1. Introduction

Increasing global warming due to the extensive use of carbon-based fossil fuels escalating environmental concerns has led to a demand for alternative technologies to meet the growing demand of energy [

1,

2]. The electrochemical oxygen reduction reaction (ORR) is a central, cathodic electrochemical reaction which plays a critical role in various energy conversion devices like fuel cells and metal–air batteries like Zn–air and Al–air batteries [

3,

4,

5]. In these devices, the ORR occurs on the cathodes, where the electrocatalysts reduce the atmospheric oxygen into H

2O/OH

−. Due to the process being inherently sluggish and requiring multiple steps, kinetically controlled ORR often requires efficient electrocatalysts to enhance effective electron transfer and the reduction of O

2 [

6,

7]. In general, the best state-of-the-art electrocatalysts for ORR are Pt nanoparticles supported by high surface-area carbon support (Pt/C) [

8]. Despite the best ORR activity of Pt/C catalysts, successful commercial application of the energy conversion devices is severely hindered due to the high cost and scarcity of Pt, together with the poor stability of the Pt/C catalysts [

9]. It is well known that a commercial Pt/C catalyst undergoes a variety of degradation pathways, such as electrochemical carbon corrosion, Pt nanoparticle dissolution and agglomeration, catalyst poisoning in the presence of gasses such as CO and SO

x, etc. Pt nanoparticles detach from the carbon support due to the loss of supported solid carbon due to carbon corrosion [

10]. Consequently, research is being conducted to develop effective and stable electrocatalysts, which incorporate stable supports to enhance catalyst stability, reducing the Pt loading, as well as cost-effective catalysts utilizing transition and inner-transition metals, including lanthanides, to diminish dependence on costly platinum-based materials [

9,

11]. To substantially decrease the quantity of Pt loading, many solutions have been implemented, such as alloying Pt with other metals. The noble Pt metal have been alloyed with various transition metals (such as Fe, Co, Ni, Mn, Cu, etc.) and inner-transition metals of lanthanides (such as, Ce, La, Y, Gd, Dy, etc.) and it was found that Pt-alloy catalysts exhibit excellent ORR activity over traditional Pt/C catalysts [

12,

13,

14]. However, even the Pt-alloys catalysts also suffer from issues like dissolution, Ostwald ripening, and nanoparticle sintering. In addition, the Pt-alloy catalysts show poor stability, suggesting the need for active and stable electrocatalysts for ORR both in acidic and alkaline electrolytes [

15].

Though basic and advanced research on Pt, Pt-alloy, and non-precious metal catalysts with active sites composed of M

x-N

y-C (M=TM, such as Fe, Co, Mn, Cu, Ni, etc.) is so popular, with tens to thousands of papers being published each month [

16,

17], it is very recently that research exploring the possibility of using inner-transition metals of lanthanides from the

f-block series has been attracting tremendous attention [

18]. Rare earth elements are composed of 17 elements: lanthanum (La), cerium (Ce), praseodymium (Pr), neodymium (Nd), promethium (Pm), samarium (Sm), europium (Eu), gadolinium (Gd), terbium (Tb), dysprosium (Dy), holmium (Ho), erbium (Er), thulium (Tm), ytterbium (Yb), lutetium (Lu), scandium (Sc), and yttrium (Y). While rare earth elements are not great electrocatalysts on their own, even in trace amounts they can change the characteristics of active sites composed of other noble and transition metals [

19]. Rare earth metals find several applications in day-to-day life, for example, several rare earth metal oxides have been used as polishing powders in the making of glass products with various rare earth metal oxides. The quality of gasoline is also improved by using catalysts that contain rare earth elements [

20]. Cerium oxide is used in the three-way catalytic converter of waste gas treatment systems to change toxic waste gas into a harmless gas that people can breathe in. Due to their use and applications in various industrial products, today, rare earth elements are termed “Industrial Gold” or “Industrial Vitamins” [

21]. Rare-earth (RE) elements exhibit various oxidation states such as RE

2+, RE

3+, and RE

4+, of which RE

3+ is the most common. The presence of these various oxidation states suggests that RE with empty, half-filled, and fully filled electron energy levels tends to be more stable, as suggested by Hende’s rule [

21]. Rare earth elements are specially characterized by the presence of unique

f-orbitals. In general, 4

f electrons are inert, meaning they do not participate in chemical bonding with other elements and are part of the ionic core of the element. However, the positioning and incomplete filling of 4f electrons gives rare earth elements unique physical and chemical properties that are suitable for electrocatalytic applications [

22,

23]. In addition, the rare earth metallic elements exhibit strong coordination ability with reactants’ molecular orbitals and as rare earth metal oxides have the features of oxygen affinity and oxygen vacancies, in various catalytic reactions, rare earth oxides act as co-catalysts by transferring the stored oxygen species and hence promote higher catalytic activity of the main catalysts [

24,

25].

Among the various RE elements, cerium (Ce)-based catalysts, either in an atomically dispersed state or in the form of Ce-oxide (CeO

2), has attracted considerable attention for various electrochemical reactions such as CO oxidation, NO reduction, water–gas-shift reaction, and for ORR [

26]. The rich oxygen vacancies and affinity and facile interchange of the oxidation state of Ce

3+ and Ce

4+ facilitates the ORR. In view of the fuel cell reaction, the ability to perform the interexchange of Ce

3+/Ce

4+ in the oxidation state is so important; for this, it is essential that Ce inactivates the hydrogen peroxide, formed from the 2-electron O

2 reduction reaction. CeO

2 has high stability under acidic conditions and CeO

2 also improves the corrosion-resistant ability of carbon in acidic electrolytes [

27]. CeO

2 also exhibits strong interaction with noble metals such as Pt and non-precious metals, thus enhancing the metal/metal oxide interactions in promoting the ORR by facilitating optimal adsorption of O

2 and ORR intermediates [

28]. Furthermore, the 4f orbit of the Ce atom allows for both unoccupied and one-electron occupied states, and the 4f shell of the Ce atom is suitable for electron sharing and bonding [

29]. Furthermore, ceria plays a key function in promoting the dispersion of noble metals; ceria can significantly enhance O

2 adsorption and ORR kinetics. Ceria-modified carbon compounds have been shown to serve as very efficient catalysts for a direct 4-electron reduction in ORR [

30,

31]. These distinct features of ceria motivated us to search for the possibility of Ce/CeO

2 materials being employed as ORR catalysts. This review paper provides an overview of the research that had been carried out recently on the applications of Ce and CeO

2 for ORR for fuel cells and metal–air batteries. The first part of this review paper describes the characteristics and properties of Ce/CeO

2 and the second part of the review paper describes the ORR kinetics of the electrocatalysts of Ce/CeO

2 alone or in combination with Pt and non-Pt metallic active sites, derived from metal–organic framework (MOF) precursors. MOFs are a class of porous materials comprising metal ions/organic linkers; after undergoing pyrolysis, they result in the formation of a porous carbon network with atomically dispersed metallic/clusters/nanoparticles of active sites [

32].

MOF-derived catalysts have recently gained tremendous interests regarding their application in various fields, including gas storage and separation, luminescence, magnetism, biology and medicine, biomass conversion, photovoltaic cells, water purification, and catalysis; this includes ORR [

33]. Due to the tendency of RE metals to readily coordinate with O- and N-containing ligands, particularly -COOH ligands, together with their high coordination numbers and varied coordination modes, the synthesis of novel structural metal–organic frameworks (MOFs) is feasible. Nevertheless, owing to steric hindrance, rare earth elements are unable to fully coordinate with ligands, resulting in one or more coordination sites being available to interact with solvent molecules, thereby forming end groups. Upon heat treatment of the synthesized rare earth MOFs, solvent molecules are expelled from the rare earth MOF, revealing coordinatively unsaturated sites within the structure that can serve as active Lewis’s acid/base centers, that can interact with reactant species like O

2 to promote the ORR [

34]. Rare earth ions possess unsaturated 4f orbitals and readily coordinate with the lone electron pairs of organic groups. The ligands most commonly used for the synthesis of RE MOFs include terephthalic acid; 1,4-benzene dicarboxylic acid (BDC); trimesic acid (TMA), also known as 1,3,5-benzenetricarboxylic acid (H

3BTC); pyridine-2,4-dicarboxylic acid (2,4-pydc); 2-aminoterephthalic acid (BDC-NH

2); zeolite imidazole framework (ZIF); Zn-triazolates; Prussian blue; and various other organic ligands [

35].

To briefly conclude, this review article provides a comprehensive understanding of (i) the significance of Ce high-spin state on the ORR activity enhancement on the Pt and non-pt electrocatalysts, (ii) the spatially confining and stabilizing effect of ceria on the generation of the atomically dispersed transition metal-based catalysts, (iii) experimental and theoretical evidence of the effect of Ce

3+ ↔ Ce

4+ redox pain on radical scavenging, (iv) the effect of the Ce 4f electrons on the d-band center and electron transfer between Ce to the N-doped carbon and transition metal catalysts for enhanced ORR activity, and (v) the effect of Pt/CeO

2/carbon heterojunctions on the stability of the Pt/CeO

2/carbon electrocatalyst for ORR (

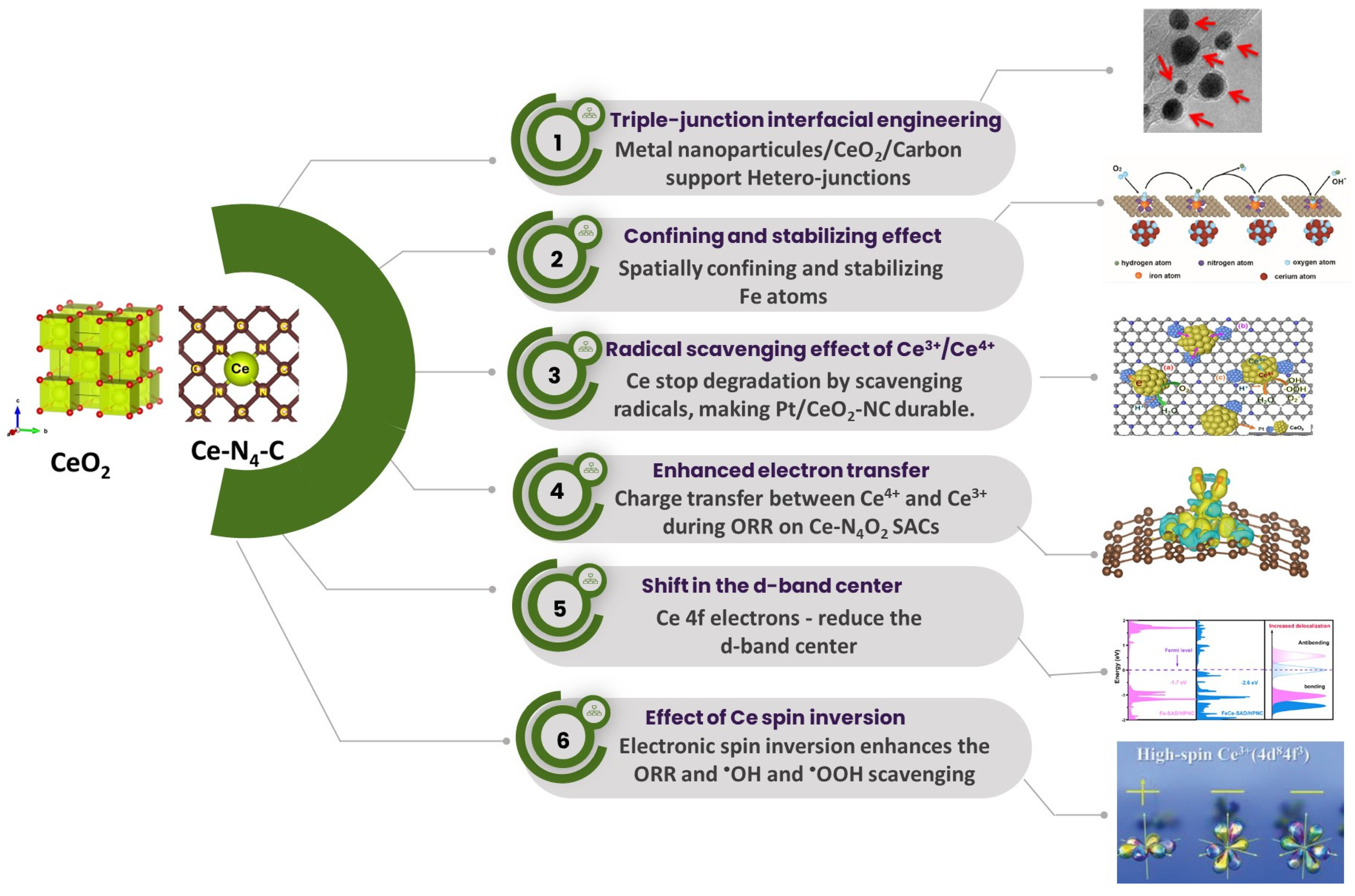

Figure 1).

