Review of Liquid Metal Fiber Based Biosensors and Bioelectronics

Abstract

1. Introduction

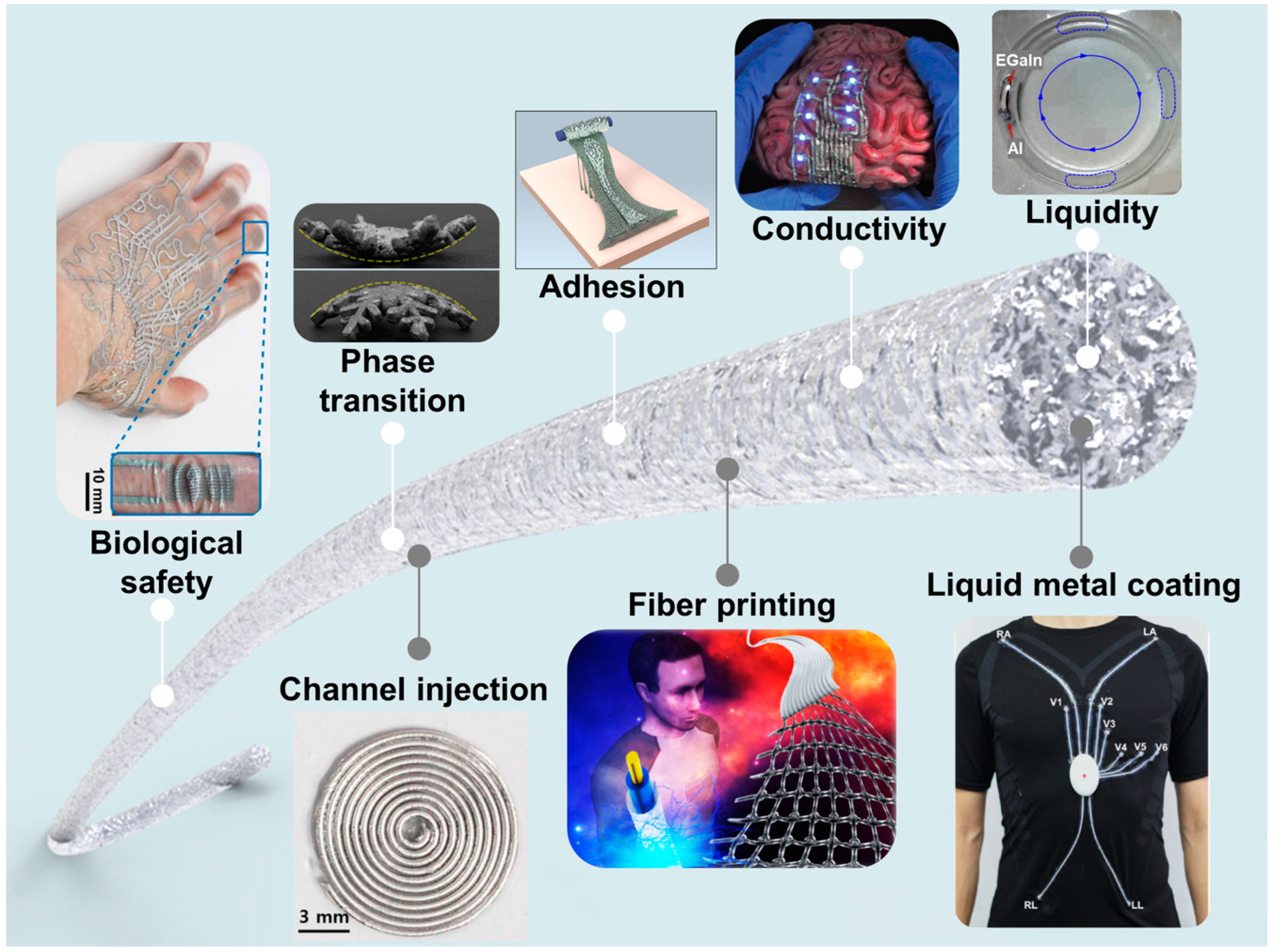

2. The Unique Properties of Liquid Metals

2.1. High Electrical Conductivity

2.2. Fluidity

2.3. Biosafety

2.4. Solid-Liquid Phase Transition

2.5. Interface Adhesion

3. Three Kinds of Liquid Metal Fibers

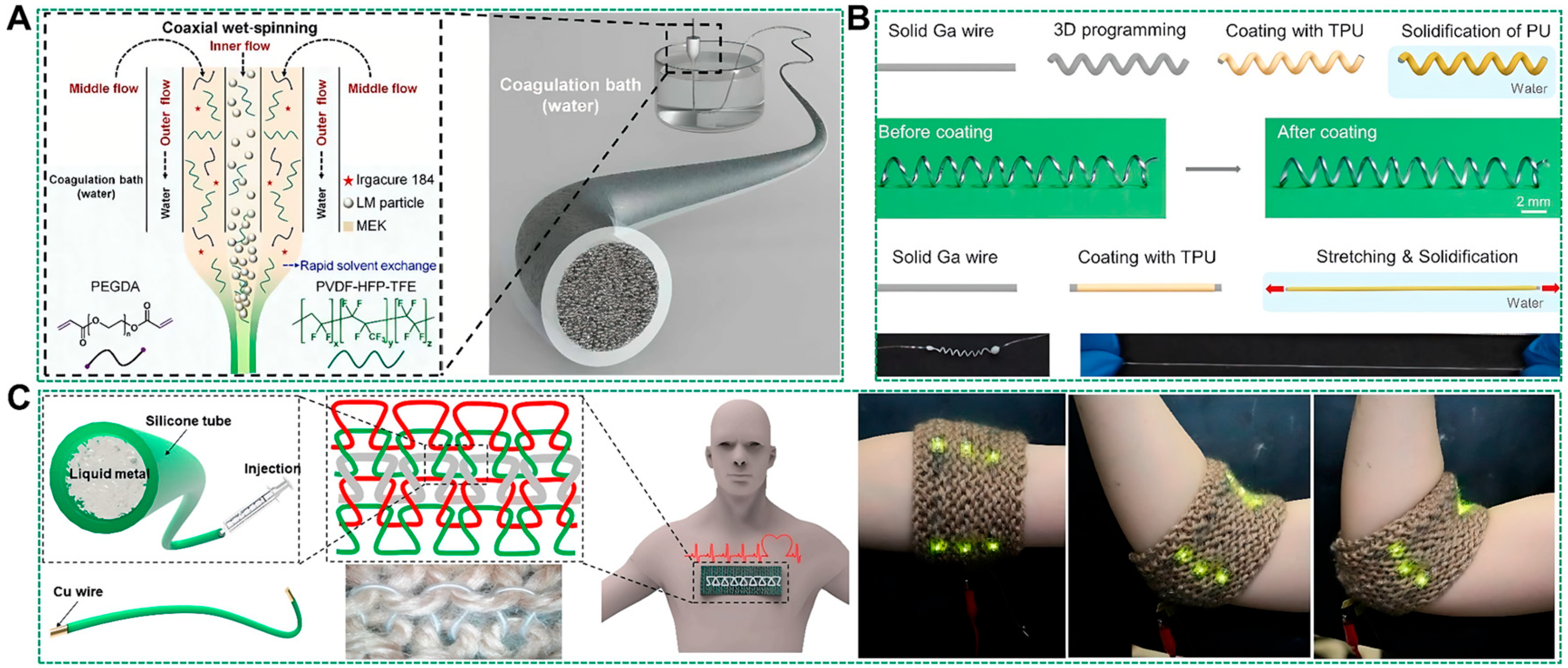

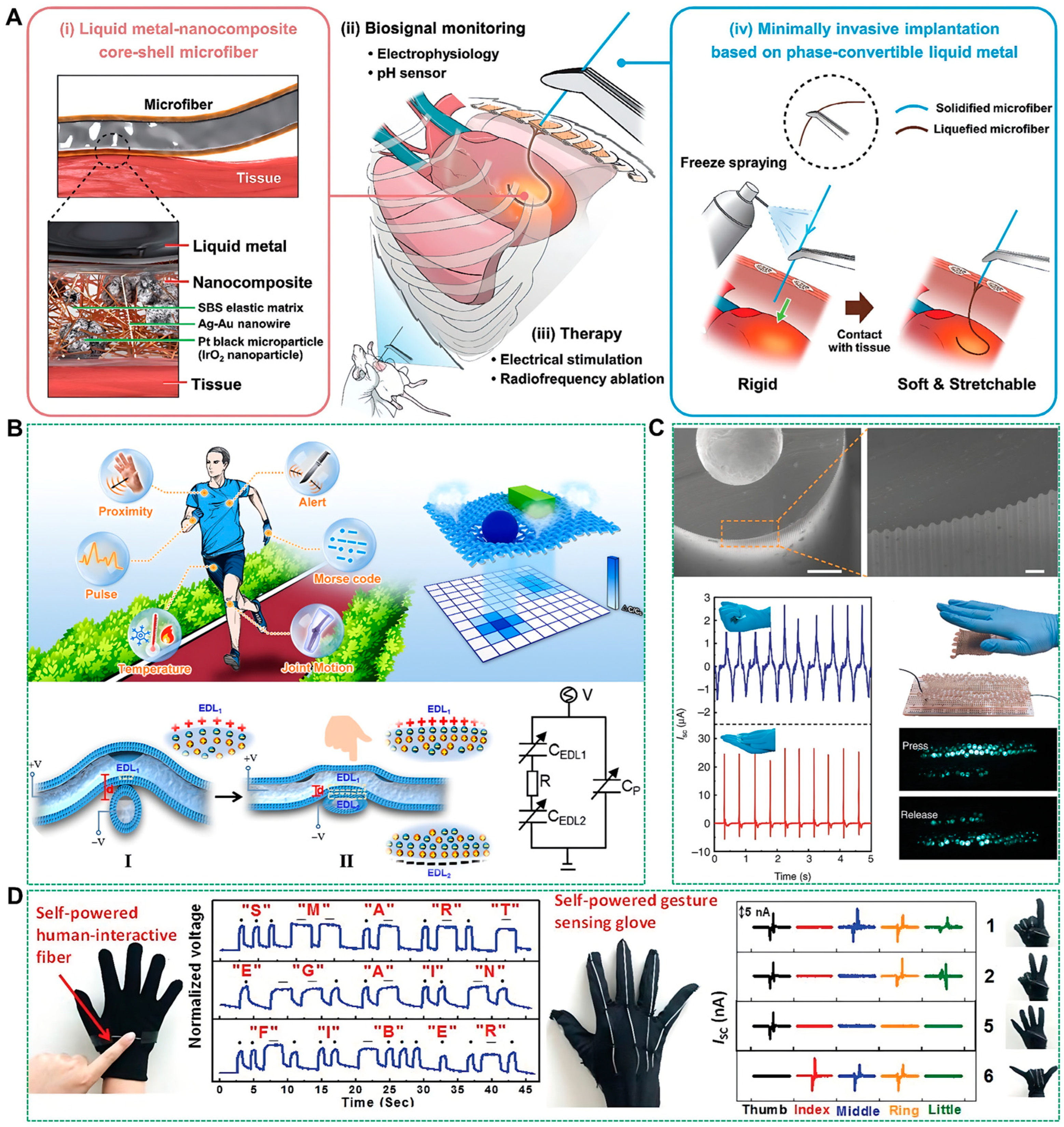

4. Internally Filled Liquid Metal-Based Tubular Textile Fibers

4.1. Preparations

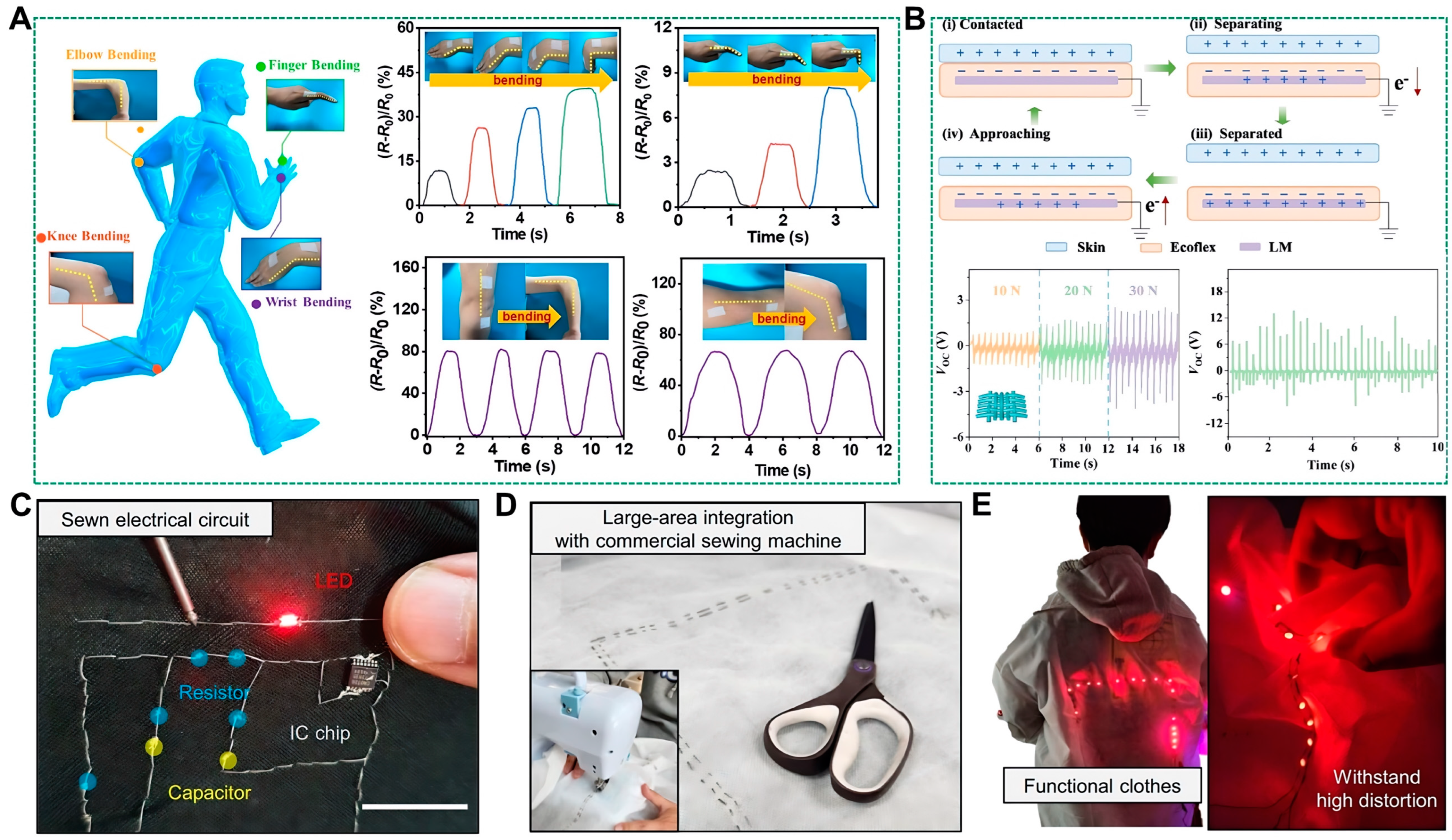

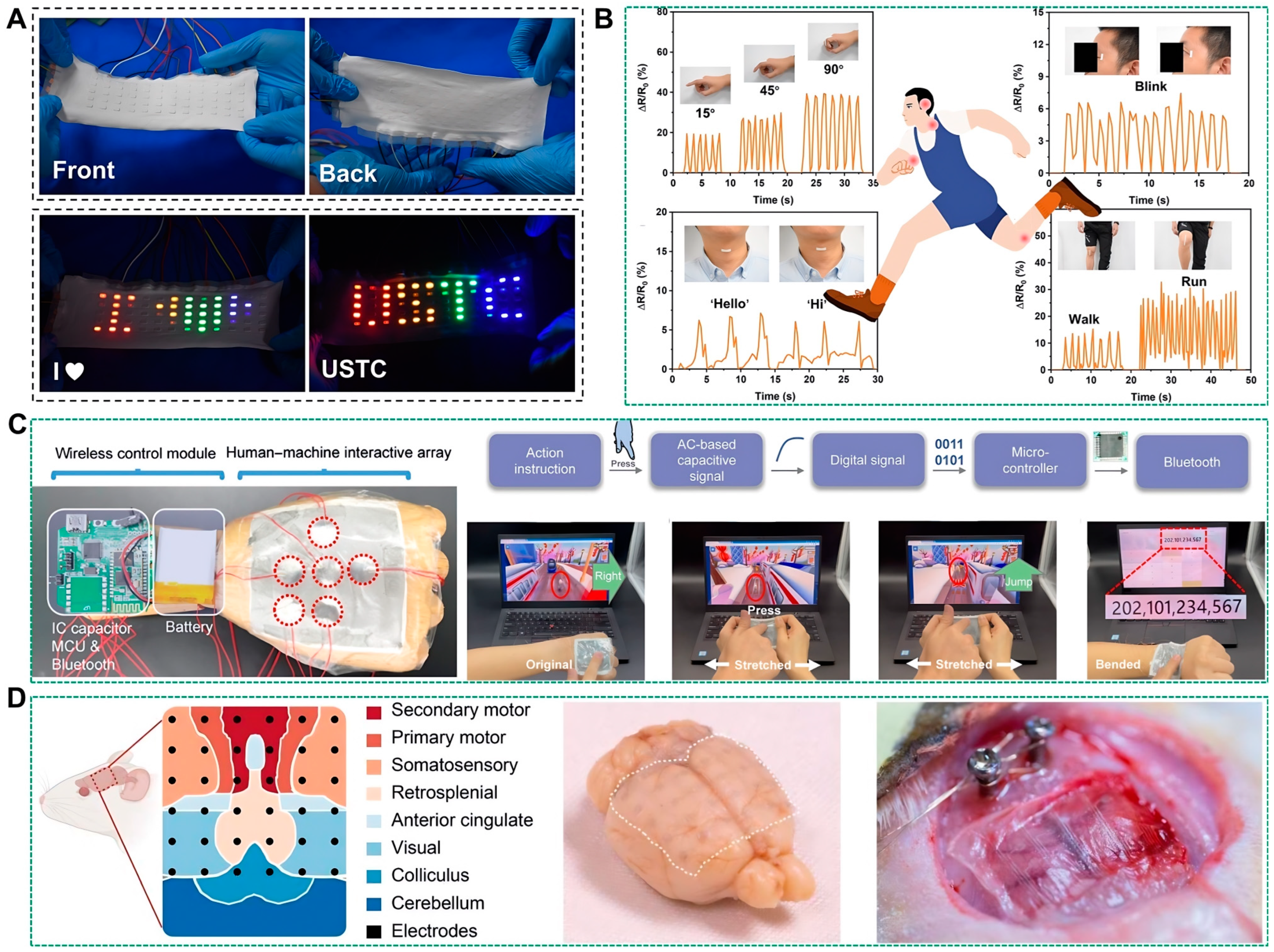

4.2. Applications

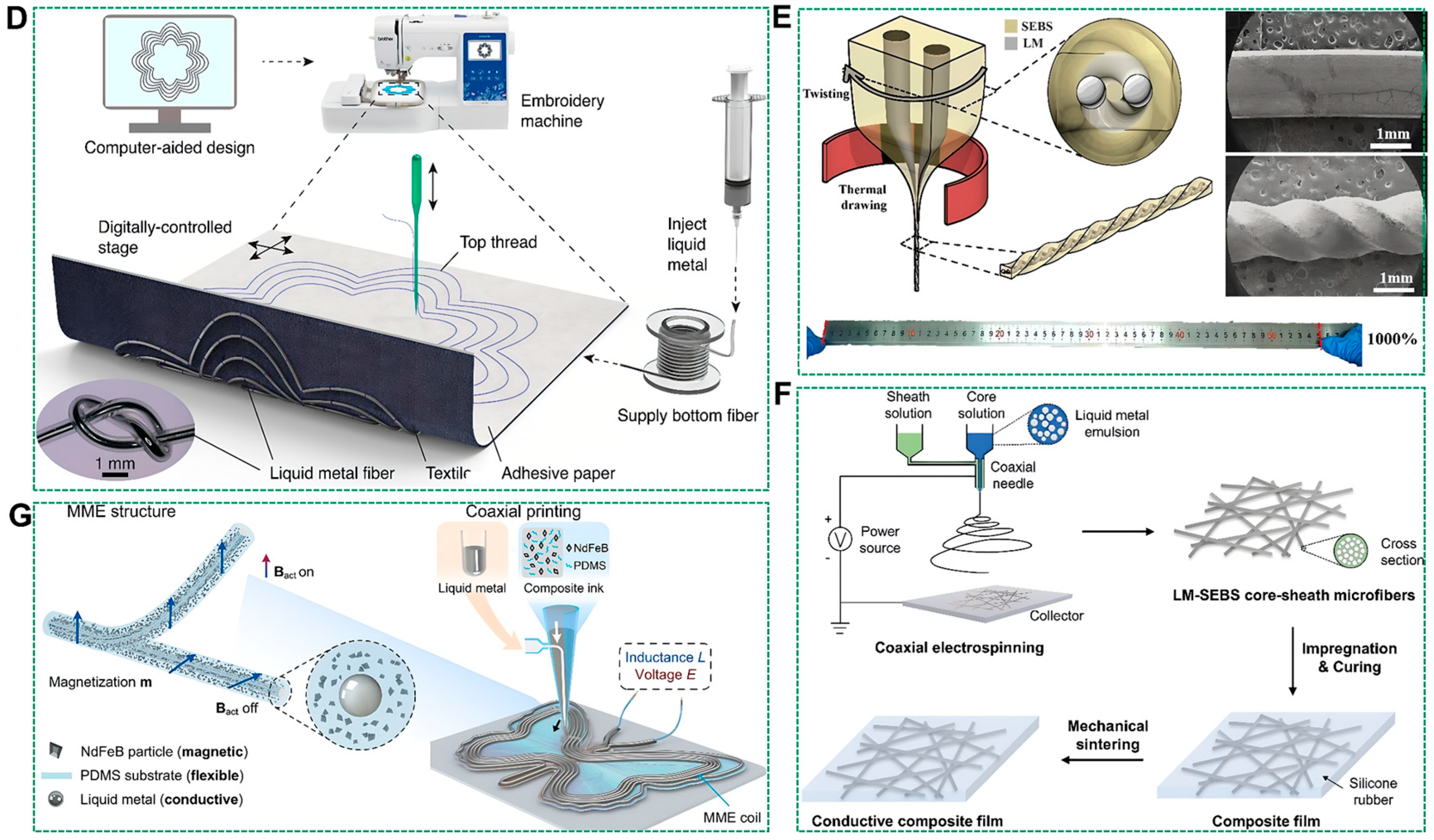

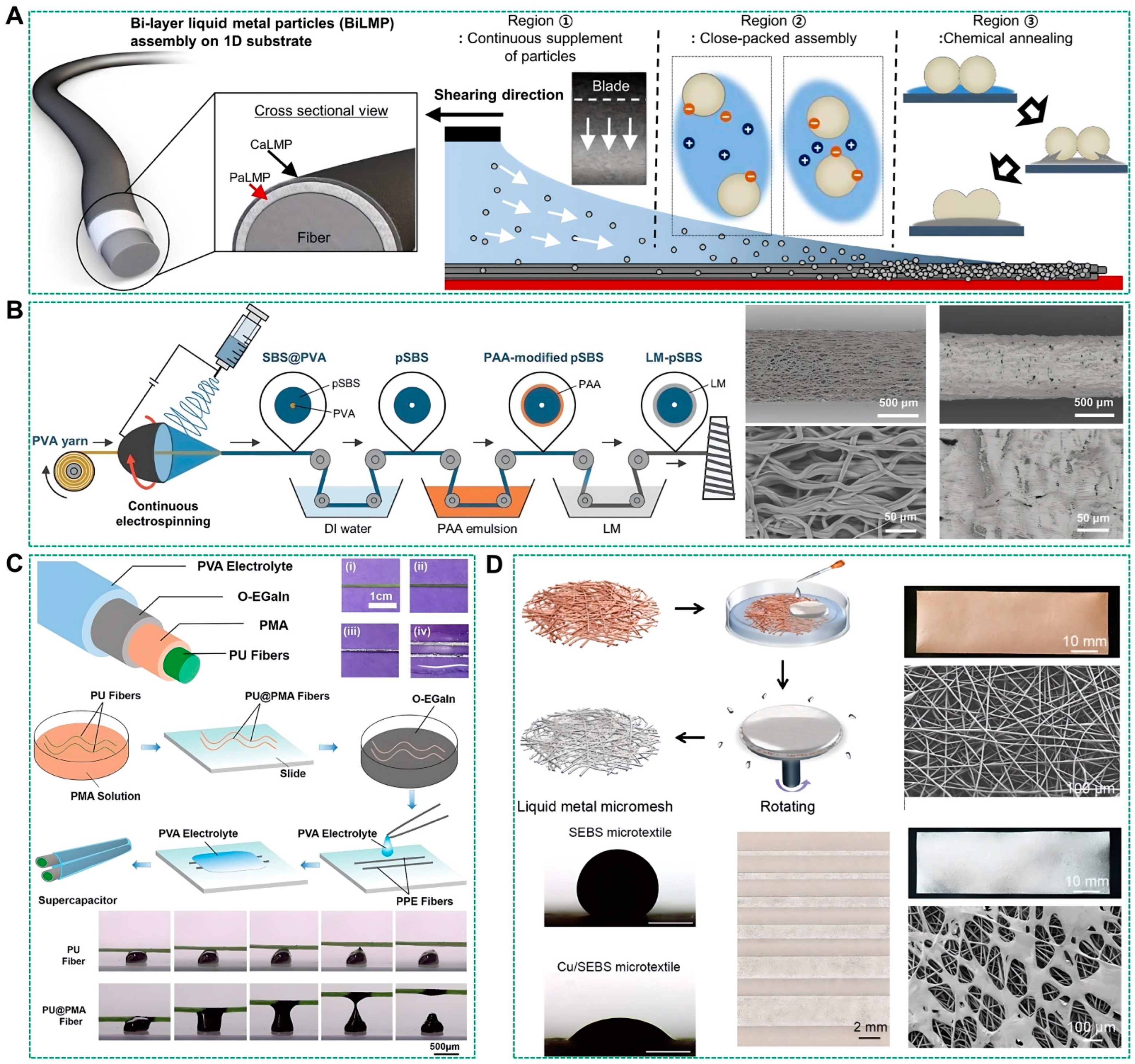

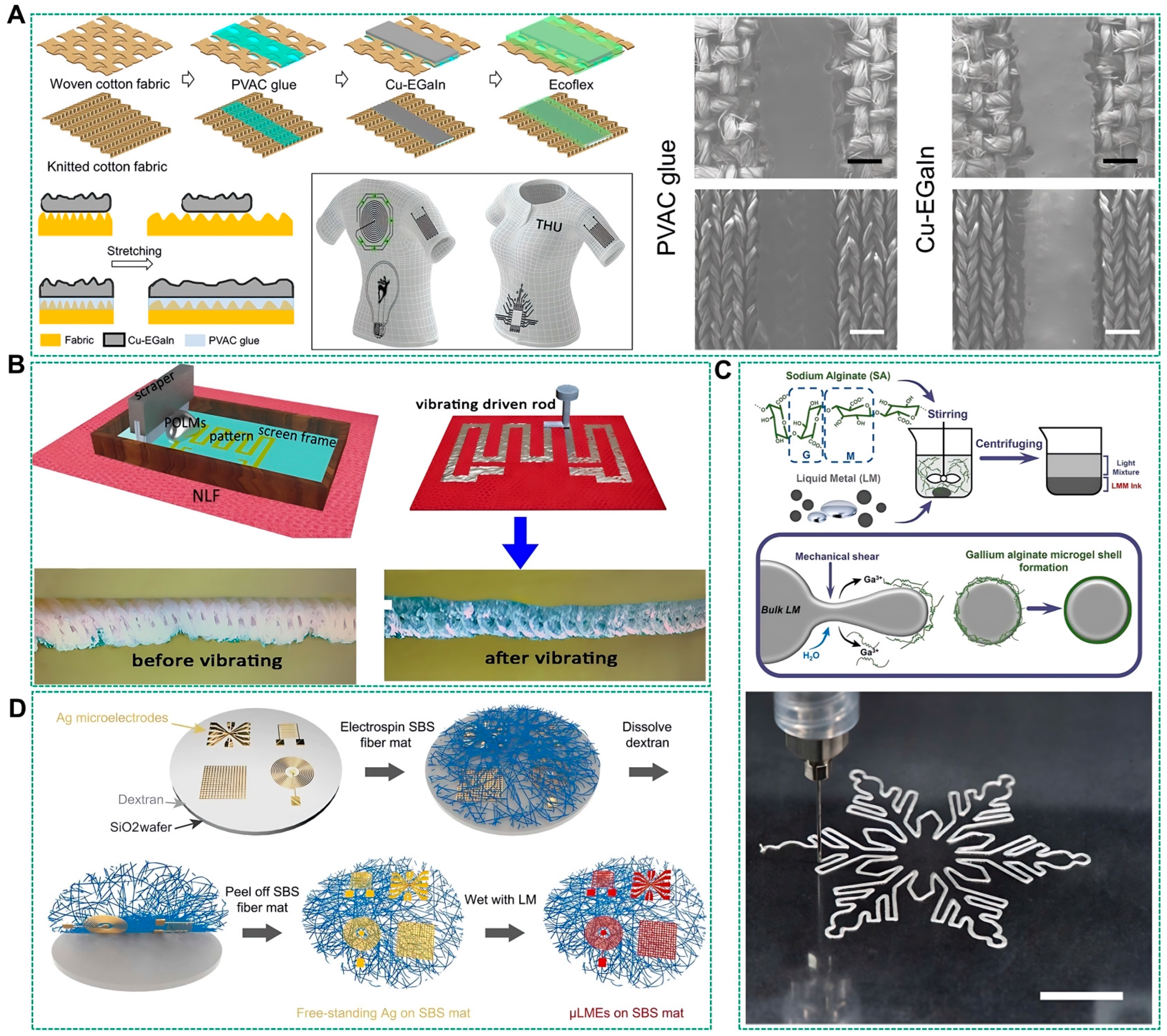

