Synthesis of Turbostratic Graphene with Micron-Sized Domains from Activated Charcoal by Fast Joule Heating

Abstract

1. Introduction

2. Materials and Methods

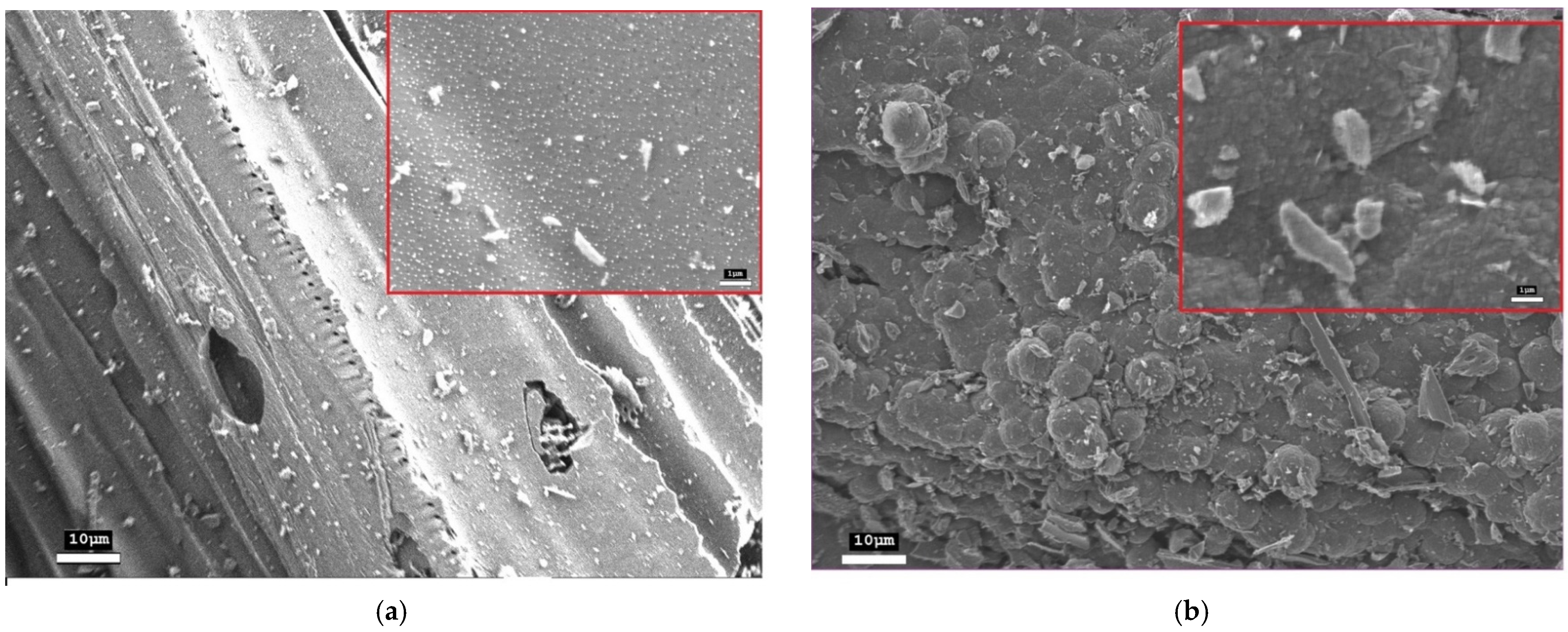

- SEM: images were acquired at an accelerating voltage of 3 kV.

- AFM: Surface morphology measurements were performed in semi-contact (tapping) mode using standard NSG10 cantilevers (TipsNano, Zelenograd, Russia) with a probe tip radius of 10 nm.

- Raman spectroscopy: Spectra were acquired using a green laser with a wavelength of 532 nm (2.33 eV). The diameter of the focused laser beam was 0.5 µm.

- XRD: Spectra were acquired using following parameters: Radiation—Cu Kα (λ = 1.5406 Å); Operating conditions: 40 kV, 40 mA; Scan range: 3–60° 2θ; Scan rate: 2°/min; Step size: 0.02°.

