Mechanical Response of FeNiCrCoAl High-Entropy Alloys at the Nanoscale: Predictions from Molecular Dynamics

Abstract

1. Introduction

2. Methods

2.1. Interaction Model

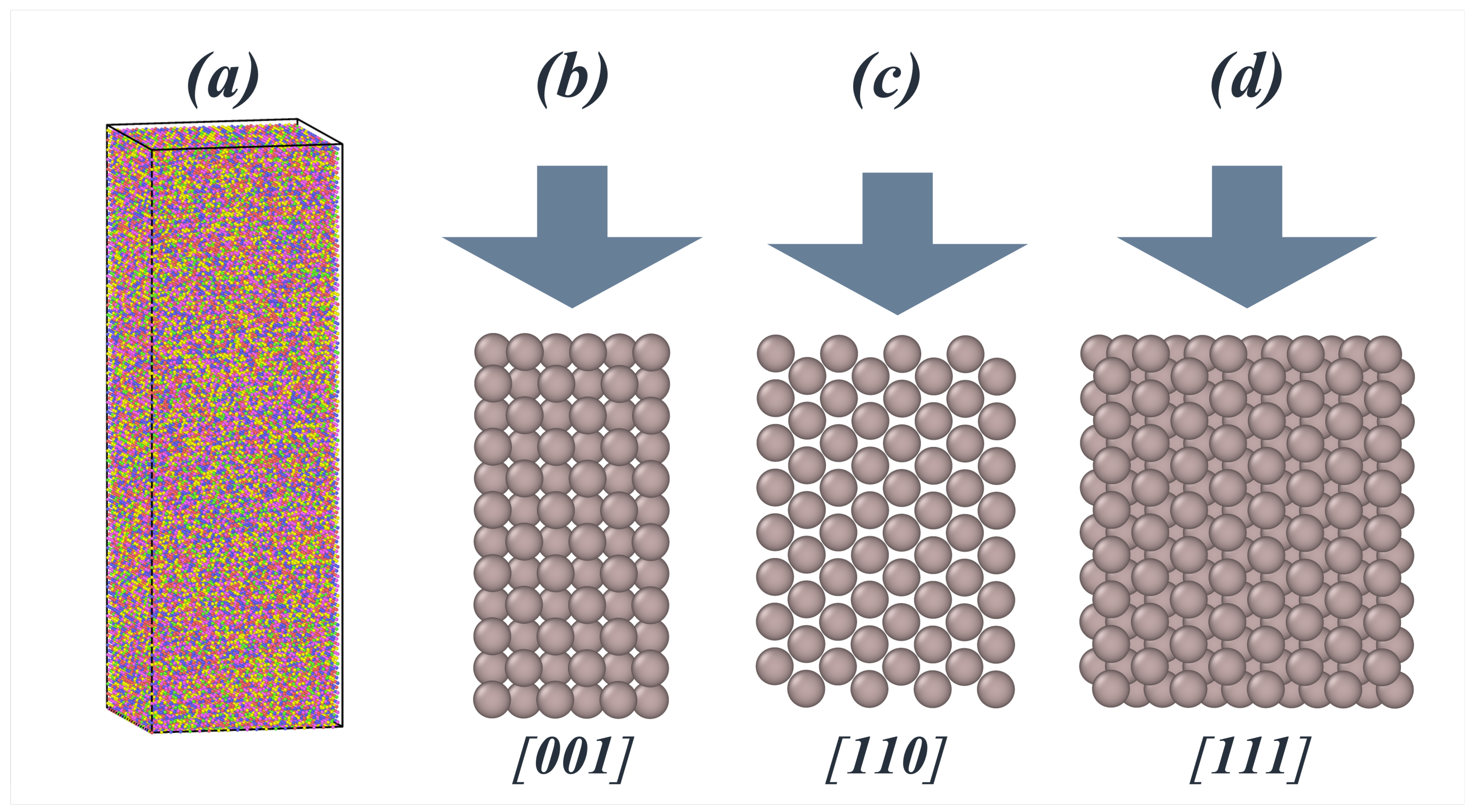

2.2. Building up the Systems

2.3. Simulation Procedure

2.4. Analysis

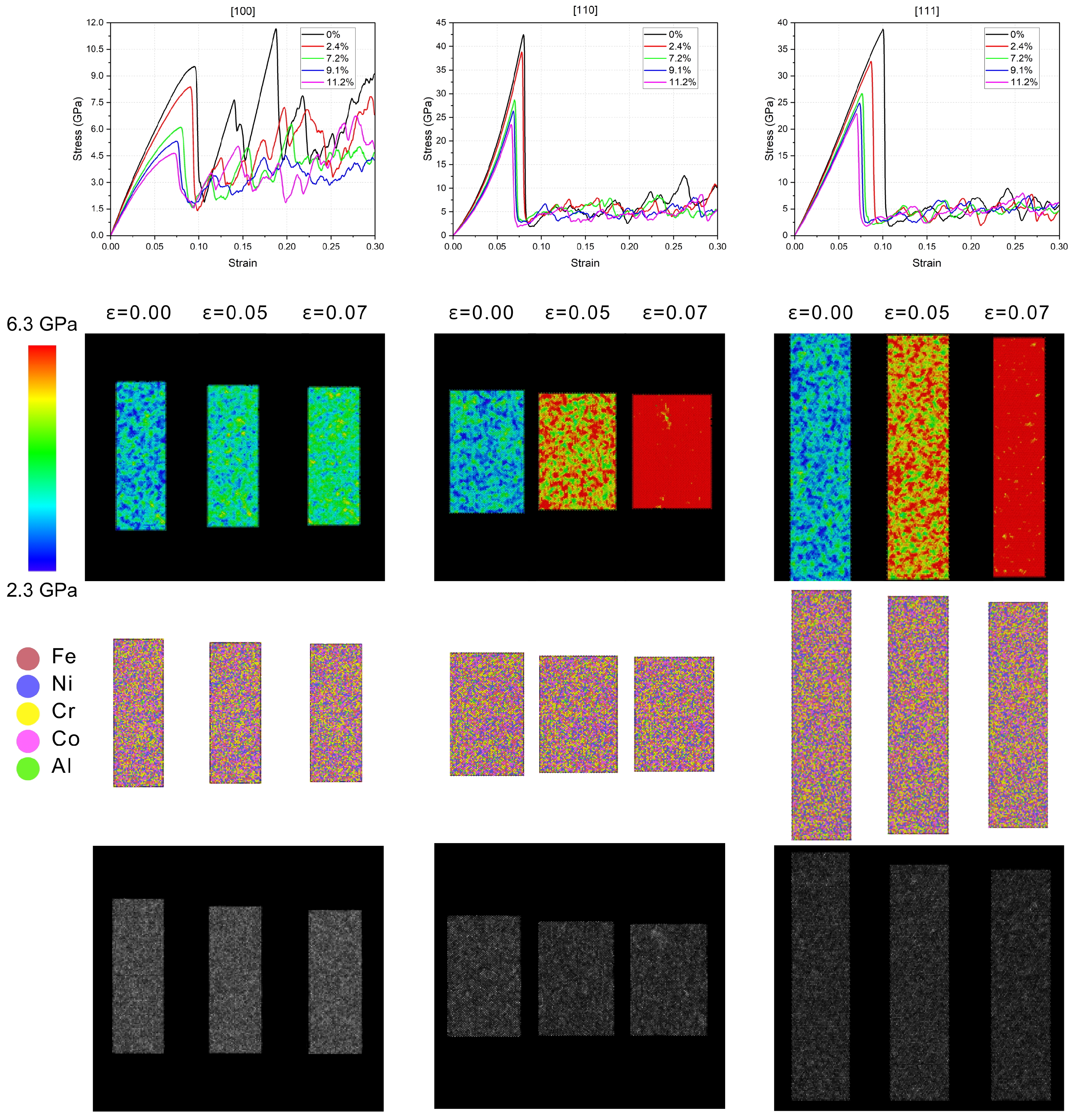

3. Results

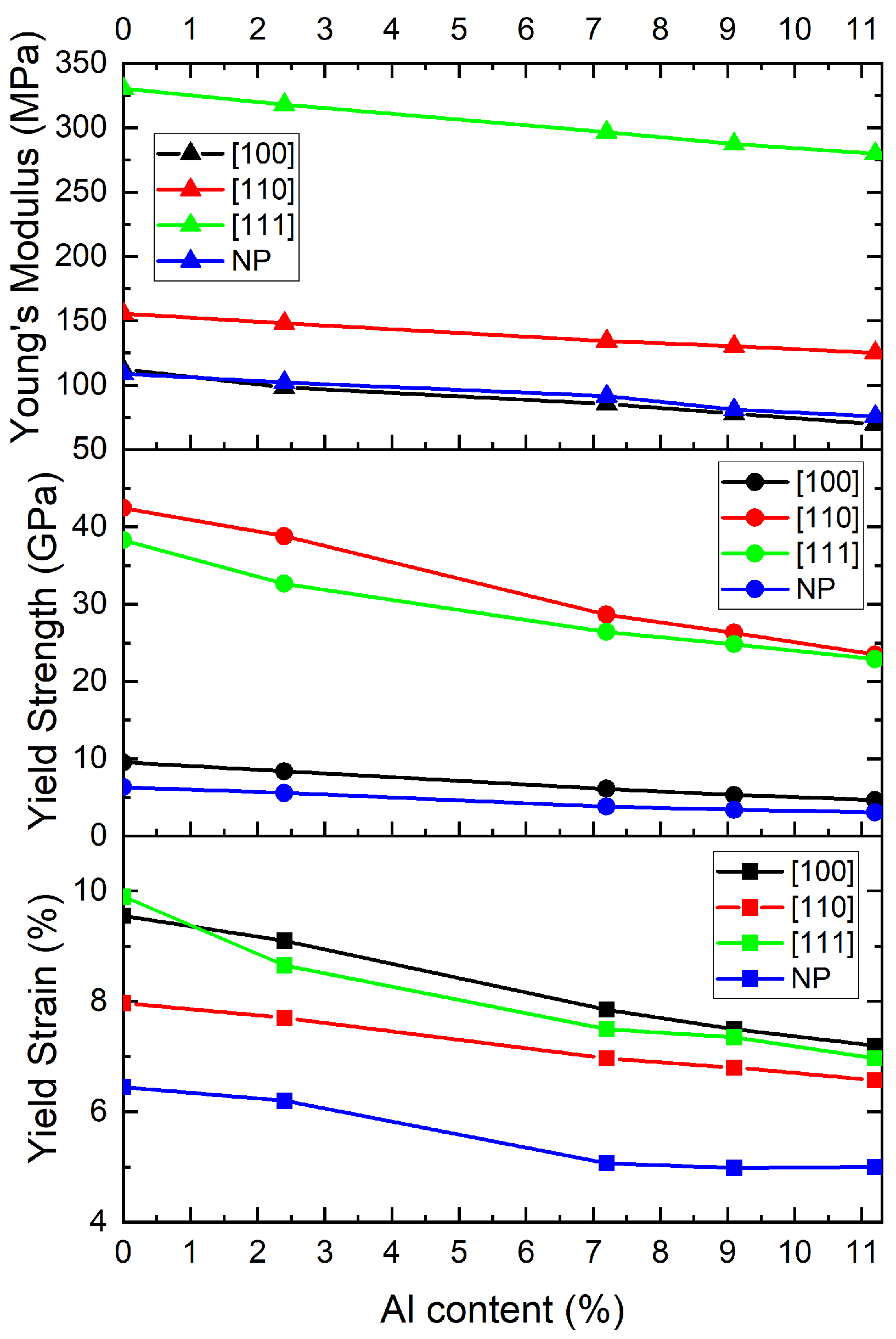

3.1. Elastic Regime

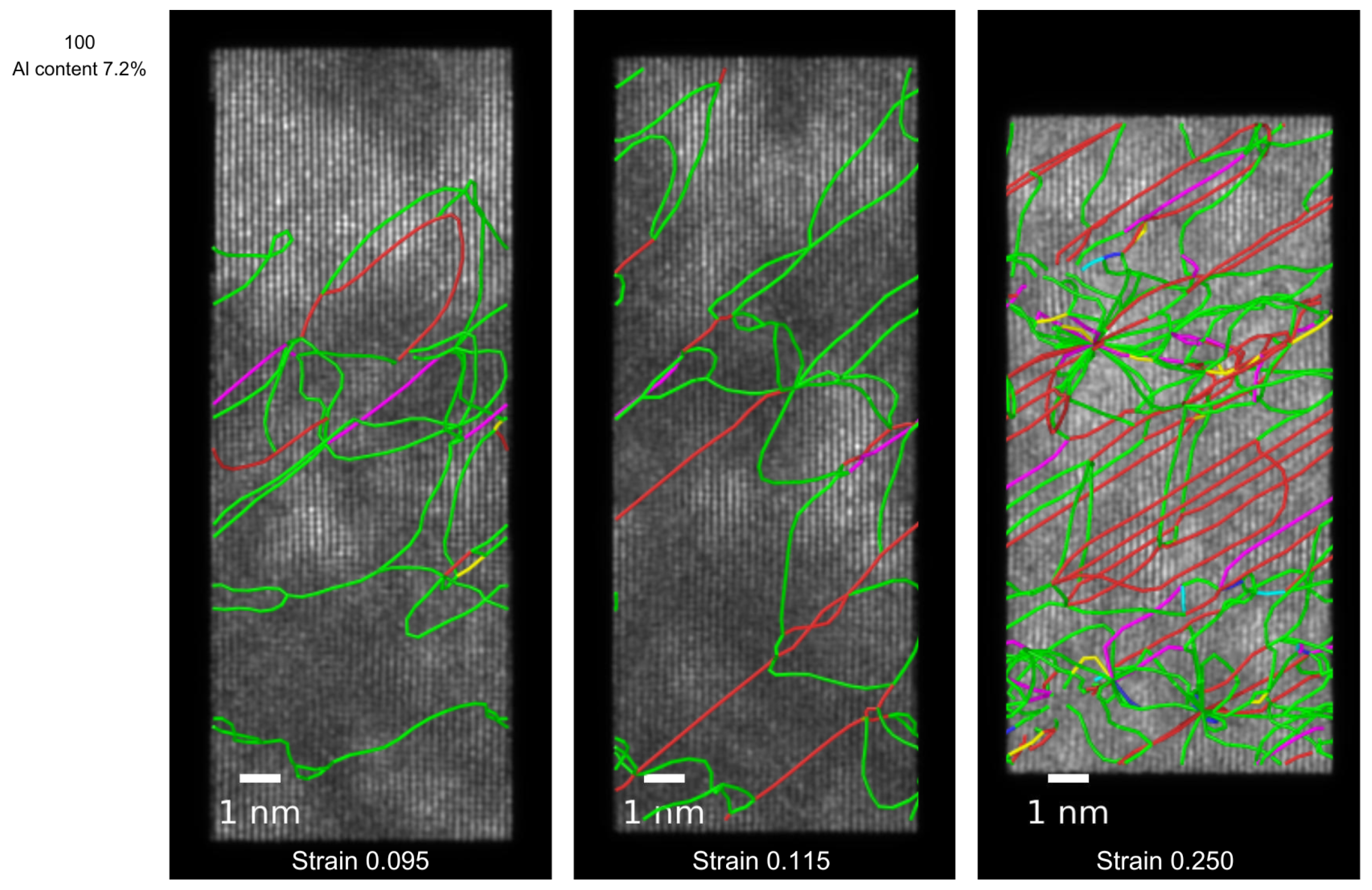

3.2. Plastic Regime