5. Surface-Printed Liquid Metal-Based Fibers

5.1. Preparations

5.2. Applications

6. Liquid Metal Coated Fibers

6.1. Preparations

6.2. Applications

7. Conclusions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Lee, J.; Kwon, H.; Seo, J.; Shin, S.; Koo, J.H.; Pang, C.; Son, S.; Kim, J.H.; Jang, Y.H.; Kim, D.E.; et al. Conductive Fiber-Based Ultrasensitive Textile Pressure Sensor for Wearable Electronics. Adv. Mater. 2015, 27, 2433–2439. [Google Scholar] [CrossRef] [PubMed]

- Zhang, L.; Liu, Z.; Wu, X.; Guan, Q.; Chen, S.; Sun, L.; Guo, Y.; Wang, S.; Song, J.; Jeffries, E.M.; et al. A Highly Efficient Self-Healing Elastomer with Unprecedented Mechanical Properties. Adv. Mater. 2019, 31, 1901402. [Google Scholar] [CrossRef] [PubMed]

- Wan, X.; Zhao, Y.; Li, Z.; Li, L. Emerging polymeric electrospun fibers: From structural diversity to application in flexible bioelectronics and tissue engineering. Exploration 2022, 2, 20210029. [Google Scholar] [CrossRef] [PubMed]

- Wang, Y.; Niu, W.; Lo, C.-Y.; Zhao, Y.; He, X.; Zhang, G.; Wu, S.; Ju, B.; Zhang, S. Interactively Full-Color Changeable Electronic Fiber Sensor with High Stretchability and Rapid Response. Adv. Funct. Mater. 2020, 30, 2000356. [Google Scholar] [CrossRef]

- Tung, W.S.; Daoud, W.A. Self-cleaning fibers via nanotechnology: A virtual reality. J. Mater. Chem. 2011, 21, 7858–7869. [Google Scholar] [CrossRef]

- Wang, L.; Zhang, F.; Liu, Y.; Leng, J. Shape Memory Polymer Fibers: Materials, Structures, and Applications. Adv. Fiber Mater. 2022, 4, 5–23. [Google Scholar] [CrossRef]

- Tonazzini, A.; Mintchev, S.; Schubert, B.; Mazzolai, B.; Shintake, J.; Floreano, D. Variable Stiffness Fiber with Self-Healing Capability. Adv. Mater. 2016, 28, 10142–10148. [Google Scholar] [CrossRef]

- Chen, G.; Au, C.; Chen, J. Textile Triboelectric Nanogenerators for Wearable Pulse Wave Monitoring. Trends Biotechnol. 2021, 39, 1078–1092. [Google Scholar] [CrossRef]

- Qi, K.; Wang, H.; You, X.; Tao, X.; Li, M.; Zhou, Y.; Zhang, Y.; He, J.; Shao, W.; Cui, S. Core-sheath nanofiber yarn for textile pressure sensor with high pressure sensitivity and spatial tactile acuity. J. Colloid. Interface Sci. 2020, 561, 93–103. [Google Scholar] [CrossRef]

