Preparation and Properties of SiBCO Aerogel and Its Composites

Abstract

:1. Introduction

2. Experiment

2.1. Materials

2.2. Preparation

2.3. Characterization

3. Results and Discussion

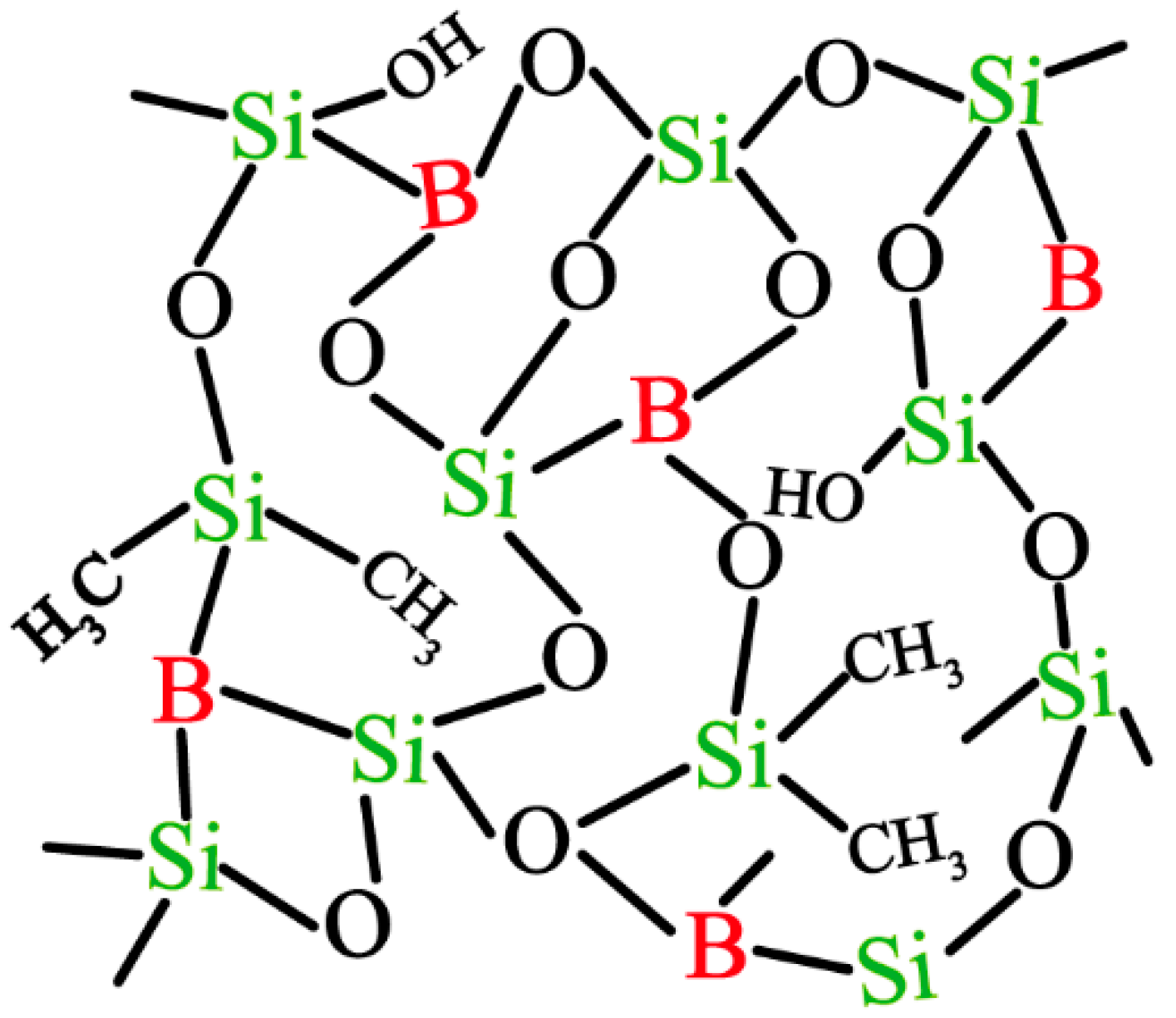