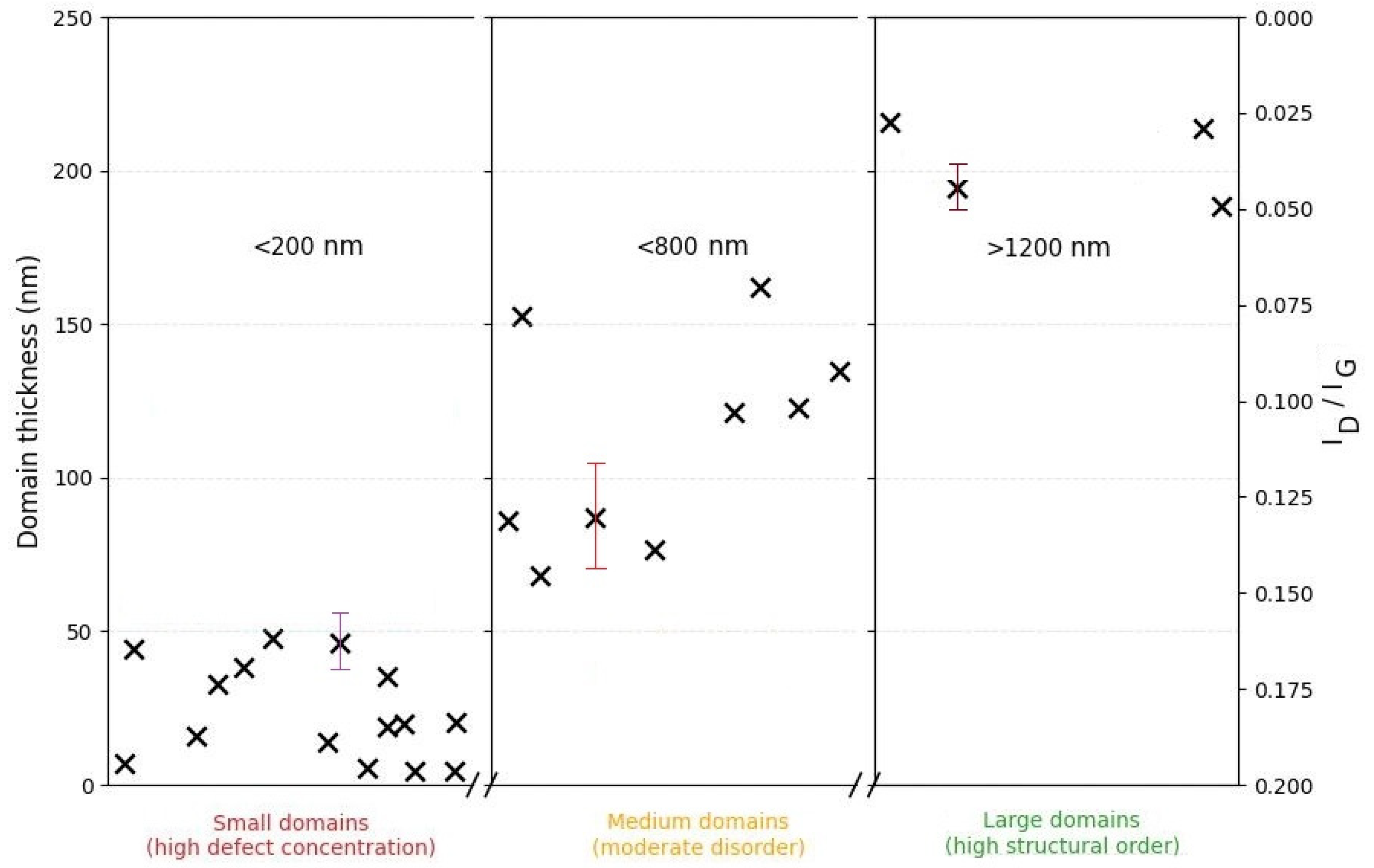

- Correlative AFM-Raman analysis: AFM imaging in tapping mode was used to locate individual flakes and measure their thickness. Raman spectra were then acquired from the center of the same flakes using a 0.5 µm laser spot.

