Enhancing Energy Density of BaTiO3-Bi(M)O3@SiO2/PVDF Nanocomposites via Filler Component Modulation and Film Structure Design

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

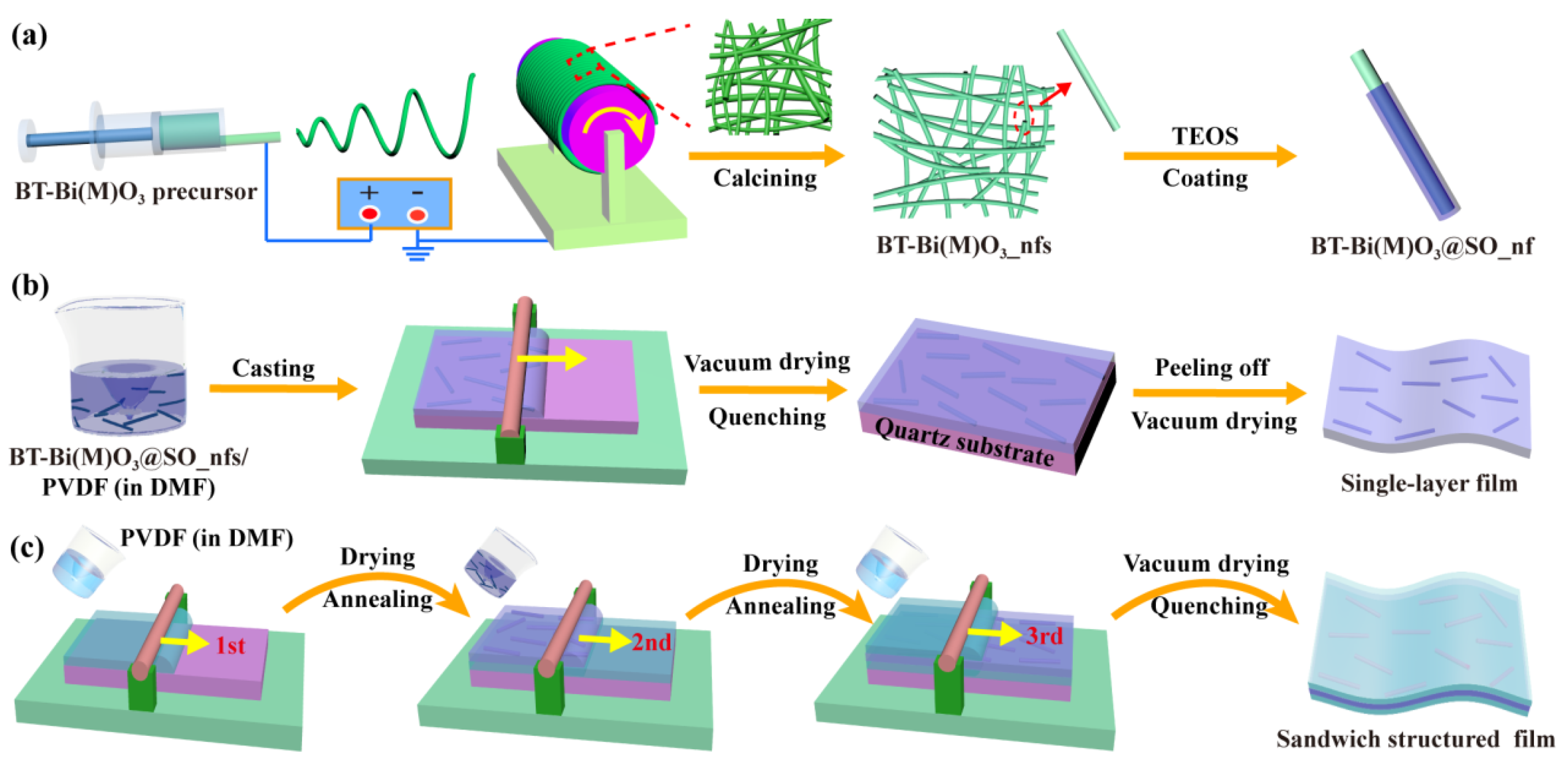

2.2. Preparation of BT-Bi(M)O3_nfs via Electrospinning