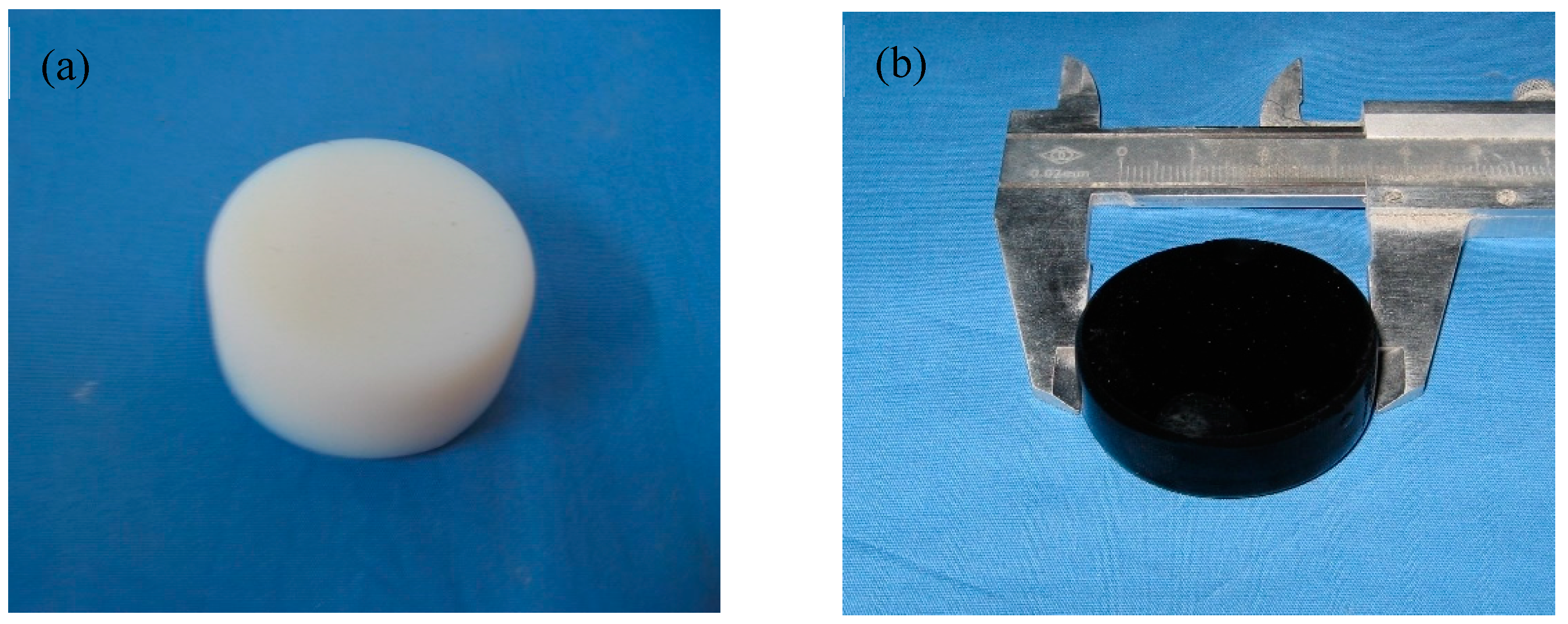

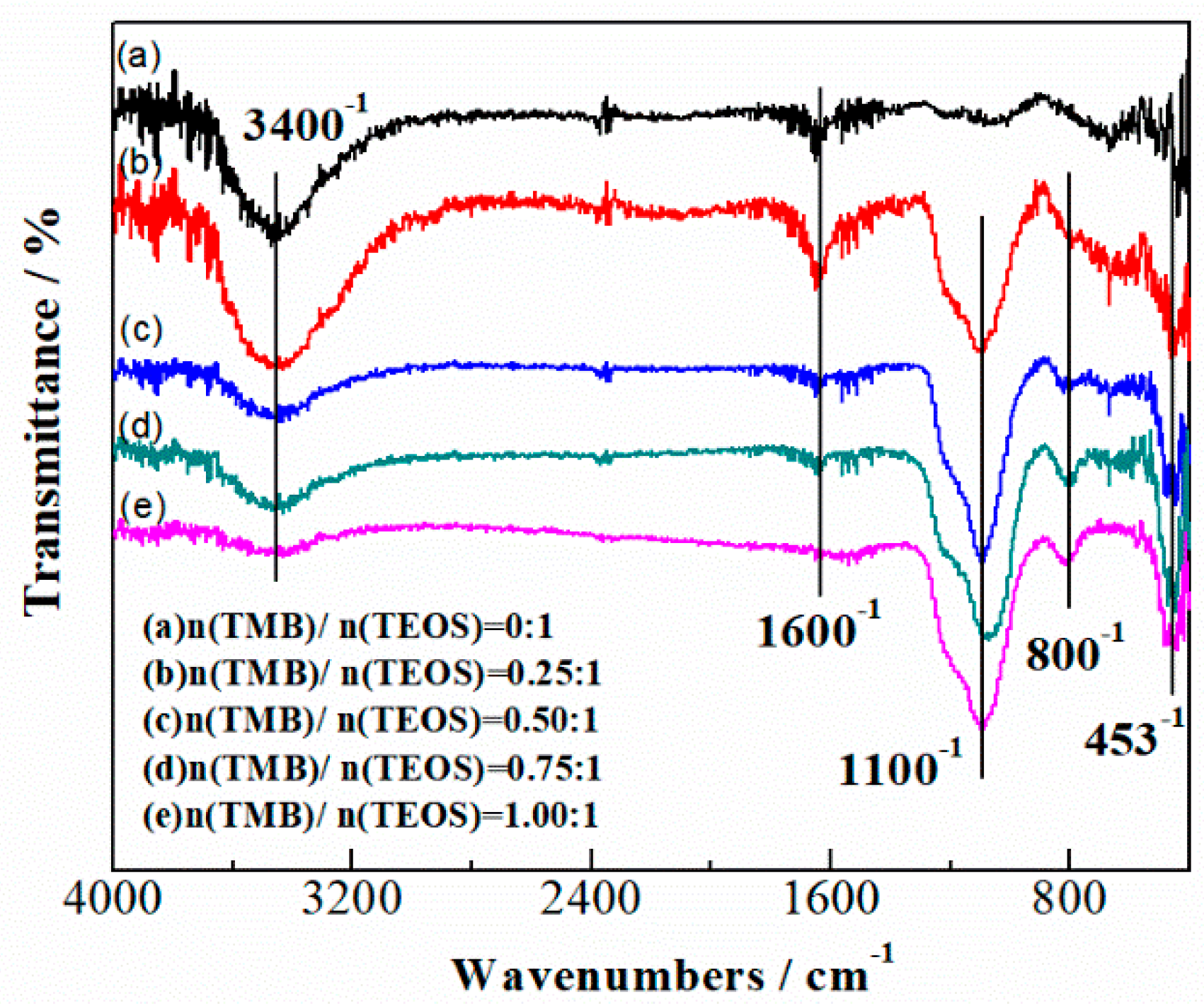

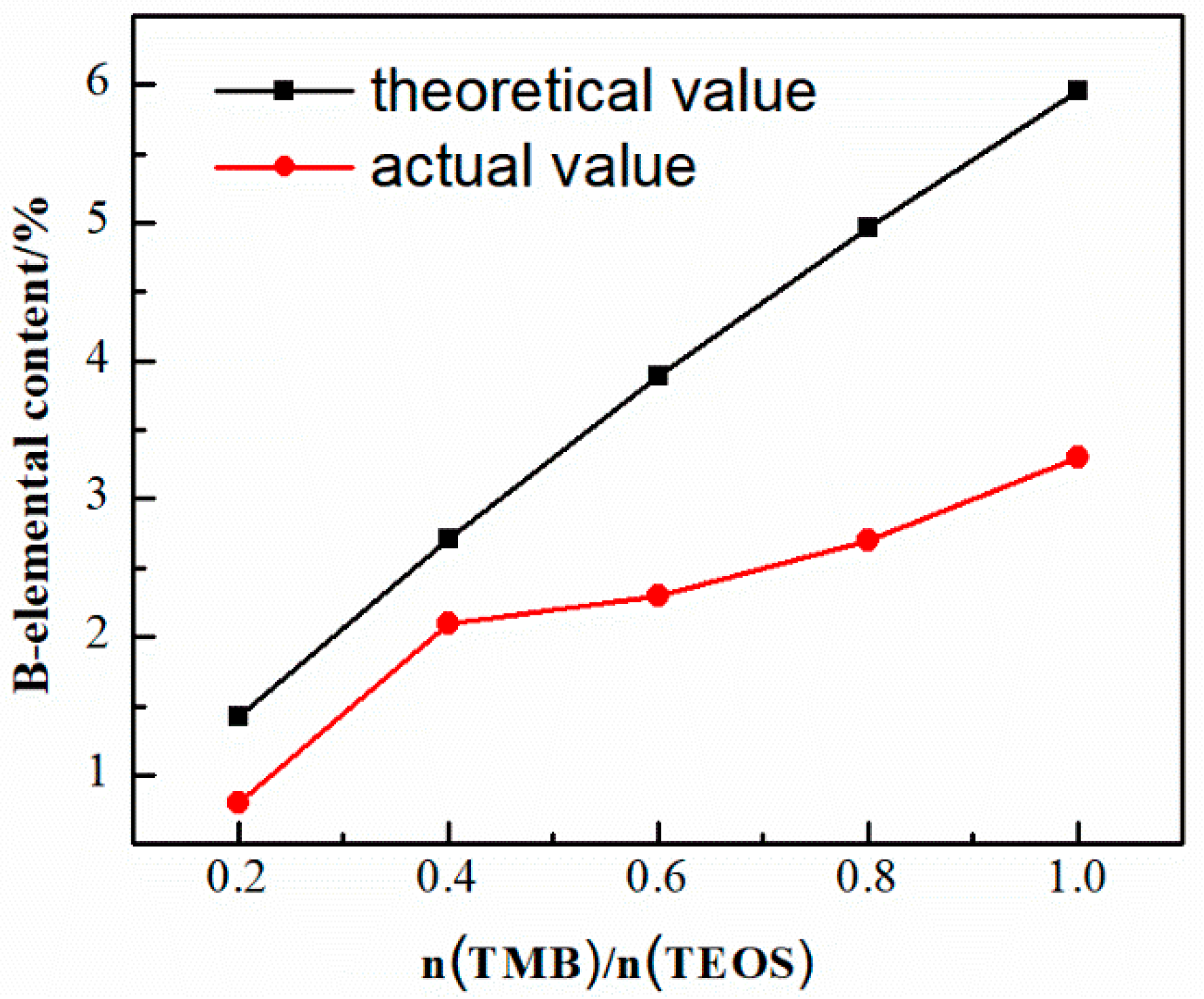

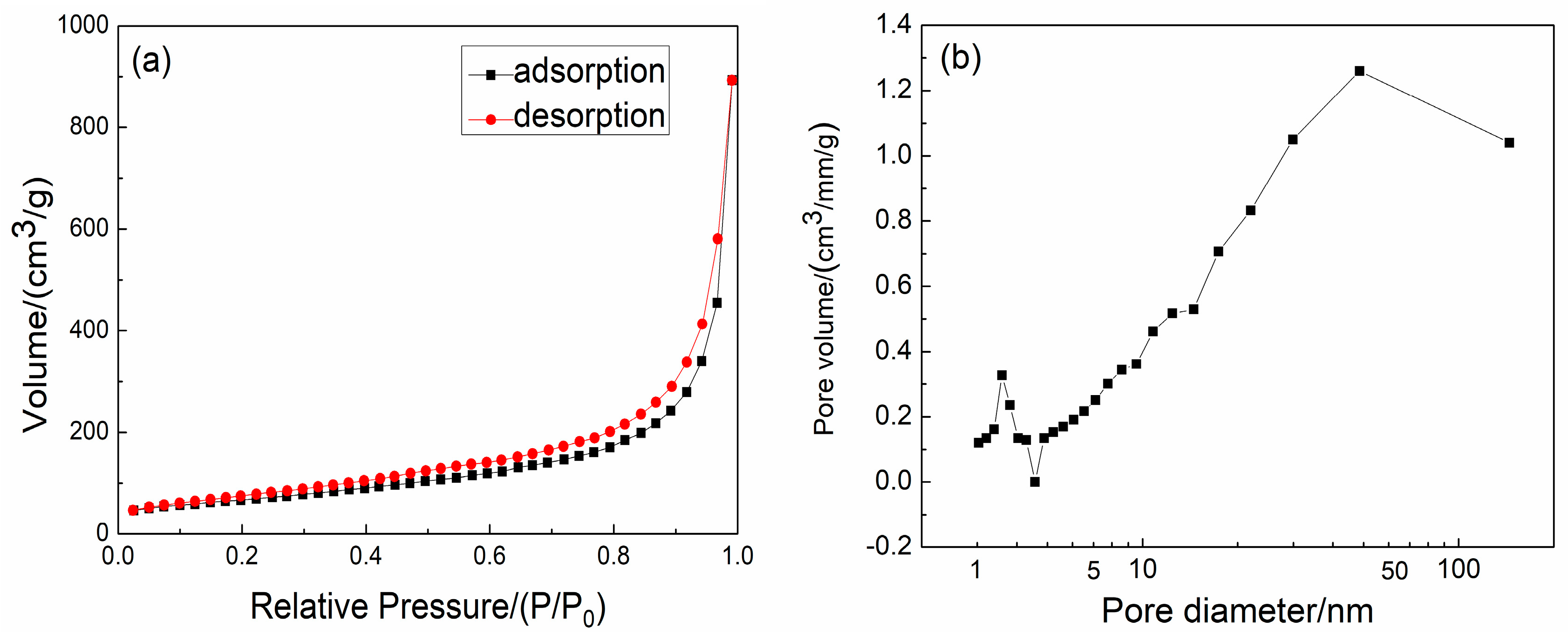

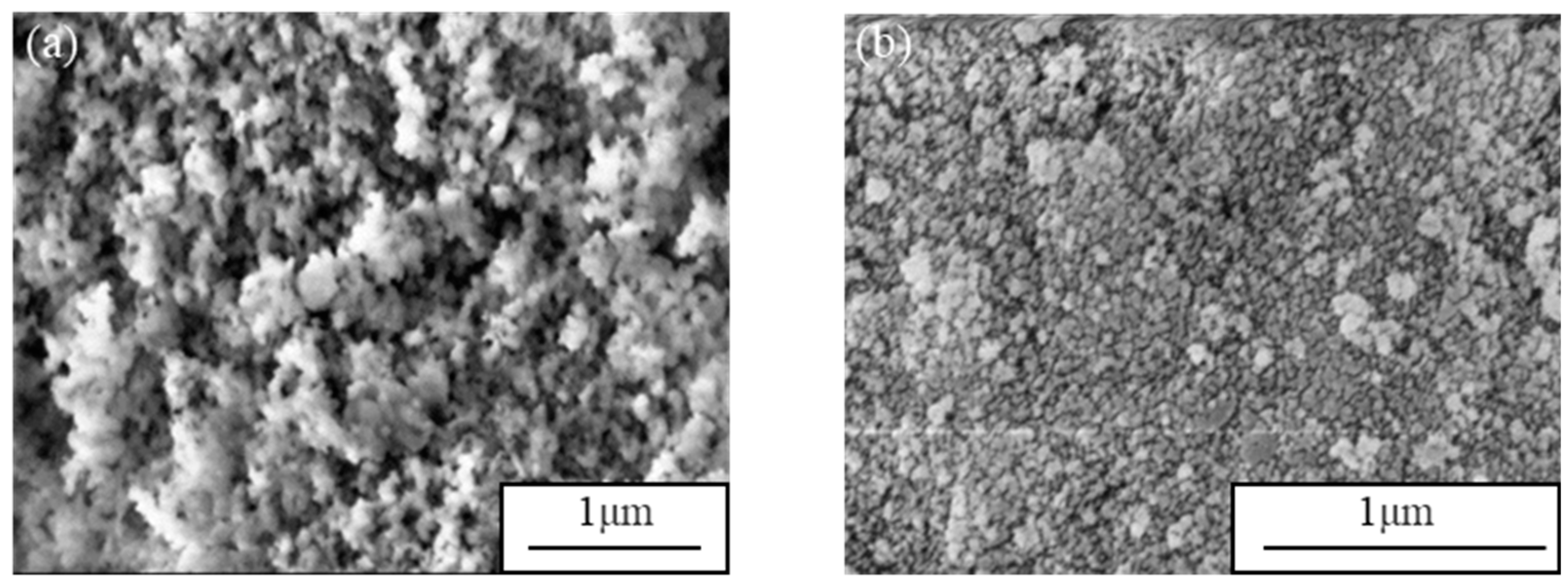

