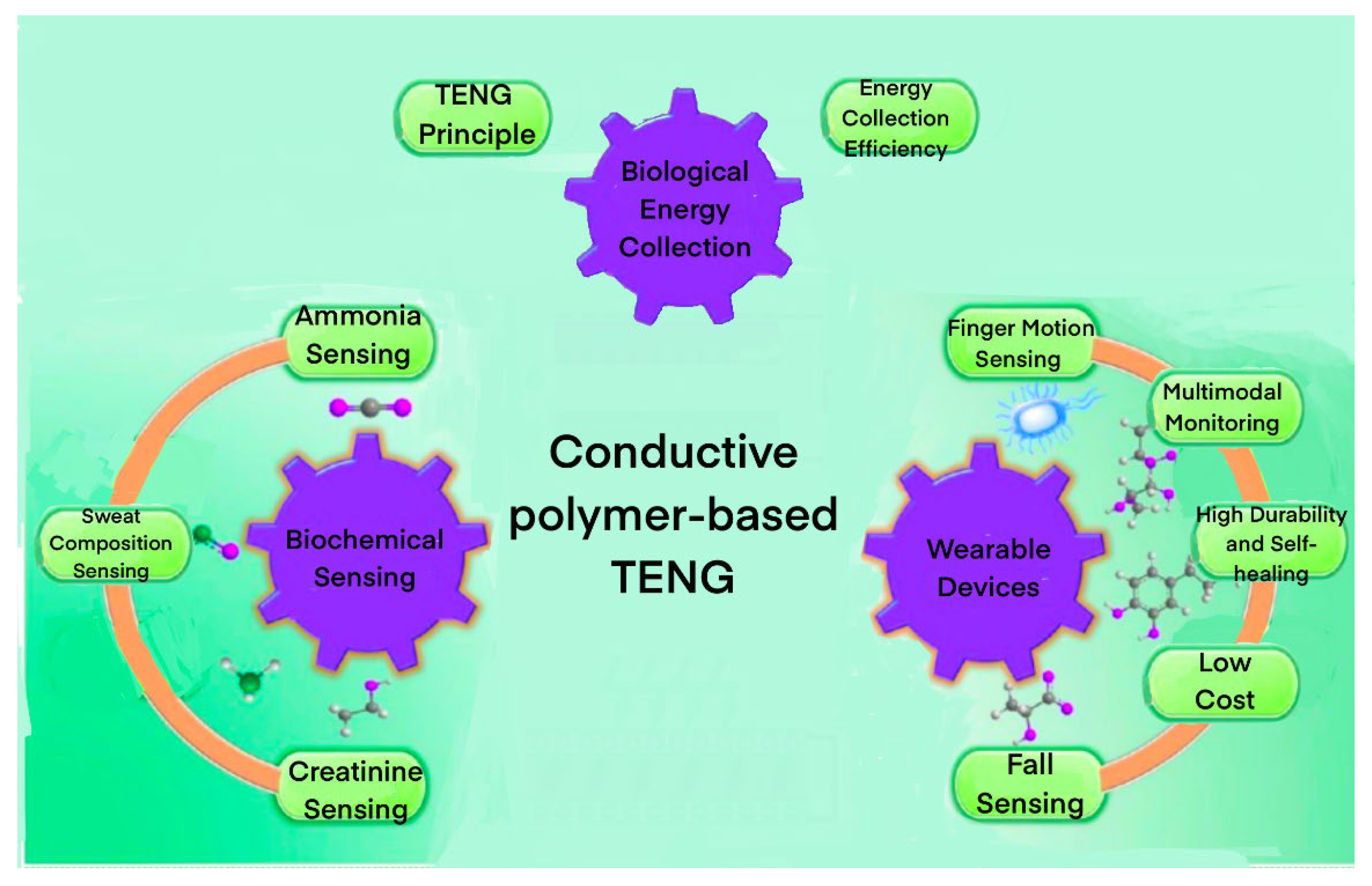

From Biochemical Sensor to Wearable Device: The Key Role of the Conductive Polymer in the Triboelectric Nanogenerator

