Period-Tuned a-C/a-C:H Multilayer DLC Coating for Tribocorrosion Protection of HSLA-100 Steel

Abstract

1. Introduction

2. Materials and Methods

2.1. Coating Preparation

2.2. Coating Characterization

2.3. Tribological Test

2.4. Electrochemical Measurements

2.5. Tribocorrosion Test

3. Results and Discussion

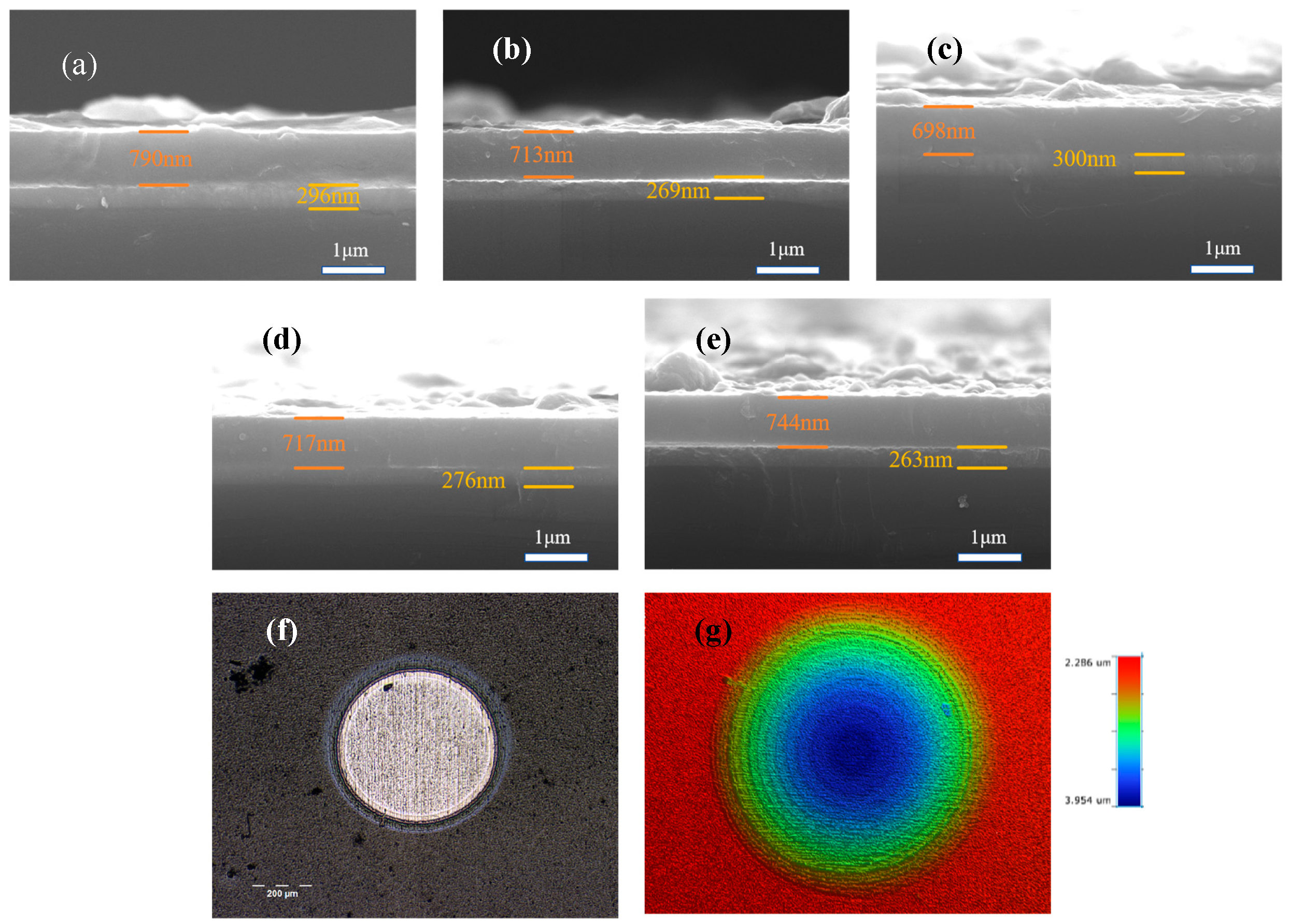