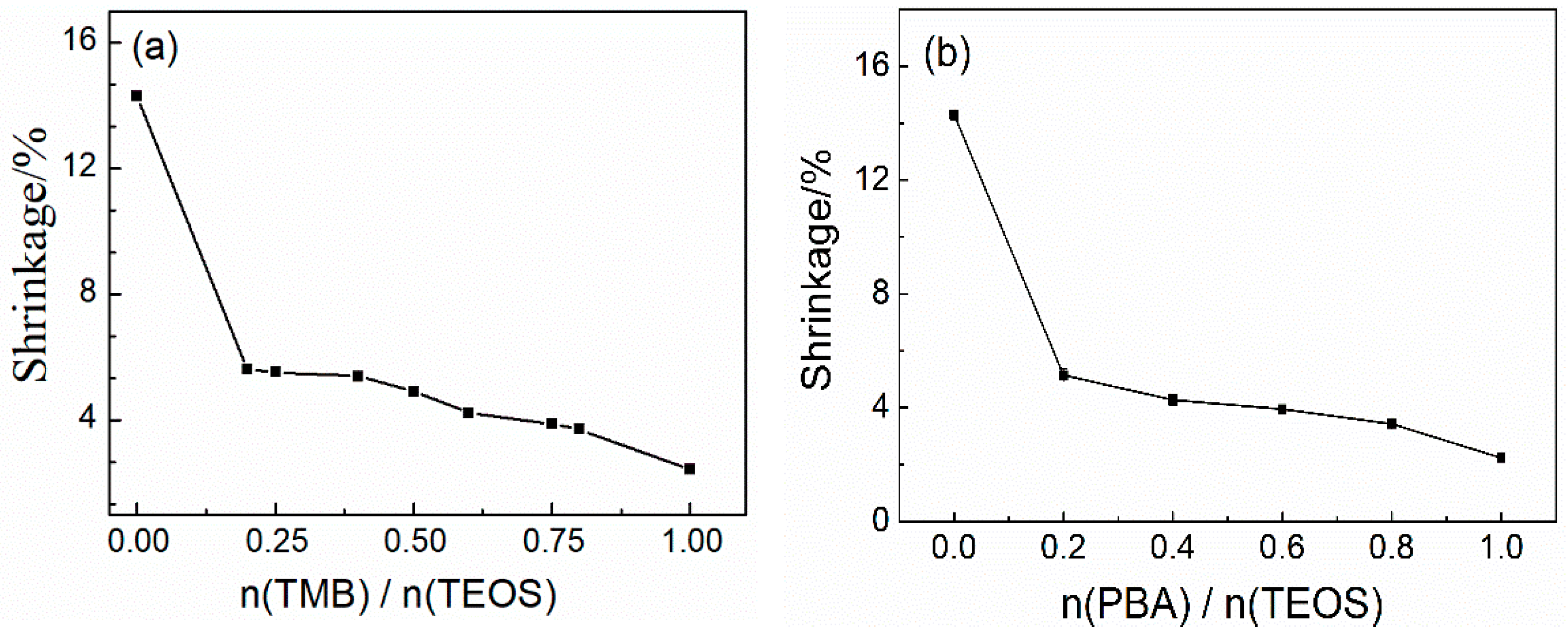

3.1. Composition and Structure of SiBCO Aerogel

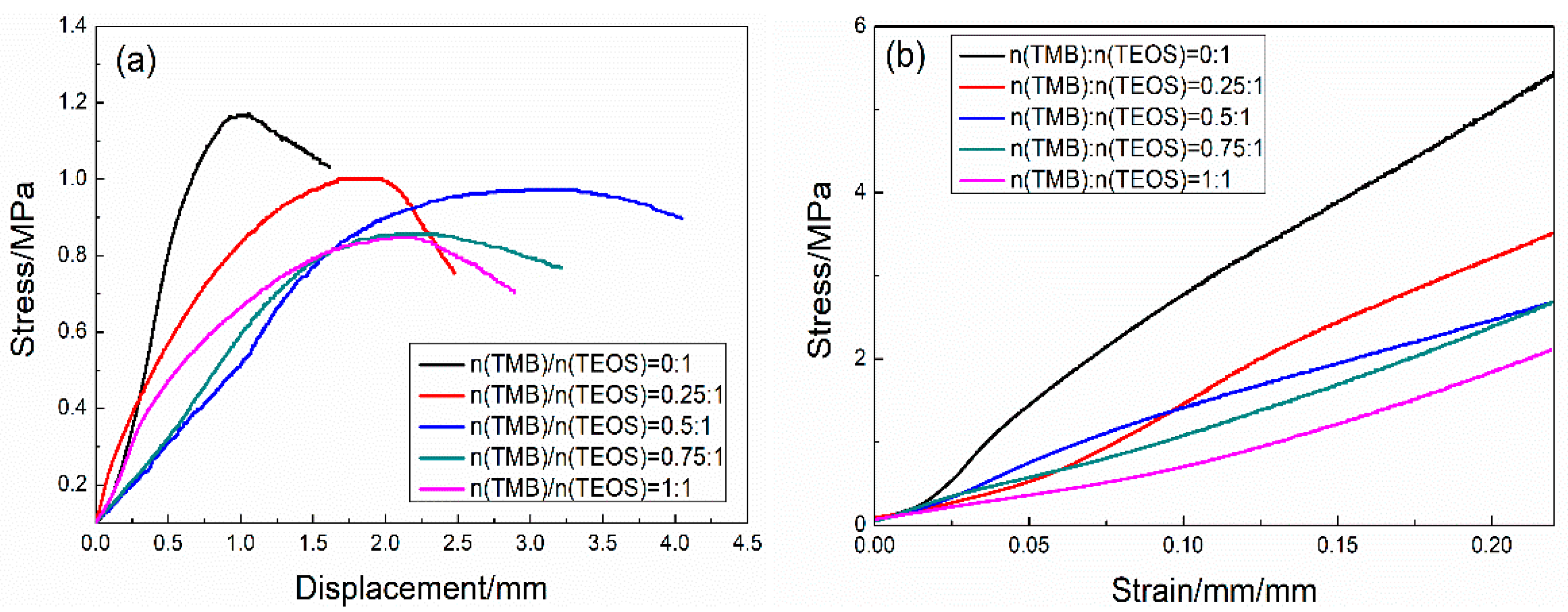

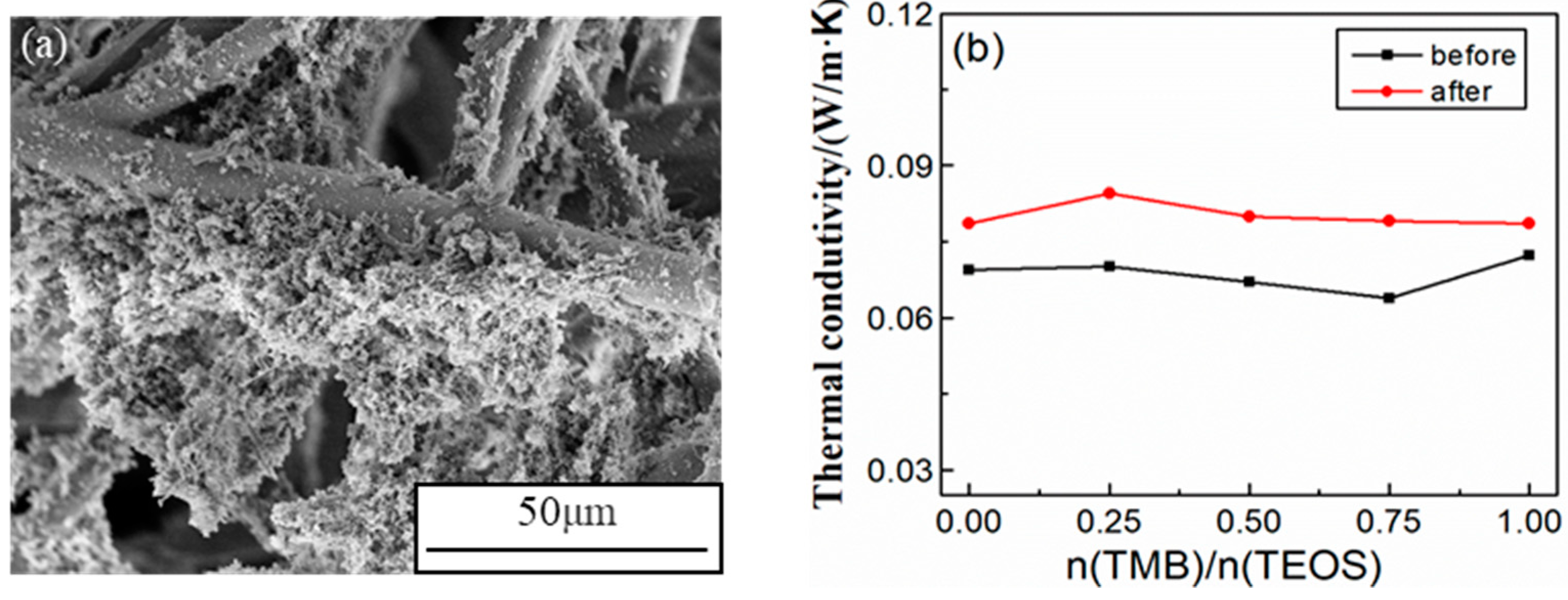

3.2. Mechanical and Thermal Insulation Properties of SiBCO Aerogel Composites