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Ma, Y.; He, J.; Zhou, L.; Zhang, K.; Gai, X.; Zhang, X. Mechanical Properties and Impact Energy Release Characteristics of Al0.5 NbZrTi1.5 Ta0.8 Ce0.85 High-Entropy Alloy. Mater. Res. Express 2022, 9, 116510. [Google Scholar] [CrossRef]

- Ma, Y.; Zhou, L.; Zhang, K.; Gai, X.; He, J.; Zhang, X. Effects of Cerium Doping on the Mechanical Properties and Energy-Releasing Behavior of High-Entropy Alloys. Materials 2022, 15, 7332. [Google Scholar] [CrossRef]

- Stepanov, N.; Shaysultanov, D.; Chernichenko, R.; Tikhonovsky, M.; Zherebtsov, S. Effect of Al on Structure and Mechanical Properties of Fe-Mn-Cr-Ni-Al Non-Equiatomic High Entropy Alloys with High Fe Content. J. Alloys Compd. 2019, 770, 194–203. [Google Scholar] [CrossRef]

- Chen, S.; Tong, Y.; Tseng, K.K.; Yeh, J.W.; Poplawsky, J.; Wen, J.; Gao, M.; Kim, G.; Chen, W.; Ren, Y.; et al. Phase Transformations of HfNbTaTiZr High-Entropy Alloy at Intermediate Temperatures. Scr. Mater. 2019, 158, 50–56. [Google Scholar] [CrossRef]

- Stepanov, N.; Shaysultanov, D.; Tikhonovsky, M.; Zherebtsov, S. Structure and High Temperature Mechanical Properties of Novel Non-Equiatomic Fe-(Co, Mn)-Cr-Ni-Al-(Ti) High Entropy Alloys. Intermetallics 2018, 102, 140–151. [Google Scholar] [CrossRef]

- Zhang, C.; Wang, H.; Wang, X.; Tang, Y.T.; Yu, Q.; Zhu, C.; Xu, M.; Zhao, S.; Kou, R.; Wang, X.; et al. Strong and Ductile Refractory High-Entropy Alloys with Super Formability. Acta Mater. 2023, 245, 118602. [Google Scholar] [CrossRef]

