Eco-Friendly Method for Tailoring Biocompatible and Antimicrobial Surfaces of Poly-L-Lactic Acid

Abstract

1. Introduction

2. Material and Methods

2.1. Materials

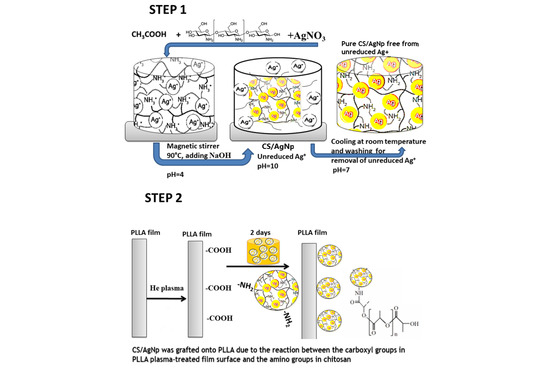

2.2. The Two Step Method

2.2.1. In Situ Formation Silver Nanoparticles on Chitosan

2.2.2. Combined Nonconventional and Conventional Treatments of PLLA Films

2.3. Characterization Methods

2.4. Culture Media Preparation and MTT Test

2.5. Antimicrobial Activity

3. Results and Discussions

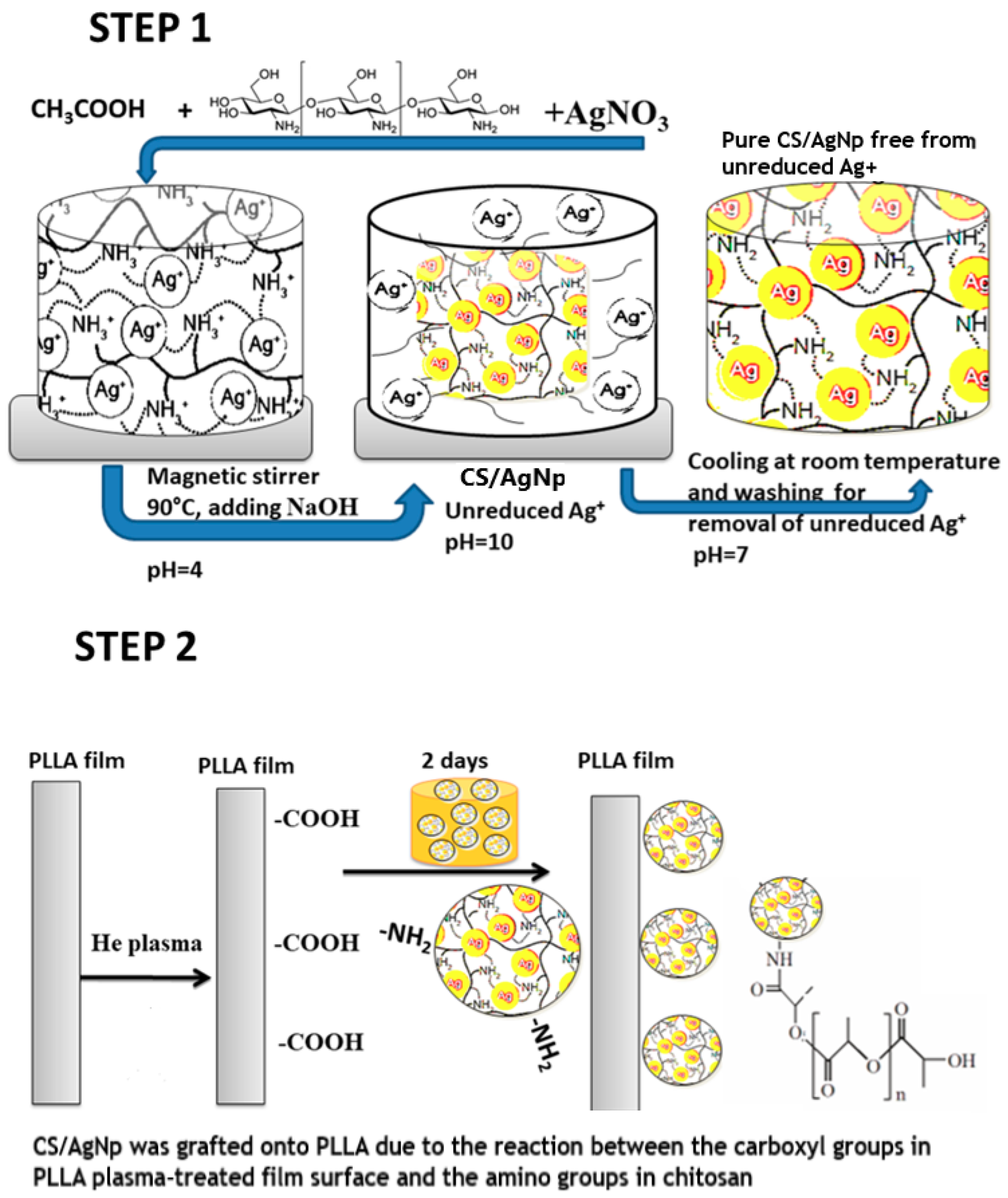

3.1. TEM Images and Particle Size Results of CS/AgNp

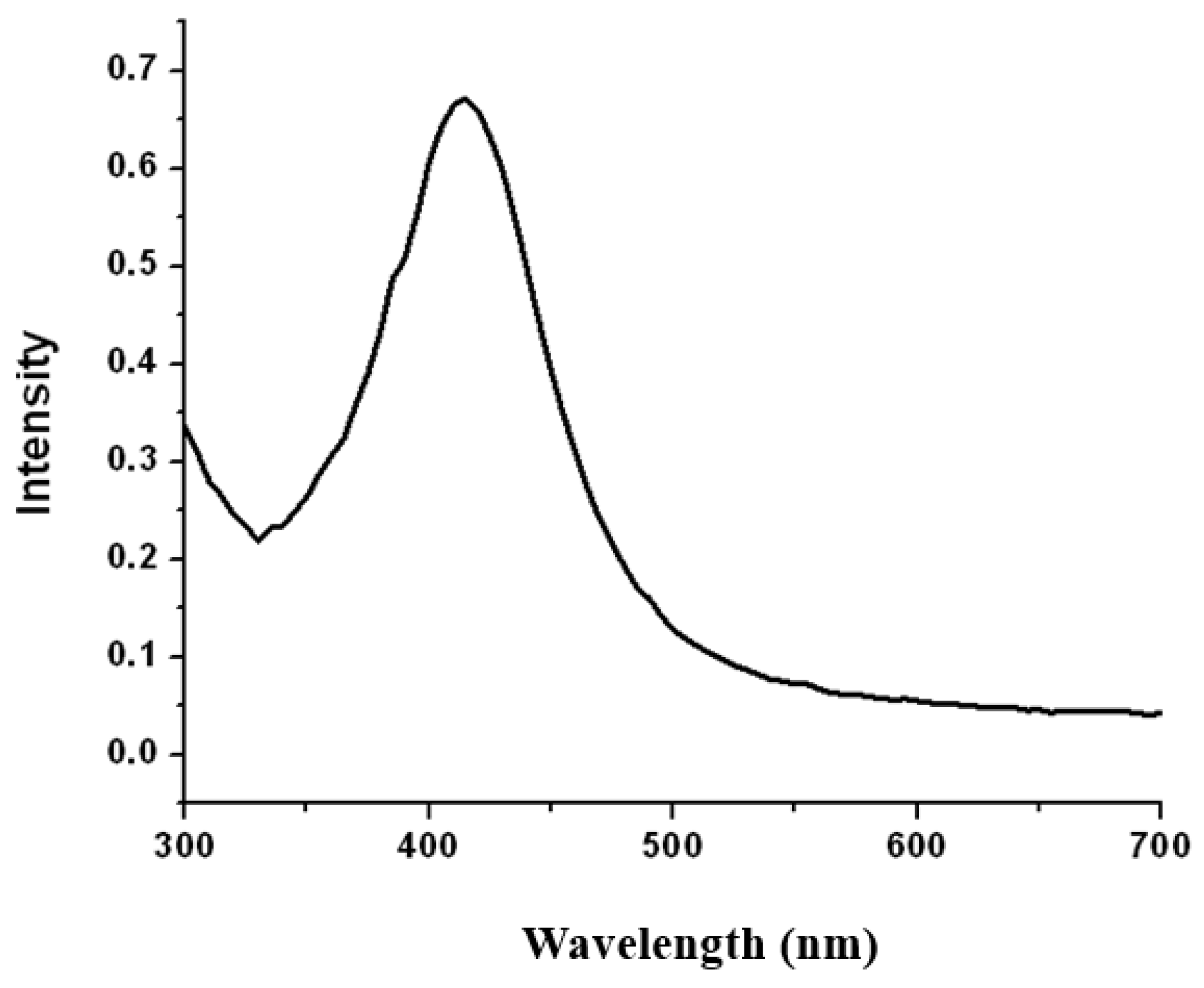

