Bipolar Switching Properties and Reaction Decay Effect of BST Ferroelectric Thin Films for Applications in Resistance Random Access Memory Devices

Abstract

1. Introduction

2. Experiment

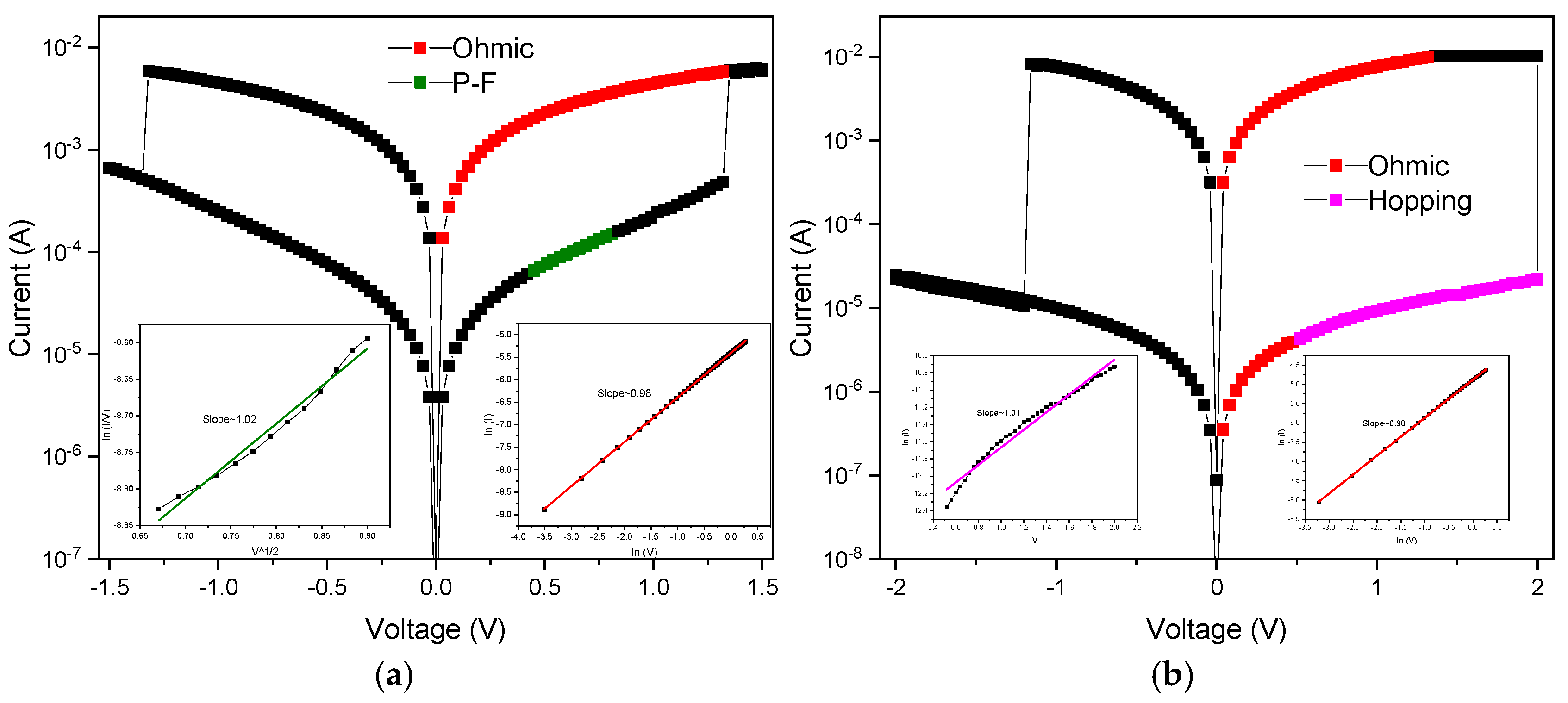

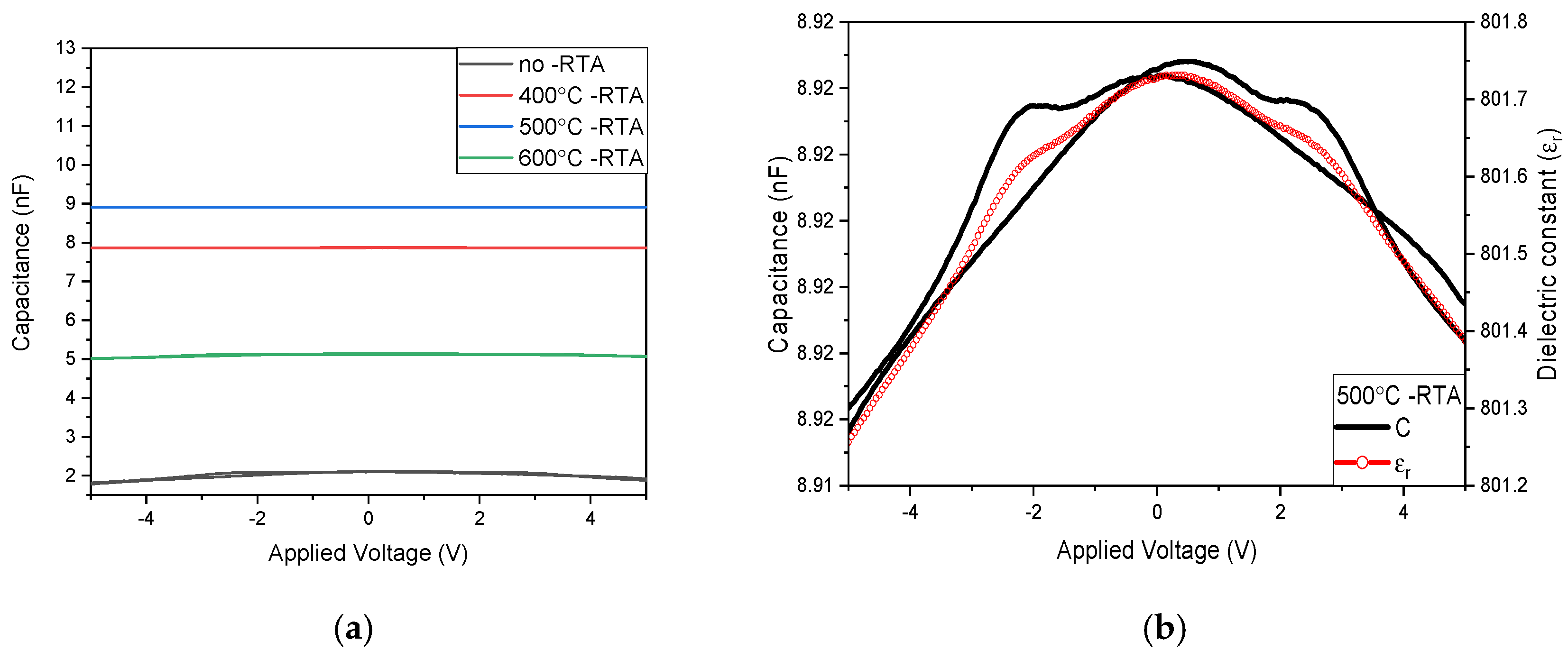

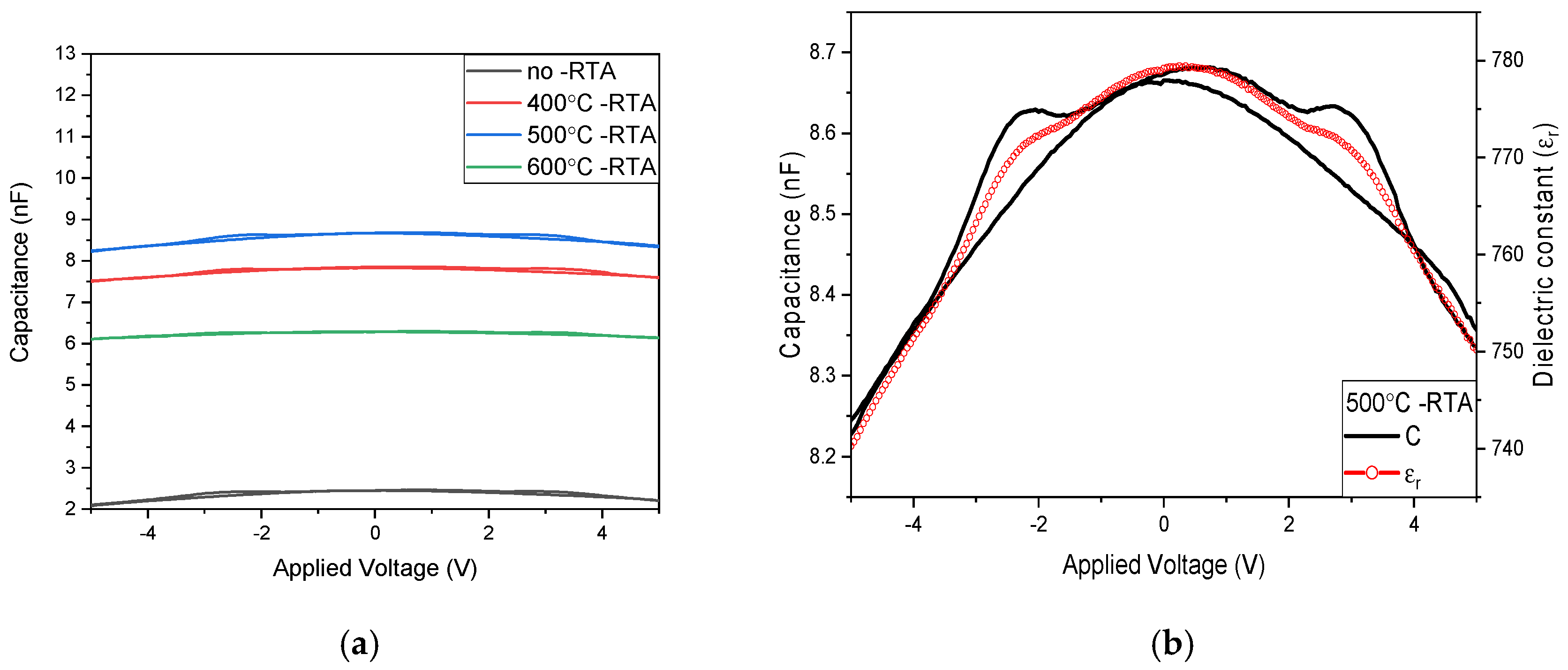

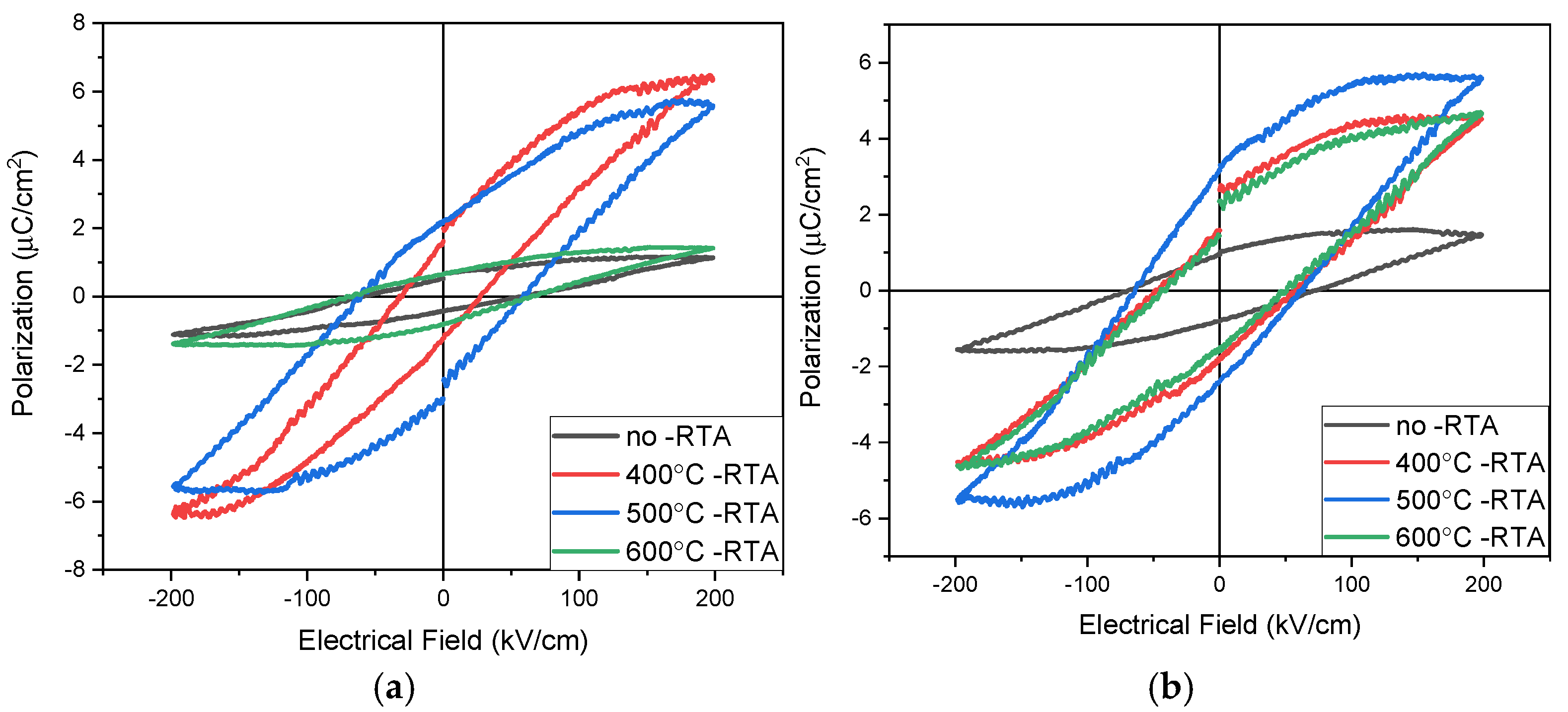

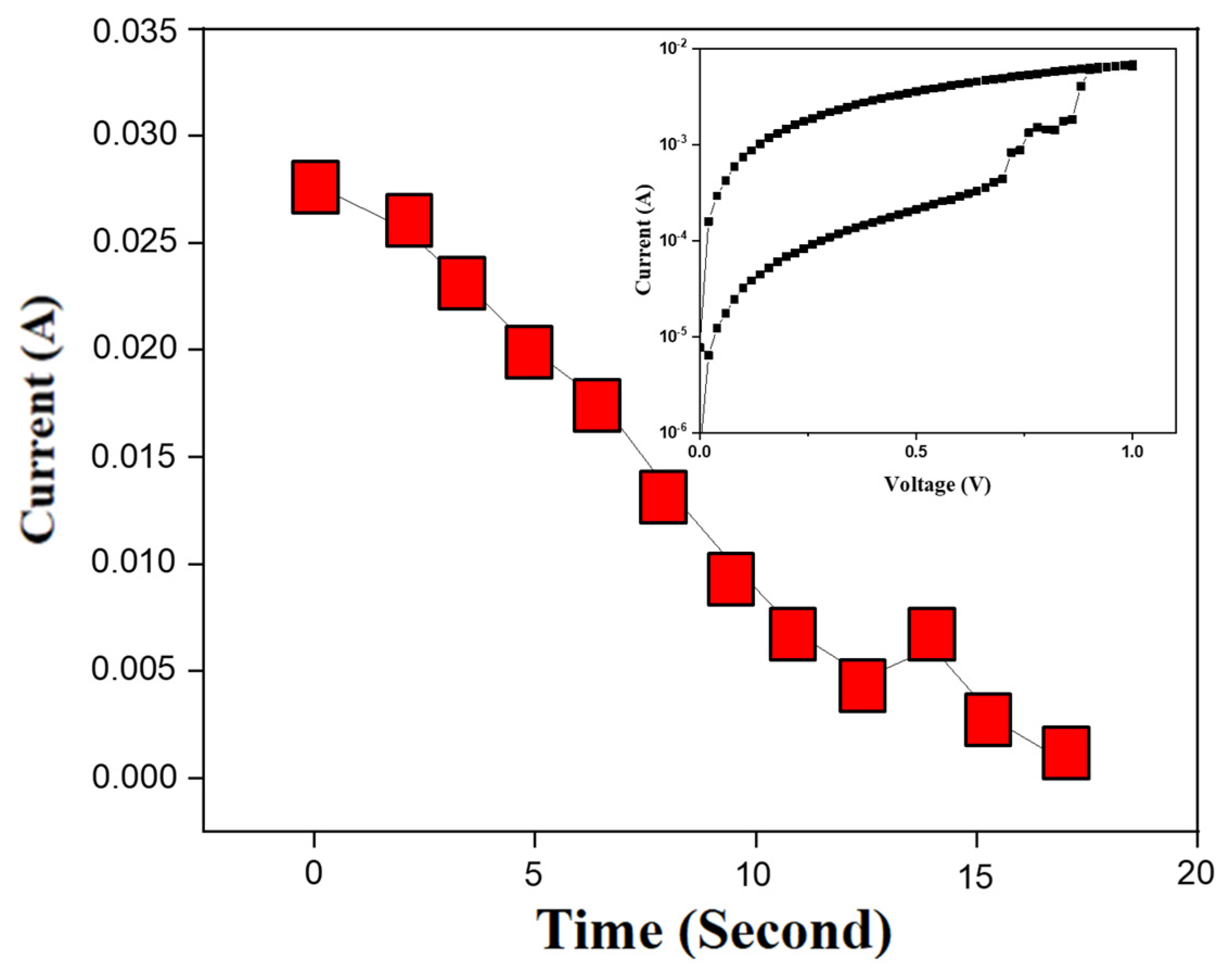

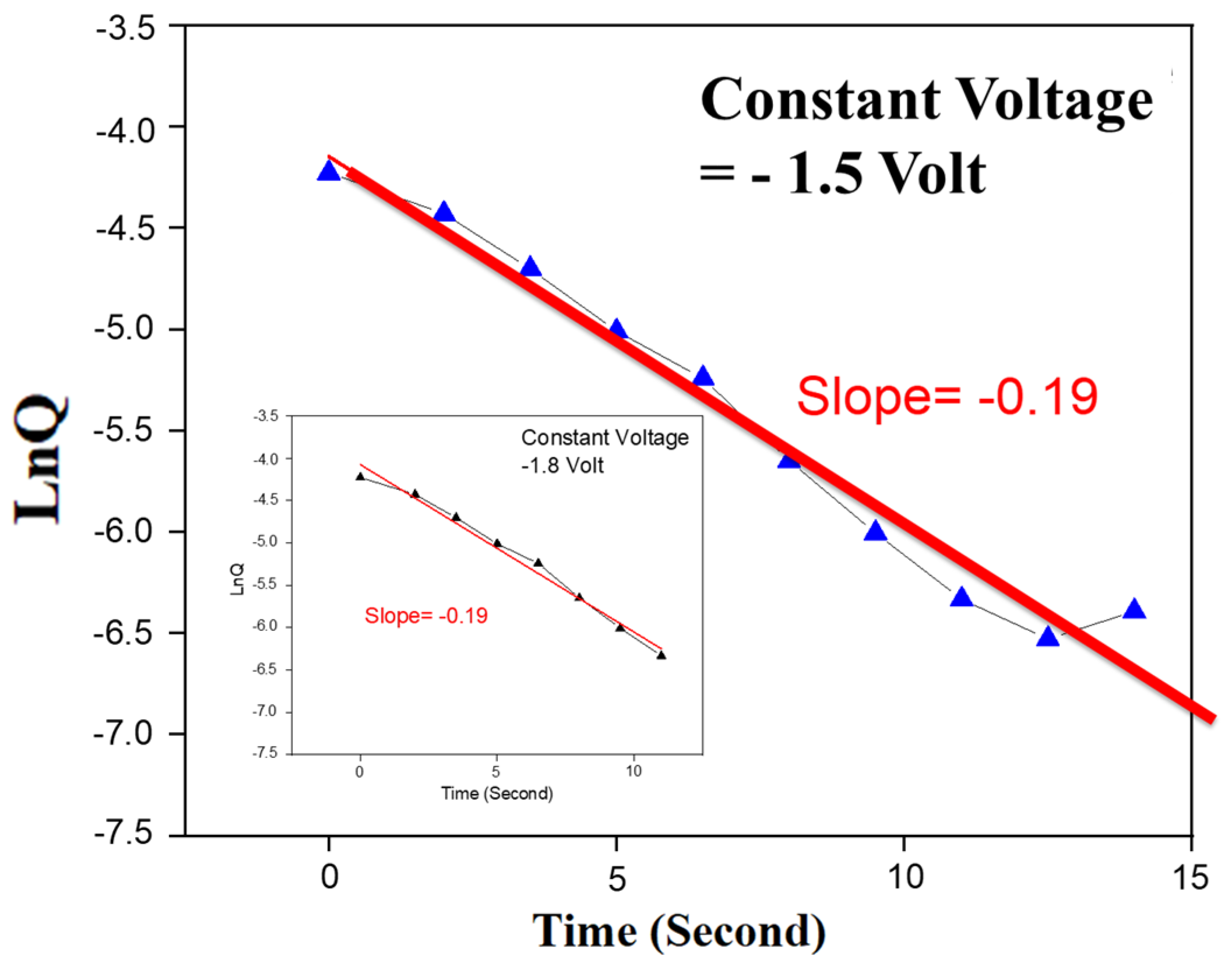

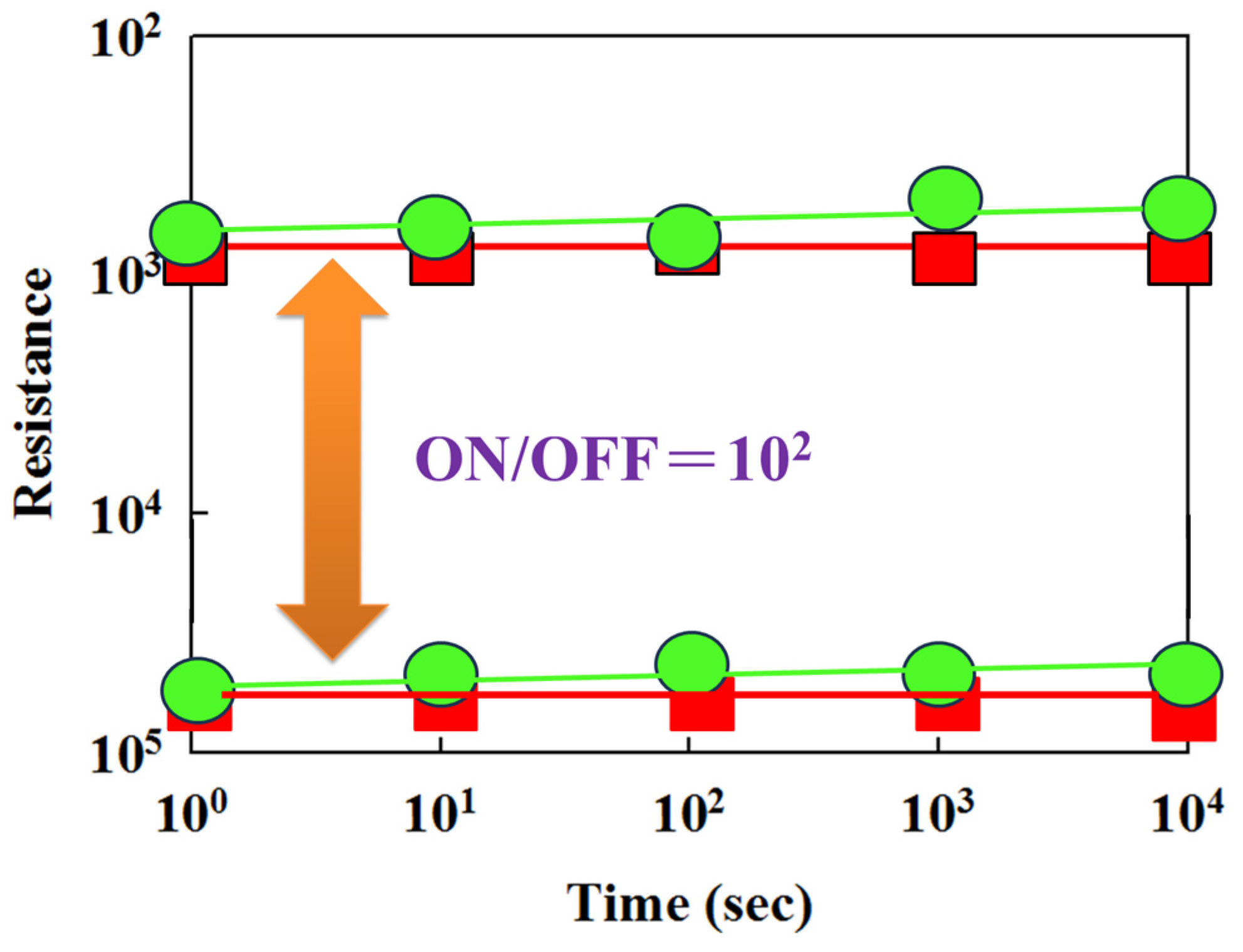

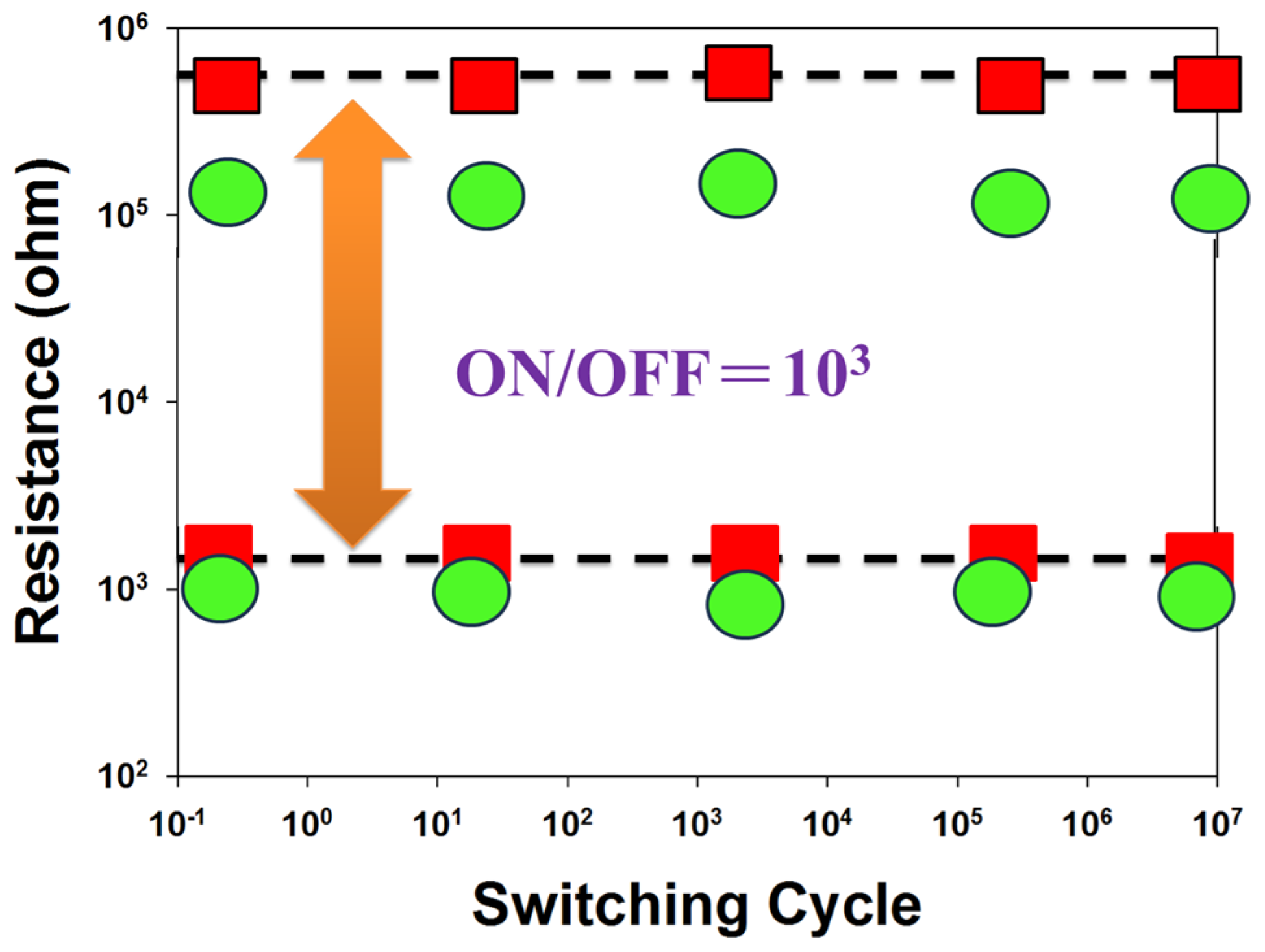

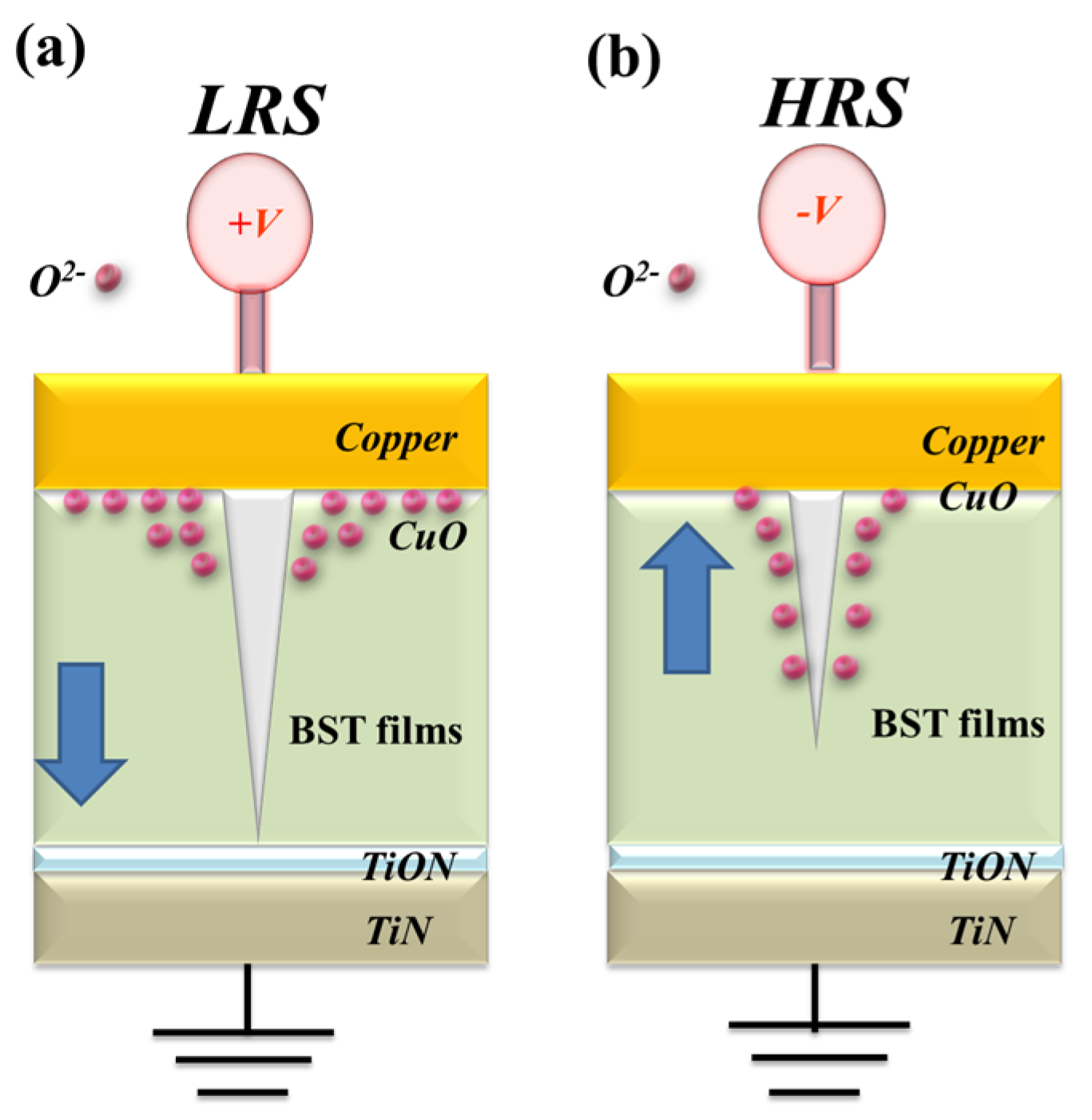

