Preparation of Filtration Sorptive Materials from Nanofibers, Bicofibers, and Textile Adsorbents without Binders Employment

Abstract

1. Introduction

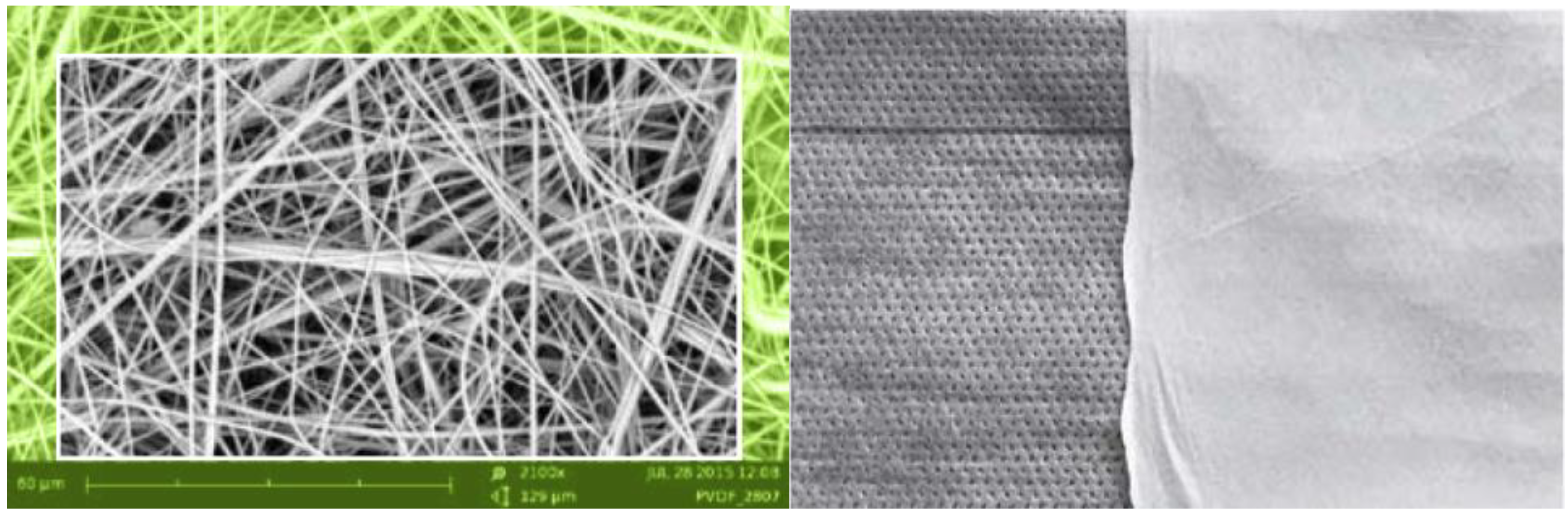

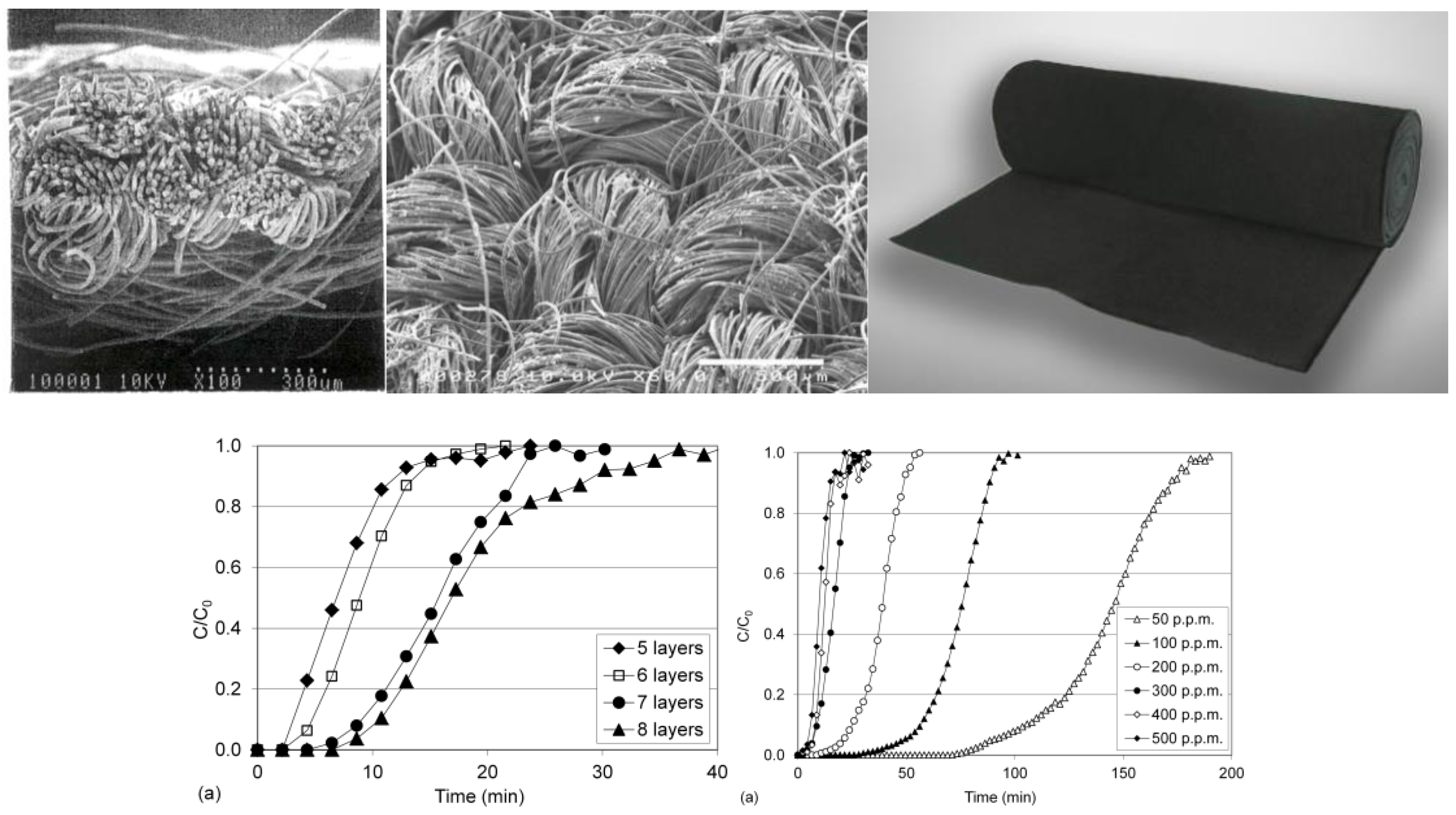

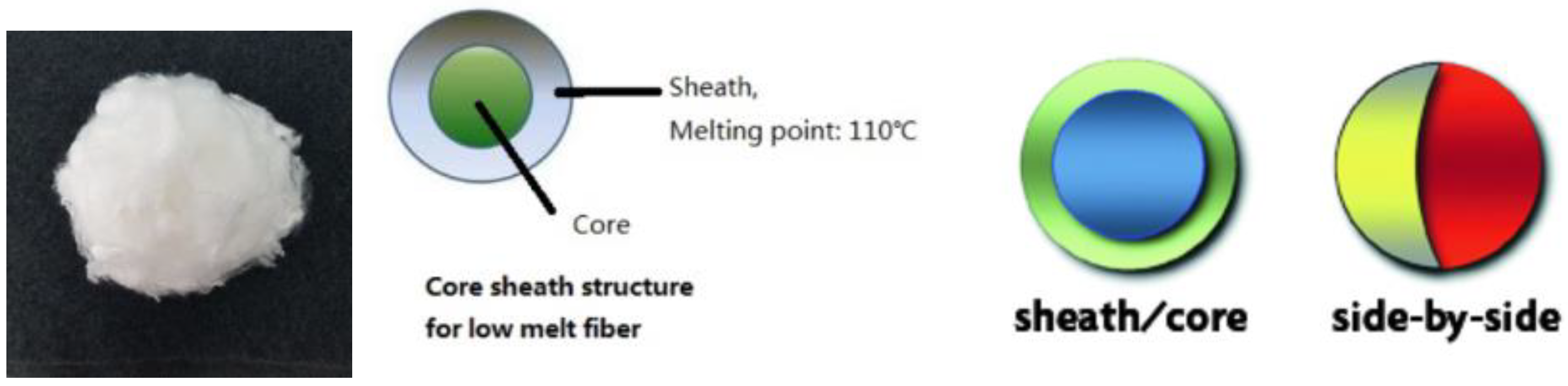

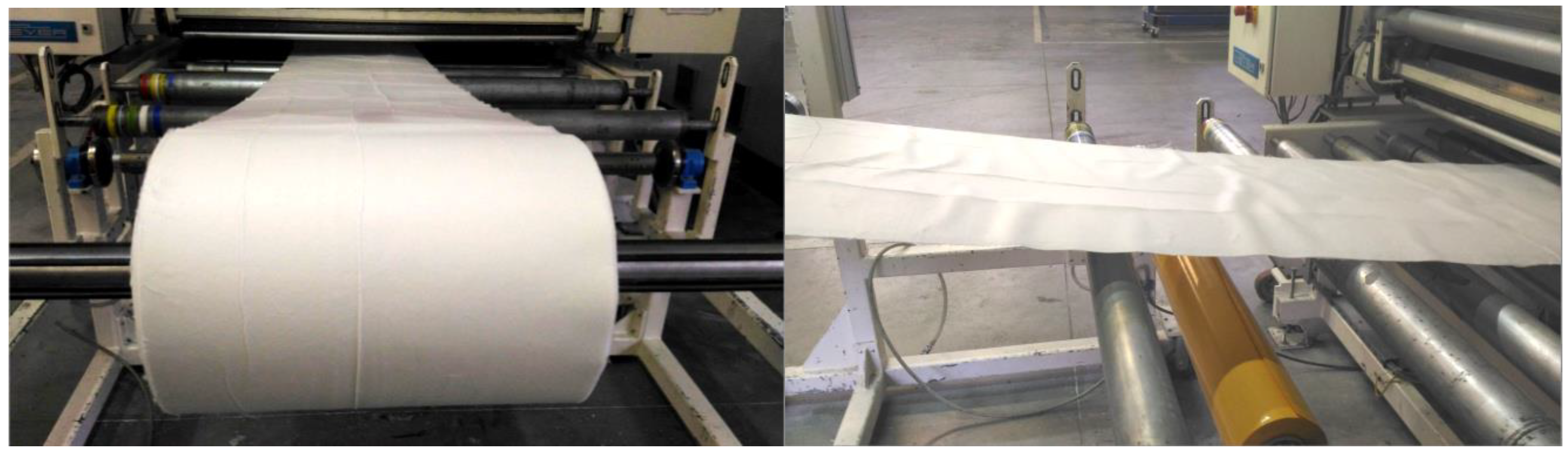

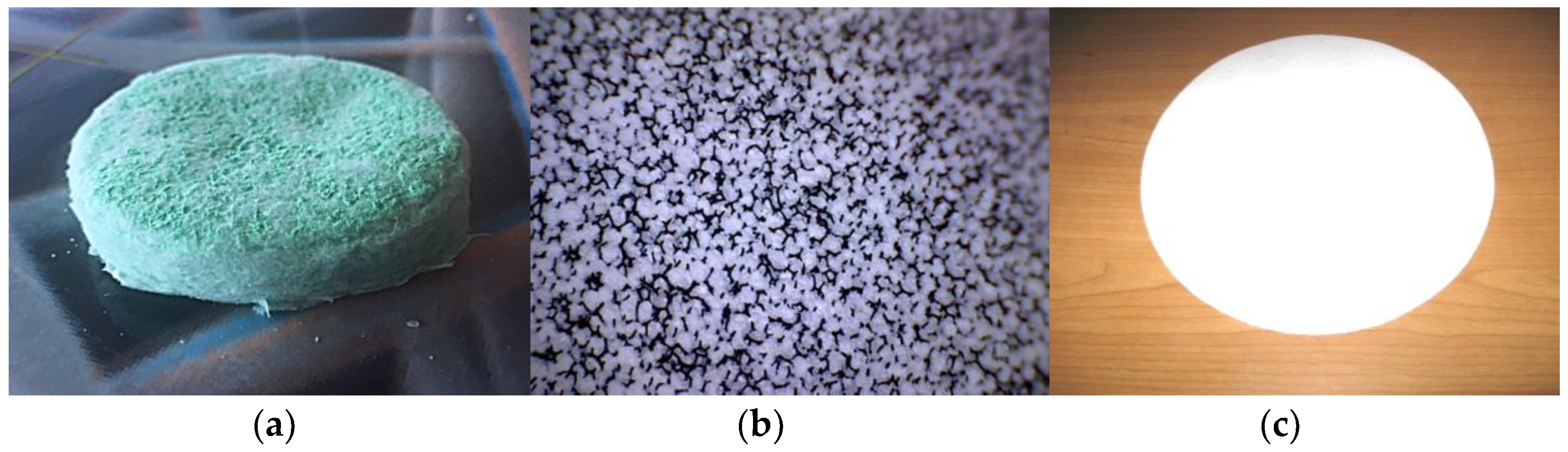

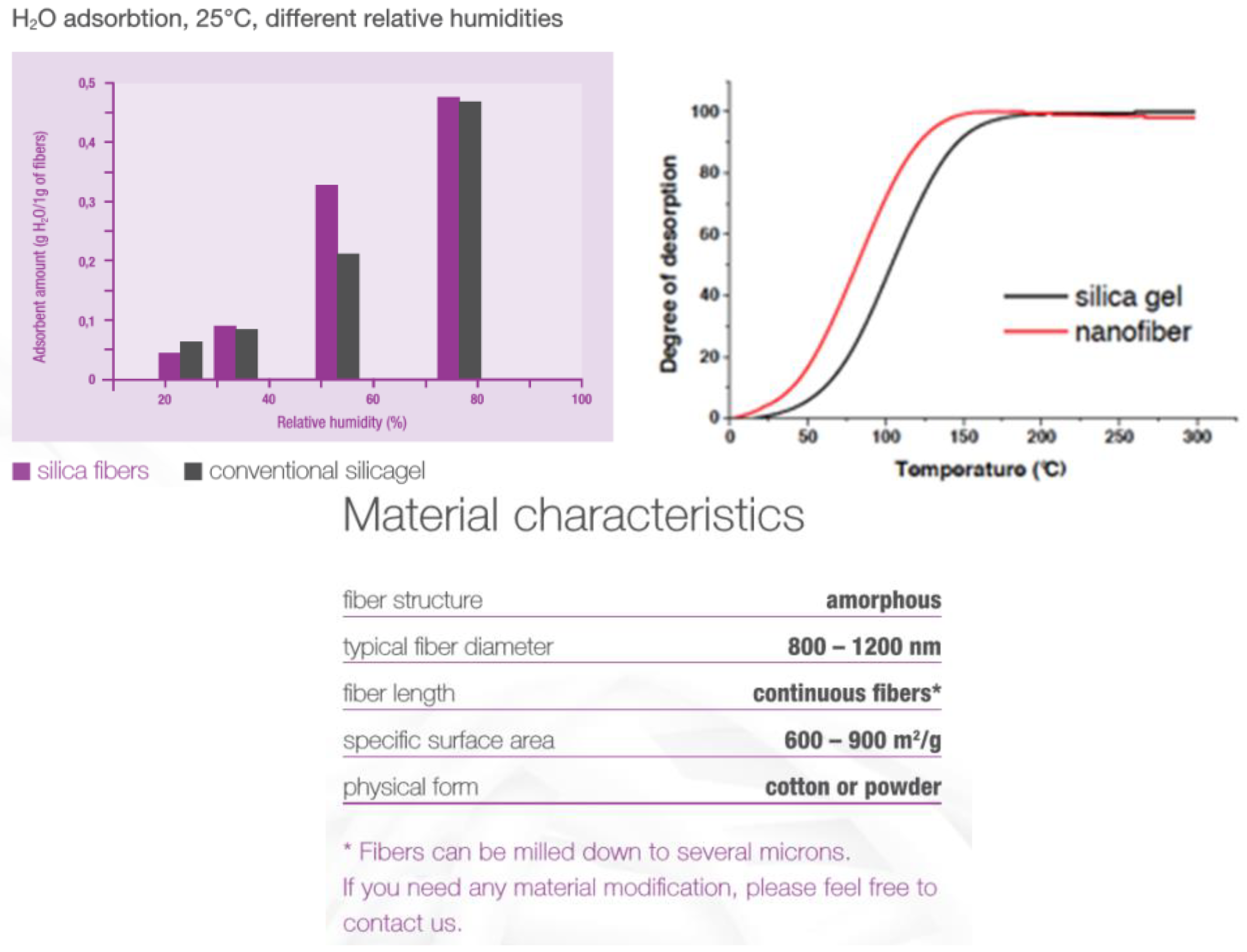

2. Materials and Methods

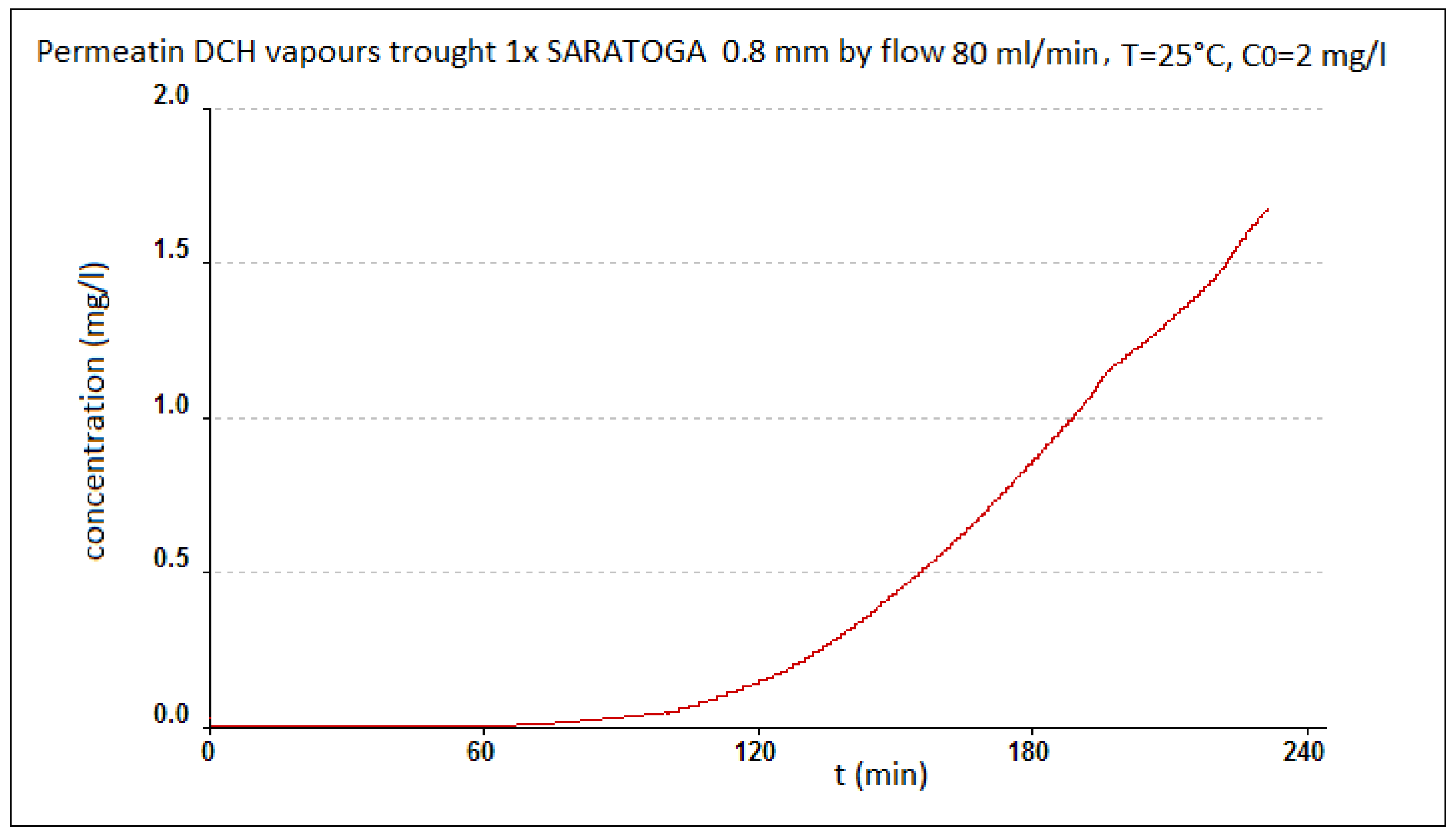

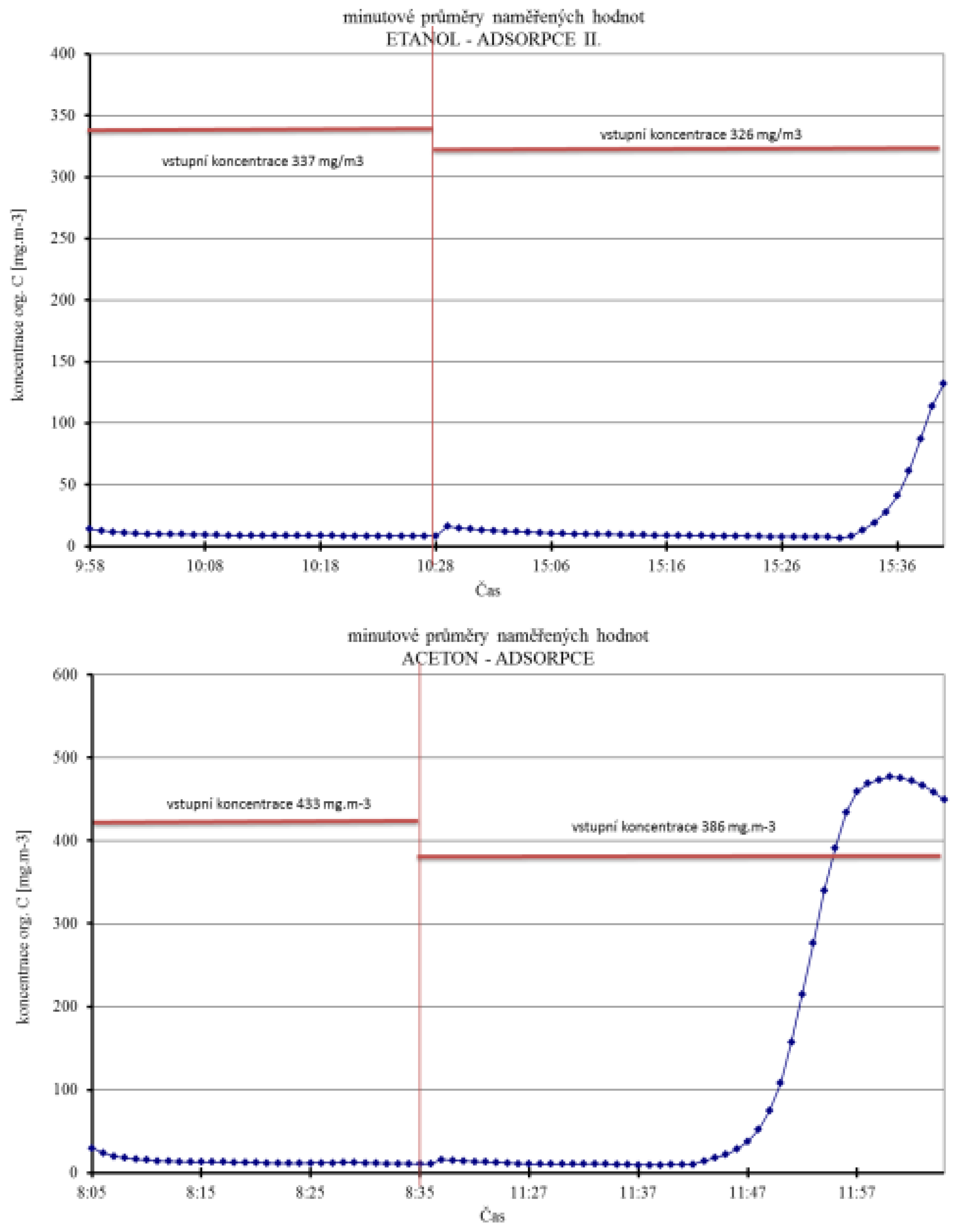