2.3. Surface Coating of BT-Bi(M)O3_nfs with SiO2

2.4. Fabrication of BT-Bi(M)O3@SO_nf/PVDF Nanocomposite Films

2.5. Finite Element Analysis of Electric Field Distribution

2.6. Characterization

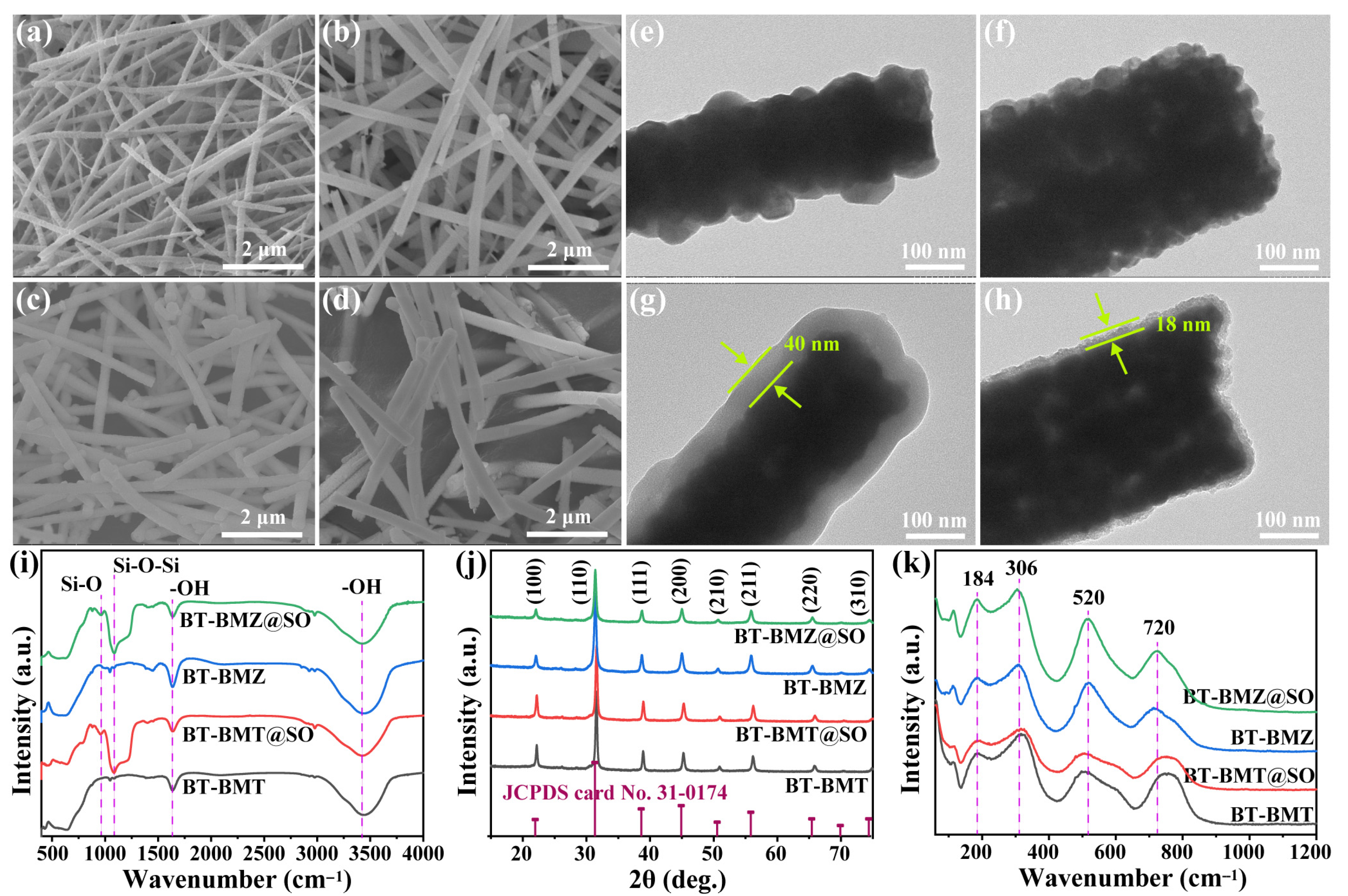

