Arrayed CdTeMicrodots and Their Enhanced Photodetectivity via Piezo-Phototronic Effect

Abstract

1. Introduction

2. Materials and Methods

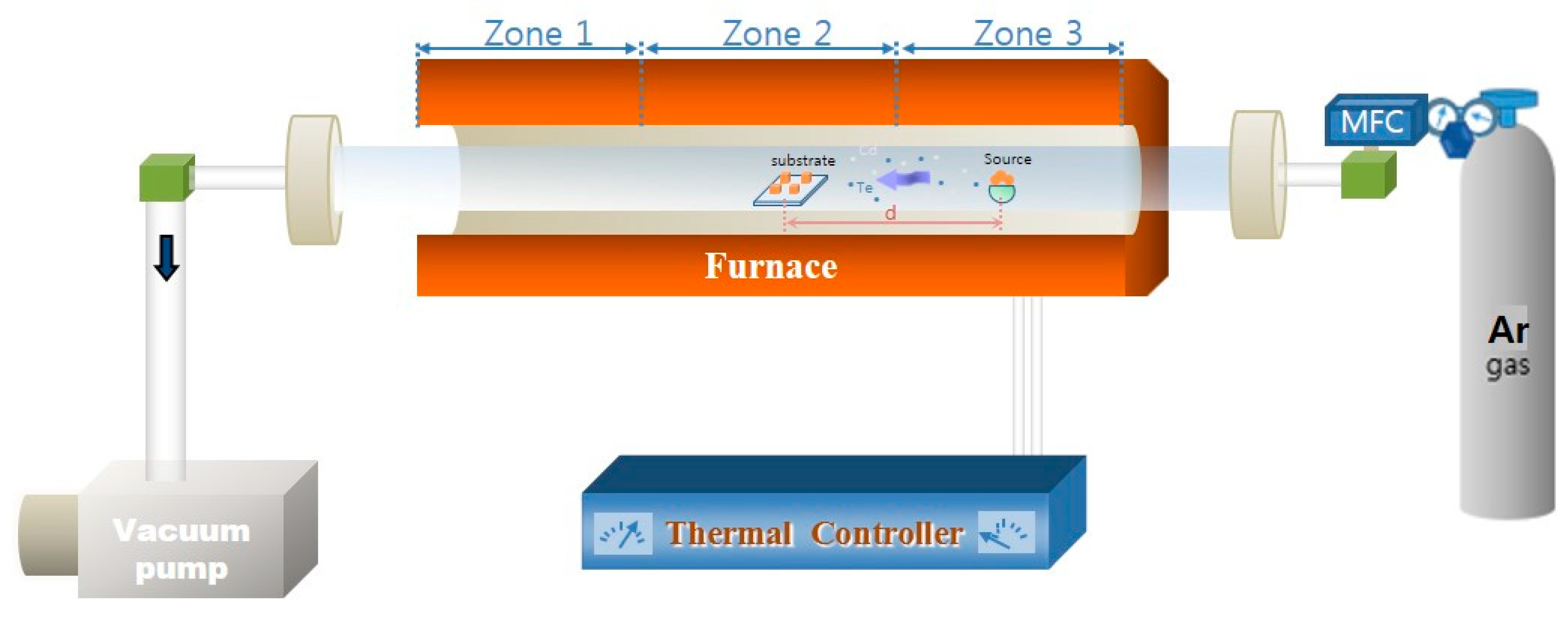

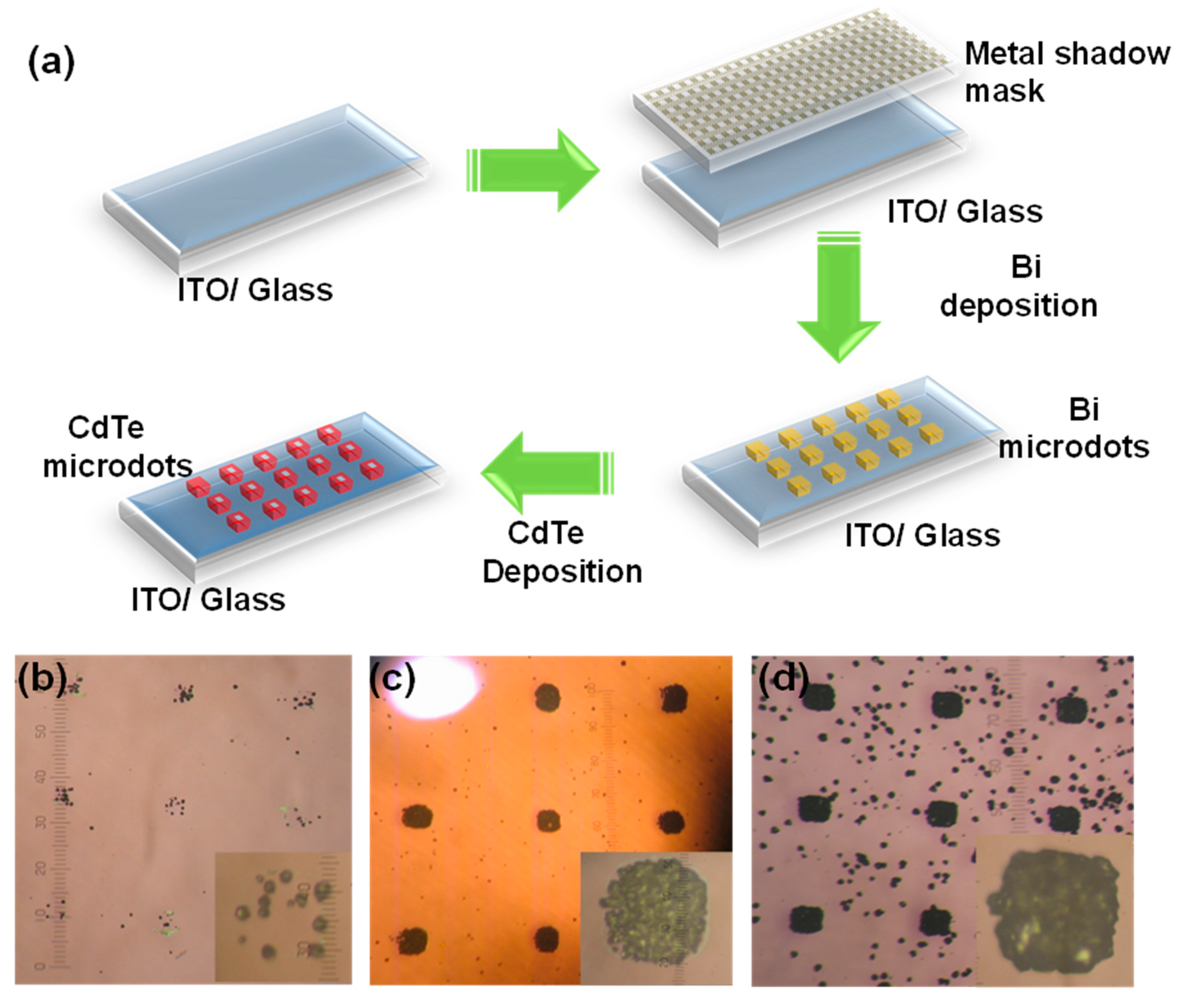

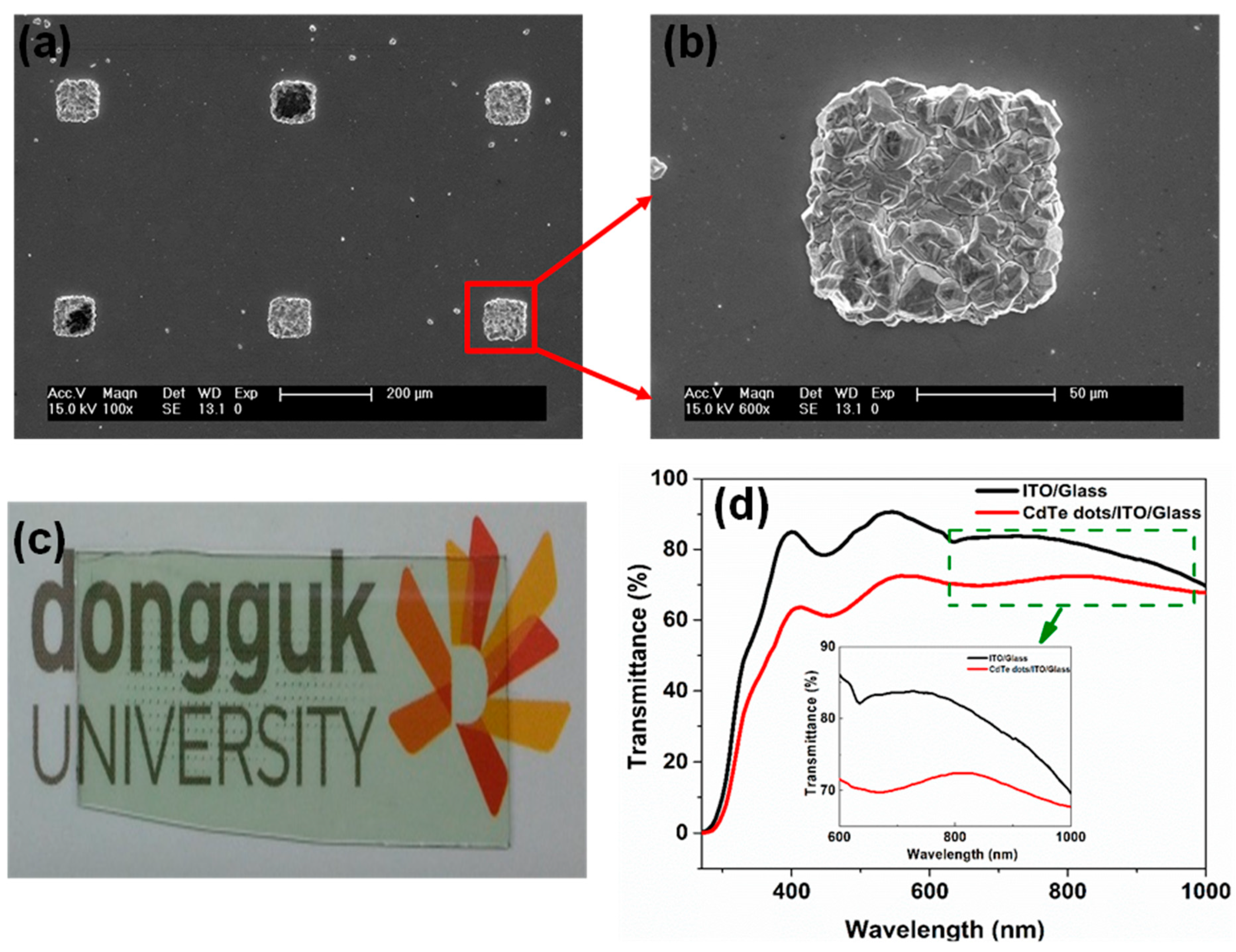

2.1. Synthesis of CdTe Films and Microdots

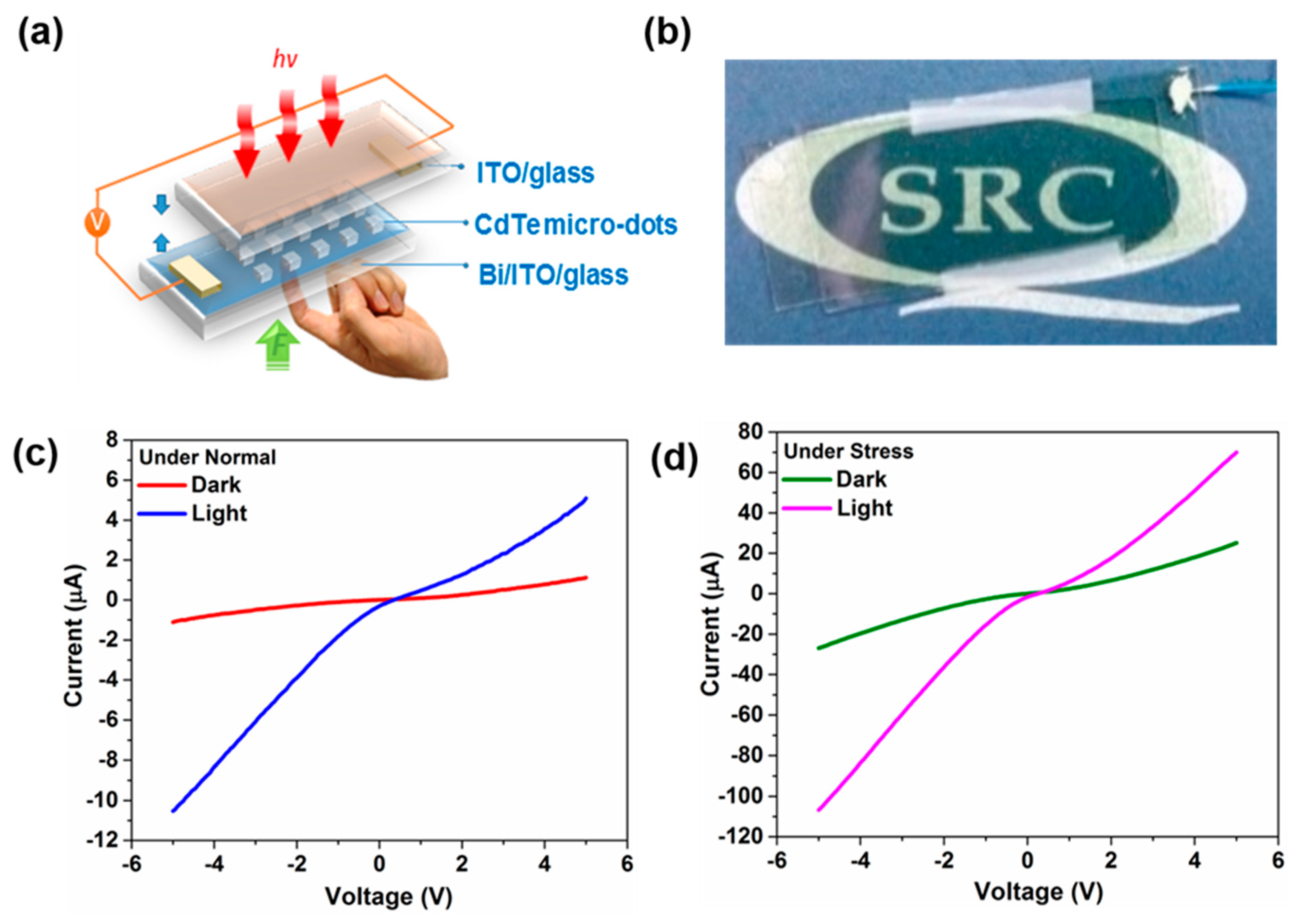

2.2. Device Fabrication

2.3. Characterization

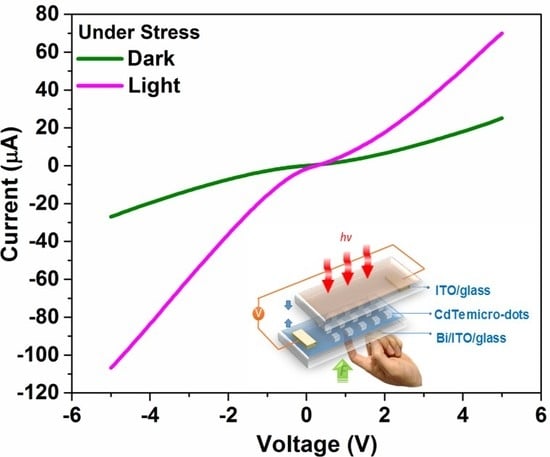

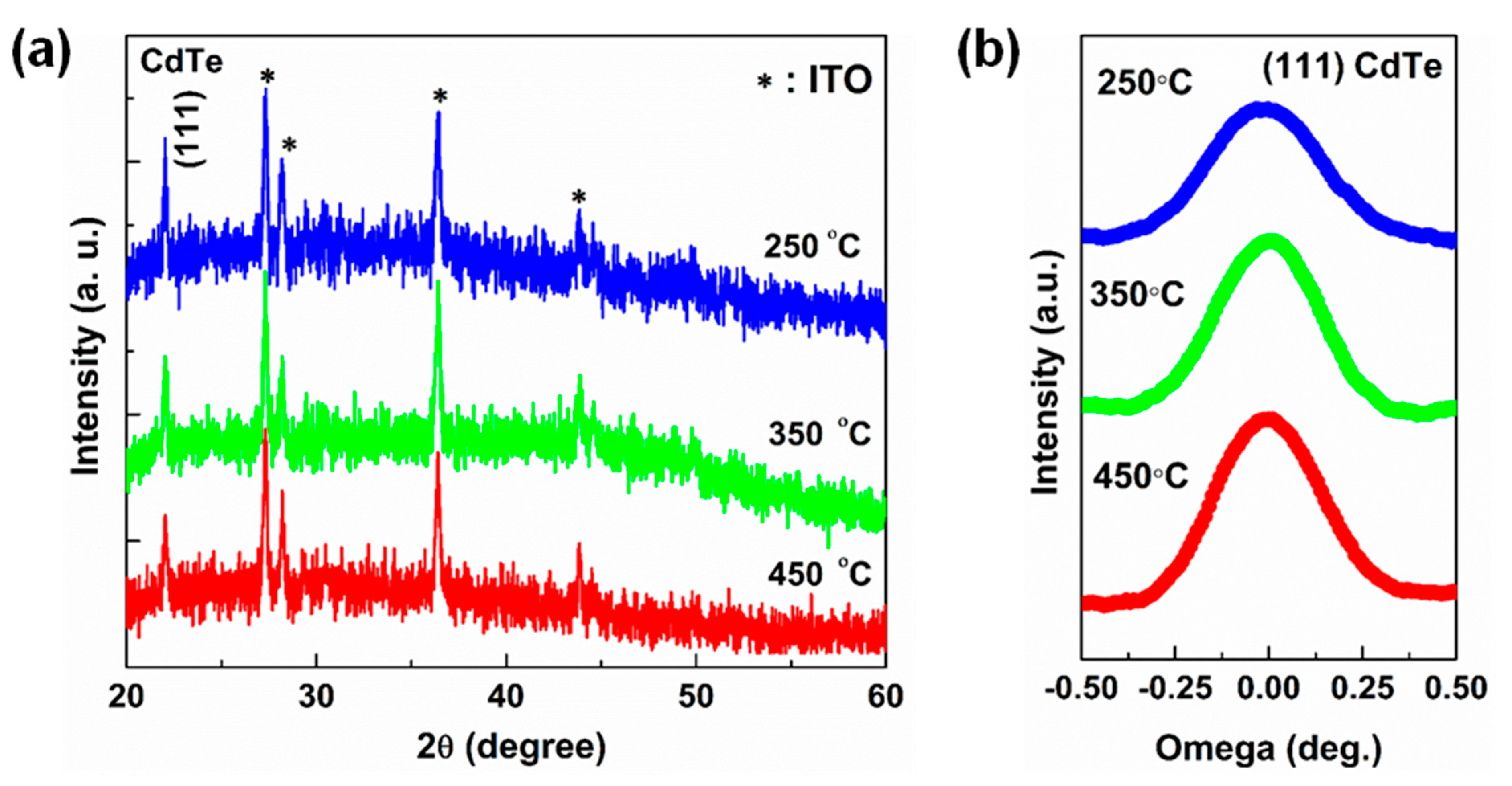

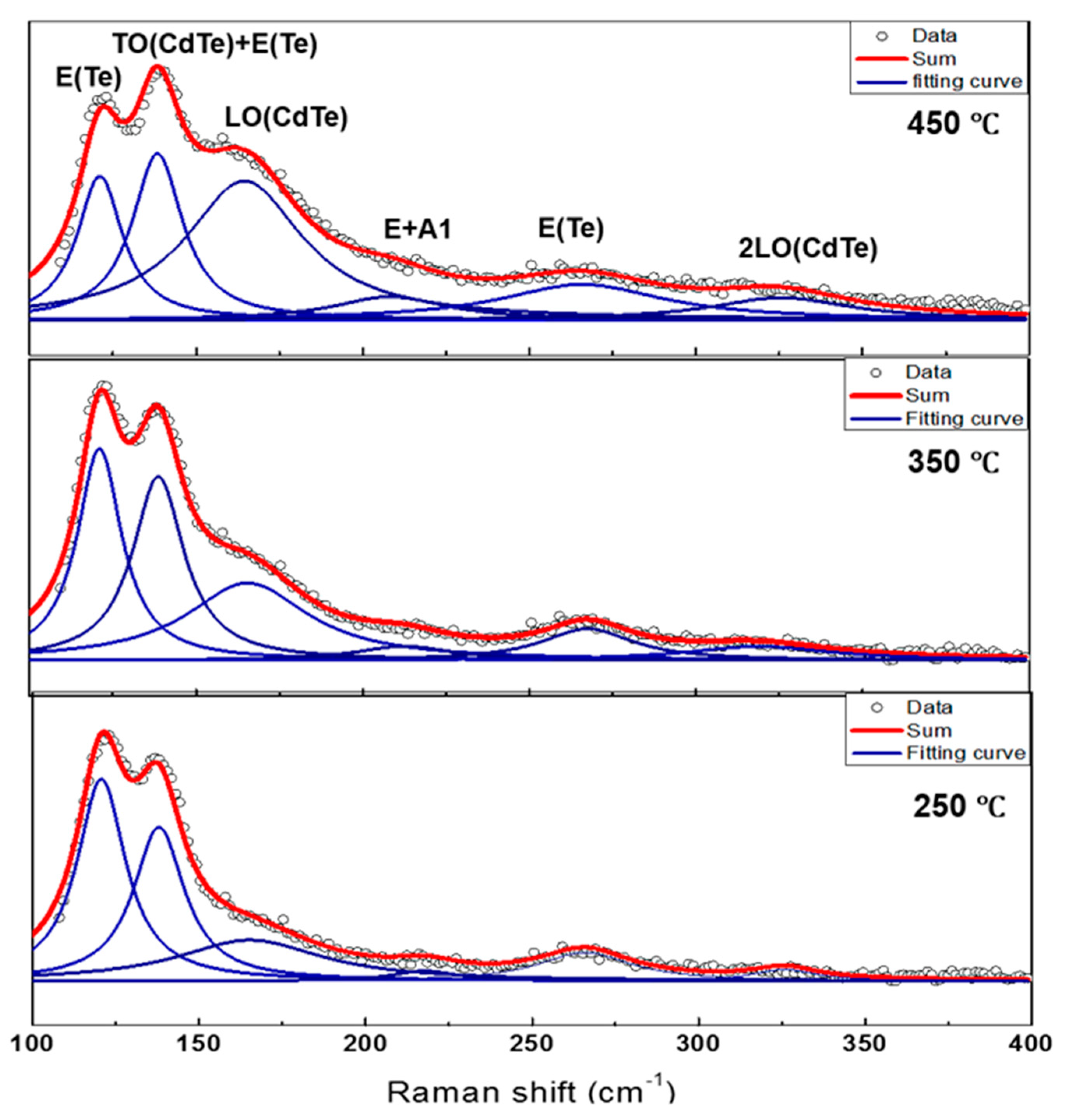

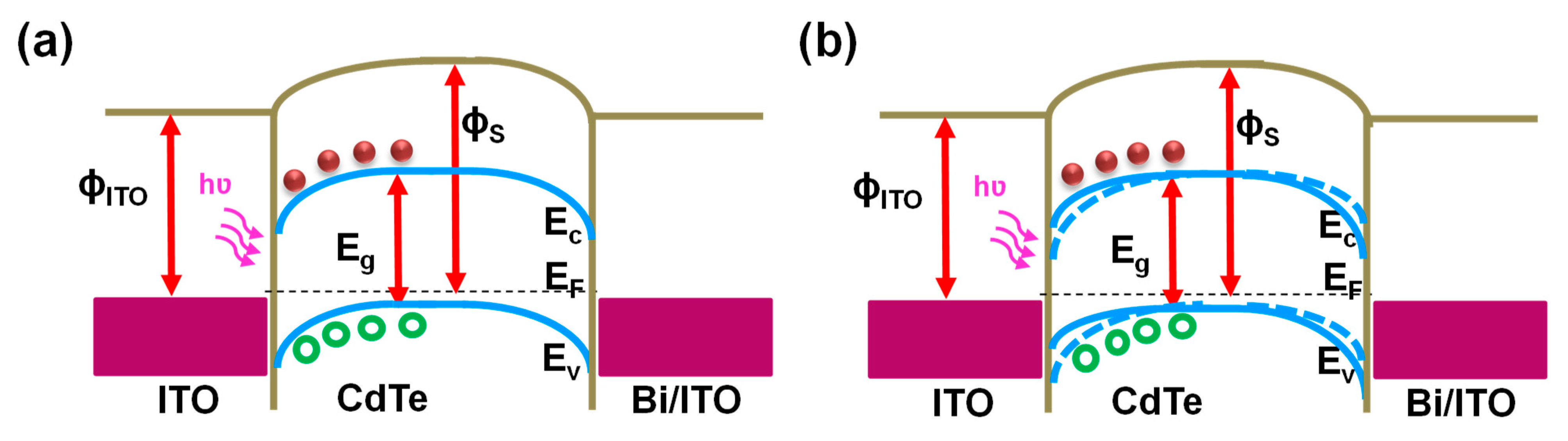

