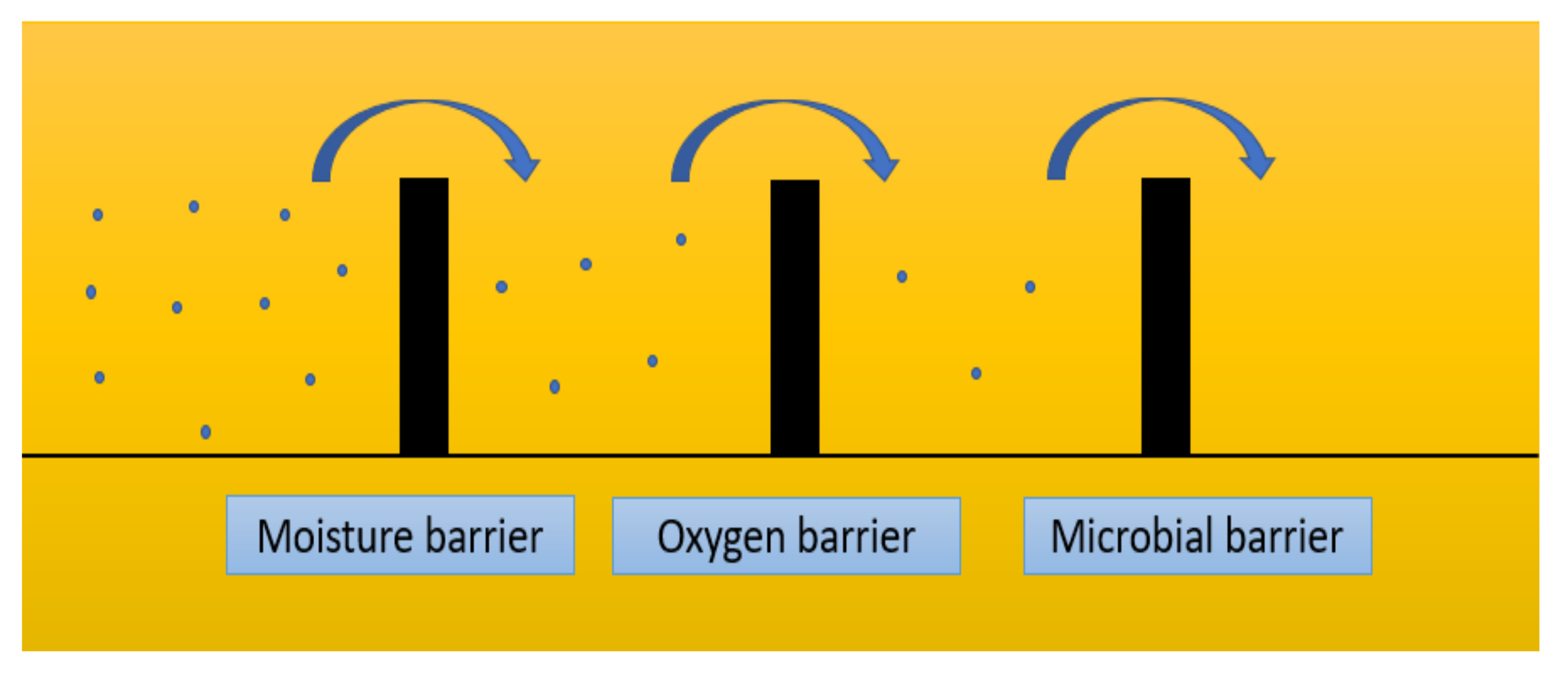

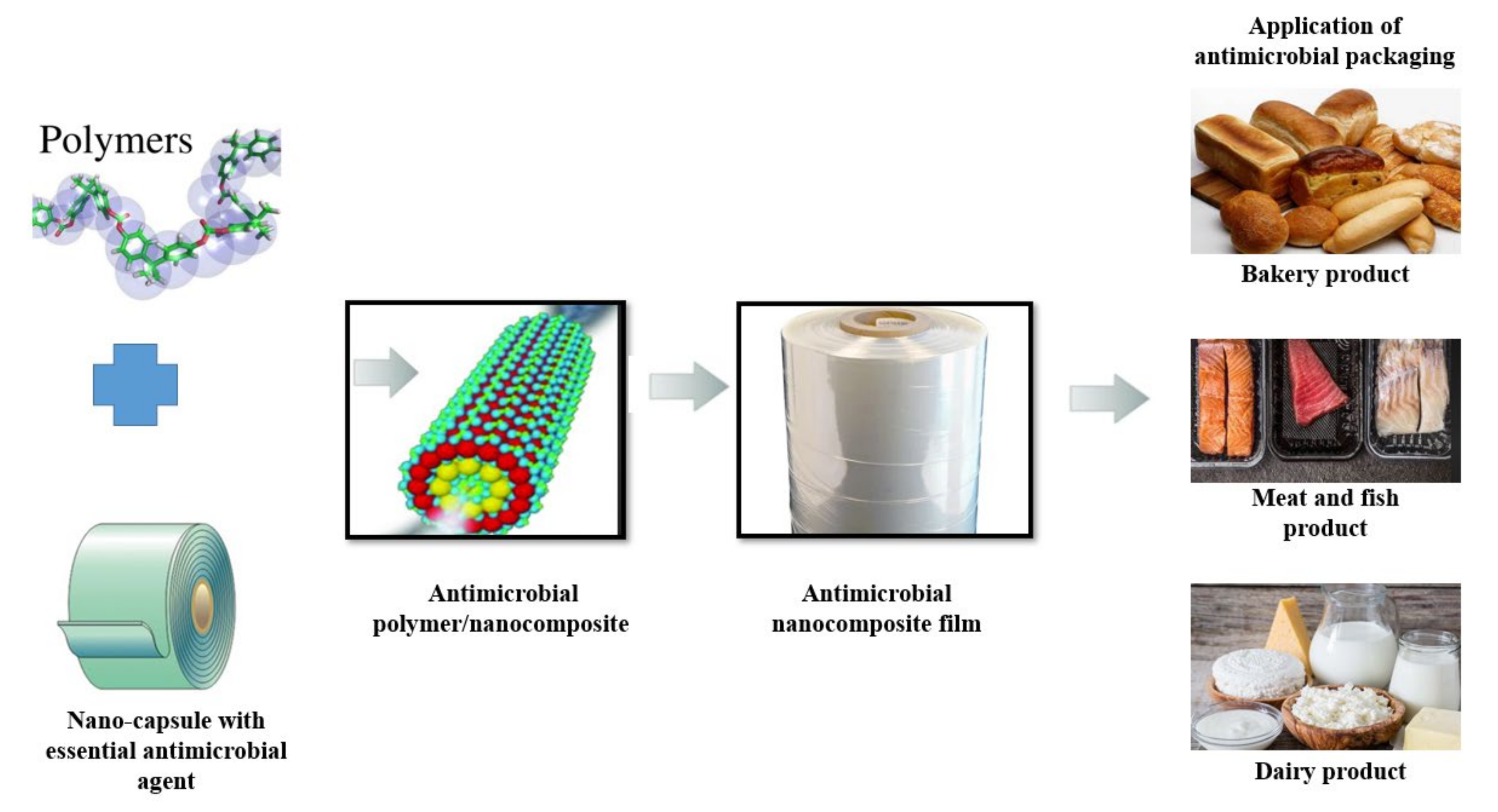

4. Potential Applications of Antimicrobial Packaging in Food

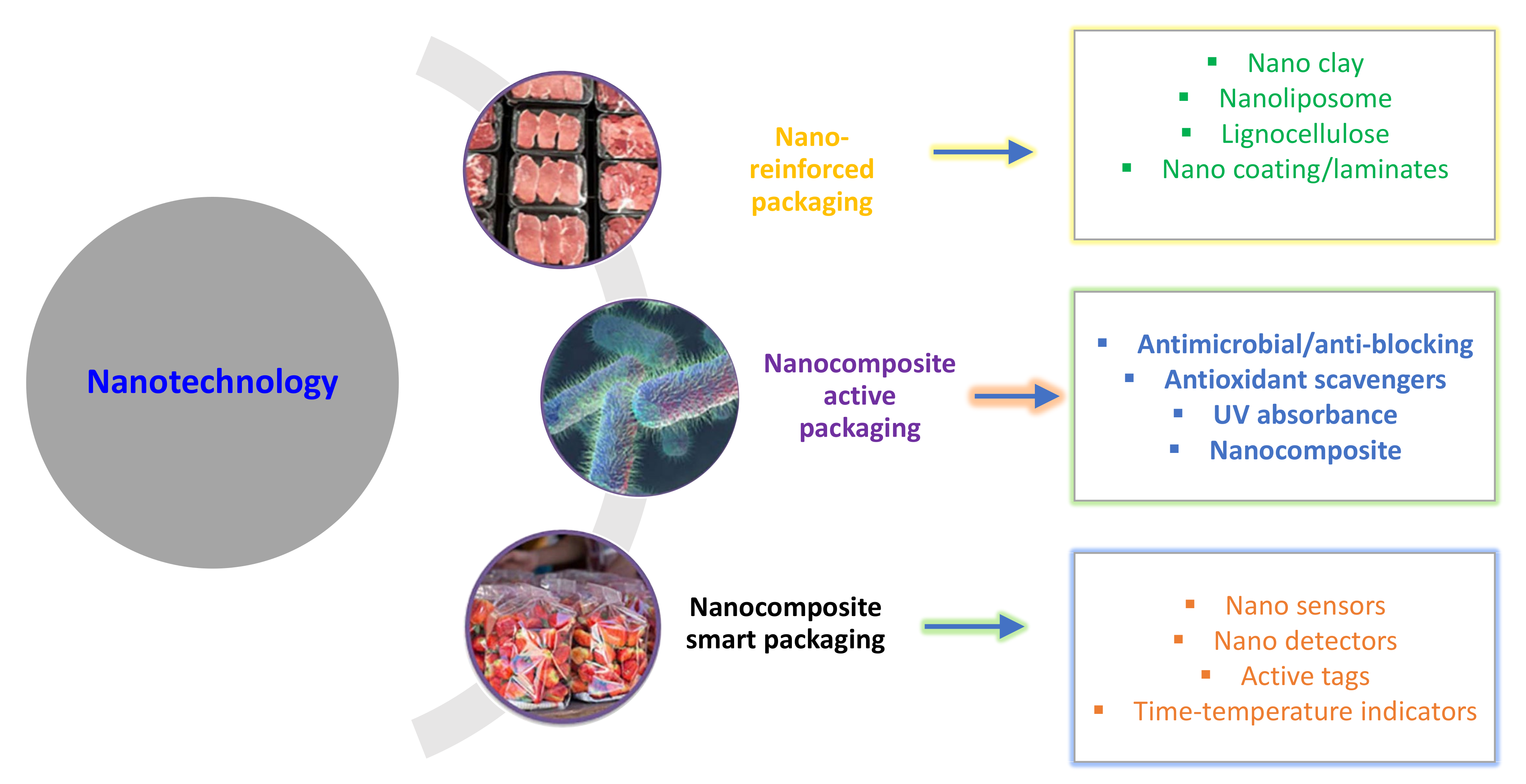

5. Nanotechnological Interventions of Green Antimicrobial Packaging

6. Sustainable Contribution to the Society

7. Conclusions and Future Prospects

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Mahmud, N.; Islam, J.; Tahergorabi, R. Marine Biopolymers: Applications in Food Packaging. Processes 2021, 9, 2245. [Google Scholar] [CrossRef]

- Zhang, W.; Roy, S.; Rhim, J.-W. Copper-based nanoparticles for biopolymer-based functional films in food packaging applications. Compr. Rev. Food Sci. Food Saf. 2023, 22, 1933–1952. [Google Scholar] [CrossRef] [PubMed]

- Grzebieniarz, W.; Biswas, D.; Roy, S.; Jamróz, E. Advances in Biopolymer-Based Multi-Layer Film Preparations and Food Packaging Applications. Food Packag. Shelf Life 2023, 35, 101033. [Google Scholar] [CrossRef]