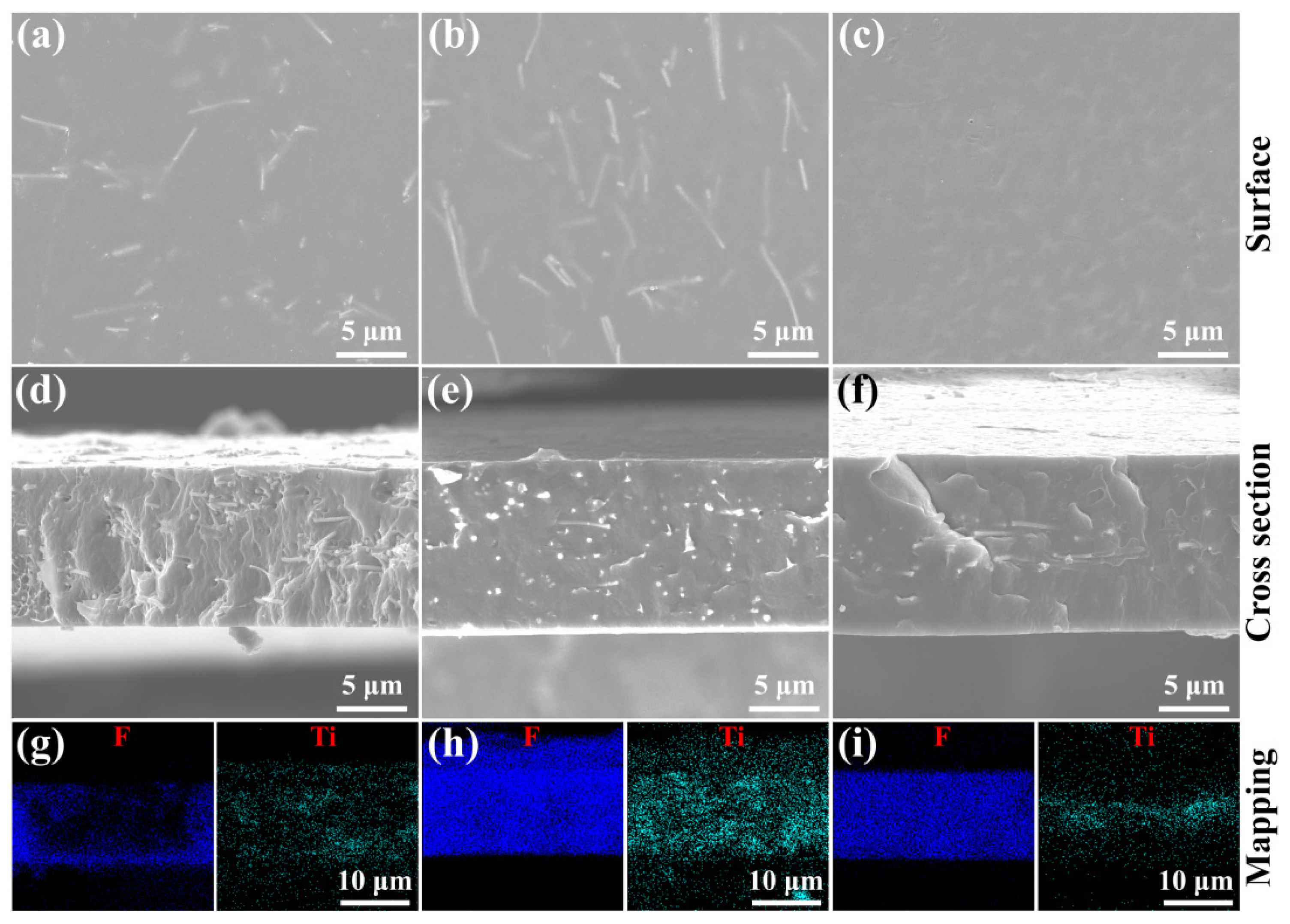

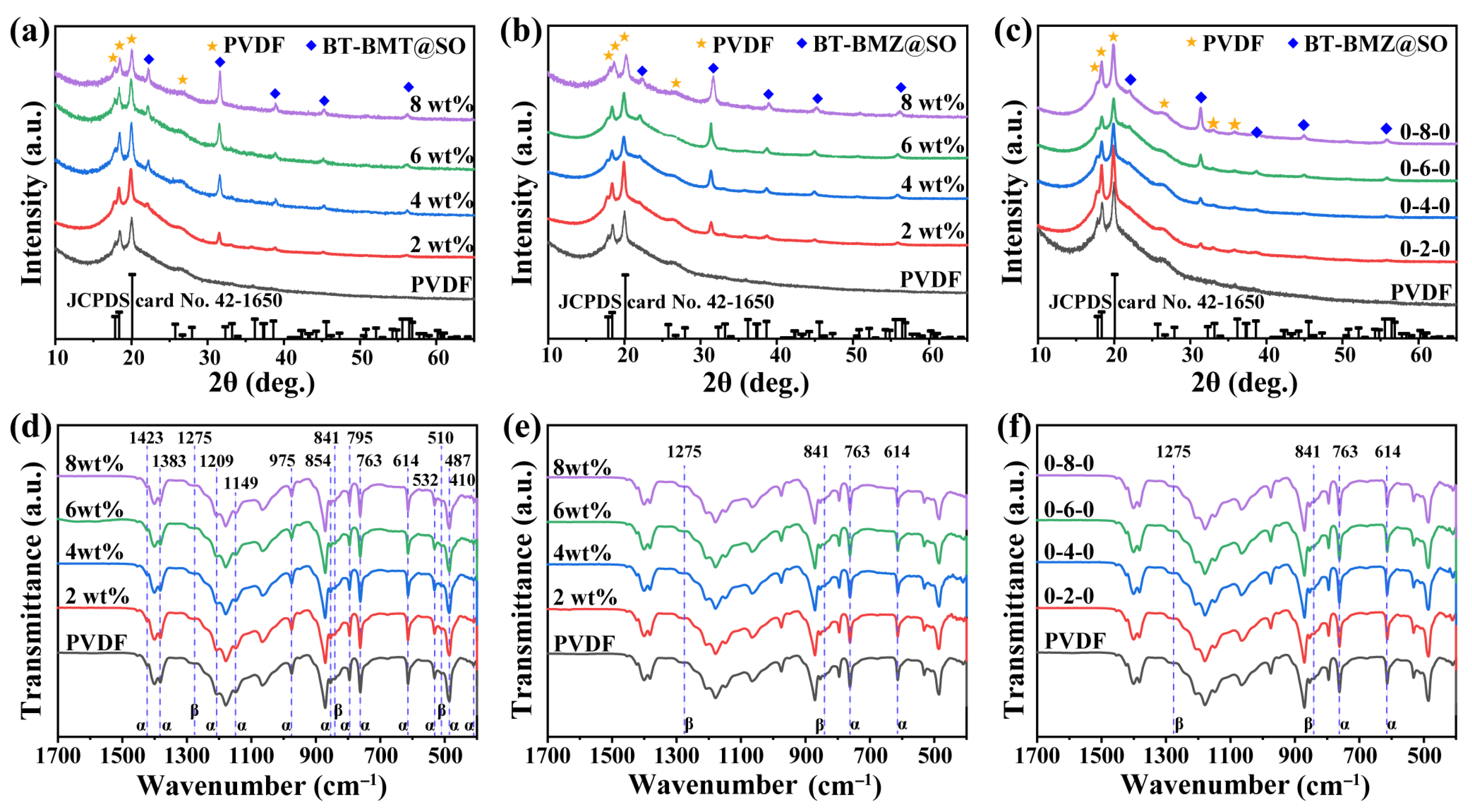

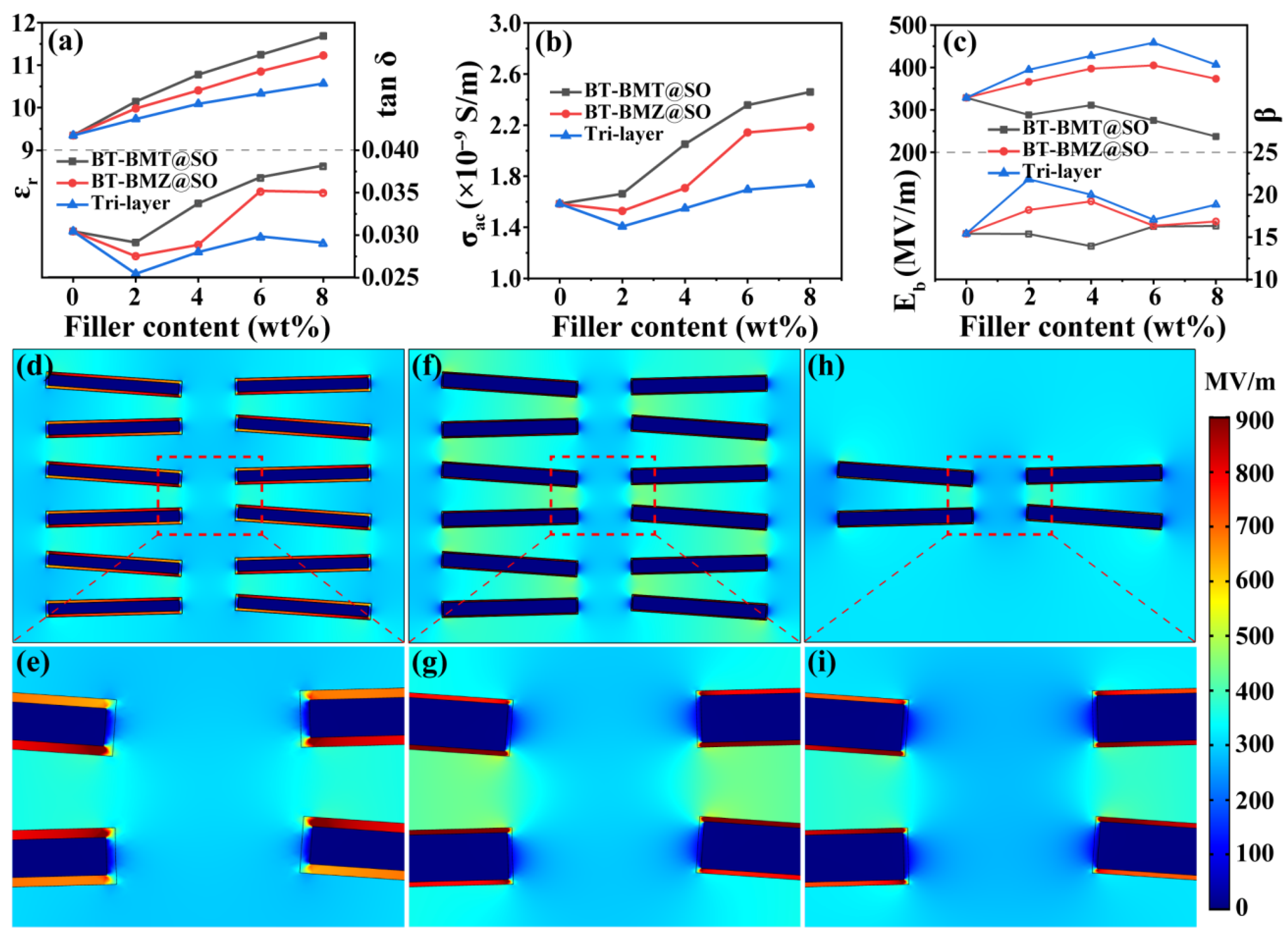

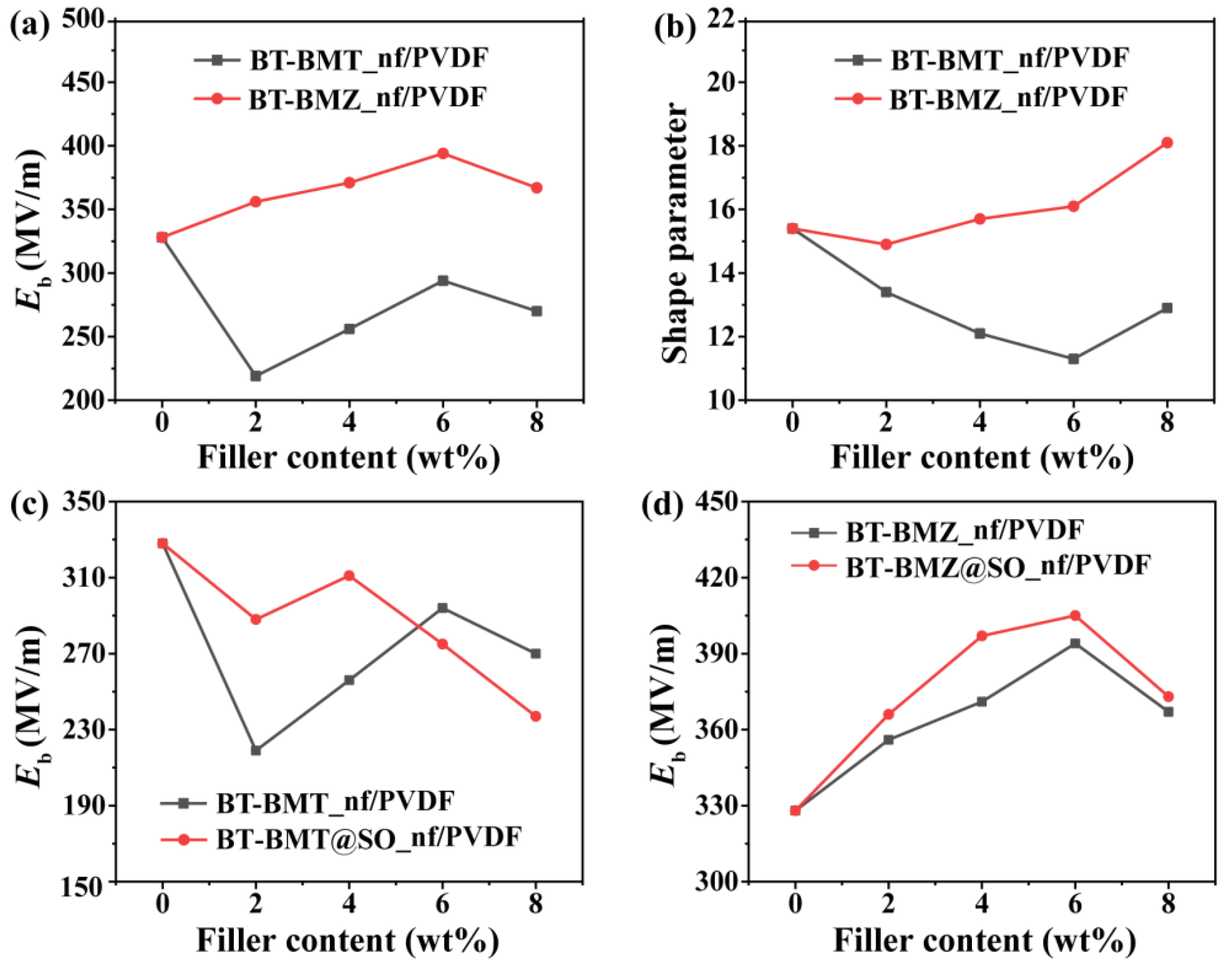

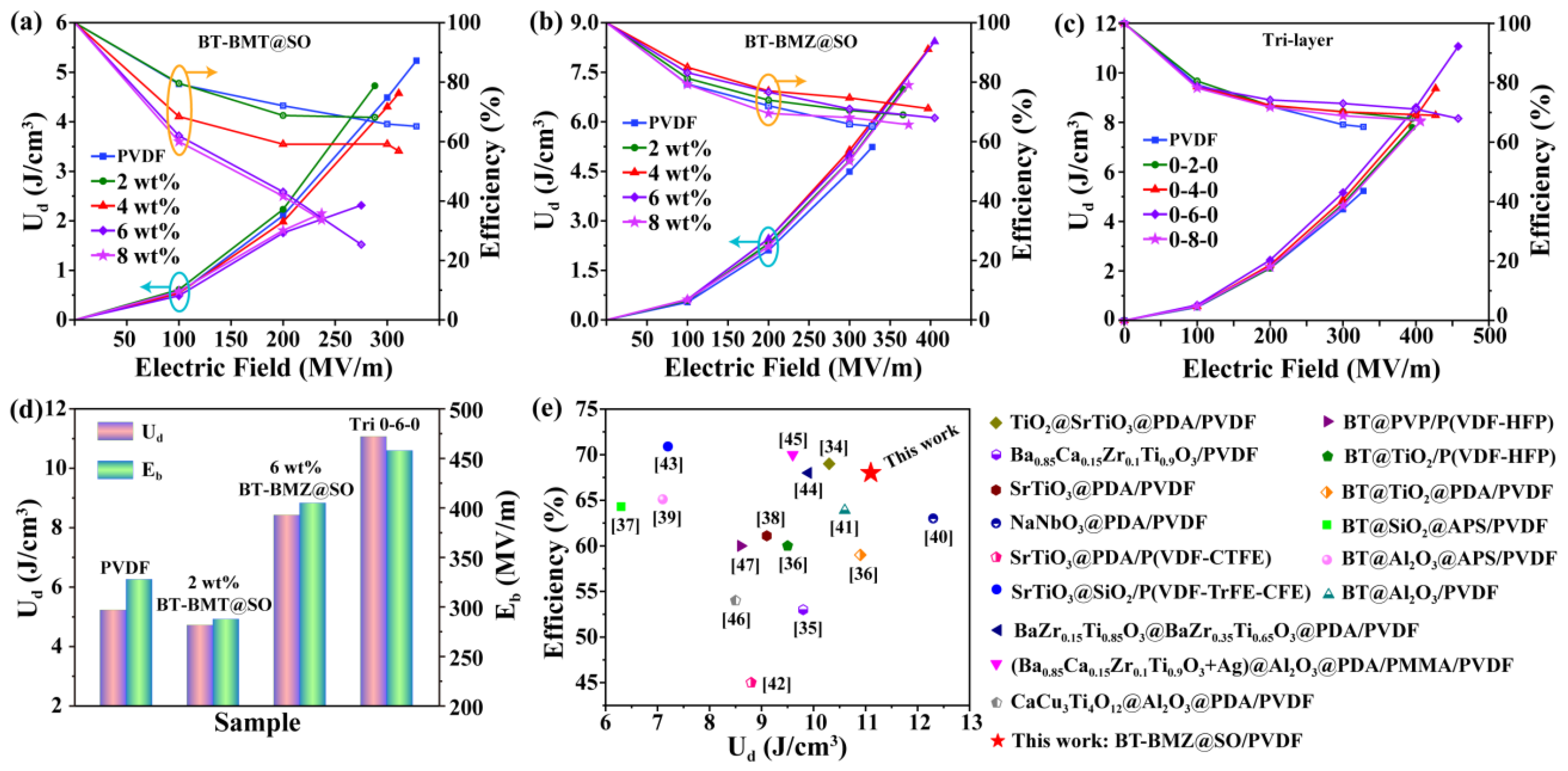

3. Results

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Li, Q.; Yao, F.Z.; Liu, Y.; Zhang, G.Z.; Wang, H.; Wang, Q. High-temperature dielectric materials for electrical energy storage. Annu. Rev. Mater. Res. 2018, 48, 219–243. [Google Scholar] [CrossRef]

- Feng, Y.; Zhou, Y.; Zhang, T.; Zhang, C.; Zhang, Y.; Zhang, Y.; Chen, Q.; Chi, Q. Ultrahigh discharge efficiency and excellent energy density in oriented core-shell nanofiber-polyetherimide composites. Energy Storage Mater. 2020, 25, 180–192. [Google Scholar] [CrossRef]