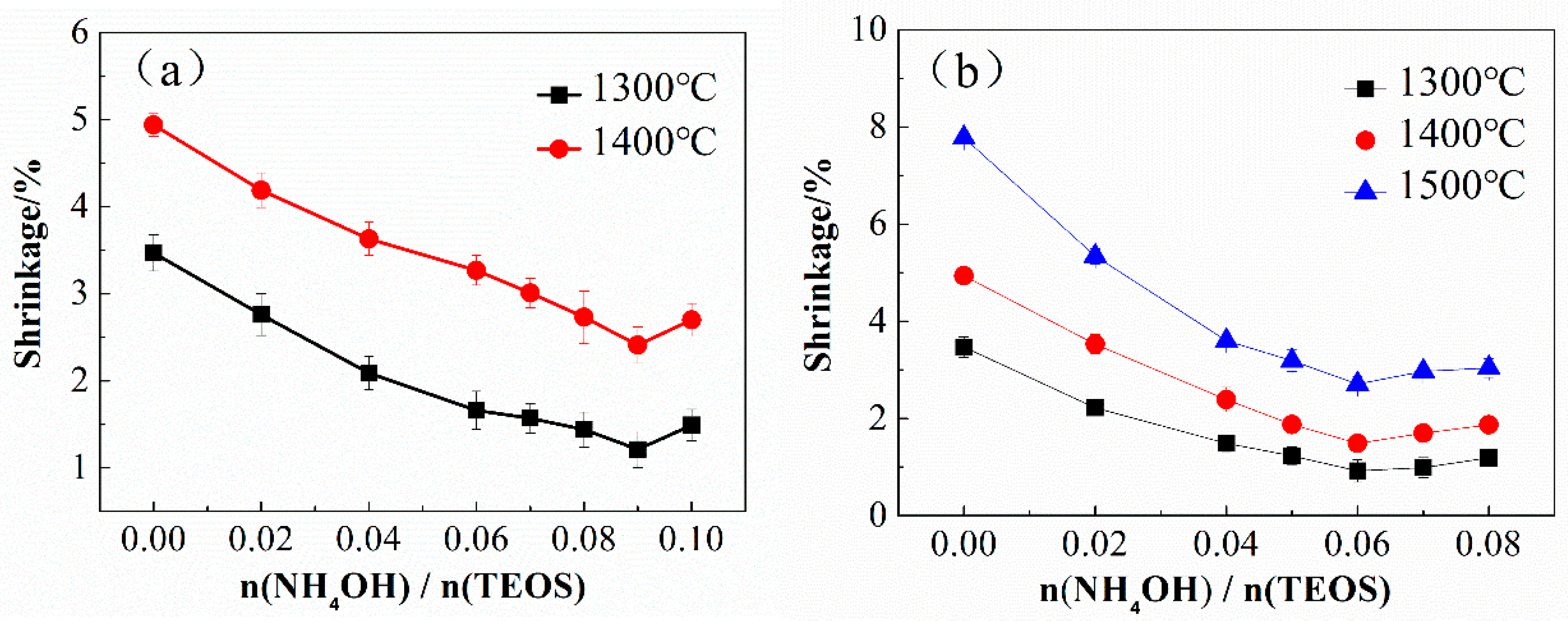

3.3. Temperature Resistance Performance of SiBCO Aerogel Composites

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Wu, X.; Zhong, Y.; Kong, Y.; Shao, G. Preparation and characterization of C/Al2O3 composites aerogel with high compressive strength and low thermal conductivity. J. Porous Mater. 2015, 22, 1235–1243. [Google Scholar] [CrossRef]

- Liu, H.; Xia, X.; Ai, Q.; Xie, X.; Sun, C. Experimental investigations on temperature-dependent effective thermal conductivity of nanoporous silica aerogel composites. Exp. Therm. Fluid Sci. 2017, 84, 67–77. [Google Scholar] [CrossRef]