- Singh, N.; Hui, D.; Singh, R.; Ahuja, I.P.S.; Feo, L.; Fraternali, F. Recycling of Plastic Solid Waste: A State of Art Review and Future Applications. Compos. B Eng. 2017, 115, 409–422. [Google Scholar] [CrossRef]

- Zhong, Y.; Godwin, P.; Jin, Y.; Xiao, H. Biodegradable Polymers and Green-Based Antimicrobial Packaging Materials: A Mini-Review. Adv. Ind. Eng. Polym. Res. 2020, 3, 27–35. [Google Scholar] [CrossRef]

- Ghosh, S.; Roy, S.; Naskar, J.; Kole, R.K. Plant-mediated synthesis of mono and bimetallic (Au-Ag) nanoparticles: Future prospects for food quality and safety. J. Nanomater. 2023, 2023, 2781667. [Google Scholar] [CrossRef]

- Yadav, D.; Borpatra Gohain, M.; Karki, S.; Ingole, P.G. A Novel Approach for the Development of Low-Cost Polymeric Thin-Film Nanocomposite Membranes for the Biomacromolecule Separation. ACS Omega 2022, 7, 47967–47985. [Google Scholar] [CrossRef]

- Mousavi Khaneghah, A.M.; Hashemi, S.M.B.; Limbo, S. Antimicrobial Agents and Packaging Systems in Antimicrobial Active Food Packaging: An Overview of Approaches and Interactions. Food Bioprod. Process. 2018, 111, 1–19. [Google Scholar] [CrossRef]

- Ramakrishnan, R.; Kulandhaivelu, S.V.; Roy, S. Alginate/carboxymethyl cellulose/starch-based active coating with grapefruit seed extract to extend the shelf life of green chilli. Ind. Crops Prod. 2023, 199, 116752. [Google Scholar] [CrossRef]

- Zhang, W.; Roy, S.; Ezati, P.; Yang, D.P.; Rhim, J.-W. Tannic acid: A green crosslinker for biopolymer-based food packaging films. Trends Food Sci. Technol. 2023, 136, 11–23. [Google Scholar] [CrossRef]

- Santos, J.C.P.; Sousa, R.C.S.; Otoni, C.G.; Moraes, A.R.F.; Souza, V.G.L.; Medeiros, E.A.A.; Espitia, P.J.P.; Pires, A.C.S.; Coimbra, J.S.R.; Soares, N.F.F. Nisin and Other Antimicrobial Peptides: Production, Mechanisms of Action, and Application in Active Food Packaging. Innov. Food Sci. Emerg. Technol. 2018, 48, 179–194. [Google Scholar] [CrossRef]

- Angane, M.; Swift, S.; Huang, K.; Butts, C.A.; Quek, S.Y. Essential Oils and Their Major Components: An Updated Review on Antimicrobial Activities, Mechanism of Action and Their Potential Application in the Food Industry. Foods 2022, 11, 464. [Google Scholar] [CrossRef] [PubMed]

- Dıblan, S.; Kaya, S. Antimicrobials Used in Active Packaging Films. Food Health 2018, 4, 63–79. [Google Scholar] [CrossRef]

- Paidari, S.; Ahari, H.; Pasqualone, A.; Anvar, A.; Beyk, S.A.Y.; Moradi, S. Bio-nanocomposites and their potential applications in physiochemical properties of cheese: An updated review. J. Food Meas. Charact. 2023, 17, 2595–2606. [Google Scholar] [CrossRef]

- Malagurski, I.; Levic, S.; Nesic, A.; Mitric, M.; Pavlovic, V.; Dimitrijevic-Brankovic, S. Mineralized Agar-Based Nanocomposite Films: Potential Food Packaging Materials with Antimicrobial Properties. Carbohydr. Polym. 2017, 175, 55–62. [Google Scholar] [CrossRef] [PubMed]

- Roy, S.; Priyadarshi, R.; Łopusiewicz, Ł.; Biswas, D.; Chandel, V.; Rhim, J.-W. Recent progress in pectin extraction, characterization, and pectin-based films for active food packaging applications: A review. Int. J. Biol. Macromol. 2023, 239, 124248. [Google Scholar] [CrossRef] [PubMed]

- Ebrahimzadeh, S.; Biswas, D.; Roy, S.; McClements, D.J. Incorporation of essential oils in edible seaweed-based films: A comprehensive review. Trends Food Sci. Technol. 2023, 135, 43–56. [Google Scholar] [CrossRef]

- Priyadarshi, P.; Roy, S.; Ghosh, T.; Biswas, D.; Rhim, J.-W. Antimicrobial nanofillers reinforced biopolymer composite films for active food packaging applications—A review. Sustain. Mater. Technol. 2022, 32, e00353. [Google Scholar] [CrossRef]

- Khare, S.; De Loid, G.M.; Molina, R.M.; Gokulan, K.; Couvillion, S.P.; Bloodsworth, K.J.; Eder, E.K.; Wong, A.R.; Hoyt, D.W.; Bramer, L.M.; et al. Effects of Ingested Nanocellulose on Intestinal Microbiota and Homeostasis in Wistar Han Rats. NanoImpact 2020, 18, 100216. [Google Scholar] [CrossRef]

- Chang, H.; Xu, J.; Macqueen, L.A.; Aytac, Z.; Peters, M.M.; Zimmerman, J.F.; Parker, K.K. High-throughput coating with biodegradable antimicrobial pullulan fibres extends shelf life and reduces weight loss in an avocado model. Nat. Food 2022, 3, 428–436. [Google Scholar] [CrossRef]

- Nile, S.H.; Baskar, V.; Selvaraj, D.; Nile, A.; Xiao, J.; Kai, G. Nanotechnologies in Food Science: Applications, Recent Trends, and Future Perspectives. Nano Micro. Lett. 2020, 12, 45. [Google Scholar] [CrossRef] [PubMed]