Abstract

1. Introduction

2. CPNG in Biological Energy Collection

2.1. The Principle of TENG

2.2. Strategies for Improving Energy Collection Efficiency by Introducing Conductive Polymers

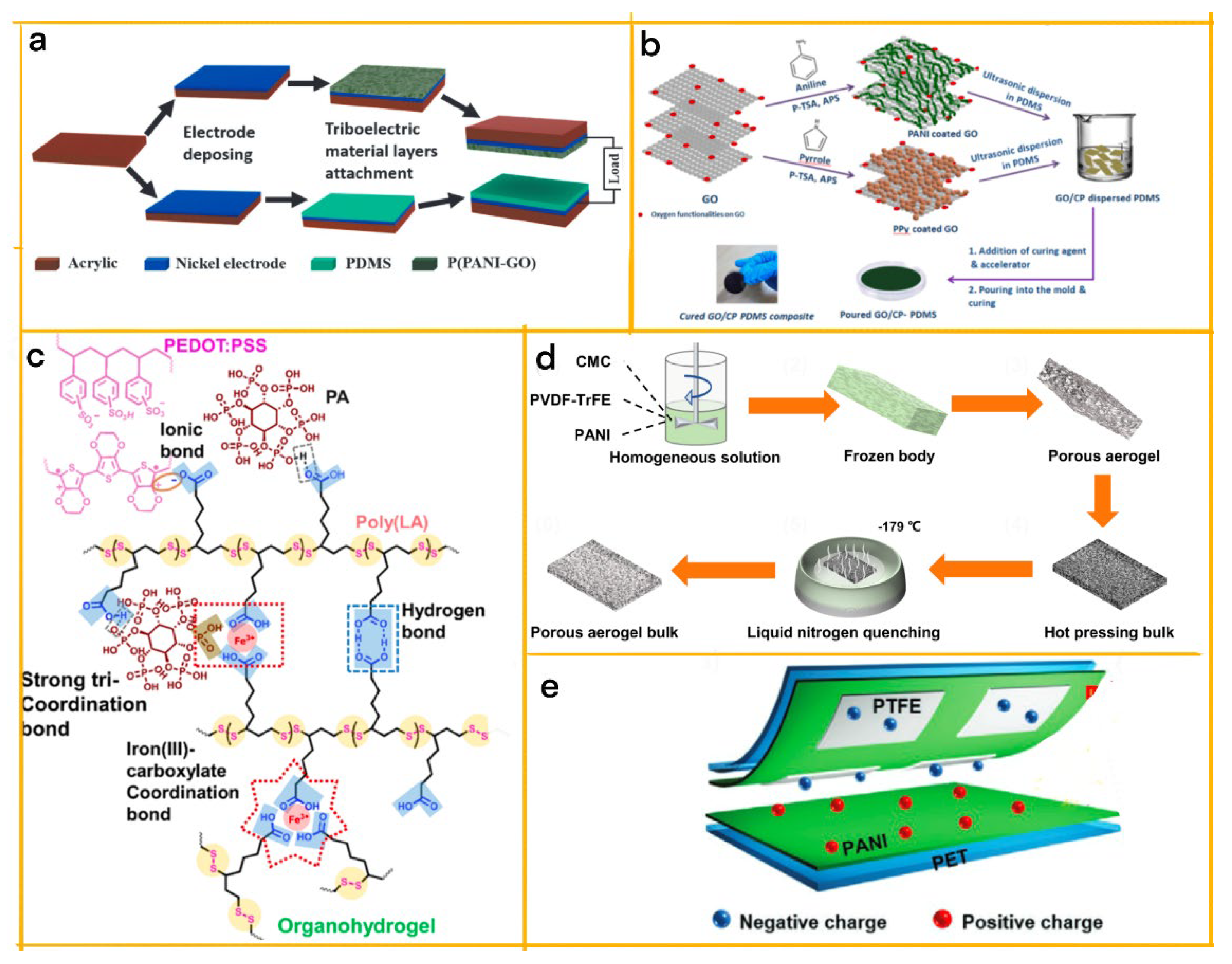

2.2.1. Doped into PDMS

2.2.2. Doped into Gel

3. CPNG in Biochemical Sensing

3.1. CPNG in Ammonia Sensing

3.1.1. Conductive Nanofibers

3.1.2. Conductive Composite Materials

3.2. CPNG in Biochemical Sensing

3.2.1. Creatinine Sensing

| Date | Sizes | Conductive Polymer | Energy Sources | Outputs | Applications |

|---|---|---|---|---|---|

| 2021 [71] | 2 × 4 cm2 | PANI | Movement | 0.32 nW | Creatinine Sensing |

| 2022 [72] | 2 × 1 cm2 | PANI | Movement | 400 V | Sweat Composition Sensing |

| 2020 [73] | 2 × 2 cm2 | PANI | Movement | 141 μW | Finger Motion Sensing |

| 2019 [74] | 10 × 10 cm2 | PANI | Movement | 200 μA | Finger Motion Sensing |

| 2022 [75] | 2 × 2 cm2 | PPy | Vibration | 20.2 V | Fall Sensing |

| 2023 [76] | None | PEDOT:PSS | Vibration | 700 V | Fall Sensing |

3.2.2. Sweat Composition Sensing

4. CPNG in other Wearable Devices

4.1. Human Motion Sensing

4.1.1. Finger Motion Sensing

4.1.2. Fall Sensing

4.2. Design Strategy of CPNG-Based Wearable Devices

4.2.1. Multimodal Monitoring

| Date | Sizes | Conductive Polymer | Energy Sources | Outputs | Applications |

|---|---|---|---|---|---|

| 2022 [96] | 1 × 1 cm2 | PEDOT:PSS | Movement | 20.5 V | Multimodal Monitoring |

| 2020 [97] | None | PEDOT:PSS | Movement | 383.8 V | High Durability and Self-healing |

| 2021 [58] | 2 × 3 cm2 | conductive cellulose hydrogels | Vibration | 35 V | High Durability and Self-healing |

| 2022 [98] | 3 × 1 cm2 | PEDOT:PSS | Vibration | 0.8 μA | High Durability and Self-healing |