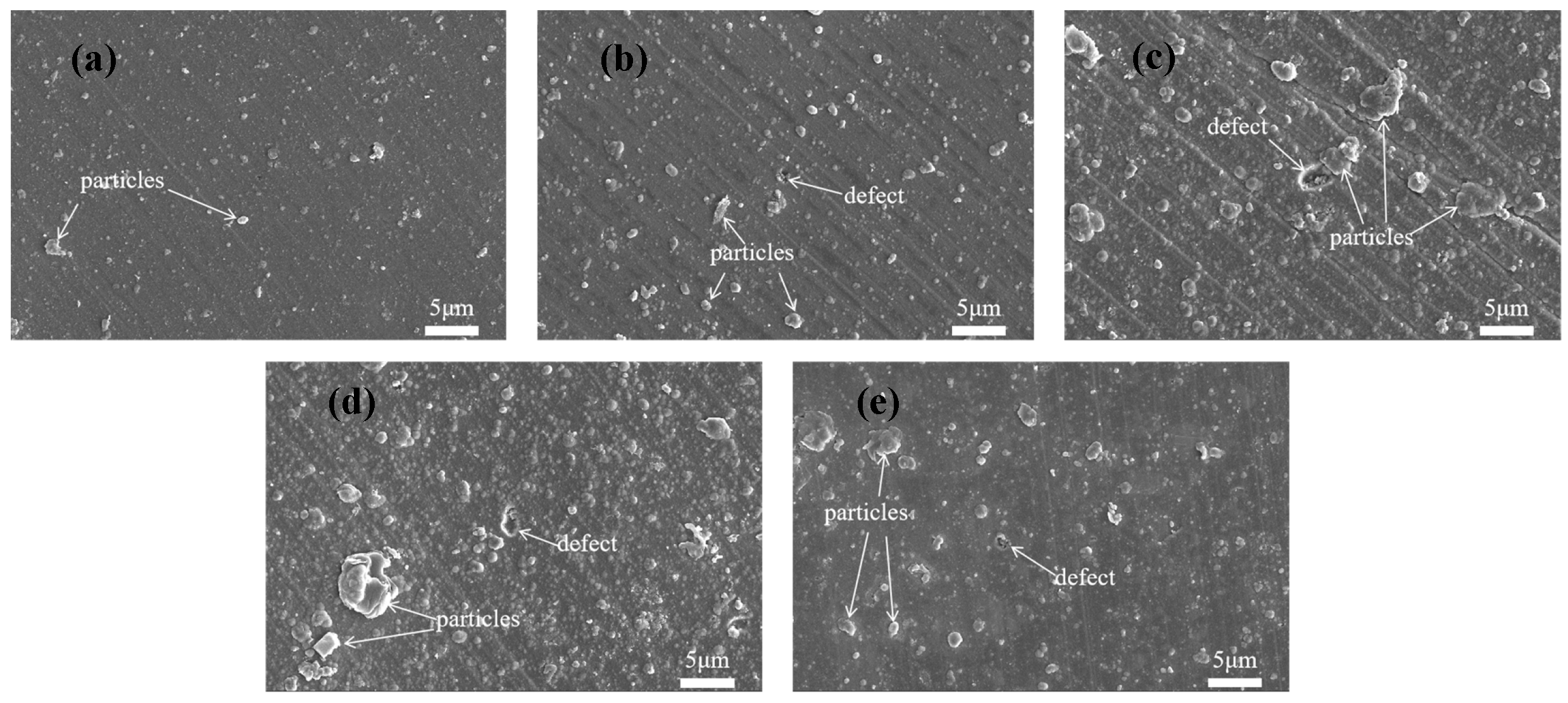

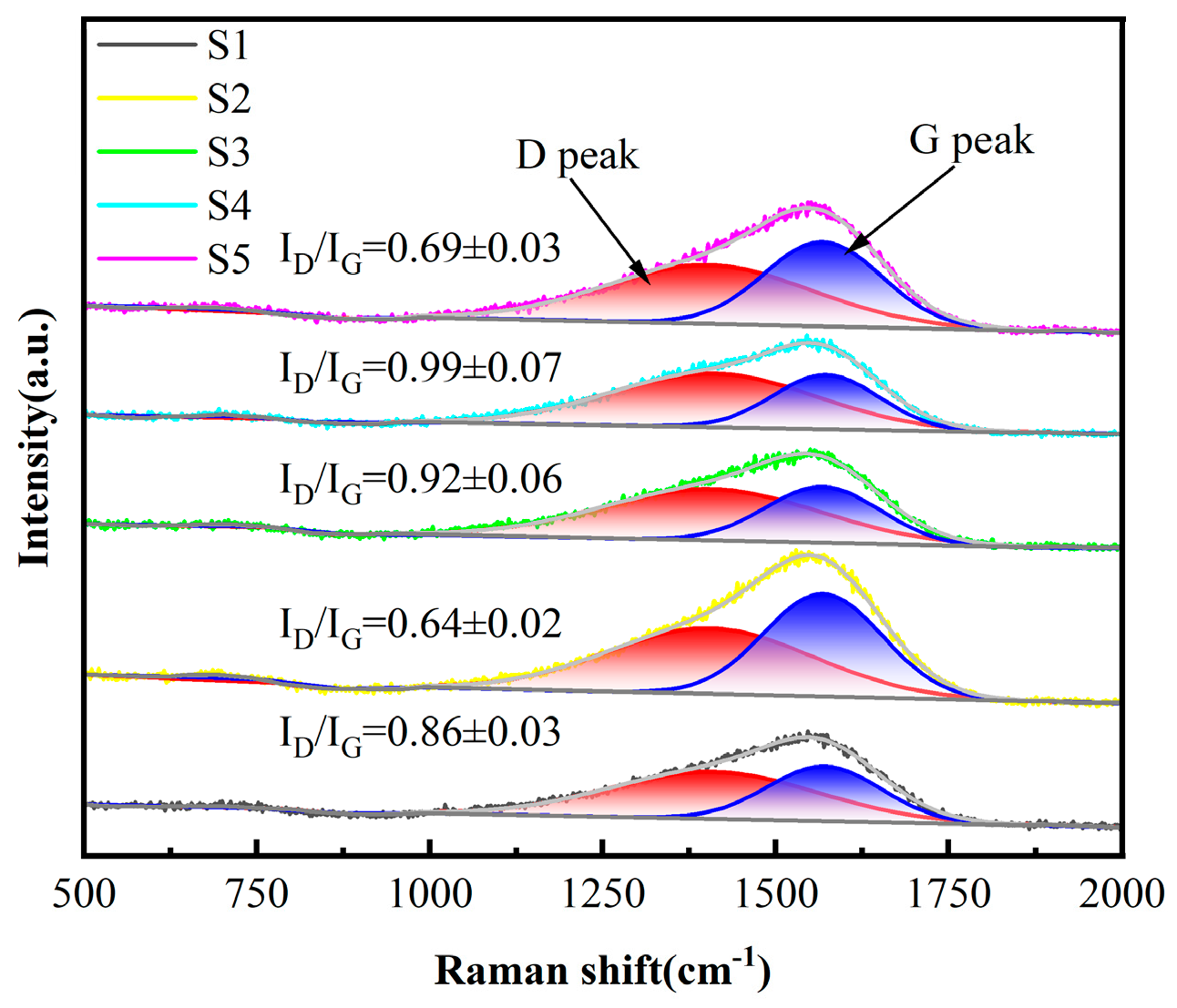

3.1. Characterization of DLC Coatings

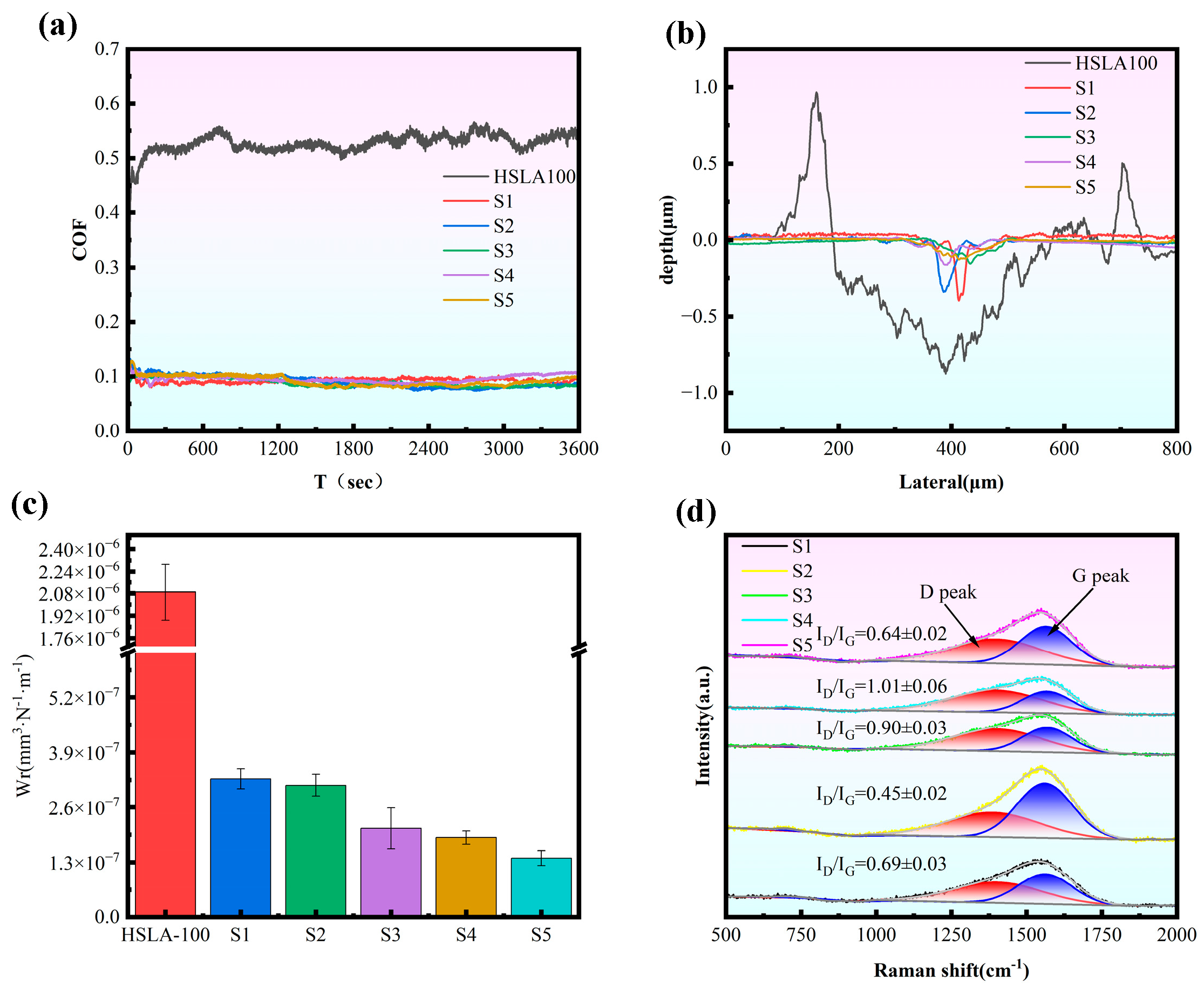

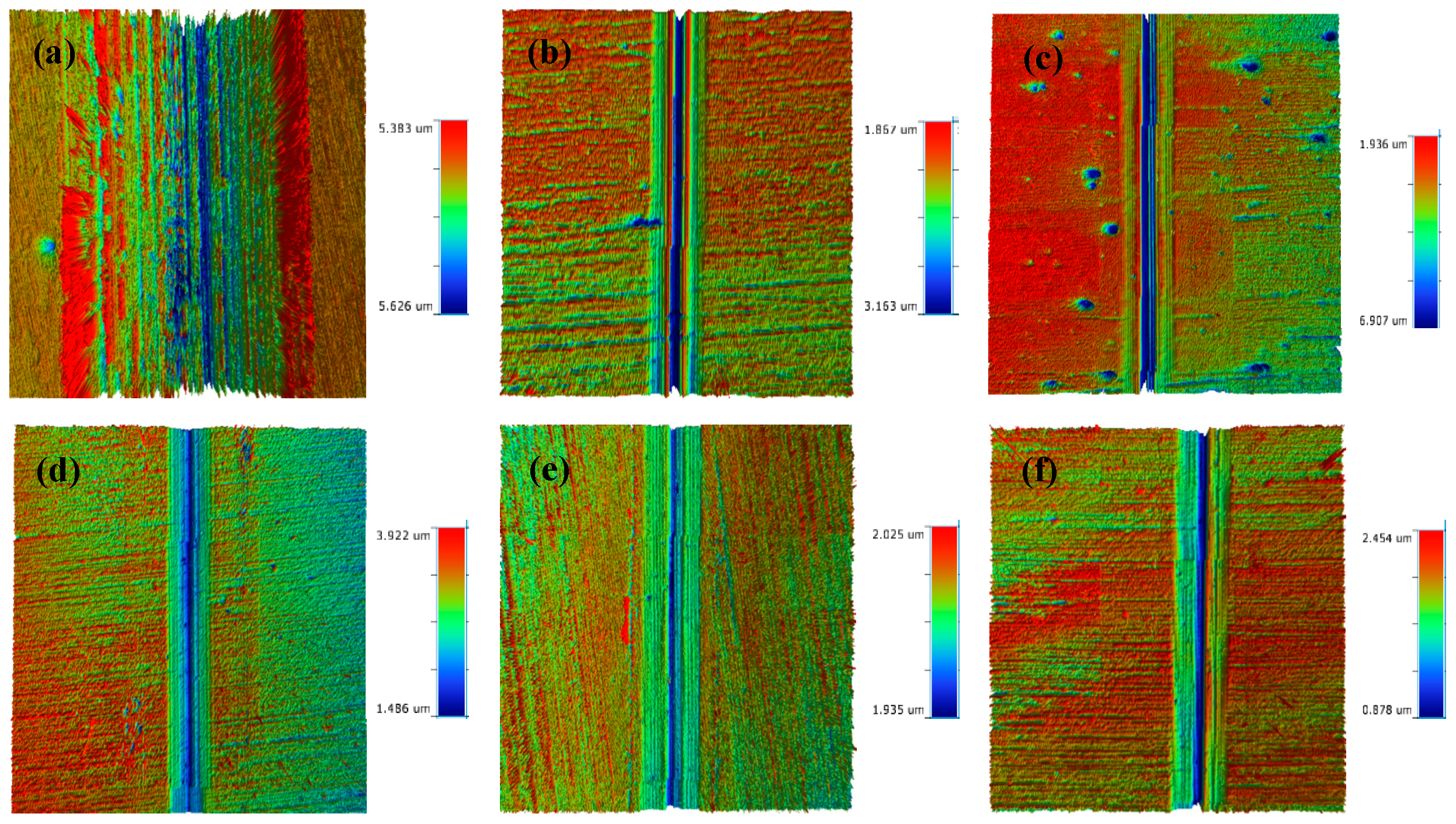

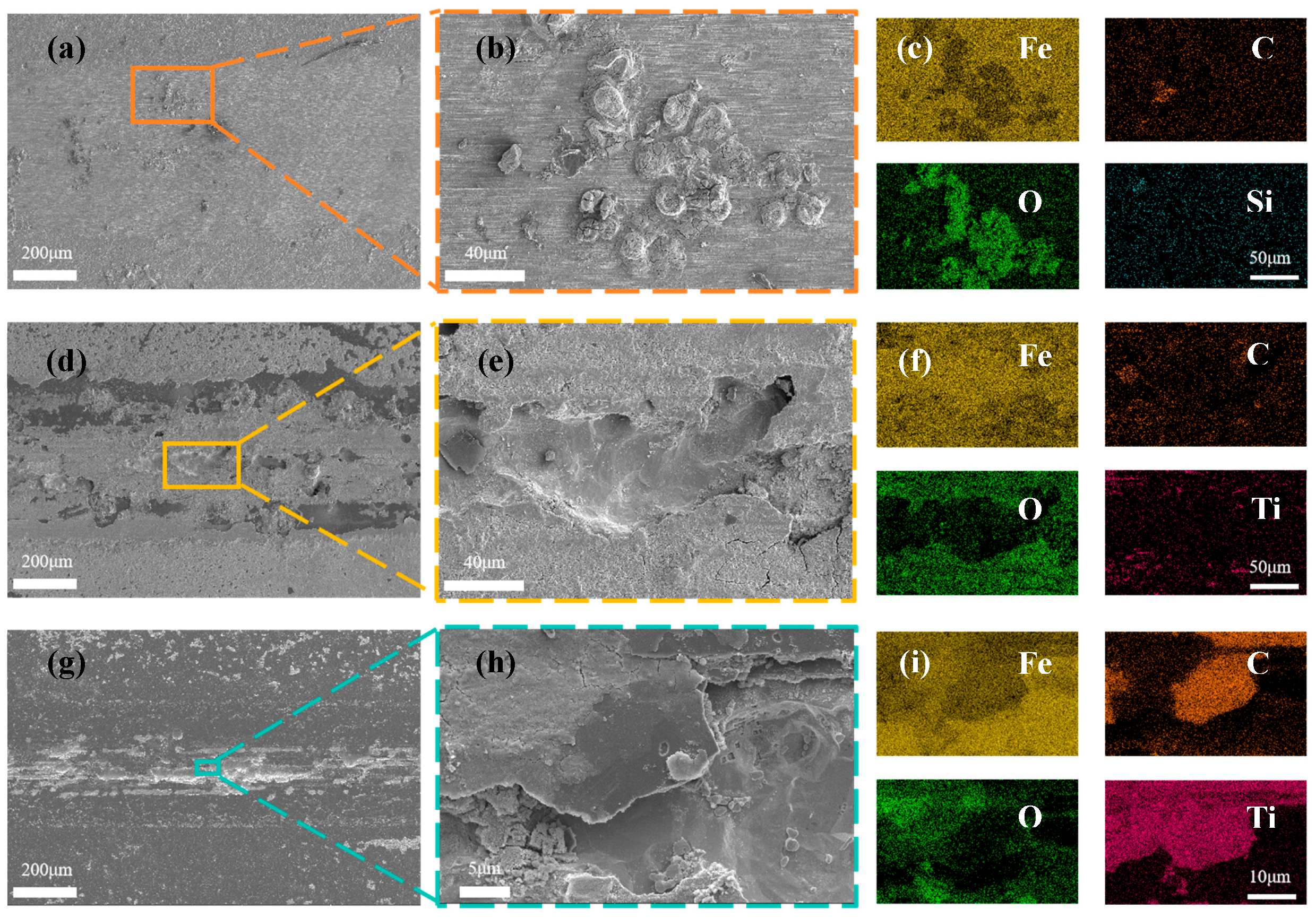

3.2. Dry Friction Behavior

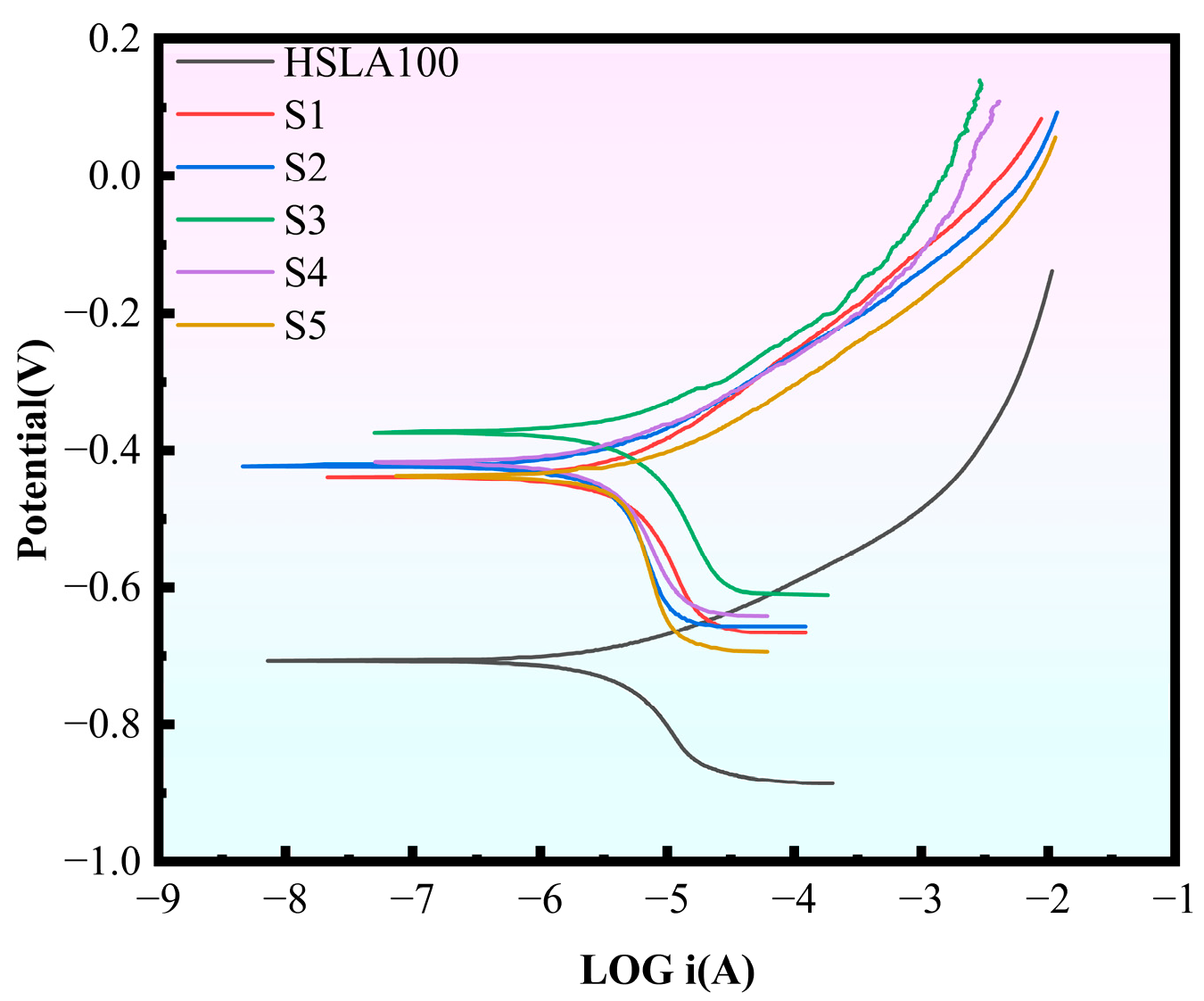