- Yang, Z.; Xiao, Y.; Jiao, T.; Zhang, Y.; Chen, J.; Gao, Y. Effects of Copper Oxide Nanoparticles on the Growth of Rice (Oryza sativa L.) Seedlings and the Relevant Physiological Responses. Int. J. Environ. Res. Public Health 2020, 17, 1260. [Google Scholar] [CrossRef] [PubMed]

- Nehra, A.; Biswas, D.; Siracusa, V.; Roy, S. Natural Gum-Based Functional Bioactive Films and Coatings: A Review. Int. J. Mol. Sci. 2022, 24, 485. [Google Scholar] [CrossRef] [PubMed]

- Abou Baker, D.H.; Al-Moghazy, M.; ElSayed, A.A.A. The In Vitro Cytotoxicity, Antioxidant and Antibacterial Potential of Satureja hortensis L. Essential Oil Cultivated in Egypt. Bioorg. Chem. 2020, 95, 103559. [Google Scholar] [CrossRef] [PubMed]

- Gholami, P.; Dinpazhoh, L.; Khataee, A.; Orooji, Y. Sonocatalytic activity of biochar-supported ZnO nanorods in degradation of gemifloxacin: Synergy study, effect of parameters and phytotoxicity evaluation. Ultrason. Sonochem. 2019, 55, 44–56. [Google Scholar] [CrossRef]

- Makaremi, M.; Yousefi, H.; Cavallaro, G.; Lazzara, G.; Goh, C.B.S.; Lee, S.M.; Solouk, A.; Pasbakhsh, P. Safely Dissolvable and Healable Active Packaging Films Based on Alginate and Pectin. Polymers 2019, 11, 1594. [Google Scholar] [CrossRef]

- Ritchie, H.; Roser, M.; Plastic Pollution. Our World Data. 2018. Available online: https://ourworldindata.org/plastic-pollution?utm_source=newsletter (accessed on 1 May 2023).

- Vinod, A.; Sanjay, M.R.; Suchart, S.; Jyotishkumar, P. Renewable and Sustainable Biobased Materials: An Assessment on Biofibers, Biofilms, Biopolymers and Biocomposites. J. Clean. Prod. 2020, 258, 120978. [Google Scholar] [CrossRef]

- Syngai, G.G.; Ahmed, G. Lysozyme: A Natural Antimicrobial Enzyme of Interest in Food Applications. In Enzymes in Food Biotechnology; Elsevier: Amsterdam, The Netherlands, 2019; pp. 169–179. [Google Scholar]

- Jha, K.; Kataria, R.; Verma, J.; Pradhan, S. Potential Biodegradable Matrices and Fiber Treatment for Green Composites: A Review. AIMS Mater. Sci. 2019, 6, 119–138. [Google Scholar] [CrossRef]

- Thyavihalli Girijappa, Y.G.; Mavinkere Rangappa, S.; Parameswaranpillai, J.; Siengchin, S. Natural Fibers as Sustainable and Renewable Resource for Development of Eco-friendly Composites: A Comprehensive Review. Front. Mater. 2019, 6, 226. [Google Scholar] [CrossRef]

- Mustapha, F.A.; Jai, J.; Hamidon, F.; Md Sharif, Z.I.M.; Yusof, N.M. Antimicrobial Agents from Malaysian Plants and Their Potential Use in Food Packaging Material: Review. Chem. Eng. Res. Bull. 2017, 19, 57–66. [Google Scholar] [CrossRef]

- Kamarudin, S.H.; Rayung, M.; Abu, F.; Ahmad, S.; Fadil, F.; Karim, A.A.; Norizan, M.N.; Sarifuddin, N.; Mat Desa, M.S.Z.; Mohd Basri, M.S.; et al. A Review on Antimicrobial Packaging from Biodegradable Polymer Composites. Polymers 2022, 14, 174. [Google Scholar] [CrossRef]

- Ghasemi, M.; Khataee, A.; Gholami, P.; Soltani, R.D.C.; Hassani, A.; Orooji, Y. In-Situ electro-generation and activation of hydrogen peroxide using a CuFeNLDH-CNTs modified graphite cathode for degradation of cefazolin. J. Environ. Manag. 2020, 267, 110629. [Google Scholar] [CrossRef]

- Talebi, F.; Misaghi, A.; Khanjari, A.; Kamkar, A.; Gandomi, H.; Rezaeigolestani, M. Incorporation of Spice Essential Oils into Poly-lactic Acid Film Matrix with the Aim of Extending Microbiological and Sensorial Shelf Life of Ground Beef. L.W.T. 2018, 96, 482–490. [Google Scholar] [CrossRef]

- Tiwari, B.K.; Valdramidis, V.P.; O’Donnell, C.P.; Muthukumarappan, K.; Bourke, P.; Cullen, P.J. Application of Natural Antimicrobials for Food Preservation. J. Agric. Food Chem. 2009, 57, 5987–6000. [Google Scholar] [CrossRef]

- Sofi, S.A.; Singh, J.; Rafiq, S.; Ashraf, U.; Dar, B.N.; Nayik, G.A. A Comprehensive Review on Antimicrobial Packaging and Its Use in Food Packaging. Curr. Nutr. Food Sci. 2018, 14, 305–312. [Google Scholar] [CrossRef]

- Yang, S.; Cao, L.; Kim, H.; Beak, S.; Song, K.B. Utilization of Foxtail Millet Starch Film Incorporated with Clove Leaf Oil for the Packaging of Queso Blanco Cheese as a Model Food. Starch-Stärke 2018, 70, 1700171. [Google Scholar] [CrossRef]

- Zaki, M.; HPS, A.K.; Sabaruddin, F.A.; Bairwan, R.D.; Oyekanmi, A.A.; Alfatah, T.; Danish, M.; Mistar, E.M.; Abdullah, C.K. Microbial treatment for nanocellulose extraction from marine algae and its applications as sustainable functional material. Bioresour. Technol. Rep. 2021, 16, 100811. [Google Scholar] [CrossRef]

- Kwon, S.J.; Chang, Y.; Han, J. Oregano Essential Oil-Based Natural Antimicrobial Packaging Film to Inactivate Salmonella enterica and Yeasts/Molds in the Atmosphere Surrounding Cherry Tomatoes. Food Microbiol. 2017, 65, 114–121. [Google Scholar] [CrossRef] [PubMed]

