This study encompasses an extensive series of welding experiments. To minimize the time required for these investigations, a detailed parametric study is conducted on the effects of pulse energy, focal position, and line spacing, as presented in

Section 3.1,

Section 3.2 and

Section 3.3. The optimized conditions identified in these sections are then applied in

Section 3.4 and

Section 3.5 to examine the influence of beam shaping and variations in material pairings, respectively. Due to the large number of different input parameter combinations tested in this study, repeated measurements of the breaking force have only been performed for selected data points. In these cases the error bars representing the standard deviation are shown in the graph, e.g., see Figure 3a. As the rest of the data points each represents a single measurement, our results should be considered as a lower bound for the maximum welding strength that can be reached. A more complete representation of the breaking strength would be given by a probability distribution such as the Weibull distribution [

14,

19].

3.1. The Effect of the Pulse Energy

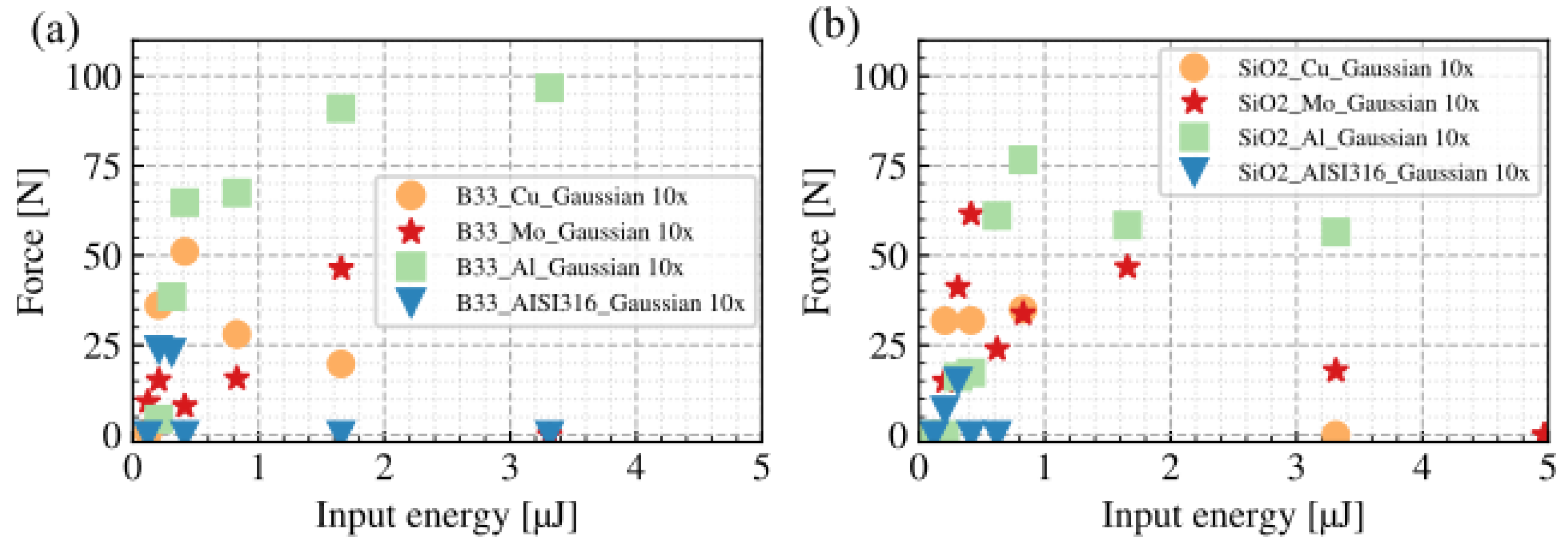

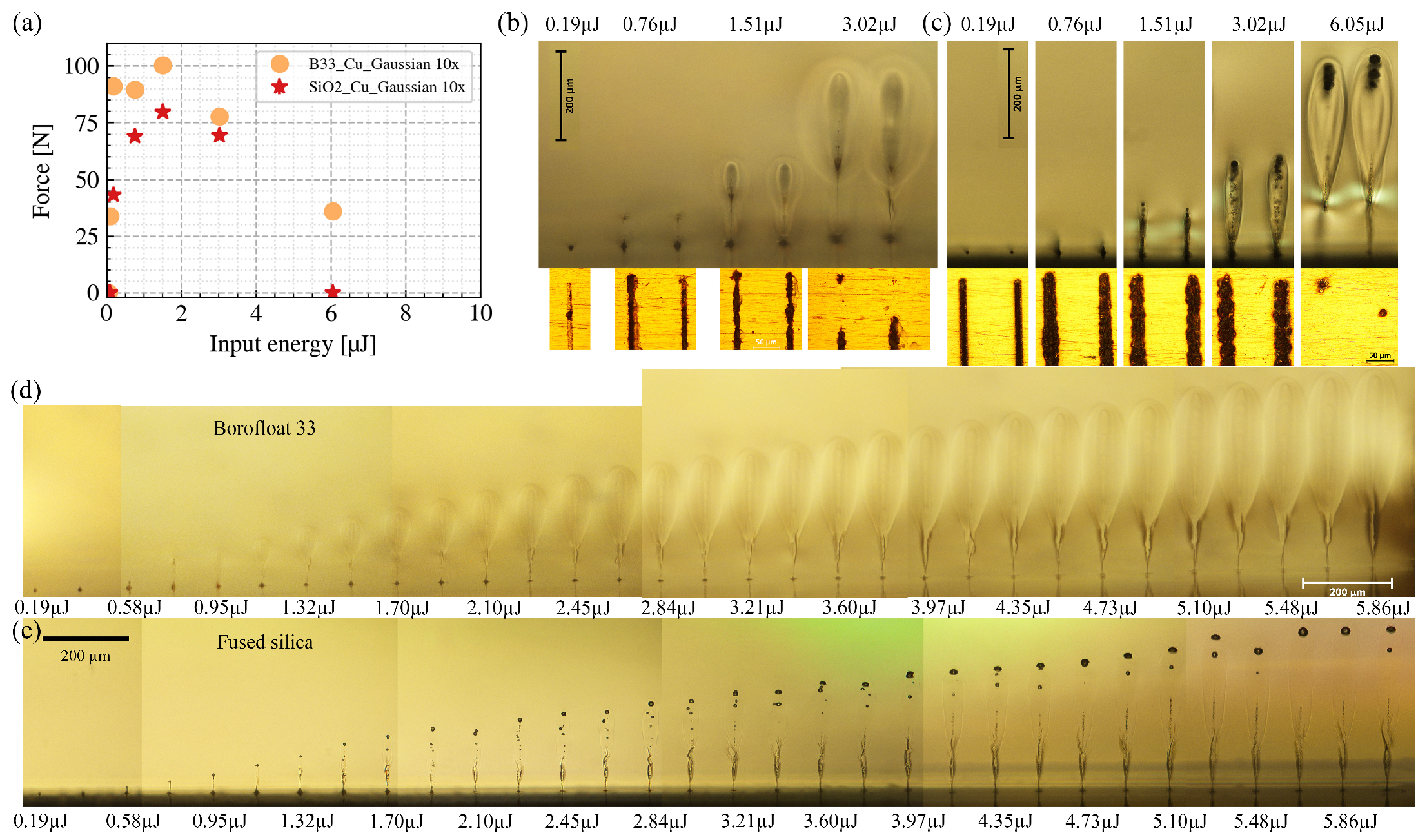

In part I, we determined the processing windows in terms of the input pulse energy for BOROFLOAT® 33 glass (B33) to copper welding when an air gap is present. In this paper, given the assembling condition has changed, we expect to find a new processing window. Therefore, starting from the same burst and focus conditions (125 kHz, eight pulses/burst, NA = 0.26), we first investigate the influence of the input pulse energy on B33-to-Cu welding. In order to gain a better insight into the generalizability of the results, we also performed the same parameter tests for the welding of UV-Grade fused silica () to Cu.