2. Properties of Cerium Dioxide/Atomically Dispersed Cerium for ORR

The element cerium (Ce), which has the atomic number 58, is by far the most abundant element from the group of rare earth metals, with almost the same abundance as Ni, Cu, and Zn in the Earth’s crust, making up around 0.0046 wt% of the crust of the Earth [

36]. The exploration of RE elements in combination with transition metals goes back to the 1970s, with the first synthesis of LaNi

5, used for water electrolysis, and the demonstration of the electrocatalytic hydrogen evolution activity [

37] from the RE-TM and noble metals including Pt, Au, and Pd, gaining considerable interest in 21st century. Among several RE metals, Ce is by far the most explored element for electrocatalytic applications due to its superior redox capability, i.e., interconversion of Ce

4+ ↔ Ce

3+. Cerium, both in the form of nanoparticles and in an atomically dispersed state, is explored as an ORR electrocatalyst. The fluorite crystal structure of the CeO

2 nanocrystal is with the space group

Fm3m and the cell parameters are 0.5411 nm (a=b=c). In the CeO

2 unit cell, each Ce

4+ is coordinated with eight adjacent O

2− to form an octahedral interstitial, and each O

2− is coordinated with four adjacent Ce

4+ to form a tetrahedral unit [

38]. Because of its high electrical energy levels and unoccupied 4

f orbital, CeO

2 shows significant promise as a catalytic agent. The remarkable physical and chemical properties of Ce are mostly derived from its unusual electronic configuration, which is [Xe]4f

15d

16s

2. Electrocatalytic activity can be enhanced by using Ce, a naturally occurring occupier of 4f orbital electrons, as an electronic modulator to build charge transfer highways close to the Fermi level [

39]. Furthermore, Ce’s electronic properties and large atomic radius cause it to frequently display a highly coordinated structure with a minimum of four ligands, and its electronic configuration allows for a flexible variation in the coordination number [

40]. This results in Ce-based materials having a highly tunable local coordination/geometry. Ce is a dopant that can be used to regulate the adsorption/desorption of chemical intermediates for electrocatalytic reactions, thanks to its high atomic radius [

41]. In addition, the multivalence feature of CeO

2 provides the potential to create robust interactions synergistically with other catalysts, hence improving the efficacy of electrocatalysis. The distinctive crystal structure and reversible valence properties of CeO

2 facilitate the creation of oxygen vacancies, resulting in a defect-rich architecture that underpins its superior catalytic activity.

The oxygen vacancy, resulting from the reduction of Ce

4+ to Ce

3+ or the migration of lattice oxygen, significantly affects the electrical and chemical characteristics of CeO

2. In catalysts, oxygen vacancies not only stabilize active component nanoparticles or clusters but also modulate the electrical structure of the catalysts and provide a faster charge transfer rate and excellent reaction kinetics [

42,

43]. During ORR electrocatalysis, the 4

f band of Ce can hybridize with a 2

p band of O

2 intermediates because the oxygen-defective CeO

2 lowers the 4f energy level of Ce below the Fermi level [

44]. As a result, CeO

2 shows promising results as an electrocatalytic promoter for improving the electrocatalytic activity of adjacent TM-based active sites [

45,

46]. Despite the several advantages of CeO

2, poor electrical conductivity hinders its direct use as an electrocatalyst; therefore, the CeO

2 nanoparticles, in general, require conducting carbon support to improve the interfacial electron transfer and to provide a platform to host the CeO

2 nanoparticles. The combination of the high conductivity of rGO and the ample active sites on CeO

2 renders the nanocomposite an effective electrocatalyst for ORR [

47]. In addition, in several studies, it is found that the noble metal nanoparticles/CeO

2/carbon support heterojunctions create a unique electrocatalyst in which CeO

2 found to improve the catalyst activity and stability [

48]. Not only are CeO2 nanoparticles known to improve electrocatalyst stability, but they are also known to improve the nafion membrane stability by averting membrane degradation. It is well known that during ORR, the electrocatalysts produce a considerable amount of H

2O

2 and OOH

−, which is produced by a 2+2 O

2 reduction pathway, detrimental to the nafion membrane and even the catalyst layer. CeO

2 is the best known OH

· radical scavenging agent for fuel cells that include both membrane and catalysts. Therefore, plenty of researchers have introduced CeO

2 nanoparticles incorporated into the membranes, aiming to improve stability [

49,

50].

Platinum group metals supported on a carbon matrix are the most popular catalysts for heterogeneous catalysts. As stated earlier, RE metals in the form of nanoparticles of metallic and metal oxides are often used as co-catalysts/promoters in combination with transition and noble metals [

51]. However, when either catalysts, or co-catalysts with heterogenous catalysis, are used, only the surface atoms participate in the reaction, with most reactants never reach atoms in the bulk, therefore rendering them surplus [

52]. Metal nanoparticles, for example, often have more than 40 atoms and have a diameter of about 1 nm. Despite environmental and chemical reaction-induced changes to the geometric configurations of exposed surface atoms (facets, corners, edges, metal–support interfaces, etc.), their geometric structures remain relatively un-stable and are thus less vulnerable [

53]. In addition, the specific electronic structure of the metal–oxide interface in supported catalysts is crucial to the catalytic process since it can influence the selectivity of the products, the absorption and activation of reactants/intermediates, and the catalysts themselves [

54]. Hence, a lot of work had gone into finding ways to make active metals more efficiently and to make supporting metal catalysts work better by making the active metals smaller [

55]. The most efficient use of precious metals would be possible with nanoparticles that were smaller; this would be especially true for metals that were disseminated in the form of single atoms [

56]. Since then, catalysis at single-atom sites has been expanding rapidly. Single-atom catalysts (SACs) illustrate the smallest dimension of metal catalysts, which not only enhances the atomic efficiency of supported metals but also boosts the quantity of interfacial sites; in contrast, the unexposed inner atoms of conventional nano-sized catalysts cannot interact with the support at interfacial sites [

57]. Accordingly, several studies have been conducted in which SACs of RE metals have been proposed for ORR and other energy conversion and storage electrochemical reactions [

51].

The rare earth metal Ce is special among the several rare earth metals with regard to electrocatalysis, especially for ORR, as shown in

Figure 2. The special features of Ce include (i) the redox couple of Ce

3+/Ce

4+ which accompanies the oxygen vacancy and

●OH radical scavenging, whereas most other RE elements largely exists in stable RE

+3 oxidation states and lack the dynamic redox coupling ability; (ii) the unique fluorite structure of CeO

2 which can host O

2 vacancies without any lattice distortions which act as active sites for O

2 adsorption, while most other rare earth oxides, for instance, La

2O

3 and Y

2O

3 with their rigid hexagonal structures, offer less oxygen vacancies and O

2 storage capacity; (iii) the radical scavenging capacity of Ce, whereas other rare earths are known to lack radical scavenging capacity; (iv) the structure stability of CeO

2, owing to its partially filled 4f orbitals; and (v) its ability to change the high-spin state in the atomically dispersed state, a unique property of Ce. These factors stand out as important aspects of Ce for ORR (

Figure 2)

3. Pt/CeO2 Catalysts for ORR

It is well accepted that various metal oxides, including RE oxides, can induce a positive effect on Pt NPs, thereby enhancing the ORR process due to restructuring of Pt surface defects induced by the RE oxides [

58]. In addition, the presence of Ce

3+ was also found to enhance the metallic ability of Pt nanoparticles and effectively inhibit the oxidation of Pt nanoparticles [

59]. In this regard, CeO

2 as a metal oxide component presence in Pt-based catalysts could bring several advantages such as Pt/CeO

2/C heterojunctions; the Pt nanoparticles’ binding strength at the CeO

2 phase was found to enhance the stability of the catalyst in strong metal support interactions (SMSI). CeO

2 can donate electrons to Pt and influence its electronic structure through electronic effects and oxygen absorption energy. Pt NPs can also be stabilized by CeO

2 anchoring. CeO

2 acts as a co-catalyst in Pt-CeO

x/C catalysts, helping the main Pt catalytic center electronically and preventing Pt oxide production at high potentials through the substitutional Ce

3+ to Ce

4+ redox reaction and oxygen buffering. Pt-CeO

x/C triple-phase hetero-interface structures improve ORR activity and fuel cell performance.

In this regard, in several studies, CeO

x-interfaced Pt catalysts have been proposed as durable ORR catalysts. One such notable work is carried out by Luo et al. [

60], who synthesized an advanced Pt/CeO

x/C nanocomposite with porous carbon with multiwalled carbon nanotubes (MWCNTs) by utilizing Ce-incorporated MOFs synthesized with an ATPT = 2-aminoteraphthalate organic ligand. After a high temperature treatment, the MOF(Ce) transformed into Ce-O

x, resulting in the formation of an oxide/carbon composite. The TEM images show that Pt nanoparticles of nearly spherical shapes, together with some amorphous carbon mixed oxide, are found to be present in an intimate, interconnecting way with Pt, Ce, O and C, forming a nanocomposite system. TEM images also clearly show the formation of fragments of Ce oxides in close connection with Pt nanoparticles (

Figure 3a,b). The ORR analysis shows proportionately increased half-wave potential and improved Tafel slopes indicate that the formation of hetero-junctions of Pt NPs and CeO

x/C helps in enhancing the ORR activity in acidic medium (

Figure 3c,d). The mass and specific activities of the Pt/CeO

x/C catalyst are shown to be 10 times greater than the commercial Pt/C catalyst. Metal oxides such as TiO

2, SnO

2, and WO

3, including CeO

2, have been used as potential carbon composites structures aiming for improved metal–metal oxide support interactions and improved corrosion resistance catalysts in fuel cells and metal–air batteries [

61]. The triple-phase interface structures formed from the Pt, CeO

x, and C, are known to be responsible for the strong metal–support interactions (SMSI). Several studies have concluded that the presence of SMSI is responsible for optimized ORR activity and stability of the catalysts. Among several metal oxides, CeO

2 is the one most investigated as an active component of triple-phase interface structures, due to its defective crystal structure and rapid interchangeable oxidation states, from Ce

3+ to Ce

4+ and vice versa. In addition to this, CeO

2 has excellent oxygen storage capacity, meaning that it has the ability to release O

2 in environments with low O

2 levels by absorbing O

2 atoms from NO, H

2O, and O

2. CeO

2 also performs excellently in scavenging hydroxyl (HO⋅) and hydroperoxyl (HOO⋅) radicals formed during the ORR process and mitigates the chemical degradation of the membrane and catalyst. Such triple-phase hetero-structures are constructed by packing nanosized CeO

2 with ZIF-8-derived NC as a novel composite, supported in a study by Zhao et al. [

62]. An abundant triple-phase hetero-junction of a Pt/CeO

2-NC catalyst is created after Pt nanoparticles are deposited (

Figure 3e). The Pt NPs are the ORR’s primary catalytic centers, and NC makes it possible for the Pt NPs to be evenly distributed and guarantees enough electrical conductivity. By donating electrons to Pt and influencing its electronic structure through electronic effects and oxygen absorption energy, CeO

2 can play the role of an electron donor. Additionally, the anchoring effect between Pt and CeO

2 can stabilize the Pt NPs. The catalyst made of 20% Pt/CeO

2-NC exhibits an E

1/2 of 0.922 V, and no loss after 10,000 cycles of ADTs in acidic media, according to RRDE tests, which is better than the commercial Pt/C. This is because of the interactions between Pt NPs, CeO

2, and NC. Furthermore, when comparing 20% commercial Pt/C to 20% Pt/CeO

2-NC in PEMFC single-cell measurements, the latter exhibits superior electrochemical activity and durability, even at lower cathode Pt loadings. To construct the effective triple-phase hetero-junctions, first, Ce@ZIF-8 structures are synthesized from 2-MIM, Ce

3+, and Zn

2+ structures in methanol solution which are then pyrolyzed under N

2 atmosphere, which results in the formation of CeO

2 nanoclusters on to which Pt nanoparticles are deposited using a microwave polyol method.