3.2. SAXS Results

3.3. FTIR Results

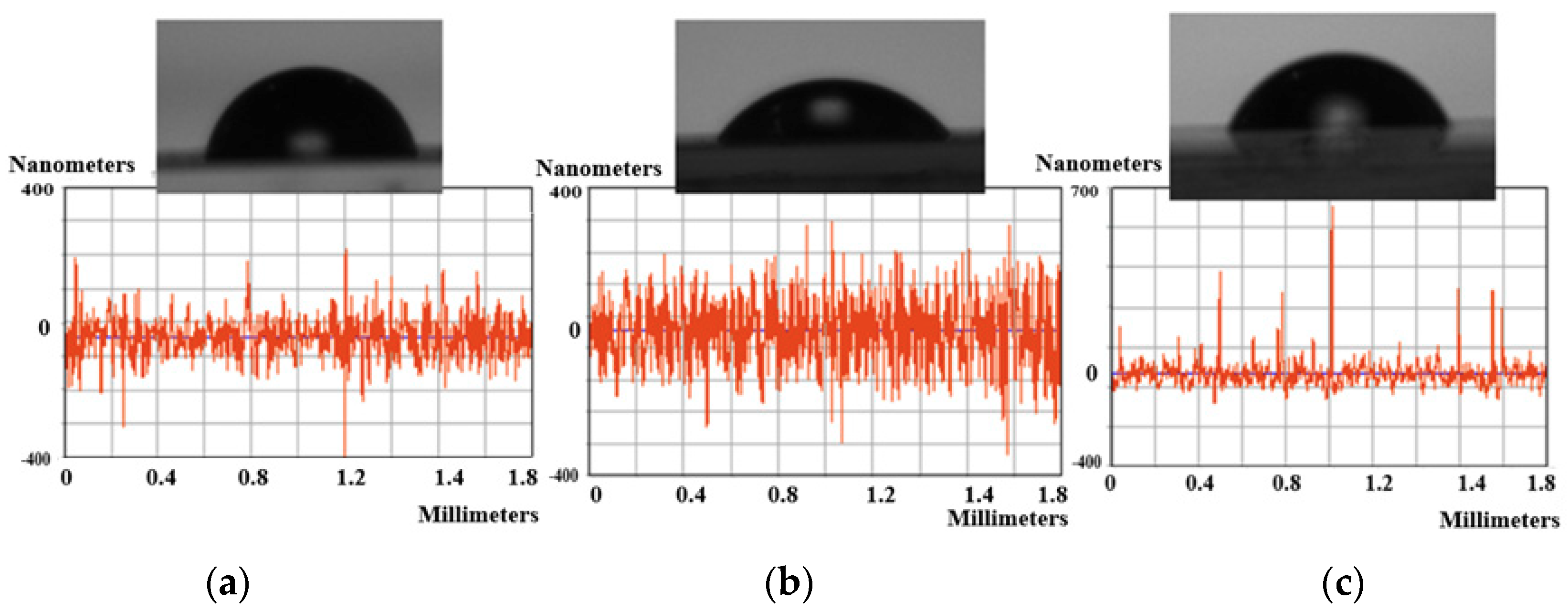

3.4. Surface Roughness and Wettability

3.5. SEM and EDAX Results

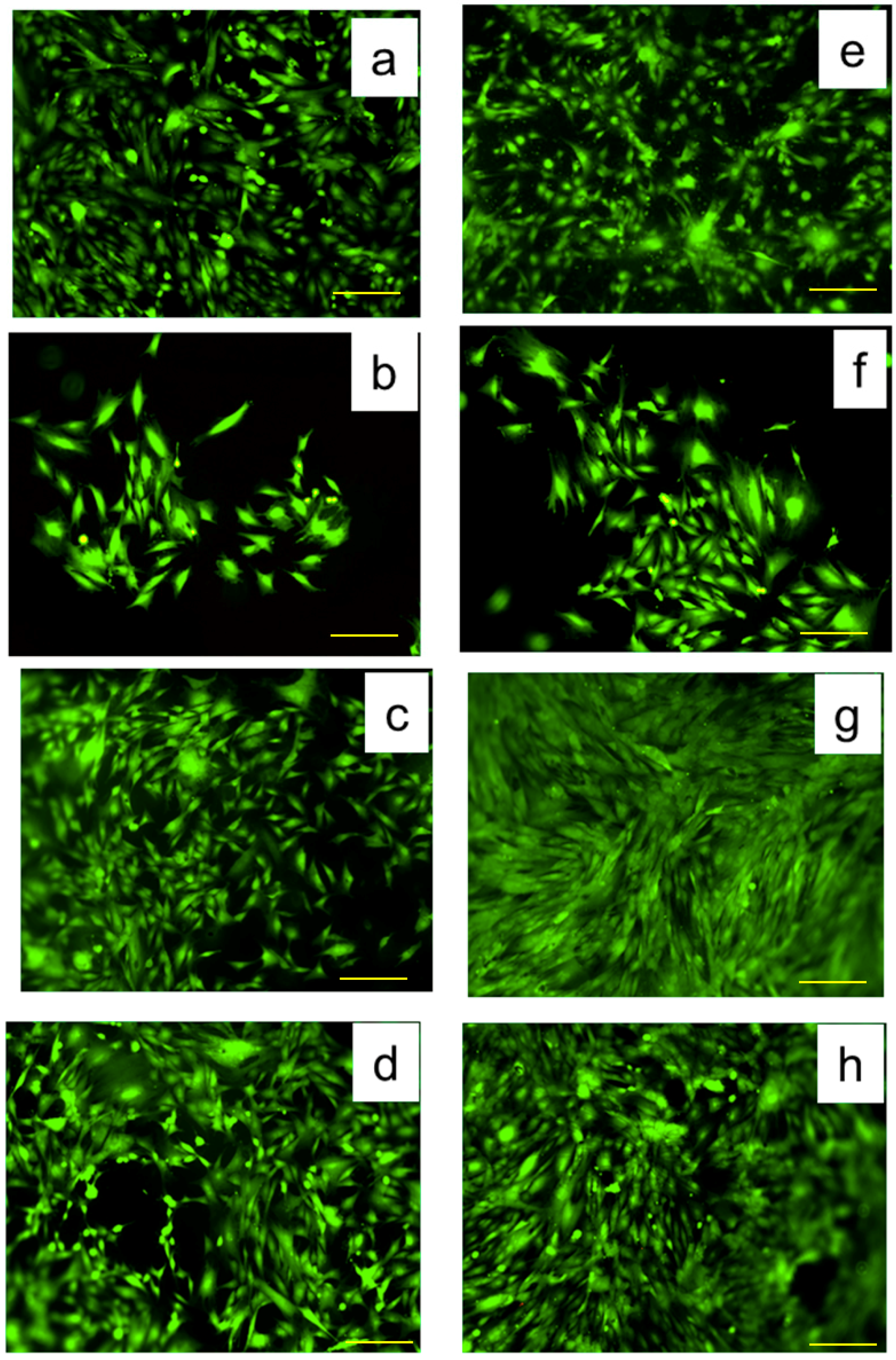

3.6. Proliferation and Morphology of on the MC3T3-E1 Cells on the PLLA Samples

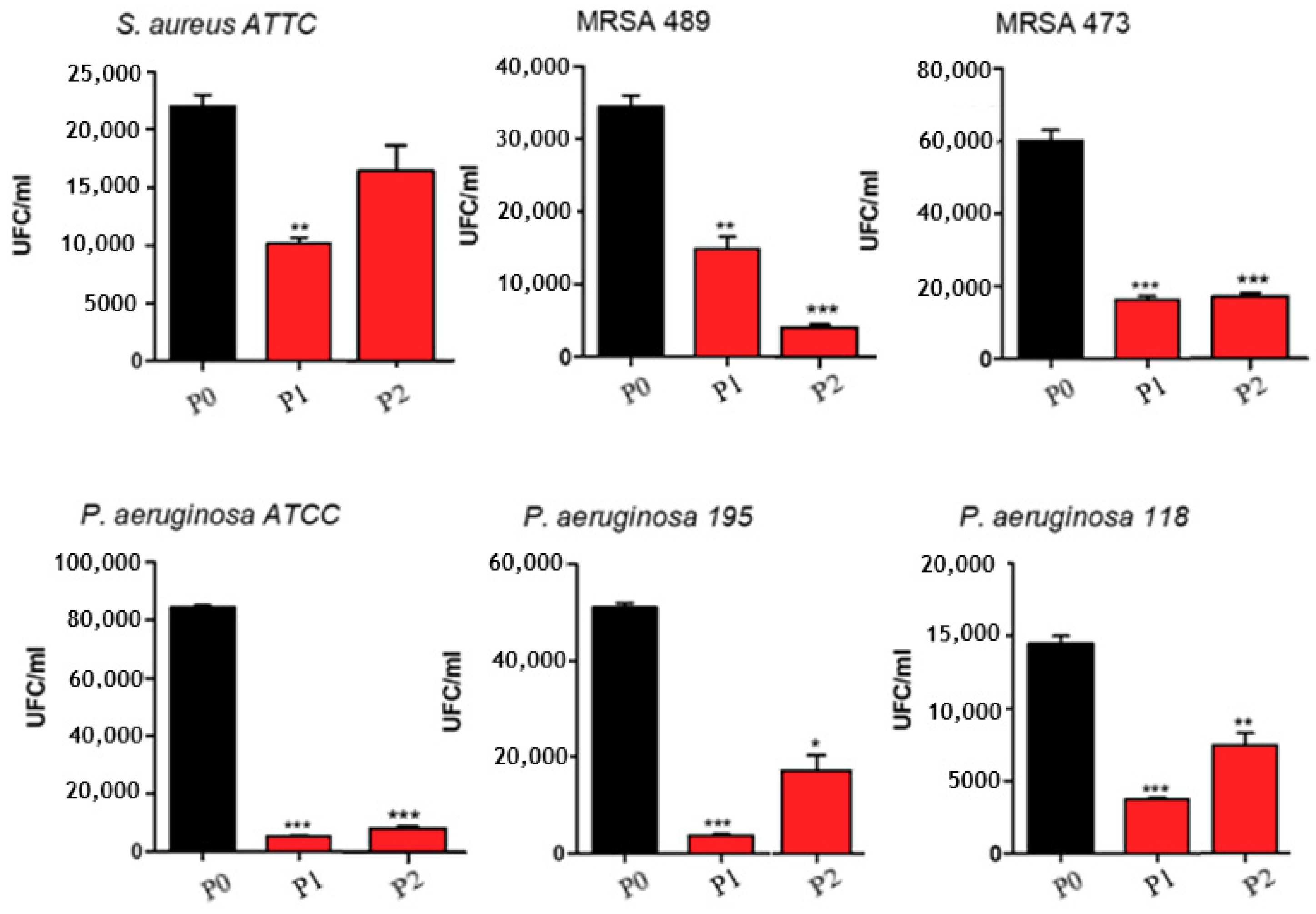

3.7. Antimicrobial Activity

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Nofar, M.; Sacligil, D.; Carreau, P.J.; Kamal, M.R.; Heuzey, M.C. Poly (lactic acid) blends: Processing, properties and applications. Int. J. Biol. Macromol. 2019, 125, 307–360. [Google Scholar] [CrossRef]