- Wu, R.; Ma, L.; Hou, C.; Meng, Z.; Guo, W.; Yu, W.; Yu, R.; Hu, F.; Liu, X.Y. Silk Composite Electronic Textile Sensor for High Space Precision 2D Combo Temperature–Pressure Sensing. Small 2019, 15, 1901558. [Google Scholar] [CrossRef]

- Lou, M.; Abdalla, I.; Zhu, M.; Wei, X.; Yu, J.; Li, Z.; Ding, B. Highly Wearable, Breathable, and Washable Sensing Textile for Human Motion and Pulse Monitoring. ACS Appl. Mater. Interfaces 2020, 12, 19965–19973. [Google Scholar] [CrossRef] [PubMed]

- Lee, J.; Llerena Zambrano, B.; Woo, J.; Yoon, K.; Lee, T. Recent Advances in 1D Stretchable Electrodes and Devices for Textile and Wearable Electronics: Materials, Fabrications, and Applications. Adv. Mater. 2020, 32, 1902532. [Google Scholar] [CrossRef] [PubMed]

- Chen, Z.; Xi, J.; Huang, W.; Yuen, M.M.F. Stretchable conductive elastomer for wireless wearable communication applications. Sci. Rep. 2017, 7, 10958. [Google Scholar] [CrossRef] [PubMed]

- Li, X.; Koh, K.H.; Farhan, M.; Lai, K.W.C. An ultraflexible polyurethane yarn-based wearable strain sensor with a polydimethylsiloxane infiltrated multilayer sheath for smart textiles. Nanoscale 2020, 12, 4110–4118. [Google Scholar] [CrossRef]

- Gupta, U.; Lau, J.L.; Chia, P.Z.; Tan, Y.Y.; Ahmed, A.; Tan, N.C.; Soh, G.S.; Low, H.Y. All Knitted and Integrated Soft Wearable of High Stretchability and Sensitivity for Continuous Monitoring of Human Joint Motion. Adv. Healthc. Mater. 2023, 12, 2202987. [Google Scholar] [CrossRef]

- Ye, X.; Shi, B.; Li, M.; Fan, Q.; Qi, X.; Liu, X.; Zhao, S.; Jiang, L.; Zhang, X.; Fu, K.; et al. All-textile sensors for boxing punch force and velocity detection. Nano Energy 2022, 97, 107114. [Google Scholar] [CrossRef]

- Jeon, H.; Hong, S.K.; Kim, M.S.; Cho, S.J.; Lim, G. Omni-Purpose Stretchable Strain Sensor Based on a Highly Dense Nanocracking Structure for Whole-Body Motion Monitoring. ACS Appl. Mater. Interfaces 2017, 9, 41712–41721. [Google Scholar] [CrossRef]

- Yin, J.; Li, J.; Reddy, V.S.; Ji, D.; Ramakrishna, S.; Xu, L. Flexible Textile-Based Sweat Sensors for Wearable Applications. Biosensors 2023, 13, 127. [Google Scholar] [CrossRef]

- Sempionatto, J.R.; Moon, J.-M.; Wang, J. Touch-Based Fingertip Blood-Free Reliable Glucose Monitoring: Personalized Data Processing for Predicting Blood Glucose Concentrations. ACS Sens. 2021, 6, 1875–1883. [Google Scholar] [CrossRef]

- Xu, Z.; Sun, H.; Zhao, X.; Gao, C. Ultrastrong Fibers Assembled from Giant Graphene Oxide Sheets. Adv. Mater. 2013, 25, 188–193. [Google Scholar] [CrossRef]

- Kil, M.S.; Kim, S.J.; Park, H.J.; Yoon, J.H.; Jeong, J.-M.; Choi, B.G. Highly Stretchable Sensor Based on Fluid Dynamics-Assisted Graphene Inks for Real-Time Monitoring of Sweat. ACS Appl. Mater. Interfaces 2022, 14, 48072–48080. [Google Scholar] [CrossRef] [PubMed]

- Chen, S.-P.; Liao, Y.-C. Highly stretchable and conductive silver nanowire thin films formed by soldering nanomesh junctions. Phys. Chem. Chem. Phys. 2014, 16, 19856–19860. [Google Scholar] [CrossRef] [PubMed]

- Jung, D.; Lim, C.; Park, C.; Kim, Y.; Kim, M.; Lee, S.; Lee, H.; Kim, J.H.; Hyeon, T.; Kim, D.-H. Adaptive Self-Organization of Nanomaterials Enables Strain-Insensitive Resistance of Stretchable Metallic Nanocomposites. Adv. Mater. 2022, 34, 2200980. [Google Scholar] [CrossRef] [PubMed]

- Li, S.; Li, H.; Lu, Y.; Zhou, M.; Jiang, S.; Du, X.; Guo, C. Advanced Textile-Based Wearable Biosensors for Healthcare Monitoring. Biosensors 2023, 13, 909. [Google Scholar] [CrossRef]

- Sharma, S.; Chhetry, A.; Sharifuzzaman, M.; Yoon, H.; Park, J.Y. Wearable Capacitive Pressure Sensor Based on MXene Composite Nanofibrous Scaffolds for Reliable Human Physiological Signal Acquisition. ACS Appl. Mater. Interfaces 2020, 12, 22212–22224. [Google Scholar] [CrossRef]

- Tavakoli, M.; Malakooti, M.H.; Paisana, H.; Ohm, Y.; Green Marques, D.; Alhais Lopes, P.; Piedade, A.P.; de Almeida, A.T.; Majidi, C. EGaIn-Assisted Room-Temperature Sintering of Silver Nanoparticles for Stretchable, Inkjet-Printed, Thin-Film Electronics. Adv. Mater. 2018, 30, 1801852. [Google Scholar] [CrossRef]

- Ren, L.; Zhang, B.-W. Room temperature liquid metals for flexible alkali metal-chalcogen batteries. Exploration 2022, 2, 20210182. [Google Scholar] [CrossRef]

- Gao, J.; Ye, J.; Chen, S.; Gong, J.; Wang, Q.; Liu, J. Liquid Metal Foaming via Decomposition Agents. ACS Appl. Mater. Interfaces 2021, 13, 17093–17103. [Google Scholar] [CrossRef]

- Zhang, J.; Yao, Y.; Liu, J. Autonomous convergence and divergence of the self-powered soft liquid metal vehicles. Sci. Bull. 2015, 60, 943–951. [Google Scholar] [CrossRef]

- Sheng, L.; Zhang, J.; Liu, J. Diverse Transformations of Liquid Metals Between Different Morphologies. Adv. Mater. 2014, 26, 6036–6042. [Google Scholar] [CrossRef]

- Jiang, C.; Li, T.; Huang, X.; Guo, R. Patterned Liquid-Metal-Enabled Universal Soft Electronics (PLUS-E) for Deformation Sensing on 3D Curved Surfaces. ACS Appl. Mater. Interfaces 2023, 15, 51958–51970. [Google Scholar] [CrossRef] [PubMed]

- Tang, L.; Shang, J.; Jiang, X. Multilayered electronic transfer tattoo that can enable the crease amplification effect. Sci. Adv. 2021, 7, eabe3778. [Google Scholar] [CrossRef] [PubMed]

- Jin, S.W.; Park, J.; Hong, S.Y.; Park, H.; Jeong, Y.R.; Park, J.; Lee, S.-S.; Ha, J.S. Stretchable Loudspeaker using Liquid Metal Microchannel. Sci. Rep. 2015, 5, 11695. [Google Scholar] [CrossRef] [PubMed]

- Guo, R.; Wang, H.; Chen, G.; Yuan, B.; Zhang, Y.; Liu, J. Smart semiliquid metal fibers with designed mechanical properties for room temperature stimulus response and liquid welding. Appl. Mater. Today 2020, 20, 100738. [Google Scholar] [CrossRef]

- Guo, R.; Li, T.; Wu, Z.; Wan, C.; Niu, J.; Huo, W.; Yu, H.; Huang, X. Thermal Transfer-Enabled Rapid Printing of Liquid Metal Circuits on Multiple Substrates. ACS Appl. Mater. Interfaces 2022, 14, 37028–37038. [Google Scholar] [CrossRef]