TEM images clearly reveal the formation of abundant three-phase (i.e., Pt NPs, CeO

2, and NC) interfacial structures in Pt/CeO

2-NC catalyst. It is seen that the CeO

2 (111) phase is in close proximity to the Pt (111) NPs, suggesting an efficient catalyst with abundant triple-phase interfacial structures. The strong anchoring effect between Pt NPs and CeO

2-NC is responsible for the more uniform distribution of Pt NPs on CeO

2-NC supports compared to NC. The strong SMSI effect is further revealed by the XPS analysis, in which there is a shift in the Pt 4f peaks which is ascribed to the strong interactions between CeO

2 and Pt. The ORR activity of the Pt/CeO

2-NC catalyst showed excellent kinetics, with obtained half-wave potentials of 0.922 V, much higher than those of Pt/C, Pt-NC, and Pt/CeO

2; also, the highest ECSA of Pt/CeO

2-NC is 86.8 m

2⋅g

Pt−1, which is the largest one among these catalysts. In addition to the ORR activity, it was found that Pt/CeO

2-NC exhibited excellent stability, with a loss of just 10 mV in its half-wave potential after 10,000 ADT cycles, in contrast to 35 mV loss in half-wave potential for Pt/C, with a proportional loss of ECSA of 26%, whereas the loss in ECSA is just 9% for Pt/CeO

2-NC catalyst. Because of this, Pt/CeO

2-NC outlasts commercial 20% Pt/C in terms of durability. This is because CeO

2-NC has an anchoring effect on Pt NPs, which forbids their growth and aggregation. Interestingly, when applied as a cathode catalyst in PEMFC fuel cell configuration, the Pt/CeO

2-NC catalyst delivered a power density of 1.08 W cm

−2, higher than the Pt/NC and Pt/C catalysts (

Figure 3f–j). The enhanced ORR activity, stability, and fuel cell performance of the Pt/CeO

2-NC catalyst was attributed to several causes, among which “an effective three phase interface structure” was the main one [

63]. By influencing the electronic structure of Pt and the energy of oxygen absorbed on Pt sites, CeO

2 can increase the activity of the ORR. Pt nanoparticles are uniformly anchored by the CeO

2-NC supports because of the anchoring effect [

64,

65]. Because the anchoring effect prevents Pt NPs from growing into aggregates, they enhance the stability of the catalysts [

66,

67]. The free radical scavenger properties of CeO

2 nanoparticles in PEMFCs are well-known. Ce

3+ and Ce

4+ are present in CeO

2 due to the presence of oxygen vacancies in the material. The antioxidant properties of CeO

2 prevent the breakdown of the nafion membrane and catalyst support, which prolongs the life of Pt/CeO

2-NC in PEMFCs [

68].

Alloying Pt with other metals and metal oxides is known to down-shift the

d-band center of Pt; as a result, the ORR intermediates absorb optimally on the active sites [

69]. However, the alloyed element or metal oxide leaches out gradually, resulting in long-term instability of the electrocatalyst [

70]. The mitigation of the effects of the alloying element and metal oxide component on the electrocatalyst is highly desired to improve the electrocatalytic performance of Pt for ORR. It is well known that CeO

2 can enhance carbon corrosion resistance in acid due to its strong electron interaction with Pt and its high stability in acidic environments [

71,

72]. Nevertheless, the use of Pt-CeO

2 binary catalysts in ORR has been greatly hindered by CeO

2’s poor electronic conductivity. An effective strategy to improve electronic conductivity while maintaining the strong interaction between Pt and CeO

2 is to construct a Pt-CeO

2/C ternary nanostructure by introducing carbon into the hybrid catalyst. Du et al. [

73] fabricated a Pt/CeO

2-C ternary mutual interacted nanostructure from a crystal feature of Ce-MOF, resulting from the thermal treatment of Ce-MOFs, resulting in the formation of abundant tiny CeO

2 nanoclusters (~2 nm) on to which Pt nanoparticles were deposited (

Figure 4a). The electronic conductivity, ORR catalytic activity, and long-term durability of ORR are all greatly enhanced by the closely packed structure, which can form enough interfaces for electronic interaction and electron transfer. HRTEM images suggest that CeO

2 nanocrystals are well-structured, with a cluster size of 2 nm, and CeO

2 NCs produced by Ce-MOF avoided aggregation, which may be explained by the unique backbone properties of Ce [

74] that cause the nanorod morphology of CeO

2/C (

Figure 4b). XPS analysis reveals that the Ce

3+ molar ratio in CeO

2/C and Pt/CeO

2/C catalysts were found to be 14.3% and 20.5%, respectively. It is possible that the partial reduction of Ce

4+ during Pt deposition is responsible for the increase in the Ce

3+ component, and that Ce

3+ acts as a reducing agent to create small Pt NCs embedded on the surface of CeO

2 in an alkaline environment. A prior study using in situ electrochemical X-ray absorption fine structure demonstrated that the small amount of Ce

3+ in CeO

2 hinders the production of Pt oxide at high potentials through the substitutional oxidation of Ce

3+ to Ce

4+. This has positive implications for enhancing the catalytic performance of Pt in ORR [

59,

75]. The ORR studies suggest that the Pt/CeO

2/C catalyst showed excellent ORR activity, with its kinetics equaling commercial Pt/C catalysts, which is attributed to the enhanced charge associated with H

2 adsorption/desorption, with nearly 4 electron transfer of O

2 reduction (

Figure 4c–e). The enhanced Pt stability may be due to the confinement of Pt NCs in the CeO

2/C hybrid and the synergistic effect between the NCs and the CeO

2 support, specifically the electron deficiency of small Pt NCs caused by the transfer of electrons from Pt to CeO

2. The decrease in the Pt-Pt bond distance because of the Pt-O interaction may be responsible for the enhancement of ORR activity [

76].

In addition to their dual role as co-catalysts and supports, metal oxides like CeO

2 can modify the electronic structure of Pt NPs and thereby produce a synergistic effect with Pt. Among the oxygen catalytic reactivity compounds, CeO

2 stands out due to its superior chemical stability and noticeably reduced cost. On the other hand, a carbon layer may be necessary to enhance the anchoring effect of Pt on CeO

2 due to its reduced electrical conductivity. Wang et al. [

77] developed a “Pt-oxide”-based composite electrocatalyst of “CeO

2 overlapped with nitrogen-doped carbon layer anchoring Pt nanoparticles” (Pt-CeO

2@CN). The TEM measurements make it very clear that the catalyst contains Pt NPs, CeO

2, and N-doped carbon. Specifically, it shows that the CeO

2 layer overlaps with the N-doped carbon layer, which makes Pt NPs well-anchored. Furthermore, the HR-TEM analysis also clearly reveals that the distinct crystal plane distances are 0.223 nm for the Pt (1 1 1) plane and 0.311 nm for the CeO

2 (1 1 1) plane, respectively. XPS analysis reveals a high abundance of graphitic-N and pyridinic-N species. Pt 4f spectra further confirm the anchoring effect of Pt on the CeO

2 interfaced by N-doped carbon, which enhances the electron transport from the support to the Pt catalytic active sites. The ORR activity of the Pt-CeO

2@CN is found to be higher than the commercial Pt/C catalyst. The onset potential and half-wave potential of the Pt-CeO

2@CN catalyst is superior by 16 and 29 mV, respectively, when compared to Pt/C catalyst, suggesting that CeO

2 and N-doped carbon helps to enhance the catalytic activity.

In a similar trend, Chen et al. [

78] developed an atomic layer deposition-produced Pt/CeO

2/CNT triple-junction interface, showing improved ORR activity and durability. SMSI have been proven to not only to enhance the strength of supported metal nanoparticles but also to help in the dispersion of Pt nanoparticles. In addition, the SMSI helped to prevent Pt detachment and further aggregation during long-term potential cycling, therefore helping to enhance the catalyst stability. Kinetically, the SMSI also promote the absorption of oxygen and cleavage of the O=O bond on the Pt surface [

79]. Although Pt-MO

x-C triple junctions are typically produced by wet chemical synthesis, it is challenging to precisely control the catalyst’s nucleation and growth during the reaction, leading to potentially larger size and uneven distribution. On the other hand, atomic layer deposition is a great way to make nano catalysts, thin films, and metal and metallic compound catalysts with clusters, single atoms, and highly dispersed nanoparticles. In this work, clusters of CeO

2-nanoparticles were deposited on a CNT which is then used as a substrate on to which Pt nanoparticles are deposited using the ALD method. It was found that the Pt/CeO

2/CNT-A triple-junction catalyst showed enhanced ORR activity compared to the Pt/CeO

2/CNT-W that is synthesized by a wet chemical synthesis method. The XRD analysis reveals that Pt nanoparticles deposited by ALD show smaller crystallite size, with an average size of 8.30 nm, whereas, for wet chemically synthesized catalysts, it is 10 nm. TEM images clearly show that the Pt NPs were deposited on the of CeO

2 and no visible CNTs were seen with Pt NPs, suggesting that most of the Pt NPs were deposited on the CeO

2/CNT, confirming that effective Pt/CeO

2/CNT-A triple-junction structures were generated. Furthermore, the XPS analysis revealed that the Pt/CeO

2/CNT-A catalyst contains abundant oxygen vacancies (V

o), which are essential for the interaction between Pt and CeO

2. The XPS spectra also reveal that Pt/CeO

2/CNT-A contains high amount of Ce

3+, resulting from the electron transfer from Pt to the CeO

2 due to the reduction in Ce

4+ ions [

80]. Pt 4f spectra of Pt/CeO

2/CNT-A and Pt/CeO

2/CNT-W also suggest a clear differentiation between the Pt nanoparticle deposition method-induced ORR activity. A negative shift of 0.14 eV is observed for Pt/CeO

2/CNT-A compared with Pt/CeO

2/CNT-W. According to the

d-band theory, negative shift in the binding energy indicates stronger electronic interaction, which is consistent with the observed increase in Ce

3+ content. The negative shift in binding energy also means the lowering the

d-band center of Pt NPS, which further helps in enhancing the electrocatalytic activity [

81]. The ORR studies indicate that both Pt/CeO

2/CNT-A and Pt/CeO

2/CNT-W catalysts show enhanced ORR activity, with 25 and 10 mV-higher half-wave potential representing the paramount interfacial structures of CeO

2 and CNT in enhancing the ORR activity. Furthermore, electron transfer from the Ce

3+ to Ce

4+ oxidation state further strengthens the nucleation and Pt-CeO

2 interface interaction. In addition, the high V

o and oxygen storage capacity of CeO

2 promotes the optimal adsorption of oxygen and cleavage of the O=O bond in the Pt surface [

82]. In addition to the excellent ORR activity, Pt/CeO

2/CNT-A also showed excellent stability.

To briefly conclude, it is found that Pt-CeOx/C triple-phase hetero-interface structures with Pt enhanced the binding strength of Pt nanoparticles with the Pt-CeOx/C junctions, which results in SMSI which is responsible for the enhanced ORR activity and stability of the catalysts. By donating electrons to Pt and influencing its electronic structure through electronic effects and oxygen absorption energy, CeO2 can play the role of an electron donor. Additionally, the anchoring effect between Pt and CeO2 can stabilize the Pt NPs. In Pt-CeOx/C catalysts, CeO2 plays the role of co-catalyst, assisting in the main Pt catalytic center electronically, and hinders the production of Pt oxide at high potentials through the substitutional Ce3+ to Ce4+ redox reaction and CeO2 oxygen buffering capacity. The presence of Pt-CeOx/C triple-phase hetero-interface structures not only enhances the ORR activity but also influences the fuel cell performance.

4. Fe/CeO2/C Catalysts for ORR

CeO

2 is an important type of metal oxide, useful for various electrochemical reactions including CO oxidation, NO reduction, and for ORR, due to its unique oxygen storage capacity and facile interconversion of Ce

3+ to Ce

4+, in addition to its superior property of corrosion resistance and optimal absorption of reaction species on to its surface [

26]. Ce is found to regulate Fe’s electronic structure and spatially confines and stabilizes Fe atoms. O

2 interaction on Fe active sites is enhanced by 4f

1 (Ce

3+) localized electron transfer to d-orbitals due to differences in electronegativity values between Ce and Fe. Transition metal atoms like Fe interact well with Ce 4f

1 of (Ce

3+). Hybridizing 4f-3d orbitals lowers the band gap and improves conduction band dispersion, boosting ORR. Thus, the catalyst must have a high Ce

3+ ratio. Hybridizing d-f orbitals reduces the Fe atom’s d-band center, making electron transfer to adsorbed OH intermediates easier and speeding up the rate-determining step and ORR. Thus, in Fe-Ce dual-atom-based catalysts, Fe is the main active center and rare earth Ce 4f electrons improve charge transfer, reduce the d-band center, and improve ORR kinetics. In this section, we will describe the various Fe/Ce-based catalysts proposed in the literature.