- Duarte, A.R.C.; Mano, J.F.; Reis, R.L. Novel 3D scaffolds of chitosan–PLLA blends for tissue engineering applications: Preparation and characterization. J. Supercrit. Fluid 2010, 54, 282–289. [Google Scholar] [CrossRef]

- Zhou, Q.; Xie, J.; Bao, M.; Yuan, H.; Ye, Z.; Lou, X.; Zhang, Y. Engineering aligned electrospun PLLA microfibers with nano-porous surface nanotopography for modulating the responses of vascular smooth muscle cells. J. Mater. Chem. B 2015, 3, 4439–4450. [Google Scholar] [CrossRef]

- Van Dijk, M.; Tunc, D.C.; Smit, T.H.; Higham, P.; Burger, E.H.; Wuisman, P.I. In vitro and in vivo degradation of bio absorbable PLLA spinal fusion cages. J. Biomed. Mater. Res. 2002, 63, 752–759. [Google Scholar] [CrossRef] [PubMed]

- Pavia, F.C.; La Carrubba, V.; Mannella, G.A.; Ghersi, G.; Brucato, V. Poly (lactic acid) based scaffolds for vascular tissue engineering. Chem. Eng. Transact. 2012, 27, 1–6. [Google Scholar]

- Evanoff, D.D.; Chumanov, G. Synthesis and optical properties of silver nanoparticles and arrays. Chem. Phys. Chem. 2005, 6, 1221–1231. [Google Scholar] [CrossRef] [PubMed]

- He, J.H.; Kunitake, T.; Nakao, A. Facile in situ synthesis of noble metal nanoparticles in porous cellulose fibers. Chem. Mater. 2003, 15, 4401–4406. [Google Scholar] [CrossRef]

- Wiley, B.; Sun, Y.G.; Mayers, B.; Xia, Y.N. Shape-controlled synthesis of metal nanostructures: The case of silver. Chem. A Eur. J. 2005, 11, 454–463. [Google Scholar] [CrossRef]

- Ocwieja, M.; Barbasz, A.; Walas, S.; Romand, M.; Paluszkiewicz, C. Physicochemical properties and cytotoxicity of cysteine-functionalized silver nanoparticles. Colloid Surf. B 2017, 160, 429–437. [Google Scholar] [CrossRef]

- Chowdhury, N.R.; Cowin, A.J.; Zilm, P.; Vasilev, K. “Chocolate” gold nanoparticles—One pot synthesis and biocompatibility. Nanomaterials 2018, 8, 496–506. [Google Scholar] [CrossRef]