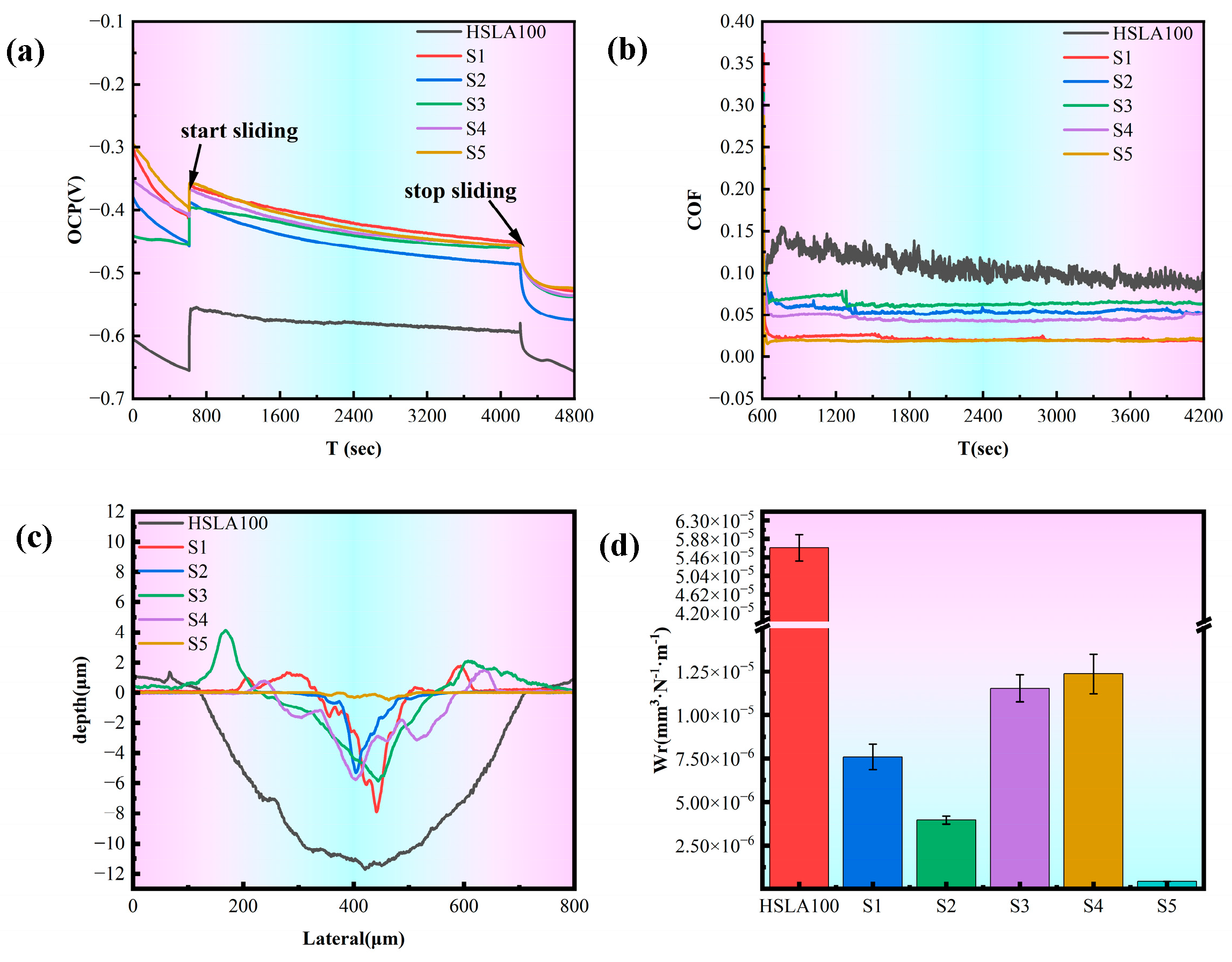

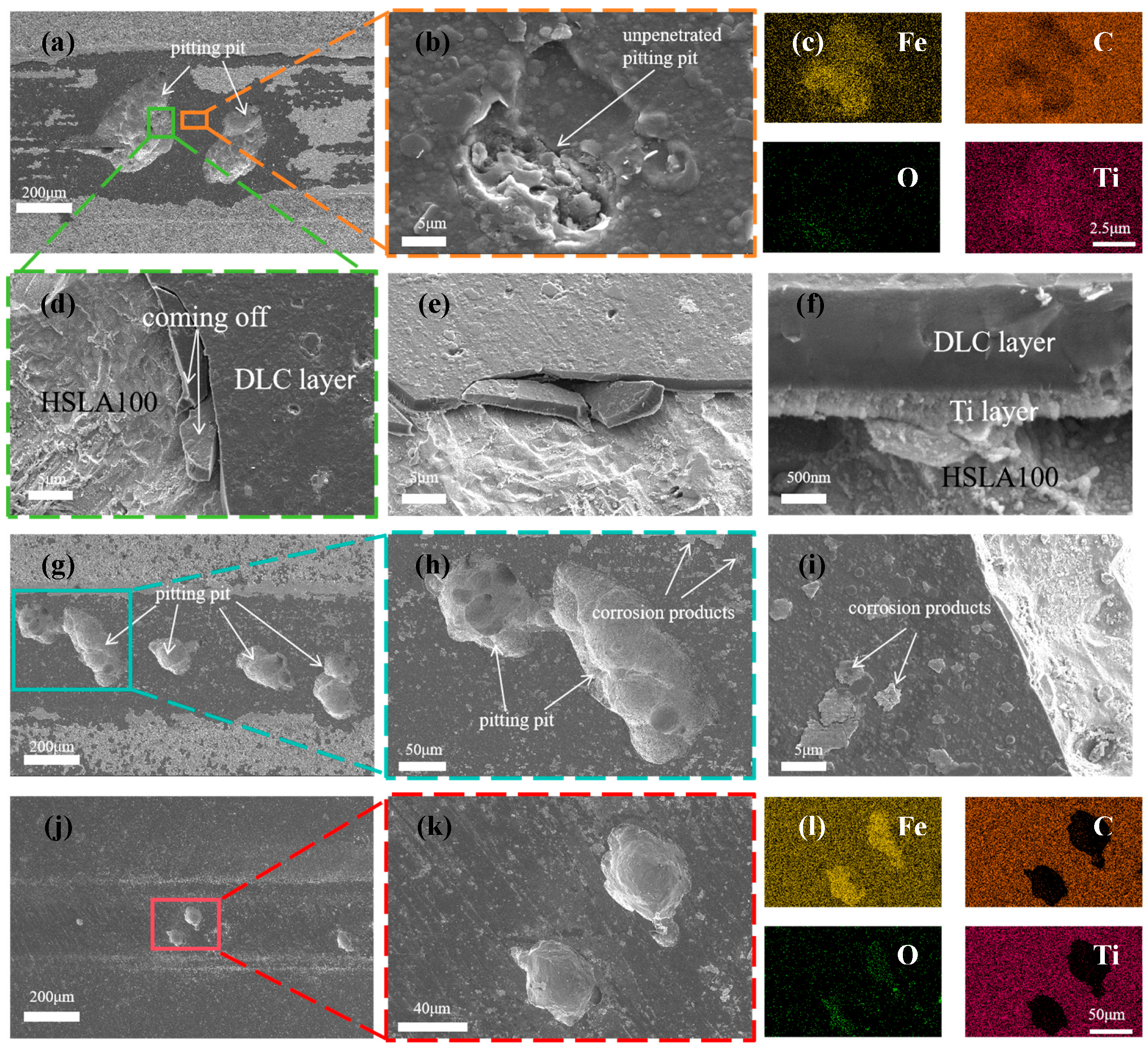

3.3. Tribocorrosion Behavior

4. Conclusions

- (1)

- Introducing C2H2 during arc-ion deposition increased the sp3 fraction, yielding harder and more corrosion-resistant DLC layers. The ten-period multilayer (S5) achieved the highest H/E (0.0767) and H3/E2 (0.171), evidencing