3. Results

3.1. Morphological and Structural Analysis

3.2. Elemental Composition

3.3. X-Ray Diffraction Analysis

3.4. Surface Topography and Flake Thickness

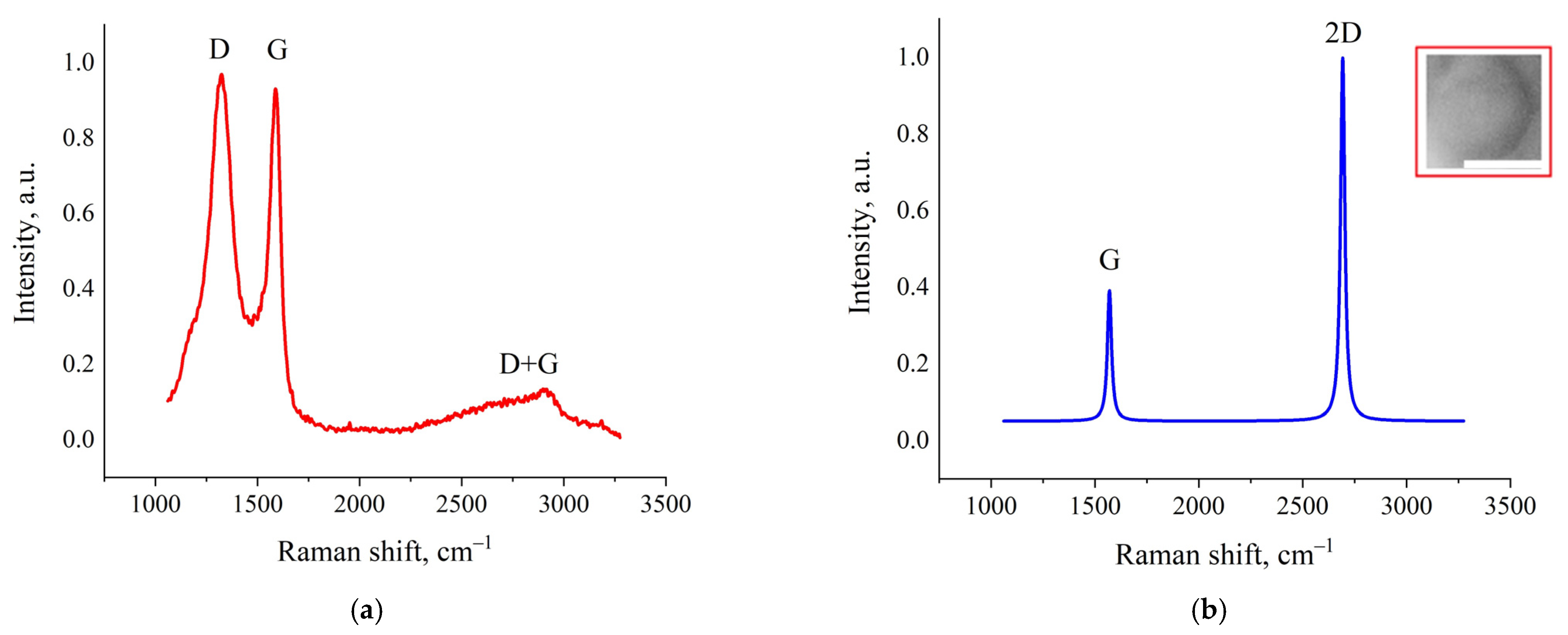

3.5. Raman Spectroscopy

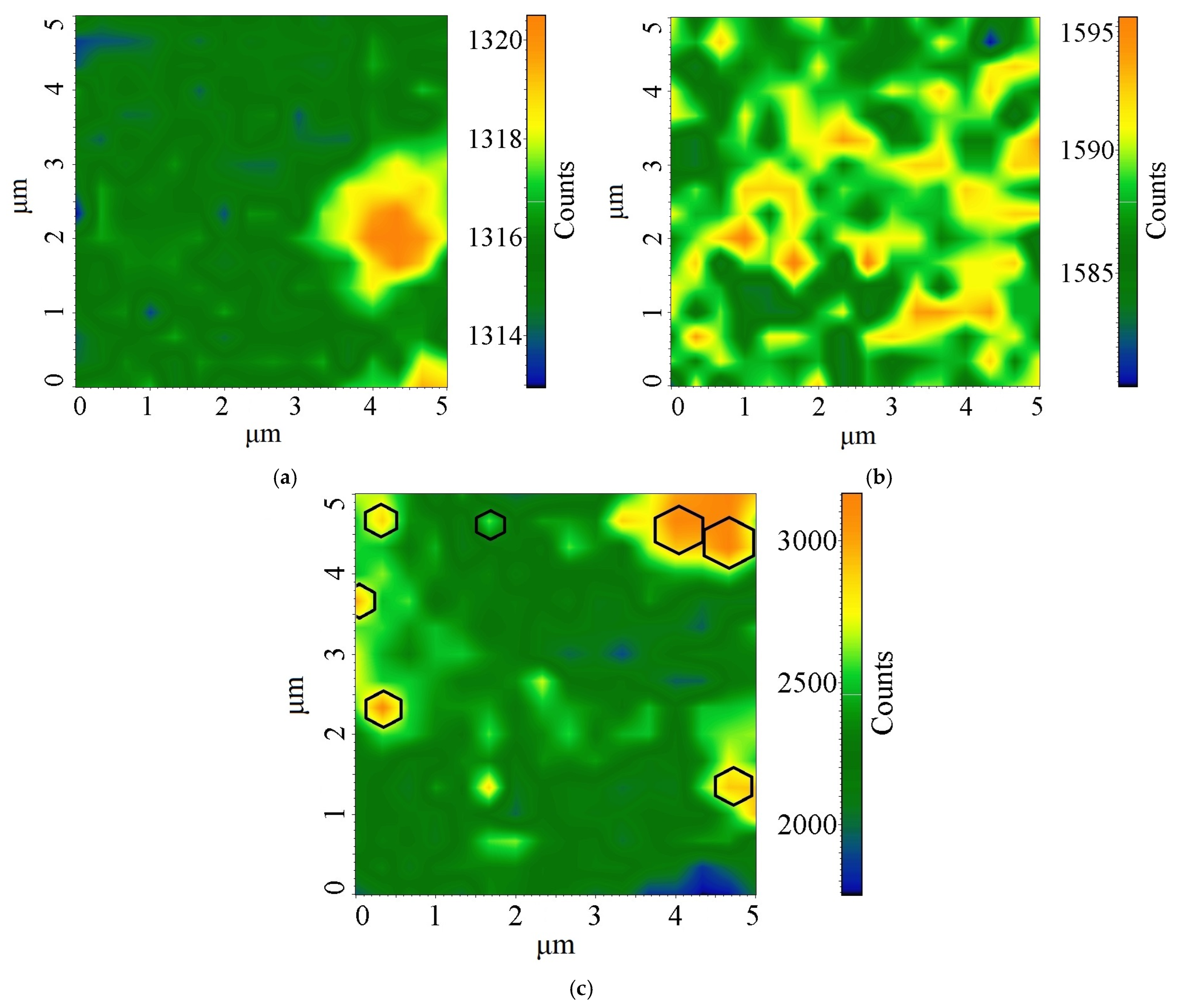

Spatial Mapping of Structural Properties

3.6. Electrical Transport Properties

4. Discussion

4.1. Model of Structural Transformation

4.2. Resolution of Key Contradictions Within the Turbostratic Graphene Model

4.3. Spatial Structural Inhomogeneity by Raman Mapping

4.4. Evolution of the Electrical Conductivity Mechanism

- A highly conductive percolating network forms with minimal processing intervention;

- The turbostratic graphene flakes possess a strong inherent tendency for efficient self-assembly and packing;

- Substantial interparticle contact is established even at relatively low compaction pressure.

4.5. Correlation of Morphological Parameters

4.6. Comparison of Turbostratic Graphene Production Methods

5. Conclusions

- This work demonstrates that fast Joule heating induces a fundamental structural rearrangement of amorphous carbon, leading to the formation of large hexagonal domains with sizes > 1 µm with thicknesses ranging from a few nanometers to 200 nm, while XRD revealed coherent domains of ~18 layers, confirming the turbostratic nature.