- Khalil, A.; Chaturbhuj, H.P.S.; Saurabha, K.; Adnan, A.S.; Nurul Fazita, M.R.; Syakir, M.I.; Davoudpour, Y.; Rafatullah, M.; Abdullah, C.K.; Haafiz, M.K.M.; et al. Biological synthesis of triangular gold nanoprisms. Carbohyd. Polym. 2016, 150, 216–226. [Google Scholar]

- Kim, M.C.; Masuoka, T. Degradation properties of PLA and PHBV films treated with CO2-plasma. React. Funct. Polym. 2009, 69, 287–292. [Google Scholar] [CrossRef]

- Wan, Y.; Wu, H.; Yu, A.; Wen, D. Biodegradable polylactide/chitosan blend membranes. Biomacromolecules 2006, 7, 1362–1372. [Google Scholar] [CrossRef] [PubMed]

- Suyatma, N.E.; Copinet, A.; Tighzert, L.; Coma, V. Mechanical and barrierproperties of biodegradable films made from chitosan andpoly(lactic acid) blends. J. Polym. Environ. 2004, 12, 1–6. [Google Scholar] [CrossRef]

- Slepička, P.; Slepičková Kasálková, N.; Pinkner, A.; Sajdl, P.; Kolská, Z.; Švorčík, V. Plasma induced cytocompatibility of stabilized poly-l-lactic acid doped with graphene nanoplatelets. React. Funct. Polym. 2018, 131, 266–275. [Google Scholar] [CrossRef]

- Murugadoss, A.; Chattopadhyay, A. A ‘green’ chitosan-silver nanoparticle composite as a heterogeneous as well as microheterogeneous catalyst. Nanotechnology 2008, 19, 1–9. [Google Scholar] [CrossRef]

- Sanpui, P.; Murugadaoss, A.; Prasad, P.V.D.; Ghosh, S.S.; Chattopadhyay, A. The antibacterial properties of a novel chitosan–Ag-nanoparticle composite. Int. J. Food Microbiol. 2008, 124, 142–146. [Google Scholar] [CrossRef]

- Shameli, K.; Ahmad, M.B.; Yunus, W.M.Z.W.; Rustaiyan, A.; Ibrahim, N.A.; Zargar, M.; Abdollahi, Y. Green synthesis of silver/montmorillonite/chitosan bionanocomposites using the UV irradiation method and evaluation of antibacterial activity. Int. J. Nanomed. 2010, 5, 875–887. [Google Scholar] [CrossRef]

- Wan, Y.; Tu, C.; Yang, J.; Bei, J.; Wang, S. Influences of ammonia plasma treatment on modifying depth and degradation of poly(l-lactide) scaffolds. Biomaterials 2006, 27, 2699–2704. [Google Scholar] [CrossRef]

- Surdu-Bob, C.C.; Sullivan, J.L.; Saied, S.O.; Layberry, R.; Aflori, M. Surface compositional changes in GaAs subjected to argon plasma treatment. Appl. Surf. Sci. 2002, 202, 183–198. [Google Scholar] [CrossRef]

- Hirotsu, T.; Nakayama, K.; Tsujisaka, T.; Mas, A.; Schue, F. Plasma surface treatments of melt-extruded sheets of poly(l-lactic acid). Polym. Eng. Sci. 2002, 42, 299–306. [Google Scholar] [CrossRef]

- Yang, J.; Shi, G.X.; Wang, S.G.; Bei, J.Z.; Cao, Y.L.; Shang, Q.; Yang, G.; Wang, W. Fabrication and surface modification of macroporous poly(l-lactic acid) and poly(l-lactic-co-glycolic acid) (70/30) cell scaffolds for human skin fibroblast cell culture. J. Biomed. Mater, Res. 2002, 62, 438–446. [Google Scholar] [CrossRef]

- Yang, J.; Bei, J.Z.; Wang, S.G. Enhanced cell affinity of poly(d,l-lactide)by combining plasma treatment with collagen anchorage. Biomaterials 2002, 23, 2607–2614. [Google Scholar] [CrossRef]

- Rasal, R.M.; Janorkar, A.V.; Hirt, D.E. Poly(lactic acid) modifications. Prog. Polym. Sci. 2010, 35, 338–356. [Google Scholar] [CrossRef]

- Aflori, M.; Miron, C.; Dobromir, M.; Drobota, M. Bactericidal effect on Foley catheters obtained by plasma and silver nitrate treatments. High Perform. Polym. 2015, 27, 655–660. [Google Scholar] [CrossRef]