the optimal hardness–toughness (elastic recovery–fracture resistance) balance.

- (2)

- Under dry sliding, all coatings reduced the friction coefficient to ~0.08–0.10 and markedly lowered wear relative to HSLA-100; the ten-period film (S5) showed the minimum dry wear rate of 1.39 × 10−7 mm3·N−1·m−1.

- (3)

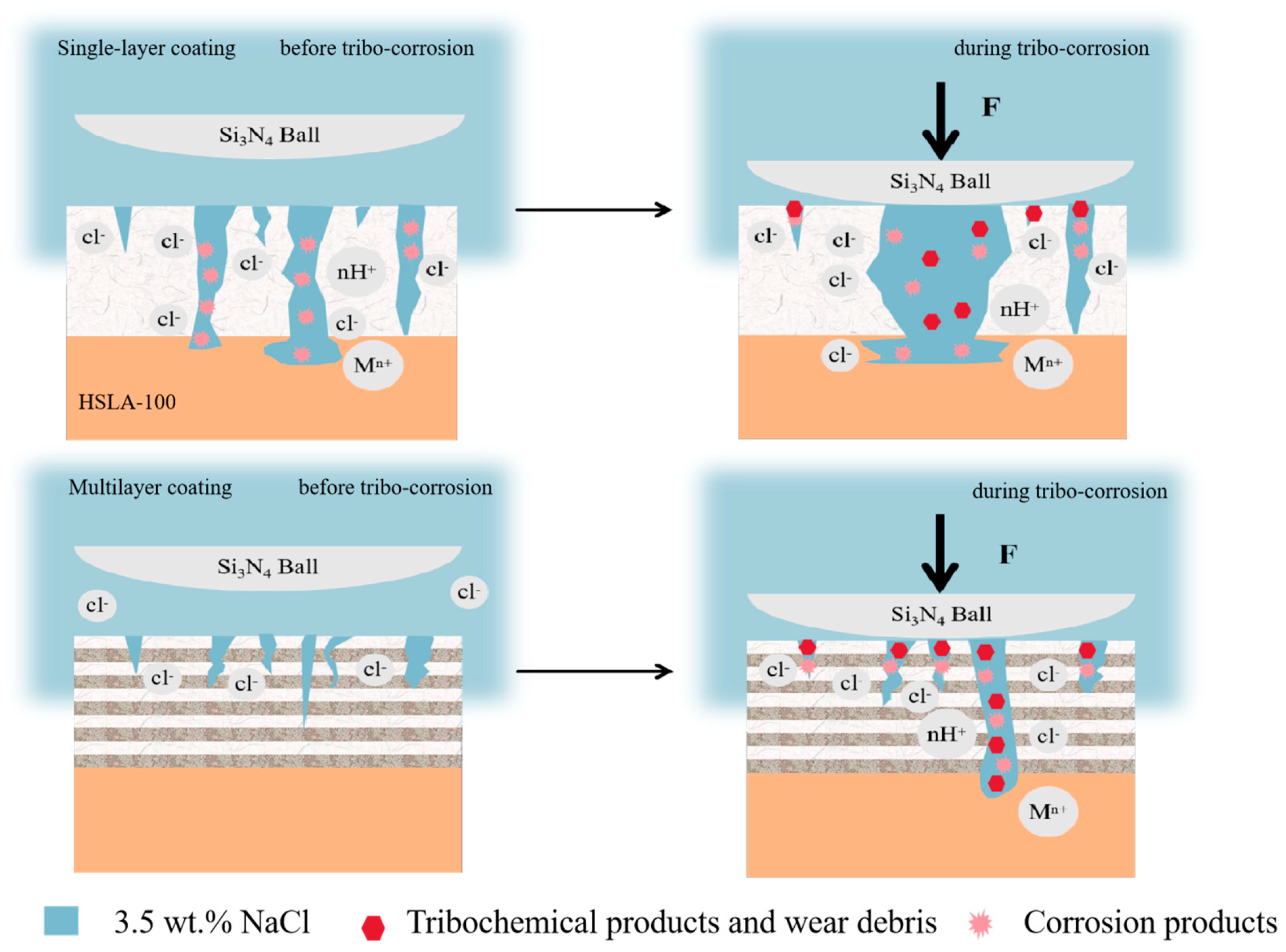

- In 3.5 wt% NaCl tribocorrosion, multilayer architectures mitigated synergistic mechanical–electrochemical attack. S5 exhibited a wear rate of 4.53 × 10−7 mm3·N−1·m−1, which is approximately 16 times lower in comparison to S1 and two orders lower than the substrate, with corrosion pit size decreasing as the period number increased.

