Benchmarking Spectroscopic Techniques Combined with Machine Learning to Study Oak Barrels for Wine Ageing

Abstract

1. Introduction

2. Materials and Methods

2.1. Reflectance Spectroscopy

2.2. Fluorescence Spectroscopy

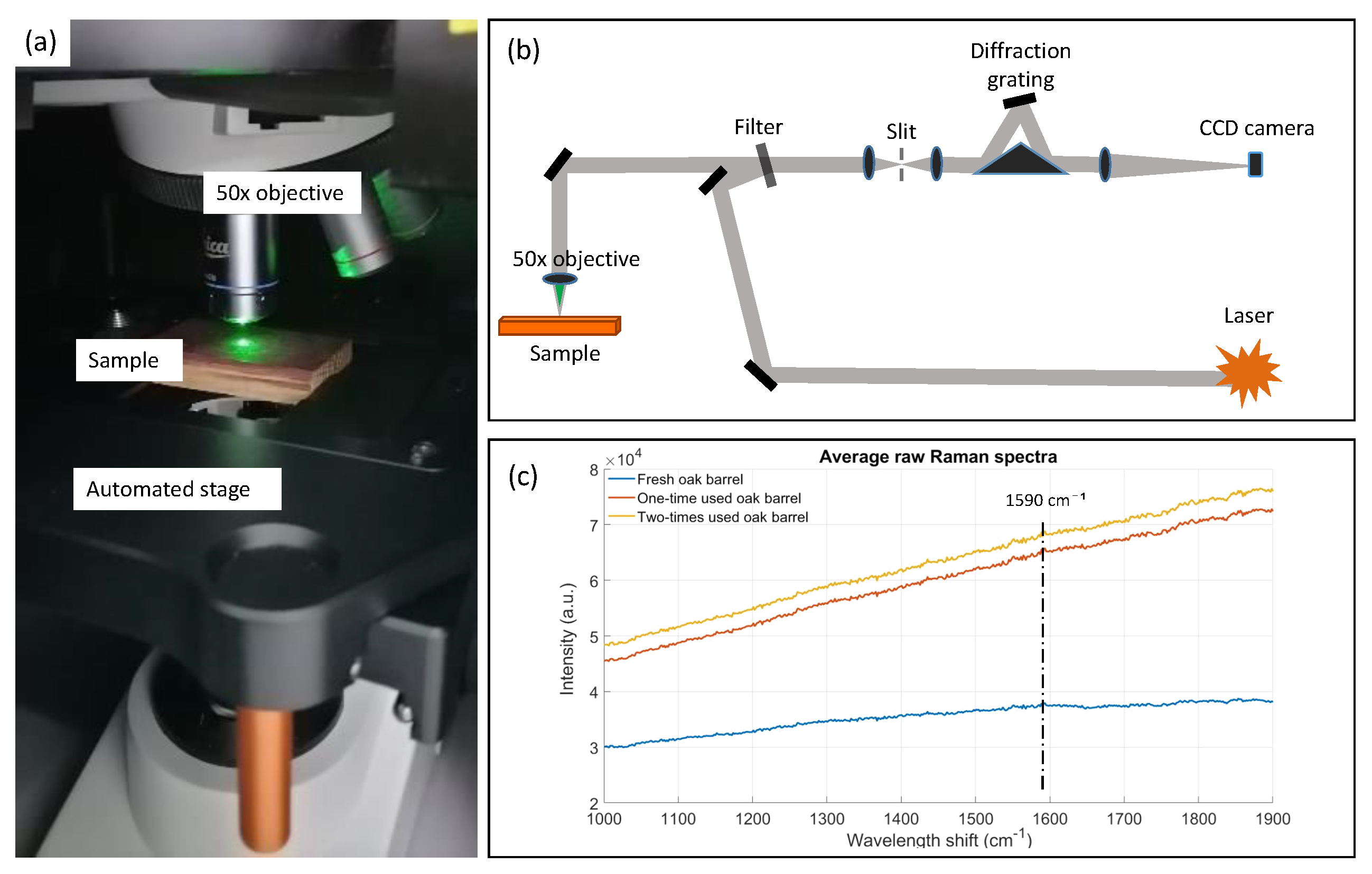

2.3. Raman Spectroscopy

2.4. Chemometrics

3. Results and Discussion

3.1. Reflectance Spectroscopy

