Fabrication and Characterization of AlGaN-Based UV LEDs with a ITO/Ga2O3/Ag/Ga2O3 Transparent Conductive Electrode

Abstract

:1. Introduction

2. Materials and Methods

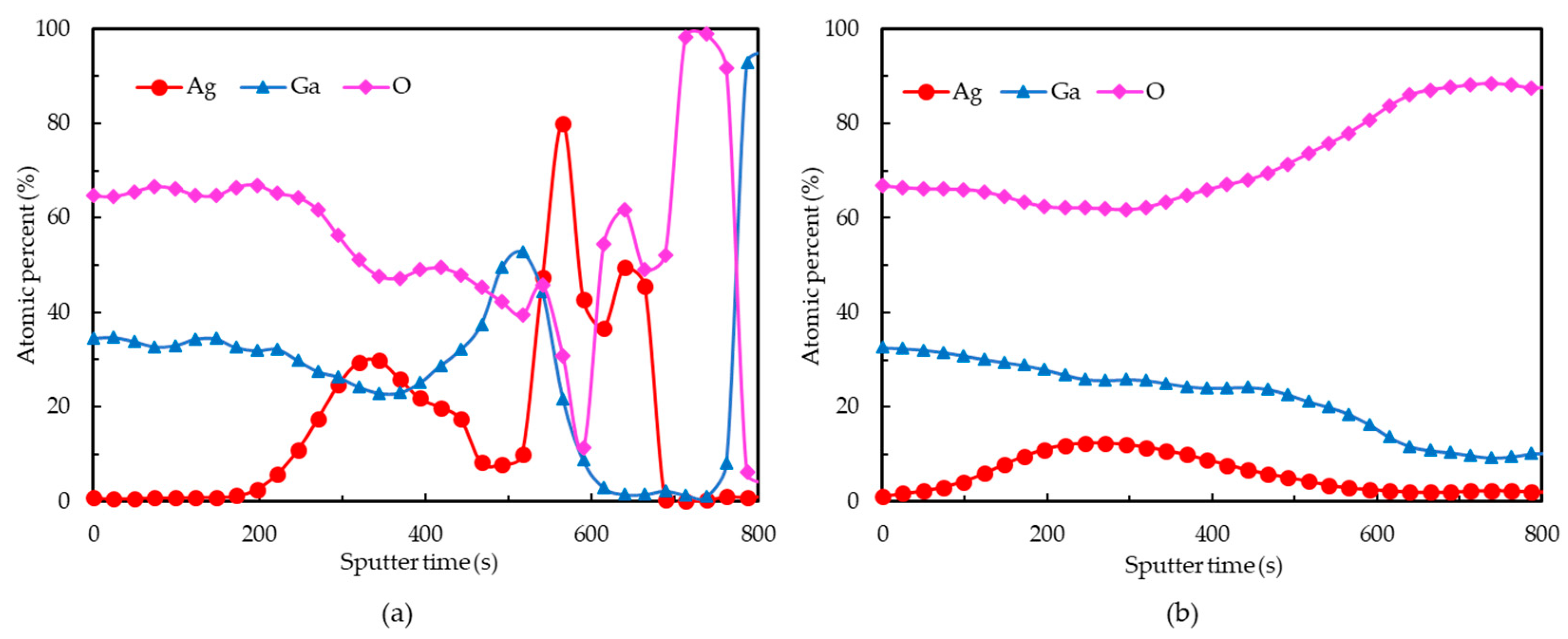

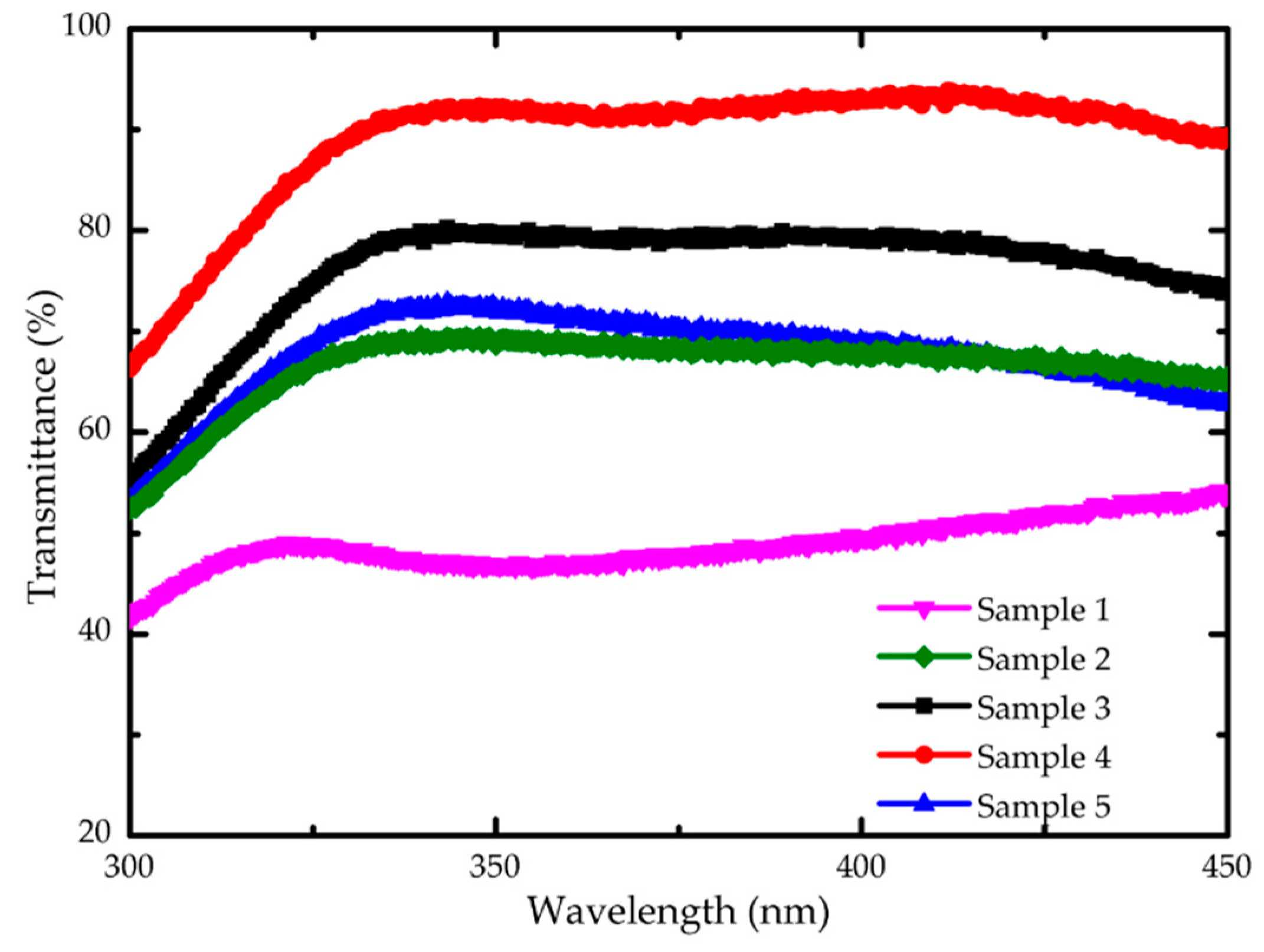

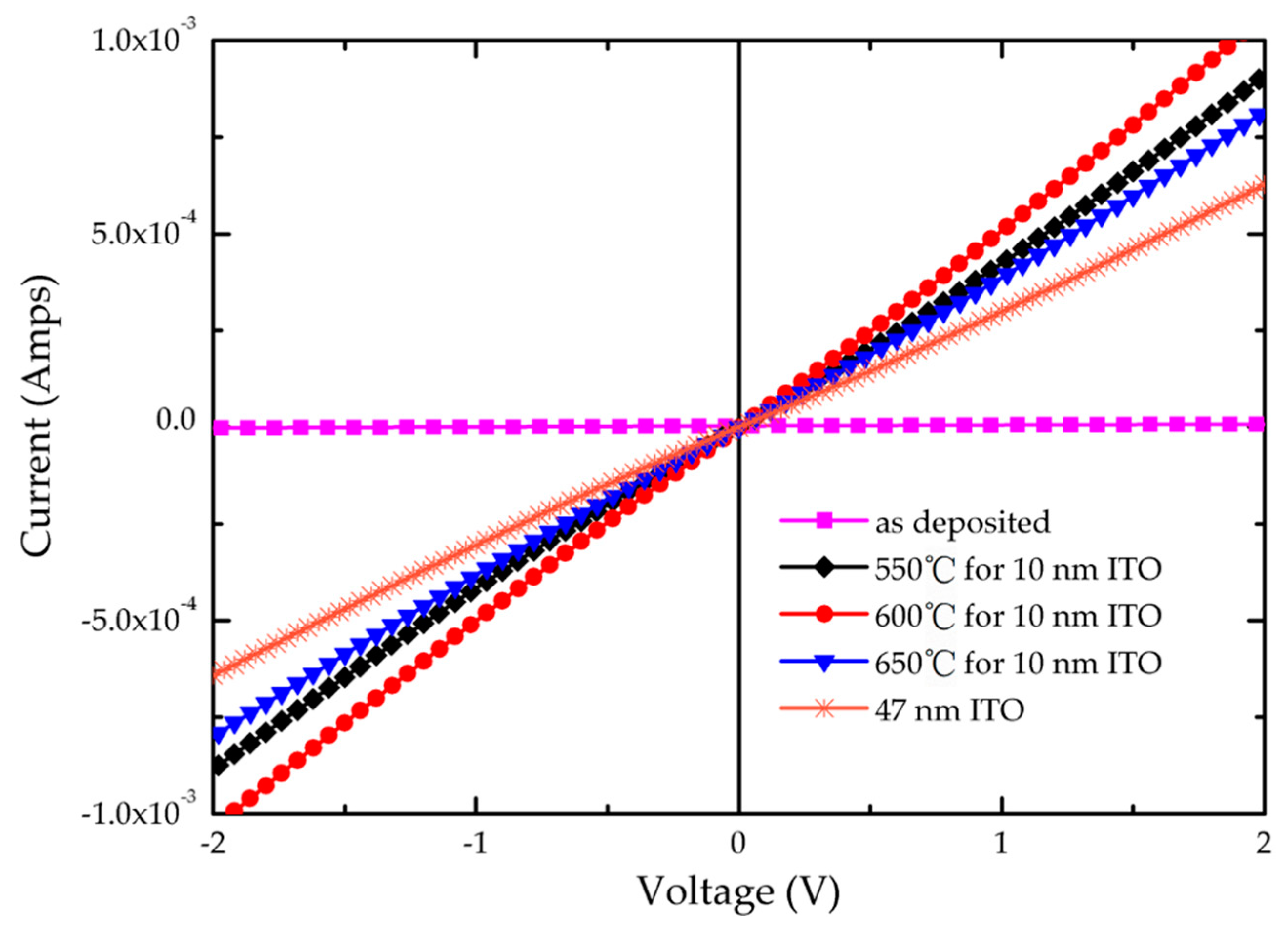

3. Results

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Maitland, J. UV curing of inks and coatings in digital printing applications. In Proceedings of the NIP & Digital Fabrication Conference, Baltimore, MD, USA, 18–23 September 2005. [Google Scholar]

- Yu, C.C.; Chuah, E.C.; Ng, Y.T.; Seah, Y.S.; Tan, P.P.; Chiu, T.H.; Hsieh, T.T. Neonatal status in cesarean section under epidural