- (4)

- These gains arise from interlayer interfaces that deflect and arrest crack propagation, dissipate stresses, and interrupt percolation pathways for electrolytes, thereby restricting corrosive species transport to the substrate.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Zhong, W.; Wang, H.; Ma, L.; Zhang, C. Impact Abrasive Wear of Cr/W-DLC/DLC Multilayer Films at Various Temperatures. Metals 2022, 12, 1981. [Google Scholar] [CrossRef]

- Zhou, F.; Qian, J.; Zhang, M.; Wu, Y.; Wang, Q.; Zhou, Z. Tribocorrosion properties of CrMoN/Ag coatings with various Ag contents in seawater. Surf. Coat. Technol. 2023, 473, 129993. [Google Scholar] [CrossRef]

- Zhang, H.; Cui, H.; Song, X.; Pang, K.; Man, C.; Liu, F.; Wang, X.; Cui, Z. Excellent tribocorrosion resistance of additively manufactured Ti-based heterogeneous composite coating via hardening and toughening effects. J. Mater. Sci. Technol. 2024, 190, 76–92. [Google Scholar] [CrossRef]

- Zhang, L.; Zhang, H.; Cao, H.; Chen, X.; Fang, Y.; Zheng, G. Enhanced tribocorrosion performance of laser-deposited Fe2CoNiCrAlTiCx high-entropy alloy coatings via in-situ graphitization in aqueous medium. Corros. Sci. 2024, 236, 112221. [Google Scholar] [CrossRef]

- Zhang, S.; Huang, T.; Sun, S.; Wu, S.; Yang, X.; Guo, F.; Zhang, B.; Dai, L. Effects of Bias Voltages on the Tribological Behaviors of DLC Coatings. Coatings 2024, 14, 176. [Google Scholar] [CrossRef]

- Zhang, Y.; Li, H.; Cui, L.; Yang, W.; Ma, G.; Chen, R.; Guo, P.; Ke, P.; Wang, A. Comparative study on tribocorrosion behavior of hydrogenated/hydrogen-free amorphous carbon coated WC-based cermet in 3.5 wt% NaCl solution. Corros. Sci. 2024, 227, 111738. [Google Scholar] [CrossRef]

- Min, J.; Wang, X.-Z.; Wang, Y.; Bai, Y.; Sabola, S.A.; Gong, W.; Wang, L.; Li, J.; Li, Z. Tribocorrosion in nitric acid of Zr alloy, Ti alloy, and 310 SS used for reprocessing of spent nuclear fuel. Tribol. Int. 2025, 201, 110184. [Google Scholar] [CrossRef]

- Wu, S.; Zhang, L.; Peng, X.; Dai, S.; Ou, Y.; Pang, P.; Chen, L.; Jin, X.; Zhang, X.; Liao, B.; et al. Relationship between residual stress and tribocorrosion behavior of high quality DLC coatings prepared by FCVA with HVP technology. Ceram. Int. 2025, 51, 3062–3074. [Google Scholar] [CrossRef]

- Xu, X.; Su, F.; Yu, H.; Liu, R.; Xu, Z. Black phosphorus nanosheet dotted with Fe3O4-PDA nanoparticles: A novel lubricant additive for tribological applications. Tribol. Int. 2025, 207, 110607. [Google Scholar] [CrossRef]

- Gascard, J.-C.; Riemann-Campe, K.; Gerdes, R.; Schyberg, H.; Randriamampianina, R.; Karcher, M.; Zhang, J.; Rafizadeh, M. Future sea ice conditions and weather forecasts in the Arctic: Implications for Arctic shipping. Ambio 2017, 46, 355–367. [Google Scholar] [CrossRef]

- ZHANG, J.; CAI, Q.-w.; WU, H.-b.; ZHANG, K.; WU, B. Effect of Tempering Temperature on Microstructure and Properties of E690 Offshore Plate Steel. J. Iron Steel Res. Int. 2012, 19, 67–72. [Google Scholar] [CrossRef]

- Lu, S.; Wang, L.; Zhou, J.; Liang, J. Microstructure and tribological properties of laser-cladded Co-Ti3SiC2 coating with Ni-based interlayer on copper alloy. Tribol. Int. 2022, 171, 107549. [Google Scholar] [CrossRef]

- Fernández, M.R.; García, A.; Cuetos, J.M.; González, R.; Noriega, A.; Cadenas, M. Effect of actual WC content on the reciprocating wear of a laser cladding NiCrBSi alloy reinforced with WC. Wear 2015, 324–325, 80–89. [Google Scholar] [CrossRef]

- López, A.; Bayón, R.; Pagano, F.; Igartua, A.; Arredondo, A.; Arana, J.L.; González, J.J. Tribocorrosion behaviour of mooring high strength low alloy steels in synthetic seawater. Wear 2015, 338–339, 1–10. [Google Scholar] [CrossRef]

- Shan, L.; Wang, Y.; Li, J.; Li, H.; Wu, X.; Chen, J. Tribological behaviours of PVD TiN and TiCN coatings in artificial seawater. Surf. Coat. Technol. 2013, 226, 40–50. [Google Scholar] [CrossRef]

- Zhang, D.; Qian, H.; Wang, L.; Li, X. Comparison of barrier properties for a superhydrophobic epoxy coating under different simulated corrosion environments. Corros. Sci. 2016, 103, 230–241. [Google Scholar] [CrossRef]

- Qian, H.; Xu, D.; Du, C.; Zhang, D.; Li, X.; Huang, L.; Deng, L.; Tu, Y.; Mol, J.M.C.; Terryn, H.A. Dual-action smart coatings with a self-healing superhydrophobic surface and anti-corrosion properties. J. Mater. Chem. A 2017, 5, 2355–2364. [Google Scholar] [CrossRef]

- He, D.; Feng, Z.; Liang, R.; Wang, Q.; Shang, L. Effect of Cr3C2 content on the tribo-corrosion behaviors of Cr3C2-NiCr/DLC duplex coatings. Surf. Coat. Technol. 2024, 489, 131134. [Google Scholar] [CrossRef]

- Wei, X.; Chen, Z.; Feng, H.; Liu, Z.; Lu, S.; Ding, J.; Du, N.; Yin, P.; Yang, W.; Li, X.; et al. Understanding the tribo-corrosion behaviors and mechanism of Si/N-DLC films in marine environment. Diam. Relat. Mater. 2024, 150, 111756. [Google Scholar] [CrossRef]

- Farfan-Cabrera, L.I.; Cao-Romero-Gallegos, J.A.; Lee, S.; Komurlu, M.U.; Erdemir, A. Tribological behavior of H-DLC and H-free DLC coatings on bearing materials under the influence of DC electric current discharges. Wear 2023, 522, 204709. [Google Scholar] [CrossRef]

- Zhang, L.; Shang, L.; Gou, C.; Zhang, G. Tribological and corrosive behavior under HCl corrosive environment of diamond-like carbon films with doped H, Cr and WC. Surf. Coat. Technol. 2024, 482, 130685. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhou, X.; Chen, R.; Yang, W.; Guo, P.; Nishimura, K.; Li, X.; Wang, A. Ultrahigh tribocorrosion resistance of hydrogenated amorphous carbon coating via trace gradient W incorporation. Corros. Sci. 2024, 240, 112504. [Google Scholar] [CrossRef]

- Liu, Y.; He, Y.; Liu, L. Atomic effect and mechanism of different hydrogen content on superlubricity properties of H-DLC films. Appl. Surf. Sci. 2025, 679, 161211. [Google Scholar] [CrossRef]

- Guan, X.; Lu, Z.; Wang, L. Achieving High Tribological Performance of Graphite-like Carbon Coatings on Ti6Al4V in Aqueous Environments by Gradient Interface Design. Tribol. Lett. 2011, 44, 315–325. [Google Scholar] [CrossRef]

- Wang, Y.; Wang, L.; Xue, Q. Improvement in the tribological performances of Si3N4, SiC and WC by graphite-like carbon films under dry and water-lubricated sliding conditions. Surf. Coat. Technol. 2011, 205, 2770–2777. [Google Scholar] [CrossRef]

- Zhang, T.; Xu, Z.; Wang, J.; Huang, W.; Hou, X.; Paddea, S.; Su, Y. Failure Behavior of Hydrogenated and Hydrogen Free Diamond Like Carbon (DLC) Films in Water Environment. J. Bio- Tribo-Corros. 2021, 7, 149. [Google Scholar] [CrossRef]

- Ye, Y.; Wang, Y.; Ma, X.; Zhang, D.; Wang, L.; Li, X. Tribocorrosion behaviors of multilayer PVD DLC coated 304L stainless steel in seawater. Diam. Relat. Mater. 2017, 79, 70–78. [Google Scholar] [CrossRef]

- Vetter, J. 60 years of DLC coatings: Historical highlights and technical review of cathodic arc processes to synthesize various DLC types, and their evolution for industrial applications. Surf. Coat. Technol. 2014, 257, 213–240. [Google Scholar] [CrossRef]

- Ru, L.; Wang, Y.; Liu, J.; Tao, S.; Xiao, J. Hydrophobic, anticorrosion, and frictional properties of F-DLC films prepared by magnetron sputtering. Vacuum 2023, 217, 112567. [Google Scholar] [CrossRef]