| 2019 [99] | 2 × 2 cm2 | PPy | Movement | 45 μA | Low Cost |

| 2019 [100] | 5 × 2 cm2 | PPy | Movement | 200 V | Low Cost |

4.2.2. High Durability and Self-Healing

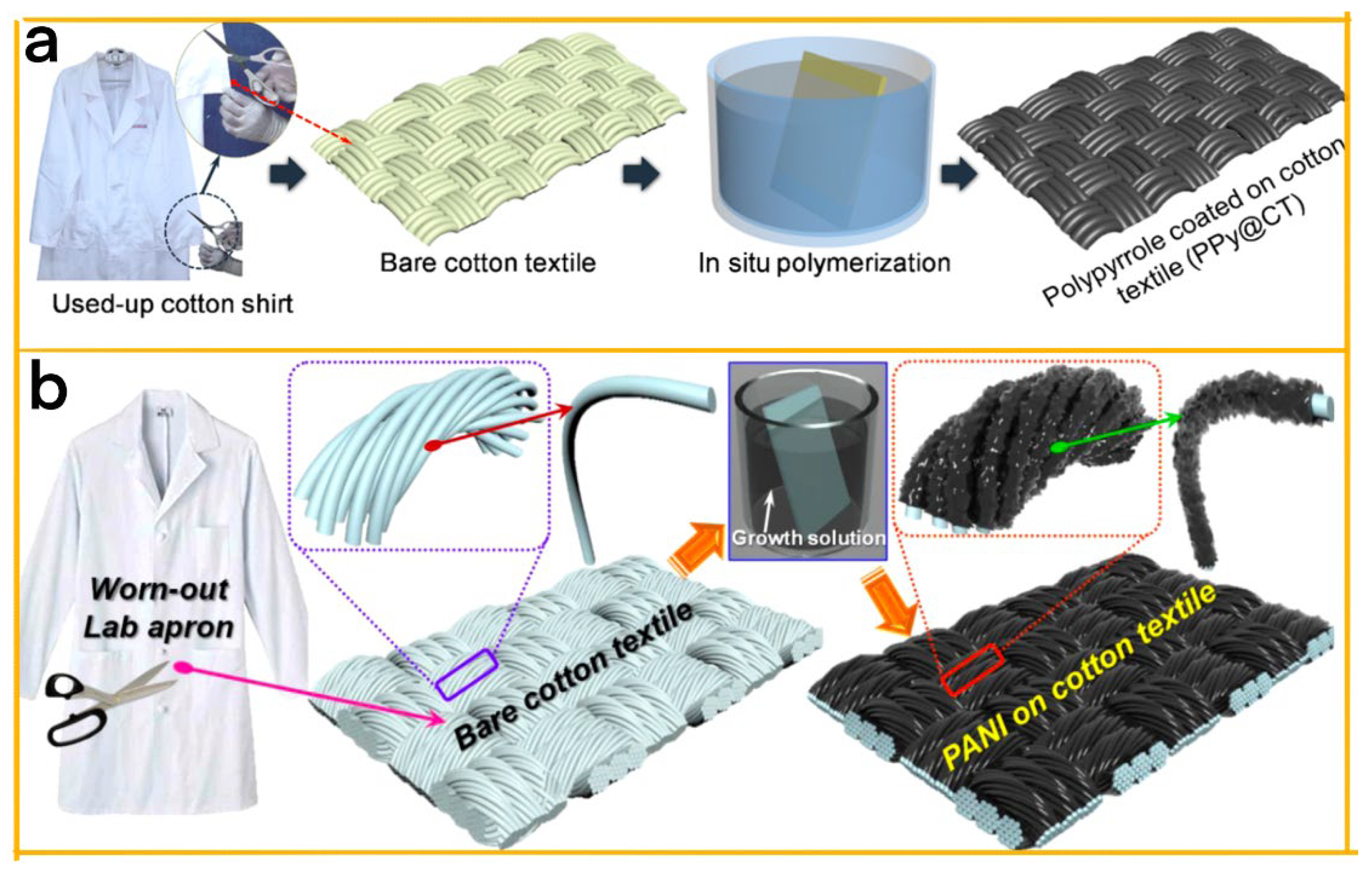

4.2.3. Low Cost

5. Conclusions and Prospect

5.1. Biological Energy Collection

5.1.1. Material Optimization

5.1.2. Device Structure and Surface Modification

5.1.3. Collecting Energy through Multiple Channels

5.2. Biochemical Sensing

5.2.1. Improve Sensitivity

5.2.2. Bio-Safety

5.2.3. Reduce Interference and Improve Sensing Accuracy

5.3. Wearable Devices

5.3.1. Personalized Devices

5.3.2. Durability

5.3.3. Comfortability

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Arakawa, T.; Dao, D.V.; Mitsubayashi, K. Biosensors and Chemical Sensors for Healthcare Monitoring: A Review. IEEJ Trans. Electr. Electron. Eng. 2022, 17, 626–636. [Google Scholar] [CrossRef]

- Chen, X.; Xie, X.; Liu, Y.; Zhao, C.; Wen, M.; Wen, Z. Advances in Healthcare Electronics Enabled by Triboelectric Nanogenerators. Adv. Funct. Mater. 2020, 30, 2004673. [Google Scholar] [CrossRef]

- Mathew, A.A.; Vivekanandan, S. Design and Simulation of Single-Electrode Mode Triboelectric Nanogenerator-Based Pulse Sensor for Healthcare Applications Using COMSOL Multiphysics. Energy Technol. 2022, 10, 2101130. [Google Scholar] [CrossRef]

- Meng, K.; Zhao, S.; Zhou, Y.; Wu, Y.; Zhang, S.; He, Q.; Wang, X.; Zhou, Z.; Fan, W.; Tan, X.; et al. A Wireless Textile-Based Sensor System for Self-Powered Personalized Health Care. Matter 2020, 2, 896–907. [Google Scholar] [CrossRef]

- Xiao, X.; Xiao, X.; Nashalian, A.; Libanori, A.; Fang, Y.; Li, X.; Chen, J. Triboelectric Nanogenerators for Self-Powered Wound Healing. Adv. Healthc. Mater. 2021, 10, e2100975. [Google Scholar] [CrossRef] [PubMed]

- Zhu, G.; Ren, P.; Yang, J.; Hu, J.; Dai, Z.; Chen, H.; Li, Y.; Li, Z. Self-Powered and Multi-Mode Flexible Sensing Film with Patterned Conductive Network for Wireless Monitoring in Healthcare. Nano Energy 2022, 98, 107327. [Google Scholar] [CrossRef]

- Fu, J.; Xia, K.; Xu, Z. A Triboelectric Nanogenerator Based on Human Fingernail to Harvest and Sense Body Energy. Microelectron. Eng. 2020, 232, 111408. [Google Scholar] [CrossRef]

- Zhang, R.; Hummelgård, M.; Örtegren, J.; Olsen, M.; Andersson, H.; Yang, Y.; Zheng, H.; Olin, H. The Triboelectricity of the Human Body. Nano Energy 2021, 86, 106041. [Google Scholar] [CrossRef]

- Zhao, Z.; Lu, Y.; Mi, Y.; Meng, J.; Wang, X.; Cao, X.; Wang, N. Adaptive Triboelectric Nanogenerators for Long-Term Self-Treatment: A Review. Biosensors 2022, 12, 1127. [Google Scholar] [CrossRef]

- Zhao, Z.; Lu, Y.; Mi, Y.; Meng, J.; Cao, X.; Wang, N. Structural Flexibility in Triboelectric Nanogenerators: A Review on the Adaptive Design for Self-Powered Systems. Micromachines 2022, 13, 1586. [Google Scholar] [CrossRef]

- Cheedarala, R.K.; Song, J.I. Integrated Electronic Skin (e-Skin) for Harvesting of TENG Energy through Push-Pull Ionic Electrets and Ion-Ion Hopping Mechanism. Sci. Rep. 2022, 12, 3879. [Google Scholar] [CrossRef]

- Ghaderiaram, A.; Bazrafshan, A.; Firouzi, K.; Kolahdouz, M. A Multi-Mode R-TENG for Self-Powered Anemometer under IoT Network. Nano Energy 2021, 87, 106170. [Google Scholar] [CrossRef]

- Huynh, N.D.; Lin, Z.-H.; Choi, D. Dynamic Balanced Hybridization of TENG and EMG via Tesla Turbine for Effectively Harvesting Broadband Mechanical Pressure. Nano Energy 2021, 85, 105983. [Google Scholar] [CrossRef]

- Cai, C.; Mo, J.; Lu, Y.; Zhang, N.; Wu, Z.; Wang, S.; Nie, S. Integration of a Porous Wood-Based Triboelectric Nanogenerator and Gas Sensor for Real-Time Wireless Food-Quality Assessment. Nano Energy 2021, 83, 105833. [Google Scholar] [CrossRef]

- Qin, K.; Chen, C.; Pu, X.; Tang, Q.; He, W.; Liu, Y.; Zeng, Q.; Liu, G.; Guo, H.; Hu, C. Magnetic Array Assisted Triboelectric Nanogenerator Sensor for Real-Time Gesture Interaction. Nano-Micro Lett. 2021, 13, 51. [Google Scholar] [CrossRef] [PubMed]

- Zhao, T.; Fu, Y.; Sun, C.; Zhao, X.; Jiao, C.; Du, A.; Wang, Q.; Mao, Y.; Liu, B. Wearable Biosensors for Real-Time Sweat Analysis and Body Motion Capture Based on Stretchable Fiber-Based Triboelectric Nanogenerators. Biosens. Bioelectron. 2022, 205, 114115. [Google Scholar] [CrossRef]