- Sun, L.; Shi, Z.; He, B.; Wang, H.; Liu, S.; Huang, M.; Shi, J.; Dastan, D.; Wang, H. Asymmetric trilayer all-polymer dielectric composites with simultaneous high efficiency and high energy density: A novel design targeting for advanced energy storage capacitors. Adv. Funct. Mater. 2021, 31, 2100280. [Google Scholar] [CrossRef]

- Chen, H.; Pan, Z.; Wang, W.; Chen, Y.; Xing, S.; Cheng, Y.; Ding, X.; Liu, J.; Zhai, J.; Yu, J. Ultrahigh discharge efficiency and improved energy density in polymer-based nanocomposite for high-temperature capacitors application. Compos. Part A Appl. Sci. Manuf. 2021, 142, 106266. [Google Scholar] [CrossRef]

- Tan, D.Q. Review of polymer-based nanodielectric exploration and film scale-up for advanced capacitors. Adv. Funct. Mater. 2019, 30, 1808567. [Google Scholar] [CrossRef]

- Zhang, T.; Zhao, X.; Zhang, C.; Zhang, Y.; Zhang, Y.; Feng, Y.; Chi, Q.; Chen, Q. Polymer nanocomposites with excellent energy storage performances by utilizing the dielectric properties of inorganic fillers. Chem. Eng. J. 2021, 408, 127314. [Google Scholar] [CrossRef]

- Yang, Z.; Wang, J.; Hu, Y.L.; Deng, C.Y.; Zhu, K.J.; Qiu, J.H. Simultaneously improved dielectric constant and breakdown strength of PVDF/Nd-BaTiO3 fiber composite films via the surface modification and subtle filler content modulation. Compos. Part A Appl. Sci. Manuf. 2020, 128, 105675. [Google Scholar] [CrossRef]

- Kim, P.; Doss, N.M.; Tillotson, J.P.; Hotchkiss, P.J.; Pan, M.J.; Marder, S.R.; Li, J.; Calame, J.P.; Perry, J.W. High energy density nanocomposites based on surface-modified BaTiO3 and a ferroelectric polymer. ACS Nano 2009, 3, 2581–2592. [Google Scholar] [CrossRef] [PubMed]

- Tang, H.; Lin, Y.; Andrews, C.; Sodano, H.A. Nanocomposites with increased energy density through high aspect ratio PZT nanowires. Nanotechnology 2011, 22, 015702. [Google Scholar] [CrossRef]

- Li, J.; Seok, S.I.; Chu, B.; Dogan, F.; Zhang, Q.; Wang, Q. Nanocomposites of ferroelectric polymers with TiO2 nanoparticles exhibiting significantly enhanced electrical energy density. Adv. Mater. 2009, 21, 217–221. [Google Scholar] [CrossRef]

- Hu, J.; Zhang, S.; Tang, B. Rational design of nanomaterials for high energy density dielectric capacitors via electrospinning. Energy Storage Mater. 2021, 37, 530–555. [Google Scholar]

- Zhang, H.; Marwat, M.A.; Xie, B.; Ashtar, M.; Liu, K.; Zhu, Y.; Zhang, L.; Fan, P.; Samart, C.; Ye, Z.G. Polymer matrix nanocomposites with 1D ceramic nanofillers for energy storage capacitor applications. ACS Appl. Mater. Interfaces 2019, 12, 1–37. [Google Scholar] [CrossRef] [PubMed]

- Wang, Y.; Yao, M.G.; Ma, R.; Yuan, Q.B.; Yang, D.S.; Cui, B.; Ma, C.R.; Liu, M.; Hu, D.W. Design strategy of barium titanate/polyvinylidene fluoride-based nanocomposite films for high energy storage. J. Mater. Chem. A 2020, 8, 884–917. [Google Scholar] [CrossRef]

- Bouharras, F.E.; Raihane, M.; Ameduri, B. Recent progress on core–shell structured BaTiO3@polymer/fluorinated polymers nanocomposites for high energy storage: Synthesis, dielectric properties and applications. Prog. Mater. Sci. 2020, 113, 100670. [Google Scholar] [CrossRef]

- Pan, Z.B.; Yao, L.M.; Zhai, J.W.; Yang, K.; Shen, B.; Wang, H.T. Ultrafast discharge and high-energy-density of polymer nanocomposites achieved via optimizing the structure design of barium titanates. ACS Sustain. Chem. Eng. 2017, 5, 4707–4717. [Google Scholar] [CrossRef]

- Li, Z.; Liu, F.; Yang, G.; Li, H.; Dong, L.; Xiong, C.; Wang, Q. Enhanced energy storage performance of ferroelectric polymer nanocomposites at relatively low electric fields induced by surface modified BaTiO3 nanofibers. Compos. Sci. Technol. 2018, 164, 214–221. [Google Scholar] [CrossRef]

- Yuan, Q.; Li, G.; Yao, F.Z.; Cheng, S.D.; Wang, Y.; Ma, R.; Mi, S.B.; Gu, M.; Wang, K.; Li, J.F.; et al. Simultaneously achieved temperature-insensitive high energy density and efficiency in domain engineered BaTiO3-Bi(Mg0.5Zr0.5)O3 lead-free relaxor ferroelectrics. Nano Energy 2018, 52, 203–210. [Google Scholar] [CrossRef]

- Beuerlein, M.A.; Kumar, N.; Usher, T.M.; Brown-Shaklee, H.J.; Raengthon, N.; Reaney, I.M.; Cann, D.P.; Jones, J.L.; Brennecka, G.L.; Green, D.J. Current understanding of structure–processing–property relationships in BaTiO3–Bi(M)O3 dielectrics. J. Am. Ceram. Soc. 2016, 99, 2849–2870. [Google Scholar] [CrossRef]

