Fabrication of Antireflective Nanostructures on a Transmission Grating Surface Using a One-Step Self-Masking Method

Abstract

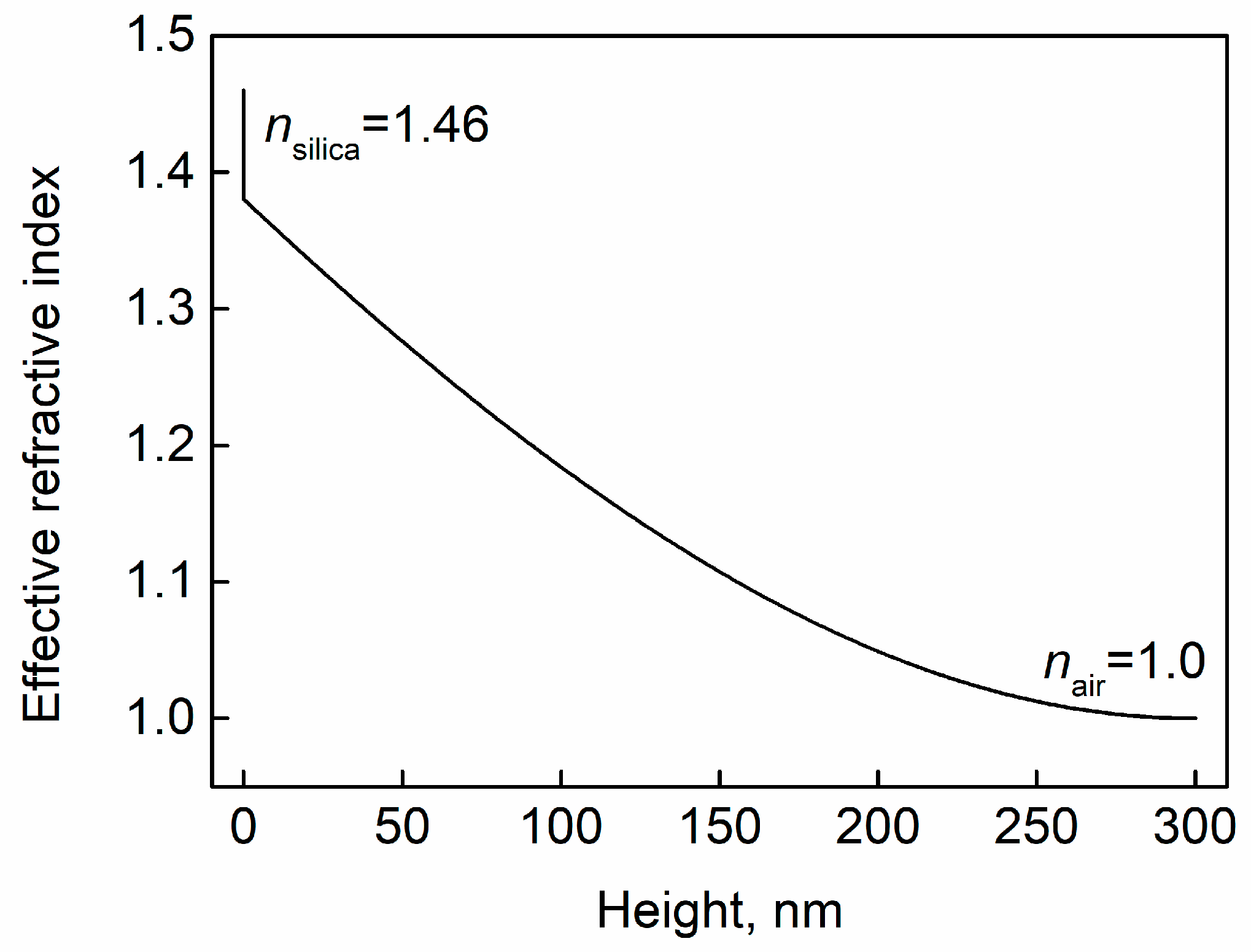

:1. Introduction

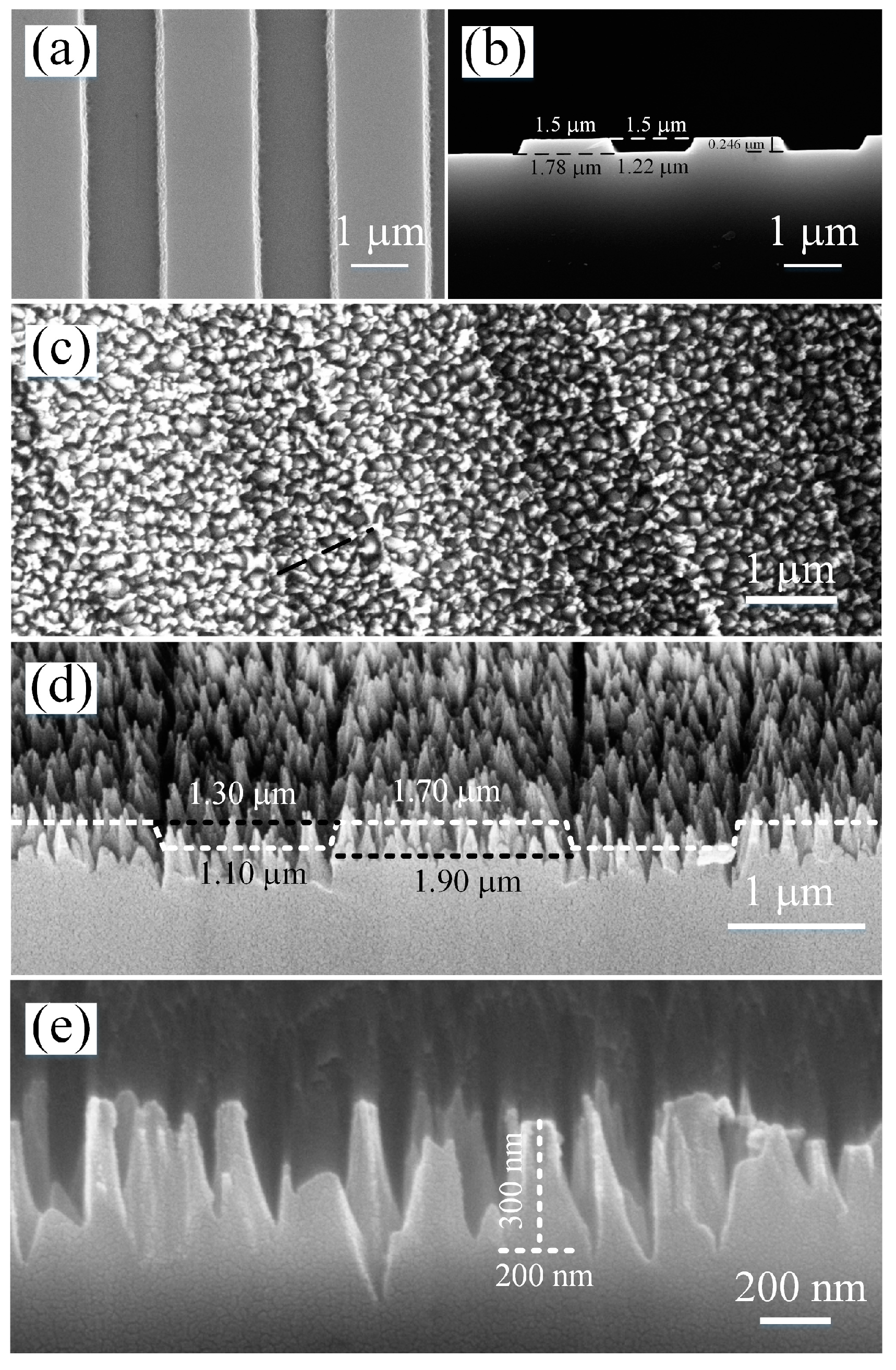

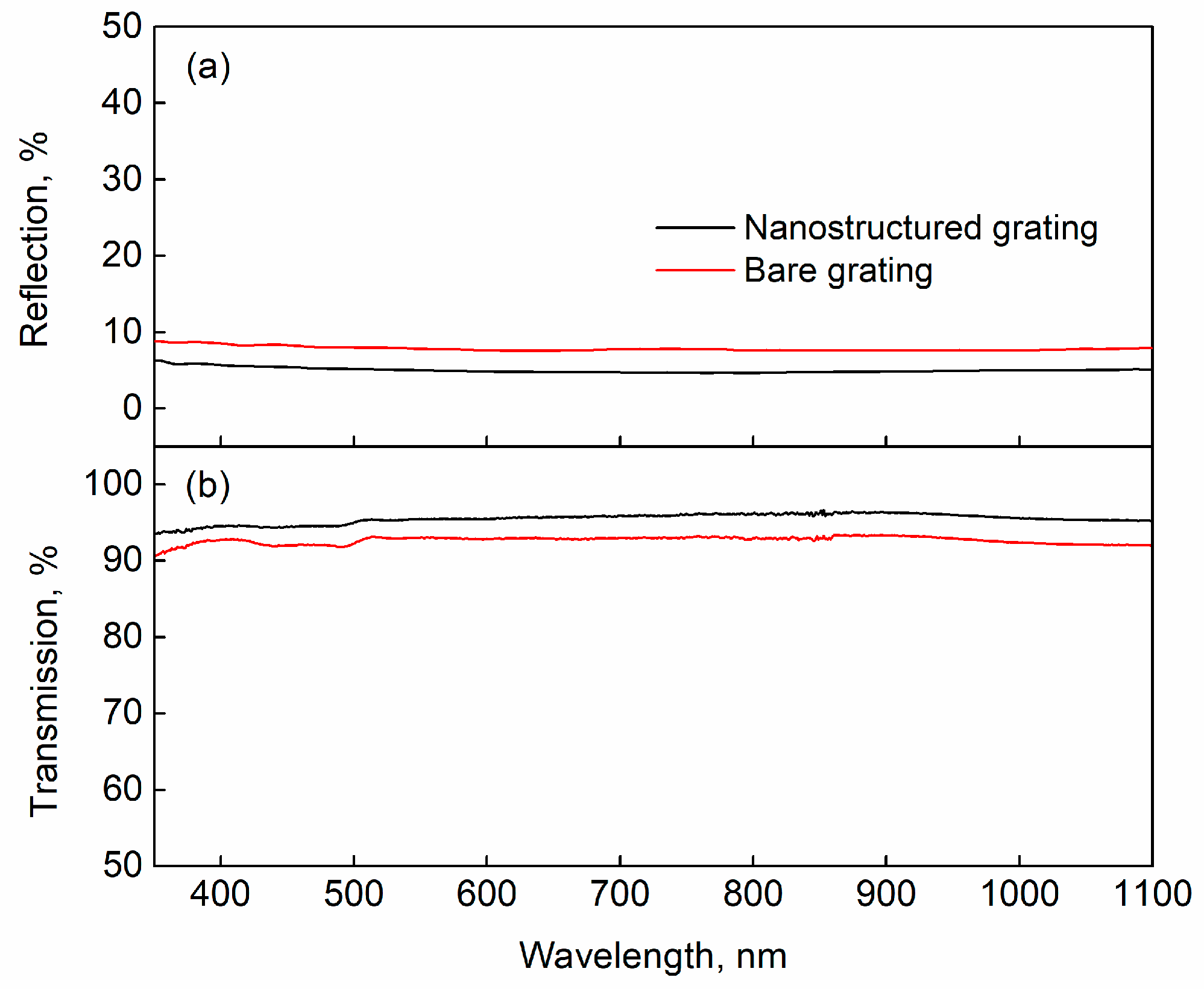

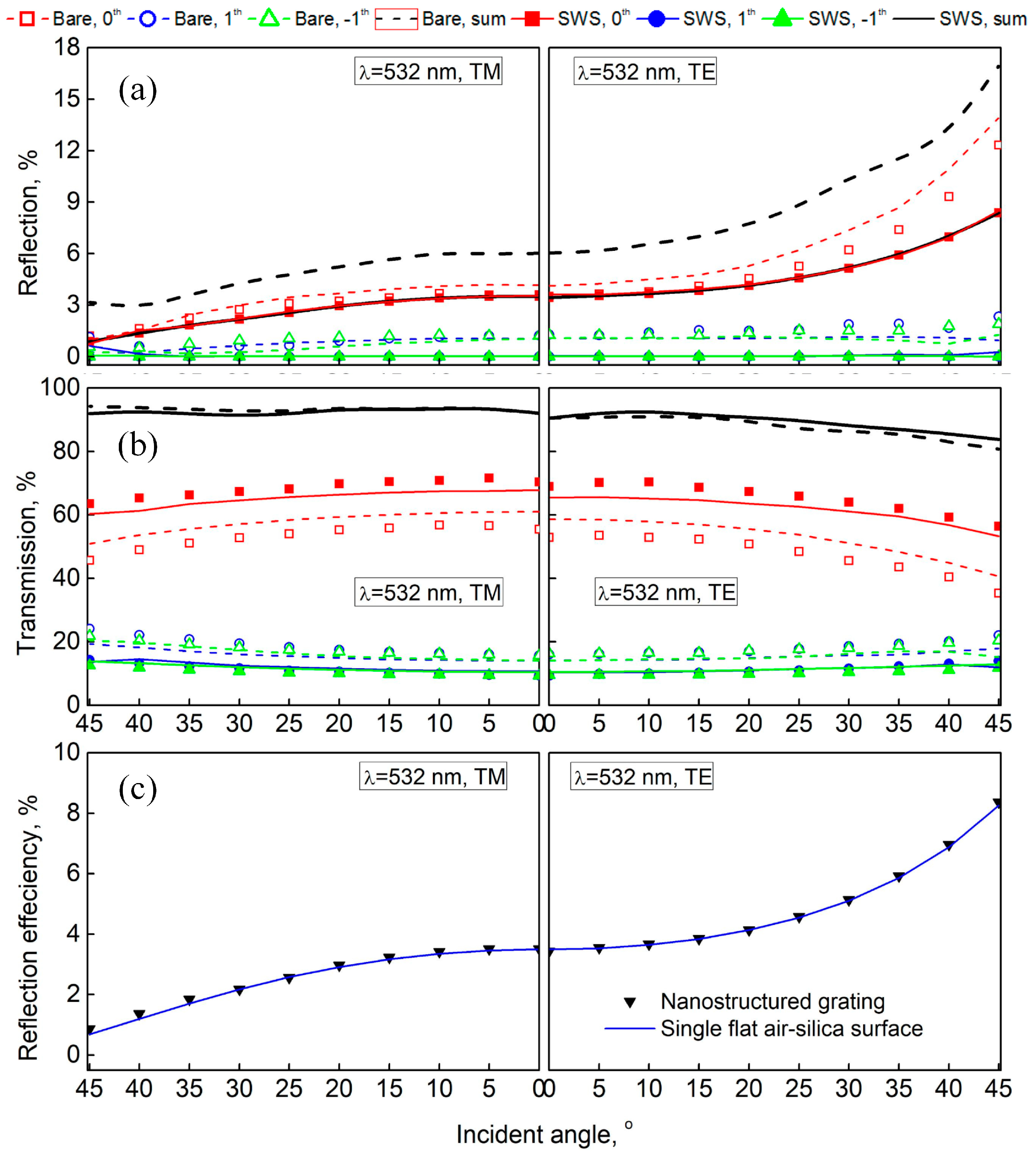

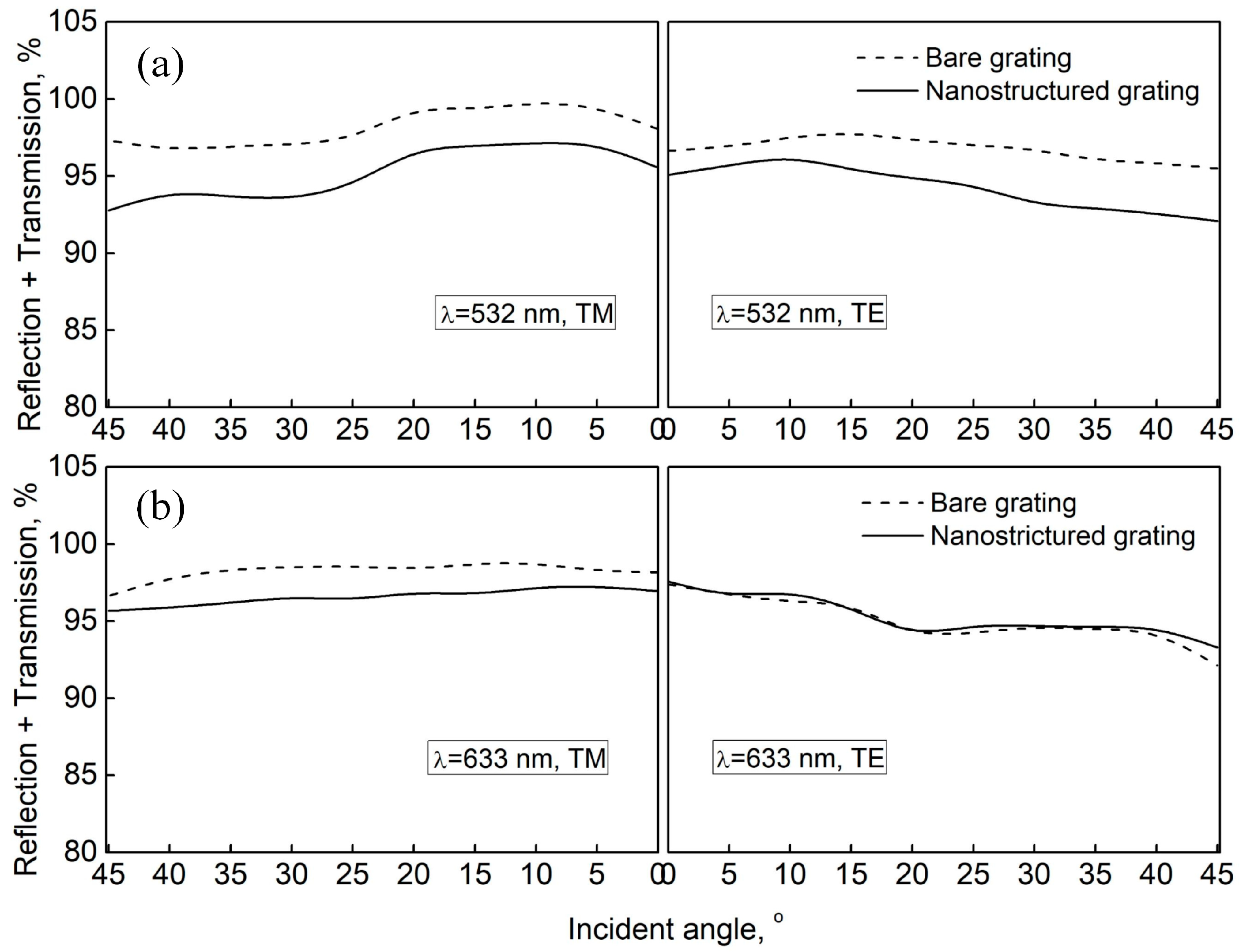

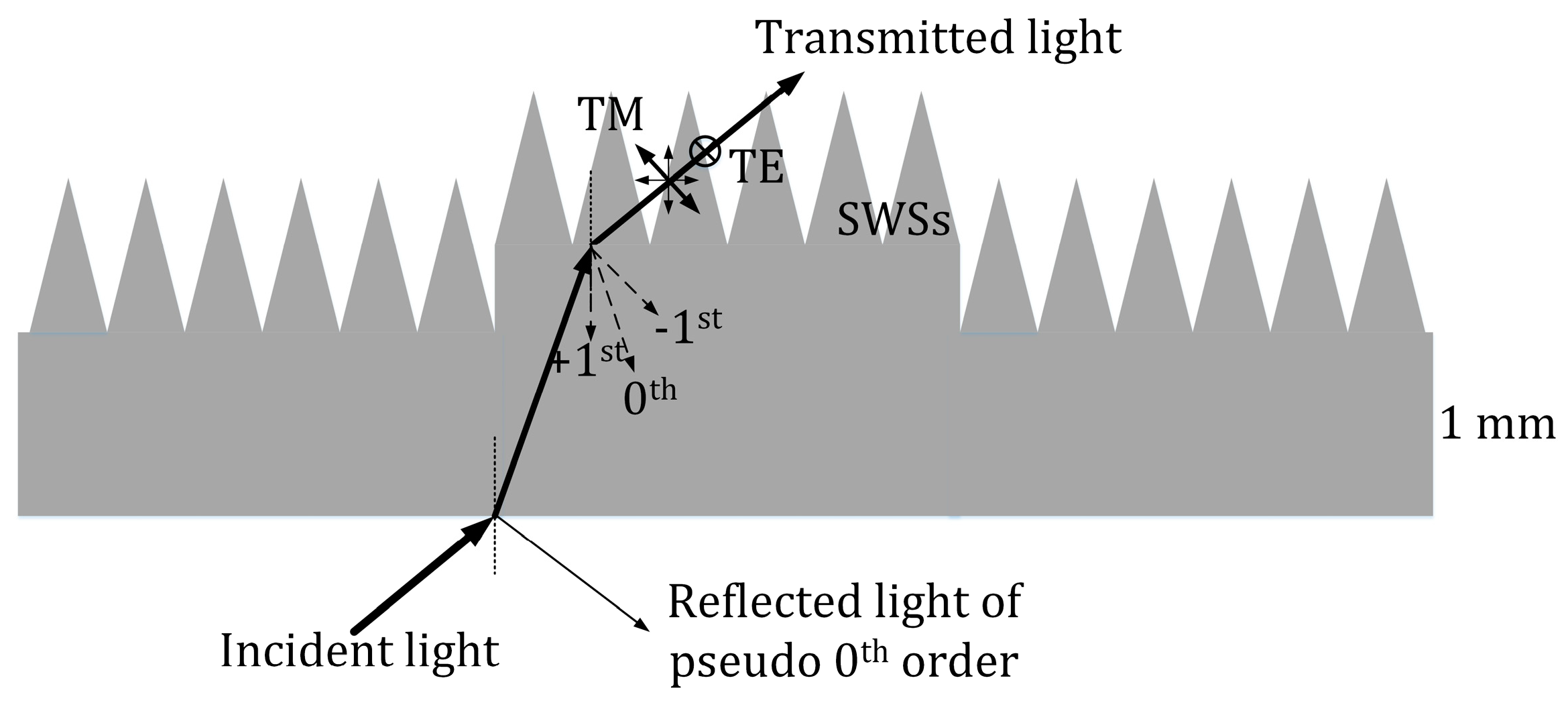

2. Results and Discussion

3. Conclusions