- Yeh, J.W.; Chen, S.K.; Lin, S.J.; Gan, J.Y.; Chin, T.S.; Shun, T.T.; Tsau, C.H.; Chang, S.Y. Nanostructured High-Entropy Alloys with Multiple Principal Elements: Novel Alloy Design Concepts and Outcomes. Adv. Eng. Mater. 2004, 6, 299–303. [Google Scholar] [CrossRef]

- Farkas, D.; Caro, A. Model Interatomic Potentials for Fe–Ni–Cr–Co–Al High-Entropy Alloys. J. Mater. Res. 2020, 35, 3031–3040. [Google Scholar] [CrossRef]

- Achmad, T.L.; Wibowo, P.A.; Sukma, F.T. Design of High Entropy Superalloy FeNiCrCoAl Using Molecular Dynamics, Computational Thermodynamics, and Machine Learning. J. Alloys Compd. 2025, 1010, 177514. [Google Scholar] [CrossRef]

- Luo, L.; Wu, J. Molecular Dynamics Study on Nanoscale Scratch Characteristics of FeNiCrCoAl High-Entropy Alloy. Aip Adv. 2023, 13, 085227. [Google Scholar] [CrossRef]

- Vailhé, C.; Farkas, D. Shear Faults and Dislocation Core Structures in B2 CoAl. J. Mater. Res. 1997, 12, 2559–2570. [Google Scholar] [CrossRef]

- Mishin, Y.; Farkas, D.; Mehl, M.J.; Papaconstantopoulos, D.A. Interatomic Potentials for Monoatomic Metals from Experimental Data and Ab Initio Calculations. Phys. Rev. 1999, 59, 3393–3407. [Google Scholar] [CrossRef]

- Purja Pun, G.P.; Yamakov, V.; Mishin, Y. Interatomic Potential for the Ternary Ni–Al–Co System and Application to Atomistic Modeling of the B2–L10 Martensitic Transformation. Model. Simul. Mater. Sci. Eng. 2015, 23, 065006. [Google Scholar] [CrossRef]

- Thompson, A.P.; Aktulga, H.M.; Berger, R.; Bolintineanu, D.S.; Brown, W.M.; Crozier, P.S.; In ’T Veld, P.J.; Kohlmeyer, A.; Moore, S.G.; Nguyen, T.D.; et al. LAMMPS—A Flexible Simulation Tool for Particle-Based Materials Modeling at the Atomic, Meso, and Continuum Scales. Comput. Phys. Commun. 2022, 271, 108171. [Google Scholar] [CrossRef]

- Koh, S.J.A.; Lee, H.P. Molecular Dynamics Simulation of Size and Strain Rate Dependent Mechanical Response of FCC Metallic Nanowires. Nanotechnology 2006, 17, 3451–3467. [Google Scholar] [CrossRef]

- Li, H.; Du, W.; Liu, Y. Molecular Dynamics Study of Tension Process of Ni-Based Superalloy. Acta Metall. Sin. (Engl. Lett.) 2020, 33, 741–750. [Google Scholar] [CrossRef]

- Stukowski, A. Visualization and Analysis of Atomistic Simulation Data with OVITO–the Open Visualization Tool. Model. Simul. Mater. Sci. Eng. 2009, 18, 015012. [Google Scholar] [CrossRef]

- Stukowski, A.; Bulatov, V.V.; Arsenlis, A. Automated Identification and Indexing of Dislocations in Crystal Interfaces. Model. Simul. Mater. Sci. Eng. 2012, 20, 085007. [Google Scholar] [CrossRef]

- Larsen, P.M.; Schmidt, S.; Schiøtz, J. Robust Structural Identification via Polyhedral Template Matching. Model. Simul. Mater. Sci. Eng. 2016, 24, 055007. [Google Scholar] [CrossRef]

- Honeycutt, J.D.; Andersen, H.C. Molecular Dynamics Study of Melting and Freezing of Small Lennard-Jones Clusters. J. Phys. Chem. 1987, 91, 4950–4963. [Google Scholar] [CrossRef]

- Kilymis, D.; Gérard, C.; Pizzagalli, L. Ductile Deformation of Core-Shell Si-SiC Nanoparticles Controlled by Shell Thickness. Acta Mater. 2019, 164, 560–567. [Google Scholar] [CrossRef]

- Olguín-Orellana, G.J.; De La Rosa Abad, J.A.; Camarada, M.B.; Mejía-Rosales, S.J.; Alzate-Morales, J.; Mariscal, M.M. On the Mechanical Response of Graphene-Capped Copper Nanoparticles. Phys. Chem. Chem. Phys. 2024, 26, 2260–2268. [Google Scholar] [CrossRef] [PubMed]

