A Method for Preparing Diamond Films with High Thermal Stability

Abstract

1. Introduction

2. Method

2.1. Preparation of Diamond Film

- (1)

- Polish the Si substrate with a silica sol solution (100 nm particle size, 40% concentration) for at least 30 min to remove the surface oxide layer.

- (2)

- Subject the Si substrate to ultrasonic treatment in an acetone suspension containing diamond micropowder. The suspension is prepared using diamond micropowder with a particle size ranging from 0.2 to 1 μm at a concentration of 3–6 g per 100 mL of acetone. The seeding process lasts 30–60 min. Subsequently, clean the substrate ultrasonically in anhydrous ethanol for 10–15 min. Finally, dry the substrate surface using compressed nitrogen for further use.

- (3)

- Modify the surface of the prepared nitrogen-doped micron diamond film using reactive ion etching (RIE) technology. Then, clean it ultrasonically in anhydrous ethanol for 5–10 min.

- (4)

- The obtained samples are placed in a muffle furnace for high-temperature vacuum annealing treatment. The vacuum pressure is maintained at 10−4 pa for a duration of 2 h to obtain a high-strength diamond film.

2.2. Characterization of Diamond Film

2.3. The Calculation Method of Thermal Conductivity

3. Results

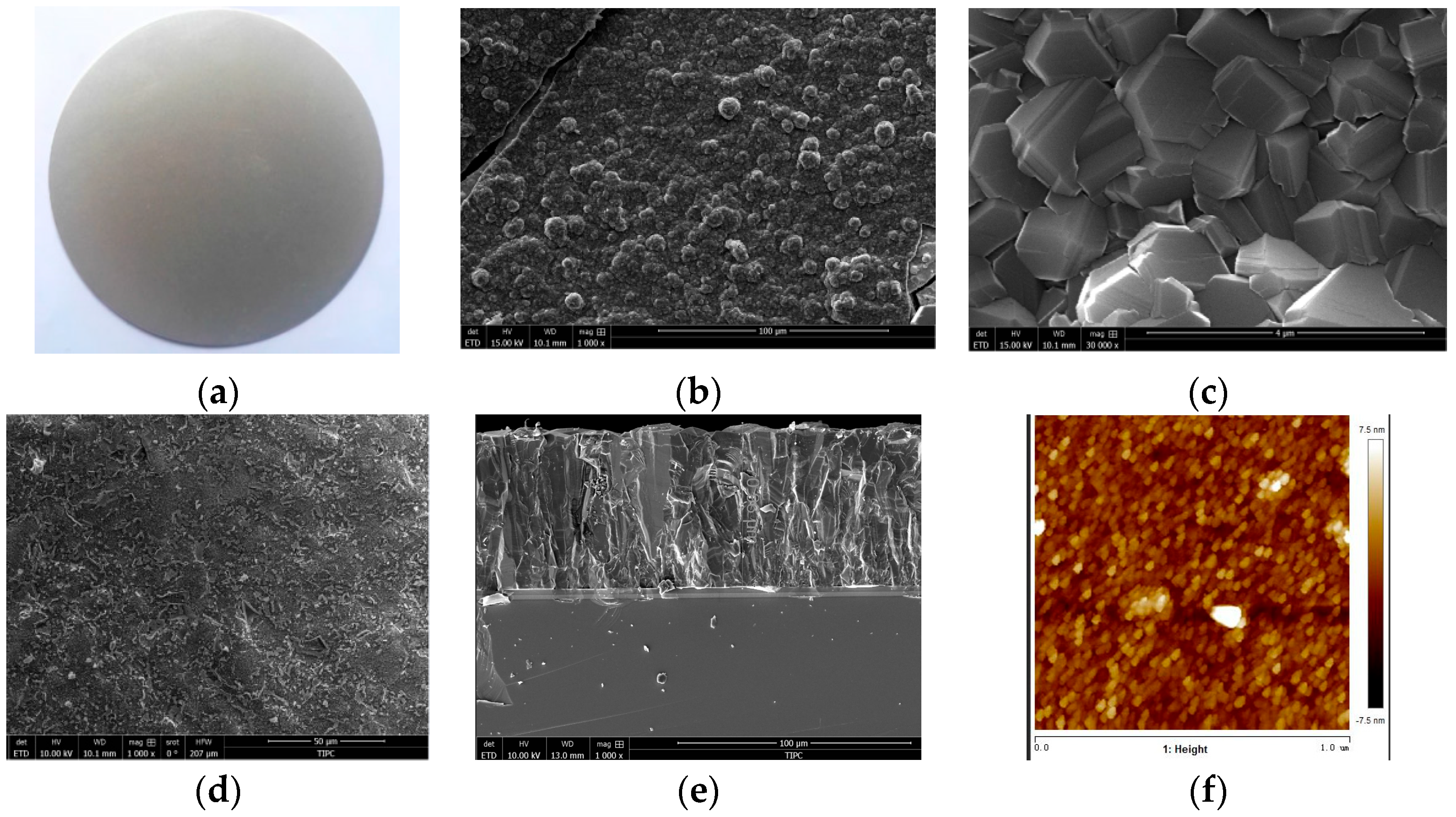