3. Results

Principle of Measurement

4. Discussion

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Mrština, V.; Kučera, F. Vrstvená Filtračně-Absorpční Textilie. Available online: https://1url.cz/Rty4j (accessed on 11 June 2018).

- CSN EN 143. Respiratory Protective Devices—Particle Filter—Requirements, Testing, Marking; Český Normalizační Institut: Praha, Czech Republic, 2000. [Google Scholar]

- ČSN EN 13274-1. Respiratory Protective Devices—Methods of Test—Part 1: Determination of Inward Leakage and Total Inward Leakage; Český Normalizační Institut: Praha, Czech Republic, 2001. [Google Scholar]

- Ndaro, M.S.; Jin, X.; Chen, T.; Yu, C. Splitting of Islands-in-the-Sea Fibers (PA6/COPET) during Hydroentangling of Nonwovens. J. Eng. Fibers Fabr. 2007, 2, 1–9. [Google Scholar]

- Khavryuchenko, V.D.; Khavryuchenko, O.V.; Shkilnyy, A.I.; Stratiichuk, D.A.; Lisnyak, V.V. Characterization by SEM, TEM and Quantum-Chemical Simulations of the Spherical Carbon with Nitrogen (SCN) Active Carbon Produced by Thermal Decomposition of Poly(vinylpyridine-divinylbenzene) Copolymer. Materials 2009, 2, 1239–1251. [Google Scholar] [CrossRef]

- Kmochova, A.; Tichy, A.; Zarybnicka, L.; Sinkorova, Z.; Vavrova, J.; Rehacek, V.; Durisova, K.; Kubelkova, K.; Pejchal, J.; Kuca, K. Modulation of ionizing radiation-induced effects by NU7441, KU55933 and VE821 in peripheral blood lymphocytes. J. Appl. Biomed. 2016, 14, 19–24. [Google Scholar] [CrossRef]

- Atwater, M.A.; Mousavi, A.K.; Leseman, Z.; Phillips, J. Direct synthesis and characterization of a nonwoven structure comprised of carbon nanofibers. Carbon 2013, 57, 363–370. [Google Scholar] [CrossRef]

- Suzuki, M. Activated carbon fiber: Fundamentals and applications. Carbon 1994, 32, 577–586. [Google Scholar] [CrossRef]

- Che, G.; Lakshmi, B.B.; Martin, C.R.; Fisher, E.R. Chemical Vapor Deposition Based Synthesis of Carbon Nanotubes and Nanofibers Using a Template Method. Chem. Mater. 1998, 10, 260–267. [Google Scholar] [CrossRef]