Zhang et al. [

83] synthesized a series of MOFs with Ce/La MOFs and investigated the effect of Lewis’s base sites, composed of rare earth metals, on the synergistic ORR activity of porous Fe-Nx active sites (

Figure 5a). The Le/Ce-doped MOFs were synthesized by a simple co-precipitation method, and then the synthesized MOFs were immersed in the Fe

3+ solution. The resulting Fe-MOFs were then pyrolyzed to obtain the xLa-CeNC-Fe. Analysis of the diffraction peaks of Ce-NC-Fe with La

3+ show that the diffraction peaks shift to a lower 2theta angle, indicating the successful incorporation of La

3+ (0.116 nm), whose ionic radius is larger than the Ce

4+ (0.097 nm). Both SEM and TEM images show CNT structures, obviously due to the ability of Fe to graphitize the carbon during the pyrolysis process. The ORR analysis of the 0.5La-CeNC-Fe catalyst showed a well-defined cathodic reduction peak in the cyclic voltametric analysis, with a peak potential of 0.886 V vs. RHE, much higher than the Pt/C catalyst of 0.875 V. The catalyst of 0.5La-CeNC-Fe with an E

1/2 of 0.870 V exhibits significantly better ORR activity than that of other catalysts and is slightly better than that of Pt/C with an E

1/2 of 0.862 V. The K-L plots indicate that the 0.5La-CeNC-Fe catalyst exhibited an ‘n’ of 3.94, indicating almost a direct four-electron reduction of O

2 to H

2O (

Figure 5b–i).

In addition to the role of Ce as a co-catalyst, O

2 buffering agent, Ce plays an important role in spatially confining and stabilizing Fe atoms [

84]. Thus, Ce can greatly improve the ORR/OER catalyst’s stability and catalytic activity when added to metal-based hybrid electrocatalysts. Wang et al. [

85] synthesized a two-dimensional ZIF assisted with a NaCl molten salt synthesis method to create a Ce/Fe-NC/Fe

3C-P nanosheet with a hierarchical porous structure (

Figure 5j). Thanks to the abundance of molten salt around the ZIF nanosheets, the precursor’s shape was kept intact. At the same time, adding molten salt of sodium chloride to a carbon matrix can improve electron transport, increase the catalyst’s durability, and raise the degree of local graphitization and graphitic N dopants. Both Fe-ZIF and Ce/Fe-ZIF exhibit an elliptical nanoflake structure, and the Fe-ZIF-derived Fe-NC/Fe

3C catalyst exhibited structures that resembled carbon nanotubes (CNTs), with a significant amount of agglomeration. On the other hand, the Ce-ZIF-pyrolyzed Ce/Fe-N-C/Fe

3C-P catalyst displayed a very small number of CNT-like structures. This is because the addition of Ce causes the Ce/Fe-ZIF nanoflakes to shrink and link with each other during the pyrolysis process, resulting in the formation of a coralloid structure. According to this, Ce is responsible for regulating the electronic structure of Fe and preventing the growth of carbon nanotubes. Furthermore, it was found that the ratio of molten salt NaCl:Ce/Fe-ZIF also plays a role in preserving the elliptical nanoflake structures. Obtaining nanosheets with a mass ratio of 1:1 between NaCl and Ce/Fe-ZIF results in significant agglomeration. The elliptical nanoflake structure of Ce/Fe-ZIF was integrally preserved when the ratio increased to 3:1. As the ratio increased to 5:1, the morphology became nearly identical to that of 3:1. HR-TEM images of the Ce/Fe-NC/Fe

3C-P catalyst show the homogeneous distribution of C, Fe, and Ce, along with the Fe

3C nanoparticles, meaning that Fe particles are surrounded by the N-doped carbon shells which act as a catalytic active site to facilitate the ORR/OER [

86,

87,

88,

89,

90]. The core–shell structure is crucial for avoiding NP agglomeration and boosts catalyst durability by halting Fe

3C nanoparticle leaching in extreme electrochemical environments. Interestingly, it is also found that the Ce also regulates the porosity of the catalysts. According to the pore size distribution analysis, micropores are more prevalent in Fe-NC/Fe

3C, but mesopores appear after Ce incorporation in the Ce/Fe-NC/Fe

3C-P catalyst. This could be because the preexisting Ce controlled the electrical structure of Fe and prevented the growth of CNTs, in contrast to Fe-NC/Fe

3C [

91]. In addition, when NaCl was introduced during the synthesis process, it was found that well-balanced micro and mesopores were identified in the catalyst [

92]. The role of micro and mesopores includes hosting the edge, highly active ORR sites in the form of Fe-N

x-C and providing a pathway for the reactants and products to the ORR active sites, respectively [

93]. The XPS analysis reveals the presence of definite Ce-N

x bonding active sites along with pyridinic-N, Fe−N

x, pyrrolic-N, and graphitic-N, which can act as ORR active sites. There is a noticeable change in the binding energy of Fe2p

3/2 between the Fe-NC/Fe

3C and Ce/Fe-NC/Fe

3C-P catalysts, which is an intriguing finding. This might be because Ce doping allows charges to migrate between Fe and N elements, among others. The charge transfer effect, according to earlier research, lowers the

d-band center value, which in turn reduces the adsorption energy of oxygen-containing intermediates in electrochemical reactions and increases the ORR electrocatalytic efficiency [

94]. The electrochemical ORR studies indicate that the Ce/Fe-NC/Fe

3C-P catalyst showed the highest ORR activity, followed by Ce/Fe-NC/Fe

3C, 20% Pt/C, and Fe-NC/Fe

3C. The Ce/Fe-NC/Fe

3C-P catalyst’s outstanding performance in ORR is likely connected to Ce species, which effectively lower the energy barrier of the rate-limiting step and promote more efficient transport of oxygen-containing intermediates containing H

2O

2, OH

−, and *OH radicals during the ORR. When applied as a cathode catalyst in Zn–air batteries and in PEMFC environments, the Ce/Fe-NC/Fe

3C-P catalyst delivered a powder density of 184 and 347 mW cm

−2, respectively (

Figure 5k,l).

Figure 5.

(

a) Schematic representation of 0.5La-CeNC-Fe. (

b) XPS deconvoluted peaks of Ce

3+ and (

c) obtained Ce

3+ content. (

d) CV and (

e) LSV curves of various 0.5La-CeNC-Fe catalysts. (

f) LSVs recorded at various rotations per minute. (

g) K–L plots. (

h) Number of electrons. (

i) Tafel plots of 0.5La-CeNC-Fe catalysts (Reproduced with permissions from Ref. [

83]). (

j) Schematic synthesis of Ce/Fe-NC/Fe

3C-P catalyst. (

k) LSV curves of various Ce/Fe-NC/Fe

3C-P catalysts in 0.1 M HClO

4. (

l) PEMFC polarization curves of Ce/Fe-NC/Fe

3C-P catalyst (Reproduced with permissions from Ref. [

85]).

Figure 5.

(

a) Schematic representation of 0.5La-CeNC-Fe. (

b) XPS deconvoluted peaks of Ce

3+ and (

c) obtained Ce

3+ content. (

d) CV and (

e) LSV curves of various 0.5La-CeNC-Fe catalysts. (

f) LSVs recorded at various rotations per minute. (

g) K–L plots. (

h) Number of electrons. (

i) Tafel plots of 0.5La-CeNC-Fe catalysts (Reproduced with permissions from Ref. [

83]). (

j) Schematic synthesis of Ce/Fe-NC/Fe

3C-P catalyst. (

k) LSV curves of various Ce/Fe-NC/Fe

3C-P catalysts in 0.1 M HClO

4. (

l) PEMFC polarization curves of Ce/Fe-NC/Fe

3C-P catalyst (Reproduced with permissions from Ref. [

85]).

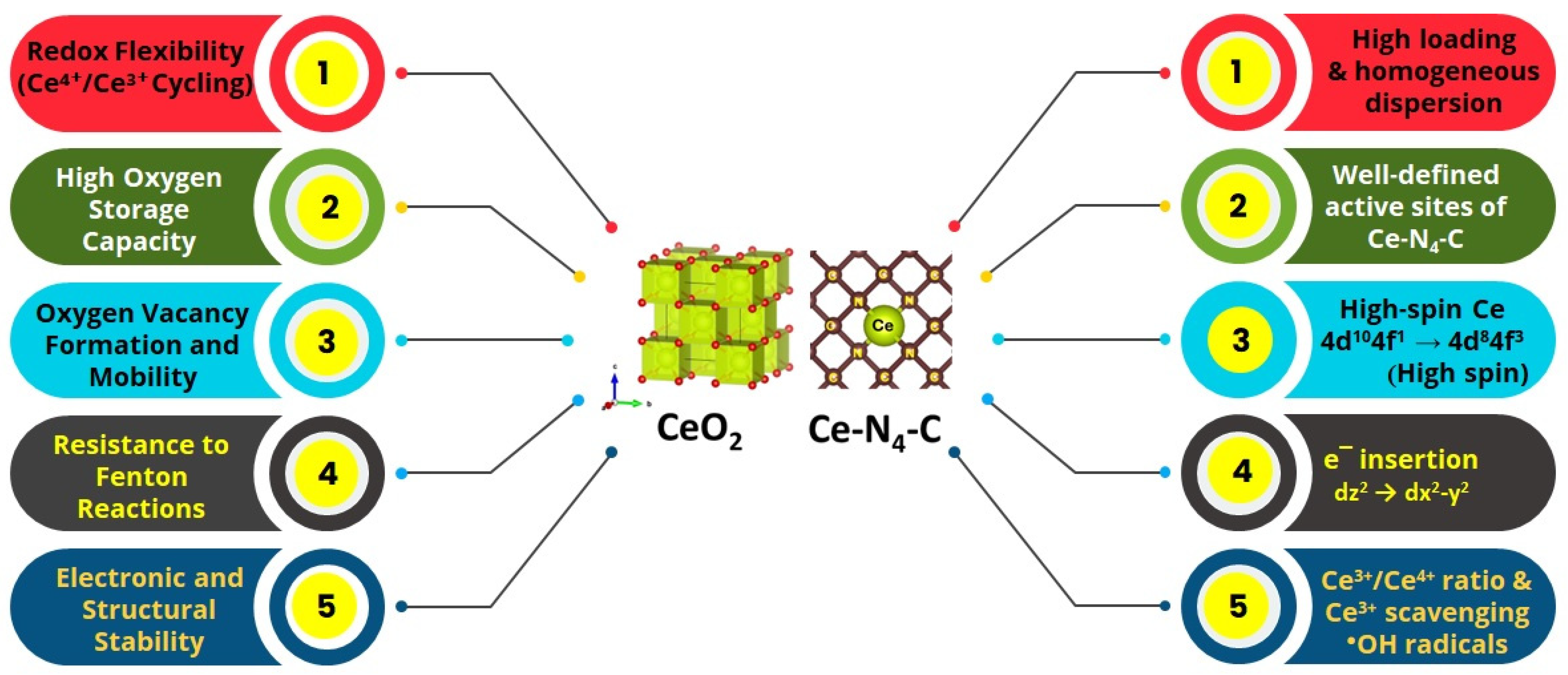

In another study, Zenghui et al. [

95] synthesized a unique three-dimensional (3D) star-like carbon material electrocatalyst made of Fe and Ce, synthesized by a ZIF-8 structures with Zn

2+ and 2-MIM and the Fe

3+ and Ce

3+ ions then incorporated into the ZIF-8 structures in the presence of a CTAB surfactant, and pyrolyzed at 910 °C, followed by acid etching (

Figure 6a). SEM and TEM measurements prove that the FeCeNC catalyst has a star shape, where each corner is of the same size and all corners are oriented in different directions in three dimensions. While the synthesis of the FeCeNC catalyst looks almost very similar to the simple, traditional ZIF-8 synthesis, the only difference is the use of the CTAB surfactant; therefore, the evolution of the 3D star-shaped FeCeNC catalyst could be primarily attributed to the use of CTAB (

Figure 6b–k). The ORR activity of FeCeNC catalyst was evaluated in 0.1 M KOH solution. The order of ORR activity is as follows: NC < CeNC < FeNC < FeCeNC catalysts with a half-wave potential of 0.796, 0.799, 0.803, and 0.855 V vs. RHE, respectively. The ORR activity of the final and optimized FeCeNC catalyst is also higher than the commercial catalysts Pt/C by 25 mV. However, the number of electrons transferred per O

2 molecule is slightly lower than the catalysts discussed so far, with an ‘n’ value of 3.7 derived from the K-L plots. Thanks to the strong bond between Fe, Ce, and the coordinating N atoms (Fe-N and Ce-N), FeCeNC also showed remarkable durability, with only a 2 mV decay after 1000 cycles. When assembled with FeCeNC as a cathode catalyst with rechargeable ZAB, it delivered a power density of 169.2 mW cm

−2, much higher than the Pt/C catalyst which only delivered 88.0 mW cm

−2. Furthermore, after 80 h of cycling, the charge–discharge efficiency of the ZAB battery dropped by just 6.8%, demonstrating excellent durability thanks to the higher power density and FeCeNC catalyst (

Figure 6l–q).