- Zhu, M.-X.; Yu, Q.-C.; Song, H.-G.; Chen, T.-X.; Chen, J.-M. Rational design of high-energy-density polymer composites by machine learning approach. ACS Appl. Energy Mater. 2021, 4, 1449–1458. [Google Scholar]

- Tang, H.; Zhou, Z.; Bowland, C.C.; Sodano, H.A. Synthesis of calcium copper titanate (CaCu3Ti4O12) nanowires with insulating SiO2 barrier for low loss high dielectric constant nanocomposites. Nano Energy 2015, 17, 302–307. [Google Scholar]

- Jiang, X.; Hao, H.; Zhang, S.; Lv, J.; Cao, M.; Yao, Z.; Liu, H. Enhanced energy storage and fast discharge properties of BaTiO3 based ceramics modified by Bi(Mg1/2Zr1/2)O3. J. Eur. Ceram. Soc. 2019, 39, 1103–1109. [Google Scholar] [CrossRef]

- Hu, Q.; Bian, J.; Jin, L.; Zhuang, Y.; Huang, Z.; Liu, G.; Shur, V.Y.; Xu, Z.; Wei, X. Debye-like relaxation behavior and electric field induced dipole re-orientation of the 0.6BaTiO3-0.4Bi(Mg1/2Ti1/2)O3 ceramic. Ceram. Int. 2018, 44, 922–930. [Google Scholar] [CrossRef]

- Hu, Q.; Tian, Y.; Zhu, Q.; Bian, J.; Jin, L.; Du, H.; Alikin, D.O.; Shur, V.Y.; Feng, Y.; Xu, Z.; et al. Achieve ultrahigh energy storage performance in BaTiO3-Bi(Mg1/2Ti1/2)O3 relaxor ferroelectric ceramics via nano-scale polarization mismatch and reconstruction. Nano Energy 2019, 67, 104264. [Google Scholar] [CrossRef]

- Bi, K.; Bi, M.H.; Hao, Y.N.; Luo, W.; Cai, Z.M.; Wang, X.H.; Huang, Y.H. Ultrafine core-shell BaTiO3@SiO2 structures for nanocomposite capacitors with high energy density. Nano Energy 2018, 51, 513–523. [Google Scholar] [CrossRef]

- Xie, B.; Wang, Q.; Zhang, Q.; Liu, Z.; Lu, J.; Zhang, H.; Jiang, S. High energy storage performance of PMMA nanocomposites utilizing hierarchically structured nanowires based on interface engineering. ACS Appl. Mater. Interfaces 2021, 13, 27382–27391. [Google Scholar] [CrossRef] [PubMed]

- Cai, X.; Lei, T.; Sun, D.; Lin, L. A critical analysis of the α, β and γ phases in poly(vinylidene fluoride) using FTIR. RSC Adv. 2017, 7, 15382–15389. [Google Scholar] [CrossRef]

- Zhu, C.; Yin, J.; Li, J.; Li, Y.; Zhao, H.; Yue, D.; Pan, L.; Wang, J.; Feng, Y.; Liu, X. Enhanced energy storage of polyvinylidene fluoride-based nanocomposites induced by high aspect ratio titania nanosheets. J. Appl. Polym. Sci. 2020, 138, 50244. [Google Scholar] [CrossRef]

- Ren, X.T.; Meng, N.; Zhang, H.; Wu, J.Y.; Abrahams, I.; Yan, H.X.; Bilotti, E.; Reece, M.J. Giant energy storage density in PVDF with internal stress polar nanostructures engineered. Nano Energy 2020, 72, 104662. [Google Scholar] [CrossRef]

- Xu, J.; Fu, C.; Chu, H.; Qian, J.; Li, W.; Ran, X.; Nie, W. Improved discharge energy density of poly(vinylidene fluoride)-based nanocomposites via a small amount of dopamine-modified TiO2 nanosheets. J. Electron. Mater. 2021, 50, 4250–4260. [Google Scholar] [CrossRef]

- Nian, W.; Wang, Z.; Wang, T.; Xiao, Y.; Chen, H. Significantly enhanced breakdown strength and energy density in sandwich-structured NBT/PVDF composites with strong interface barrier effect. Ceram. Int. 2018, 44, S50–S53. [Google Scholar] [CrossRef]

- Guo, R.; Luo, H.; Yan, M.; Zhou, X.; Zhou, K.; Zhang, D. Significantly enhanced breakdown strength and energy density in sandwich-structured nanocomposites with low-level BaTiO3 nanowires. Nano Energy 2021, 79, 105412. [Google Scholar] [CrossRef]

- Ru, J.; Min, D.; Lanagan, M.; Li, S.; Chen, G. Enhanced energy storage properties of thermostable sandwich-structured BaTiO3/polyimide nanocomposites with better controlled interfaces. Mater. Des. 2021, 197, 109270. [Google Scholar] [CrossRef]

- Wang, Y.F.; Wang, L.X.; Yuan, Q.B.; Chen, J.; Niu, Y.J.; Xu, X.W.; Cheng, Y.T.; Yao, B.; Wang, Q.; Wang, H. Ultrahigh energy density and greatly enhanced discharged efficiency of sandwich-structured polymer nanocomposites with optimized spatial organization. Nano Energy 2018, 44, 364–370. [Google Scholar] [CrossRef]

- Xu, J.; Fu, C.; Chu, H.; Wu, X.; Tan, Z.; Qian, J.; Li, W.; Song, Z.; Ran, X.; Nie, W. Enhanced energy density of PVDF-based nanocomposites via a core–shell strategy. Sci. Rep. 2020, 10, 17084. [Google Scholar] [CrossRef]

