Thermoplastic Starch Composites Reinforced with Functionalized POSS: Fabrication, Characterization, and Evolution of Mechanical, Thermal and Biological Activities

Abstract

1. Introduction

2. Results and Discussion

2.1. Characterization of the fn-POSS Nanoparticles

2.2. Characterization of the TS/fn-POSS Composite Films

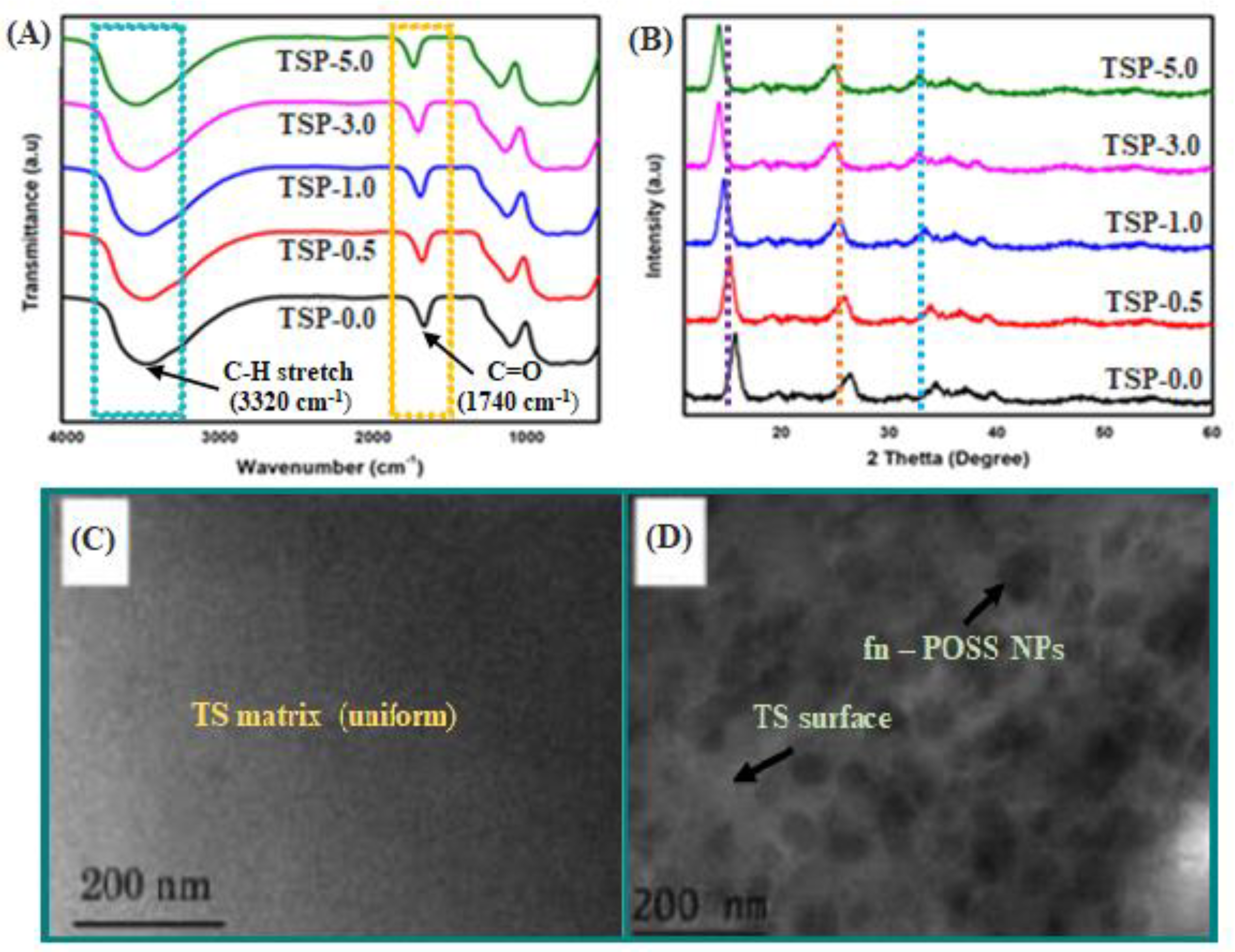

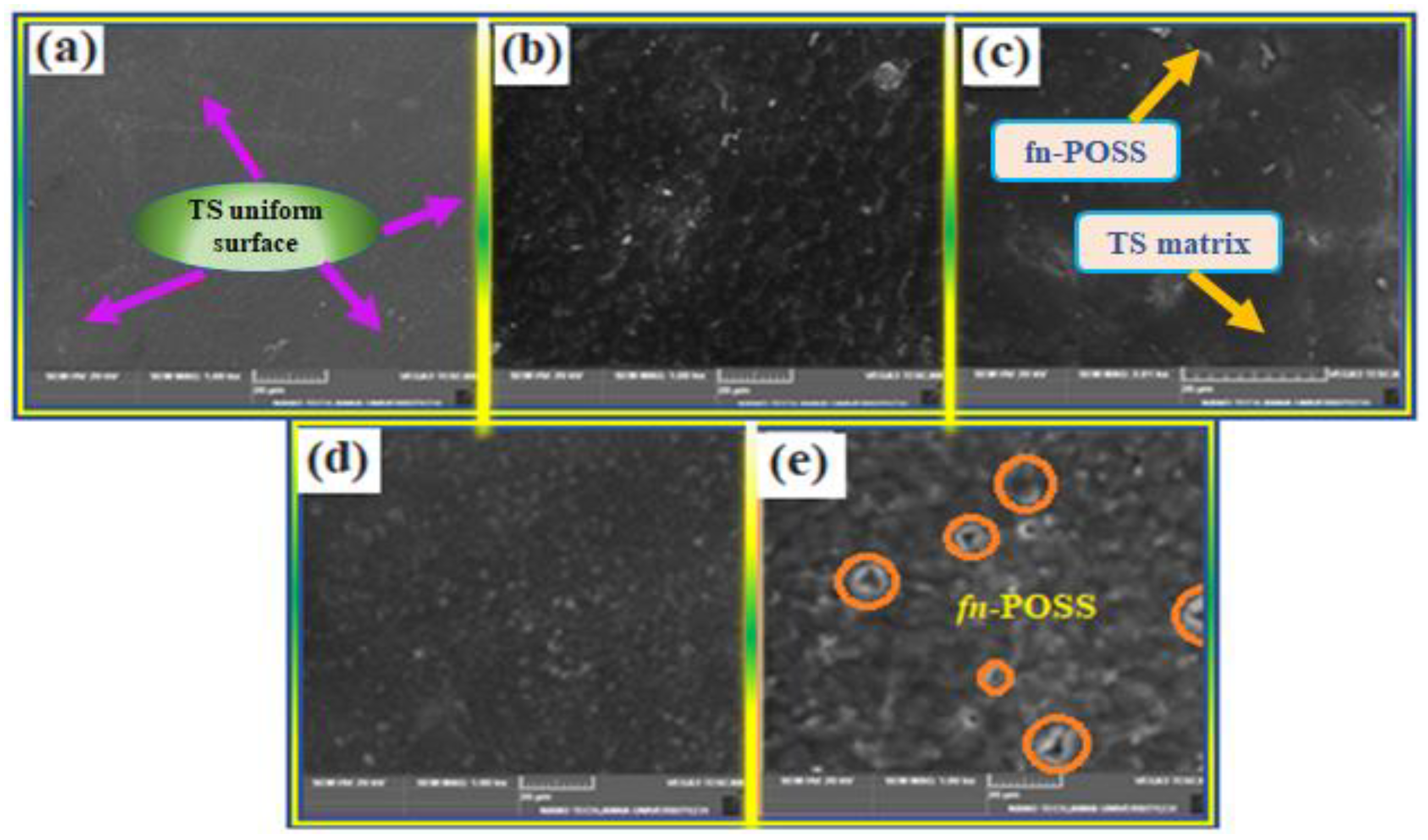

2.2.1. Structural and Morphological Analysis

2.2.2. Thermal Stability

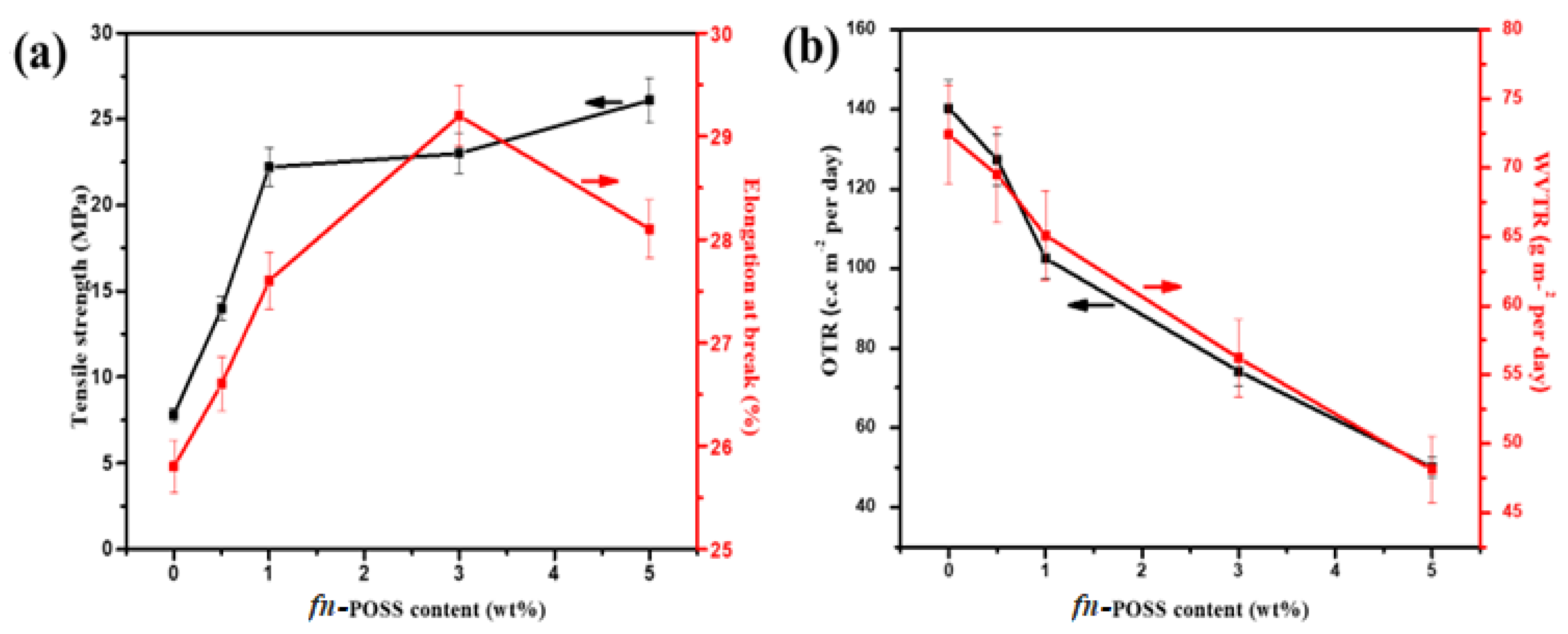

2.2.3. Mechanical and Barrier Properties

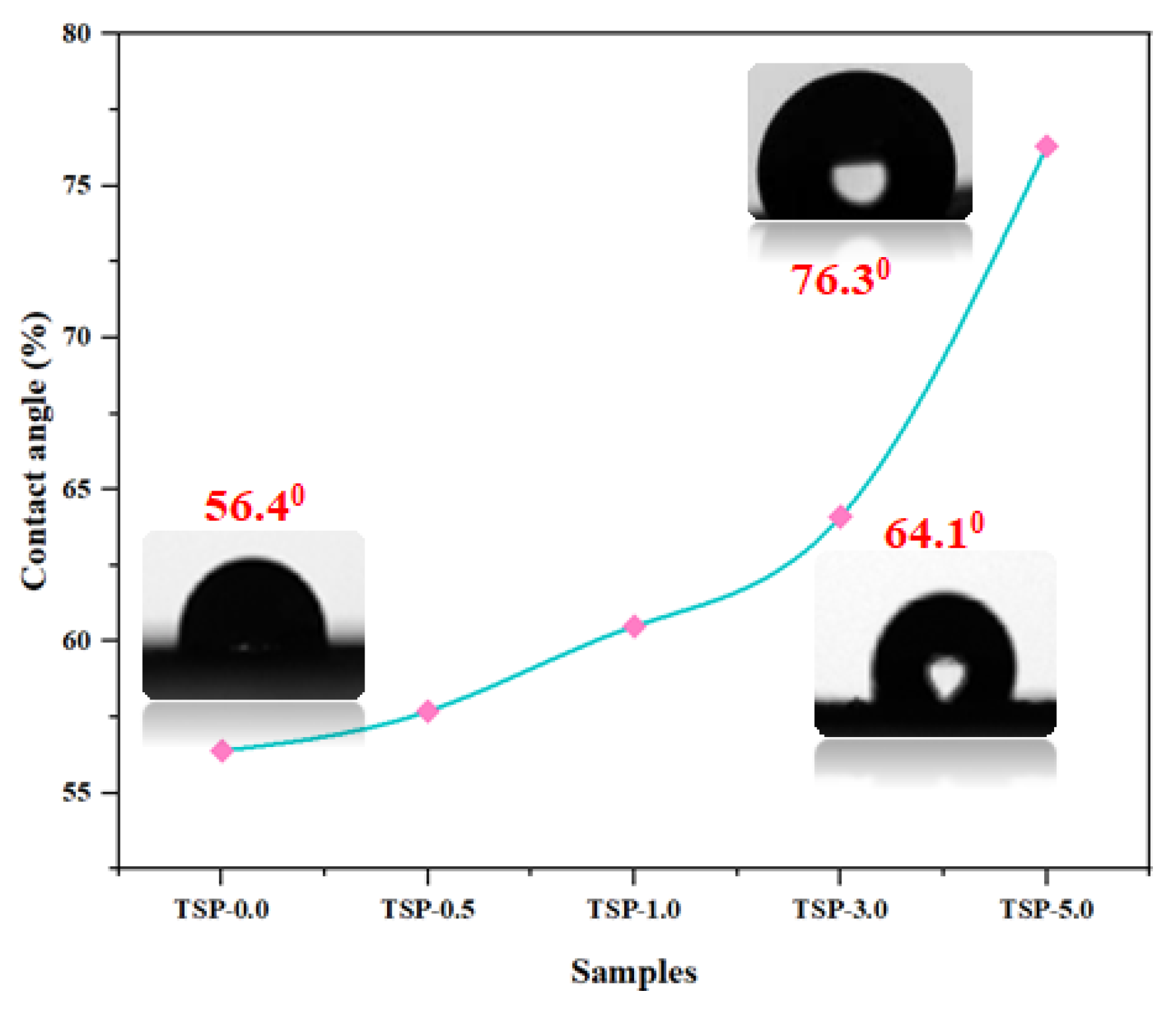

2.2.4. Water Contact Angle Analysis (WCA)

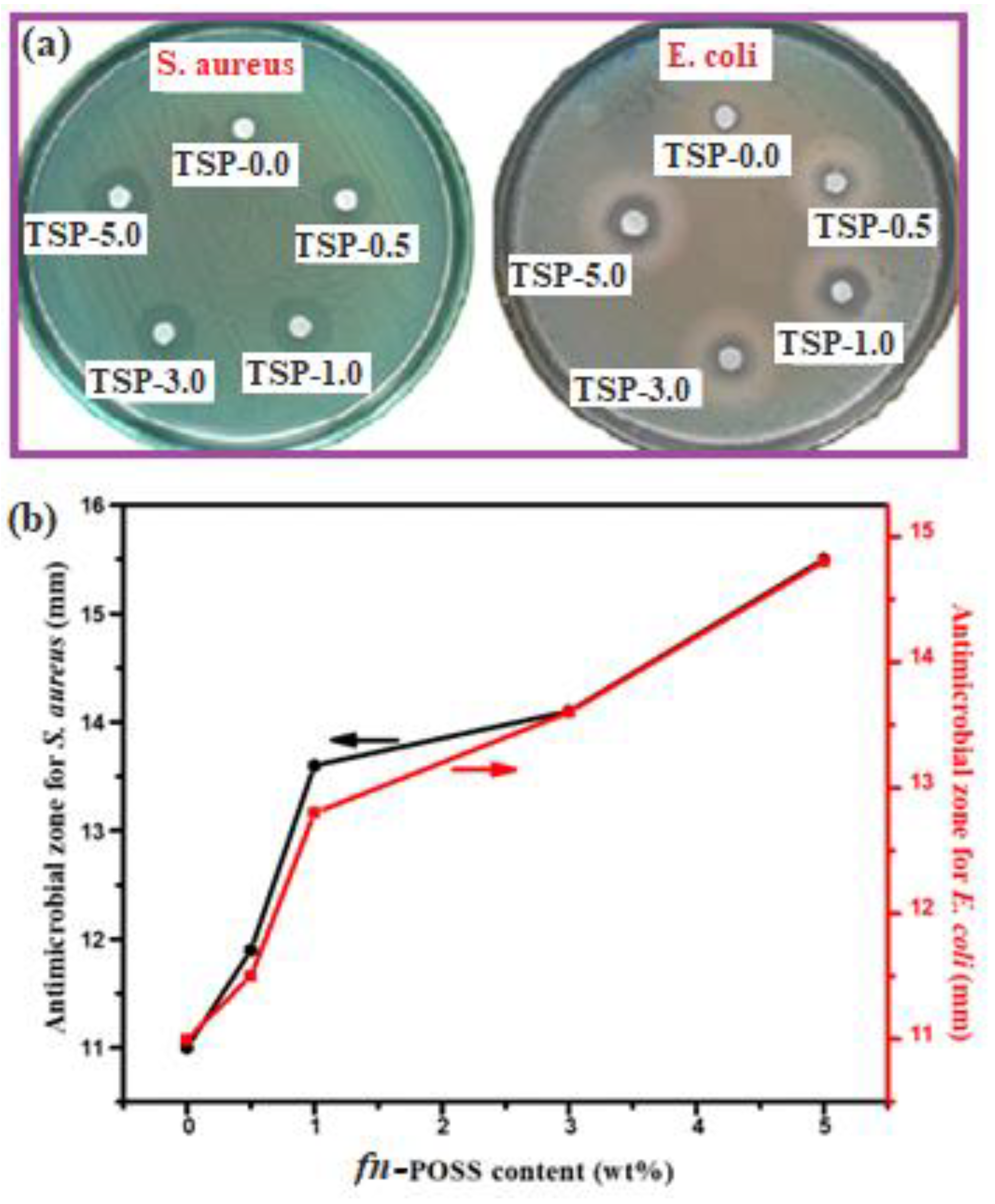