3.1. The Morphological Characteristics of Diamond Film

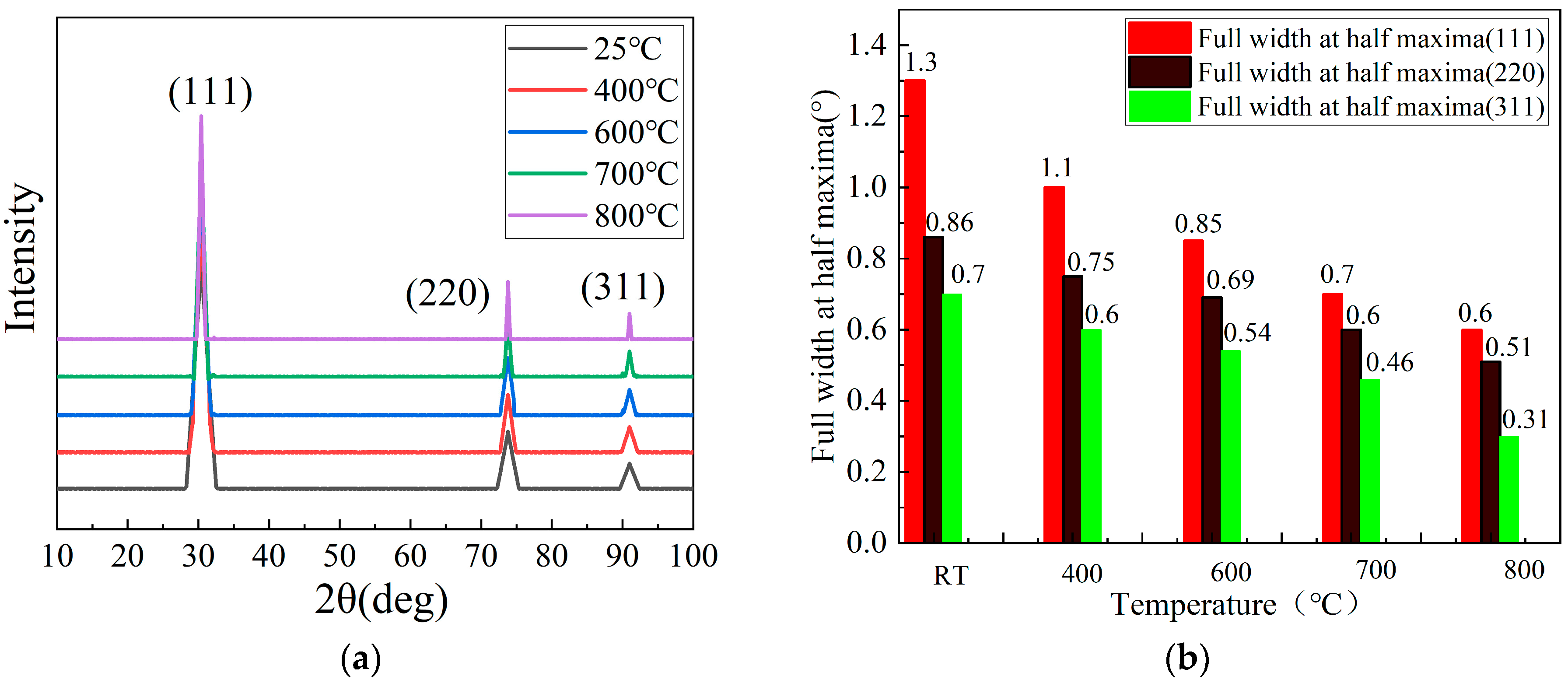

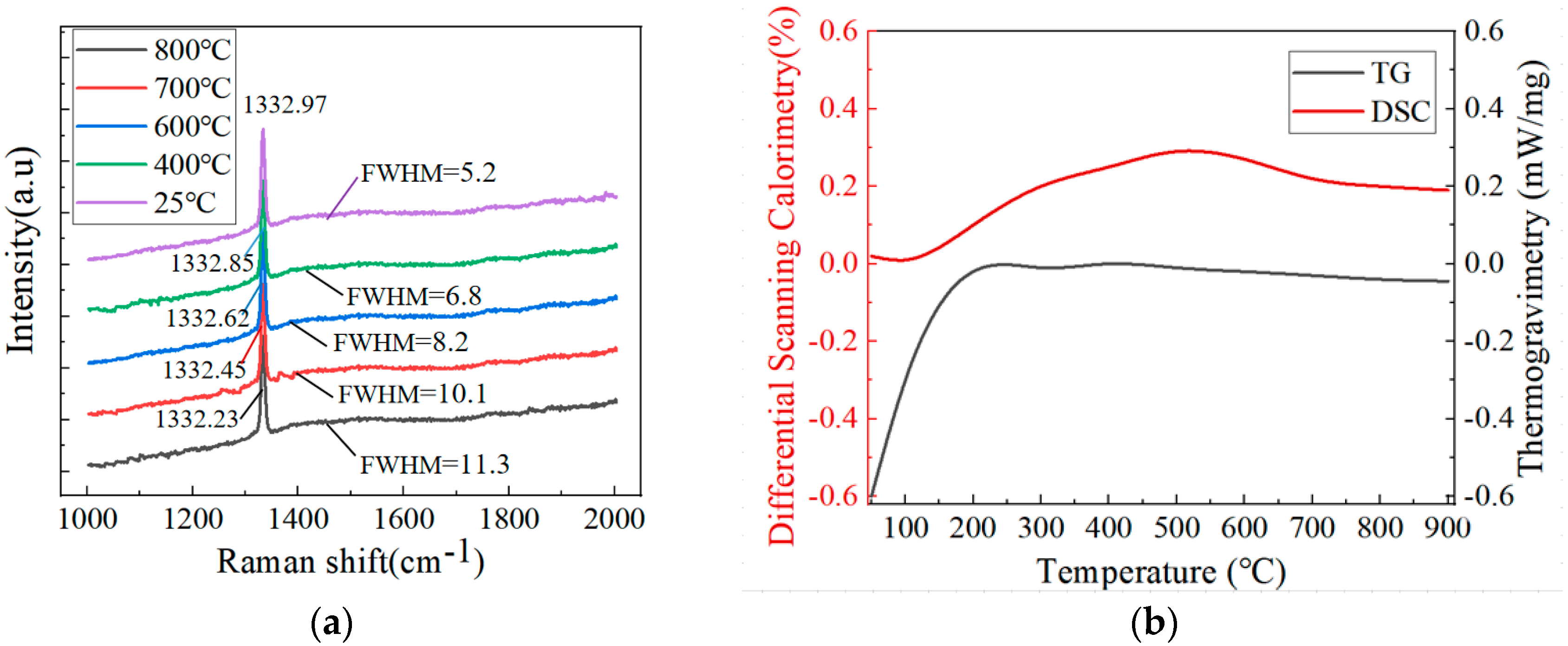

3.2. The XRD Patterns of Diamond Film

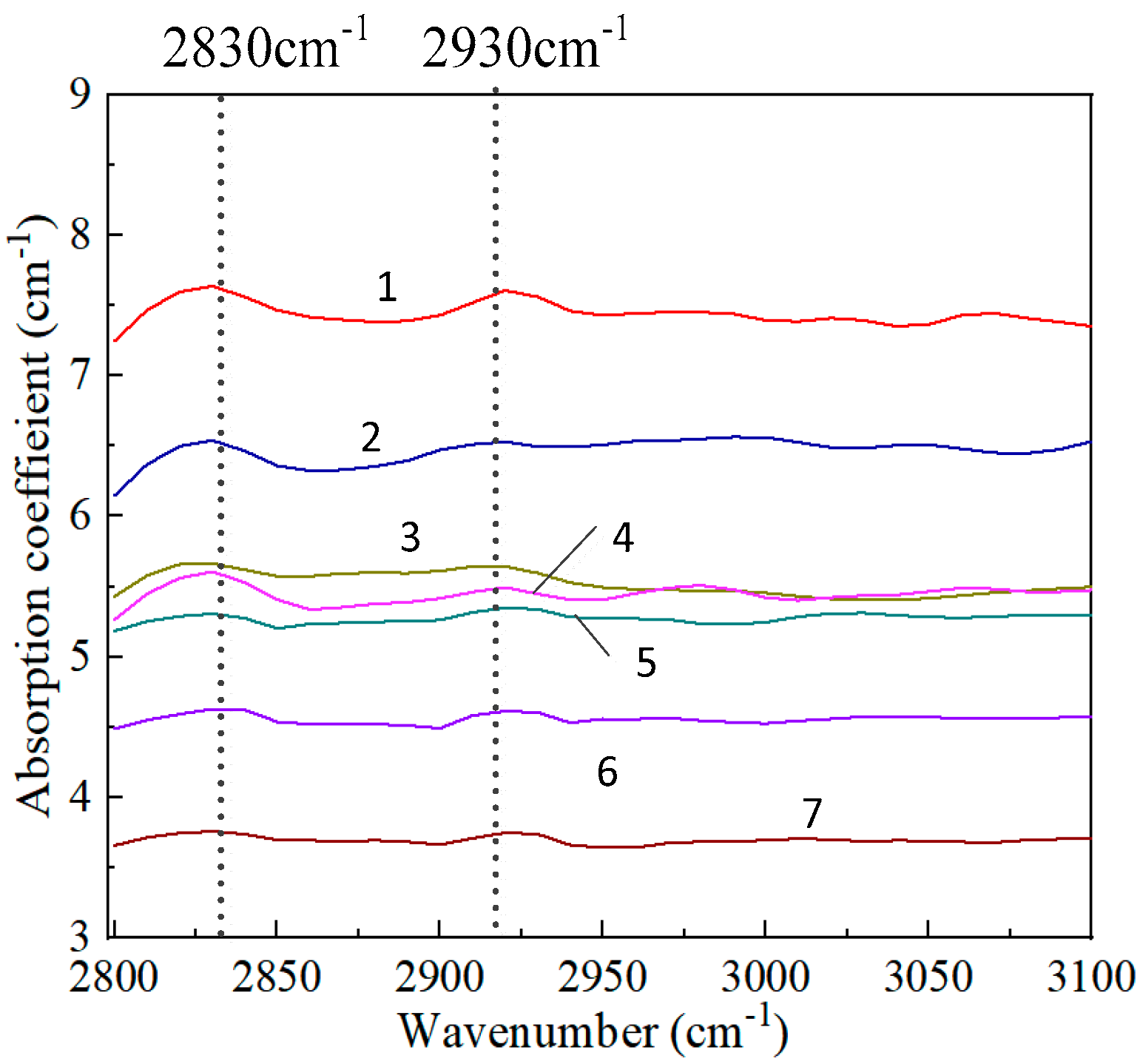

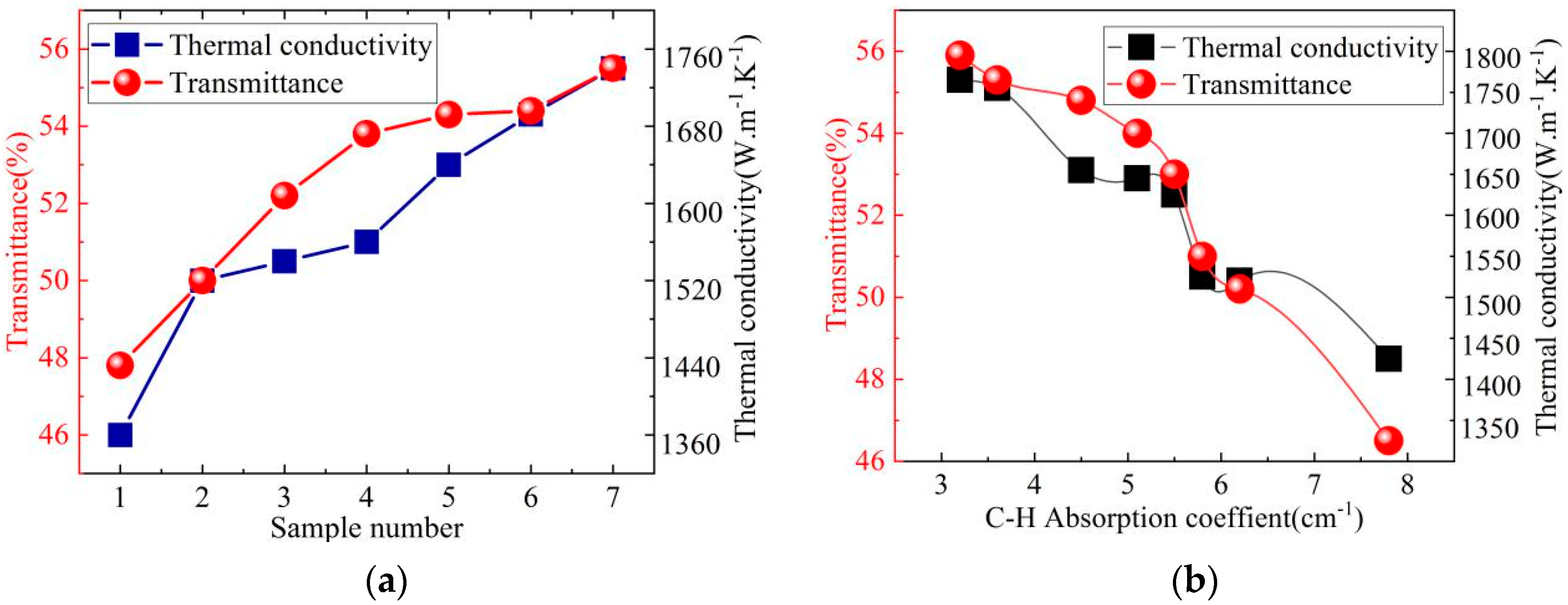

3.3. The Thermal Conductivity and Optical Properties of Diamond Film

3.4. Analysis of the Heat Dissipation Performance of Diamond Film

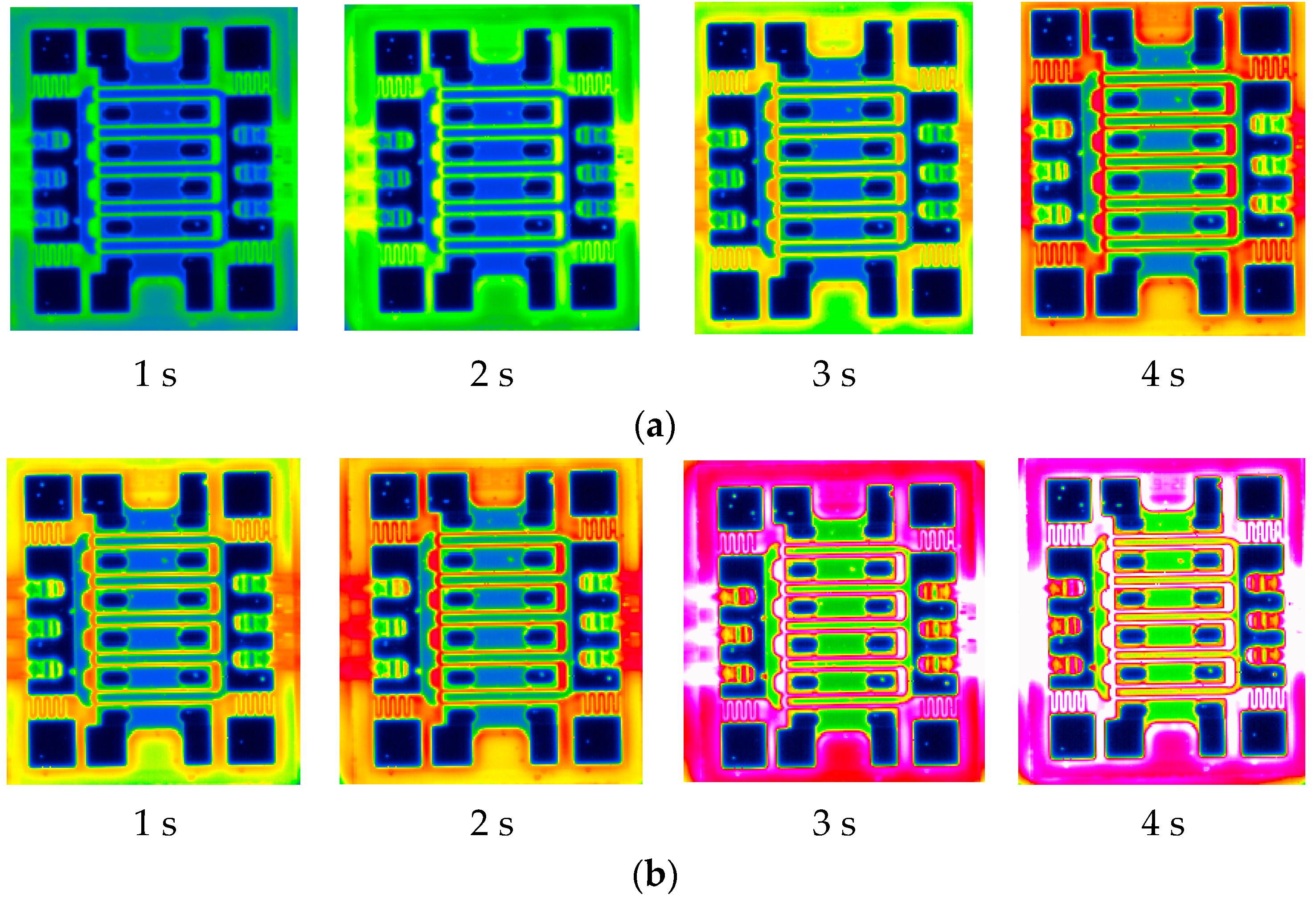

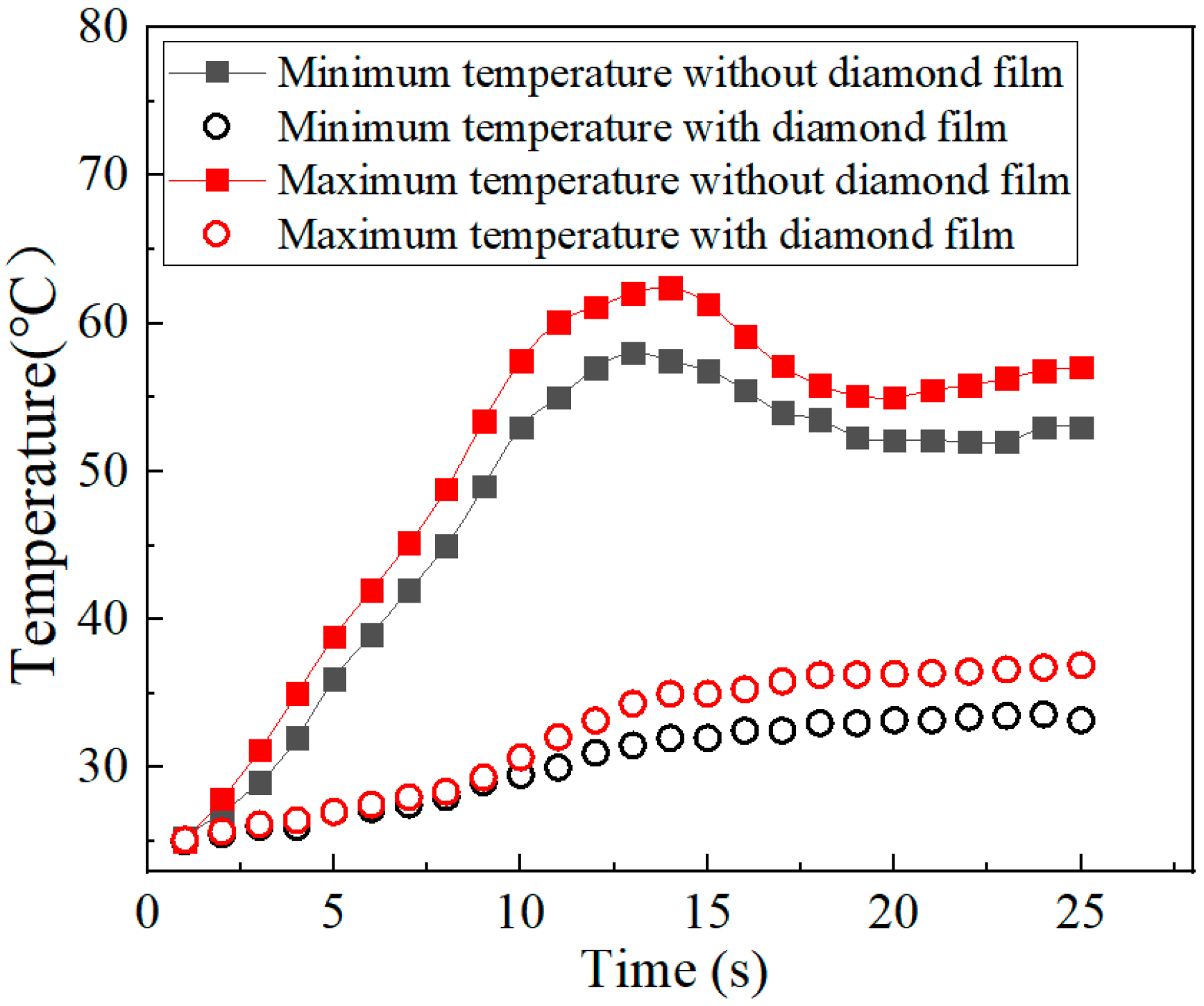

3.5. The Heat Dissipation Effect of Diamond Chips

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Fodchuk, I.M.; Balovsyak, S.V.; Solodkyi, M.S.; Borcha, M.D.; Băilă, D.I.; Labudzki, R.; Bonilla, M. Spatial