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Li, L.; Dai, T.J.; Liu, K.; Chang, K.C.; Zhang, R.; Lin, X.; Liu, H.J.; Lai, Y.C.; Kuo, T.P. Achieving complementary resistive switching and multi-bit storage goals by modulating the dual-ion reaction through supercritical fluid-assisted ammoniation. Nanoscale 2021, 13, 14035–14040. [Google Scholar] [CrossRef]

- Li, L.; Chang, K.C.; Zhang, R.; Lin, X.; Lai, Y.C.; Kuo, T.P. Variable-temperature activation energy extraction to clarify the physical and chemical mechanisms of the resistive switching process. Nanoscale 2020, 12, 15721–15724. [Google Scholar] [CrossRef]

- Li, L.; Chang, K.C.; Ye, C.; Lin, X.; Zhang, R.; Xu, Z.; Xiong, W.; Zhou, Y.; Kuo, T.P. An Indirect Way to Achieve Comprehensive Performance Improvement of Resistive Memory: When Hafnium Meets ITO in Electrode. Nanoscale 2020, 12, 3267–3272. [Google Scholar] [CrossRef]

- Chang, K.C.; Dai, T.J.; Li, L.; Lin, X.N.; Zhang, S.D.; Lai, Y.C.; Liu, H.J.; Syu, Y.E. Unveiling the influence of surrounding materials and realization of multi-level storage in resistive switching memory. Nanoscale 2020, 12, 22070–22074. [Google Scholar] [CrossRef]