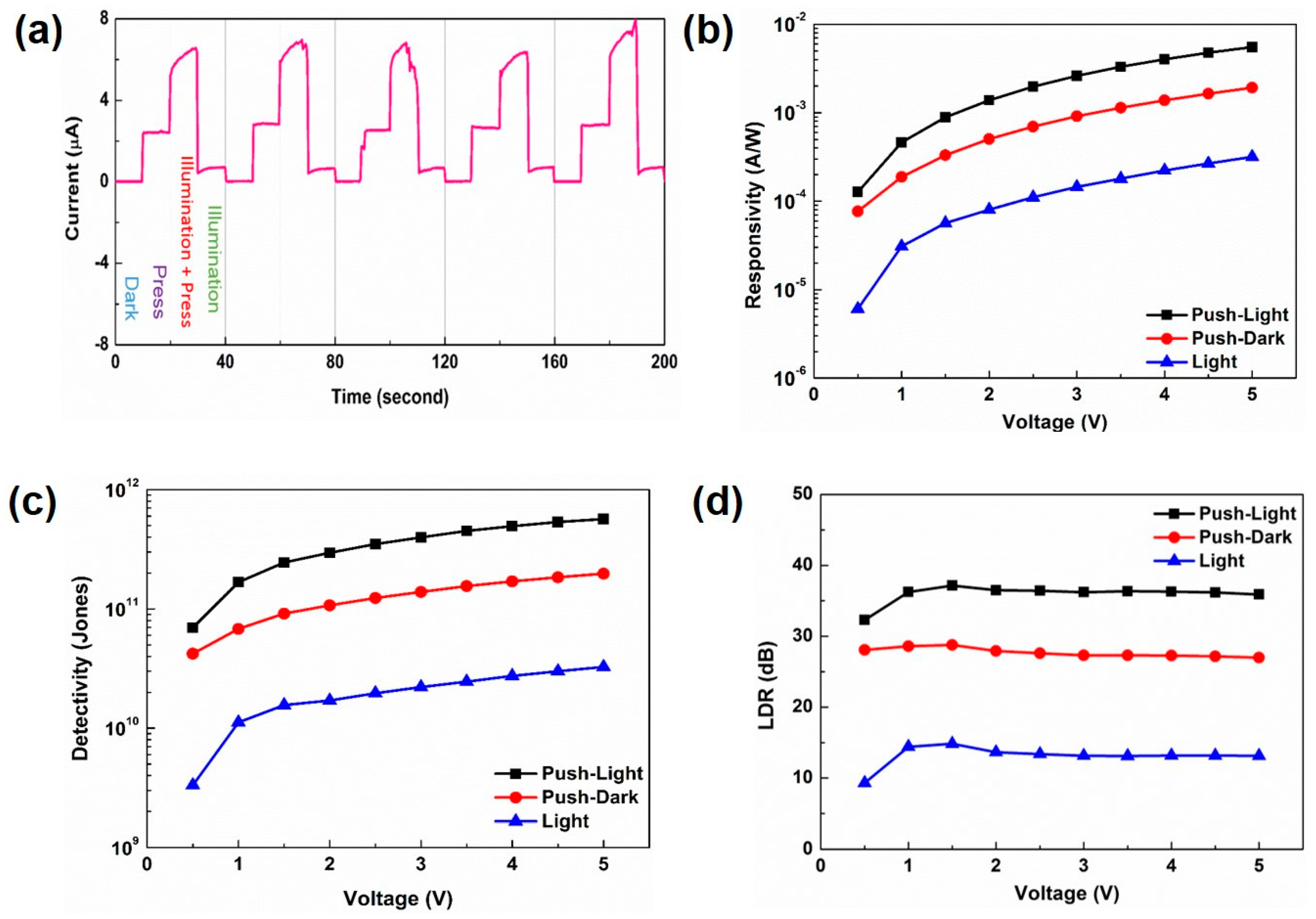

3. Results and Discussion

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Conflicts of Interest

References

- Law, M.; Greene, L.E.; Johnson, J.C.; Saykally, R.; Yang, P. Nanowire dye-sensitized solar cells. Nat. Mater. 2005, 4, 455–459. [Google Scholar] [CrossRef] [PubMed]

- Duan, X.F.; Huang, Y.; Agarwal, R.; Lieber, C.M. Single-nanowire electrically driven lasers. Nature 2003, 421, 241–245. [Google Scholar] [CrossRef] [PubMed]

- Yang, Q.; Guo, X.; Wang, W.; Zhang, Y.; Xu, S.; Lien, D.H.; Wang, Z.L. Enhancing