- Rangel DaCosta, L.; Brown, H.G.; Pelz, P.M.; Rakowski, A.; Barber, N.; O’Donovan, P.; McBean, P.; Jones, L.; Ciston, J.; Scott, M.; et al. Prismatic 2.0 – Simulation Software for Scanning and High Resolution Transmission Electron Microscopy (STEM and HRTEM). Micron 2021, 151, 103141. [Google Scholar] [CrossRef]

- Brown, W.M.; Wang, P.; Plimpton, S.J.; Tharrington, A.N. Implementing Molecular Dynamics on Hybrid High Performance Computers – Short Range Forces. Comput. Phys. Commun. 2011, 182, 898–911. [Google Scholar] [CrossRef]

- Chen, W.; Fu, Z.; Fang, S.; Xiao, H.; Zhu, D. Alloying Behavior, Microstructure and Mechanical Properties in a FeNiCrCo0.3Al0.7 High Entropy Alloy. Mater. Des. 2013, 51, 854–860. [Google Scholar] [CrossRef]

- Deng, Y.; Song, H. Atomic Simulation for the Effect of Short-Range Order and Twin Boundary on Mechanical Behavior of FeNiCrCoAl High-Entropy Alloys. J. Mater. Res. Technol. 2024, 33, 7147–7156. [Google Scholar] [CrossRef]

- Jiang, J.; Chen, P.; Qiu, J.; Sun, W.; Saikov, I.; Shcherbakov, V.; Alymov, M. Microstructural Evolution and Mechanical Properties of AlxCoCrFeNi High-Entropy Alloys under Uniaxial Tension: A Molecular Dynamics Simulations Study. Mater. Today Commun. 2021, 28, 102525. [Google Scholar] [CrossRef]

- Yuan, L.; Tao, R.; Wen, P.; Li, J.; Wang, S.; Li, D. Molecular Dynamics Simulation of Chemical Short-Range Order Strengthening in FCC FeNiCrCoAl Alloys. Phys. Condens. Matter 2023, 649, 414447. [Google Scholar] [CrossRef]

- Li, Q.J.; Sheng, H.; Ma, E. Strengthening in Multi-Principal Element Alloys with Local-Chemical-Order Roughened Dislocation Pathways. Nat. Commun. 2019, 10, 3563. [Google Scholar] [CrossRef]

- Cao, P. Maximum Strength and Dislocation Patterning in Multi–Principal Element Alloys. Sci. Adv. 2022, 8, eabq7433. [Google Scholar] [CrossRef]

- Jian, W.R.; Xie, Z.; Xu, S.; Su, Y.; Yao, X.; Beyerlein, I.J. Effects of Lattice Distortion and Chemical Short-Range Order on the Mechanisms of Deformation in Medium Entropy Alloy CoCrNi. Acta Mater. 2020, 199, 352–369. [Google Scholar] [CrossRef]

- Yang, X.; Xi, Y.; He, C.; Chen, H.; Zhang, X.; Tu, S. Chemical Short-Range Order Strengthening Mechanism in CoCrNi Medium-Entropy Alloy under Nanoindentation. Scr. Mater. 2022, 209, 114364. [Google Scholar] [CrossRef]

- Woodgate, C.D.; Marchant, G.A.; Pártay, L.B.; Staunton, J.B. Structure, Short-Range Order, and Phase Stability of the AlxCrFeCoNi High-Entropy Alloy: Insights from a Perturbative, DFT-based Analysis. npj Comput. Mater. 2024, 10, 271. [Google Scholar] [CrossRef]

- Cai, W.; Bulatob, V.V.; Chang, J.; Li, J.; Yip, S. Periodic Image Effects in Dislocation Modelling. Philos. Mag. 2003, 83, 539–567. [Google Scholar] [CrossRef]

- Madec, R.; Devincre, B.; Kubin, L. On the Use of Periodic Boundary Conditions in Dislocation Dynamics Simulations. In IUTAM Symposium on Mesoscopic Dynamics of Fracture Process and Materials Strength; Gladwell, G.M.L., Kitagawa, H., Shibutani, Y., Eds.; Springer: Dordrecht, The Netherlands, 2004; Volume 115, pp. 35–44. [Google Scholar] [CrossRef]

- Shima, K.; Izumi, S.; Sakai, S. Reaction Pathway Analysis for Dislocation Nucleation from a Sharp Corner in Silicon: Glide Set versus Shuffle Set. J. Appl. Phys. 2010, 108, 063504. [Google Scholar] [CrossRef]