- Bui, V.-T.; Chau, N.M.; Huynh, D.P.; Huynh, N.D.; Choi, D.; Nhat Do, H. Honeycomb-Patterned Polyimide-Based Triboelectric Nanogenerator with Excellent Thermal Stability and Enhanced Electrification Performance. ACS Appl. Energy Mater. 2022, 5, 9791–9800. [Google Scholar] [CrossRef]

- Yang, Y.; Zhang, D.; Wang, D.; Xu, Z.; Zhang, J. A High-Stability Weighing Paper/Polytetrafluoroethylene-Based Triboelectric Nanogenerator for Self-Powered In2O3 Nanocubes/SnS2 Nanoflower NO2 Gas Sensors. J. Mater. Chem. A 2021, 9, 14495–14506. [Google Scholar] [CrossRef]

- Kim, H.; Choi, S.; Hong, Y.; Chung, J.; Choi, J.; Choi, W.-K.; Park, I.W.; Park, S.H.; Park, H.; Chung, W.-J.; et al. Biocompatible and Biodegradable Triboelectric Nanogenerators Based on Hyaluronic Acid Hydrogel Film. Appl. Mater. Today 2021, 22, 100920. [Google Scholar] [CrossRef]

- Lee, J.H.; Rim, Y.S.; Min, W.K.; Park, K.; Kim, H.T.; Hwang, G.; Song, J.; Kim, H.J. Biocompatible and Biodegradable Neuromorphic Device Based on Hyaluronic Acid for Implantable Bioelectronics. Adv. Funct. Mater. 2021, 31, 2107074. [Google Scholar] [CrossRef]

- Mukherjee, S.; Rananaware, P.; Brahmkhatri, V.; Mishra, M. Polyvinylpyrrolidone-Curcumin Nanoconjugate as a Biocompatible, Non-Toxic Material for Biological Applications. J. Clust. Sci. 2022, 34, 395–414. [Google Scholar] [CrossRef]

- Panda, S.; Hajra, S.; Jeong, H.; Panigrahi, B.K.; Pakawanit, P.; Dubal, D.; Hong, S.; Kim, H.J. Biocompatible CaTiO3-PVDF Composite-Based Piezoelectric Nanogenerator for Exercise Evaluation and Energy Harvesting. Nano Energy 2022, 102, 107682. [Google Scholar] [CrossRef]

- Selvarajan, S.; Alluri, N.R.; Chandrasekhar, A.; Kim, S.-J. Biocompatible Electronic Platform for Monitoring Protein-Drug Interactions with Potential in Future Theranostics. Sens. Actuators B Chem. 2020, 305, 127497. [Google Scholar] [CrossRef]

- Ahn, J.; Kim, J.; Jeong, Y.; Hwang, S.; Yoo, H.; Jeong, Y.; Gu, J.; Mahato, M.; Ko, J.; Jeon, S.; et al. All-Recyclable Triboelectric Nanogenerator for Sustainable Ocean Monitoring Systems. Adv. Energy Mater. 2022, 12, 2201341. [Google Scholar] [CrossRef]

- Bai, Q.; Liao, X.-W.; Chen, Z.-W.; Gan, C.-Z.; Zou, H.-X.; Wei, K.-X.; Gu, Z.; Zheng, X.-J. Snap-through Triboelectric Nanogenerator with Magnetic Coupling Buckled Bistable Mechanism for Harvesting Rotational Energy. Nano Energy 2022, 96, 107118. [Google Scholar] [CrossRef]

- Bhat, T.S.; Patil, P.S.; Rakhi, R.B. Recent Trends in Electrolytes for Supercapacitors. J. Energy Storage 2022, 50, 104222. [Google Scholar] [CrossRef]

- Cai, Y.-W.; Zhang, X.-N.; Wang, G.-G.; Li, G.-Z.; Zhao, D.-Q.; Sun, N.; Li, F.; Zhang, H.-Y.; Han, J.-C.; Yang, Y. A Flexible Ultra-Sensitive Triboelectric Tactile Sensor of Wrinkled PDMS/MXene Composite Films for E-Skin. Nano Energy 2021, 81, 105663. [Google Scholar] [CrossRef]

- Cao, Y.; Shao, H.; Wang, H.; Li, X.; Zhu, M.; Fang, J.; Cheng, T.; Lin, T. A Full-Textile Triboelectric Nanogenerator with Multisource Energy Harvesting Capability. Energy Convers. Manag. 2022, 267, 115910. [Google Scholar] [CrossRef]

- Cao, S.; Zou, H.; Jiang, B.; Li, M.; Yuan, Q. Incorporation of ZnO Encapsulated MoS2 to Fabricate Flexible Piezoelectric Nanogenerator and Sensor. Nano Energy 2022, 102, 107635. [Google Scholar] [CrossRef]

- Dong, J.; Huang, S.; Luo, J.; Zhao, J.; Fan, F.R.; Tian, Z.-Q. Supercapacitor-Inspired Triboelectric Nanogenerator Based on Electrostatic Double Layer. Nano Energy 2022, 95, 106971. [Google Scholar] [CrossRef]

- Huo, Z.; Lee, D.; Jeong, J.; Kim, Y.; Kim, J.; Suh, I.; Xiong, P.; Kim, S. Microbial Disinfection with Supercoiling Capacitive Triboelectric Nanogenerator. Adv. Energy Mater. 2022, 12, 2103680. [Google Scholar] [CrossRef]

- Mi, Y.; Lu, Y.; Shi, Y.; Zhao, Z.; Wang, X.; Meng, J.; Cao, X.; Wang, N. Biodegradable Polymers in Triboelectric Nanogenerators. Polymers 2022, 15, 222. [Google Scholar] [CrossRef] [PubMed]

- Xiang, H.; Yang, J.; Cao, X.; Wang, N. Flexible and Highly Sensitive Triboelectric Nanogenerator with Magnetic Nanocomposites for Cultural Heritage Conservation and Human Motion Monitoring. Nano Energy 2022, 101, 107570. [Google Scholar] [CrossRef]

- Mi, Y.; Lu, Y.; Wang, X.; Zhao, Z.; Cao, X.; Wang, N. From Triboelectric Nanogenerator to Uninterrupted Power Supply System: The Key Role of Electrochemical Batteries and Supercapacitors. Batteries 2022, 8, 215. [Google Scholar] [CrossRef]