Figure 2a shows how the breaking force of the weld is influenced by the input pulse energies

. For all cases presented here, the focus is positioned at the glass-to-metal interface, the processing speed

is 1 mm/s, the welding area

A is 4.5 mm × 2 mm, and it was hatched using a bi-directional scanning strategy with a line interval of 100 µm.

For B33-to-Cu welding, as the input pulse energy increases from low to an intermediate value (e.g., 1.51 µJ), the breaking force increases correspondingly. However, when the input pulse energy further increases, the breaking force starts to decrease. Similar trends apply to the -to-Cu welding; when the input pulse energy increases to 6.05 µJ, the breaking force decreases to 0 N (i.e., is not welded to Cu in this case).

To understand the mechanism of such relations, we carried out the welding experiments under the same processing conditions with side-polished glasses. After the welding, we selected four typical input energies and performed ex situ side and top observations of the seams. The upper half of

Figure 2b shows the modifications in B33 under different input energies, and the lower half shows the modifications at the B33–Cu interface. As the input energy increases, the volume of the in-glass modification increases. However, the modified line width at the B33–Cu interface follows another trend, i.e., from 1.51 µJ to 3.02 µJ; as the energy increases, the modified line width decreases. Specifically, when the input energy increases to 3.02 µJ, the previously continuous line becomes discontinuous, and consequently, the breaking force of the welds decreases.

Figure 2c shows the same study on

-to-Cu welding. The previously described empirical relation also applies here. Moreover, when the input energy increases to 6.05 µJ, modifications at the interface are almost fully suppressed, and most of the laser energy is absorbed in the bulk of

.

In

Figure 2d,e, we further investigate the laser-induced modifications near the B33/

-to-Cu interface for incrementally increasing input pulse energies (step size 0.19 µJ). To better visualize in side view, we chose to have single-site modifications, and to mimic the welding condition, the number of pulses per site was set to 10,000 (125 kHz, eight pulses/burst). The focus was positioned at the interface for all measurements. When the pulse energy is low (e.g., 0.19 µJ), the absorption occurs only within the Rayleigh range of the laser beam, and the modification is confined near (<10 µm) the interface. As the pulse energy increases (e.g., 2.45 µJ), the modification grows far beyond the Rayleigh range of the laser beam; in other words, absorption occurs outside of the focal region. When the input pulse energy is high (e.g., 5.86 µJ), the modification grows even further beyond the focal region. In this case, most of the laser energy is absorbed in the bulk of the glass, and there are no more modifications on the copper surface. To summarize, we have observed a shift of the absorption region towards the incoming laser direction as the input pulse energy increases. This phenomenon has been studied by many groups [

7,

20,

21,

22,

23,

24] and can be explained as follows. For the first laser pulse, the energy of the pulse is absorbed by electrons in the valence band to generate free electrons by photonionization and cascade ionization. However, the photonionization-induced plasma defocusing and the optical Kerr effect shift the maximum intensity position from the linear focal position. For B33 and

, in our tested energy range, this shift is small (<5 µm). For later pulses, however, heat accumulation and a temperature rise in the material can lead to increased ionization. When the temperature of the ‘hot area’ reaches 3000 K or more, the pulse energy is almost linearly absorbed, and the glass becomes even opaque. For our experimental conditions, heat accumulation results in peak temperatures of up to several thousand degrees, as calculated by the thermal model that we use for the calculation of thermal stress in

Section 3.6. These findings agree with previous experimental observations [

25]. At those temperatures, thermal ionization becomes crucial for producing high-density free electrons, which serve as the initial free electrons for the plasma formation induced by subsequent pulses. The teardrop-shaped modifications beyond the Rayleigh range of the laser beam can be explained in terms of the thermal ionization front that moves towards the laser source as the temperatures increase. It is worth noting that the geometrical shape of the modifications is different in B33 and

. With the same input pulse energy, the width of the modifications in the B33 is about twice that of

. This can be briefly attributed to the fact that the band-gap energy of B33 (4 eV) is lower than that of

(9 eV) [

26].