- Feng, J.Z.; Feng, J.; Jiang, Y.G.; Zhang, C.R. Ultralow density carbon aerogels with low thermal conductivity up to 2000 °C. Mater. Lett. 2011, 65, 3454–3456. [Google Scholar] [CrossRef]

- Ni, X.Y.; Wang, J.C.; Liu, G.W.; Zhang, Z.H.; Shen, J.; Zhou, B.; Wu, G.M. Preparation and properties of super insulation material SiO2 aerogel. Adv. Mater. Res. 2012, 516–517, 1531–1535. [Google Scholar] [CrossRef]

- Feng, J.; Gao, Q.F.; Feng, J.Z.; Jiang, Y.G. Preparation and properties of fiber reinforced SiO2 aerogel insulation composites. J. Natl. Univ. Defense Technol. 2010, 32, 40–44. [Google Scholar]

- He, J.; Li, X.; Su, D.; Ji, H.; Wang, X.J. Ultra-low thermal conductivity and high strength of aerogels/fibrous ceramic composites. J. Eur. Ceram Soc. 2016, 36, 1487–1493. [Google Scholar] [CrossRef]

- Jiang, Y.G.; Qin, Y.Q.; Feng, J.Z.; Feng, J.; Xu, L. Effect of heat-treatment on the microstructure and properties of SiO2-TiO2, aerogels synthesized via supercritical drying. Mater. Sci. Forum 2016, 848, 770–776. [Google Scholar] [CrossRef]

- Kim, H.M.; Kim, H.S.; Kim, S.Y.; Youn, J.R. Silica aerogel/epoxy composites with preserved aerogel pores and low thermal conductivity. E-Polymers 2015, 15, 111–117. [Google Scholar] [CrossRef]

- Shi, J.; Lu, L.; Guo, W.; Zhang, J.; Cao, Y. Heat insulation performance, mechanics and hydrophobic modification of cellulose-SiO2 composite aerogels. Carbohydr. Polym. 2013, 98, 282–289. [Google Scholar] [CrossRef]

- Vedenin, A.D.; Vityaz, P.A.; Ivanova, I.S.; Mazalova, Y.A.; Pustovgarc, A.P.; Sudnik, L.V. Experimental investigation of thermal insulating aerogel composites of hydrothermal reactor for biomass-to-hydrogen conversion. Int. J. Hydrogen Energy 2018, 43, 6899–6903. [Google Scholar] [CrossRef]

- Tian, H.; Ma, Q.S.; Pan, Y.; Liu, W.D. Structure and mechanical properties of porous silicon oxycarbide ceramics derived from silicone resin with different filler content. Ceram. Int. 2013, 39, 71–74. [Google Scholar] [CrossRef]

- Schmidt, H.; Koch, D.; Grathwohl, G.; Cokombo, P. Micro-/macroporous ceramics from preceramic precursors. J. Am. Ceram Soc. 2001, 10, 2252–2255. [Google Scholar] [CrossRef]

- Colombo, P.; Hellmann, J.R.; Shelleman, D.L. Mechanical properties of silicon oxycarbide ceramic foams. J. Am. Ceram. Soc. 2001, 10, 2245–2251. [Google Scholar] [CrossRef]

- Nyczyk-Malinowska, A.; Wójcik-Bania, M.; Gumuła, T.; Hasika, M.; Cyprykb, M.; Olejniczak, Z. New precursors to SiCO ceramics derived from linear poly(vinylsiloxanes) of regular chain composition. J. Eur. Ceram. Soc. 2014, 34, 889–902. [Google Scholar] [CrossRef]

- Oteo, J.L.; Mazo, M.A.; Palencia, C.; Rubio, F.; Rubio, J. Synthesis and characterization of silicon oxycarbide derived nanocomposites obtained through ceramic processing of TEOS/PDMS preceramic materials. J. Nano Res.-SW 2011, 14, 27–38. [Google Scholar] [CrossRef]

- Dirè, S.; Borovin, E.; Narisawa, M.; Sorarù, G.D. Synthesis and characterization of the first transparent silicon oxycarbide aerogel obtained through H2 decarbonization. J. Mater. Chem. A 2015, 3, 24405–24413. [Google Scholar] [CrossRef]

- Ma, J.; Ye, F.; Yang, C.; Lin, S.; Zhang, B.; Liu, Q. Heat-resistant, strong alumina-modified silica aerogel fabricated by impregnating silicon oxycarbide aerogel with boehmite sol. Mater. Des. 2017, 131, 226–231. [Google Scholar] [CrossRef]

- Weinberger, M.; Puchegger, S.; Fröschl, T.; Babonneau, F.; Peterlik, H.; Hüsing, N. Sol-gel processing of a glycolated cyclic organosilane and its pyrolysis to silicon oxycarbide monoliths with multiscale porosity and large surface areas. Chem. Mater. 2010, 22, 1509–1520. [Google Scholar] [CrossRef]

- Zhao, N.; Feng, J.Z.; Jiang, Y.G.; Feng, J. Preparation and characterization of Si-C-O aerogel composites for thermal insulation. J. Chin. Ceram. Soc. 2012, 40, 19081–19086. [Google Scholar]

- Ngoumeniyappi, R.; Fasel, C.; Riedel, R.; Ischenko, V.; Pippel, E.; Woltersdorf, J.; Clade, J. Tuning of the rheological properties and thermal behavior of boron-containing polysiloxanes. Chem. Mater. 1999, 20, 1931–1940. [Google Scholar]

- Klonczynski, A.; Schneider, G.; Riedel, R.; Theissmann, R. Influence of boron on the microstructure of polymer derived SiCO ceramics. Adv. Eng. Mater. 2010, 6, 64–68. [Google Scholar] [CrossRef]