anesthesia with supplementary oxygen. Ma Zui Xue Za Zhi = Anaesthesiologica Sinica 1992, 30, 229. [Google Scholar] [PubMed]

- Hockberger, P.E. A history of ultraviolet photobiology for humans, animals and microorganisms. Photochem. Photobiol. 2010, 76, 561–579. [Google Scholar] [CrossRef]

- Schreiner, M.; Martínez-Abaigar, J.; Glaab, J.; Jansen, M. Uv-b induced secondary plant metabolites. Opt. Photonik 2014, 9, 34–37. [Google Scholar] [CrossRef]

- Lui, G.Y.; Roser, D.; Corkish, R.; Ashbolt, N.; Jagals, P.; Stuetz, R. Photovoltaic powered ultraviolet and visible light-emitting diodes for sustainable point-of-use disinfection of drinking waters. Sci. Total Environ. 2014, 493, 185–196. [Google Scholar] [CrossRef]

- Hodgkinson, J.; Tatam, R.P. Optical gas sensing: A review. Meas. Sci. Technol. 2013, 24, 012004. [Google Scholar] [CrossRef]

- Takano, T.; Mino, T.; Sakai, J.; Noguchi, N.; Tsubaki, K.; Hirayama, H. Deep-ultraviolet light-emitting diodes with external quantum efficiency higher than 20% at 275 nm achieved by improving light-extraction efficiency. Appl. Phys. Express 2017, 10, 031002. [Google Scholar] [CrossRef]

- Inoue, S.; Tamari, N.; Taniguchi, M. 150 mw deep-ultraviolet light-emitting diodes with large-area aln nanophotonic light-extraction structure emitting at 265 nm. Appl. Phys. Lett. 2017, 110, 141106. [Google Scholar] [CrossRef]