- The combined analysis of Raman spectroscopy and AFM data identified the material as turbostratic graphene. This is indicated by the combination of significant particle thickness and Raman spectral characteristics typical of few-layer graphene (minimal D-band intensity, narrow symmetric 2D-peak with I2D/IG > 2.5), which is explained by the weakened interlayer interaction due to chaotic angular orientation of the layers.

- The formation of a mosaic heterostructure with domain sizes > 1 µm was clearly demonstrated using Raman mapping.

- The resistivity of pressed pellets of the synthesized material was found to be as low as 0.51 Ω·cm. This indicates the formation of a dense conductive network with minimal contact resistance between individual graphene domains during pellet formation.

Outlook for Future Work

- Fundamental Mechanisms, Parameter Mapping, and Structural Optimization.

- 2.

- Transition from Material to Device: Electrodes and Performance Evaluation.

6. Patents

- Prokopiev, A.R.; Matveev, V.I.; Loskin, N.N.; Popov, D.N. Method for Synthesis of Graphene-Containing Products from Polymer Materials. Russian Patent RU 2835422 C1, 25 February 2025.

- Prokopiev, A.R.; Matveev, V.I.; Loskin, N.N.; Popov, D.N. Device for Fast Joule Heating for Synthesis of Graphene-Containing Products from Polymer Materials. Russian Utility Model RU 229234 U1, 27 September 2024.