- Wang, Y.; Cao, X.; Wang, N. Recent Progress in Piezoelectric-Triboelectric Effects Coupled Nanogenerators. Nanomaterials 2023, 13, 385. [Google Scholar] [CrossRef]

- Zhu, Q.; Cao, X.; Wang, N. Triboelectric Nanogenerators in Sustainable Chemical Sensors. Chemosensors 2022, 10, 484. [Google Scholar] [CrossRef]

- Yan, L.; Mi, Y.; Lu, Y.; Qin, Q.; Wang, X.; Meng, J.; Liu, F.; Wang, N.; Cao, X. Weaved Piezoresistive Triboelectric Nanogenerator for Human Motion Monitoring and Gesture Recognition. Nano Energy 2022, 96, 107135. [Google Scholar] [CrossRef]

- Zhang, T.; Yang, T.; Zhang, M.; Bowen, C.R.; Yang, Y. Recent Progress in Hybridized Nanogenerators for Energy Scavenging. iScience 2020, 23, 101689. [Google Scholar] [CrossRef]

- Ahmad, R.U.S.; Haleem, A.; Haider, Z.; Claver, U.P.; Fareed, A.; Khan, I.; Mbogba, M.K.; Memon, K.; Ali, W.; He, W.; et al. Realizing the Capability of Negatively Charged Graphene Oxide in the Presence of Conducting Polyaniline for Performance Enhancement of Tribopositive Material of Triboelectric Nanogenerator. Adv. Electron. Mater. 2020, 6, 2000034. [Google Scholar] [CrossRef]

- Jelmy, E.J.; Jose, D.; Vijoy, K.V.; Saji, K.J.; John, H. Enhanced Triboelectric Performance of Graphene Oxide-Conducting Polymer Hybrid Modified Polydimethylsiloxane Composites. Mater. Adv. 2022, 3, 6897–6907. [Google Scholar] [CrossRef]

- Khan, A.; Ginnaram, S.; Wu, C.-H.; Lu, H.-W.; Pu, Y.-F.; Wu, J.I.; Gupta, D.; Lai, Y.-C.; Lin, H.-C. Fully Self-Healable, Highly Stretchable, and Anti-Freezing Supramolecular Gels for Energy-Harvesting Triboelectric Nanogenerator and Self-Powered Wearable Electronics. Nano Energy 2021, 90, 106525. [Google Scholar] [CrossRef]

- Yu, S.; Zhang, Y.; Yu, Z.; Zheng, J.; Wang, Y.; Zhou, H. PANI/PVDF-TrFE Porous Aerogel Bulk Piezoelectric and Triboelectric Hybrid Nanogenerator Based on in-Situ Doping and Liquid Nitrogen Quenching. Nano Energy 2021, 80, 105519. [Google Scholar] [CrossRef]

- Liu, S.; Yuan, G.; Zhang, Y.; Xie, L.; Shen, Q.; Lei, H.; Wen, Z.; Sun, X. A Self-Powered Gas Sensor Based on Coupling Triboelectric Screening and Impedance Matching Effects. Adv. Mater. Technol. 2021, 6, 2100310. [Google Scholar] [CrossRef]

- Pooja; Kumar, A.; Prasher, P.; Mudila, H. Factors Affecting the Electrical Conductivity of Conducting Polymers. Carbon Lett. 2023, 33, 307–324. [Google Scholar] [CrossRef]

- De Keersmaecker, M.; Garrett, B.S.; Shen, D.E.; Jones, A.L.; Österholm, A.M.; Mirotznik, M.; Reynolds, J.R. Conducting Polymer Switches Permit the Development of a Frequency-Reconfigurable Antenna. ACS Appl. Electron. Mater. 2023, 5, 1697–1706. [Google Scholar] [CrossRef]

- Çetin, M.Z.; Guven, N.; Apetrei, R.-M.; Camurlu, P. Highly Sensitive Detection of Glucose via Glucose Oxidase Immobilization onto Conducting Polymer-Coated Composite Polyacrylonitrile Nanofibers. Enzyme Microb. Technol. 2023, 164, 110178. [Google Scholar] [CrossRef] [PubMed]

- Kang, J.; Yan, Z.; Gao, L.; Zhang, Y.; Liu, W.; Yang, Q.; Zhao, Y.; Deng, N.; Cheng, B.; Kang, W. Improved Ionic Conductivity and Enhancedinterfacial Stability of Solid Polymer Electrolytes with Porous Ferroelectric Ceramic Nanofibers. Energy Storage Mater. 2022, 53, 192–203. [Google Scholar] [CrossRef]

- Khandelwal, G.; Ediriweera, M.K.; Kumari, N.; Maria Joseph Raj, N.P.; Cho, S.K.; Kim, S.-J. Metal-Amino Acid Nanofibers Based Triboelectric Nanogenerator for Self-Powered Thioacetamide Sensor. ACS Appl. Mater. Interfaces 2021, 13, 18887–18896. [Google Scholar] [CrossRef]

- Mekbuntoon, P.; Kaeochana, W.; Prada, T.; Appamato, I.; Harnchana, V. Power Output Enhancement of Natural Rubber Based Triboelectric Nanogenerator with Cellulose Nanofibers and Activated Carbon. Polymers 2022, 14, 4495. [Google Scholar] [CrossRef]

- Peng, X.; Dong, K.; Zhang, Y.; Wang, L.; Wei, C.; Lv, T.; Wang, Z.L.; Wu, Z. Sweat-Permeable, Biodegradable, Transparent and Self-Powered Chitosan-Based Electronic Skin with Ultrathin Elastic Gold Nanofibers. Adv. Funct. Mater. 2022, 32, 2112241. [Google Scholar] [CrossRef]

- Sun, F.; Qi, H.; Xie, Y.; Xu, D.; Shao, H.; Yu, W.; Li, F.; Dong, X. Conjugated Electrospinning-Made Heterostructured TiO2//Bi2WO6 Janus Nanofibers for Ethanol Gas Sensing. Mater. Lett. 2023, 336, 133904. [Google Scholar] [CrossRef]

- Wang, S.K.; Wang, A.C.; Zhang, C.Y.; Liu, Q.Y.; Cheng, J.D.; Wang, Y.C.; Gao, X.P.; Xie, Q.F.; Zhang, Z.X.; Sun, G.Z.; et al. Sandwich-Structured In2S3/In2O3/In2S3 Hollow Nanofibers as Sensing Materials for Ethanol Detection. ACS Appl. Nano Mater. 2023, 6, 2625–2635. [Google Scholar] [CrossRef]

- Multifunctional Poly(Vinyl Alcohol)/Ag Nanofibers-Based Triboelectric Nanogenerator for Self-Powered MXene/Tungsten Oxide Nanohybrid NO2 Gas Sensor. Nano Energy 2021, 89, 106410. [CrossRef]