- Shatalov, M.; Sun, W.; Lunev, A.; Hu, X.; Dobrinsky, A.; Bilenko, Y.; Yang, J.; Shur, M.; Gaska, R.; Moe, C. Algan deep-ultraviolet light-emitting diodes with external quantum efficiency above 10%. Appl. Phys. Express 2012, 5, 2101. [Google Scholar] [CrossRef]

- Toyota, A.; Nakashima, N.; Sagara, T. Uv–visible transmission–absorption spectral study of au nanoparticles on a modified ito electrode at constant potentials and under potential modulation. J. Electroanal. Chem. 2004, 565, 335–342. [Google Scholar] [CrossRef]

- Lin, Y.H.; Liu, C.Y. Reflectivity and abnormal absorption at ito/al interface. J. Electron. Mater. 2009, 38, 108–112. [Google Scholar] [CrossRef]

- Lin, Y.H.; Liu, Y.S.; Liu, C.Y. Light output enhancement of near uv-led by using ti-doped ito transparent conducting layer. IEEE Photonics Technol. Lett. 2010, 22, 1443–1445. [Google Scholar] [CrossRef]

- Jae Hoon, L.; Kie Young, W.; Kyeong Heon, K.; Hee-Dong, K.; Tae Geun, K. Ito/ag/ito multilayer-based transparent conductive electrodes for ultraviolet light-emitting diodes. Opt. Lett. 2013, 38, 5055–5058. [Google Scholar]

- Kim, M.J.; Kim, T.G. Fabrication of metal-deposited indium tin oxides: Its applications to 385 nm light-emitting diodes. ACS Appl. Mater. Interfaces 2016, 8, 5453–5457. [Google Scholar] [CrossRef] [PubMed]

- Xu, J.; Zhang, W.; Peng, M.; Dai, J.; Chen, C. Light-extraction enhancement of gan-based 395 nm flip-chip light-emitting diodes by an al-doped ito transparent conductive electrode. Opt. Lett. 2018, 43, 2684–2687. [Google Scholar] [CrossRef] [PubMed]

- Orita, M.; Hiramatsu, H.; Ohta, H.; Hirano, M.; Hosono, H. Preparation of highly conductive, deep ultraviolet transparent β-ga 2 o 3 thin film at low deposition temperatures. Thin Solid Films 2002, 411, 134–139. [Google Scholar] [CrossRef]

- Liu, J.; Yan, J.; Shi, L.; Li, T. Semiconductor materials electrical and optical properties of deep ultraviolet transparent conductive Ga2O3/ito films by magnetron sputtering. J. Semicond. 2010, 31, 5–9. [Google Scholar]

- Passlack, M.; Schubert, E.F.; Hobson, W.S.; Hong, M.; Moriya, N.; Chu, S.N.G.; Konstadinidis, K.; Mannaerts, J.P.; Schnoes, M.L.; Zydzik, G.J. Ga2O3 films for electronic and optoelectronic applications. J. Appl. Phys. 1995, 77, 686–693. [Google Scholar] [CrossRef]

- Higashiwaki, M.; Sasaki, K.; Murakami, H.; Kumagai, Y.; Koukitu, A.; Kuramata, A.; Masui, T.; Yamakoshi, S. Recent progress in Ga2O3 power devices. Semicond. Sci. Technol. 2016, 31, 034001. [Google Scholar] [CrossRef]

- Kim, J.K.; Lee, J.M. Electrical and optical properties of near uv transparent conductive ito/Ga2O3 multilayer films deposited by rf magnetron sputtering. Appl. Phys. Lett. 2016, 109, 4166. [Google Scholar] [CrossRef]

- Woo, K.Y.; Lee, J.H.; Kim, K.H.; Kim, S.J.; Kim, T.G. Highly transparent conductive ag/Ga2O3 electrode for near-ultraviolet light-emitting diodes. Phys. Status Solidi 2015, 211, 1760–1763. [Google Scholar] [CrossRef]

- Wang, G.; Liu, H.; Zhao, C.; Yang, B.; Huang, X. Optical and electrical properties of annealed ito films. Acta scientiarium Naturalium Universitatis Jilinensis 1999, 4, 61–65. [Google Scholar]

- Cai, Q.; Cao, C.; Jiang, X.; Song, X.; Sun, Z. Microstructures and stoichiometrics of indium-tin-oxide films. Zhenkong Kexue Yu Jishu Xuebao/J. Vac. Sci. Technol. 2007, 27, 195–199. [Google Scholar]

- He, J.; Sun, L.; Chen, S.; Chen, Y.; Yang, P.; Chu, J. Composition dependence of structure and optical properties of cu2znsn (s, se) 4 solid solutions: An experimental study. J. Alloy. Compd. 2012, 511, 129–132. [Google Scholar] [CrossRef]