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| AFM | Atomic force microscopy |

| SEM | Scanning electron microscopy |

| EDS | Energy-dispersive X-ray spectroscopy |

| XRD | X-ray diffraction |

| FWHM | Full width at half maximum |

| fJH | Fast Joule heating or rapid Joule heating |

| FJH | Flash Joule heating |

| DC-LPJH | Direct current long pulse joule heating |

References

- Geim, A.K.; Novoselov, K.S. The rise of graphene. Nat. Mater. 2007, 6, 183–191. [Google Scholar] [CrossRef] [PubMed]

- Madurani, K.A.; Suprapto, S.; Machrita, N.I.; Bahar, S.L.; Illiya, W.; Kurniawan, F. Progress in Graphene Synthesis and its Application: History, Challenge and the Future Outlook for Research and Industry. ECS J. Solid State Sci. Technol. 2020, 9, 093013. [Google Scholar] [CrossRef]

- Zhu, Y.; Ji, H.; Cheng, H.M.; Ruoff, R.S. Mass production and industrial applications of graphene materials. Natl. Sci. Rev. 2018, 5, 90–101. [Google Scholar] [CrossRef]

- Urade, A.R.; Lahiri, I.; Suresh, K.S. Graphene Properties, Synthesis and Applications: A Review. JOM 2022, 75, 614–630. [Google Scholar] [CrossRef]

- Li, W.; Yi, Y.; Yang, H.; Cheng, S.; Yang, W.; Zhang, H.; Liu, Z.; Li, J. Active tunable terahertz bandwidth absorber based on single layer graphene. Commun. Theor. Phys. 2023, 75, 045503. [Google Scholar] [CrossRef]

- Gao, S.; Zhao, J.; Hu, Z.; Zheng, L.; Zhai, S.; Wei, L.; Liu, X.; Wang, L. Three-dimensional porous carbon-supported Co/Fe bimetallic nanoparticles derived from carboxymethyl cellulose for enhanced supercapacitor electrodes. J. Alloys Compd. 2024, 1003, 175747. [Google Scholar] [CrossRef]

- Chaitoglou, S.; Ma, Y.; Ospina, R.; Farid, G.; Serafin, J.; Rovira, R.A.; Bertran-Serra, E. Laser-induced vertical graphene nanosheets for electrocatalytic hydrogen evolution. ACS Appl. Nano Mater. 2024, 7, 22631–22639. [Google Scholar] [CrossRef]

- Wang, P.; Jian, M.; Wu, M.; Zhang, C.; Zhou, C.; Ling, X.; Yi, Z.; Li, H.; Yao, W.; Wu, P. Highly sandwich-structured silver nanowire hybrid transparent conductive films for flexible transparent heater applications. Compos. Part A Appl. Sci. Manuf. 2022, 159, 106998. [Google Scholar] [CrossRef]

- Chen, K.; Shi, L.; Zhang, Y.; Liu, Z. Scalable chemical-vapour-deposition growth of three-dimensional graphene materials towards energy-related applications. Chem. Soc. Rev. 2018, 47, 3018–3036. [Google Scholar] [CrossRef] [PubMed]

- Shih, M.H.; Lin, Z.; Lin, W.; Xu, K.; Chen, Y.H.; Chen, J.C. Toward large-scale CVD graphene growth by enhancing reaction kinetics via an efficient interdiffusion mediator and mechanism study utilizing CFD simulations. J. Taiwan Inst. Chem. Eng. 2021, 128, 400–408. [Google Scholar] [CrossRef]

- Liu, X.; Wu, L.; Yu, X.; Peng, H.; Xu, S.; Zhou, Z. In-Situ Growth of Graphene Films to Improve Sensing Performances. Materials 2022, 15, 7814. [Google Scholar] [CrossRef]

- Mahmood, F.; Mbeugang, C.F.M.; Asghar, F.; Xie, X.; Lin, D.; Liu, D.; Sharma, A.; Chen, J.; Liu, B. Understanding the Synthesis of Turbostratic/Flash Graphene via Joule Heating. Materials 2025, 18, 2892. [Google Scholar] [CrossRef]

- Pandit, N.; Keshri, S.; Singh, P.; Singh, T.N.; Keshri, A.K. Ultra-Fast and Facile Fabrication of Turbostratic Holey Graphene and Its Supercapacitor Applications. ACS Appl. Nano Mater. 2025, 8, 6052–6062. [Google Scholar] [CrossRef]

- Sukasem, W.; Janphuang, N.; Chueangam, W.; Srisom, K.; Rueangwittayanon, A.; Rittihong, U.; Tunmee, S.; Chanlek, N.; Pornsetmetakul, P.; Wirojsirasak, W.; et al. Synthesis of Turbostratic Graphene Derived from Biomass Waste Using Long Pulse Joule Heating Technique. Nanomaterials 2025, 15, 468. [Google Scholar] [CrossRef]