- Wang, S.; Liu, B.; Duan, Z.; Zhao, Q.; Zhang, Y.; Xie, G.; Jiang, Y.; Li, S.; Tai, H. PANI Nanofibers-Supported Nb2CTx Nanosheets-Enabled Selective NH3 Detection Driven by TENG at Room Temperature. Sens. Actuators B Chem. 2021, 327, 128923. [Google Scholar] [CrossRef]

- Liu, Y.; Zheng, Y.; Wu, Z.; Zhang, L.; Sun, W.; Li, T.; Wang, D.; Zhou, F. Conductive Elastic Sponge-Based Triboelectric Nanogenerator (TENG) for Effective Random Mechanical Energy Harvesting and Ammonia Sensing. Nano Energy 2021, 79, 105422. [Google Scholar] [CrossRef]

- Wang, X.; Zhang, D.; Zhang, H.; Gong, L.; Yang, Y.; Zhao, W.; Yu, S.; Yin, Y.; Sun, D. In Situ Polymerized Polyaniline/MXene (V2C) as Building Blocks of Supercapacitor and Ammonia Sensor Self-Powered by Electromagnetic-Triboelectric Hybrid Generator. Nano Energy 2021, 88, 106242. [Google Scholar] [CrossRef]

- Chang, J.; Zhang, X.; Wang, Z.; Li, C.; Hu, Q.; Gao, J.; Feng, L. Polyaniline-Reduced Graphene Oxide Nanosheets for Room Temperature NH 3 Detection. ACS Appl. Nano Mater. 2021, 4, 5263–5272. [Google Scholar] [CrossRef]

- Hu, Y.; Zhang, M.; Qin, C.; Qian, X.; Zhang, L.; Zhou, J.; Lu, A. Transparent, Conductive Cellulose Hydrogel for Flexible Sensor and Triboelectric Nanogenerator at Subzero Temperature. Carbohydr. Polym. 2021, 265, 118078. [Google Scholar] [CrossRef]

- Min, S.-B.; Kim, M.; Hyun, K.; Ahn, C.-W.; Kim, C.B. Thermally Conductive 2D Filler Orientation Control in Polymer Using Thermophoresis. Polym. Test. 2023, 117, 107838. [Google Scholar] [CrossRef]

- Na, S.; Yeom, J.; Chang, Y.; Kwon, Y.; Park, C.; Shin, Y.-E.; Park, Y.-J.; Ko, H. Stretchable Skin Hydration Sensor Based on Hygroscopic and Ion Conductive Polymer Composites. Chem. Eng. J. 2023, 455, 140957. [Google Scholar] [CrossRef]

- Oberhaus, F.V. Carbonyl Compounds and Inorganic Brønsted Acids as Catalysts for Electropolymerization of Conductive Polymers. Electrochimica Acta 2023, 449, 142237. [Google Scholar] [CrossRef]

- Wang, W.; Zhou, W.; Shi, H.; He, D.; Pang, Y.; Zeng, X.; Li, C. Soft and Thermally Conductive Gels by Introducing Free-Movable Polymer Chains into Network. Polymer 2023, 267, 125642. [Google Scholar] [CrossRef]

- Yan, Y.; Jiang, Y.; Ng, E.L.L.; Zhang, Y.; Owh, C.; Wang, F.; Song, Q.; Feng, T.; Zhang, B.; Li, P.; et al. Progress and Opportunities in Additive Manufacturing of Electrically Conductive Polymer Composites. Mater. Today Adv. 2023, 17, 100333. [Google Scholar] [CrossRef]

- Mohan, A.; Menon, R. Conducting Polymers near Metal-Insulator Transition: Scaling and Criticality. Phys. B Condens. Matter 2023, 655, 414755. [Google Scholar] [CrossRef]

- Adhav, P.; Pawar, D.; Diwate, B.; Bora, M.; Jagtap, S.; Chourasia, A.; Dallavalle, S.; Chabukswar, V. Room Temperature Operable Ultra-Sensitive Ammonia Sensor Based on Polyaniline-Silver (PANI-Ag) Nanocomposites Synthesized by Ultra-Sonication. Synth. Met. 2023, 293, 117237. [Google Scholar] [CrossRef]

- Ahmad, A.A.; Bani-Salameh, A.A.; Al-Bataineh, Q.M.; Jum’h, I.; Telfah, A.D. Optical, Structural and Morphological Properties of Synthesized PANI-CSA-PEO-Based GaN Nanocomposite Films for Optoelectronic Applications. Polym. Bull. 2023, 80, 809–828. [Google Scholar] [CrossRef]

- Elumalai, P.; Charles, J. Investigation of Structural and Optical Properties of Ternary Polyaniline-Polypyrrole-Nickel Oxide (PANI-PPy-NiO) Nanocomposite for Optoelectronic Devices. Polym. Int. 2023, 72, 176–188. [Google Scholar] [CrossRef]

- Hassen, M.M.; Ibrahim, I.M.; Abdullah, O.G.; Suhail, M.H. Improving Photodetector Performance of PANI Nanofiber by Adding Rare-Earth La2O3 Nanoparticles. Appl. Phys. A 2023, 129, 135. [Google Scholar] [CrossRef]

- Idrees, M.; Inayat, A.; Ullah, I.; Alabbad, E.A.; Almarhoon, Z.M.; Hassan, H.M.A.; El-Zahhar, A.A.; Ata-ur-Rehman; Haider, A.; Abbas, S.M.; et al. Sulphonated Graphene-Encapsulated Fe2N in the PANI Matrix as a High Performance Lithium Ion Battery Anode. Mater. Today Chem. 2023, 29, 101451. [Google Scholar] [CrossRef]

- Matar, H.A.; Ibrahim, M.A.; El-Hagary, M. Simple and Cost-Effective Route for PANI-ZnO-RGO Nanocomposite as a Biosensor for L-Arginine Detection. Diam. Relat. Mater. 2023, 133, 109703. [Google Scholar] [CrossRef]

- Luo, Y.; Zhao, T.; Dai, Y.; Li, Q.; Fu, H. Flexible Nanosensors for Non-Invasive Creatinine Detection Based on Triboelectric Nanogenerator and Enzymatic Reaction. Sens. Actuators Phys. 2021, 320, 112585. [Google Scholar] [CrossRef]

- Qin, Y.; Mo, J.; Liu, Y.; Zhang, S.; Wang, J.; Fu, Q.; Wang, S.; Nie, S. Stretchable Triboelectric Self-Powered Sweat Sensor Fabricated from Self-Healing Nanocellulose Hydrogels. Adv. Funct. Mater. 2022, 32, 2201846. [Google Scholar] [CrossRef]