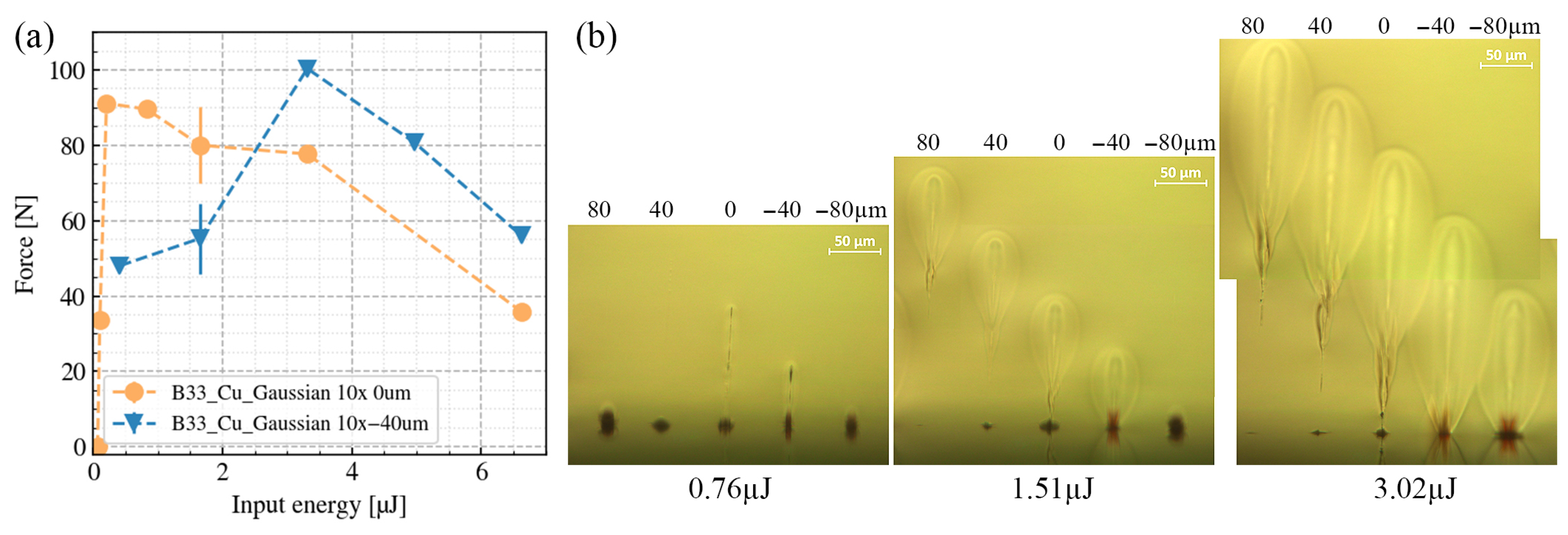

3.2. The Effect of the Focal Position

In the last section, we observed that, as the input pulse energy increases, the center of the laser-induced modification shifts upstream from the geometrical focus position towards the laser source. In this section, we investigate the influence of the longitudinal focus-to-interface displacement on the welding quality.

Figure 3b shows the side observations of the single-site modifications under different pulse energies and different

. Under the high-pulse-energy conditions (e.g., 3.02 µJ), when the focal position is 80 µm above the interface, a tear-drop shaped modification is confined in the bulk of B33. When the focal position coincides with the interface, the tear-drop-shaped modification extends to the interface as well; however, most of the modification remains inside the glass. By further moving the focal position to 80 µm below the interface, the modification at the interface covers a larger width; however, the volume of the tear-drop-shaped modification in B33 decreases.

Under the intermediate-pulse-energy conditions (e.g., 1.51 µJ), when the focal position is 80 µm above the interface, an in-bulk tear-drop-shaped modification can still be induced. The same applies for the 0 µm case; however, the tear-drop-shaped modification disappears as the focal position shifts 80 µm below the interface.

Under the low-pulse-energy conditions (e.g., 0.76 µJ), when the focal position is above the interface, the pulse energy is not sufficient to generate the tear-drop-shaped modification in the bulk of B33. However, given the fact that copper has a lower laser-induced damage threshold than B33 [

1], interface ablation occurs even under the +80 µm conditions. Surprisingly, such ablation is prevented in those intermediate- and high-energy conditions. When the focal position shifts to the interface or 40 µm below, laser-induced free electrons at the Cu-B33 interface act as a seed and induce further laser energy absorption in the bulk of B33.