sensitivity of a single ZnO micro-/nanowire photodetector by piezo-phototronic effect. ACS Nano 2010, 4, 6285–6291. [Google Scholar] [CrossRef] [PubMed]

- Williams, B.L.; Halliday, D.P.; Mendis, B.G.; Durose, K. Microstructure and point defects in CdTe nanowires for photovoltaic applications. Nanotechnology 2013, 24, 135703. [Google Scholar] [CrossRef] [PubMed][Green Version]

- Kranz, L.; Gretener, C.; Perrenoud, J.; Schmitt, R.; Pianezzi, F.; La Mattina, F.; Blösch, P.; Cheah, E.; Chirilă, A.; Fella, C.M.; et al. Doping of polycrystalline CdTe for high-efficiency solar cells on flexible metal foil. Nat. Commun. 2013, 4, 2306. [Google Scholar] [CrossRef] [PubMed]

- Shaygan, M.; Davami, K.; Kheirabi, N.; Baek, C.K.; Cuniberti, G.; Meyyappan, M.; Lee, J.-S. Single-crystalline CdTe nanowire field effect transistors as nanowire-based photodetector. Phys. Chem. Chem. Phys. 2014, 16, 22687–22693. [Google Scholar] [CrossRef]

- Yang, G.; Kim, D.; Kim, J. Self-aligned growth of CdTe photodetectors using a graphene seed layer. Opt. Express 2015, 23, A1081–A1086. [Google Scholar] [CrossRef]