In another study, Kumar et al. [

96] synthesized highly efficient ZIF-derived Fe

xCe

y@N–C composite catalysts for ORR. In this study, a simple ZIF-8 synthesis in the presence of Ce

3+ and Fe

3+ with ZIF-8 and MWCNTs, which were then pyrolyzed at 900 °C, generated highly defect-rich and disordered structured electrocatalysts of a Fe

xCe

y@N–C (x:y =1:1) composition, which offer a greater tendency to adsorb O

2 and promote the ORR kinetics which contains Fe-N

x and Ce-N

x active sites for ORR. In particular, it was well documented that Fe-N

x is the most accepted form of catalytic active site of M

x-N

y-C, and Ce-N

x takes a dual role as an ORR active site and a scavenger of free radical that are generated from Fe-Nx sites, as a result of the 2+2 electron reduction reaction, and mitigate catalyst degradation from reactive oxygen species (ROS) generated nearby the iron centers.

The XRD analysis of the catalysts reveals both metallic Fe and Ce and Fe-Ce alloy phases. XPS analysis reveals several important reasons contributing to the ORR activity of the Fe

xCe

y@N–C catalyst, especially in Fe3p and Ce3d XPS spectra, as discussed below. The XPS peaks at 710.8 and 723.1 eV could potentially be indicative of the Fe

3+ and Fe

2+ species present in the octahedral places. The exclusive presence of divalent Fe is indicated by the satellite peak at approximately 716.0 eV. The adsorption of O

2 intermediates is directly impacted by the movement of Fe in or out of the N

4 plane, caused by changes in potential which correspond to changes in its oxidation state from +2 to +3. The structural distortion caused by substituting Fe

3+ for Zn

2+ in ZIF-8, as shown in experimental studies, is less stable because of the smaller ion radius (49–55 pm) [

97]. Initial reduction of Fe

3+ to Fe

2+ in active sites improves ORR kinetics, which in turn helps to displace adsorbed H

2O with O

2 and facilitates electron transfer from Fe

2+ to O

2 [

98,

99]. Thus, by supplying evenly distributed Fe-N

x moieties and easing the adsorption of O

2 intermediates, Fe

2+ improves the ORR electrocatalytic activity. The Ce

3d XPS spectra show the co-existence of Ce

3+3d

3/2 (3d

10 4f

1) and Ce

4+ (3d

104f

0). In particular, the presence of Ce

3+3d

3/2 (3d

10 4f

1) with the 4f

1 orbital and a lone pair of electrons is an important aspect of the Ce-based catalysts. Ce 4f

1 electrons a have high affinity to interact with transition metal atoms such as Fe and help in electron transfer from Ce → Fe, further enhancing the interaction of O

2 on Fe active sites, due to the 4f

1 localized electron transfer to d-orbitals of Fe active site due to their difference in their electronegativity values [

100]. This hybridization of 4f-3d orbitals reduces the band gap and enhances the conduction band dispersion, facilitating efficient ORR. To briefly conclude, the Fe

2+/

3+ and Ce

3+/

4+ redox active couples promote enhanced ORR kinetics. As expected, a clear demonstration of the synergistic effects of Fe

2+/

3+ and Ce

3+/

4+ on the ORR activity has been established in the RDE studies in 0.1 M KOH solution. The ORR onset potential of 0.92 V is recorded for the Ce@NC catalyst, whereas the Fe1Ce1@NC catalyst ORR onset potential was found to be around 0.981 V, with a half-wave potential of 0.867 V vs. RHE, higher than that of 30 mV from the Pt/C catalyst.

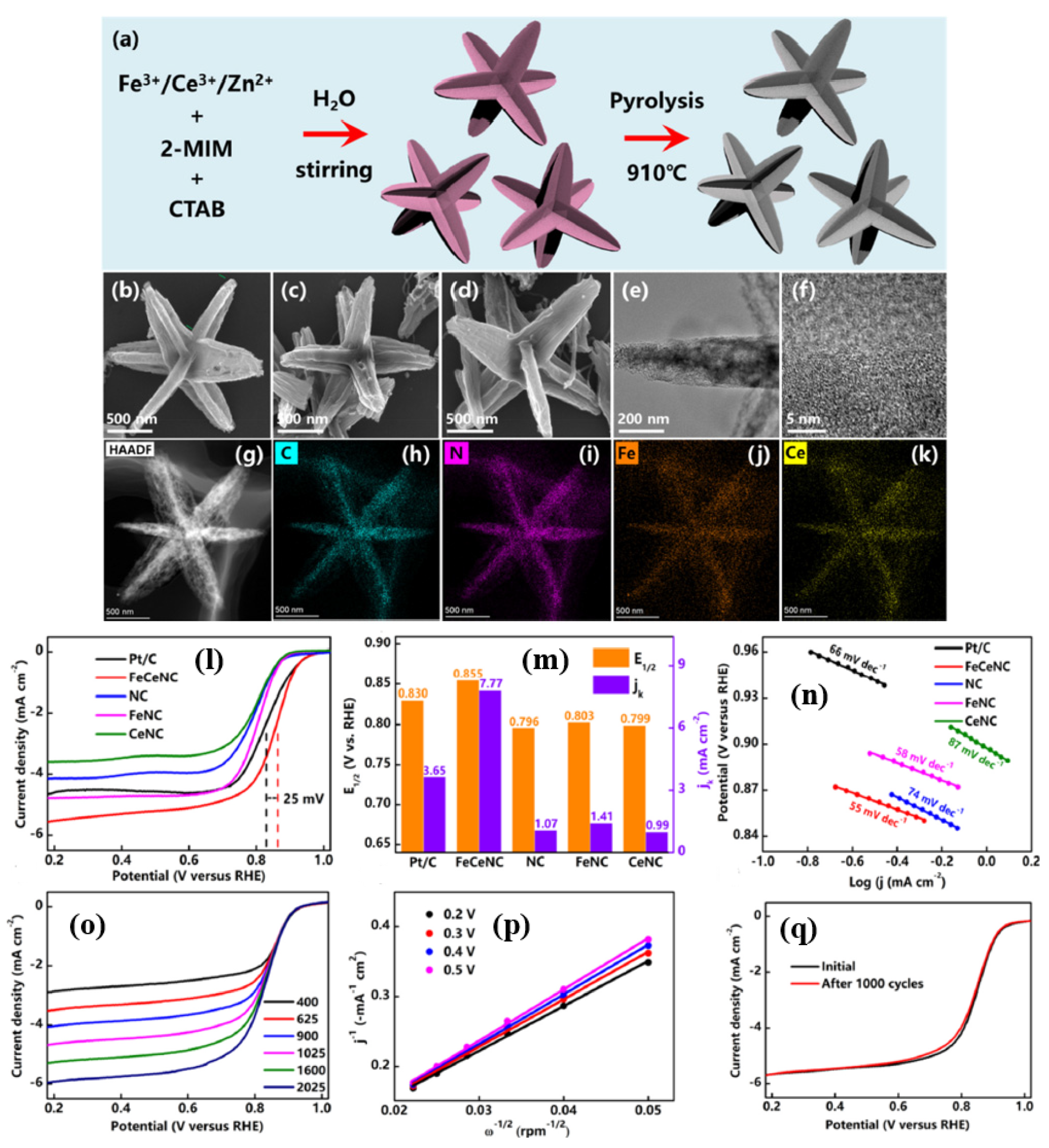

From the discovery of single-atom catalysts, research on embedding two or more atoms of different properties, creating dual-atom and multiple-atom catalysts, has become popular. Due to complexity of the multi-atom-based catalysts, dual-atom-based catalytic systems have recently attracted tremendous attention due to the easier gauge of the synergistic effects between the different metal atoms. Yang et al. [

101] demonstrated the effect of Fe and Ce dual-metal catalysts (Fe-Ce-SAD/HPNC) to modulate the d-f orbital hybridization with an optimal O-binding energy to create an excellent ORR catalyst. It was found that, by hybridizing d-f orbitals, the d-band center of the Fe atom decreases, thus making the transfer of electrons to the adsorbed OH intermediates easier, therefore helping in accelerating the rate-determining step and thus the ORR (

Figure 7a–e). The XANES study of the Fe-Ce-SAD/HPNC revealed that Fe atoms were positively charged, with Ce in the form of a valence between +3 and +4. Furthermore, the Ce L

3-edge XANES spectrum suggests that Ce can exist in the form of isolated atoms, not bonded to Fe. However, the EXAFS spectrum indicates that Ce is bonded to -N due to Ce−N scattering, indicating that catalyst have atomically dispersed Ce-N sites. The ORR studies indicate that the Fe-Ce-SAD/HPNC catalyst showed a positive ORR onset potential of 0.91 V, a half-wave potential of 0.81 V, and a J

k of 32.7 mA cm

−2 at 0.75 V vs. RHE.

In addition, the Fe-Ce-SAD/HPNC catalyst exhibited the highest double-layer capacitance of 53 mF cm

−2 among all the catalysts in the study, indicating that the Fe-Ce-SAD/HPNC catalyst possess a higher surface area and hence high ORR activity. Furthermore, the reactive oxygen species (ROS) that include H

2O

− or H

2O

2 and OH

● formed during the ORR process is one of the major issues that elevates the degradation of several components; therefore, it is important to quantify the ROS of the catalysts [

102]. The qualitative and quantitative analysis of ROS is generally performed by the UV spectroscopy analysis with the help of 2,20-azinobis(3-ethylbenzthiazoline-6-sulfonate) (ABTS) as a substrate, that reacts with ROS formed during the ORR to form a green-colored solution upon reacting with ROS, with an absorption maxima at 417 nm. Interestingly, the Fe-Ce-SAD/HPNC catalysts showed lower intensity of the peak at 417 nm, along with the visual appearance of a light-colored solution, indicating that the Fe-Ce-SAD/HPNC catalyst forma less ROS during ORR. In addition to the RDE studies, the authors also evaluated the practical application of the Fe-Ce-SAD/HPNC catalyst in PEMFC conditions. The Fe-Ce-SAD/HPNC catalyst delivered a powder density of 0.771 W cm

−2, with a catalyst loading of 3 mg cm

−2, at a pressure of 1 bar H

2-O

2 and 0.498 W cm

−2 in H

2-O

2 (

Figure 7f–k).