Despite the differences in the laser-induced modification phenomena under the different focal conditions, we are more concerned about the quality of the welding seams.

Figure 3a shows how the breaking force of the welding varies against the input pulse energies under different focal conditions. The orange curve indicates the condition when the focal position coincides with the interface, and the blue curve indicates the condition where the focal position is 40 µm below the interface. From the two curves, one can see that the maximum breaking force for the two focal conditions is similar. However, for the de-focused condition, to achieve a similar breaking force, higher input energy is required. As shown in

Figure 3a, a higher input pulse energy ultimately degrades the welding quality. This can be understood as the combined action of the mismatch in thermal expansion between glass and metal and the increased thermal load at higher pulse energies. Together they can lead to excessive internal stress in the glass leading to crack formation. This is in contrast to findings for glass-to-glass welding, where an increase in energy can suppress the formation of cracks [

27]. For the subsequent studies, we chose to align the focal position with the glass-to-metal interface.

3.3. The Effect of the Line Spacing

As one may have noticed, in the previous sections, we have only mentioned the breaking force rather than the breaking strength of the welding. Conventionally, the breaking strength of the welding seams is calculated according to this relation: . The breaking force F can be experimentally measured; however the cross-section area A has different definitions. In some definitions, this area only refers to the welding seams covered regions, and the blank intervals between the seams are excluded. In other definitions, the whole welding affected regions (include the seams and the blank intervals) are defined as the cross-section area. By using the second definition, the size of the blank interval (or in another term, the welding seams density) has a strong influence on the breaking strength .