3.2. Fluorescence Spectroscopy

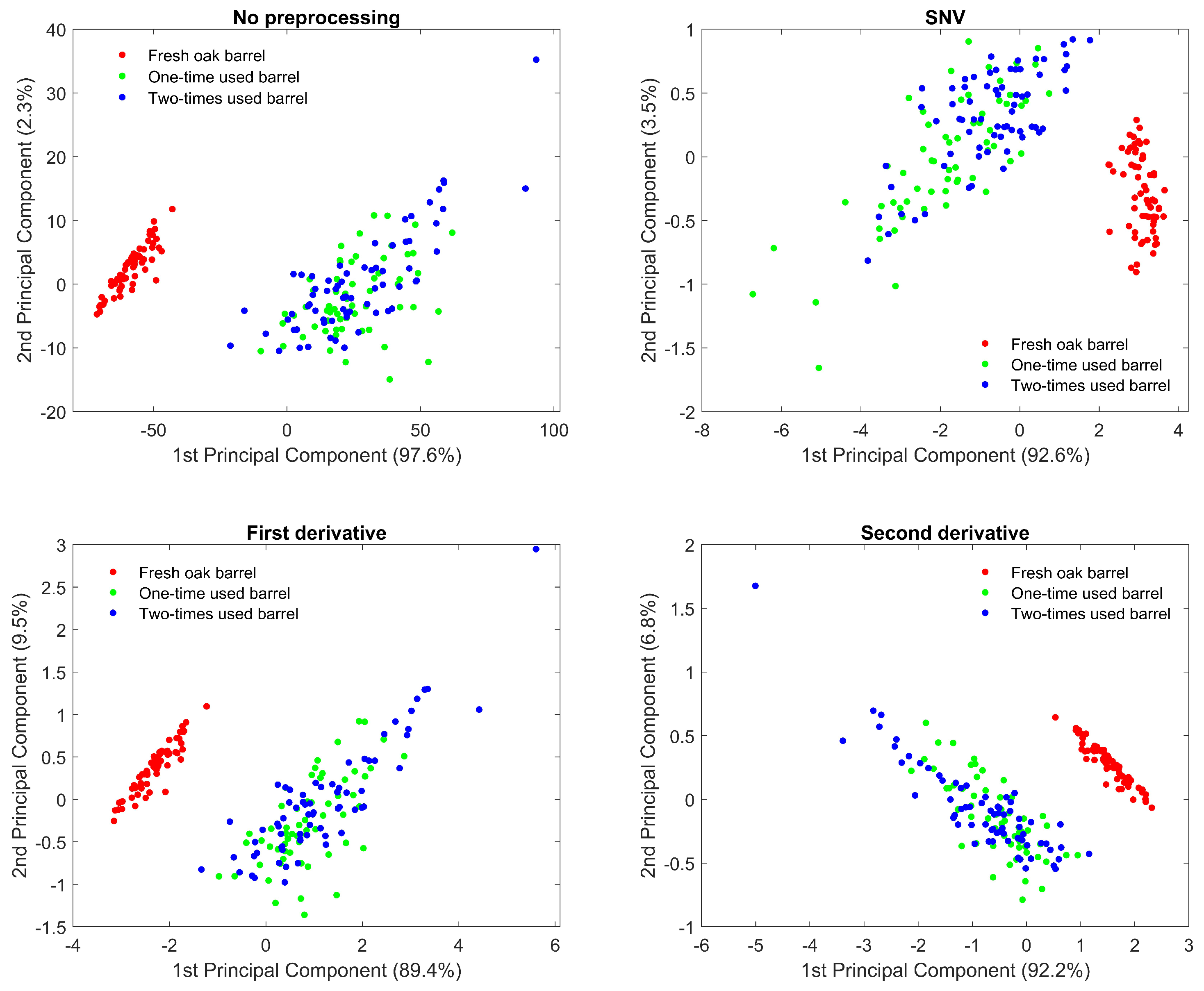

3.3. Raman Spectroscopy

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- European Commission. Evaluation of the CAP Measures Applicable to the Wine Sector; Commission Staff Working Document; Publications Office of the European Union: Luxembourg, 2020. [Google Scholar]