The ORR mechanism of Fe-Ce-SAD/HPNC catalysts is assessed using density functional theory analysis by constructing a model of an active site composed of N

4−Fe−Ce−N

6−C and Fe−N

4−C active sites for understanding the differences in the ORR mechanism [

101]. The distance between Fe and Ce atoms was adjusted to 0.385 nm. The obtained Bader charge analysis reveals charge transfers of 0.81 and 1.10e

− for Fe-SAD HPNC and Fe-Ce-SAD/HPNC for the adsorbed *OH, confirming that the higher electron density around the Fe-Ce-SAD/HPNC catalyst is due to efficient electron transfer from Ce to Fe, enhancing the adsorption of O

2. The density of states (DOS) further reveals that the d-band center of Fe in Fe-Ce-SAD/HPNC catalyst significantly decreased and that more occupied orbitals start to appear near the Fermi level due to

f-d orbital interaction. The decreased

d-band center means that more and more electrons are being added from Fe to the ORR intermediates such as -OH, which, therefore, reduces the adsorption strength between the ORR intermediate and the Fe-Ce-SAD/HPNC catalyst surface. The obtained

d-band center from the DOS values relative to the Femi levels are −1.7 and −2.6 eV, respectively. The calculated free energy values were derived for various ORR intermediates such as *OOH, *O, and *OH. It is seen that there is a significant difference in the RDS of Fe-SAD HPNC and Fe-Ce-SAD/HPNC catalysts. For FeCe-SAD/HPNC catalysts, it is *O + H

+ + e− → *OH, whereas for Fe-SAD/HPNC, it was *OH + H

+ + e− → H

2O, indicating that Ce 4F weakens the adsorption strength between the Fe active sites and the ORR intermediates, shifting the reaction mechanism with *OH desorption to *O > *OH. Therefore, it can be inferred that in Fe-Ce dual-atom-based catalysts, Fe is the main active center and rare earth Ce 4f electrons help to enhance the charge transfer and reduce the

d-band center and hence enhance the ORR kinetics.

In a study, it was found that, in the process of Pt anchoring onto CeO

2 through a high temperature treatment, the Pt atoms are tightly trapped on the ceria surface. Rather than diffusing int to the bulk phase of ceria and DFT, studies further indicate the stabilization effect of ceria for various metals such as Ni/Pd/Pt; essentially, CeO

2 acts as dispersing agent. Based on these assumptions, Li et al. [

103] explored the possibilities of stabilizing atomically dispersed Fe via ceria confining and trapping. With the CeO

2 confining and trapping strategy, an Fe content as high as 4.6 wt% has been achieved. The Ce

3+ and Fe

3+ were adsorbed on the polypyrrole nanowires through electrostatic attraction. The metal ions are attached to the polypyrrole via backbone N atoms and the resulting material is then thermally treated to synthesize Ce/Fe-NCNW. Among various compositions of Ce

3+ and Fe

3+, the atomic ratio of 1:1 Ce

3+ and Fe

3+ is found to be optimal in terms of ORR activity. The Ce/Fe-NCNW catalyst showed an excellent half-wave potential of 0.915 V, higher than Pt/C by 49 mV, and a 3.3-times higher kinetic current density than Pt/C in 0.1 M KOH electrolyte, with a HO

2− yield of 2.5%. In a fuel cell comprising an alkaline membrane, the Ce/Fe-NCNW catalyst delivered a power density of 496 mW cm

−2, with a catalyst loading of 1.0 mg cm

−2 at 30 pis pressure. The catalyst synthesized without Ce showed lower ORR activity, confirming the definite role of ceria in ORR catalysis. The structural analysis of the Ce/Fe-NCNW catalyst indicates no visible agglomeration of Fe, whereas nanoparticles of CeO

2 were observed. A high content of atomically dispersed Fe (4.6 wt.%) in Ce/Fe-NCNW is achieved by the bonding of Fe atoms to O in the lattice during heat treatment and the effective suppression of agglomeration of isolated Fe atoms, made possible by ceria’s spatial confinement and strong trapping in this process. In addition, the synergistic effect of Fe and Ce further improves O

2 adsorption and reduction kinetics, leading to enhanced ORR activity.

Though Fe-N-C-based catalysts are sought for as the best alternatives to the traditional Pt/C catalysts, they suffer from poor stability due to surface carbon oxidation, demetallation, protonation of the N-groups, and anion adsorption. One of the greatest limitations of Fe-N-C-based catalysts is the formation of reaction oxygen species (ROS) such as

●OH, which irreversibly destroys the carbon support and membrane. Carbon support corrosion leads to the demetallation or loss of FeN

x active sites. To mitigate the effect of ROS, Chu et al. [

104] designed atomically dispersed Fe and Ce atoms on the microporous carbon derived from the MOFs. While synthesizing the Fe/Ce through ZIF-8 strategy, the presence of Ce

3+ ions could dynamically alter the growth of ZIF-8 and significantly alters (decreases) the particle size. This feature may be linked to the comparatively reduced growth rate of ZIF-8 in the presence of Ce, resulting in a smaller particle size and enhanced encapsulation of Fe ions within the framework. Consequently, in addition to the potential radical scavenging effect, the introduction of Ce enhances catalytic activity through effective Fe incorporation (augmenting active site density) and ZIF-8 particle size reduction (enhancing Fe utilization). DFT studies suggest that the reaction of H

2O

2 decomposition to O

2 and H

2O are similar on both FeCe-N-C and Fe-N-C catalysts. However, a significant difference is observed in the potential energy diagram of the FeCe-N-C catalyst, in which Ce sites catalyzing the *O to O

2 step are thermodynamically faster, which is beneficial to reduce ROS conversion into H

2O. Furthermore, the Gibbs free energy profiles suggests that the FeCe-N-C catalyst showed the lowest energy barrier for facilitating the adsorbed *OH species from the Fe site. Exploration of the electronic density distribution through Badar charge analysis reveals lower adsorption energy for oxygen species on the FeCe-N-C catalyst due to electron delocalization between Fe and Ce. The independent active sites of CeN

x are highly active towards catalyzing OOH* (to yield O

2*) and O* (to yield OH*). This DFT analysis clearly reveals the participation of Ce on the radical scavenging of ROS, thereby protecting the Fe-Nx active sites. The experimentally synthesized catalysts showed that FeCe-N-C catalysts exhibited enhanced ORR activity in the order of Fe,Ce-N-C > Fe-N-C >> Ce-N-C with the half-wave potential of 0.808, 0.791, and 0.454 V vs. RHE, respectively, in 0.1 M HClO

4. Experimental and direct evidence of the FeCe-N-C catalyst could be deduced from the RRDE experiments and estimation of H

2O

2, which is found to be <1% in all the potential range, suggesting that the FeCe-N-C catalyst is a great choice for the ORR. In addition, the effect of Ce radical scavenging can also be translated from the stability test, in which the FeCe-N-C catalyst presented excellent stability with just a loss of 22 mV after 30,000 potential cycles, better than the Fe-N-C catalyst and Pt/C catalyst, suggesting that Ce radical scavenging helps to enhance the stability of the catalysts. The experiment and theoretical analyses indicate that Ce single sites promote catalysis, scavenging ROS and promoting the 4e ORR process by decomposing H

2O

2 (

Figure 8a–h).

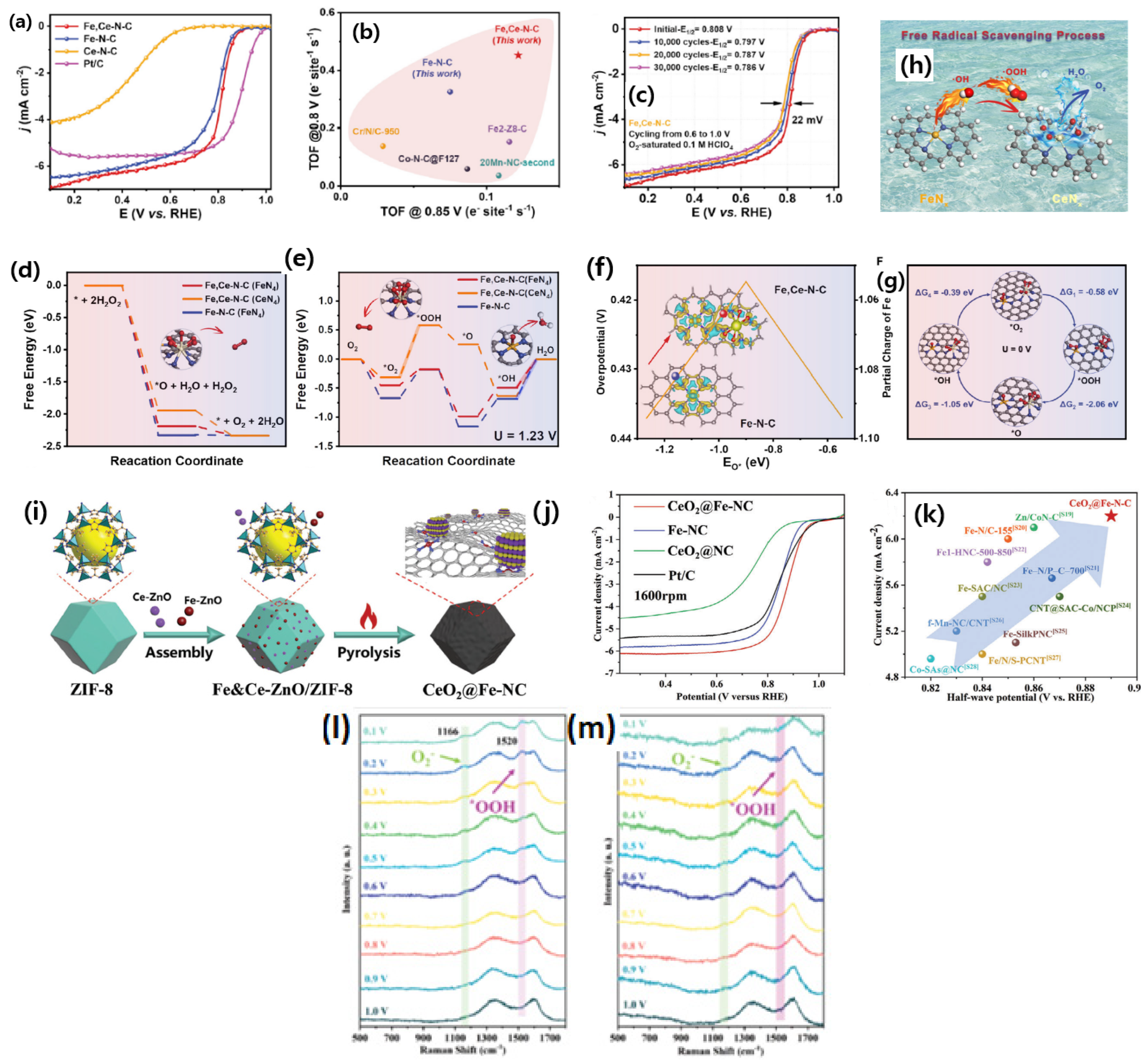

In another study, there is a similar approach to improving electrocatalytic activity and stability by introducing CeO

2 as an antioxidant agent, presented by Luo et al. [

105]. An interesting in situ Raman spectroscopy analysis revealed the gradual appearance of Raman shift at 1166 and 1520 cm

−1, corresponding to the O

2¯ and *OOH intermediates as the potential rises from 1.0 to 0.1 V for CeO

2@Fe-NC, whereas these Raman shift peaks are barely visible in the case of Fe-NC catalysts, indicating a definite role of Ce in enhancing ORR activity. Theoretical simulations indicate a strong electronic interaction between Fe-N

x moieties and CeO

2. The Gibbs free energy for the RDS of *OH was found to be 0.39 eV for the CeO

2@Fe-NC catalyst, whereas it was 1.01 eV for the Fe-NC catalyst, indicating that the presence of CeO

2 enhances the ORR activity significantly. Similar observations were drawn from the experimental studies, in which the CeO

2@Fe-NC catalyst showed a half-wave potential of 0.89 V vs. RHE. The number of electrons transferred per O

2 molecules was found to be four, suggesting that CeO

2@Fe-NC ORR proceeds by a direct four-electron pathway. The H

2O

2 UV-Vis absorption spectra shows that H

2O

2 begins to decompose at 80 s for the CeO

2@Fe-NC catalyst, whereas it is 225 sec in case of the Fe-NC catalyst, indicating that CeO

2 played a crucial role in eliminating H

2O

2 during ORR (

Figure 8i–m). In another study [

106], it was found that Ce incorporation into CL-Fe/(Fe,Ce)

xO

y-NC enhances the concentration of active sites, including pyridinic nitrogen, graphitic nitrogen, and metal-chelated nitrogen. The CL-Fe/(Fe,Ce)

xO

y-NC shows both a micro- and mesoporous nature, with a specific surface area of 891 m

2 g

−1. XPS analysis reveals that presence of Ce

3+ (5s

25p

64f

1) can interact positively with the intermediate p electrons of the reaction intermediates, promoting charge transfer and proton coupling, whereas the Ce in the form of Ce

4+ with the electronic configuration of Ce

4+(5s

25p

6) is completely occupied, and the internal electronic structure is closed, resulting in poor catalytic activity. Therefore, the electrocatalyst with high Ce

3+ results in enhanced ORR activity. The resulting CL-Fe/(Fe,Ce)

xO

y-NC exhibits a

E1/2 of 0.861V vs. RHE and acceptable stability.