- Zhang, Y.; Chi, Q.; Liu, L.; Zhang, T.; Zhang, C.; Chen, Q.; Wang, X.; Lei, Q. PVDF-Based dielectric composite films with excellent energy storage performances by design of nanofibers composition gradient structure. ACS Appl. Energy Mater. 2018, 1, 6320–6329. [Google Scholar] [CrossRef]

- Lin, X.; Hu, P.; Jia, Z.; Gao, S. Enhanced electric displacement induces large energy density in polymer nanocomposites containing core–shell structured BaTiO3@TiO2 nanofibers. J. Mater. Chem. A 2016, 4, 2314–2320. [Google Scholar] [CrossRef]

- Wang, G.; Huang, Y.; Wang, Y.; Jiang, P.; Huang, X. Substantial enhancement of energy storage capability in polymer nanocomposites by encapsulation of BaTiO3 NWs with variable shell thickness. Phys. Chem. Chem. Phys. 2017, 19, 21058–21068. [Google Scholar] [CrossRef]

- Liu, S.; Xue, S.; Shen, B.; Zhai, J. Reduced energy loss in poly(vinylidene fluoride) nanocomposites by filling with a small loading of core–shell structured BaTiO3/SiO2 nanofibers. Appl. Phys. Lett. 2015, 107, 032907. [Google Scholar] [CrossRef]

- Yao, L.M.; Pan, Z.B.; Zhai, J.W.; Zhang, G.Z.; Liu, Z.Y.; Liu, Y.H. High-energy-density with polymer nanocomposites containing of SrTiO3 nanofibers for capacitor application. Compos. Part A Appl. Sci. Manuf. 2018, 109, 48–54. [Google Scholar] [CrossRef]

- Liu, S.H.; Wang, J.; Shen, B.; Zhai, J.W.; Hao, H.S.; Zhao, L.M. Poly(vinylidene fluoride) nanocomposites with a small loading of core–shell structured BaTiO3@Al2O3 nanofibers exhibiting high discharged energy density and efficiency. J. Alloys Compd. 2017, 696, 136–142. [Google Scholar] [CrossRef]

- Pan, Z.B.; Yao, L.M.; Ge, G.L.; Shen, B.; Zhai, J.W. High-performance capacitors based on NaNbO3 nanowires/poly(vinylidene fluoride) nanocomposites. J. Mater. Chem. A 2018, 6, 14614–14622. [Google Scholar] [CrossRef]

- Pan, Z.; Yao, L.; Zhai, J.; Fu, D.; Shen, B.; Wang, H. High-energy-density polymer nanocomposites composed of newly structured one-dimensional BaTiO3@Al2O3 nanofibers. ACS Appl. Mater. Interfaces 2017, 9, 4024–4033. [Google Scholar] [CrossRef] [PubMed]

- Zhang, H.; Zhu, Y.; Li, Z.; Fan, P.; Ma, W.; Xie, B. High discharged energy density of polymer nanocomposites containing paraelectric SrTiO3 nanowires for flexible energy storage device. J. Alloys Compd. 2018, 744, 116–123. [Google Scholar] [CrossRef]

- Xue, J.; Zhang, T.; Zhang, C.; Zhang, Y.; Feng, Y.; Zhang, Y.; Chi, Q. Excellent energy storage performance for P(VDF-TrFE-CFE) composites by filling core–shell structured inorganic fibers. J. Mater. Sci. Mater. Electron. 2020, 31, 21128–21141. [Google Scholar] [CrossRef]

- Hu, J.; Liu, Y.; Zhang, S.; Tang, B. Novel designed core–shell nanofibers constituted by single element-doped BaTiO3 for high-energy-density polymer nanocomposites. Chem. Eng. J. 2022, 428, 131046. [Google Scholar] [CrossRef]

- Cui, Y.; Zhang, T.; Feng, Y.; Zhang, C.; Chi, Q.; Zhang, Y.; Chen, Q.; Wang, X.; Lei, Q. Excellent energy storage density and efficiency in blend polymer-based composites by design of core-shell structured inorganic fibers and sandwich structured films. Compos. Part B Eng. 2019, 177, 107429. [Google Scholar] [CrossRef]

- Chi, Q.; Wang, X.; Zhang, C.; Chen, Q.; Chen, M.; Zhang, T.; Gao, L.; Zhang, Y.; Cui, Y.; Wang, X.; et al. High energy storage density for poly(vinylidene fluoride) composites by introduced core–shell CaCu3Ti4O12@Al2O3 nanofibers. ACS Sustain. Chem. Eng. 2018, 6, 8641–8649. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hu, J.; Liu, F. Enhancing Energy Density of BaTiO3-Bi(M)O3@SiO2/PVDF Nanocomposites via Filler Component Modulation and Film Structure Design. Nanomaterials 2025, 15, 569. https://doi.org/10.3390/nano15080569

Hu J, Liu F. Enhancing Energy Density of BaTiO3-Bi(M)O3@SiO2/PVDF Nanocomposites via Filler Component Modulation and Film Structure Design. Nanomaterials. 2025; 15(8):569. https://doi.org/10.3390/nano15080569

Chicago/Turabian StyleHu, Jin, and Fangfang Liu. 2025. "Enhancing Energy Density of BaTiO3-Bi(M)O3@SiO2/PVDF Nanocomposites via Filler Component Modulation and Film Structure Design" Nanomaterials 15, no. 8: 569. https://doi.org/10.3390/nano15080569

APA StyleHu, J., & Liu, F. (2025). Enhancing Energy Density of BaTiO3-Bi(M)O3@SiO2/PVDF Nanocomposites via Filler Component Modulation and Film Structure Design. Nanomaterials, 15(8), 569. https://doi.org/10.3390/nano15080569