- Luong, D.X.; Bets, K.V.; Algozeeb, W.A.; Stanford, M.G.; Kittrell, C.; Chen, W.; Salvatierra, R.V.; Ren, M.; McHugh, E.A.; Advincula, P.A.; et al. Gram-scale bottom-up flash graphene synthesis. Nature 2020, 577, 647–651. [Google Scholar] [CrossRef]

- Cheng, J.; Wan, W.; Chen, X.; Zheng, Q. Preparation and structural characterization of graphene by rice husk. Trans. Chin. Soc. Agric. Eng. 2015, 31, 288–294. [Google Scholar]

- Advincula, P.A.; Luong, D.X.; Chen, W.; Raghuraman, S.; Shahsavari, R.; Tour, J.M. Flash graphene from rubber waste. Carbon 2021, 178, 649–656. [Google Scholar] [CrossRef]

- Yang, Y.; Fang, Y.; Feng, E.; Jiang, W.; Zhang, X.; Liu, L.; Cheng, Y.; Yang, F.; Li, W.; Liang, F.; et al. Scalable, Universal In Situ Self-Heating Chemical Vapor Deposition Strategy for High-Quality Thick Turbostratic Graphene via Combined Twist–Tilt Configuration Engineering. J. Am. Chem. Soc. 2025, 147, 43805–43815. [Google Scholar] [CrossRef] [PubMed]

- Wei, C.; Li, S.; Zhang, Y.; Tanaka, S.; Ago, H. Turbostratic multilayer graphene synthesis on CVD graphene template toward improving electrical performance. Jpn. J. Appl. Phys. 2019, 58, SIIB04. [Google Scholar] [CrossRef]

- Athanasiou, M.; Samartzis, N.; Sygellou, L.; Andrikopoulos, K.S.; Galiotis, C. High-quality laser-assisted biomass-based turbostratic graphene for high-performance supercapacitors. Carbon 2021, 172, 750–761. [Google Scholar] [CrossRef]

- Bhorkar, K.; Bansal, S.; Ayyub, P.; Jayaram, V.; Kumar, P. Laser-assisted explosive synthesis and transfer of turbostratic graphene-related materials for energy conversion applications. npj 2D Mater. Appl. 2022, 6, 56. [Google Scholar] [CrossRef]

- Algozeeb, W.A.; Savas, P.E.; Luong, D.X.; Chen, W.; Kittrell, C.; Bhat, M.; Shahsavari, R.; Tour, J.M. Flash Graphene from Plastic Waste. ACS Nano 2020, 14, 15595–15604. [Google Scholar] [CrossRef] [PubMed]

- Hosny, M.; Elbay, A.S.; Abdelfatah, A.M.; El-Maghrabi, N.; Fawzy, M. Recent trends in transforming different waste materials into graphene via Flash Joule Heating. Environ. Res. 2025, 270, 121033. [Google Scholar] [CrossRef] [PubMed]

- Prokopiev, A.R.; Loskin, N.N.; Popov, D.N. Fast Joule heating for the synthesis of graphene-containing powders from plastic waste. RENSIT 2025, 17, 305–312. [Google Scholar] [CrossRef]

- Manoj, B.; Kunjomana, A.G. Study of stacking structure of amorphous carbon by X-ray diffraction technique. Int. J. Electrochem. Sci. 2012, 7, 3127–3134. [Google Scholar] [CrossRef]

- Klug, H.P.; Alexander, L.E. X-Ray Diffraction Procedures: For Polycrystalline and Amorphous Materials; John Wiley & Sons: New York, NY, USA, 1974. [Google Scholar]

- Mohapatra, A.; Rao, M.S.R.; Jaiswal, M. Thermal transport in turbostratic multilayer graphene. Carbon 2023, 201, 120–128. [Google Scholar] [CrossRef]

- Barbhuiya, N.H.; Kumar, A.; Singh, A.; Chandel, M.K.; Arnusch, C.J.; Tour, J.M.; Singh, S.P. The future of flash graphene for the sustainable management of solid waste. ACS Nano 2021, 15, 15461–15470. [Google Scholar] [CrossRef]

- Li, Z.Q.; Lu, C.J.; Xia, Z.P.; Zhou, Y.; Luo, Z. X-ray diffraction patterns of graphite and turbostratic carbon. Carbon 2007, 45, 1686–1695. [Google Scholar] [CrossRef]