- Sharma, S.; Barkauskaite, S.; Duffy, B.; Jaiswal, A.K.; Jaiswal, S. Characterization and Antimicrobial Activity of Biodegradable Active Packaging Enriched with Clove and Thyme Essential Oil for Food Packaging Application. Foods 2020, 9, 1117. [Google Scholar] [CrossRef]

- Luís, Â.; Duarte, A.; Gominho, J.; Domingues, F.; Duarte, A.P. Chemical Composition, Antioxidant, Antibacterial and Anti-quorum Sensing Activities of Eucalyptus globulus and Eucalyptus radiata Essential Oils. Ind. Crops Prod. 2016, 79, 274–282. [Google Scholar] [CrossRef]

- Khah, M.D.; Ghanbarzadeh, B.; Roufegarinejad Nezhad, L.R.; Ostadrahimi, A. Effects of Virgin Olive Oil and Grape Seed Oil on Physicochemical and Antimicrobial Properties of Pectin-Gelatin Blend Emulsified Films. Int. J. Biol. Macromol. 2021, 171, 262–274. [Google Scholar] [CrossRef]

- Priyadarshi, R.; Sauraj, B.; Kumar, B.; Deeba, F.; Kulshreshtha, A.; Negi, Y.S. Chitosan Films Incorporated with Apricot (Prunus armeniaca) Kernel Essential Oil as Active Food Packaging Material. Food Hydrocoll. 2018, 85, 158–166. [Google Scholar] [CrossRef]

- Bahl, K.; Miyoshi, T.; Jana, S.C. Hybrid Fillers of Lignin and Carbon Black for Lowering of Viscoelastic Loss in Rubber Compounds. Polymer 2014, 55, 3825–3835. [Google Scholar] [CrossRef]

- Chenni, M.; El Abed, D.; Rakotomanomana, N.; Fernandez, X.; Chemat, F. Comparative Study of Essential Oils Extracted from Egyptian Basil Leaves (Ocimum basilicum L.) Using Hydro-distillation and Solvent-Free Microwave Extraction. Molecules 2016, 21, 113. [Google Scholar] [CrossRef]

- Ye, J.; Wang, S.; Lan, W.; Qin, W.; Liu, Y. Preparation and Properties of Polylactic Acid-Tea Polyphenol-Chitosan Composite Membranes. Int. J. Biol. Macromol. 2018, 117, 632–639. [Google Scholar] [CrossRef] [PubMed]

- Moldovan, R.I.; Oprean, R.; Benedec, D.; Hanganu, D.; Duma, M.; Oniga, I.; Vlase, L. LC-MS Analysis, Antioxidant and Antimicrobial Activities for Five Species of Mentha Cultivated in Romania. Dig. J. Nanomater. Biostruct. 2014, 9, 559–566. [Google Scholar]

- Duran, M.; Aday, M.S.; Zorba, N.N.D.; Temizkan, R.; Büyükcan, M.B.; Caner, C. Potential of Antimicrobial Active Packaging ‘Containing Natamycin, Nisin, Pomegranate and Grape Seed Extract in Chitosan coating’ to Extend Shelf Life of Fresh Strawberry. Food Bioprod. Process. 2016, 98, 354–363. [Google Scholar] [CrossRef]

- Sundaram, J.; Pant, J.; Goudie, M.J.; Mani, S.; Handa, H. Antimicrobial and Physicochemical Characterization of Biodegradable, Nitric Oxide-Releasing Nanocellulose–Chitosan Packaging Membranes. J. Agric. Food Chem. 2016, 64, 5260–5266. [Google Scholar] [CrossRef]

- Pisoschi, A.M.; Pop, A.; Georgescu, C.; Turcuş, V.; Olah, N.K.; Mathe, E. An Overview of Natural Antimicrobials Role in Food. Eur. J. Med. Chem. 2018, 143, 922–935. [Google Scholar] [CrossRef]

- Nemeş, N.S.; Ardean, C.; Davidescu, C.M.; Negrea, A.; Ciopec, M.; Duţeanu, N.; Negrea, P.; Paul, C.; Duda-Seiman, D.; Muntean, D. Antimicrobial Activity of Cellulose Based Materials. Polymers 2022, 14, 735. [Google Scholar] [CrossRef]

- Emolaga, C.S.; Paglicawan, M.A.; Bigol, U.P.; de Yro, P.A.N.; Sy, J.A.; Visaya, B.A.; Bauca, M.T.A. Preparation of Starch Nanocrystals with Antimicrobial Property. MSF 2022, 1073, 143–148. [Google Scholar] [CrossRef]

- Irkin, R.; Esmer, O.K. Novel Food Packaging Systems with Natural Antimicrobial Agents. J. Food Sci. Technol. 2015, 52, 6095–6111. [Google Scholar] [CrossRef] [PubMed]

- Hossain, M.I.; Sadekuzzaman, M.; Ha, S.D. Probiotics as Potential Alternative Biocontrol Agents in the Agriculture and Food Industries: A Review. Food Res. Int. 2017, 100, 63–73. [Google Scholar] [CrossRef] [PubMed]

- Al-Hashimi, G.A.; Ammar, A.B.; Cacciola, F.; Lakhssassi, N. Development of a millet starch edible film containing clove essential oil. Foods 2020, 9, 184. [Google Scholar] [CrossRef]

- Ali, G.; Sharma, M.; Salama, E.-S.; Ling, Z.; Li, X. Applications of chitin and chitosan as natural biopolymer: Potential sources, pretreatments, and degradation pathways. Biomass-Convers. Biorefin. 2022, 1–15. [Google Scholar] [CrossRef]

- Wen, P.; Zhu, D.H.; Wu, H.; Zong, M.H.; Jing, Y.R.; Han, S.Y. Encapsulation of Cinnamon Essential Oil in Electrospun Nanofibrous Film for Active Food Packaging. Food Control 2016, 59, 366–376. [Google Scholar] [CrossRef]