- Aflori, M. Chitosan-based silver nanoparticles incorporated at the surface of plasma-treated PHB. Chem. Lett. 2017, 46, 65–67. [Google Scholar] [CrossRef]

- Beer, C.; Foldbjerg, R.; Hayashi, Y.; Sutherland, D.S.; Autrup, H. Toxicity of silver nanoparticles—Nanoparticle or silver ion? Toxicol. Lett. 2012, 208, 286–292. [Google Scholar] [CrossRef]

- Berridge, M.V.; Herst, P.M.; Tan, A.S. Tetrazolium dyes as tools in cell biology: New insights into their cellular reduction. Biotechn. Annu. Rev. 2005, 11, 127–152. [Google Scholar]

- Berridge, M.V.; Tan, A.S. Subcellular localization, substrate dependence, and involvement of mitochondrial electron transport in MTT reduction. Arch. Biochem. Biophys. 1993, 303, 474–482. [Google Scholar] [CrossRef]

- Ximing, X.; Gengenbach, T.R.; Griesser, H.J. Changes in wettability with time of plasma modified perfluorinated polymers. J. Adhes. Sci. Tech. 1992, 6, 1411–1431. [Google Scholar] [CrossRef]

- Puiso, J.; Adliene, D.; Guobiene, A.; Prosycevas, I.; Plaipaite-Nalivaiko, R. Modification of Ag–PVP nanocomposites by gamma irradiation. Mater. Sci. Eng. B 2011, 176, 1562–1567. [Google Scholar] [CrossRef]

- Pal, S.; Tak, Y.K.; Song, J.M. Does the antibacterial activity of silver nanoparticles depend on the shape of the nanoparticle? A study of the Gram-negative bacterium Escherichia coli. Appl. Environ. Microbiol. 2012, 73, 1712–1720. [Google Scholar] [CrossRef] [PubMed]

- Wei, D.; Sun, W.; Qian, W.; Ye, Y.; Ma, X. The synthesis of chitosan-based silver nanoparticles and their antibacterial activity. Carbohyd. Res. 2009, 344, 2375–2382. [Google Scholar] [CrossRef] [PubMed]

- Darroudi, M.; Khorsand Zak, A.; Muhamad, M.R.; Huang, N.M.; Hakimi, M. Green synthesis of colloidal silver nanoparticles by sonochemical method. Mater. Lett. 2012, 66, 117–120. [Google Scholar] [CrossRef]

- Occhiello, E.; Morra, M.; Morini, G.; Garbassi, F.; Humphrey, P. Oxygen plasma-treated polypropylene interfaces with air, water, and epoxy resins. Part I. Air and water. J. Appl. Polym. Sci. 1991, 42, 551–559. [Google Scholar] [CrossRef]

- Tverdokhlebov, S.I.; Bolbasov, E.N.; Shesterikov, E.V.; Antonova, L.V.; Golovkin, A.S.; Matveeva, V.G.; Petlin, D.G.; Anissimov, Y.G. Modification of polylactic acid surface using RF plasma discharge with sputter deposition of a hydroxyapatite target for increased biocompatibility. Appl. Surf. Sci. 2015, 329, 32–39. [Google Scholar] [CrossRef]

- Krikorian, V.; Pochan, D.J. Crystallization behavior of poly(L-lactic acid) nanocomposites: Nucleation and growth probed by infrared spectroscopy. Macromolecules 2005, 38, 6520–6527. [Google Scholar] [CrossRef]

- Tsai, C.C.; Wu, R.J.; Cheng, H.Y.; Li, S.C.; Siao, Y.Y.; Kong, D.C.; Jang, G.W. Crystallinity and dimensional stability of biaxial oriented poly(lactic acid) films. Polym. Degrad. Stab. 2010, 95, 1292–1298. [Google Scholar] [CrossRef]

- Elzein, T.; Nasser-Eddine, M.; Delaite, C.; Bistac, S.; Dumas, P. FTIR study of polycaprolactone chain organization at interfaces. J. Colloid Interf. Sci. 2004, 273, 381–387. [Google Scholar] [CrossRef]

- Chandran, S.P.; Chaudhary, M.; Pasricha, R.; Ahmad, A.; Sastry, M. Synthesis of gold nanotriangles and silver nanoparticles using Aloevera plant extract. Biotech. Prog. 2006, 22, 577–583. [Google Scholar] [CrossRef]

- Jia, R.; Jiang, H.; Jin, M.; Wang, X.; Huang, J. Silver/chitosan-based Janus particles: Synthesis, characterization, and assessment of antimicrobial activity in vivo and vitro. Food Res. Int. 2015, 78, 433–441. [Google Scholar] [CrossRef]