- Sorarù, G.D.; Pena-Alonso, R.; Kleebe, H.J. The effect of annealing at 1400 C on the structural evolution of porous C-rich silicon (boron)oxycarbide glass. J. Eur. Ceram. Soc. 2012, 32, 1751–1757. [Google Scholar] [CrossRef]

- Pena-Alonso, R.; Mariotto, G.; Gervais, C.; Babonneau, F.; Soraru, G.D. New insights on the high-temperature nanostructure evolution of SiOC and B-doped SiBOC polymer-derived glasses. Chem. Mater. 2007, 19, 5694–5702. [Google Scholar] [CrossRef]

- Sorarù, G.D.; Campostrini, R.; Maurina, S.; Babonneau, F. Gel precursor to silicon oxycarbide glasses with ultrahigh ceramic yield. J. Am. Ceram. Soc. 1997, 80, 999–1004. [Google Scholar] [CrossRef]

- Muralidharan, M.N.; Pramanik, N.C.; Abraham, P.A.; Jacob, K.S.; Panicker, N.R. Crystallization and oxidation resistance properties of boron modified silicon oxycarbides derived from polymeric precursors by sol–gel method. Mater. Lett. 2008, 62, 2547–2550. [Google Scholar] [CrossRef]

- Tamayo, A.; Peña-Alonso, R.; Rubio, F.; Rubio, J.; Oteo, J.L. Synthesis and characterization of boron silicon oxycarbide glass fibers. J. Non-Cryst. Solids 2012, 358, 155–162. [Google Scholar] [CrossRef]

- Feng, J.Z.; Xiao, Y.Y.; Jiang, Y.G.; Feng, J. Synthesis, structure, and properties of silicon oxycarbide aerogels derived from tetraethylortosilicate/polydimethylsiloxane. Ceram. Int. 2015, 41, 5281–5286. [Google Scholar] [CrossRef]

- Feng, J.Z.; Zhao, N.; Jiang, Y.; Feng, J. Preparation and characterization of Si-C-O aerogels using Tetraethoxysilane and Dimethyldiethoxysilane as precursors. Rare Met. Mater. Eng. 2012, 41, 458–461. [Google Scholar]

- Rao, A.V.; Pajonk, G.M.; Parvathy, N.N. Effect of solvents and catalysts on monolithicity and physical properties of silica aerogels. J. Mater Sci. 1994, 29, 1807–1817. [Google Scholar]

- Gervais, C.; Babonneau, F.; Dallabonna, N.; Sorarù, G.D. Sol-Gel-Derived Silicon-Boron Oxycarbide Glasses Containing Mixed Silicon Oxycarbide (SiCxO4-x) and Boron Oxycarbide (BCyO3-y) Units. J. Am. Ceram. Soc. 2001, 84, 2160–2164. [Google Scholar] [CrossRef]

- Annamalai, J.; Gill, W.N.; Tobin, A. Modeling, analysis and kinetics of transformations in BlackglasTM preceramic polymer pyrolysis. Chem. Eng. Sci. 1995, 16, 225–232. [Google Scholar]

- Yu, J.; Su, Y.; Cheng, B.; Zhou, M. Effects of pH on the microstructures and photocatalytic activity of mesoporous nanocrystalline titania powders prepared via hydrothermal method. J. Mol. Catal. A Chem. 2006, 258, 104–112. [Google Scholar] [CrossRef]

- Esquivias, L.; Rodriguez-Ortega, J.; Barrera-Solano, C.; Rosa-Fox, N.D.L. Structural models of dense aerogels. J. Non-Cryst. Solids 1998, 225, 239–243. [Google Scholar] [CrossRef]

- Lu, X.; Caps, R.; Fricke, J.; Alviso, C.T.; Pekala, R.W. Correlation between structure and thermal conductivity of organic aerogels. J. Non-Cryst. Solids 1995, 188, 226–234. [Google Scholar] [CrossRef]

- Zhao, J.J.; Duan, Y.Y.; Wang, X.D.; Wang, B.X. Effects of solid–gas coupling and pore and particle microstructures on the effective gaseous thermal conductivity in aerogels. J. Nanopart. Res. 2012, 14, 1–15. [Google Scholar] [CrossRef]

| n(NH3·H2O)/n(TEOS) | n(EN)/n(TEOS) | |||||

|---|---|---|---|---|---|---|

| 0.06 | 0.07 | 0.08 | 0.06 | 0.07 | 0.08 | |

| Boron Element Content | 1.78 | 1.64 | 1.61 | 2.29 | 2.16 | 2.09 |

| Temperature/(°C) | 1300 | 1400 | 1500 |

|---|---|---|---|

| Thermal Conductivity/(W/(m·K)) | 0.1343 | 0.1382 | 0.1380 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, X.; Feng, J.; Yin, J.; Jiang, Y.; Feng, J. Preparation and Properties of SiBCO Aerogel and Its Composites. Nanomaterials 2019, 9, 40. https://doi.org/10.3390/nano9010040

Li X, Feng J, Yin J, Jiang Y, Feng J. Preparation and Properties of SiBCO Aerogel and Its Composites. Nanomaterials. 2019; 9(1):40. https://doi.org/10.3390/nano9010040

Chicago/Turabian StyleLi, Xiafei, Junzong Feng, Jie Yin, Yonggang Jiang, and Jian Feng. 2019. "Preparation and Properties of SiBCO Aerogel and Its Composites" Nanomaterials 9, no. 1: 40. https://doi.org/10.3390/nano9010040

APA StyleLi, X., Feng, J., Yin, J., Jiang, Y., & Feng, J. (2019). Preparation and Properties of SiBCO Aerogel and Its Composites. Nanomaterials, 9(1), 40. https://doi.org/10.3390/nano9010040