2.2.5. Antimicrobial Activity of TS/fn-POSS Composite Films

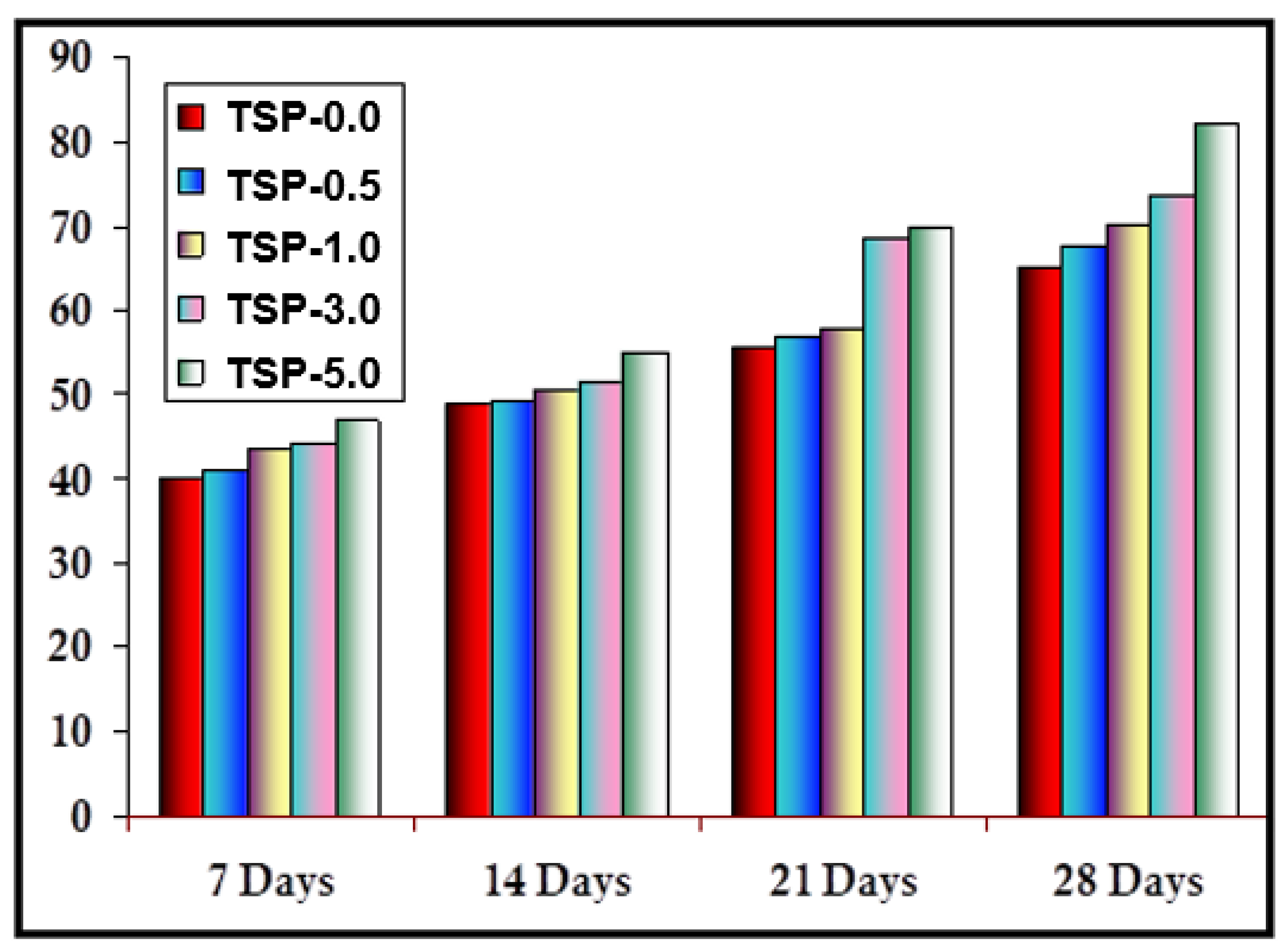

2.2.6. Biodegradability of TS and TS/fn-POSS Composite Films

3. Materials and Methods

3.1. Chemical and Materials

3.2. Synthesis of fn-POSS Nanoparticles

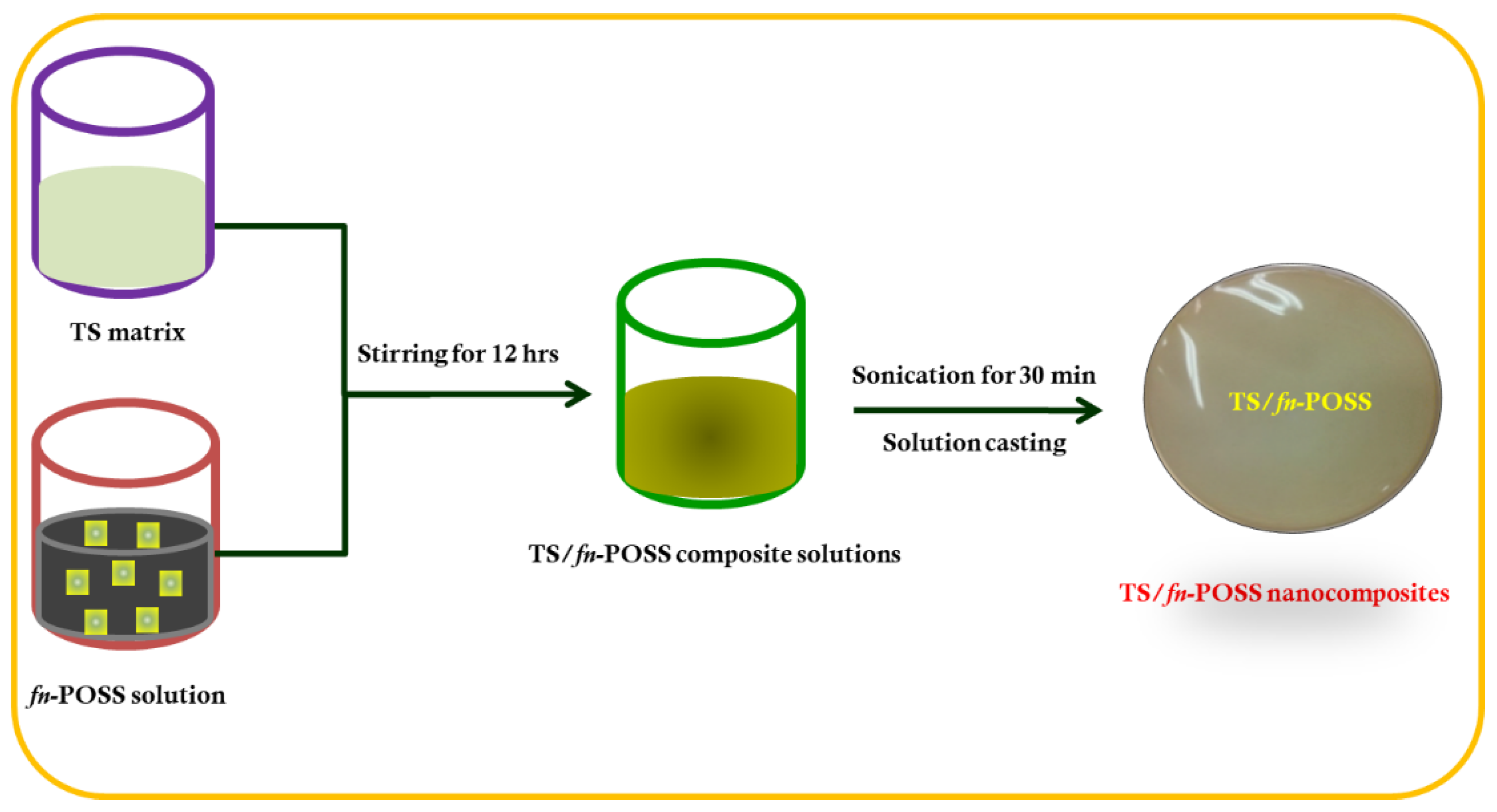

3.3. Preparation of TPS/fn-POSS Nanocomposites

3.4. Characterization

3.4.1. Fourier Transform Infrared Spectroscopy (FTIR)

3.4.2. X-ray Diffraction Analysis (XRD)

3.4.3. Morphological Analysis

3.4.4. Thermogravimetric Analysis (TGA)

3.4.5. Mechanical Strength

3.4.6. Oxygen Transmission Rate (OTR)

3.4.7. Water Vapor Transmission Rate (WVTR)

3.4.8. Water Contact Angle Analysis