- Wei, X.; Shi, S.; Ning, C.; Lu, Z.; Zhang, G. Si-DLC films deposited by a novel method equipped with a co-potential auxiliary cathode for anti-corrosion and anti-wear application. J. Mater. Sci. Technol. 2022, 109, 114–128. [Google Scholar] [CrossRef]

- Ma, F.; Li, J.; Zeng, Z.; Gao, Y. Structural, mechanical and tribocorrosion behaviour in artificial seawater of CrN/AlN nano-multilayer coatings on F690 steel substrates. Appl. Surf. Sci. 2018, 428, 404–414. [Google Scholar] [CrossRef]

- Wei, J.; Li, H.; Liu, L.; Guo, P.; Ke, P.; Wang, A. Enhanced tribological and corrosion properties of multilayer ta-C films via alternating sp3 content. Surf. Coat. Technol. 2019, 374, 317–326. [Google Scholar] [CrossRef]

- Ferrari, A.C.; Robertson, J. Interpretation of Raman spectra of disordered and amorphous carbon. Phys. Rev. B 2000, 61, 14095–14107. [Google Scholar] [CrossRef]

- Ferrari, A. Determination of bonding in diamond-like carbon by Raman spectroscopy. Diam. Relat. Mater. 2002, 11, 1053–1061. [Google Scholar] [CrossRef]

- Maruno, H.; Nishimoto, A. Adhesion and durability of multi-interlayered diamond-like carbon films deposited on aluminum alloy. Surf. Coat. Technol. 2018, 354, 134–144. [Google Scholar] [CrossRef]

- Han, C.; Yang, T.; Lin, X.; Song, Y.; Xie, M.; Deng, Q.; Wen, F. Effect of bias gradient delta on mechanical and tribological properties of DLC films sputtered on ACM. Surf. Coat. Technol. 2024, 481, 130626. [Google Scholar] [CrossRef]

- McMaster, S.J.; Kosarieh, S.; Liskiewicz, T.W.; Neville, A.; Beake, B.D. Utilising H/E to predict fretting wear performance of DLC coating systems. Tribol. Int. 2023, 185, 108524. [Google Scholar] [CrossRef]

- Murugan, V.S.; Madhu, S. Analysis of Mechanical and Tribological Properties of Silicon Incorporated Diamond like Carbon Nanocomposite Coating. Silicon 2021, 14, 6053–6061. [Google Scholar] [CrossRef]

- Li, H.; Liu, L.; Guo, P.; Sun, L.; Wei, J.; Liu, Y.; Li, S.; Wang, S.; Lee, K.-R.; Ke, P.; et al. Long-term tribocorrosion resistance and failure tolerance of multilayer carbon-based coatings. Friction 2022, 10, 1707–1721. [Google Scholar] [CrossRef]

- Beliardouh, N.E.; Ramoul, C.E.; Nouveau, C.; Kaleli, E.H.; Montagne, A. Synthesis and tribocorrosion performances of multilayer (Ta/ZrN)n coatings. Thin Solid Film. 2022, 749, 139184. [Google Scholar] [CrossRef]

- Zhao, Y.; Xu, F.; Zhang, D.; Xu, J.; Shi, X.; Sun, S.; Zhao, W.; Gao, C.; Zuo, D. Enhanced tribological and corrosion properties of DLC/CrN multilayer films deposited by HPPMS. Ceram. Int. 2022, 48, 25569–25577. [Google Scholar] [CrossRef]

- Celis, J.P.; Ponthiaux, P.; Wenger, F. Tribo-corrosion of materials: Interplay between chemical, electrochemical, and mechanical reactivity of surfaces. Wear 2006, 261, 939–946. [Google Scholar] [CrossRef]

- Andersson, J.; Erck, R.A.; Erdemir, A. Friction of diamond-like carbon films in different atmospheres. Wear 2003, 254, 1070–1075. [Google Scholar] [CrossRef]

- Wang, L.; Cui, L.; Lu, Z.; Zhou, H. Understanding the unusual friction behavior of hydrogen-free diamond-like carbon films in oxygen atmosphere by first-principles calculations. Carbon 2016, 100, 556–563. [Google Scholar] [CrossRef]

- Wan, Z.; Zhang, T.F.; Lee, H.-B.-R.; Yang, J.H.; Choi, W.C.; Han, B.; Kim, K.H.; Kwon, S.-H. Improved Corrosion Resistance and Mechanical Properties of CrN Hard Coatings with an Atomic Layer Deposited Al2O3 Interlayer. ACS Appl. Mater. Interfaces 2015, 7, 26716–26725. [Google Scholar] [CrossRef] [PubMed]

| Architecture | Deposition | Thickness | Environment | Wr (mm3·N−1·m−1) | References |

|---|---|---|---|---|---|

| N/Ti/TiN/GLC | MFMS | 1.4 μm | Sea water | 2.12 × 10−6 | [24] |

| DLC | FCVA/HVP | 5.75 μm | 3.5 wt% NaCl | 1.04 × 10−6 | [8] |

| Cr/WC/a-C:H | UBMS | 2.98 μm | Sea water | 1.09 × 10−7 | [27] |

| WC/a-C | HVOF/DCMS | 1.7 μm | 3.5 wt% NaCl | 1.92 × 10−7 | [6] |

| CrN/AlN | RMS | 2.4 μm | Sea water | 2.33 × 10−7 | [31] |

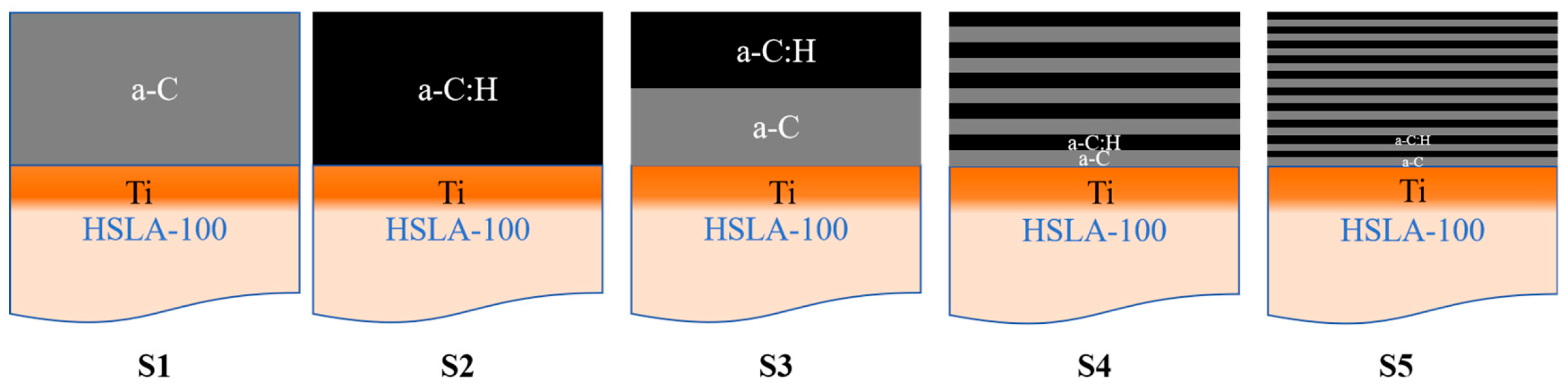

| Sample | Layers | Ar (sccm) | C2H2 (sccm) | Time | Work Pressure | Bias Voltage |