- Guo, R.; Li, T.; Jiang, C.; Zong, H.; Li, X.; Wan, C.; Yu, H.; Huang, X. Pressure Regulated Printing of Semiliquid Metal on Electrospinning Film Enables Breathable and Waterproof Wearable Electronics. Adv. Fiber Mater. 2024, 6, 354–366. [Google Scholar] [CrossRef]

- Wang, X.; Guo, R.; Liu, J. Liquid Metal Based Soft Robotics: Materials, Designs, and Applications. Adv. Mater. Technol. 2019, 4, 1800549. [Google Scholar] [CrossRef]

- Morley, N.B.; Burris, J.; Cadwallader, L.C.; Nornberg, M.D. GaInSn usage in the research laboratory. Rev. Sci. Instrum. 2008, 79, 056107. [Google Scholar] [CrossRef]

- Park, Y.-G.; An, H.S.; Kim, J.-Y.; Park, J.-U. High-resolution, reconfigurable printing of liquid metals with three-dimensional structures. Sci. Adv. 2019, 5, eaaw2844. [Google Scholar] [CrossRef]

- Fassler, A.; Majidi, C. 3D structures of liquid-phase GaIn alloy embedded in PDMS with freeze casting. Lab. Chip 2013, 13, 4442–4450. [Google Scholar] [CrossRef]

- Yu, Y.; Miyako, E. Manipulation of Biomolecule-Modified Liquid-Metal Blobs. Angew. Chem. Int. Ed. 2017, 56, 13606–13611. [Google Scholar] [CrossRef] [PubMed]

- Lu, Y.; Hu, Q.; Lin, Y.; Pacardo, D.B.; Wang, C.; Sun, W.; Ligler, F.S.; Dickey, M.D.; Gu, Z. Transformable liquid-metal nanomedicine. Nat. Commun. 2015, 6, 10066. [Google Scholar] [CrossRef] [PubMed]

- Yi, L.; Jin, C.; Wang, L.; Liu, J. Liquid-solid phase transition alloy as reversible and rapid molding bone cement. Biomaterials 2014, 35, 9789–9801. [Google Scholar] [CrossRef] [PubMed]

- Wang, L.; Liu, J. Liquid phase 3D printing for quickly manufacturing conductive metal objects with low melting point alloy ink. Sci. China Technol. Sci. 2014, 57, 1721–1728. [Google Scholar] [CrossRef]

- Sun, X.; Guo, R.; Yuan, B.; Chen, S.; Wang, H.; Dou, M.; Liu, J.; He, Z.-Z. Low-Temperature Triggered Shape Transformation of Liquid Metal Microdroplets. ACS Appl. Mater. Interfaces 2020, 12, 38386–38396. [Google Scholar] [CrossRef]

- Sun, X.; Guo, R.; Yuan, B.; Wang, H.; Duan, M.; Yang, Y.; Zhu, X.; Wang, X.; Chen, S.; Cheng, J.; et al. Stiffness tunable implanted electrode enabled by magnetic liquid metal for wireless hyperthermia. Appl. Mater. Today 2022, 27, 101495. [Google Scholar] [CrossRef]

- Sun, X.; Cui, B.; Yuan, B.; Wang, X.; Fan, L.; Yu, D.; He, Z.; Sheng, L.; Liu, J.; Lu, J. Liquid Metal Microparticles Phase Change Medicated Mechanical Destruction for Enhanced Tumor Cryoablation and Dual-Mode Imaging. Adv. Funct. Mater. 2020, 30, 2003359. [Google Scholar] [CrossRef]

- Byun, S.-H.; Sim, J.Y.; Zhou, Z.; Lee, J.; Qazi, R.; Walicki, M.C.; Parker, K.E.; Haney, M.P.; Choi, S.H.; Shon, A.; et al. Mechanically transformative electronics, sensors, and implantable devices. Sci. Adv. 2019, 5, eaay0418. [Google Scholar] [CrossRef]

- Guo, R.; Sun, X.; Yao, S.; Duan, M.; Wang, H.; Liu, J.; Deng, Z. Semi-Liquid-Metal-(Ni-EGaIn)-Based Ultraconformable Electronic Tattoo. Adv. Mater. Technol. 2019, 4, 1900183. [Google Scholar] [CrossRef]

- Guo, R.; Zhen, Y.; Huang, X.; Liu, J. Spatially selective adhesion enabled transfer printing of liquid metal for 3D electronic circuits. Appl. Mater. Today 2021, 25, 101236. [Google Scholar] [CrossRef]

- Zhang, S.; Wang, B.; Jiang, J.; Wu, K.; Guo, C.F.; Wu, Z. High-Fidelity Conformal Printing of 3D Liquid Alloy Circuits for Soft Electronics. ACS Appl. Mater. Interfaces 2019, 11, 7148–7156. [Google Scholar] [CrossRef] [PubMed]

- Zhao, R.; Guo, R.; Xu, X.; Liu, J. A Fast and Cost-Effective Transfer Printing of Liquid Metal Inks for Three-Dimensional Wiring in Flexible Electronics. ACS Appl. Mater. Interfaces 2020, 12, 36723–36730. [Google Scholar] [CrossRef] [PubMed]

- Lin, Y.; Genzer, J.; Dickey, M.D. Attributes, Fabrication, and Applications of Gallium-Based Liquid Metal Particles. Adv. Sci. 2020, 7, 2000192. [Google Scholar] [CrossRef] [PubMed]

- Park, J.-E.; Kang, H.S.; Koo, M.; Park, C. Autonomous Surface Reconciliation of a Liquid-Metal Conductor Micropatterned on a Deformable Hydrogel. Adv. Mater. 2020, 32, 2002178. [Google Scholar] [CrossRef]

- Zheng, L.; Zhu, M.; Wu, B.; Li, Z.; Sun, S.; Wu, P. Conductance-stable liquid metal sheath-core microfibers for stretchy smart fabrics and self-powered sensing. Sci. Adv. 2021, 7, eabg4041. [Google Scholar] [CrossRef]

- Liu, J.; Wang, P.; Li, G.; Yang, L.; Yu, W.; Meng, C.; Guo, S. A highly stretchable and ultra-sensitive strain sensing fiber based on a porous core–network sheath configuration for wearable human motion detection. Nanoscale 2022, 14, 12418–12430. [Google Scholar] [CrossRef]

- Yu, Y.; Guo, J.; Ma, B.; Zhang, D.; Zhao, Y. Liquid metal-integrated ultra-elastic conductive microfibers from microfluidics for wearable electronics. Sci. Bull. 2020, 65, 1752–1759. [Google Scholar] [CrossRef]

- Bhuyan, P.; Singh, M.; Wei, Y.; Thanh Tran, D.; Ha, M.; Jeong, K.-U.; Jeon, H.; Park, S. Thread-analogous elastic fibers with liquid metal core by drawing at room temperature for multifunctional smart textiles. Chem. Eng. J. 2024, 480, 147944. [Google Scholar] [CrossRef]

- Qi, X.; Zhao, H.; Wang, L.; Sun, F.; Ye, X.; Zhang, X.; Tian, M.; Qu, L. Underwater sensing and warming E-textiles with reversible liquid metal electronics. Chem. Eng. J. 2022, 437, 135382. [Google Scholar] [CrossRef]

- Yu, X.; Fan, W.; Liu, Y.; Dong, K.; Wang, S.; Chen, W.; Zhang, Y.; Lu, L.; Liu, H.; Zhang, Y. A One-Step Fabricated Sheath-Core Stretchable Fiber Based on Liquid Metal with Superior Electric Conductivity for Wearable Sensors and Heaters. Adv. Mater. Technol. 2022, 7, 2101618. [Google Scholar] [CrossRef]

- Sun, Z.; Yu, H.; Chen, C.; Qin, M.; Feng, W. Core-sheath smart polymer fiber composites with high elasticity and thermal conductivity. Compos. Sci. Technol. 2024, 252, 110610. [Google Scholar] [CrossRef]

- Long, L.; Che, X.; Yao, P.; Zhang, X.; Wang, J.; Li, M.; Li, C. Interfacial Electrochemical Polymerization for Spinning Liquid Metals into Core-shell Wires. ACS Appl. Mater. Interfaces 2022, 14, 18690–18696. [Google Scholar] [CrossRef] [PubMed]

- Ma, B.; Zhang, J.; Chen, G.; Chen, Y.; Xu, C.; Lei, L.; Liu, H. Shape-Programmable Liquid Metal Fibers. Biosensors 2023, 13, 28. [Google Scholar] [CrossRef] [PubMed]