3.4.9. Antimicrobial Activity

3.4.10. Biodegradability Tests

3.4.11. Statistical Analysis

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Pekmezovic, M.; Krusic, M.K.; Malagurski, I.; Milovanovic, J.; Stępień, K.; Guzik, M.; Charifou, R.; Babu, R.; O’Connor, K.; Nikodinovic-Runic, J. Polyhydroxyalkanoate/Antifungal Polyene Formulations with Monomeric Hydroxyalkanoic Acids for Improved Antifungal Efficiency. Antibiotics 2021, 10, 737. [Google Scholar] [CrossRef] [PubMed]

- Suvarna, V.; Nair, A.; Mallya, R.; Khan, T.; Omri, A. Antimicrobial Nanomaterials for Food Packaging. Antibiotics 2022, 11, 729. [Google Scholar] [CrossRef]

- Gaba, A.B.M.; Hassan, M.A.; Abd EL-Tawab, A.A.; Abdelmonem, M.A.; Morsy, M.K. Protective Impact of Chitosan Film Loaded Oregano and Thyme Essential Oil on the Microbial Profile and Quality Attributes of Beef Meat. Antibiotics 2022, 11, 583. [Google Scholar] [CrossRef] [PubMed]

- Khalid, M.Y.; Arif, Z.U. Novel biopolymer-based sustainable composites for food packaging applications: A narrative review. Food Packag. Shelf Life 2022, 33, 100892. [Google Scholar] [CrossRef]

- Arrieta, M.P.; López, J.; Hernández, A.; Rayónc, E. Ternary PLA–PHB–Limonene blends intended for biodegradable food packaging applications. Eur. Polym. J. 2014, 50, 255–270. [Google Scholar] [CrossRef]

- Oshani, B.N.; Davachi, S.M.; Hejazi, I.; Seyfi, J.; Khonakdar, H.A.; Abbaspourrad, A. Enhanced compatibility of starch with poly(lactic acid) and poly(ɛ-caprolactone) by incorporation of POSS nanoparticles: Study on thermal properties. Int. J. Biol. Macromol. 2019, 141, 578–584. [Google Scholar] [CrossRef] [PubMed]

- Rammak, T.; Boonsuk, P.; Kaewtati, K. Mechanical and barrier properties of starch blend films enhanced with kaolin for application in food packaging. Int. J. Biol. Macromol. 2021, 192, 1013–1020. [Google Scholar] [CrossRef] [PubMed]

- Castillo, L.; Lopez, O.; Lopez, C.; Zaritzky, N.; Garcia, M.A.; Barbosa, S.; Villar, M. Thermoplastic starch films reinforced with talc nanoparticles. Carbohydr. Polym. 2013, 95, 664–674. [Google Scholar] [CrossRef]