- Li, C.; Li, J.; Zhao, M.; Jiang, Q. Effect of Alloying Elements on Microstructure and Properties of Multiprincipal Elements High-Entropy Alloys. J. Alloys Compd. 2009, 475, 752–757. [Google Scholar] [CrossRef]

| Material | This Work | Literature/Experimental | |

|---|---|---|---|

| Fe | 189.99 | 153.8 [11], 154 [12] | |

| Ni | 247.99 | 246.5 | |

| Cr | 198.76 | 410.7 | |

| Co | 264.63 | 260.225 [13] | |

| Fe | 159.24 | 121.76 [11], 122 [12] | |

| Ni | 147.87 | 147.3 | |

| Cr | 140.52 | 106.7 | |

| Co | 191.69 | 160.186 [13] | |

| Fe | 76.86 | 76.9 [11], 77 [12] | |

| Ni | 125.04 | - | |

| Cr | 111.73 | 105 | |

| Co | 142.06 | 110.92 [13] | |

| Bulk Modulus | Fe | 169.49 | - |

| Ni | 181.24 | - | |

| Cr | 159.94 | - | |

| Co | 216.008 | - | |

| Shear Modulus ([100] plane) | Fe | 76.86 | - |

| Ni | 125.04 | - | |

| Cr | 111.73 | - | |

| Co | 142.06 | - | |

| Shear Modulus ([110] plane) | Fe | 15.37 | - |

| Ni | 50.05 | - | |

| Cr | 29.11 | - | |

| Co | 36.46 | - | |

| Poisson Ratio | Fe | 0.455 | - |

| Ni | 0.373 | - | |

| Cr | 0.414 | - | |

| Co | 0.42 | - |

| Orientation | Al Content | Main Features |

|---|---|---|

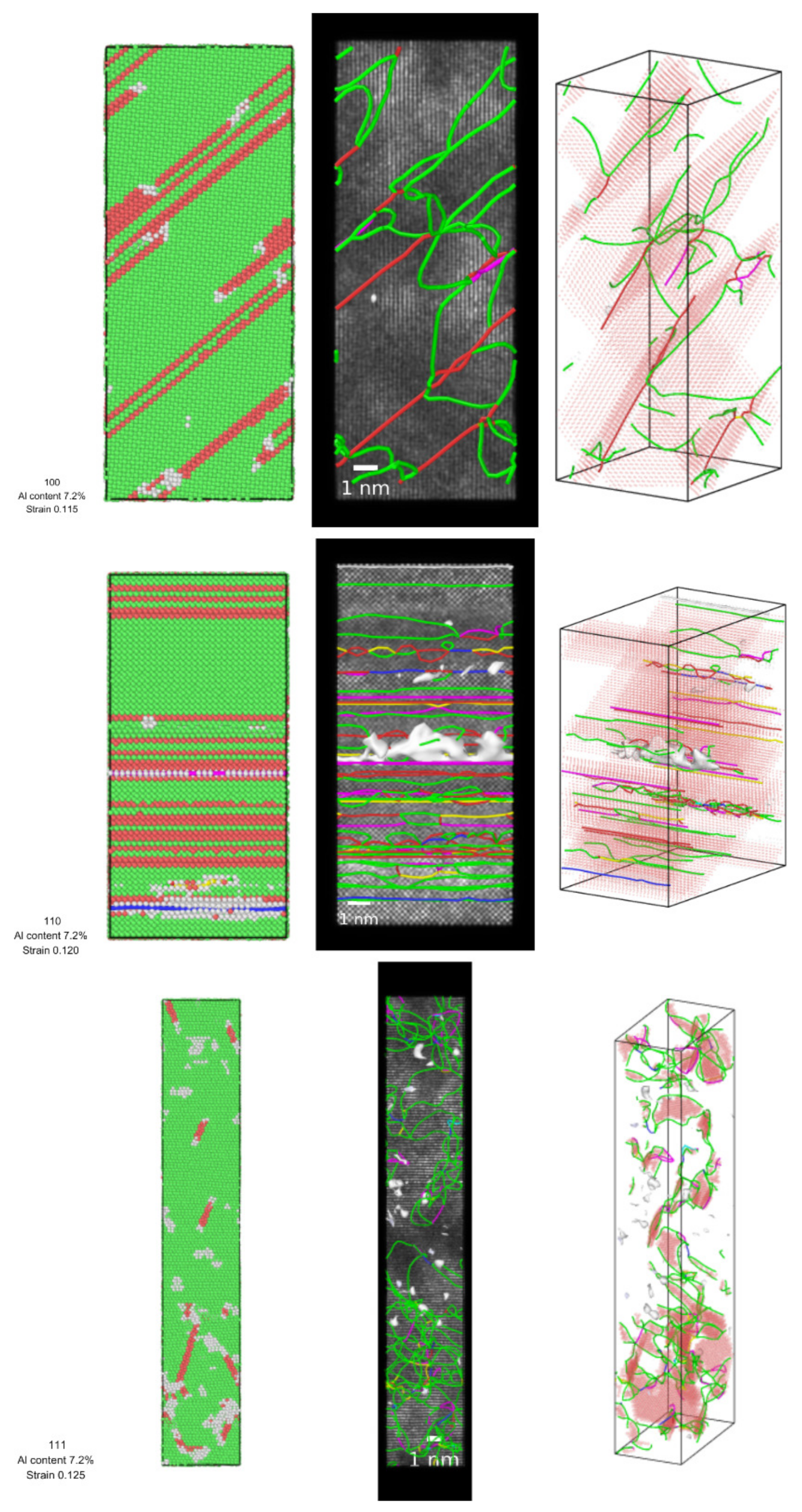

| [100] | 0% | First dislocation at 9.5%, HCP lamellae form in a honeycomb pattern, BCC at 6.3%, nanotwins at 9.74% |

| 2.4% | Dislocations at 9.05%, more ductility, nanotwins at 9.25% but more diffuse | |

| 7.2% | HCP disrupted by dislocations, nanotwins at 8.3% in a zigzag pattern | |

| 9.1% | FCC structures appear and disappear until 17.45% compression, nanotwins fluctuate before stabilizing | |

| 11.2% | More amorphous regions, lower structural stability, decreased elastic modulus | |

| [110] | 0% | No dislocations in elastic regime, sudden and dense dislocations at plastic transition, minimal BCC, stable FCC |

| 2.4% | Similar to 0% Al, but increased ductility | |

| 7.2% | Dual orientation nanotwins, more structural diffusion | |

| 9.1% | HCP lamellae interconnect, dislocations travel through amorphous structures, nanotwins diminish at high strain | |