In a unique study, Zhang et al. [

107] introduced cerium oxide cyanamide (Ce

2O

2CN

2) into the Fe-N-C active sites due to the presence of unique (N=C=N)

2−, which can enhance the conduction of the carbon support through a conjugation effect. Since the (N=C=N)

2− group has a lower electronegativity than metal oxides such as CeO

2, it is possible to alter the distribution of electronic clouds, which in turn affects the material’s charge transfer capability. Therefore, the cerium oxide cyanamide can act as promoter to improve the catalytic activity and stability of M–N–C catalysts. Based on these assumptions, a heterostructure of Fe–N–C@Ce

2O

2CN

2 has been synthesized. As expected, the Fe–N–C@Ce

2O

2CN

2 catalyst showed remarkable electrocatalytic performance and methanol tolerance for the ORR, surpassing that of Fe-N-C and commercial Pt/C, due to the surface oxygen density modulation ability of the Ce

4+/Ce

3+ redox pair and the high density of the Fe-N

x active sites. The Fe–N–C@Ce

2O

2CN

2 catalyst outperforms the Pt/C catalyst in terms of ORR activity, with a half-wave potential (E

1/2) of 0.89 V vs. RHE in a 0.1 M KOH solution. In addition, in Zn–air batteries, the catalyst shows a much higher peak power density (119.35 mW cm

2) than commercial Pt/C (80 mW cm

2).

In brief, Ce is shown to be in charge of Fe’s electronic structure regulation as well as for spatially confining and stabilizing Fe atoms. Because 4f1 (Ce3+) localized electron transfer to d-orbitals of the Fe active site is due to their difference in electronegativity values in electrons, transfer from Ce → Fe further enhances the interaction of O2 on Fe active sites. Ce 4f1 of (Ce3+) has great affinity for interacting with transition metal atoms such as Fe. By lowering the band gap and improving conduction band dispersion, this hybridization of 4f-3d orbitals promotes effective ORR. Therefore, it is important to have a high ratio of Ce3+ in the catalyst. It was observed that hybridizing d-f orbitals reduces the d-band center of the Fe atom, so facilitating easy transfer of electrons to the adsorbed OH intermediates and accelerates the rate-determining step and hence the ORR. Consequently, it can be deduced that in Fe-Ce dual-atom-based catalysts, Fe is the main active center and rare earth Ce 4f electrons help to improve the charge transfer and hence reduce the d-band center and thus enhance the ORR kinetics.

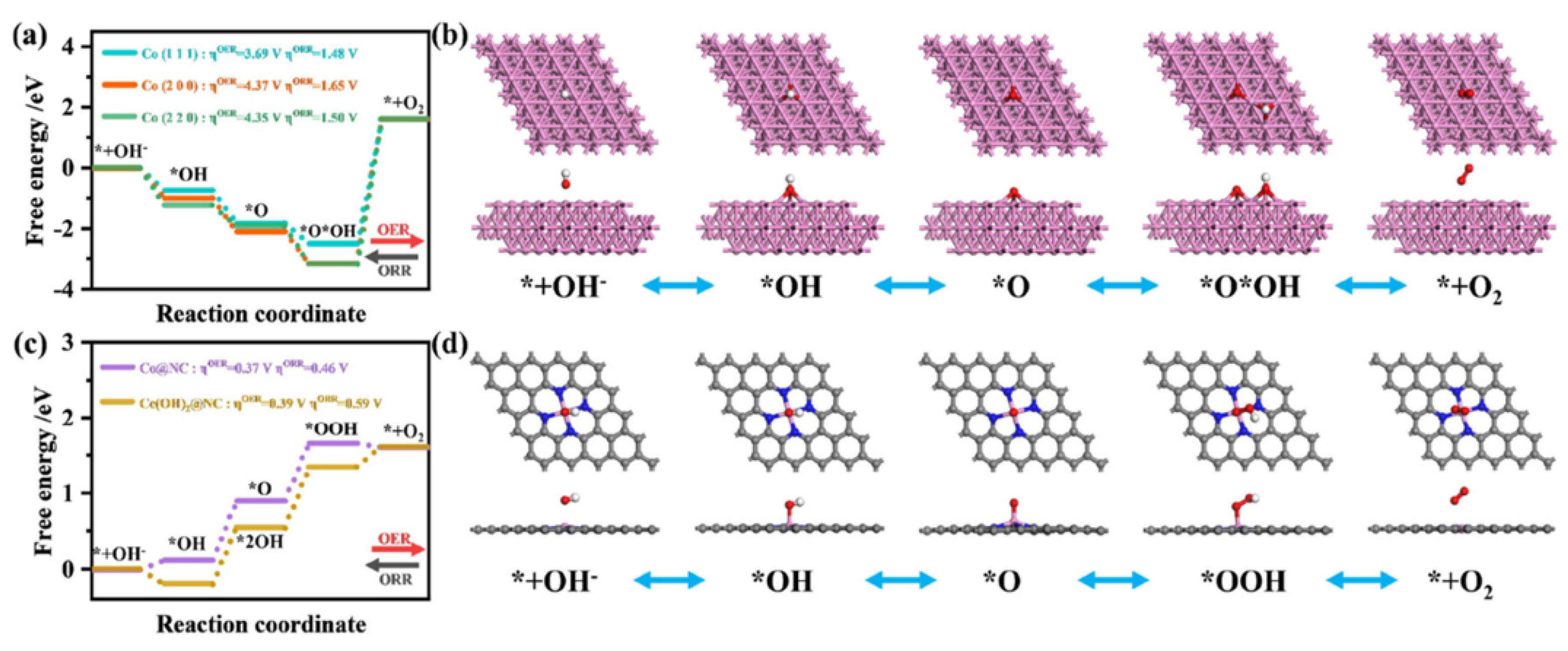

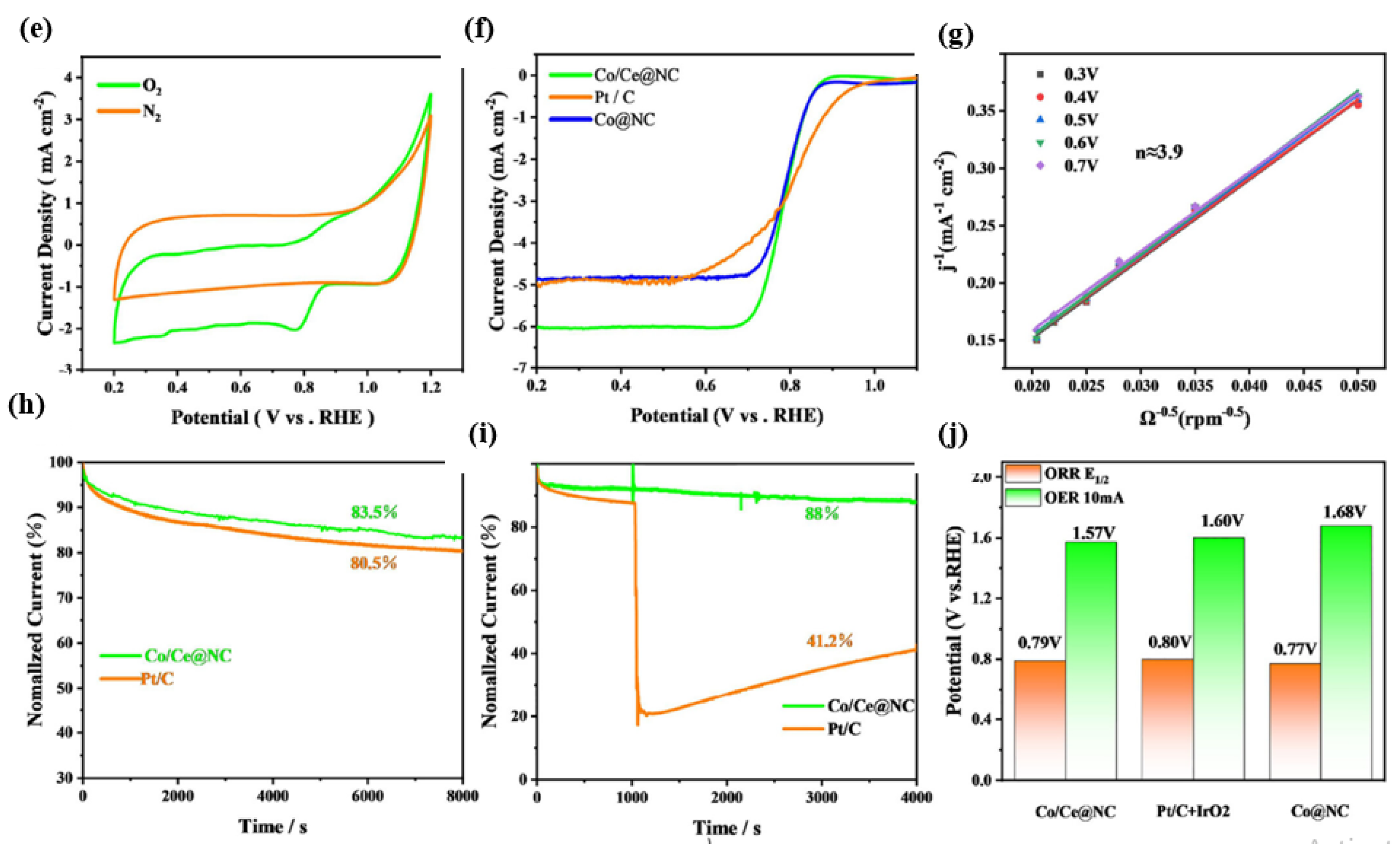

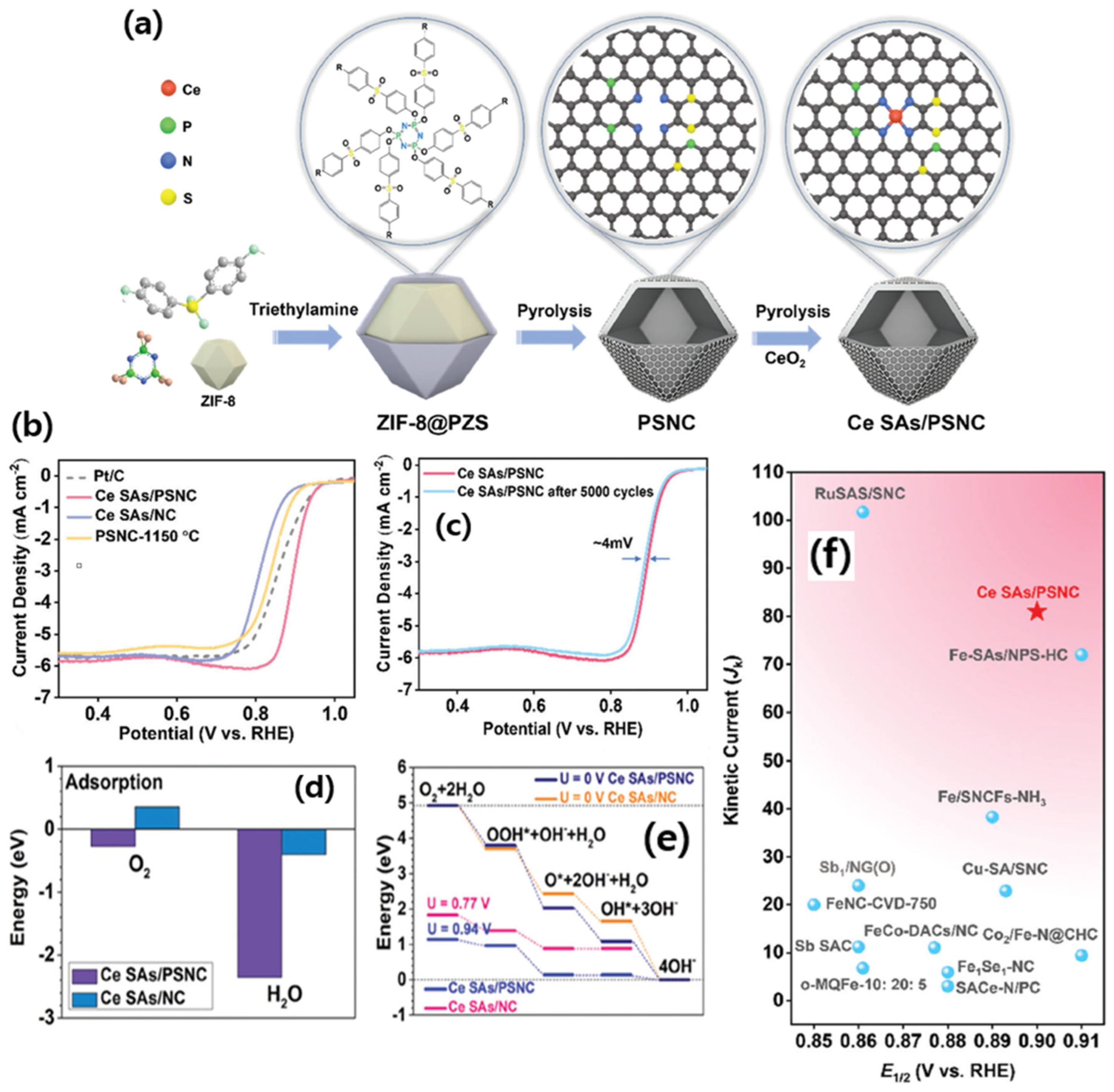

5. Co/CeO2/C Catalysts for ORR

Due to their lower radical oxygen species production, Co-N-C catalysts have gained tremendous attention as an alternative to of Fe-N-C. Since Co-N-C electrocatalysts are inactive for Fenton-like reactions and stable under harsh conditions, they have been pursued as ORR catalysts. Due to modified catalyst electron structure, O2 storage capacity, and shift in the d-band center, combining Co and Ce could improve ORR activity. Furthermore, the O2 buffering (store/release mechanism of oxygen) capacity of CeO2 can further be tuned by choosing alternative Ce precursors to the traditional Ce nitrates.