- Sedayu, B.B.; Cran, M.J.; Bigger, S.W. A Review of Property Enhancement Techniques for Carrageenan-Based Films and Coatings. Carbohydr. Polym. 2019, 216, 287–302. [Google Scholar] [CrossRef]

- Mandolini, M.; Campi, F.; Favi, C.; Germani, M. Manufacturing Processes Re-Engineering for Cost Reduction: The Investment Casting Case Study. In International Design Engineering Technical Conferences and Computers and Information in Engineering Conference; American Society of Mechanical Engineers: New York, NY, USA, 2019; p. V004T05A018. [Google Scholar] [CrossRef]

- Motelica, L.; Ficai, D.; Ficai, A.; Oprea, O.C.; Kaya, D.A.; Andronescu, E. Biodegradable Antimicrobial Food Packaging: Trends and Perspectives. Foods 2020, 9, 1438. [Google Scholar] [CrossRef]

- Coban, H.B. Organic Acids as Antimicrobial Food Agents: Applications and Microbial Productions. Bioprocess Biosyst. Eng. 2020, 43, 569–591. [Google Scholar] [CrossRef]

- Liu, Y.; Liang, X.; Wang, S.; Qin, W.; Zhang, Q. Electrospun Antimicrobial Polylactic Acid/Tea Polyphenol Nanofibers for Food-Packaging Applications. Polymers 2018, 10, 561. [Google Scholar] [CrossRef]

- Liu, L.; Zhu, Y.; Li, J.; Wang, M.; Lee, P.; Du, G.; Chen, J. Microbial Production of Propionic Acid from Propionibacteria: Current State, Challenges and Perspectives. Crit. Rev. Biotechnol. 2012, 32, 374–381. [Google Scholar] [CrossRef] [PubMed]

- Song, X.; Wang, L.; Liu, L.; Li, J.; Wu, X. Impact of Tea Tree Essential Oil and Citric Acid/Choline Chloride on Physical, Structural and Antibacterial Properties of Chitosan-Based Films. Food Control 2022, 141, 109186. [Google Scholar] [CrossRef]

- Eastoe, C.J. Stable Chlorine Isotopes in Arid Non-marine Basins: Instances and Possible Fractionation Mechanisms. Appl. Geochem. 2016, 74, 1–12. [Google Scholar] [CrossRef]

- Kumar, R.; Chandar, B.; Parani, M. Use of Succinic & Oxalic Acid in Reducing the Dosage of Colistin Against New Delhi Metallo-β-lactamase-1 Bacteria. Indian J. Med. Res. 2018, 147, 97–101. [Google Scholar] [CrossRef] [PubMed]

- Venugopal, V. Marine Polysaccharides: Food Applications; CRC Press: Boca Raton, FL, USA, 2016. [Google Scholar]

- Jideani, V.A.; Vogt, K. Antimicrobial Packaging for Extending the Shelf Life of Bread—A Review. Crit. Rev. Food Sci. Nutr. 2016, 56, 1313–1324. [Google Scholar] [CrossRef]

- Morey, A.; Bowers, J.W.J.; Bauermeister, L.J.; Singh, M.; Huang, T.S.; McKee, S.R. Effect of Salts of Organic Acids on Listeria monocytogenes, Shelf Life, Meat Quality, and Consumer Acceptability of Beef Frankfurters. J. Food Sci. 2014, 79, M54–M60. [Google Scholar] [CrossRef]

- Huang, T.; Qian, Y.; Wei, J.; Zhou, C. Polymeric Antimicrobial Food Packaging and Its Applications. Polymers 2019, 11, 560. [Google Scholar] [CrossRef]

- Sethi, S.; Gupta, S. Antimicrobial Spices: Use in Antimicrobial Packaging. In Antimicrobial Food Packaging; Elsevier: Amsterdam, The Netherlands, 2016; pp. 433–444. [Google Scholar]

- Sung, S.Y.; Sin, L.T.; Tee, T.T.; Bee, S.T.; Rahmat, A.R.; Rahman, W.A.W.A.; Tan, A.; Vikhraman, M. Antimicrobial Agents for Food Packaging Applications. Trends Food Sci. Technol. 2013, 33, 110–123. [Google Scholar] [CrossRef]

- Chana-Thaworn, J.; Chanthachum, S.; Wittaya, T. Properties and Antimicrobial Activity of Edible Films Incorporated with Kiam Wood (Cotyleobium lanceotatum) Extract. L.W.T. Food Sci. Technol. 2011, 44, 284–292. [Google Scholar] [CrossRef]

- Kuorwel, K.K.; Cran, M.J.; Sonneveld, K.; Miltz, J.; Bigger, S.W. Antimicrobial Activity of Biodegradable Polysaccharide and Protein-Based Films Containing Active Agents. J. Food Sci. 2011, 76, R90–R102. [Google Scholar] [CrossRef]

- Díaz-Montes, E. Polysaccharides: Sources, Characteristics, Properties, and Their Application in Biodegradable Films. Polysaccharides 2022, 3, 480–501. [Google Scholar] [CrossRef]

- Gurav, R.; Bhatia, S.K.; Choi, T.R.; Hyun Cho, D.; Chan Kim, B.; Hyun Kim, S.; Ju Jung, H.; Joong Kim, H.; Jeon, J.M.; Yoon, J.J.; et al. Lignocellulosic Hydrolysate Based Biorefinery for Marine Exopolysaccharide Production and Application of the Produced Biopolymer in Environmental Clean-Up. Bioresour. Technol. 2022, 359, 127499. [Google Scholar] [CrossRef] [PubMed]

- Mukurumbira, A.R.; Shellie, R.A.; Keast, R.; Palombo, E.A.; Jadhav, S.R. Encapsulation of Essential Oils and Their Application in Antimicrobial Active Packaging. Food Control 2022, 136, 108883. [Google Scholar] [CrossRef]

- Trindade, M.A.; Nunes, C.; Coimbra, M.A.; Gonçalves, F.J.M.; Marques, J.C.; Gonçalves, A.M.M. Sustainable and Biodegradable Active Films Based on Seaweed Compounds to Improve Shelf Life of Food Products. In Sustainable Global Resources of Seaweeds Volume 2: Food, Pharmaceutical and Health Applications; Springer: Berlin/Heidelberg, Germany, 2022; pp. 235–252. [Google Scholar]