- Washizu, E.; Yamamoto, A.; Abe, Y.; Kawamura, M.; Sasaki, K. Optical and electrochromic properties of rf reactively sputtered wo 3 films. Solid State Ionics 2003, 165, 175–180. [Google Scholar] [CrossRef]

- Chandramohan, S.; Kanjilal, A.; Tripathi, J.K.; Sarangi, S.N.; Sathyamoorthy, R.; Som, T. Structural and optical properties of mn-doped cds thin films prepared by ion implantation. J. Appl. Phys. 2009, 105, 3272. [Google Scholar] [CrossRef]

- Lu, X.; Zhuang, Z.; Peng, Q.; Li, Y. Wurtzite cu 2 znsns 4 nanocrystals: A novel quaternary semiconductor. Chem. Commun. 2011, 47, 3141–3143. [Google Scholar] [CrossRef] [PubMed]

| No. | Annealing Temperature | Annealing Ambient | Annealing Time | Sheet Resistance (Ω/sq) |

|---|---|---|---|---|

| 1 | As deposited | As deposited | As deposited | 23.86 |

| 2 | 400 °C | N2 200 sccm:O2 35 sccm | 1 min | 32.1 |

| 3 | 500 °C | N2 200 sccm:O2 35 sccm | 1 min | 27.74 |

| 4 | 600 °C | N2 200 sccm:O2 35 sccm | 1 min | 16.45 |

| 5 | 600 °C | O2 35 sccm | 3 min | 30.6 |

| 6 | 600 °C | O2 100 sccm | 1 min | 40.93 |

| Name | As Deposited | Annealing | As Deposited | Annealing | As Deposited | Annealing | As Deposited | Annealing |

|---|---|---|---|---|---|---|---|---|

| Peak BE | Height CPS | FWHM eV | Atomic % | |||||

| Ag3d | 367.24 | 367.06 | 13,581.03 | 6651.81 | 0.95 | 0.95 | 0.47 | 0.29 |

| O1s | 530.89 | 530.7 | 224,669.16 | 265,423 | 2.04 | 1.7 | 50.67 | 50.97 |

| Ga2p3 | 1118.21 | 1117.93 | 705,296.57 | 772,390.77 | 1.66 | 1.62 | 34.31 | 35.62 |

| Sample | Annealing Temperature | Sheet Resistance | Transmittance at 365 nm | |

|---|---|---|---|---|

| 10 nm ITO | ITO/Ga2O3/Ag/Ga2O3 | |||

| 1 | No annealing | No annealing | 386.7 Ω/sq | 48.04% |

| 2 | No annealing | 600 °C | 164.0 Ω/sq | 69.35% |

| 3 | 550 °C | 36.9 Ω/sq | 80.31% | |

| 4 | 600 °C | 20.1 Ω/sq | 92.68% | |

| 5 | 650 °C | 48.1 Ω/sq | 72.09% | |

| Sample | 47 nm ITO | Sample 4 |

|---|---|---|

| Transmittance at 365 nm | 79.15% | 92.68% |

| Sheet resistance | 57.63 Ω/sq | 20.1 Ω/sq |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, H.; Zhou, Q.; Liang, S.; Wen, R. Fabrication and Characterization of AlGaN-Based UV LEDs with a ITO/Ga2O3/Ag/Ga2O3 Transparent Conductive Electrode. Nanomaterials 2019, 9, 66. https://doi.org/10.3390/nano9010066

Wang H, Zhou Q, Liang S, Wen R. Fabrication and Characterization of AlGaN-Based UV LEDs with a ITO/Ga2O3/Ag/Ga2O3 Transparent Conductive Electrode. Nanomaterials. 2019; 9(1):66. https://doi.org/10.3390/nano9010066

Chicago/Turabian StyleWang, Hong, Quanbin Zhou, Siwei Liang, and Rulian Wen. 2019. "Fabrication and Characterization of AlGaN-Based UV LEDs with a ITO/Ga2O3/Ag/Ga2O3 Transparent Conductive Electrode" Nanomaterials 9, no. 1: 66. https://doi.org/10.3390/nano9010066

APA StyleWang, H., Zhou, Q., Liang, S., & Wen, R. (2019). Fabrication and Characterization of AlGaN-Based UV LEDs with a ITO/Ga2O3/Ag/Ga2O3 Transparent Conductive Electrode. Nanomaterials, 9(1), 66. https://doi.org/10.3390/nano9010066