Supplementary Materials

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Appendix A

References

- Martin, D.C.; Schiminovich, D.; Hamden, E.T.; Greer, F.; Blacksberg, J.; Dickie, M.R.; Hoenk, M.E.; Nikzad, S. Ultraviolet antireflection coatings for use in silicon detector design. Appl. Opt. 2011, 50, 4180–4188. [Google Scholar]

- Zang, Z.; Mukai, K.; Navaretti, P.; Duelk, M. Thermal resistance reduction in high power superluminescent diodes by using active multi-mode interferometer. Appl. Phys. Lett. 2012, 100, 031108. [Google Scholar] [CrossRef]

- Leem, J.W.; Kim, S.; Lee, S.H.; Rogers, J.A.; Kim, E.; Yu, J.S. Efficiency Enhancement of Organic Solar Cells Using Hydrophobic Antireflective Inverted Moth-Eye Nanopatterned PDMS Films. Adv. Energy Mater. 2014, 4, 1301315. [Google Scholar] [CrossRef]

- Nole, J.P. Nanotextured optical surfaces advance laser power and reliability. Laser Focus World 2014, 50, 38–43. [Google Scholar]

- De Nicola, S.; Ferraro, P.; Finizio, A.; Pesce, G.; Pierattini, G. Reflective grating interferometer for measuring the refractive index of transparent materials. Opt. Commun. 1995, 118, 491–494. [Google Scholar] [CrossRef]

- Merola, F.; Mandracchia, B.; Miccio, L.; Memmolo, P.; Bianco, V.; Mugnano, M.; Maffettone, P.L.; Villone, M.; Di Maio, E.; Ferraro, V.; et al. Recent advancements and perspective about digital holography: A super-tool in biomedical and bioengineering fields. In Advancement of Optical Methods & Digital Image Correlation in Experimental Mechanics; Springer: New York, NY, USA, 2019; Volume 3, pp. 235–241. [Google Scholar]

- Paturzo, M.; Merola, F.; Grilli, S.; De Nicola, S.; Finizio, A.; Ferraro, P. Super-resolution in digital holography by a two-dimensional dynamic phase grating. Opt. Express 2008, 16, 17107–17118. [Google Scholar] [CrossRef]

- Bianco, V.; Mandracchia, B.; Marchesano, V.; Pagliarulo, V.; Olivieri, F.; Coppola, S.; Paturzo, M.; Ferraro, P. Endowing a plain fluidic chip with micro-optics: A holographic microscope slide. Light Sci. Appl. 2017, 6, e17055. [Google Scholar] [CrossRef]

- Pawlowski, E. Antireflection-coated diffractive optical elements fabricated by thin-film deposition. Opt. Eng. 1994, 33, 3537–3546. [Google Scholar] [CrossRef]