- Romani, V.P.; Martins, V.G.; Goddard, J.M. Radical scavenging polyethylene films as antioxidant active packaging materials. Food Control 2020, 109, 106946. [Google Scholar] [CrossRef]

- Van Willige, R.M.G.; Linssen, J.P.H.; Legger-Huysman, A.; Voragen, A.G.J. Influence of flavour absorption by food-packaging materials (low-density polyethylene, polycarbonate and polyethylene terephthalate) on taste perception of a model solution and orange juice. Food Addit. Contam. 2003, 20, 84–91. [Google Scholar] [CrossRef]

- Zhai, X.; Zhou, S.; Zhang, R.; Wang, W.; Hou, H. Antimicrobial starch/poly(butylene adipate-co-terephthalate) nanocomposite films loaded with a combination of silver and zinc oxide nanoparticles for food packaging. Int. J. Biol. Macromol. 2022, 206, 298–305. [Google Scholar] [CrossRef] [PubMed]

- Dhapte, V.; Gaikwad, N.; More, P.V.; Banerjee, S.; Dhapte, V.V.; Kadam, S.; Khanna, P.K. Transparent ZnO/polycarbonate nanocomposite for food packaging application. Nanocomposites 2015, 1, 106–112. [Google Scholar] [CrossRef]

- Mlalila, N.; Hilonga, A.; Swai, H.; Devlieghere, F.; Ragaert, P. Antimicrobial packaging based on starch, poly(3-hydroxybutyrate) and poly(lactic-co-glycolide) materials and application challenges. Trends Food Sci. Technol. 2018, 74, 1–11. [Google Scholar] [CrossRef]

- Biduski, B.; Silva, W.M.F.; Colussi, R.; de Mello El Halal, S.L.; Lim, L.-T.; Dias, A.R.G.; Zavareze, E.R. Starch hydrogels: The influence of the amylose content and gelatinization method. Int. J. Biol. Macromol. 2018, 113, 443–449. [Google Scholar] [CrossRef] [PubMed]

- Liu, Y.-Y.; He, J.; Li, Y.-D.; Zhao, X.-L.; Zeng, J.-B. Biobased epoxy vitrimer from epoxidized soybean oil for reprocessable and recyclable carbon fiber reinforced composite. Compos. Commun. 2020, 22, 100445. [Google Scholar] [CrossRef]

- Zhou, S.-Y.; Huang, H.-D.; Xu, L.; Yan, Z.; Zhong, G.-J.; Hsiao, B.S.; Li, Z.-M. In situ nanofibrillar networks composed of densely oriented polylactide crystals as efficient reinforcement and promising barrier wall for fully biodegradable poly (butylene succinate) composite films. ACS Sustain. Chem. Eng. 2016, 4, 2887–2897. [Google Scholar] [CrossRef]

- Li, X.; Yin, H.-M.; Su, K.; Zheng, G.-S.; Mao, C.-Y.; Liu, W.; Wang, P.; Zhang, Z.; Xu, J.-Z.; Li, Z.-M.; et al. Polydopamine-assisted anchor of chitosan onto porous composite scaffolds for accelerating bone regeneration. ACS Biomater. Sci. Eng. 2019, 5, 2998–3006. [Google Scholar] [CrossRef]

- Venkatesan, R.; Rajeswari, N. ZnO/PBAT nanocomposite films: Investigation on the mechanical and biological activity for antimicrobial food packaging. Polym. Adv. Technol. 2017, 28, 20–27. [Google Scholar] [CrossRef]

- Qiu, Z.; Pan, H. Preparation, crystallization and hydrolytic degradation of biodegradable poly(l-lactide)/polyhedral oligomeric silsesquioxanes nanocomposite. Compos. Sci. Technol. 2010, 70, 1089–1094. [Google Scholar] [CrossRef]

- Basta, A.H.; Lotfy, V.F. Assessment of carbohydrate derivatives as synergistic with carbon materials in production environmentally friendly agro-based composites. Compos. Commun. 2019, 16, 94–105. [Google Scholar] [CrossRef]

- Liu, D.; Dong, Y.; Bhattacharyya, D.; Sui, G. Novel sandwiched structures in starch/cellulose nanowhiskers (CNWs) composite films. Compos. Commun. 2017, 4, 5–9. [Google Scholar] [CrossRef]

- Zhou, L.; Ke, K.; Yang, M.-B.; Yang, W. Recent progress on chemical modification of cellulose for high mechanical-performance poly (lactic acid)/cellulose composite: A review. Compos. Commun. 2020, 29, 100548. [Google Scholar] [CrossRef]

- Huang, M.-F.; Yu, J.-G.; Ma, X.-F. Studies on the properties of montmorillonite-reinforced thermoplastic starch composites. Polymer 2004, 45, 7017–7023. [Google Scholar] [CrossRef]

- Moriana, R.; Vilaplana, F.; Karlsson, S.; Amparo, R.-G. Improved thermo-mechanical properties by the addition of natural fibres in starch-based sustainable biocomposites. Compos. Part A Appl. Sci. Manuf. 2011, 42, 30–40. [Google Scholar] [CrossRef]

- Ma, X.; Yu, J.; Kennedy, J.F. Studies on the properties of natural fibers-reinforced thermoplastic starch composites. Carbohydr. Polym. 2005, 62, 19–24. [Google Scholar] [CrossRef]

- Venkatesan, R.; Rajeswari, N.; Tamilselvi, A. Antimicrobial, mechanical, barrier and thermal properties of bio-based poly(butylene adipate-co-terephthalate) (PBAT)/Ag2O nanocomposite films for packaging application. Polym. Adv. Technol. 2018, 29, 61–68. [Google Scholar] [CrossRef]

- Liu, G.; Song, Y.; Wang, J.; Zhuang, H.; Ma, L.; Li, C.; Liu, Y.; Zhang, J. Effects of nanoclay type on the physical and antimicrobial properties of PVOH-based nanocomposite films. LWT 2014, 57, 562–568. [Google Scholar] [CrossRef]