- Matche, R.S.; Anup, G.J.; Mrudula, G. Development of Biodegradable Films from Marine Ingredients Incorporated with Natural Antimicrobial Agents for Food Packaging. J. Packag. Technol. Res. 2020, 4, 45–55. [Google Scholar] [CrossRef]

- Firmanda, A.; Fahma, F.; Warsiki, E.; Syamsu, K.; Arnata, I.W.; Sartika, D.; Suryanegara, L.; Qanytah; Suyanto, A. Antimicrobial Mechanism of Nanocellulose Composite Packaging Incorporated with Essential Oils. Food Control 2023, 147, 109617. [Google Scholar] [CrossRef]

- Suderman, N.; Isa, M.I.N.; Sarbon, N.M. The Effect of Plasticizers on the Functional Properties of Biodegradable Gelatin-Based Film: A Review. Food Biosci. 2018, 24, 111–119. [Google Scholar] [CrossRef]

- Sinthupachee, A.; Matan, N.; Matan, N. Development of Smoke Flavour-Antimicrobial Packaging from Coconut Fibre Using Litsea Cubeba Essential Oil and Wood Smoke for Dried Fish Preservation and Reduction of PAH. Food Control 2023, 148, 109629. [Google Scholar] [CrossRef]

- Aliabbasi, N.; Emam-Djomeh, Z.; Amighi, F. Active Food Packaging with Nano/Microencapsulated Ingredients. In Application of Nano/Microencapsulated Ingredients in Food Products; Elsevier: Amsterdam, The Netherlands, 2021; pp. 171–210. [Google Scholar]

- Bahmid, N.A.; Pepping, L.; Dekker, M.; Fogliano, V.; Heising, J. Using Particle Size and Fat Content to Control the Release of Allyl Isothiocyanate from Ground Mustard Seeds for Its Application in Antimicrobial Packaging. Food Chem. 2020, 308, 125573. [Google Scholar] [CrossRef]

- Mlalila, N.; Hilonga, A.; Swai, H.; Devlieghere, F.; Ragaert, P. Antimicrobial Packaging Based on Starch, Poly (3-Hydroxybutyrate) and Poly (Lactic-Co-Glycolide) Materials and Application Challenges. Trends Food Sci. Technol. 2018, 74, 1–11. [Google Scholar] [CrossRef]

- Bouletis, A.D.; Arvanitoyannis, I.S.; Hadjichristodoulou, C. Application of Modified Atmosphere Packaging on Aquacultured Fish and Fish Products: A Review. Crit. Rev. Food Sci. Nutr. 2017, 57, 2263–2285. [Google Scholar] [CrossRef]

- Ordoñez, R.; Atarés, L.; Chiralt, A. Biodegradable Active Materials Containing Phenolic Acids for Food Packaging Applications. Compr. Rev. Food Sci. Food Saf. 2022, 21, 3910–3930. [Google Scholar] [CrossRef] [PubMed]

- Jung, J.; Zhao, Y. Antimicrobial Packaging for Fresh and Minimally Processed Fruits and Vegetables. In Antimicrobial Food Packaging; Elsevier: Amsterdam, The Netherlands, 2016; pp. 243–256. [Google Scholar]

- Nakata, S.; Murata, K.; Hashimoto, W.; Kawai, S. Uncovering the Reactive Nature of 4-Deoxy-l-erythro-5-hexoseulose Uronate for the Utilization of Alginate, a Promising Marine Biopolymer. Sci. Rep. 2019, 9, 17147. [Google Scholar] [CrossRef] [PubMed]

- Correa, M.G.; Martínez, F.B.; Vidal, C.P.; Streitt, C.; Escrig, J.; de Dicastillo, C.L. Antimicrobial Metal-Based Nanoparticles: A Review on Their Synthesis, Types and Antimicrobial Action. Beilstein J. Nanotechnol. 2020, 11, 1450–1469. [Google Scholar] [CrossRef] [PubMed]

- Ceballos, R.L.; Von Bilderling, C.; Guz, L.; Bernal, C.; Famá, L. Effect of Greenly Synthetized Silver Nanoparticles on the Properties of Active Starch Films Obtained by Extrusion and Compression Molding. Carbohydr. Polym. 2021, 261, 117871. [Google Scholar] [CrossRef] [PubMed]

- Hu, P.; Li, Z.; Chen, M.; Sun, Z.; Ling, Y.; Jiang, J.; Huang, C. Structural Elucidation and Protective Role of a Polysaccharide from Sargassum fusiforme on Ameliorating Learning and Memory Deficiencies in Mice. Carbohydr. Polym. 2016, 139, 150–158. [Google Scholar] [CrossRef] [PubMed]

- Karki, S.; Gohain, M.B.; Yadav, D.; Ingole, P.G. Nanocomposite and bio-nanocomposite polymeric materials/membranes development in energy and medical sector: A review. Int. J. Biol. Macromol. 2021, 193, 2121–2139. [Google Scholar] [CrossRef]

- Sarwar, M.S.; Niazi, M.B.K.; Jahan, Z.; Ahmad, T.; Hussain, A. Preparation and Characterization of PVA/nanocellulose/Ag Nanocomposite Films for Antimicrobial Food Packaging. Carbohydr. Polym. 2018, 184, 453–464. [Google Scholar] [CrossRef]

- Pandhi, S.; Kumar, A.; Mishra, S.; Rai, D.C. Potential of Green Nanotechnology in Food Processing and Preservation. In Handbook of Research on Food Processing and Preservation Technologies; Apple Academic Press: Waretown, NJ, USA, 2021; pp. 135–161. [Google Scholar]

- Broquá, J.; Zanin, B.G.; Flach, A.M.; Mallmann, C.; Taborda, F.G.D. Different Aspects of Chemical and Biochemical Methods for Chitin Production a Short Review. J. Nanomed Nanosci. JNAN 2018, 10, 1477–2577. [Google Scholar]