- Chang, K.C.; Zhang, R.; Chang, T.C.; Tsai, T.M.; Chu, T.J.; Chen, H.L.; Shih, C.C.; Pan, C.H.; Su, Y.T.; Wu, P.J.; et al. High performance, excellent reliability multifunctional graphene oxide doped memristor achieved by self-protective compliance current structure. In Proceedings of the IEEE International Electron Devices Meeting (IEDM), San Francisco, CA, USA, 15–17 December 2014; pp. 33–34. [Google Scholar]

- Ye, C.; Xu, Z.; Chang, K.C.; Li, L.; Lin, X.N.; Zhang, R.; Zhou, Y.; Xiong, W.; Kuo, T.P. Hafnium nanocrystals observed in a HfTiO compound film bring about excellent performance of flexible selectors in memory integration. Nanoscale 2019, 11, 20792–20796. [Google Scholar] [CrossRef]

- Hao, C.; Peng, J.; Zierold, R.; Blick, R.H. Atomic Layer Deposition Films for Resistive Random-Access Memories. Adv. Mater. Technol. 2024, 9, 2301762. [Google Scholar] [CrossRef]

- Nithya, N.; Paramasivam, K. MINI Logic 1-Bit Adder: A Comparison with Hybrid NMOS-Memristor-Logic Styles Using Ta2O5/Al2O3 Based RRAM Device. Adv. Electr. Comput. Eng. 2024, 24, 33–44. [Google Scholar] [CrossRef]

- Kumar, S.; Yadav, D.; Ramesh, R.; Stathopoulos, S.; Tsiamis, A.; Prodromakis, T. Electrical Analysis of Atomic Layer Deposited Thin HfO2 and HfO2/Ta2O5-Based Memristive Devices. IEEE Trans. Electron Devices 2025, 72, 1780–1787. [Google Scholar] [CrossRef]

- Mohanty, S.K.; Reddy, K.P.K.; Wu, C.H.; Lee, P.T.; Chang, K.M.; Busa, P.; Kuthati, Y. Investigation of Barrier Layer Effect on Switching Uniformity and Synaptic Plasticity of AlN Based Conductive Bridge Random Access Memory. Electronics 2022, 11, 3432. [Google Scholar] [CrossRef]

- Gan, K.J.; Liu, P.T.; Lin, S.J.; Ruan, D.B.; Chien, T.C.; Chiu, Y.C.; Sze, S.M. Bipolar Resistive Switching Characteristics of Tungsten-Doped Indium–Zinc oxide Conductive-Bridging Random Access Memory. Vacuum 2019, 166, 226–230. [Google Scholar] [CrossRef]