- Cong, Z.; Guo, W.; Zhang, P.; Sha, W.; Guo, Z.; Chang, C.; Xu, F.; Gang, X.; Hu, W.; Pu, X. Wearable Antifreezing Fiber-Shaped Zn/PANI Batteries with Suppressed Zn Dendrites and Operation in Sweat Electrolytes. ACS Appl. Mater. Interfaces 2021, 13, 17608–17617. [Google Scholar] [CrossRef]

- Li, W.; Lu, L.; Kottapalli, A.G.P.; Pei, Y. Bioinspired Sweat-Resistant Wearable Triboelectric Nanogenerator for Movement Monitoring during Exercise. Nano Energy 2022, 95, 107018. [Google Scholar] [CrossRef]

- Li, H.; Chang, T.; Gai, Y.; Liang, K.; Jiao, Y.; Li, D.; Jiang, X.; Wang, Y.; Huang, X.; Wu, H.; et al. Human Joint Enabled Flexible Self-Sustainable Sweat Sensors. Nano Energy 2022, 92, 106786. [Google Scholar] [CrossRef]

- Lin, Y.-C.; Rinawati, M.; Chang, L.-Y.; Wang, Y.-X.; Wu, Y.-T.; Yen, Y.-H.; Chen, K.-J.; Ho, K.-C.; Yeh, M.-H. A Non-Invasive Wearable Sweat Biosensor with a Flexible N-GQDs/PANI Nanocomposite Layer for Glucose Monitoring. Sens. Actuators B Chem. 2023, 383, 133617. [Google Scholar] [CrossRef]

- Mazzara, F.; Patella, B.; D’Agostino, C.; Bruno, M.G.; Carbone, S.; Lopresti, F.; Aiello, G.; Torino, C.; Vilasi, A.; O’Riordan, A.; et al. PANI-Based Wearable Electrochemical Sensor for PH Sweat Monitoring. Chemosensors 2021, 9, 169. [Google Scholar] [CrossRef]

- Sonner, Z.; Wilder, E.; Heikenfeld, J.; Kasting, G.; Beyette, F.; Swaile, D.; Sherman, F.; Joyce, J.; Hagen, J.; Kelley-Loughnane, N.; et al. The Microfluidics of the Eccrine Sweat Gland, Including Biomarker Partitioning, Transport, and Biosensing Implications. Biomicrofluidics 2015, 9, 031301. [Google Scholar] [CrossRef]

- Zhao, Y.; Yu, Y.; Zhao, S.; Zhu, R.; Zhao, J.; Cui, G. Highly Sensitive PH Sensor Based on Flexible Polyaniline Matrix for Synchronal Sweat Monitoring. Microchem. J. 2023, 185, 108092. [Google Scholar] [CrossRef]

- Zhu, C.; Xue, H.; Zhao, H.; Fei, T.; Liu, S.; Chen, Q.; Gao, B.; Zhang, T. A Dual-Functional Polyaniline Film-Based Flexible Electrochemical Sensor for the Detection of PH and Lactate in Sweat of the Human Body. Talanta 2022, 242, 123289. [Google Scholar] [CrossRef]

- Seurre, L.; Aréna, H.; Ghenna, S.; Soyer, C.; Grondel, S.; Plesse, C.; Nguyen, G.T.M.; Vidal, F.; Cattan, E. Behavior of Conducting Polymer-Based Micro-Actuators under a DC Voltage. Sens. Actuators B Chem. 2023, 380, 133338. [Google Scholar] [CrossRef]

- Morais, J.P.L.; Bernardino, D.V.; Batista, B.D.S.; Pereira, W.O.; Amaral, F.M.B.; Branca, M.C.M.P.; Gasparin, F.P.; Santos, A.O.D.; Sombra, A.S.B.; Mendes, F.; et al. Conductive Polymer Blend Based on Polyaniline and Galactomannan: Optical and Electrical Properties. Synth. Met. 2023, 295, 117346. [Google Scholar] [CrossRef]

- Shi, K.; Zou, H.; Sun, B.; Jiang, P.; He, J.; Huang, X. Dielectric Modulated Cellulose Paper/PDMS-Based Triboelectric Nanogenerators for Wireless Transmission and Electropolymerization Applications. Adv. Funct. Mater. 2020, 30, 1904536. [Google Scholar] [CrossRef]

- Qiu, H.-J.; Song, W.-Z.; Wang, X.-X.; Zhang, J.; Fan, Z.; Yu, M.; Ramakrishna, S.; Long, Y.-Z. A Calibration-Free Self-Powered Sensor for Vital Sign Monitoring and Finger Tap Communication Based on Wearable Triboelectric Nanogenerator. Nano Energy 2019, 58, 536–542. [Google Scholar] [CrossRef]

- Zhang, H.; Zhang, P.; Deng, L.; Zhang, W.; Liu, B.; Ren, D.; Yang, Z. Three-Dimensional Polypyrrole Nanoarrays for Wearable Triboelectric Nanogenerators. ACS Appl. Nano Mater. 2022, 5, 11219–11228. [Google Scholar] [CrossRef]

- Wang, S.; Gao, J.; Lu, F.; Wang, F.; You, Z.; Huang, M.; Fang, W.; Liu, X.; Li, Y.; Liu, Y. Human Motion Recognition by a Shoes-Floor Triboelectric Nanogenerator and Its Application in Fall Detection. Nano Energy 2023, 108, 108230. [Google Scholar] [CrossRef]

- Respiration-Mediated Self-Switched Triboelectric Nanogenerator for Wearable Point-of-Care Prevention and Alarm of Asthma. Nano Energy 2023, 106, 108058. [CrossRef]

- Xing, X.; Du, L.; Feng, D.; Wang, C.; Tian, Y.; Li, Z.; Liu, H.; Yang, D. Twistable and Tailorable V2O5/PANI/GO Nanocomposites Textile for Wearable Ammonia Sensing. Sens. Actuators B Chem. 2022, 351, 130944. [Google Scholar] [CrossRef]

- Xiao, X.; Chen, G.; Libanori, A.; Chen, J. Wearable Triboelectric Nanogenerators for Therapeutics. Trends Chem. 2021, 3, 279–290. [Google Scholar] [CrossRef]