- Xie, X.; Kwok, S.-Y.; Lu, Z.; Liu, Y.; Cao, Y.; Luo, L.; Zapien, J.A.; Bello, I.; Lee, C.-S.; Lee, S.-T.; et al. Visible-NIR photodetectors based on CdTe nanoribbons. Nanoscale 2012, 4, 2914–2919. [Google Scholar] [CrossRef]

- Eisen, Y.; Shor, A. CdTe and CdZnTe materials for room-temperature X-ray and gamma ray detectors. J. Cryst. Growth 1998, 184, 1302–1312. [Google Scholar] [CrossRef]

- Huang, M.H.; Mao, S.; Feick, H.; Yan, H.Q.; Wu, Y.Y.; Kind, H.; Weber, E.; Russo., R.; Yang, P.D. Room-Temperature Ultraviolet Nanowire Nanolasers. Science 2001, 292, 1897–1899. [Google Scholar] [CrossRef]

- Olson, J.D.; Rodriguez, Y.W.; Yang, L.D.; Alers, G.B.; Carter, S.A. CdTe Schottky diodes from colloidal nanocrystals. Appl. Phys. Lett. 2010, 96, 242103. [Google Scholar] [CrossRef]

- Baines, T.; Papageorgiou, G.; Hutter, O.S.; Bowen, L.; Durose, K.; Major, J.D. Self-Catalyzed CdTe Wires. Nanomaterials 2018, 8, 274. [Google Scholar] [CrossRef] [PubMed]

- Wang, X.N.; Wang, J.; Zhou, M.J.; Wang, H.; Xiao, X.D.; Li, Q. CdTe nanorods formation via nanoparticle self-assembly by thermal chemistry method. J. Cryst. Growth 2010, 312, 2310–2314. [Google Scholar] [CrossRef]