- Huang, P.Y.; Ruiz-Vargas, C.S.; van der Zande, A.M.; Whitney, W.S.; Levendorf, M.P.; Kevek, J.W.; Garg, S.; Alden, J.S.; Hustedt, C.J.; Zhu, Y.; et al. Grains and grain boundaries in single-layer graphene atomic patchwork quilts. Nature 2011, 469, 389–392. [Google Scholar] [CrossRef]

- Pimenta, M.A.; Dresselhaus, G.; Dresselhaus, M.S.; Cançado, L.G.; Jorio, A.; Saito, R. Studying disorder in graphite-based systems by Raman spectroscopy. Phys. Chem. Chem. Phys. 2007, 9, 1276–1290. [Google Scholar] [CrossRef]

- Ferrari, A.C.; Robertson, J. Interpretation of Raman spectra of disordered and amorphous carbon. Phys. Rev. B 2000, 61, 14095–14107. [Google Scholar] [CrossRef]

- Cançado, L.G.; Takai, K.; Enoki, T.; Endo, M.; Kim, Y.A.; Mizusaki, H.; Jorio, A.; Pimenta, M.A. General equation for the determination of the crystallite size La of nanographite by Raman spectroscopy. Appl. Phys. Lett. 2006, 88, 163106. [Google Scholar] [CrossRef]

- Ferrari, A.C.; Basko, D.M. Raman spectroscopy as a versatile tool for studying the properties of graphene. Nat. Nanotechnol. 2013, 8, 235–246. [Google Scholar] [CrossRef]

- Hao, Y.; Wang, Y.; Wang, L.; Ni, Z.; Wang, Z.; Wang, R.; Koo, C.K.; Shen, Z.; Thong, J.T. Probing Layer Number and Stacking Order of Few-Layer Graphene by Raman Spectroscopy. Small 2010, 6, 195–200. [Google Scholar] [CrossRef]

- Mohapatra, A.; Poudyal, S.; Ramachandra Rao, M.S.; Jaiswal, M. Resonance Raman spectroscopy of twisted interfaces in turbostratic multilayer graphene. J. Phys. Condens. Matter 2024, 36, 205703. [Google Scholar] [CrossRef]

- Tomidokoro, M.; Tunmee, S.; Rittihong, U.; Euaruksakul, C.; Supruangnet, R.; Nakajima, H.; Hirata, Y.; Ohtake, N.; Akasaka, H. Electrical Conduction Properties of Hydrogenated Amorphous Carbon Films with Different Structures. Materials 2021, 14, 2355. [Google Scholar] [CrossRef] [PubMed]

- Wu, J.B.; Lin, M.L.; Cong, X.; Liu, H.N.; Tan, P.H. Raman spectroscopy of graphene-based materials and its applications in related devices. Chem. Soc. Rev. 2018, 47, 1822–1873. [Google Scholar] [CrossRef] [PubMed]

- Eckmann, A.; Felten, A.; Mishchenko, A.; Britnell, L.; Krupke, R.; Novoselov, K.S.; Casiraghi, C. Probing the Nature of Defects in Graphene by Raman Spectroscopy. Nano Lett. 2012, 12, 3925–3930. [Google Scholar] [CrossRef]

- Joung, D.; Khondaker, S.I. Efros-Shklovskii variable-range hopping in reduced graphene oxide sheets of varying carbon sp2 fraction. Phys. Rev. B 2012, 86, 235423. [Google Scholar] [CrossRef]

- Marinho, B.; Ghislandi, M.; Tkalya, E.; Koning, C.E.; de With, G. Electrical conductivity of compacts of graphene, multi-wall carbon nanotubes, carbon black, and graphite powder. Powder Technol. 2012, 221, 351–358. [Google Scholar] [CrossRef]

- Kokmat, P.; Surinlert, P.; Ruammaitree, A. Growth of high-purity and high-quality turbostratic graphene with different interlayer spacings. ACS Omega 2023, 8, 4010–4018. [Google Scholar] [CrossRef] [PubMed]

- Goldstein, J.I.; Newbury, D.E.; Michael, J.R.; Ritchie, N.W.M.; Scott, J.H.J.; Joy, D.C. Scanning Electron Microscopy and X-Ray Microanalysis; Springer: New York, NY, USA, 2018. [Google Scholar] [CrossRef]

- Chacón-Torres, J.C.; Wirtz, L.; Pichler, T. Raman spectroscopy of graphite intercalation compounds: Charge transfer, strain, and electron–phonon coupling in graphene layers. Phys. Status Solidi B 2014, 251, 2337–2355. [Google Scholar] [CrossRef]