distributions of local strains in synthesized diamond crystals from the normalized parameters of Kikuchi patterns. Phys. Chem. Solid State 2024, 25, 773–781. [Google Scholar] [CrossRef]

- Zuo, P.J.; Wang, Z.; Yu, C.C.; Wu, R.Q. Impact of Magnetic Adsorbates on Shallow Nitrogen-Vacancy Centers: Insights from Diamond C(001) Surface Studies. J. Phys. Chem. C 2023, 127, 18706–18717. [Google Scholar] [CrossRef]

- Zhu, R. Preparation and Thermophysical Characteristics of Self-Standing Diamond Films. Ph.D. Thesis, University of Science and Technology Beijing, Beijing, China, 2015. [Google Scholar]

- Kutsay, O.M.; Gontar’, A.G.; Novikov, N.V.; Dub, S.N.; Tkach, V.N.; Gorshteĭn, B.A.; Mozkova, O.V. Diamond-like Carbon Films in Multilayered Interference Coatings for IR Optical Elements. Diam. Relat. Mater. 2020, 10, 1846–1849. [Google Scholar]

- Wort, C.J.H.; Pickles, C.S.J.; Beale, A.C.; Sweeney, C.G.; McClymont, M.R.; Saunders, R.J.; Sussmann, R.S.; Lewis, K.L. Recent Advances in the Quality of CVD Diamond Optical Components. In Proceedings of the AeroSense ’99, Orlando, FL, USA, 5–9 April 1999; Volume 3705, pp. 119–128. [Google Scholar]

- Lu, F.X.; Guo, H.B.; Guo, S.B.; He, Q.; Li, C.M.; Tang, W.Z.; Chen, G.C. Magnetron Sputtered Oxidation Resistant and Antireflection Protective Coatings for Freestanding Diamond Film IR Windows. Diam. Relat. Mater. 2019, 18, 244–248. [Google Scholar]