- Mosteanu, D.; Barsan, G.; Otrisal, P.; Giurgiu, L.; Oancea, R. Obtaining the Volatile Oils from Wormwood and Tarragon Plants by a new Microwave Hydrodistillation Method. Rev. Chim. 2017, 68, 2499–2502. [Google Scholar]

- Kalebek, N.A.; Babaarslan, O. Non-Woven Fabrics: Fiber Selection for the Production of Nonwovens; Jeon, H.-Y., Ed.; Inha University: Inha, Korea, 2016; Chapter 1; pp. 1–32. ISBN 978-953-51-2271-5. [Google Scholar]

- Obšel, V.; Buk, J.; Kuchař, A.; Kučera, F. A Filtration and Filtration-Sorption Plane Formation. Available online: https://1url.cz/Wty4d (accessed on 11 June 2018).

- Turbak, A.F. Nonwovens: Theory, Process, Performance, and Testing; TAPPI Press: Atlanta, GA, USA, 1993; 256p, ISBN 978-089-852-265-5. [Google Scholar]

- Horova, I.; Kolacek, J.; Vopatova, K. Full bandwidth matrix selectors for gradient kernel density estimate. Comput. Stat. Data Anal. 2013, 57, 364–376. [Google Scholar] [CrossRef]

- ČSN EN 16523-1. Determination of Material Resistance to Permeation by Chemicals—Part 1: Permeation by Liquid Chemical under Conditions of Continuous Contact; European Committee for Standardization: Brussel, Belgium, 2015. [Google Scholar]

- (CSN) EN 16523-2. Determination of Material Resistance to Permeation by Chemicals—Part 1: Permeation by Gaseous Chemicals under Conditions of Continuous Contact; European Committee for Standardization: Brussel, Belgium, 2015. [Google Scholar]

- Kudryavtseva, L.Y.; Shkrabo, M.L.; Ivakhnyuk, G.K.; Bolkunov, O.A.; Malinin, V.R. Preparation and properties of activated carbon fabrics for gas-protecting respirators. Russ. J. Appl. Chem. 1998, 71, 1155–1159. [Google Scholar]

- Schonfeld, M.; Schonfeld, R. Methods for Producing Spherical Activated Carbon. Available online: https://1url.cz/utyD9 (accessed on 12 June 2018).

- Lee, T.; Ooi, C.H.; Othman, R.; Yeoh, F. Activated carbon fiber—The Hybrid of Carbon Fiber and Activated Carbon. Rev. Adv. Mater. Sci. 2014, 36, 119–136. [Google Scholar]

- Hayashi, T.; Lee, T.G.; Hazelwood, M.; Hedrick, E.; Biswas, P. Characterization of Activated Carbon Fiber Filters for Pressure Drop, Submicrometer Particulate Collection, and Mercury Capture. J. Air Waste Manag. Assoc. 2000, 50, 922–929. [Google Scholar] [CrossRef] [PubMed]

- Bhargavi, R.; Kadirvelu, K.; Kumar, N.S. Vapor Phase Adsorption of Homologous Aliphatic Ketones on Activated Spherical Carbon. Int. J. Environ. Sci. 2011, 71, 1155–1159. [Google Scholar]

- Otrisal, P.; Florus, S.; Svorc, L.; Barsan, G.; Mosteanu, D. A New Colorimetric Assay for Determination of Selected Toxic Vapors and Liquids Permeation through Barrier Materials Using the Minitest Device. Rev. Plast. 2017, 54, 748–751. [Google Scholar]

- Karkalic, R.M.; Ivankovic, N.D.; Jovanovic, D.B.; Markovic, S.M.; Indjic, D.R.; Micovic, M.D.; Kovacevic, B.V. Dynamic adsorption characteristics of thin layered activated charcoal materials used in chemical protective overgarments. Indian J. Fibre Text. Res. 2016, 41, 402–410. [Google Scholar]

- Huang, X. Fabrication and Properties of Carbon Fibers. Materials 2009, 1, 938–947. [Google Scholar] [CrossRef]

- Hoskova-Mayerova, S.; Maturo, A. Algebraic hyperstructures and social relations. Ital. J. Pure Appl. Math. 2018, 39, 701–709. [Google Scholar]

- Macák, J.M.; Hromádko, L.; Bulánek, R.; Koudelková, E.; Buk, J.; Tejkl, M. Process for Preparing Submicron Fibers of Amorphous Silica and Submicron Fibers of Amorphous Silica Prepared in Such a Manner. Available online: https://1url.cz/qtyDc (accessed on 12 June 2018).

- ČSN EN 149+A1 83 2225. Respiratory Protective Devices—Filtering Half Masks to Protect against Particles—Requirements, Testing, Marking; Český Normalizační Institut: Praha, Czech Republic, 2009. [Google Scholar]

- Li, W.; Linag, C.; Zhou, W.; Qiu, J.; Sun, G.; Xin, Q. Preparation and Characterization of Multiwalled Carbon Nanotube-Supported Platinum for Cathode Catalysts of Direct Methanol Fuel Cells. J. Phys. Chem. B 2003, 107, 6292–6299. [Google Scholar] [CrossRef]

- Hajipour, M.H.; Fromm, K.M.; Ashkarran, A.A.; Aiba, S.; Aberasturi, D.J.A.; Larramendi, I.R.; Rojo, T.; Serpooshan, V.; Parak, W.J.; Mahmoudi, M. Antibacterial properties of nanoparticles. Trends Biotechnol. 2012, 30, 499–511. [Google Scholar] [CrossRef] [PubMed]