| 11.2% | Nanotwins form instantly at elastic limit but destabilize over compression | |

| [111] | 0% | High dislocation density, FCC stable in elastic regime, amorphous structures form but retain orientation |

| 2.4% | FCC retains stability, nanotwins weak at plastic transition, BCC appears but remains unstable | |

| 7.2% | HCP/amorphous formations more aggressive, stable nanotwins appear but disappear after 15% compression | |

| 9.1% | Dislocations cluster in the lower simulation box, increased amorphous and HCP fractions | |

| 11.2% | Higher structural diffusion, unstable HCP lamellae, frequent FCC reversion | |

| Nanoparticle | 0% | Dislocations intermittently appear and disappear, allowing localized stability |

| 2.4% | Higher aluminum promotes greater amorphous and HCP diffusion | |

| 7.2% | Nanotwins connect distinct regions, linked by thin HCP lamellae | |

| 9.1% | Central nanotwin replaces original FCC, minimal branching | |

| 11.2% | Rapid structural reorganization, amorphous structures dominate, increased plasticity |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Amaro, E.; Delgado-Alvarez, J.; Martínez-Uribe, J.A.; Mejía-Rosales, S. Mechanical Response of FeNiCrCoAl High-Entropy Alloys at the Nanoscale: Predictions from Molecular Dynamics. Nanomaterials 2025, 15, 652. https://doi.org/10.3390/nano15090652

Amaro E, Delgado-Alvarez J, Martínez-Uribe JA, Mejía-Rosales S. Mechanical Response of FeNiCrCoAl High-Entropy Alloys at the Nanoscale: Predictions from Molecular Dynamics. Nanomaterials. 2025; 15(9):652. https://doi.org/10.3390/nano15090652

Chicago/Turabian StyleAmaro, Ernesto, Joaly Delgado-Alvarez, Jairo Andrés Martínez-Uribe, and Sergio Mejía-Rosales. 2025. "Mechanical Response of FeNiCrCoAl High-Entropy Alloys at the Nanoscale: Predictions from Molecular Dynamics" Nanomaterials 15, no. 9: 652. https://doi.org/10.3390/nano15090652

APA StyleAmaro, E., Delgado-Alvarez, J., Martínez-Uribe, J. A., & Mejía-Rosales, S. (2025). Mechanical Response of FeNiCrCoAl High-Entropy Alloys at the Nanoscale: Predictions from Molecular Dynamics. Nanomaterials, 15(9), 652. https://doi.org/10.3390/nano15090652