- Chen, K.-H.; Cheng, C.-M.; Wang, N.-F.; Hung, H.-W.; Li, C.-Y.; Wu, S. First Order Rate Law Analysis for Reset State in Vanadium Oxide Thin Film Resistive Random Access Memory Devices. Nanomaterials 2023, 13, 198. [Google Scholar] [CrossRef]

- Chekol, S.A.; Menzel, S.; Ahmad, R.W.; Waser, R.; Eifert, S.H. Effect of the Threshold Kinetics on the Filament Relaxation Behavior of Ag-Based Diffusive Memristors. Adv. Funct. Mater. 2021, 32, 2111242. [Google Scholar] [CrossRef]

- Yu, S.; Chen, P.Y. Emerging Memory Technologies: Recent Trends and Prospects. IEEE Solid-State Circuits Mag. 2016, 8, 43–56. [Google Scholar] [CrossRef]

- Su, Y.T.; Liu, H.W.; Chen, P.H.; Chang, T.C.; Tsai, T.M.; Chu, T.J.; Pan, C.H.; Wu, C.H.; Yang, C.C.; Wang, M.C.; et al. A Method to Reduce Forming Voltage Without Degrading Device Performance in Hafnium Oxide-Based 1T1R Resistive Random Access Memory. IEEE J. Electron Devices Soc. 2018, 6, 341–345. [Google Scholar] [CrossRef]

- Huang, Y.J.; Shen, T.H.; Lee, L.H.; Wen, C.Y.; Lee, S.C. Low-Power Resistive Random Access Memory by Confining the Formation of Conducting Filaments. AIP Adv. 2016, 6, 065022. [Google Scholar] [CrossRef]

- Lu, W.; Chen, W.; Li, Y.; Jha, R. Self Current Limiting MgO ReRAM Devices for Low-Power Non-Volatile Memory Applications. IEEE J. Emerg. Sel. Top. Circuits Syst. 2016, 6, 163–170. [Google Scholar] [CrossRef]

- Tsigkourakos, M.; Bousoulas, P.; Aslanidis, V.; Skotadis, E.; Tsoukalas, D. Ultra-Low Power Multilevel Switching with Enhanced Uniformity in Forming Free TiO2−x-Based RRAM with Embedded Pt Nanocrystals. Phys. Status Solidi A 2017, 214, 1700570. [Google Scholar] [CrossRef]

- Bousoulas, P.; Stathopoulos, S.; Tsialoukis, D.; Tsoukalas, D. Low-Power and Highly Uniform 3-b Multilevel Switching in Forming Free TiO2–x-Based RRAM With Embedded Pt Nanocrystals. IEEE Electron Device Lett. 2016, 37, 874–877. [Google Scholar] [CrossRef]

- Yang, L.; Kuegeler, C.; Szot, K.; Ruediger, A.; Waser, R. The Influence of Copper Top Electrodes on the Resistive Switching Effect in TiO2 thin Films Studied by Conductive Atomic Force Microscopy. Appl. Phys. Lett. 2009, 95, 013109. [Google Scholar] [CrossRef]

- Chen, S.X.; Chang, S.P.; Chang, S.J.; Hsieh, W.K.; Lin, C.H. Highly Stable Ultrathin TiO2 Based Resistive Random Access Memory with Low Operation Voltage. ECS J. Solid State Sci. Technol. 2018, 7, 3183–3188. [Google Scholar] [CrossRef]

- Ma, G.; Tang, X.; Zhang, H.; Zhong, Z.; Li, J.; Su, H. Effects of Stress on Resistive Switching Property of the NiO RRAM Device. Microelectron. Eng. 2015, 139, 43–47. [Google Scholar] [CrossRef]

- Yang, C.C.; Huang, J.Q.; Chen, K.Y.; Chiu, P.H.; Vu, H.T.; Su, Y.K. Effect of Oxygen Concentration Ratio on a Ga2O3-Based Resistive Random Access Memory. IEEE Access 2019, 7, 175186–175191. [Google Scholar] [CrossRef]

- Chang, T.C.; Chang, K.C.; Tsai, T.M.; Chu, T.J.; Sze, S.M. Resistance Random Access Memory. Mater. Today 2016, 19, 254–264. [Google Scholar] [CrossRef]

- Abbas, H.; Li, J.; Ang, D.S. Conductive Bridge Random Access Memory (CBRAM): Challenges and Opportunities for Memory and Neuromorphic Computing Applications. Micromachines 2022, 13, 725. [Google Scholar] [CrossRef]

- Chen, K.-H.; Kao, M.-C.; Cheng, C.-M.; Wang, Y.-C.; Hsieh, C.-C.; Hung, G.-J. Study on Supercritical Fluid Technique for Application in Nonvolatile Resistive Random Access Memory (RRAM) Device Using SBT Ferroelectric Thin Films. In Proceedings of the 2024 IEEE Ultrasonics, Ferroelectrics, and Frequency Control Joint Symposium (UFFC-JS), Taipei, China, 22–26 September 2024. [Google Scholar] [CrossRef]

- Chen, K.-H.; Chen, Y.-C.; Chen, Z.-S.; Yang, C.-F.; Chang, T.-C. Temperature and frequency dependence of the ferroelectric characteristics of BaTiO3 thin films for nonvolatile memory applications. Appl. Phys. A 2007, 89, 533–536. [Google Scholar] [CrossRef]

- Kao, M.-C.; Chen, H.-Z.; Young, S.-L.; Chen, K.-H.; Chiang, J.-L.; Shi, J.-B. Structural, Electrical, Magnetic and Resistive Switching Properties of the Multiferroic/Ferroelectric Bilayer Thin Films. Materials 2017, 10, 1327. [Google Scholar] [CrossRef]

- Wang, X.; Zhao, X.; Li, Z.; Tao, Y.; Wang, Z.; Lin, Y.; Xu, H.; Liu, Y. A Self-powered Multimodal Sen-memory System. IEEE Electron Device Lett. 2024, 45, 1189–1192. [Google Scholar] [CrossRef]

- Huh, W.; Lee, D.; Lee, C.H. Memristors based on 2D materials as an artificial synapse for neuromorphic electronics. Adv. Mater. 2020, 32, 2002092. [Google Scholar] [CrossRef]