- Brandelli, A.; Taylor, T.M. Nanostructured and Nanoencapsulated Natural Antimicrobials for Use in Food Products. In Handbook of Natural Antimicrobials for Food Safety and Quality; Woodhead Publishing Oxford: Cambridge, UK, 2015; pp. 229–257. [Google Scholar]

- Duncan, T.V. Applications of Nanotechnology in Food Packaging and Food Safety: Barrier Materials, Antimicrobials and Sensors. J. Colloid Interface Sci. 2011, 363, 1–24. [Google Scholar] [CrossRef]

- Roy, S.; Zhang, W.; Biswas, D.; Ramakrishnan, R.; Rhim, J.-W. Grapefruit Seed Extract-Added Functional Films and Coating for Active Packaging Applications: A Review. Molecules 2023, 28, 730. [Google Scholar] [CrossRef]

- Bumbudsanpharoke, N.; Ko, S. Nano-food Packaging: An Overview of Market, Migration Research, and Safety Regulations. J. Food Sci. 2015, 80, R910–R923. [Google Scholar] [CrossRef] [PubMed]

- Gheysari, H.; Mohandes, F.; Mazaheri, M.; Dolatyar, B.; Askari, M.; Simchi, A. Extraction of Hydroxyapatite Nanostructures from Marine Wastes for the Fabrication of Biopolymer-Based Porous Scaffolds. Mar. Drugs 2019, 18, 26. [Google Scholar] [CrossRef] [PubMed]

- Sangroniz, A.; Sangroniz, L.; Gonzalez, A.; Santamaria, A.; del Rio, J.; Iriarte, M.; Etxeberria, A. Improving the Barrier Properties of a Biodegradable Polyester for Packaging Applications. Eur. Polym. J. 2019, 115, 76–85. [Google Scholar] [CrossRef]

| Natural Extract | Active Compounds | Antimicrobial Action | Reference |

|---|---|---|---|

| Oregano | Carvacrol and thymol | Salmonella enteric, mold and yeast, and mesophilic aerobic bacteria | [40] |

| Clove and thyme | Eugenol and thymol | Escherichia coli | [41] |

| Eucalyptus radiata | eucalyptol | Gram-negative bacteria | [42] |

| Grapefruit seed | phenolic compounds | Pseudomonas fluorescence and Escherichia coli | [43] |

| Apricot kernels | oleic acid | Escherichia coli and Bacillus subtilis | [44] |

| cinnamon | cinnamaldehyde | R. nigricans and S. aureus | [45] |

| Basil | Chavicol and eugenol | L. curvatus and S. cerevisiae | [46] |

| Tea polyphenols | Polyphenols | Escherichia coli and Staphylococcus aureus | [47] |

| Mentha rotundifolia L. | Ferulic acid | Salmonella typhimurium, Escherichia coli, S. aureus | [48] |

| Olive leaf extract | polyphenolic compounds | Escherichia coli and L. innocua | [49] |

| Chitosin | polycationic compounds | S. aureus, Listeria monocytogenes, and Enterococcus faecalis | [50] |

| Bacteriocins | Peptide | Micrococcus luteus, S. aureus, and Bacillus cereus | [51] |

| Cellulose | Staphylococcus aureus, Escherichia coli, and Candida albicans. | [52] | |

| Starch | Escherichia coli | [53] | |

| Lysozyme | Gram-positive bacteria | [54] |

| Organic Acids | Antimicrobial Action | Reference |

|---|---|---|

| Malic acid | L. monocytogenes, S. gaminara | [62] |

| Phenyllactic acid | E. cloacae | [63] |

| Propionic acid | E. coli and Salmonella | [64] |

| Citric acid | Sh. flexneri | [65] |

| Sorbic acid | Yeast and mold | [66] |

| Oxalic acid | Escherichia coli | [67] |

| Acetic acid | Shigella | [68] |

| potassium sorbate | Bacteria and molds | [69] |

| Sodium citrate | Listeria, bladder, and Escherichia coli | [70] |

| Allyl isothiocyanate | E. coli | [71] |

| Antimicrobial Agent | Food Product | Targeted Microorganism | Reference |

|---|---|---|---|

| triclosan | Meat | Triclosan, S. aureus, B. thermosphacta | [73] |

| wasabi extract AM | Raw meat | E. coli and S. aureus, fungi A. niger, P. italicum. | [74] |

| Olive leaf extract | cheese | S. aureus | [75] |

| Grape seed extract | pork loin | L. monocytogenes, E. coli, E. faecalis, E. faecium, S. typhimurium, and B. thermosphaceta B2 | [76] |

| Chitosan and cinnamaldehyde | vacuum-packed cured meat products (bologna, cooked ham, and pastrami) | Enterobacteriaceae, Serratia liquefaciens, and Lactobacillus sakei | [77] |

| Corn zein | Ready-to-eat chicken | L. monocytogenes | [78] |

| Pimento EOs | Beef muscle slices | Pseudomonas spp. and E. coli O157:H7 | [79] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bose, I.; Roy, S.; Pandey, V.K.; Singh, R. A Comprehensive Review on Significance and Advancements of Antimicrobial Agents in Biodegradable Food Packaging. Antibiotics 2023, 12, 968. https://doi.org/10.3390/antibiotics12060968

Bose I, Roy S, Pandey VK, Singh R. A Comprehensive Review on Significance and Advancements of Antimicrobial Agents in Biodegradable Food Packaging. Antibiotics. 2023; 12(6):968. https://doi.org/10.3390/antibiotics12060968

Chicago/Turabian StyleBose, Ipsheta, Swarup Roy, Vinay Kumar Pandey, and Rahul Singh. 2023. "A Comprehensive Review on Significance and Advancements of Antimicrobial Agents in Biodegradable Food Packaging" Antibiotics 12, no. 6: 968. https://doi.org/10.3390/antibiotics12060968

APA StyleBose, I., Roy, S., Pandey, V. K., & Singh, R. (2023). A Comprehensive Review on Significance and Advancements of Antimicrobial Agents in Biodegradable Food Packaging. Antibiotics, 12(6), 968. https://doi.org/10.3390/antibiotics12060968