- Li, M.; Gholami, F.; Yue, L.; Fratarcangeli, M.R.; Black, E.; Shimokawa, S.; Nomura, T.; Tanaka, M.; Kobayashi, H.; Song, Y.; et al. Coaxial-Spun Hollow Liquid Crystal Elastomer Fiber as a Versatile Platform for Functional Composites. Adv. Funct. Mater. 2024, 2406847. [Google Scholar] [CrossRef]

- Ping, B.; Zhang, Z.; Liu, Q.; Li, M.; Yang, Q.; Guo, R. Liquid Metal Fibers with a Knitted Structure for Wearable Electronics. Biosensors 2023, 13, 715. [Google Scholar] [CrossRef]

- Lin, R.; Kim, H.-J.; Achavananthadith, S.; Xiong, Z.; Lee, J.K.W.; Kong, Y.L.; Ho, J.S. Digitally-embroidered liquid metal electronic textiles for wearable wireless systems. Nat. Commun. 2022, 13, 2190. [Google Scholar] [CrossRef]

- Zhang, Y.; He, Y.; Niu, L.; Xing, X.; Jiang, Y.; Fang, J.; Liu, Y. Enhanced sensing performance of superelastic thermally drawn liquid metal fibers through helical architecture while eliminating directional signal errors. J. Mater. Sci. Technol. 2024, 195, 136–145. [Google Scholar] [CrossRef]

- Fu, C.; Tang, W.; Miao, Y.; Xu, A.; Nilghaz, A.; Xu, W.; Dong, K.; Su, B.; Xia, Z. Large-scalable fabrication of liquid metal-based double helix core-spun yarns for capacitive sensing, energy harvesting, and thermal management. Nano Energy 2023, 106, 108078. [Google Scholar] [CrossRef]

- Ma, J.; Liu, Z.; Nguyen, Q.-K.; Zhang, P. Lightweight Soft Conductive Composites Embedded with Liquid Metal Fiber Networks. Adv. Funct. Mater. 2024, 34, 2308128. [Google Scholar] [CrossRef]

- Zhang, Y.; Pan, C.; Liu, P.; Peng, L.; Liu, Z.; Li, Y.; Wang, Q.; Wu, T.; Li, Z.; Majidi, C.; et al. Coaxially printed magnetic mechanical electrical hybrid structures with actuation and sensing functionalities. Nat. Commun. 2023, 14, 4428. [Google Scholar] [CrossRef]

- Mun, S.; Lee, S.; Bae, K.J.; Bae, Y.; Lee, H.-M.; Kim, B.-J.; Yu, J.; Park, S. Bio-imitative Synergistic Color-Changing and Shape-Morphing Elastic Fibers with a Liquid Metal Core. Adv. Fiber Mater. 2024, 6, 900–910. [Google Scholar] [CrossRef]

- Lu, S.; Jiao, J.; Li, X.; Wang, H.; Wu, H.; Li, Q. An Ultrawide Range, Highly Stretchable Liquid Metal Force and Strain Sensor Based on Spiral Multilayer Microfluidic Fibers. IEEE Trans. Ind. Inf. 2024, 20, 4–11. [Google Scholar] [CrossRef]

- Peng, Y.; Liu, H.; Xin, Y.; Zhang, J. Rheological conductor from liquid metal-polymer composites. Matter 2021, 4, 3001–3014. [Google Scholar] [CrossRef]

- Nam, S.; Cha, G.D.; Sunwoo, S.-H.; Jeong, J.H.; Kang, H.; Park, O.K.; Lee, K.-Y.; Oh, S.; Hyeon, T.; Choi, S.H.; et al. Needle-Like Multifunctional Biphasic Microfiber for Minimally Invasive Implantable Bioelectronics. Adv. Mater. 2024, 2404101. [Google Scholar] [CrossRef] [PubMed]

- Agno, K.-C.; Yang, K.; Byun, S.-H.; Oh, S.; Lee, S.; Kim, H.; Kim, K.; Cho, S.; Jeong, W.-I.; Jeong, J.-W. A temperature-responsive intravenous needle that irreversibly softens on insertion. Nat. Biomed. Eng. 2024, 8, 963–976. [Google Scholar] [CrossRef]

- Nan, K.; Babaee, S.; Chan, W.W.; Kuosmanen, J.L.P.; Feig, V.R.; Luo, Y.; Srinivasan, S.S.; Patterson, C.M.; Jebran, A.M.; Traverso, G. Low-cost gastrointestinal manometry via silicone–liquid-metal pressure transducers resembling a quipu. Nat. Biomed. Eng. 2022, 6, 1092–1104. [Google Scholar] [CrossRef]

- Cooper, C.B.; Arutselvan, K.; Liu, Y.; Armstrong, D.; Lin, Y.; Khan, M.R.; Genzer, J.; Dickey, M.D. Stretchable Capacitive Sensors of Torsion, Strain, and Touch Using Double Helix Liquid Metal Fibers. Adv. Funct. Mater. 2017, 27, 1605630. [Google Scholar] [CrossRef]

- Ding, L.; Wang, Q.; Wang, S.; Su, Z.; Zhang, D. A liquid metal core-shell fiber for stretchable smart fabrics. Cell Rep. Phys. Sci. 2023, 4, 101603. [Google Scholar] [CrossRef]

- Leber, A.; Dong, C.; Chandran, R.; Das Gupta, T.; Bartolomei, N.; Sorin, F. Soft and stretchable liquid metal transmission lines as distributed probes of multimodal deformations. Nat. Electron. 2020, 3, 316–326. [Google Scholar] [CrossRef]

- Chen, J.; Zhu, G.; Wang, J.; Chang, X.; Zhu, Y. Multifunctional Iontronic Sensor Based on Liquid Metal-Filled Ho llow Ionogel Fibers in Detecting Pressure, Temperature, and Proximity. ACS Appl. Mater. Interfaces 2023, 15, 7485–7495. [Google Scholar] [CrossRef]

- Dong, C.; Leber, A.; Das Gupta, T.; Chandran, R.; Volpi, M.; Qu, Y.; Nguyen-Dang, T.; Bartolomei, N.; Yan, W.; Sorin, F. High-efficiency super-elastic liquid metal based triboelectric fibers and textiles. Nat. Commun. 2020, 11, 3537. [Google Scholar] [CrossRef] [PubMed]

- Lai, Y.-C.; Lu, H.-W.; Wu, H.-M.; Zhang, D.; Yang, J.; Ma, J.; Shamsi, M.; Vallem, V.; Dickey, M.D. Elastic Multifunctional Liquid–Metal Fibers for Harvesting Mechanical and Electromagnetic Energy and as Self-Powered Sensors. Adv. Energy Mater. 2021, 11, 2100411. [Google Scholar] [CrossRef]

- Liang, S.; Li, J.; Li, F.; Hu, L.; Chen, W.; Yang, C. Flexible Tactile Sensing Microfibers Based On Liquid Metals. ACS Omega 2022, 7, 12891–12899. [Google Scholar] [CrossRef] [PubMed]

- Lee, G.-H.; Lee, D.H.; Jeon, W.; Yoon, J.; Ahn, K.; Nam, K.S.; Kim, M.; Kim, J.K.; Koo, Y.H.; Joo, J.; et al. Conductance stable and mechanically durable bi-layer EGaIn composite-coated stretchable fiber for 1D bioelectronics. Nat. Commun. 2023, 14, 4173. [Google Scholar] [CrossRef]

- Li, H.; Qu, R.; Ma, Z.; Zhou, N.; Huang, Q.; Zheng, Z. Permeable and Patternable Super-Stretchable Liquid Metal Fiber for Constructing High-Integration-Density Multifunctional Electronic Fibers. Adv. Funct. Mater. 2024, 34, 2308120. [Google Scholar] [CrossRef]

- Duan, M.; Ren, Y.; Sun, X.; Zhu, X.; Wang, X.; Sheng, L.; Liu, J. EGaIn Fiber Enabled Highly Flexible Supercapacitors. ACS Omega 2021, 6, 24444–24449. [Google Scholar] [CrossRef]

- Ma, X.; Zhang, M.; Zhang, J.; Wang, S.; Cao, S.; Li, Y.; Hu, G.; Kong, D. Highly Permeable and Ultrastretchable Liquid Metal Micromesh for Skin-Attachable Electronics. ACS Mater. Lett. 2022, 4, 634–641. [Google Scholar] [CrossRef]