|---|---|---|---|---|---|---|

| Ti etching layer | 200 | 0 | 300 s | 0.5 Pa | −600 V | |

| Ti transition layer | 200 | 0 | 1500 s | 0.5 Pa | −100 V | |

| S1 | a-C | 90 | 0 | 1320 s | 0.2 Pa | −50 V |

| S2 | a-C:H | 90 | 10 | 1260 s | 0.2 Pa | −50 V |

| S3 | a-C (1) | 90 | 0 | 660 s | 0.2 Pa | −50 V |

| a-C:H (1) | 90 | 10 | 900 s | 0.2 Pa | −50 V | |

| S4 | a-C (5) | 90 | 0 | 132 s | 0.2 Pa | −50 V |

| a-C:H (5) | 90 | 10 | 180 s | 0.2 Pa | −50 V | |

| S5 | a-C (10) | 90 | 0 | 71 s | 0.2 Pa | −50 V |

| a-C:H (10) | 90 | 10 | 95 s | 0.2 Pa | −50 V |

| Sample | HSLA100 | S1 | S2 | S3 | S4 | S5 |

|---|---|---|---|---|---|---|

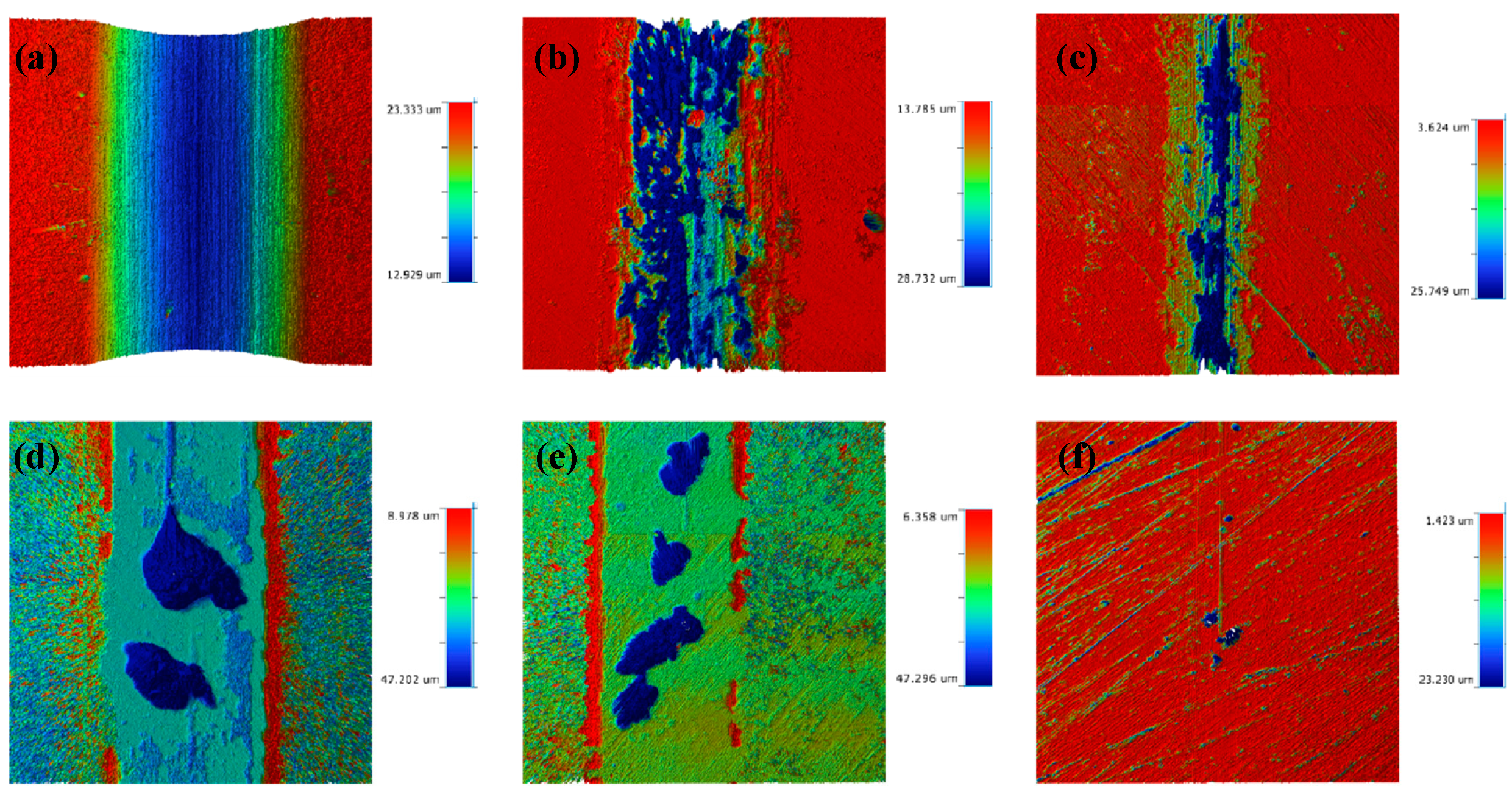

| Sa (μm) | 0.049 (±0.006) | 0.066 (±0.008) | 0.101 (±0.008) | 0.177 (±0.010) | 0.116 (±0.006) | 0.091 (±0.007) |

| Sq (μm) | 0.065 (±0.008) | 0.091 (±0.01) | 0.117 (±0.009) | 0.185 (±0.012) | 0.141 (±0.011) | 0.117 (±0.009) |

| Grinding Mark Center Sa (μm) | 0.959 (±0.012) | 0.499 (±0.011) | 0.933 (±0.013) | 0.267 (±0.010) | 0.257 (±0.011) | 0.106 (±0.009) |

| Grinding Mark Center Sq (μm) | 1.073 (±0.015) | 0.503 (±0.013) | 0.965 (±0.014) | 0.268 (±0.012) | 0.257 (±0.013) | 0.113 (±0.009) |

| Sample | Wr (mm3·N−1·m−1) |

|---|---|

| HSLA100 | 2.09 (±0.20) × 10−6 |

| S1 | 3.27 (±0.24) × 10−7 |

| S2 | 3.12 (±0.26) × 10−7 |

| S3 | 2.10 (±0.48) × 10−7 |

| S4 | 1.88 (±0.16) × 10−7 |

| S5 | 1.39 (±0.18) × 10−7 |

| Sample | HSLA100 | S1 | S2 | S3 | S4 | S5 |

|---|---|---|---|---|---|---|

| Ecorr (V) | −0.707 | −0.439 | −0.423 | −0.375 | −0.416 | −0.437 |

| icorr (A/cm2) | 1.43 (±0.06) × 10−5 | 2.76 (±0.09) × 10−6 | 2.59 (±0.05) × 10−6 | 2.46 (±0.07) × 10−6 | 2.41 (±0.04) × 10−6 | 2.15 (±0.09) × 10−6 |

| Sample | Wr (mm3·N−1·m−1) |

|---|---|

| HSLA100 | 5.68 (±0.29) × 10−5 |

| S1 | 7.59 (±0.72) × 10−6 |

| S2 | 3.95 (±0.23) × 10−6 |

| S3 | 1.15 (±0.07) × 10−5 |

| S4 | 1.24 (±0.11) × 10−5 |

| S5 | 4.53 (±0.02) × 10−7 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jin, T.; Feng, J.-A.; Huang, Y.; Wu, Z.; Guo, X.; Zhu, K.; Dai, W.; Yin, Y.; Wu, H. Period-Tuned a-C/a-C:H Multilayer DLC Coating for Tribocorrosion Protection of HSLA-100 Steel. Nanomaterials 2025, 15, 1704. https://doi.org/10.3390/nano15221704

Jin T, Feng J-A, Huang Y, Wu Z, Guo X, Zhu K, Dai W, Yin Y, Wu H. Period-Tuned a-C/a-C:H Multilayer DLC Coating for Tribocorrosion Protection of HSLA-100 Steel. Nanomaterials. 2025; 15(22):1704. https://doi.org/10.3390/nano15221704

Chicago/Turabian StyleJin, Tong, Ji-An Feng, Yan Huang, Zhenghua Wu, Xinyi Guo, Kailin Zhu, Wei Dai, Yansheng Yin, and Hao Wu. 2025. "Period-Tuned a-C/a-C:H Multilayer DLC Coating for Tribocorrosion Protection of HSLA-100 Steel" Nanomaterials 15, no. 22: 1704. https://doi.org/10.3390/nano15221704

APA StyleJin, T., Feng, J.-A., Huang, Y., Wu, Z., Guo, X., Zhu, K., Dai, W., Yin, Y., & Wu, H. (2025). Period-Tuned a-C/a-C:H Multilayer DLC Coating for Tribocorrosion Protection of HSLA-100 Steel. Nanomaterials, 15(22), 1704. https://doi.org/10.3390/nano15221704