- Wang, X.; Xu, Y.; Zhu, H.; Liu, R.; Wang, H.; Li, Q. Crystalline Te nanotube and Te nanorods-on-CdTe nanotube arrays on ITO via a ZnO nanorod templating-reaction. CrystEngComm 2011, 13, 2955–2959. [Google Scholar] [CrossRef]

- Kret, S.; Szuszkiewicz, W.; Dynowska, E.; Domagala, J.; Aleszkiewicz, M.; Baczewski, L.T.; Petroutchik, A. MBE Growth and Properties of ZnTe- and CdTe-Based Nanowires. J. Korean Phys. Soc. 2008, 53, 3055–3063. [Google Scholar]

- Lee, S.K.C.; Yu, Y.; Perez, O.; Puscas, S.; Kosel, T.H.; Kuno, M. Bismuth-assisted CdSe and CdTe nanowire growth on plastics. Chem. Mater. 2010, 22, 77–84. [Google Scholar] [CrossRef]

- Consonni, V.; Rey, G.; Bonaim, J.; Karst, N.; Doisneau, B.; Roussel, H.; Renet, S.; Bellet, D. Synthesis and physical properties of ZnO/CdTe core shell nanowires grown by low-cost deposition methods. Appl. Phys. Lett. 2011, 98, 96–99. [Google Scholar] [CrossRef]

- Salim, H.I.; Patel, V.; Abbas, A.; Walls, J.M.; Dharmadasa, I.M. Electrodeposition of CdTe thin films using nitrate precursor for applications in solar cells. J. Mater. Sci. Mater. Electron. 2015, 26, 3119–3128. [Google Scholar] [CrossRef]

- Yang, G.; Jung, Y.; Chun, S.; Kim, D.; Kim, J. Catalytic growth of CdTe nanowires by closed space sublimation method. Thin Solid Films 2013, 546, 375–378. [Google Scholar] [CrossRef]

- Kulkarni, R.; Rondiya, S.; Pawbake, A.; Waykar, R.; Jadhavar, A.; Jadkar, V.; Bhorde, A.; Date, A.; Pathan, H.; Jadkar, S. Structural and optical properties of CdTe thin films deposited using RF magnetron sputtering. Energy Procedia 2017, 110, 188–195. [Google Scholar] [CrossRef]

- Mahabaduge, H.P.; Rance, W.L.; Burst, J.M.; Reese, M.O.; Meysing, D.M.; Wolden, C.A.; Li, J.; Beach, J.D.; Gessert, T.A.; Metzger, W.K.; et al. High-efficiency, flexible CdTe solar cells on ultra-thin glass substrates. Appl. Phys. Lett. 2015, 106, 133501. [Google Scholar] [CrossRef]

- Xie, C.; Luo, L.-B.; Zeng, L.-H.; Zhu, L.; Chen, J.-J.; Nie, B.; Hu, J.-G.; Li, Q.; Wu, C.-Y.; Wang, L.; et al. p-CdTe nanoribbon/n-silicon nanowires array heterojunctions: Photovoltaic devices and zero-power photodetectors. CrystEngComm 2012, 14, 7222–7228. [Google Scholar] [CrossRef]

- Yang, G.; Kim, B.-J.; Kim, D.; Kim, J. Single CdTe microwire photodetectors grown by close-spaced sublimation method. Opt. Express 2014, 22, 18843–18848. [Google Scholar] [CrossRef] [PubMed]

- Boxberg, F.; Søndergaard, N.; Xu, H.Q. Elastic and Piezoelectric properties of Zinc blende and Wurtzite crystalline nanowire heterostructures. Adv. Mater. 2012, 24, 4692–4706. [Google Scholar] [CrossRef] [PubMed]

- Cibert, J.; Andre, R.; Dang, L.S. Piezoelectric effect in strained CdTe-based heterostructures. Acta Phys. Pol. A 1995, 88, 591–600. [Google Scholar] [CrossRef]

- Xin, J.; Zheng, Y.; Shi, E. Piezoelectricity of zinc-blende and wurtzite structure binary compounds. Appl. Phys. Lett. 2007, 91, 112902. [Google Scholar]

- Corso, A.D.; Resta., R.; Baroni, S. Nonlinear piezoelectricity in CdTe. Phys. Rev. B 1993, 47, 16252–16256. [Google Scholar] [CrossRef]

- Hou, T.-C.; Yang, Y.; Lin, Z.-H.; Ding, Y.; Park, C.; Pradel, K.C.; Chen, L.-J.; Wang, Z.L. Nanogenerator based on zinc blende CdTe micro/nanowires. Nano Energy 2013, 2, 387–393. [Google Scholar] [CrossRef]

- Matsune, K.; Oda, H.; Toyoma, T.; Okamoto, H.; Kudriavysevend, Y.; Asomoza, R. 15% efficiency CdS/CdTe thin film solar cells using CdS layers doped with metal organic compounds. Sol. Energy Mater. Sol. Cells 2006, 90, 3108–3114. [Google Scholar] [CrossRef]

- Ilanchezhiyan, P.; Mohan Kumar, G.; Xiao, F.; Siva, C.; Yuldasheva, S.U.; Lee, D.J.; Jeon, H.C.; Kang, T.W. Surface induced charge transfer in CuxIn2-xS3 nanostructures and their enhanced photoelectronic and photocatalytic performance. Sol. Energy Mater. Sol. Cells 2019, 191, 100–107. [Google Scholar] [CrossRef]