- Chattopadhyay, S.; Huang, Y.F.; Jen, Y.J.; Ganguly, A.; Chen, K.H.; Chen, L.C. Anti-reflecting and photonic nanostructures. Mater. Sci. Eng. R 2010, 69, 1–35. [Google Scholar] [CrossRef]

- Shimomura, H.; Gemici, Z.; Cohen, R.E.; Rubner, M.F. Layer-by-layer-assembled high-performance broadband antireflection coatings. ACS Appl. Mater. Interfaces 2010, 2, 813–820. [Google Scholar] [CrossRef]

- Yang, T.; Wang, X.; Liu, W.; Shi, Y.; Yang, F. Double-layer anti-reflection coating containing a nanoporous anodic aluminum oxide layer for GaAs solar cells. Opt. Express 2013, 21, 18207–18215. [Google Scholar] [CrossRef] [PubMed]

- Tian, L.; Li, L.; Ban, C.; Wu, M. Fabrication and characterization of TiO2 antireflection coatings with gradient-index. In Proceedings of the IEEE International Conference on Nano/micro Engineered and Molecular Systems, Los Angeles, CA, USA, 9–12 April 2017; pp. 131–136. [Google Scholar]

- Hobbs, D.S.; Macleod, B.D.; Riccobono, J.R. Update on the development of high performance anti-reflecting surface relief micro-structures. In Proceedings of the Window Dome Technologies and Materials X, Orlando, FL, USA, 2 May 2007; p. 65450Y-14. [Google Scholar]

- Ye, X.; Jiang, X.D.; Huang, J.; Sun, L.X.; Geng, F.; Yi, Z.; Zu, X.T.; Wu, W.D.; Zheng, W.G. Subwavelength structures for high power laser antireflection application on fused silica by one-step reactive ion etching. Opt. Lasers Eng. 2016, 78, 48–54. [Google Scholar] [CrossRef]

- Ye, X.; Shao, T.; Sun, L.; Wu, J.; Wang, F.; He, J.; Jiang, X.; Wu, W.; Zheng, W. One-step approach to an ultrabroadband antireflective and superhydrophilic subwavelength nanostructured fused silica surface. ACS Appl. Mater. Interfaces 2018, 10, 13851–13859. [Google Scholar] [CrossRef] [PubMed]

- Pawlowski, E.; Engel, H.; Ferstl, M.; Fuerst, W.; Kuhlow, B. Diffractive microlenses with antireflection coatings fabricated by thin film deposition. Opt. Eng. 1994, 33, 647–652. [Google Scholar] [CrossRef]

- Elfström, H.; Vallius, T.; Kuittinen, M.; Turunen, J.; Clausnitzer, T.; Kley, E.-B. Diffractive elements with novel antireflection film stacks. Opt. Express 2004, 12, 6385–6390. [Google Scholar] [CrossRef] [PubMed]

- Chang, C.H.; Barbastathis, G.; Waller, L. Design and optimization of broadband wide-angle antireflection structures for binary diffractive optics. Opt. Lett. 2010, 35, 907–909. [Google Scholar] [CrossRef]

- Nagashima, K.; Kosuge, A.; Ochi, Y.; Tanaka, M. Improvement of diffraction efficiency of dielectric transmission gratings using anti-reflection coatings. Opt. Express 2013, 21, 18640–18645. [Google Scholar] [CrossRef]

- Mao, S.; Cui, Q.; Piao, M. Optimal design method on diffractive optical elements with antireflection coatings. Opt. Express 2017, 25, 11673. [Google Scholar] [CrossRef]

- Mao, S.; Cui, Q. Optimal design method for multi-layer diffractive optical elements with consideration of antireflection coatings. J. Mod. Opt. 2018, 65, 1554–1558. [Google Scholar] [CrossRef]

- Thomas, A.I.M.; Burnham, A.K.; Ertel, J.R.; Frieders, S.C. Method for reducing the effect of environmental contamination of sol-gel optical coatings. In Proceedings of the SPIE-The International Society for Optical Engineering, San Jose, CA, USA, 24–25 January 1998; Volume 3492, pp. 220–229. [Google Scholar]

- Xi, J.Q.; Schubert, M.F.; Kim, J.K.; Schubert, E.F.; Chen, M.; Lin, S.Y.; Liu, W.; Smart, J.A. Optical thin-film materials with low refractive index for broadband elimination of Fresnel reflection. Nat. Photonics 2007, 1, 176–179. [Google Scholar] [CrossRef]