- Lai, H.Z.; Chen, W.Y.; Wu, C.Y.; Chen, Y.C. Potent antibacterial nanoparticles for pathogenic bacteria. ACS Appl. Mater. Interfaces 2015, 7, 2046–2054. [Google Scholar] [CrossRef] [PubMed]

- Guzman, G.; Dille, J.; Godet, S. Synthesis and antibacterial activity of silver nanoparticles against gram-positive and gram-negative bacteria. Nanomed. Nanotechnol. Biol. Med. 2012, 8, 37–45. [Google Scholar] [CrossRef] [PubMed]

- Tokiwa, Y.; Calabia, B.P.; Ugwu, C.U.; Aiba, S. Biodegradability of Plastics. Int. J. Mol. Sci. 2009, 10, 3722–3742. [Google Scholar] [CrossRef] [PubMed]

- Balanay, J.A.; Bartolucci, A.A.; Lungu, C.T. Adsorption characteristics of activated carbon fibers (ACFs) for toluene: Application in respiratory protection. J. Occup. Environ. Hyg. 2014, 33, 133–143. [Google Scholar] [CrossRef] [PubMed]

- Balanay, J.A.; Floyd, E.L.; Lungu, C.T. Breakthrough Curves for Toluene Adsorption on Different Types of Activated Carbon Fibers: Application in Respiratory Protection. Ann. Occup. Hyg. 2014, 59, 481–490. [Google Scholar] [PubMed]

- Míša, M.; Obšel, V. System for Measuring Permeation of Gases and Vapors through Barrier Membranes. Available online: https://1url.cz/Bty4h (accessed on 11 June 2018).

- ČSN EN 13274-2 (83 2205). Respiratory Protective Devices—Methods of Test—Part 2: Practical Performance Tests; Český Normalizační Institut: Praha, Czech Republic, 2001. [Google Scholar]

- ČSN EN 13274-3 (83 2205). Respiratory Protective Devices—Methods of Test—Part 3: Determination of Breathing Resistance; Český Normalizační Institut: Praha, Czech Republic, 2001. [Google Scholar]

- ČSN EN 149 (83 2225). Respiratory Protective Devices—Filtering Half Masks to Protect against Particles—Requirements, Testing, Marking; Český Normalizační Institut: Praha, Czech Republic, 2002. [Google Scholar]

- SRPS EN 60068-2-38 (34 5791). Environmental Testing—Part 2-38: Tests—Test Z/AD: Composite Temperature/Humidity Cyclic Test; Serbian Normalization Institute: Beograd, Serbia, 2010. [Google Scholar]

| Article No. | Weight | Thickness | Specific Surface Area | Typical Size/Roll | |

|---|---|---|---|---|---|

| Width | Length | ||||

| (g/m2) | (mm) | (m2/g) | (cm) | (m) | |

| ACC5092-10 | 200 | 0.65 | >800 | 115 | 35 |

| ACC5092-15 | 170 | 0.60 | >1300 | 110 | 35 |

| ACC5092-20 | 135 | 0.55 | >1800 | 105 | 35 |

| Testing Samples NANO for Water Filtration | ||

|---|---|---|

| Sample No. | Sample Specification Materials, Time, and Pressing Temperature | Results |

| VI | Nonwoven textile (NT) BICO Vigona (VIG) + NANO PVDF 140 °C, 30 s | Best |

| I | NT STRUTO (Jilana) JIL + NANO PA6 + NT STRUTO JIL 140 °C, 30 s | Good |

| IV | NANO PVDF + adsprption carbon textile (ACT) KYNOL + NT BICO VIG 140 °C, 30 s | Good |

| IX | NT BICO VIG + NANO PVDF + NT BICO VIG 140 °C, 30 s, lesser pressure | Good |

| X | Adsorption textile (AT) of the Filtration protective suit (hereinafter “FOP”) + NT BICO VIG + NANO PVDF 140 °C, 30 s | Best |

| Vll | AT FOP + NANO PVDF + AT FOP 140 °C 30 s | Good |

| V | AT FOP + NANO PVDF 140 °C, 30 s, lesser pressure | Bad |

| Effectivity of Paraffin Oil Aerosol Capture 0.4 μm at a Flow Rate of 30 L/min | |||||

| Sample | Permeation coefficient KP (%) | Average | |||

| 1 | 99.38 | 99.56 | 100.00 | 99.74 | 99.78 |

| 2 | 99.08 | 99.04 | 99.55 | 99.00 | 99.30 |

| 3 | 80.34 | 80.34 | 92.02 | 88.53 | 86.96 |

| Permeability at a Pressure of 140 Pa with an Area of 150 cm2 | |||||

| Sample | Flow (L/min) | ||||

| 1 | 99.30 | 93.60 | 84.30 | 95.90 | 93.28 |

| 2 | 202.00 | 205.00 | 244.00 | 206.00 | 214.28 |

| 3 | 450.00 | 479.00 | 478.00 | 468.25 | |

| Pressure Loss at Flow Rate of 200 L/min through the Material Surface 150 cm2 | |||||

| Sample | Pa | ||||

| 1 | 82.1 | 87.3 | 91.5 | 85.2 | 86.5 |

| 2 | 133.5 | 154.7 | 137.6 | 141.1 | 141.7 |

| 3 | 211.2 | 217.6 | 205.7 | 223.5 | 214.5 |

| Measured Part: Respirator | Number of Particles Surroundings | Number of Particles in Respirator | Fit Factor (Fc) | Uncertainty (extensive) 0.2·Fc |