Xia et al. [

108] found that by adding a Ce

2(OH)

4SO

4.2H

2O precursor during the nucleation process of ZIF, 2D-hexagonal-leaf-like ZIF lamellae (ZIF-L) can be obtained which could generate more oxygen vacancies than by using traditional Ce precursors such as Ce nitrates (

Figure 9a–g). The leaf-like ZIF-L structures are formed by careful control of the 2-MIM and Co

3+ and Zn

2+ ions. In general, the amine N-groups from the 2-MIM interact with the H atoms of H

2O, forming H-bonds and bridging 2MIM-N-H bonds, making it further extended with other molecules of N-2MIM through sodalite layers, leading to the formation of leaflike structures. Based on this assumption, the leaf-like 2D ZIF-like structures have been observed to have a unique, smooth surface. Although the surfaces of the leaf-like lamellae become rough and numerous nanoparticles (white dots) are embedded in the surfaces of the Ce-HPCNs, the pristine leaf-like morphology of the Ce-HPCN precursor is preserved in the resulting Ce-HPCNs, as anticipated. The HR-TEM analysis shows clear leaf-like structures, with Co and CeO

2 nanoparticles in close contact with each other. The RDE studies further showed that the ORR onset potential of 0.923 V and a half-wave potential of 0.831 V for Ce-HPCN are higher than the Pt/C catalysts, due to ther unique leaf-like morphology, highly 2D open pore structure, higher content of pyridinic-N and graphitic-N sites, and the synergistic effect of Co-N

x, along with the oxygen buffering properties of CeO

2 (

Figure 9h). The O

2 buffering capacity of Ce is further determined from the O

2 temperature-programmed desorption (O

2-TPD) spectra, which clearly show a high-intensity O

2 desorption peak, indicating the enhanced adsorption energy of O

2 for the sample of Ce–HPCNs [

109]. All of these findings point to the possibility that doped CeO

2 could significantly improve O

2 adsorption capacity and the interaction between Co-N

x active sites, leading to outstanding ORR performance.

Mixed metal oxides are known examples of synergistic catalysts, in which two types of dissimilar metal oxides are known to improve electrochemical properties. For instance, a heterostructure of the CO

3O

4-MnO

2/C catalyst delivered enhanced ORR activity, owing to a direct four-electron reduction of O

2 as a result of covalent coupling between Co

3O

4-MnO

2 [

110]

. Similarly, the Pd@PdO-CO

3O

4 heterostructure catalysts delivered high ORR/OER activity [

111]. In the same way, coupling CO

3O

4 with a rare earth CeO

2 could be the best choice, owing to their abundant oxygen vacancies and oxygen storage capacity, along with reversible surface ion exchange capacity, leading to enhanced ORR activity. Li et al. [

112] synthesized Co

3O

4@Z67-NT@CeO

2 by a sequential synthesis process in which CeO

2 nanoparticles were introduced onto the surface of Co

3O

4@Z67-NT by a hydrothermal synthesis method. The XRD analysis revealed characteristic diffraction peaks of both Co

3O

4 and CeO

2, indicating the crystalline nature of bi-metal oxides in the catalysts. The XPS analysis showed the presence of high pyridinic-N, which is responsible for enhancing electronic conductivity, and onset potential for ORR, whereas graphitic-N content is known to enhance the limiting current density [

113,

114]. The XPS analysis of Co

3O

4@Z67-NT@CeO

2 shows a high proportion of Ce

2+, which are responsible for high ORR activity, along with Ce

3+ ions. Furthermore, the electrostatic interaction between Co and Ce is ascertained from the positive shift in the binding energy of Ce

3+. The relative atomic composition of Ce

3+ and Ce

4+ hint at the reason behind the ORR activity of Co

3O

4@Z67-NT@CeO

2 catalysts. It was found that the relative abundance of Ce

3+ is about 36.91%, indicating that the ORR activity of the Co

3O

4@Z67-NT@CeO

2 catalyst is due to the role of charge compensation by Ce

3+, which will generate oxygen vacancies to promote the oxygen adsorption on the catalyst surface [

115]. Furthermore, the continuous availability of a higher valance state of Co is possible due to the lattice oxygen provided by the CeO

2, keeping the catalytic cycle happening continuously. The ORR half-wave potential of Co

3O

4@Z67-NT@CeO

2 is found to be higher than Co

3O

4@Z67-NT by 20 mV, being 0.88 V vs. RHE in 0.1 M KOH electrolyte, indicating that CeO

2 guarantees enhanced activity.

Figure 9.

(

a,

b) SEM and (

c–

g) TEM images and elemental mapping of different elements of Ce–HPCN. (

h) ORR curves of Ce–HPCN catalysts Inset of (

e) shows the SAED picture of Co and CeO

2. (

f) ORR LSV curves of 3D-Co–Zn/C, HPCNs, and Ce–HPCNs catalysts @ 1600 rpm (Reproduced with permissions from Ref. [

108]). (

i) Schematic representation of synthesis of Ce@Co

3O

4/CNFs. (

j–

m) SEM and TEM images and elemental mapping of Ce@Co

3O

4/CNFs catalysts. (

n) LSV curves. (

o) K-L plots. (

p) Number of electrons. (

q) Tafel plots of Ce@Co

3O

4/CNFs catalyst (Reproduced with permissions from Ref. [

116]).

Figure 9.

(

a,

b) SEM and (

c–

g) TEM images and elemental mapping of different elements of Ce–HPCN. (

h) ORR curves of Ce–HPCN catalysts Inset of (

e) shows the SAED picture of Co and CeO

2. (

f) ORR LSV curves of 3D-Co–Zn/C, HPCNs, and Ce–HPCNs catalysts @ 1600 rpm (Reproduced with permissions from Ref. [

108]). (

i) Schematic representation of synthesis of Ce@Co

3O

4/CNFs. (

j–

m) SEM and TEM images and elemental mapping of Ce@Co

3O

4/CNFs catalysts. (

n) LSV curves. (

o) K-L plots. (

p) Number of electrons. (

q) Tafel plots of Ce@Co

3O

4/CNFs catalyst (Reproduced with permissions from Ref. [

116]).

In another study that examined the effect of rare earth metal oxide, CeO

2 was combined with Co

3O

4, gaining the advantage of CeO

2 as a redox couple and oxygen buffering agent. In a three-step strategy, Ce is introduced into the carbon nanofibers loaded with Co

3O

4 (Ce@Co

3O

4/CNFs) using an electrospinning (

Figure 9i) method [

116]. The XRD analysis reveals almost no visible CeO

2 peaks, indicating that either Ce is doped into the Co

3O

4 or dispersed on the catalyst due to low Ce content. This is further confirmed when Ce atoms have no effect on the polyhedral morphologies of MOF–fiber composites. TEM images show the highly dispersed, tiny Co

3O

4 nanoparticles evenly dispersed on the nanofiber surface, ensuring abundant exposed active sites for ORR (

Figure 9j–m). The XPS analysis revealed that Co

3+/(Co

3+ + Co

2+) molar ratio increases in Ce@Co

3O

4/CNFs, indicating the possibility of Ce atoms being in close contact with Co

3O

4 or inserted into the crystal structure of Co

3O

4. Furthermore, the significantly increased Co

3+ species infer that the electronic structure of Co in Co

3O

4 can be easily fine-tuned by introducing the Ce species, owing to their redox coupling reaction between Co

3+/Co

2+ and Ce

3+/Ce

4+. Moreover, the presence of a high proportion of Ce

3+ is found to be beneficial for electrocatalytic activity [

117]. The ORR curves clearly establish the synergistic effect of Co

3O

4 and Ce on the ORR activity as the Ce@Co

3O

4/CNF catalyst shows almost similar activity as that of the commercial Pt/C catalyst (

Figure 9n–q). The Ce@Co

3O

4/CNFs ZAB exhibits remarkable electrocatalytic activity, which can be attributed to the combination of Co

3O

4 and CeO

2 as well as the high conductivity of CNFs.

Metal oxides such as Co

3O

4-based spinel oxides, which are a kind of

p-type semiconductor, have been explored as efficient ORR catalysts due to their unique crystal structure in which Co

2+ occupies tetrahedral sites and Co

3+ occupy octahedral sites [

118,

119]. CeO

2, a rare earth based on Ce, is an

n-type semiconductor that is an interesting metal oxide due to its high ionic/electronic conductivity and oxygen storage capacity and can influence the oxygen reduction catalysis [

120]. Because of the strong electronic coupling effect, it is believed that hybridizing

p-type Co

3O

4 and

n-type CeO

2 will increase the activity of oxygen catalysis. By combining

n and

p-type materials, engineers can design and fine-tune an electrical structure that is advantageous for optimizing surface properties for enhanced ORR. Guo et al. [

121] synthesized a Co

3O

4/CeO

2 heterostructure in situ embedded in Co/N-doped carbon nanofibers through a facile electrospinning process (

Figure 10a–j). The bimetallic ZIF grows in a tiled pattern due to the attractive force of metal ions on the surface of the nanofibers, which facilitates the cross-linking with 2-MIM. The following in situ secondary growth method is then used to synthesize regular ZIF nanoparticles. The subsequent hydrolysis of Ce

3+ in the presence of oxygen from the surrounding environment yields CeO

2 product, which is then loaded onto the surface of the fiber and appears yellow. After that, annealing in an Ar environment yields a composite of Co

3O

4/CeO

2@Co/N-CNF and an air environment yields a composite of the same composition. A distinct heterointerface structure was observed in the synthesized Co

3O

4/CeO

2@Co/N-CNF.

At the interface, there was a distinct boundary between the two phases, with distinct groups of lattice fringes with interplanar spacings of 0.286 and 0.271 nm, representing the (220) and (200) planes of Co3O4 and CeO2, respectively. The heterointerface between Co3O4 and CeO2 is a clear indication of the strong interfacial electronic interaction between them. The XPS analysis reveals the presence of Co in the form of metallic, Co2+ and Co3+ and Ce in the form of Ce3+/Ce4+ oxidation states. The Ovac calculated from the O1s spectra; it was found that the Ovac ratio is found to be higher for the Co3O4/CeO2@Co/N-CNF catalyst compared to Co3O4@Co/N-CNF, indicating the significance of CeO2 in creating the Ovac in the catalyst. The unsaturated coordination environment is conducive to electron delocalization, and it has been generally reported that oxygen vacancies can accelerate the charge transfer rate by promoting more carriers to pass through. Also, oxygen vacancies can control the adsorption energy of the intermediate and enhance oxygen adsorption, which can lead to more efficient ORR kinetics.

According to the DFT studies by Li et al. [

122], the oxygen adsorption on the defected oxygen vacancy metal oxides is ascribed to less filling of the antibonding states. In other words, the presence of oxygen defects moves the