- Schulze, M.; Lehr, D.; Helgert, M.; Kley, E.B.; Tünnermann, A. Transmission enhanced optical lenses with self-organized antireflective subwavelength structures for the UV range. Opt. Lett. 2011, 36, 3924–3926. [Google Scholar] [CrossRef] [PubMed]

- Taylor, C.D.; Busse, L.E.; Frantz, J.; Sanghera, J.S.; Aggarwal, I.D.; Poutous, M.K. Angle-of-incidence performance of random anti-reflection structures on curved surfaces. Appl. Opt. 2016, 55, 2203. [Google Scholar] [CrossRef] [PubMed]

- Schulze, M.; Damm, M.; Helgert, M.; Kley, E.B.; Nolte, S.; Tünnermann, A. Durability of stochastic antireflective structures--analyses on damage thresholds and adsorbate elimination. Opt. Express 2012, 20, 18348–18355. [Google Scholar] [CrossRef] [PubMed]

- Song, Y.M.; Park, G.C.; Jang, S.J.; Ha, J.H.; Yu, J.S.; Lee, Y.T. Multifunctional light escaping architecture inspired by compound eye surface structures: From understanding to experimental demonstration. Opt. Express 2010, 19, A157–A165. [Google Scholar] [CrossRef] [PubMed]

- Leem, J.W.; Song, Y.M.; Yu, J.S. Biomimetic artificial Si compound eye surface structures with broadband and wide-angle antireflection properties for Si-based optoelectronic applications. Nanoscale 2013, 5, 10455–10460. [Google Scholar] [CrossRef] [PubMed]

- Dudem, B.; Leem, J.W.; Yu, J.S. A multifunctional hierarchial nano/micro-structured silicon surface with omnidirectional antireflection and superhydrophilicity via anodic aluminum oxide etch mask. RSC Adv. 2016, 6, 3764–3773. [Google Scholar] [CrossRef]

- Chang, C.H.; Dominguezcaballero, J.A.; Choi, H.J.; Barbastathis, G. Nanostructured gradient-index antireflection diffractive optics. Opt. Lett. 2011, 36, 2354–2356. [Google Scholar] [CrossRef]

- Kunala, K.; Poutous, M.K. Diffraction efficiency performance of random anti-reflecting subwavelength surface structures on prefabricated fused silica binary gratings. Appl. Opt. 2018, 57, 4421–4427. [Google Scholar] [CrossRef]

- Hobbs, D.S.; Macleod, B.D.; Sabatino, E.; Britten, J.A.; Stolz, C.J. Contamination resistant antireflection nano-textures in fused silica for laser optics. In Proceedings of the Laser-Induced Damage in Optical Materials, Boulder, CO, USA, 2 December 2013; p. 88850J. [Google Scholar]

- Chen, F.T.; Craighead, H.G. Diffractive phase elements based on two-dimensional artificial dielectrics. Opt. Lett. 1995, 20, 121–123. [Google Scholar] [CrossRef]

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shao, T.; Tang, F.; Sun, L.; Ye, X.; He, J.; Yang, L.; Zheng, W. Fabrication of Antireflective Nanostructures on a Transmission Grating Surface Using a One-Step Self-Masking Method. Nanomaterials 2019, 9, 180. https://doi.org/10.3390/nano9020180

Shao T, Tang F, Sun L, Ye X, He J, Yang L, Zheng W. Fabrication of Antireflective Nanostructures on a Transmission Grating Surface Using a One-Step Self-Masking Method. Nanomaterials. 2019; 9(2):180. https://doi.org/10.3390/nano9020180

Chicago/Turabian StyleShao, Ting, Feng Tang, Laixi Sun, Xin Ye, Junhui He, Liming Yang, and Wanguo Zheng. 2019. "Fabrication of Antireflective Nanostructures on a Transmission Grating Surface Using a One-Step Self-Masking Method" Nanomaterials 9, no. 2: 180. https://doi.org/10.3390/nano9020180

APA StyleShao, T., Tang, F., Sun, L., Ye, X., He, J., Yang, L., & Zheng, W. (2019). Fabrication of Antireflective Nanostructures on a Transmission Grating Surface Using a One-Step Self-Masking Method. Nanomaterials, 9(2), 180. https://doi.org/10.3390/nano9020180