- Gartner, H.; Li, Y.; Almenar, E. Improved wettability and adhesion of polylactic acid/chitosan coating for bio-based multilayer film development. Appl. Surf. Sci. 2015, 332, 488–493. [Google Scholar] [CrossRef]

- Jia, C.; Chen, P.; Wang, Q.; Li, B.; Chen, M. Surface wettability of atmospheric dielectric barrier discharge processed Armos fibers. Appl. Surf. Sci. 2011, 258, 388–393. [Google Scholar] [CrossRef]

- Cory, A.H.; Owen, T.C.; Barltrop, J.A.; Cory, J.G. Use of an aqueous soluble tetrazolium/formazan assay for cell growth assays in culture. Cancer Commun. 1991, 3, 207–212. [Google Scholar] [CrossRef] [PubMed]

- Erbil, H.Y. Surface Chemistry of Solid and Liquid Interfaces; Blackwell Publishing: Hoboken, NJ, USA, 2006. [Google Scholar]

- Mittal, K.L. Contact Angle, Wettability and Adhesion; VSP: London, UK, 2002; Volume 2. [Google Scholar]

- Stamm, M. Polymer surfaces and interfaces. In Characterization, Modification and Applications; Springer: Berlin, Germany, 2008. [Google Scholar]

- Mamonova, I.A.; Babushkina, I.V.; Norkin, I.A.; Gladkova, E.V.; Matasov, M.D.; Puchinyan, D.M. Biological activity of metal nanoparticles and their oxides and their effect on bacterial cells. Nanotechnol. Russ. 2015, 10, 128–134. [Google Scholar] [CrossRef]

- Rabea, E.I.; Badawy, M.E.-T.; Stevens, C.V.; Smagghe, G.; Steurbaut, W. Chitosan as antimicrobial agent: Applications and mode of action. Biomacromolecules 2003, 4, 1457–1465. [Google Scholar] [CrossRef]

- No, H.K.; Park, N.Y.; Lee, S.H.; Meyers, S.P. Antibacterial activity of chitosans and chitosan oligomers with different molecular weights. Int. J. Food Microbiol. 2002, 74, 65–72. [Google Scholar] [CrossRef]

- Eaton, P.; Fernandes, J.C.; Pereira, E.; Pintado, M.E.; Malcata, F.X. Atomic force microscopy study of the antibacterial effects of chitosans on Escherichia coli and Staphylococcus aureus. Ultramicroscopy 2008, 108, 1128–1134. [Google Scholar] [CrossRef]

| Roughness | Contact Angle Measurements Parameters | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| Ra (nm) | θw | θEG | Ww | WEG | γSVp | γSVd | γSV | γSL | |

| P0 | 43.103 | 79.9 | 52.19 | 86.19 | 77.42 | 8.05 | 23.93 | 31.98 | 18.58 |

| P1 | 86.448 | 51.54 | 34 | 118.07 | 87.79 | 38.93 | 9.61 | 48.55 | 3.27 |

| P2 | 63.831 | 70.11 | 42.22 | 97.56 | 83.54 | 13.96 | 22.39 | 36.36 | 11.60 |

| Element (%) | CK | OK | NK | AgL |

|---|---|---|---|---|

| P0 | 70.49 | 29.51 | - | - |

| P1 | 71.73 | 14.36 | 13.46 | 00.45 |

| P2 | 72.43 | 14.61 | 12.14 | 00.82 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Aflori, M.; Butnaru, M.; Tihauan, B.-M.; Doroftei, F. Eco-Friendly Method for Tailoring Biocompatible and Antimicrobial Surfaces of Poly-L-Lactic Acid. Nanomaterials 2019, 9, 428. https://doi.org/10.3390/nano9030428

Aflori M, Butnaru M, Tihauan B-M, Doroftei F. Eco-Friendly Method for Tailoring Biocompatible and Antimicrobial Surfaces of Poly-L-Lactic Acid. Nanomaterials. 2019; 9(3):428. https://doi.org/10.3390/nano9030428

Chicago/Turabian StyleAflori, Magdalena, Maria Butnaru, Bianca-Maria Tihauan, and Florica Doroftei. 2019. "Eco-Friendly Method for Tailoring Biocompatible and Antimicrobial Surfaces of Poly-L-Lactic Acid" Nanomaterials 9, no. 3: 428. https://doi.org/10.3390/nano9030428

APA StyleAflori, M., Butnaru, M., Tihauan, B.-M., & Doroftei, F. (2019). Eco-Friendly Method for Tailoring Biocompatible and Antimicrobial Surfaces of Poly-L-Lactic Acid. Nanomaterials, 9(3), 428. https://doi.org/10.3390/nano9030428