- Reynolds, A.G. Viticultural and vineyard management practices and their effects on grape and wine quality. In Managing Wine Quality Viticulture and Wine Quality; Reynolds, A.G., Ed.; Woodhead Publishing Series in Food Science, Technology and Nutrition; Elsevier B.V.: North York, ON, Canada, 2010; pp. 365–444. [Google Scholar]

- Alamo-Sanza, M. Oak Wine Barrel as an Active Vessel: A Critical Review of Past and Current Knowledge. Crit. Rev. Food 2017, 58, 2711–2726. [Google Scholar] [CrossRef] [PubMed]

- Carpena, M. Wine ageing Technology: Fundamental Role of Wood Barrels. Foods 2020, 9, 1160. [Google Scholar] [CrossRef] [PubMed]

- A Peek Inside of Oak. Available online: https://www.worldcooperage.com/oak-constituents/ (accessed on 28 March 2022).

- Considine, J.A. Table Wine Production. In A Complete Guide to Quality in Small-Scale Wine Making; Considine, J.A., Ed.; Elsevier Inc.: Crawley, Australia, 2014; pp. 57–77. [Google Scholar]

- Oak in Winemaking. Dissecting the Origin, Selection and Science of Barrels. Available online: https://rb.gy/fvm0ba (accessed on 28 March 2022).

- New 225L/59 Gallon French Oak. Available online: https://www.barrelsdirect.com/product/new-225l-59-gallon-french-oak/ (accessed on 28 March 2022).

- Wine Oak Barrels. Available online: https://www.wineoakbarrels.com/index.html#.Yiyr-nrMI2w (accessed on 28 March 2022).

- Bautista-Ortin, A.B. The use of oak chips during the ageing of a red wine in stainless steel tanks or used barrels: Effect of the contact time and size of the oak chips on aroma compounds. Aust. J. Grape Wine Res. 2008, 142, 63–70. [Google Scholar] [CrossRef]

- Khodabakhshian, R. Feasibility of using Raman spectroscopy for detection of tannin changes in pomegranate fruits during maturity. Sci. Hortic. 2019, 257, 108670. [Google Scholar] [CrossRef]

- Bock, P. Infrared and Raman spectra of lignin substructures: Coniferyl alcohol, abietin, and coniferyl aldehyde. J. Raman Spectrosc. 2019, 50, 778–792. [Google Scholar] [CrossRef] [PubMed]

- Donaldson, L. Softwood and Hardwood Lignin Fluorescence Spectra of Wood Cell Walls in Different Mounting Media. IAWA J. 2013, 34, 3–19. [Google Scholar] [CrossRef]

- Albinsson, B. The origin of lignin fluorescence. J. Mol. Struct. 1999, 508, 19–27. [Google Scholar] [CrossRef]

- Oluwatosin, E.A. Classification of Red Oak (Quercus Rubra) and White Oak (Quercus Alba) Wood Using a near Infrared Spectrometer and Soft Independent Modelling of Class Analogies. J. Near Infrared Spectrosc. 2008, 16, 49–57. [Google Scholar]

- Wolf, M. Machine learning for aquatic plastic litter detection, classification and quantification (APLASTIC-Q). Environ. Res. Lett. 2020, 15, 114042. [Google Scholar] [CrossRef]

- Magnus, I. Combining optical spectroscopy and machine learning to improve food classification. Food Control 2021, 130, 108342. [Google Scholar] [CrossRef]

- Pradhan, P. Deep learning a boon for biophotonics? J. Biophotonics 2019, 13, 60186. [Google Scholar] [CrossRef] [PubMed]

- Wines of Crete. Available online: https://www.winesofcrete.gr/en/ (accessed on 28 March 2022).

- In Via™ Confocal Raman Microscope. Available online: https://www.renishaw.com/en/invia-confocal-raman-microscope–6260 (accessed on 28 March 2022).