- Venkatesan, R.; Rajeswari, N. Nano-silica reinforced poly (butylene adipate-co-terephthalate) nanocomposites: Preparation, characterization and properties. Polym. Bull. 2019, 76, 4785–4801. [Google Scholar] [CrossRef]

- Zhang, C.; Li, T.; Song, H.; Han, Y.; Dong, Y.; Wang, Y.; Wang, Q. Improving the thermal conductivity and mechanical property of epoxy composites by introducing polyhedral oligomeric silsesquioxane-grafted graphene oxide. Polym. Compos. 2018, 39, E1890–E1899. [Google Scholar] [CrossRef]

- Cai, H.L.; Xu, K.; Liu, H.; Liu, X.; Fu, Z.E.; Chen, M.C. Influence of polyhedral oligomeric silsesquioxanes on thermal and mechanical properties of polycarbonate/POSS hybrid composites. Polym. Compos. 2011, 32, 1343–1351. [Google Scholar] [CrossRef]

- Priya, B.; Gupta, V.K.; Pathania, D.; Singha, A.S. Synthesis, characterization and antibacterial activity of biodegradable starch/PVA composite films reinforced with cellulosic fibre. Carbohydr. Polym. 2014, 109, 171–179. [Google Scholar] [CrossRef] [PubMed]

- Dong, Y.; He, J.; Yang, R. Phenolic resin/polyhedral oligomeric silsesquioxane (POSS) composites: Mechanical, ablative, thermal, and flame-retardant properties. Polym. Adv. Technol. 2019, 30, 2075–2085. [Google Scholar] [CrossRef]

- Wang, L.; Song, G.; Guo, R.; Qiao, X.; Chen, G.; Zhou, Z.; Li, Q. Enhancing aerogel mechanical properties with incorporation of POSS. Ceram. Int. 2019, 45, 14585–14593. [Google Scholar] [CrossRef]

- Patel, R.R.; Mohanraj, R.; Pittmam, C.U., Jr. Properties of polystyrene and polymethyl methacrylate copolymers of polyhedral oligomeric silsesquioxanes: A molecular dynamics study. J. Polym. Sci. B 2006, 44, 234–248. [Google Scholar] [CrossRef]

- Leu, C.M.; Reddy, G.M.; Wei, K.H.; Shu, S.F. Synthesis and dielectric properties of polyimide-chain-end tethered polyhedral oligomeric silsesquioxane nanocomposites. Chem. Mater. 2003, 15, 2261–2265. [Google Scholar] [CrossRef]

- Shaoxia, S.; Yaoyao, D.; Qi, L.; Tingting, L.; Xiuzhu, Y. Morphology, structural, thermal and rheological properties of wheat starch–palmitic acid complexes prepared during steam cooking. RSC Adv. 2020, 10, 30087–30093. [Google Scholar] [CrossRef]

- Haidan, W.; Li, W.; Shengying, Y.; Xianliang, S. Construction of Bi2WO6–TiO2/starch nanocomposite films for visible-light catalytic degradation of ethylene. Food Hydrocoll. 2017, 88, 92–100. [Google Scholar] [CrossRef]

- Rongfei, Z.; Xiangyou, W.; Meng, C. Preparation and characterization of potato starch film with various size of nano-SiO2. Polymers 2018, 10, 1172. [Google Scholar] [CrossRef]

- Zhao, H.; Zhao, S.-Q.; Li, Q.; Khan, M.R.; Liu, Y.; Lu, P.; Huang, C.-X.; Huang, L.-J.; Jiang, T. Fabrication and properties of waterborne thermoplastic polyurethane nanocomposite enhanced by the POSS with low dielectric constants. Polymer 2020, 209, 122992. [Google Scholar] [CrossRef]

- Marra, A.; Silvestre, C.; Duraccio, D.; Cimmino, S. polylactic acid/zinc oxide biocomposite films for food packaging applications. Int. J. Biol. Macromol. 2016, 88, 254–262. [Google Scholar] [CrossRef]

- Orsuwan, A.; Shankar, S.; Wang, L.F.; Sothornvit, R.; Rhim, J.-W. One-step preparation of banana powder/silver nanoparticles composite films. Int. J. Food Sci. Technol. 2017, 54, 497–506. [Google Scholar] [CrossRef] [PubMed]

- Oliveira Gama, R.; Bretas, R.E.S.; Oréfice, R.L. Control of the hydrophilic/hydrophobic behavior of biodegradable natural polymers by decorating surfaces with nano- and micro-components. Adv. Polym. Technol. 2018, 37, 654–661. [Google Scholar] [CrossRef]

- Diez-Pascual, A.M. Antibacterial nanocomposites based on thermosetting polymers derived from vegetable oils and metal oxide nanoparticles. Polymers 2019, 11, 1790. [Google Scholar] [CrossRef]

- Raigond, P.; Sood, A.; Kalia, A.; Joshi, A.; Kaundal, B.; Raigond, B.; Dutt, S.; Singh, B.; Chakrabarti, S.K. Antimicrobial activity of potato starch-based active biodegradable nanocomposite films. Potato Res. 2019, 62, 69–83. [Google Scholar] [CrossRef]

- Costa, S.M.; Ferreira, D.P.; Teixeira, P.; Ballesteros, L.F.; Teixeira, J.A.; Fangueiro, R. Active natural-based films for food packaging applications: The combined effect of chitosan and nanocellulose. Int. J. Biol. Macromol. 2021, 177, 241–251. [Google Scholar] [CrossRef]

- Al-Tayyar, N.A.; Youssef, A.M.; Al-Hindi, R.R. Antimicrobial packaging efficiency of ZnO-SiO2 nanocomposites infused into PVA/CS film for enhancing the shelf life of food products. Food Packag. Shelf Life 2020, 25, 100523. [Google Scholar] [CrossRef]

- Abdel-Halim, E.S.; Al-Dey, S.S. Antimicrobial activity of silver/starch/polyacrylamide nanocomposite. Int. J. Biol. Macromol. 2014, 68, 33–38. [Google Scholar] [CrossRef] [PubMed]