- Wang, R.; Mu, L.; Bao, Y.; Lin, H.; Ji, T.; Shi, Y.; Zhu, J.; Wu, W. Holistically Engineered Polymer-Polymer and Polymer-Ion Interactions in Biocompatible Polyvinyl Alcohol Blends for High-Performance Triboelectric Devices in Self-Powered Wearable Cardiovascular Monitorings. Adv. Mater. 2020, 32, 2002878. [Google Scholar] [CrossRef]

- Wang, S.; Liu, S.; Zhou, J.; Li, F.; Li, J.; Cao, X.; Li, Z.; Zhang, J.; Li, B.; Wang, Y.; et al. Advanced Triboelectric Nanogenerator with Multi-Mode Energy Harvesting and Anti-Impact Properties for Smart Glove and Wearable e-Textile. Nano Energy 2020, 78, 105291. [Google Scholar] [CrossRef]

- Wang, D.; Zhang, D.; Tang, M.; Zhang, H.; Chen, F.; Wang, T.; Li, Z.; Zhao, P. Rotating Triboelectric-Electromagnetic Nanogenerator Driven by Tires for Self-Powered MXene-Based Flexible Wearable Electronics. Chem. Eng. J. 2022, 446, 136914. [Google Scholar] [CrossRef]

- Wang, B.; Li, G.; Zhu, Q.; Liu, W.; Ke, W.; Hua, W.; Zhou, Y.; Zeng, X.; Sun, X.; Wen, Z.; et al. Bone Repairment via Mechanosensation of Piezo1 Using Wearable Pulsed Triboelectric Nanogenerator. Small 2022, 18, 2201056. [Google Scholar] [CrossRef] [PubMed]

- Buzalewicz, I.; Karwańska, M.; Wieliczko, A.; Podbielska, H. On the Application of Multi-Parametric Optical Phenotyping of Bacterial Colonies for Multipurpose Microbiological Diagnostics. Biosens. Bioelectron. 2021, 172, 112761. [Google Scholar] [CrossRef] [PubMed]

- Liu, S.; Yuan, F.; Sang, M.; Zhou, J.; Zhang, J.; Wang, S.; Li, J.; Xuan, S.; Gong, X. Functional Sponge-Based Triboelectric Nanogenerators with Energy Harvesting, Oil–Water Separating and Multi-Mode Sensing Performance. J. Mater. Chem. A 2021, 9, 6913–6923. [Google Scholar] [CrossRef]

- Xiao, Y.; Xu, Y.; Qu, C.; Liu, H.; Zhang, S.; Lin, F.; Wu, W.; Song, G. Micro-Crack Assisted Wrinkled PEDOT: PSS to Detect and Distinguish Tensile Strain and Pressure Based on a Triboelectric Nanogenerator. Adv. Mater. Technol. 2022, 7, 2100423. [Google Scholar] [CrossRef]

- Sun, H.; Zhao, Y.; Wang, C.; Zhou, K.; Yan, C.; Zheng, G.; Huang, J.; Dai, K.; Liu, C.; Shen, C. Ultra-Stretchable, Durable and Conductive Hydrogel with Hybrid Double Network as High Performance Strain Sensor and Stretchable Triboelectric Nanogenerator. Nano Energy 2020, 76, 105035. [Google Scholar] [CrossRef]

- Dong, L.; Wang, M.; Wu, J.; Zhu, C.; Shi, J.; Morikawa, H. Stretchable, Adhesive, Self-Healable, and Conductive Hydrogel-Based Deformable Triboelectric Nanogenerator for Energy Harvesting and Human Motion Sensing. ACS Appl. Mater. Interfaces 2022, 14, 9126–9137. [Google Scholar] [CrossRef]

- Dudem, B.; Mule, A.R.; Patnam, H.R.; Yu, J.S. Wearable and Durable Triboelectric Nanogenerators via Polyaniline Coated Cotton Textiles as a Movement Sensor and Self-Powered System. Nano Energy 2019, 55, 305–315. [Google Scholar] [CrossRef]

- Mule, A.R.; Dudem, B.; Patnam, H.; Graham, S.A.; Yu, J.S. Wearable Single-Electrode-Mode Triboelectric Nanogenerator via Conductive Polymer-Coated Textiles for Self-Power Electronics. ACS Sustain. Chem. Eng. 2019, 7, 16450–16458. [Google Scholar] [CrossRef]

| Date | Sizes | Conductive Polymer | Energy Sources | Outputs | Applications |

|---|---|---|---|---|---|

| 2020 [39] | 1 × 2 cm2 | PANI | Vibration | 37.81 mA m−2 | Enhance power generation capacity |

| 2022 [40] | None | PANI | Vibration | 40 nA | Enhance power generation capacity |

| 2021 [41] | 5 × 5 cm2 | PEDOT:PSS | Vibration | 2000 μW m2 | Enhance power generation capacity |

| 2021 [42] | 1 × 2 cm2 | PEDOT:PSS | Vibration | 6.69 W/m2 | Enhance power generation capacity |

| 2021 [43] | None | PANI | Movement | 519 μW | Improve NH3 sensing sensitivity |

| 2021 [44] | 4 × 4 cm2 | PANI | Vibration | 540 V | Improve NH3 sensing performance |

| 2021 [45] | 5 × 10 cm2 | PANI | Movement | 500 V | Enhancing the self power capability of NH3 sensors |

| 2021 [46] | 5 × 5 cm2 | PANI | Vibration | 7.3 μA | Improve NH3 sensing sensitivity |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhao, Z.; Mi, Y.; Lu, Y.; Zhu, Q.; Cao, X.; Wang, N. From Biochemical Sensor to Wearable Device: The Key Role of the Conductive Polymer in the Triboelectric Nanogenerator. Biosensors 2023, 13, 604. https://doi.org/10.3390/bios13060604

Zhao Z, Mi Y, Lu Y, Zhu Q, Cao X, Wang N. From Biochemical Sensor to Wearable Device: The Key Role of the Conductive Polymer in the Triboelectric Nanogenerator. Biosensors. 2023; 13(6):604. https://doi.org/10.3390/bios13060604

Chicago/Turabian StyleZhao, Zequan, Yajun Mi, Yin Lu, Qiliang Zhu, Xia Cao, and Ning Wang. 2023. "From Biochemical Sensor to Wearable Device: The Key Role of the Conductive Polymer in the Triboelectric Nanogenerator" Biosensors 13, no. 6: 604. https://doi.org/10.3390/bios13060604

APA StyleZhao, Z., Mi, Y., Lu, Y., Zhu, Q., Cao, X., & Wang, N. (2023). From Biochemical Sensor to Wearable Device: The Key Role of the Conductive Polymer in the Triboelectric Nanogenerator. Biosensors, 13(6), 604. https://doi.org/10.3390/bios13060604