- Newnam, B.E. CVD-grown Diamond: A New Material for High-power CO2 Lasers. In Proceedings of the 27th Annual Boulder Damage Symposium: Laser-Induced Damage in Optical Materials: 1995, Boulder, CO, USA, 27 May 1996; Volume 2714, pp. 177–184. [Google Scholar]

- Zhu, Y.; Ye, T.; Wen, H.; Xu, R.; Zhong, Y.; Lin, G.; Liang, D.; Cai, W.; Yu, D.; Lin, W. Quasi-2D Phonon Transport in Diamond Nanosheet. Adv. Funct. Mater. 2024, 34, 2407333. [Google Scholar] [CrossRef]

- Kim, J.W.; Yang, H.S.; Jun, Y.H.; Kim, K.C. Interfacial effect on thermal conductivity of diamond-like carbon films. J. Mech. Sci. Technol. 2020, 24, 1511–1514. [Google Scholar] [CrossRef]

- Grotjohn, T.A.; Schuelke, T.; Reinhard, D.K.; Fan, J.; Brussee, G.L.A.; Smith, J.R. High-Thermal-Conductivity CVD Diamond for Electronic Applications. In Proceedings of the 2021 32nd SEMI Advanced Semiconductor Manufacturing Conference (ASMC), Milpitas, CA, USA, 10–12 May 2021; pp. 1–4. [Google Scholar]

- Jia, H.; Liang, L.-L.; Liu, D.; Wang, Z.; Liu, Z.; Xie, L.-J.; Tao, Z.-C.; Kong, Q.-Q.; Chen, C.-M. A review of three-dimensional graphene networks for thermal management and electromagnetic protection. New Carbon Mater. 2021, 36, 1–868. [Google Scholar] [CrossRef]