- Gautam, R. Review of multidimensional data processing approaches for Raman and infrared spectroscopy. EPJ Techn. Instrum. 2015, 2, 1–38. [Google Scholar] [CrossRef]

- Gorry, P.A. General least-squares smoothing and differentiation by the convolution (Savitzky-Golay) method. Anal. Chem. 1990, 62, 570–573. [Google Scholar] [CrossRef]

- Wold, S. Principal Component Analysis. Chemom. Intell. Lab. Syst. 1987, 2, 37–52. [Google Scholar] [CrossRef]

- Barker, M. Partial least squares for discrimination. J. Chemom. J. Chemom. Soc. 2003, 17, 166–173. [Google Scholar] [CrossRef]

- Ghojogh, B. Linear and quadratic discriminant analysis: Tutorial. arXiv 2019, arXiv:1906.02590. [Google Scholar]

- Marchessault, R.H. Application of infra-red spectroscopy to cellulose and wood polysaccharides. Pure Appl. Chem. 2009, 5, 107–129. [Google Scholar] [CrossRef]

- Pandey, K.K. A study of chemical structure of soft and hardwood and wood polymers by FTIR spectroscopy. J. Appl. Polym. Sci. 1999, 71, 1969–1975. [Google Scholar] [CrossRef]

- Boeriu, C.G. Characterisation of structure-dependent functional properties of lignin with infrared spectroscopy. Ind. Crops Prod. 2004, 20, 205–218. [Google Scholar] [CrossRef]

- Sundaram, J. Application of NIR Reflectance Spectroscopy on Rapid Determination of Moisture Content of Wood Pellets. Am. J. Anal. Chem. 2015, 6, 923–932. [Google Scholar] [CrossRef]

- Varma, S. Bias in error estimation when using cross-validation for model selection. BMC Bioinform. 2006, 7, 1–8. [Google Scholar] [CrossRef] [PubMed]

- Katsara, K. Polyethylene Migration from Food Packaging on Cheese Detected by Raman and Infrared (ATR/FT-IR) Spectroscopy. Materials 2021, 14, 3872. [Google Scholar] [CrossRef] [PubMed]

- Das, A.J. Ultra-portable, wireless smartphone spectrometer for rapid, non-destructive testing of fruit ripeness. Sci. Rep. 2016, 6, 32504. [Google Scholar] [CrossRef] [PubMed]

| Pre-Proc. | Dim. Red. | Classifier | Acc. Fresh Oak (%) | Acc. One Time Used (%) | Acc. Two Times Used (%) |