|---|---|---|---|---|

| DEZA 3/1 + NT BICO FIB + nano PA6 | 33,571 | 348 | 97 | 19.4 |

| DEZA 3/2 + NT BICO FIB + nano PA-6 | 37,214 | 747 | 50 | 10 |

| DEZA 3/3 + NT BICO FIB + nano PA-6 | 37,143 | 706 | 48 | 9.6 |

| DEZA 3/4 + NT BICO FIB + nano PA-6 | 31,900 | 550 | 57 | 11.4 |

| DEZA 3/5 + NT BICO FIB+ nano PA-6 | 34,714 | 684 | 51 | 10.2 |

| NANOVIA 1 + NT BICO FIB + NVA nano | 35,100 | 1587 | 21 | 4.2 |

| NANOVIA 2 + NT BICO FIB + NVA nano | 35,429 | 2344 | 14 | 2.8 |

| NANOVIA 3 + NT BICO FIB + NVA nano | 36,800 | 1650 | 21 | 4.2 |

| DEZA 3/1 + AT FOP − outer site | 50,829 | 1176 | 42 | 8.4 |

| DEZA 3/2 + AT FOP − outer site | 53,343 | 786 | 67 | 13.4 |

| NT BICO FIB + AT FOP − outer site | 55,400 | 2596 | 20 | 4 |

| NT BICO FIB + AT FOP − outer site | 51,343 | 3344 | 14 | 2.8 |

| RESPIMASK − 12 | 42,914 | 1089 | 6.3 | 1.3 |

| DEZA 3/1 + AUT | 37,386 | 547 | 67 | 13.4 |

| Chemical Compounds | Heptane I | Heptane II | Ethanol I | Cyclohexanone | Acetone | Ethanol II | Heptane III |

|---|---|---|---|---|---|---|---|

| Input Concentration (ppm) | 1350 | 380 | 530 | 780 | 255 | 206.5 | 300 |

| Output Measured Concentration (mg/m3) | 10 | 3 | 28 | 3 | 13 | 10 | 54 |

| Conversion to a Given Substance | 1.2 | 1.2 | 2.41 | 1.36 | 1.61 | 2.41 | 1.2 |

| Time until Breakthrough (min) | 7 | 24 | 21 | 80 | 53 | 66 | 10 |

| Flow-input (L/min) | 2 | 1.6 | 4 | 1.4 | 3.5 | 3.4 | 3.2 |

| Convert to mg/m3 | 2168.6 | 610.4 | 851.4 | 1253.0 | 409.6 | 331.7 | 481.9 |

| Flow-input (L/min) | 0.6 | 0.43 | 0.6 | 0.54 | 0.55 | 0.6 | 0.56 |

| Desorption within Concentration (mg/m3) | 6826 | 2293 | 4556 | 3071 | 3348 | 2758 | 1870 |

| Efficiency | 9.5 | 99.5 | 96.7 | 99.8 | 96.8 | 97.0 | 88.8 |

| Time until Breakthrough | 7.0 | 24.0 | 21.0 | 80.0 | 53.0 | 66.0 | 10.0 |

| Force amounts | 14.0 | 38.4 | 84.0 | 112.0 | 185.5 | 224.4 | 32.0 |

| Amount of sorbed Substance | 36.4 | 28.1 | 172.4 | 190.9 | 122.3 | 179.4 | 18.5 |

| Conversion to 1 g of Sorbent | 8.7 | 6.7 | 41.0 | 45.4 | 29.1 | 42.7 | 4.4 |

| Degree of Concentration | 3.1 | 3.8 | 5.4 | 2.5 | 8.2 | 8.3 | 3.9 |

| Flow rate | 3.3 | 3.7 | 6.7 | 2.6 | 6.4 | 5.7 | 5.7 |

| Grade | |

|---|---|

| 0 | No growth apparent under a nominal magnification of 50×. |

| 1 | Traces of growth plainly visible under the microscope. |

| 2a | Sparse growth visible to the naked eye and/or under the microscope scattered only or localized to a few places covering all together not more than 5% of the test surface. |

| 2b | Growth plainly visible to the naked eye and/or under the microscope, distributed more or less homogenously on many places covering all together not more than 25% of the test surface. |

| 3 | Growth plainly visible to the naked eye and covering more than 25% of the test surface. |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Otrisal, P.; Obsel, V.; Buk, J.; Svorc, L. Preparation of Filtration Sorptive Materials from Nanofibers, Bicofibers, and Textile Adsorbents without Binders Employment. Nanomaterials 2018, 8, 564. https://doi.org/10.3390/nano8080564

Otrisal P, Obsel V, Buk J, Svorc L. Preparation of Filtration Sorptive Materials from Nanofibers, Bicofibers, and Textile Adsorbents without Binders Employment. Nanomaterials. 2018; 8(8):564. https://doi.org/10.3390/nano8080564

Chicago/Turabian StyleOtrisal, Pavel, Vladimir Obsel, Jan Buk, and Lubomír Svorc. 2018. "Preparation of Filtration Sorptive Materials from Nanofibers, Bicofibers, and Textile Adsorbents without Binders Employment" Nanomaterials 8, no. 8: 564. https://doi.org/10.3390/nano8080564

APA StyleOtrisal, P., Obsel, V., Buk, J., & Svorc, L. (2018). Preparation of Filtration Sorptive Materials from Nanofibers, Bicofibers, and Textile Adsorbents without Binders Employment. Nanomaterials, 8(8), 564. https://doi.org/10.3390/nano8080564