- Liu, Y.; Qiu, L.; Wang, Z.; Haimo, L.; Yanhui, F. Enhancing interfacial thermal transport efficiently in diamond/graphene heterostructure by involving vacancy defects. Compos. Part A Appl. Sci. Manuf. 2024, 178, 108008. [Google Scholar] [CrossRef]

- Zhang, L.; Wei, Q.; Ma, L.; Zhou, K.; Ye, W.; Yu, Z.; Gan, X.; Lin, C.-T.; Luo, J. Construction of 3D interconnected diamond networks in Al-matrix composite for high-efficiency thermal management. Chem. Eng. J. 2020, 380, 122551. [Google Scholar] [CrossRef]

- Chen, J.; Liu, B.; Gao, X. Thermal Properties of Graphene-Based Polymer Composite Materials: A molecular dynamics study. Results Phys. 2020, 16, 102974. [Google Scholar] [CrossRef]

- Delmas, W.; Jarzembski, A.; Bahr, M.; McDonald, A.; Hodges, W.; Lu, P.; Deitz, J.; Ziade, E.; Piontkowski, Z.T.; Yates, L. Thermal transport and mechanical stress mapping of a compression bonded GaN/diamond interface for vertical power devices. ACS Appl. Mater. Interfaces 2024, 16, 11003–11012. [Google Scholar] [CrossRef] [PubMed]

- Zhao, F.; He, Y.; Huang, B.; Tianyi, Z.; Hao, Z. A review of diamond materials and applications in power semiconductor devices. Materials 2024, 17, 3437. [Google Scholar] [CrossRef] [PubMed]

- Seal, M. Thermal and Optical Applications of Thin Film Diamond. Philos. Trans. R. Soc. Lond. 1993, 342, 313–322. [Google Scholar] [CrossRef]

- Coe, S.E.; Sussmann, R.S. Optical, Thermal and Mechanical Properties of CVD Diamond. Diam. Relat. Mater. 2000, 9, 1726–1729. [Google Scholar] [CrossRef]

- Yin, Z.; Akkerman, Z.; Yang, B.; Smith, F. Optical Properties and Microstructure of CVD Diamond Films. Diam. Relat. Mater. 2019, 6, 153–158. [Google Scholar] [CrossRef]

- Zaitsev, A.M. Optical Properties of Diamond: A Data Handbook; Springer: Berlin/Heidelberg, Germany, 2013. [Google Scholar]

- Twitchen, D.J.; Pickles, C.S.J.; Coe, S.E.; Sussmann, R.S. Thermal Conductivity Measurements on CVD Diamond. Diam. Relat. Mater. 2015, 10, 731–735. [Google Scholar] [CrossRef]

- Ralchenko, V.; Pimenov, S.; Konov, V.; Khomich, A.; Saveliev, A.; Popovich, A.; Vlasov, I.; Zavedeev, E.; Bozhko, A.; Loubnin, E.; et al. Nitrogenated Nanocrystalline Diamond Films: Thermal and Optical Properties. Diam. Relat. Mater. 2017, 16, 2067–2073. [Google Scholar] [CrossRef]

- Mollart, T.; Lewis, K. The Infrared Optical Properties of CVD Diamond at Elevated Temperatures. Phys. Status Solidi (A) 2019, 186, 309–318. [Google Scholar] [CrossRef]

| Temperature/°C | Power/kW | Pc/kPa | Duration/h | CH4 (sccm) | H2 (sccm) | N2 (sccm) | Ar (sccm) |

|---|---|---|---|---|---|---|---|

| 850~900 | 15 | 12 | 200 | 120 | 20~40 | 0~50 | 10~30 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhao, X.; Han, C.; Jia, X.; Fan, Z. A Method for Preparing Diamond Films with High Thermal Stability. Nanomaterials 2025, 15, 1606. https://doi.org/10.3390/nano15211606

Zhao X, Han C, Jia X, Fan Z. A Method for Preparing Diamond Films with High Thermal Stability. Nanomaterials. 2025; 15(21):1606. https://doi.org/10.3390/nano15211606

Chicago/Turabian StyleZhao, Xia, Chao Han, Xin Jia, and Zifeng Fan. 2025. "A Method for Preparing Diamond Films with High Thermal Stability" Nanomaterials 15, no. 21: 1606. https://doi.org/10.3390/nano15211606

APA StyleZhao, X., Han, C., Jia, X., & Fan, Z. (2025). A Method for Preparing Diamond Films with High Thermal Stability. Nanomaterials, 15(21), 1606. https://doi.org/10.3390/nano15211606