- Bo, Z.; Yu, K.; Lu, G.; Mao, S.; Chen, J.; Fan, S. Plasma-enhanced chemical vapor deposition synthesis of vertically oriented graphene nanosheets. Nanoscale 2013, 5, 5180–5204. [Google Scholar] [CrossRef] [PubMed]

| Samples | C, at. % | O, at. % | O/C | R (Ends of the Electrodes), Ω |

|---|---|---|---|---|

| Initial activated charcoal | ~95.0 ± 0.5 | ~5.0 ± 0.5 | 0.052 | ~4–6 ± 0.2 |

| Activated charcoal after fJH | ~98.5 ± 0.5 | ~1.5 ± 0.5 | 0.015 | ~1–1.5 ± 0.2 |

| Parameter | Pristine Graphite (HOPG) [26] | Turbostratic Graphene [15,27] | This Work |

|---|---|---|---|

| (002) peak | ~26.5° d = ~0.335 nm | Shifted downwards: 25.5–26.2° d = 0.340–0.349 nm | ~25.95° Wide, intense |

| (100)/(101) peak | ~42.3° | ~42–43° | ~42.72° (small, wide) |

| (004) peak | ~54.5° | ~53–54° | ~53.96° (small) |

| La, AFM (µm) | La, SEM (µm) | FWHM (G), cm−1 | FWHM (2D), cm−1 | ID/IG | I2D/IG | La, Raman (µm) |

|---|---|---|---|---|---|---|

| ≥1 | ≥1.5 | 16 | 20 | n/d | ≥2.5 | - |

| ≤0.8 | ≤0.7 | 22 | 31 | ≥0.04 | ≤1.5 | ≥0.45 |

| ≤0.2 | ≤0.3 | 29 | 45 | ≤0.2 | ≤0.8 | ≤0.13 |

| Carbon Precursor | Method | Energy/Power or Temperature | Raman (I2D/IG) | Interlayer (d002) | Domain Size | Eco Impact | Applications | Ref. |

|---|---|---|---|---|---|---|---|---|

| Charcoal | fast Joule heating | ~16 kJ/g | ≥2.5 | 3.44 Å | ≥1 µm | Very Low (Green) | Energy Storage | This work |

| Various carbon sources (coal, petroleum coke, biochar, plastics, etc.) | Flash Joule heating | 7.2–18 kJ/g | ≤17 | 3.45 Å | >100 nm | Very Low (Green) | Composite materials | [15] |

| Biomass | Direct Current Long Pulse Joule Heating (DC-LPJH) | 10 kJ/g | ≤1.2 | - | - | Low (Sustainable) | Composite materials | [14] |

| Biomass | Laser (LIG) | 5–15 J/cm2 | ~1.1–1.5 | ~3.40 Å | ~20–50 nm | Low (Sustainable) | Supercapacitors | [20] |

| Plastic Waste | AC and DC flash | ~23 kJ/g | Up to 6 | ~3.45 Å | ~10–60 nm | Very Low (Waste use) | Cement/Composites | [22] |

| Methane | PECVD | 100–1000 W | D-peak present | Vertical | 0.5–5 µm | High (Energy) | Sensing/Emission | [45] |

| Ethanol vapor | Direct CVD | ~1573 K | ~0.67–1.13 | - | ~60–100 nm | High (Energy) | Conductive Films | [19] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Prokopiev, A.R.; Loskin, N.N.; Vinokurov, P.V. Synthesis of Turbostratic Graphene with Micron-Sized Domains from Activated Charcoal by Fast Joule Heating. Nanomaterials 2025, 15, 1885. https://doi.org/10.3390/nano15241885

Prokopiev AR, Loskin NN, Vinokurov PV. Synthesis of Turbostratic Graphene with Micron-Sized Domains from Activated Charcoal by Fast Joule Heating. Nanomaterials. 2025; 15(24):1885. https://doi.org/10.3390/nano15241885

Chicago/Turabian StyleProkopiev, Aisen Ruslanovich, Nikolay Nikolaevich Loskin, and Pavel Vasilievich Vinokurov. 2025. "Synthesis of Turbostratic Graphene with Micron-Sized Domains from Activated Charcoal by Fast Joule Heating" Nanomaterials 15, no. 24: 1885. https://doi.org/10.3390/nano15241885

APA StyleProkopiev, A. R., Loskin, N. N., & Vinokurov, P. V. (2025). Synthesis of Turbostratic Graphene with Micron-Sized Domains from Activated Charcoal by Fast Joule Heating. Nanomaterials, 15(24), 1885. https://doi.org/10.3390/nano15241885