|---|---|---|---|---|---|

| NIR | PLS-DA (15) | 100.0 ± 0.0 | 99.8 ± 0.2 | 100.0 ± 0.0 | |

| NIR | LDA | 100.0 ± 0.0 | 95.6 ± 0.6 | 95.1 ± 1.1 | |

| None | Absorption | LDA | 100.0 ± 0.0 | 88.2 ± 0.4 | 69.0 ± 0.8 |

| PCA (10) | LDA | 100.0 ± 0.0 | 89.6 ± 1.6 | 84.6 ± 2.4 | |

| NIR | PLS-DA (18) | 100.0 ± 0.0 | 100.0 ± 0.0 | 99.1 ± 0.3 | |

| NIR | LDA | 99.8 ± 0.2 | 94.9 ± 0.5 | 94.9 ± 1.0 | |

| SNV | Absorption | LDA | 100.0 ± 0.0 | 88.9 ± 0.2 | 88.2 ± 0.2 |

| PCA (25) | LDA | 100.0 ± 0.0 | 90.4 ± 1.7 | 91.0 ± 1.4 | |

| NIR | PLS-DA (22) | 100.0 ± 0.0 | 99.2 ± 0.3 | 99.6 ± 0.2 | |

| NIR | LDA | 100.0 ± 0.0 | 97.1 ± 0.8 | 96.5 ± 0.8 | |

| 1st der. | Absorption | LDA | 100.0 ± 0.0 | 89.2 ± 0.1 | 82.4 ± 0.0 |

| PCA (26) | LDA | 100.0 ± 0.0 | 96.3 ± 0.6 | 96.0 ± 0.5 | |

| NIR | PLS-DA (22) | 100.0 ± 0.0 | 99.3 ± 0.4 | 99.7 ± 0.2 | |

| NIR | LDA | 100.0 ± 0.0 | 97.3 ± 0.7 | 95.6 ± 0.8 | |

| 2nd der. | Absorption | LDA | 100.0 ± 0.0 | 85.2 ± 0.3 | 80.4 ± 0.4 |

| PCA (30) | LDA | 100.0 ± 0.0 | 94.5 ± 1.2 | 93.5 ± 1.3 | |

| NIR | PLS-DA (22) | 100.0 ± 0.0 | 99.0 ± 0.2 | 98.2 ± 0.4 | |

| NIR | LDA | 100.0 ± 0.0 | 94.9 ± 0.6 | 93.8 ± 0.9 | |

| SNV + 1st der. | Absorption | LDA | 100.0 ± 0.0 | 89.0 ± 0.4 | 88.2 ± 0.0 |

| PCA (40) | LDA | 100.0 ± 0.0 | 96.5 ± 0.7 | 97.1 ± 0.4 | |

| NIR | PLS-DA (35) | 100.0 ± 0.0 | 99.5 ± 0.5 | 97.4 ± 0.7 | |

| NIR | LDA | 100.0 ± 0.0 | 96.7 ± 0.4 | 96.5 ± 0.7 | |

| SNV + 2nd der. | Absorption | LDA | 100.0 ± 0.0 | 87.4 ± 0.2 | 82.9 ± 0.3 |

| PCA (34) | LDA | 100.0 ± 0.0 | 89.3 ± 0.9 | 92.9 ± 0.7 |

| Pre-Proc. | Dim. Red. | Classifier | Acc. Fresh Oak (%) | Acc. One Time Used (%) | Acc. Two Times Used (%) |

|---|---|---|---|---|---|

| None | PLS-DA (7) | 100.0 ± 0.0 | 84.2 ± 0.5 | 67.9 ± 0.5 | |

| None | None | LDA | 79.4 ± 2.4 | 31.5 ± 2.3 | 35.7 ± 2.1 |

| PCA (5) | LDA | 100.0 ± 0.0 | 87.1 ± 0.7 | 70.3 ± 0.7 | |

| None | PLS-DA (7) | 100.0 ± 0.0 | 77.9 ± 0.9 | 67.2 ± 0.4 | |

| SNV | None | LDA | 78.9 ± 2.5 | 33.5 ± 1.8 | 34.1 ± 1.8 |

| PCA (8) | LDA | 100.0 ± 0.0 | 77.9 ± 1.2 | 69.7 ± 0.7 | |

| None | PLS-DA (7) | 100.0 ± 0.0 | 81.5 ± 0.8 | 67.5 ± 0.8 | |

| 1st der. | None | LDA | 85.1 ± 1.7 | 38.3 ± 1.9 | 32.7 ± 1.6 |

| PCA (8) | LDA | 100.0 ± 0.0 | 80.9 ± 0.5 | 68.8 ± 0.6 | |

| None | PLS-DA (7) | 100.0 ± 0.0 | 78.9 ± 1.1 | 64.5 ± 0.7 | |

| 2nd der. | None | LDA | 83.8 ± 1.3 | 36.9 ± 1.9 | 35.8 ± 2.7 |

| PCA (20) | LDA | 100.0 ± 0.0 | 57.2 ± 1.9 | 46.2 ± 2.3 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chalyan, T.; Magnus, I.; Konstantaki, M.; Pissadakis, S.; Diamantakis, Z.; Thienpont, H.; Ottevaere, H. Benchmarking Spectroscopic Techniques Combined with Machine Learning to Study Oak Barrels for Wine Ageing. Biosensors 2022, 12, 227. https://doi.org/10.3390/bios12040227

Chalyan T, Magnus I, Konstantaki M, Pissadakis S, Diamantakis Z, Thienpont H, Ottevaere H. Benchmarking Spectroscopic Techniques Combined with Machine Learning to Study Oak Barrels for Wine Ageing. Biosensors. 2022; 12(4):227. https://doi.org/10.3390/bios12040227

Chicago/Turabian StyleChalyan, Tatevik, Indy Magnus, Maria Konstantaki, Stavros Pissadakis, Zacharias Diamantakis, Hugo Thienpont, and Heidi Ottevaere. 2022. "Benchmarking Spectroscopic Techniques Combined with Machine Learning to Study Oak Barrels for Wine Ageing" Biosensors 12, no. 4: 227. https://doi.org/10.3390/bios12040227

APA StyleChalyan, T., Magnus, I., Konstantaki, M., Pissadakis, S., Diamantakis, Z., Thienpont, H., & Ottevaere, H. (2022). Benchmarking Spectroscopic Techniques Combined with Machine Learning to Study Oak Barrels for Wine Ageing. Biosensors, 12(4), 227. https://doi.org/10.3390/bios12040227