- Dong, J.; Tang, X.; Peng, Y.; Fan, C.; Li, L.; Zhang, C.; Lai, F.; He, G.; Ma, P.; Wang, Z.; et al. Highly permeable and ultrastretchable E-textiles with EGaIn-superlyophilicity for on-skin health monitoring, joule heating, and electromagnetic shielding. Nano Energy 2023, 108, 108194. [Google Scholar] [CrossRef]

- Chen, G.; Wang, H.; Guo, R.; Duan, M.; Zhang, Y.; Liu, J. Superelastic EGaIn Composite Fibers Sustaining 500% Tensile Strain with Superior Electrical Conductivity for Wearable Electronics. ACS Appl. Mater. Interfaces 2020, 12, 6112–6118. [Google Scholar] [CrossRef]

- Yuan, X.; Kong, W.; Xia, P.; Wang, Z.; Gao, Q.; Xu, J.; Shan, D.; Yao, Q.; Guo, B.; He, Y. In Situ Synthesis of Liquid Metal Conductive Fibers toward Smart Cloth. ACS Appl. Mater. Interfaces 2024, 16, 27850–27865. [Google Scholar] [CrossRef]

- Zhou, N.; Jiang, B.; He, X.; Li, Y.; Ma, Z.; Zhang, H.; Zhang, M. A Superstretchable and Ultrastable Liquid Metal–Elastomer Wire for Soft Electronic Devices. ACS Appl. Mater. Interfaces 2021, 13, 19254–19262. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Q.; Roach, D.J.; Geng, L.; Chen, H.; Qi, H.J.; Fang, D. Highly stretchable and conductive fibers enabled by liquid metal dip-coating. Smart Mater. Struct. 2018, 27, 035019. [Google Scholar] [CrossRef]

- Zhuang, Q.; Ma, Z.; Gao, Y.; Zhang, Y.; Wang, S.; Lu, X.; Hu, H.; Cheung, C.; Huang, Q.; Zheng, Z. Liquid–Metal-Superlyophilic and Conductivity–Strain-Enhancing Scaffold for Permeable Superelastic Conductors. Adv. Funct. Mater. 2021, 31, 2105587. [Google Scholar] [CrossRef]

- Gui, H.; Tan, S.; Wang, Q.; Yu, Y.; Liu, F.; Lin, J.; Liu, J. Spraying printing of liquid metal electronics on various clothes to compose wearable functional device. Sci. China Technol. Sci. 2017, 60, 306–316. [Google Scholar] [CrossRef]

- Guo, R.; Wang, H.; Sun, X.; Yao, S.; Chang, H.; Wang, H.; Liu, J.; Zhang, Y. Semiliquid Metal Enabled Highly Conductive Wearable Electronics for Smart Fabrics. ACS Appl. Mater. Interfaces 2019, 11, 30019–30027. [Google Scholar] [CrossRef]

- Ou, M.; Qiu, W.; Huang, K.; Feng, H.; Chu, S. Ultrastretchable Liquid Metal Electrical Conductors Built-in Cloth Fiber Networks for Wearable Electronics. ACS Appl. Mater. Interfaces 2020, 12, 7673–7678. [Google Scholar] [CrossRef]

- Wu, P.; Fu, J.; Xu, Y.; He, Y. Liquid Metal Microgels for Three-Dimensional Printing of Smart Electronic Clothes. ACS Appl. Mater. Interfaces 2022, 14, 13458–13467. [Google Scholar] [CrossRef]

- Zhuang, Q.; Yao, K.; Wu, M.; Lei, Z.; Chen, F.; Li, J.; Mei, Q.; Zhou, Y.; Huang, Q.; Zhao, X.; et al. Wafer-patterned, permeable, and stretchable liquid metal microelectrodes for implantable bioelectronics with chronic biocompatibility. Sci. Adv. 2023, 9, eadg8602. [Google Scholar] [CrossRef]

- Ma, Z.; Huang, Q.; Xu, Q.; Zhuang, Q.; Zhao, X.; Yang, Y.; Qiu, H.; Yang, Z.; Wang, C.; Chai, Y.; et al. Permeable superelastic liquid-metal fibre mat enables biocompatible and monolithic stretchable electronics. Nat. Mater. 2021, 20, 859–868. [Google Scholar] [CrossRef]

- Kwon, K.Y.; Cheeseman, S.; Frias-De-Diego, A.; Hong, H.; Yang, J.; Jung, W.; Yin, H.; Murdoch, B.J.; Scholle, F.; Crook, N.; et al. A Liquid Metal Mediated Metallic Coating for Antimicrobial and Antiviral Fabrics. Adv. Mater. 2021, 33, 2104298. [Google Scholar] [CrossRef]

- Dong, J.; Peng, Y.; Pu, L.; Chang, K.; Li, L.; Zhang, C.; Ma, P.; Huang, Y.; Liu, T. Perspiration-Wicking and Luminescent On-Skin Electronics Based on Ultrastretchable Janus E-Textiles. Nano Lett. 2022, 22, 7597–7605. [Google Scholar] [CrossRef] [PubMed]

- Wang, X.; Liu, J.; Zheng, Y.; Shi, B.; Chen, A.; Wang, L.; Shen, G. Biocompatible liquid metal coated stretchable electrospinning film for strain sensors monitoring system. Sci. China Mater. 2022, 65, 2235–2243. [Google Scholar] [CrossRef]

- Wang, M.; Wang, K.; Ma, C.; Uzabakiriho, P.C.; Chen, X.; Zhao, G. Mechanical Gradients Enable Highly Stretchable Electronics Based on Nanofiber Substrates. ACS Appl. Mater. Interfaces 2022, 14, 35997–36006. [Google Scholar] [CrossRef] [PubMed]

- Wang, M.; Ma, C.; Uzabakiriho, P.C.; Chen, X.; Chen, Z.; Cheng, Y.; Wang, Z.; Zhao, G. Stencil Printing of Liquid Metal upon Electrospun Nanofibers Enables High-Performance Flexible Electronics. ACS Nano 2021, 15, 19364–19376. [Google Scholar] [CrossRef]

- Cao, J.; Liang, F.; Li, H.; Li, X.; Fan, Y.; Hu, C.; Yu, J.; Xu, J.; Yin, Y.; Li, F.; et al. Ultra-robust stretchable electrode for e-skin: In situ assembly using a nanofiber scaffold and liquid metal to mimic water-to-net interaction. InfoMat 2022, 4, e12302. [Google Scholar] [CrossRef]

| Materials | Max. Stretchability | Conductivity (S m−1) |

|---|---|---|

| Au/polydimethylsiloxane | 150% | 4.5 × 107 |

| Graphene/polyimide | 240% | 106 |

| Carbon nanotube/polydimethylsiloxane | 280% | 400 |

| Ag nanoflowers/PU | 776% | 4.1 × 106 |

| EGaIn | 1400% | 3.4 × 106 |

| Cu-EGaIn | 850% | 9.0 × 106 |

| Liquid Material Fiber Types | Characteristics | Fabrication Methods | Applications |

|---|---|---|---|

| Internally filled liquid metal-based tubular textile fiber | High electrical Conductivity High compliance | Injecting | Smart textiles Pressure sensing Energy storage systems |

| Surface-printed liquid metal-based fiber | Simple manufacturing process Easy to integrate | Coating | Wearable electronics Body electrode Flexible sensors |

| Liquid metal-coated fiber | Morphological controllability High stretchability | Screen printing 3D printing | Flexible circuits Flexible sensors |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, X.; Xu, H.; Li, J.; Liu, Y.; Fan, H. Review of Liquid Metal Fiber Based Biosensors and Bioelectronics. Biosensors 2024, 14, 490. https://doi.org/10.3390/bios14100490

Liu X, Xu H, Li J, Liu Y, Fan H. Review of Liquid Metal Fiber Based Biosensors and Bioelectronics. Biosensors. 2024; 14(10):490. https://doi.org/10.3390/bios14100490

Chicago/Turabian StyleLiu, Xiaotong, Hui Xu, Jiameng Li, Yanqing Liu, and Haojun Fan. 2024. "Review of Liquid Metal Fiber Based Biosensors and Bioelectronics" Biosensors 14, no. 10: 490. https://doi.org/10.3390/bios14100490

APA StyleLiu, X., Xu, H., Li, J., Liu, Y., & Fan, H. (2024). Review of Liquid Metal Fiber Based Biosensors and Bioelectronics. Biosensors, 14(10), 490. https://doi.org/10.3390/bios14100490