- Ilanchezhiyan, P.; Mohan, K.G.; Xiao, F.; Poongothai, S.; Madhan, K.A.; Siva, C.; Yuldashev, S.U.; Lee, D.J.; Kwon, Y.H.; Kang, T.W. Ultrasonic-assisted synthesis of ZnTe nanostructures and their structural, electrochemical and photoelectrical properties. Ultrason. Sonochem. 2017, 39, 414–419. [Google Scholar] [PubMed]

- Xi, L.; Chua, K.H.; Zhao, Y.; Zhang, J.; Xiong, Q.; Lam, Y.M. Controlled synthesis of CdE (E = S, Se and Te) nanowires. RSC Adv. 2012, 2, 5243–5253. [Google Scholar] [CrossRef]

- Nayak, T.R.; Wang, H.; Pant, A.; Zheng, M.; Junginger, H.; Goh, W.J.; Lee, C.K.; Zou, S.; Alonso, S.; Czarny, B.; et al. ZnO Nano-Rod Devices for Intradermal Delivery and Immunization. Nanomaterials 2017, 7, 147. [Google Scholar]

- Cheng, H.; Li, J.; Wu, D.; Li, Y.; Wang, Z.; Wang, X.; Zheng, X. Effects of Precursor-Substrate Distances on the Growth of GaN Nanowires. J. Nanomater. 2015, 2015, 343541. [Google Scholar] [CrossRef]

- Bartolomeo, A.D.; Grillo, A.; Urban, F.; Iemmo, L.; Giubileo, F.; Luongo, G.; Amato, G.; Croin, L.; Sun, L.; Liang, S.-J.; et al. Asymmetric schottky contacts in bilayer MoS2 field effect transistors. Adv. Funct. Mater. 2018, 28, 1800657. [Google Scholar] [CrossRef]

- Yang, R.; Qin, Y.; Dai, L.; Wang, Z.L. Power generation with laterally packaged piezoelectric fine wires. Nat. Nanotechnol. 2009, 4, 34–39. [Google Scholar] [CrossRef] [PubMed]

- Jeong, S.; Kim, M.W.; Jo, Y.-R.; Kim, T.-Y.; Leem, Y.-C.; Kim, S.-W.; Kim, B.-J.; Park, S.-J. Crystal-structure-dependent piezotronic and piezo-phototronic effects of ZnO/ZnS core/shell nanowires for enhanced electrical transport and photosensing performance. ACS Appl. Mater. Interfaces 2018, 10, 28736–28744. [Google Scholar] [CrossRef] [PubMed]

- Zhang, X.; Qiu, Y.; Yang, D.; Li, B.; Zhang, H.; Hu, L. Enhancing performance of Ag–ZnO–Ag UV photodetector by piezo-phototronic effect. RSC Adv. 2018, 8, 15290–15296. [Google Scholar] [CrossRef]

- Lu, S.; Qi, J.; Liu, S.; Zhang, Z.; Wang, Z.; Lin, P.; Liao, Q.; Liang, Q.; Zhang, Y. Piezotronic interface engineering on ZnO/Au-based schottky junction for enhanced photoresponse of a flexible self-powered uv detector. ACS Appl. Mater. Interfaces 2014, 6, 14116–14122. [Google Scholar] [CrossRef]

- Wang, Z.; Yu, R.; Pan, C.; Liu, Y.; Ding, Y.; Wang, Z.L. Piezo-phototronic uv/visible photosensing with optical-fiber-nanowire hybridized structures. Adv. Mater. 2015, 27, 1553–1560. [Google Scholar] [CrossRef] [PubMed]

- Oh, S.; Kim, C.-K.; Kim, J. High responsivity β-Ga2O3 metal−semiconductor−metal solar-blind photodetectors with ultraviolet transparent graphene electrodes. ACS Photonics 2018, 5, 1123–1128. [Google Scholar] [CrossRef]

- Kong, W.Y.; Wu, G.A.; Wang, K.Y.; Zhang, T.F.; Zou, Y.F.; Wang, D.D.; Luo, L.B. Graphene-β-Ga2O3 heterojunction for highly sensitive deep UV photodetector application. Adv. Mater 2016, 28, 10725–10731. [Google Scholar] [CrossRef] [PubMed]

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lee, D.J.; Mohan Kumar, G.; Ilanchezhiyan, P.; Xiao, F.; Yuldashev, S.U.; Woo, Y.D.; Kim, D.Y.; Kang, T.W. Arrayed CdTeMicrodots and Their Enhanced Photodetectivity via Piezo-Phototronic Effect. Nanomaterials 2019, 9, 178. https://doi.org/10.3390/nano9020178

Lee DJ, Mohan Kumar G, Ilanchezhiyan P, Xiao F, Yuldashev SU, Woo YD, Kim DY, Kang TW. Arrayed CdTeMicrodots and Their Enhanced Photodetectivity via Piezo-Phototronic Effect. Nanomaterials. 2019; 9(2):178. https://doi.org/10.3390/nano9020178

Chicago/Turabian StyleLee, Dong Jin, G. Mohan Kumar, P. Ilanchezhiyan, Fu Xiao, Sh.U. Yuldashev, Yong Deuk Woo, Deuk Young Kim, and Tae Won Kang. 2019. "Arrayed CdTeMicrodots and Their Enhanced Photodetectivity via Piezo-Phototronic Effect" Nanomaterials 9, no. 2: 178. https://doi.org/10.3390/nano9020178

APA StyleLee, D. J., Mohan Kumar, G., Ilanchezhiyan, P., Xiao, F., Yuldashev, S. U., Woo, Y. D., Kim, D. Y., & Kang, T. W. (2019). Arrayed CdTeMicrodots and Their Enhanced Photodetectivity via Piezo-Phototronic Effect. Nanomaterials, 9(2), 178. https://doi.org/10.3390/nano9020178