- Xu, J.; Wang, X.; Zhao, X.; Xie, D.; Wang, Z.; Xu, H.; Liu, Y. Light-controlled stateful reconfigurable logic in a carbon dot-based optoelectronic memristor. Appl. Phys. Lett. 2024, 124, 073507. [Google Scholar] [CrossRef]

- Tsai, T.-M.; Chang, K.-C.; Chang, T.-C.; Zhang, R.; Wang, T.; Pan, C.-H.; Chen, K.-H.; Chen, H.-M.; Chen, M.-C.; Tseng, Y.-T.; et al. Resistive Switching Mechanism of Oxygen-Rich Indium Tin Oxide Resistance Random Access Memory. IEEE Electron. Device Lett. 2016, 37, 408–411. [Google Scholar] [CrossRef]

- Zhang, R.; Young, T.-F.; Chen, M.-C.; Chen, H.-L.; Liang, S.-P.; Syu, Y.-E.; Sze, S.M.; Chang, K.-C.; Chang, T.-C.; Tsai, T.-M.; et al. Characterization of Oxygen Accumulation in Indium-Tin-Oxide for Resistance Random Access Memory. IEEE Electron. Device Lett. 2014, 35, 630–632. [Google Scholar] [CrossRef]

- Lin, C.-Y.; Chang, K.-C.; Chang, T.-C.; Tsai, T.-M.; Pan, C.-H.; Zhang, R.; Liu, K.-H.; Chen, H.-M.; Tseng, Y.-T.; Hung, Y.-C.; et al. Effects of Varied Negative Stop Voltages on Current Self-Compliance in Indium Tin Oxide Resistance Random Access Memory. IEEE Electron. Device Lett. 2015, 36, 564–566. [Google Scholar] [CrossRef]

- Chen, K.-H.; Kao, M.-C.; Huang, S.-J.; Li, J.-Z. Bipolar Switching Properties of Neodymium Oxide RRAM Devices Using by a Low Temperature Improvement Method. Materials 2017, 10, 1415. [Google Scholar] [CrossRef]

- Chen, K.H.; Cheng, C.M.; Li, C.Y.; Huang, S.J. Hopping conduction distance of bipolar switching GdOx resistance random access memory thin films devices modified by different constant compliance current. Microelectron. Reliab. 2018, 91, 330–334. [Google Scholar] [CrossRef]

- Chen, K.H.; Zhang, R.; Chang, T.C.; Tsai, T.M.; Chang, K.C.; Lou, J.C.; Young, T.F.; Chen, J.H.; Shih, C.C.; Tung, C.W.; et al. Hopping conduction distance dependent activation energy characteristics of Zn:SiO2 resistance random access memory devices. Appl. Phys. Lett. 2013, 102, 133503. [Google Scholar] [CrossRef]

- Chen, K.H.; Chang, K.C.; Chang, K.C.; Chang, K.M.; Sze, S.M. Effect of different constant compliance current for hopping conduction distance properties of the Sn:SiOx thin film RRAM device. Appl. Phys. A 2016, 122, 228. [Google Scholar] [CrossRef]

- Chang, K.-C.; Chang, T.-C.; Tsai, T.-M.; Zhang, R.; Hung, Y.-C.; Syu, Y.-E.; Chang, Y.-F.; Chen, M.-C.; Chu, T.-J.; Chen, H.-L.; et al. Physical and chemical mechanisms in oxide-based resistance random access memory. Nanoscale Res. Lett. 2015, 10, 120. [Google Scholar] [CrossRef]

- Ding, Y.; Yang, J.; Liu, Y.; Gao, J.; Wang, Y.; Jiang, P.; Lv, S.; Chen, Y.; Wang, B.; Wei, W.; et al. 16-layer 3D Vertical RRAM with Low Read Latency (18ns), High Nonlinearity (>5000) and Ultra-low Leakage Current (~pA) Self-Selective Cells. In Proceedings of the 2023 IEEE Symposium on VLSI Technology and Circuits (VLSI Technology and Circuits), Kyoto, Japan, 11–16 June 2023. [Google Scholar] [CrossRef]

- Wang, Y.H.; Gong, T.C.; Ding, Y.X.; Li, Y.; Wang, W.; Chen, Z.A.; Du, N.; Covi, E.; Farronato, M.; Ielmini, D.; et al. Redox Memristors with Volatile Threshold Switching Behavior for Neuromorphic Computing. J. Electron. Sci. Technol. 2022, 20, 100177. [Google Scholar] [CrossRef]

- Huo, Q.; Yang, Y.; Wang, Y.; Lei, D.; Fu, X.; Ren, Q.; Xu, X.; Luo, Q.; Xing, G.; Chen, C.; et al. A computing-in-memory macro based on three-dimensional resistive random-access memory. Nat. Electron. 2022, 5, 469–477. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, Y.-C.; Chen, K.-H.; Kao, M.-C.; Chen, H.-C.; Cheng, C.-M.; Huang, H.-X.; Huang, K.-C. Bipolar Switching Properties and Reaction Decay Effect of BST Ferroelectric Thin Films for Applications in Resistance Random Access Memory Devices. Nanomaterials 2025, 15, 602. https://doi.org/10.3390/nano15080602

Wang Y-C, Chen K-H, Kao M-C, Chen H-C, Cheng C-M, Huang H-X, Huang K-C. Bipolar Switching Properties and Reaction Decay Effect of BST Ferroelectric Thin Films for Applications in Resistance Random Access Memory Devices. Nanomaterials. 2025; 15(8):602. https://doi.org/10.3390/nano15080602

Chicago/Turabian StyleWang, Yao-Chin, Kai-Huang Chen, Ming-Cheng Kao, Hsin-Chin Chen, Chien-Min Cheng, Hong-Xiang Huang, and Kai-Chi Huang. 2025. "Bipolar Switching Properties and Reaction Decay Effect of BST Ferroelectric Thin Films for Applications in Resistance Random Access Memory Devices" Nanomaterials 15, no. 8: 602. https://doi.org/10.3390/nano15080602

APA StyleWang, Y.-C., Chen, K.-H., Kao, M.-C., Chen, H.-C., Cheng, C.-M., Huang, H.-X., & Huang, K.-C. (2025). Bipolar Switching Properties and Reaction Decay Effect of BST Ferroelectric Thin Films for Applications in Resistance Random Access Memory Devices. Nanomaterials, 15(8), 602. https://doi.org/10.3390/nano15080602