- Zahran, A.; Marei, A.H. Innovative natural polymer metal nanocomposites and their antimicrobial activity. Int. J. Biol. Macromol. 2019, 136, 586–596. [Google Scholar] [CrossRef]

- Tharanathan, R.N. Biodegradable films and composite coatings: Past, present, and future. Trends Food Sci. Technol. 2003, 14, 71–78. [Google Scholar] [CrossRef]

- Marsh, K.; Bugusu, B. Food packaging-Roles, materials, and environmental issues. J. Food Sci. 2007, 72, R39–R55. [Google Scholar] [CrossRef] [PubMed]

- Onyeaka, H.; Mansa, R.F.; Wong, C.M.V.L.; Miri, T. Bioconversion of starch base food waste into bioethanol. Sustainability 2022, 14, 11401. [Google Scholar] [CrossRef]

- Masset, J.; Calusinska, M.; Hamilton, C.; Hiligsmann, S.; Joris, B.; Wilmotte, A.; Thonart, P. Fermentative hydrogen production from glucose and starch using pure strains and artificial co-cultures of Clostridium spp. Biotechnol. Biofuels 2012, 5, 35. [Google Scholar] [CrossRef]

- Khongkliang, P.; Kongjan, P.; O-Thong, S. Hydrogen and methane production from starch processing wastewater by thermophilic two-stage anaerobic digestion. Energy Procedia 2015, 79, 827–832. [Google Scholar] [CrossRef]

- Tang, S.; Zou, P.; Xiong, H.; Tang, H. Effect of nano-SiO2 on the performance of starch/polyvinyl alcohol blend films. Carbohydr. Polym. 2008, 72, 521–526. [Google Scholar] [CrossRef]

- Bogdan, M.; Michal, D.; Hieronim, M.; Maciej, K. New, effective method of synthesis and structural characterization of Octakis(3-chloropropyl)octasilsesquioxane. Organometallics 2008, 27, 793–794. [Google Scholar] [CrossRef]

- Balaji, S.; Venkatesan, R.; Mugeeth, L.; Dhamodharan, R. Hydrophobic nanocomposites of PBAT with Cl-fn-POSS nanofiller as compostable food packaging films. Polym. Eng. Sci. 2021, 61, 314–326. [Google Scholar] [CrossRef]

- Venkatesan, R.; Zhang, Y.; Chen, G. Preparation of poly (butylene adipate-co-terephthalate)/ZnSnO3 composites with enhanced antimicrobial activity. Compos. Commun. 2020, 22, 100469. [Google Scholar] [CrossRef]

- Zhang, Y.; Fuentes, C.A.; Koekoekx, R.; Clasen, C.; Van Vuure, A.W.; Coninck, J.D.; Seveno, D. Spreading dynamics of molten polymer drops on glass substrates. Langmuir 2017, 33, 8447–8454. [Google Scholar] [CrossRef]

- Balouiri, M.; Sadiki, M.; Ibnsouda, S.K. Methods for in vitro evaluating antimicrobial activity: A review. J. Pharm. Anal. 2016, 6, 71–79. [Google Scholar] [CrossRef] [PubMed]

- Cunha, F.A.; Maia, K.R.; Mallman, E.J.; Cunha, M.D.; Maciel, A.A.; Souza, I.P.; Menezes, E.A.; Fechine, P.B. Silver nanoparticles-disk diffusion test against Escherichia coli isolates. Rev. Inst. Med. Trop. Sao Paulo 2016, 58, 73. [Google Scholar] [CrossRef] [PubMed]

- CLSI. Performance Standards for Antimicrobial Disk Susceptibility Tests, 7th ed.; Approved Standard; CLSI document M02-A11; Clinical and Laboratory Standards Institute: Wayne, PA, USA, 2012. [Google Scholar]

- Yadav, M.; Behera, K.; Chang, Y.H.; Chiu, F.C. Cellulose nanocrystal reinforced chitosan-based UV barrier composite films for sustainable packaging. Polymers 2020, 12, 202. [Google Scholar] [CrossRef] [PubMed]

- Azahari, N.A.; Othman, N.; Ismail, H. Biodegrdation studies of polyvinyl alcohol/corn starch blend films in soild and solution media. J. Phys. Sci. 2011, 22, 15–31. [Google Scholar]

- Schlemmer, D.; Sales, M.J.A.; Resck, I.S. Degradation of different polystyrene/thermoplastic starch blends buried in soil. Carbohydr. Polym. 2009, 75, 58–62. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Venkatesan, R.; Vanaraj, R.; Alagumalai, K.; Asrafali, S.P.; Raorane, C.J.; Raj, V.; Kim, S.-C. Thermoplastic Starch Composites Reinforced with Functionalized POSS: Fabrication, Characterization, and Evolution of Mechanical, Thermal and Biological Activities. Antibiotics 2022, 11, 1425. https://doi.org/10.3390/antibiotics11101425

Venkatesan R, Vanaraj R, Alagumalai K, Asrafali SP, Raorane CJ, Raj V, Kim S-C. Thermoplastic Starch Composites Reinforced with Functionalized POSS: Fabrication, Characterization, and Evolution of Mechanical, Thermal and Biological Activities. Antibiotics. 2022; 11(10):1425. https://doi.org/10.3390/antibiotics11101425

Chicago/Turabian StyleVenkatesan, Raja, Ramkumar Vanaraj, Krishnapandi Alagumalai, Shakila Parveen Asrafali, Chaitany Jayprakash Raorane, Vinit Raj, and Seong-Cheol Kim. 2022. "Thermoplastic Starch Composites Reinforced with Functionalized POSS: Fabrication, Characterization, and Evolution of Mechanical, Thermal and Biological Activities" Antibiotics 11, no. 10: 1425. https://doi.org/10.3390/antibiotics11101425

APA StyleVenkatesan, R., Vanaraj, R., Alagumalai, K., Asrafali, S. P., Raorane, C. J., Raj, V., & Kim, S.-C. (2022). Thermoplastic Starch Composites Reinforced with Functionalized POSS: Fabrication, Characterization, and Evolution of Mechanical, Thermal and Biological Activities. Antibiotics, 11(10), 1425. https://doi.org/10.3390/antibiotics11101425