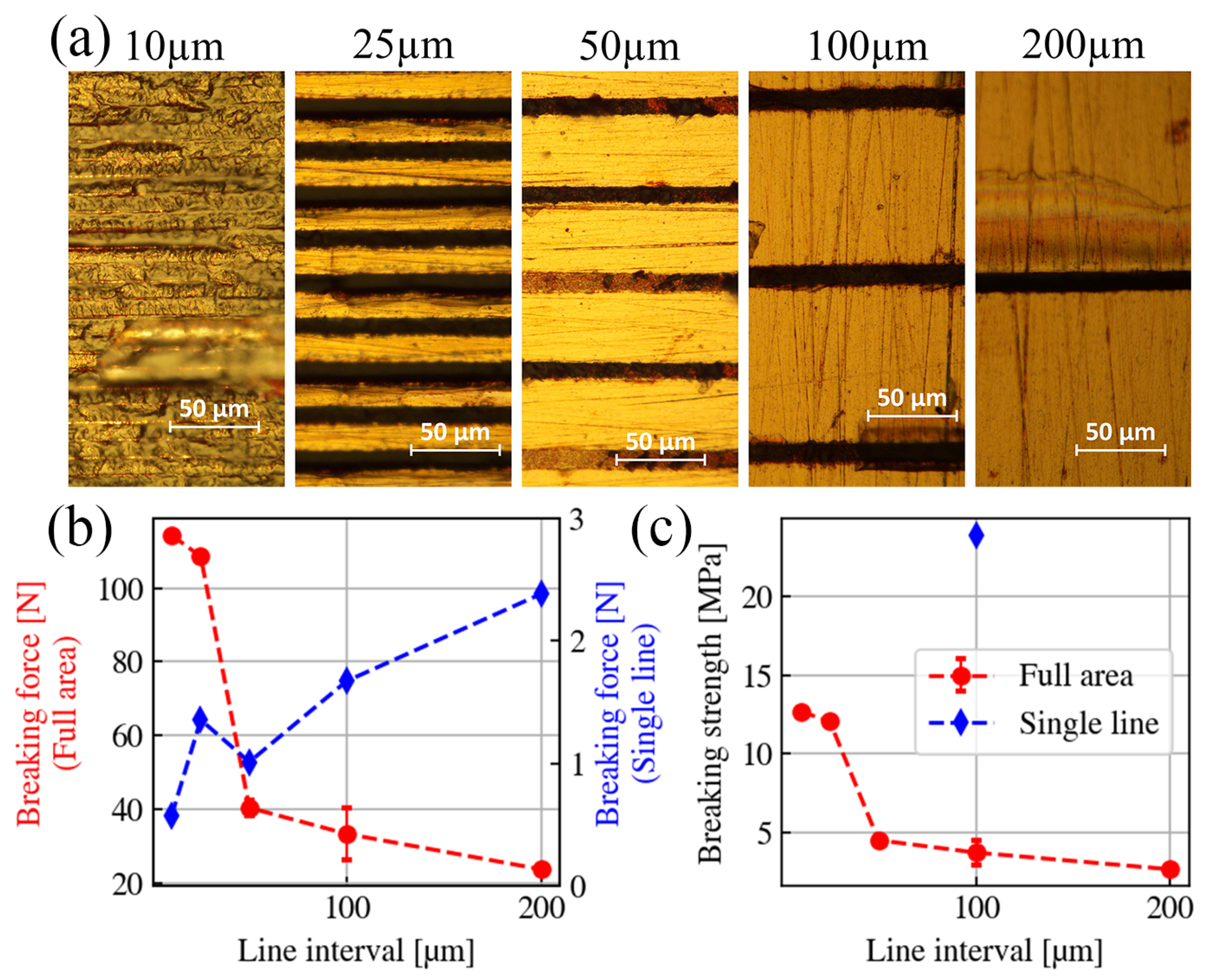

In the aforementioned investigations, the laser welding process is hatched by a bi-directional scanning strategy. Therefore, for certain welding-affected regions, the blank intervals are directly linked to the line spacing

. In

Figure 4a, under the constant laser processing parameters (125 kHz, eight pulses/burst, NA = 0.26,

= 0.38 µJ,

= 0 µm, and

= 1 mm/s), we present the top views of the welding seams under different line spacing values (10–200 µm). As shown in the microscopic images, when

100 µm, the width of the processed lines is constantly 13 µm. However, as

25 µm, the processed lines start to interfere with each other. When

25 µm, the width of the first line is still 13 µm, but the second following line width shrinks to 10 µm, and the third returns to 13 µm again. Under this line spacing condition, a ’breathing’ effect occurs during the hatching. When the line space further decreases to 10 µm, the welding-affected area is fully covered by the seams, and there are no more blank intervals. For all cases, the welding-affected region is fixed at 4.5 mm × 2 mm. Under this condition, the breaking forces for each line spacing condition are plotted in

Figure 4b in the red curve. By dividing those measured breaking forces by the number of lines, we obtained the force contributions of a single welding line and plotted them in the blue curve. The red curve shows an intuitive trend which indicates that when the line space gets closer, the breaking force increases. However, the blue curve indicates that the force contributed by a single welding line follows a contradictory trend. As the lines become denser, the force induced by a single line decreases due to the interference.

Finally, we divided the breaking force by the area (4.5 mm × 2 mm) and presented the breaking strength in

Figure 4c. According to the second definition of the welding area, the maximum breaking strength (12.7 MPa) is achieved when the line space is set at 10 µm, i.e., the lowest line spacing within our measurement range. However, the welding force per line decreases for smaller line spacing, and thus, the process efficiency is reduced. If we calculate the breaking strength induced by a single welding line under the condition of

100 µm, the breaking strength induced by a single line is 23.9 MPa. In practice, better hatching strategies should be applied to reach this limit value. However, finding such a strategy is beyond the scope of this paper. In the rest of this paper, we kept the line space at 100 µm and quantified the welding quality by the breaking force.

3.4. The Effect of the Beam Shape

Beam shaping is another important control parameter in the pursuit of process optimization. An annular beam, which has an intensity distribution concentrated in a ring with no on-axis intensity, has important implications for thermal and mechanical effects in materials [

13,

28,

29]. In this paper, our annular beam (optical vortex) is generated by a spiral phase plate. From

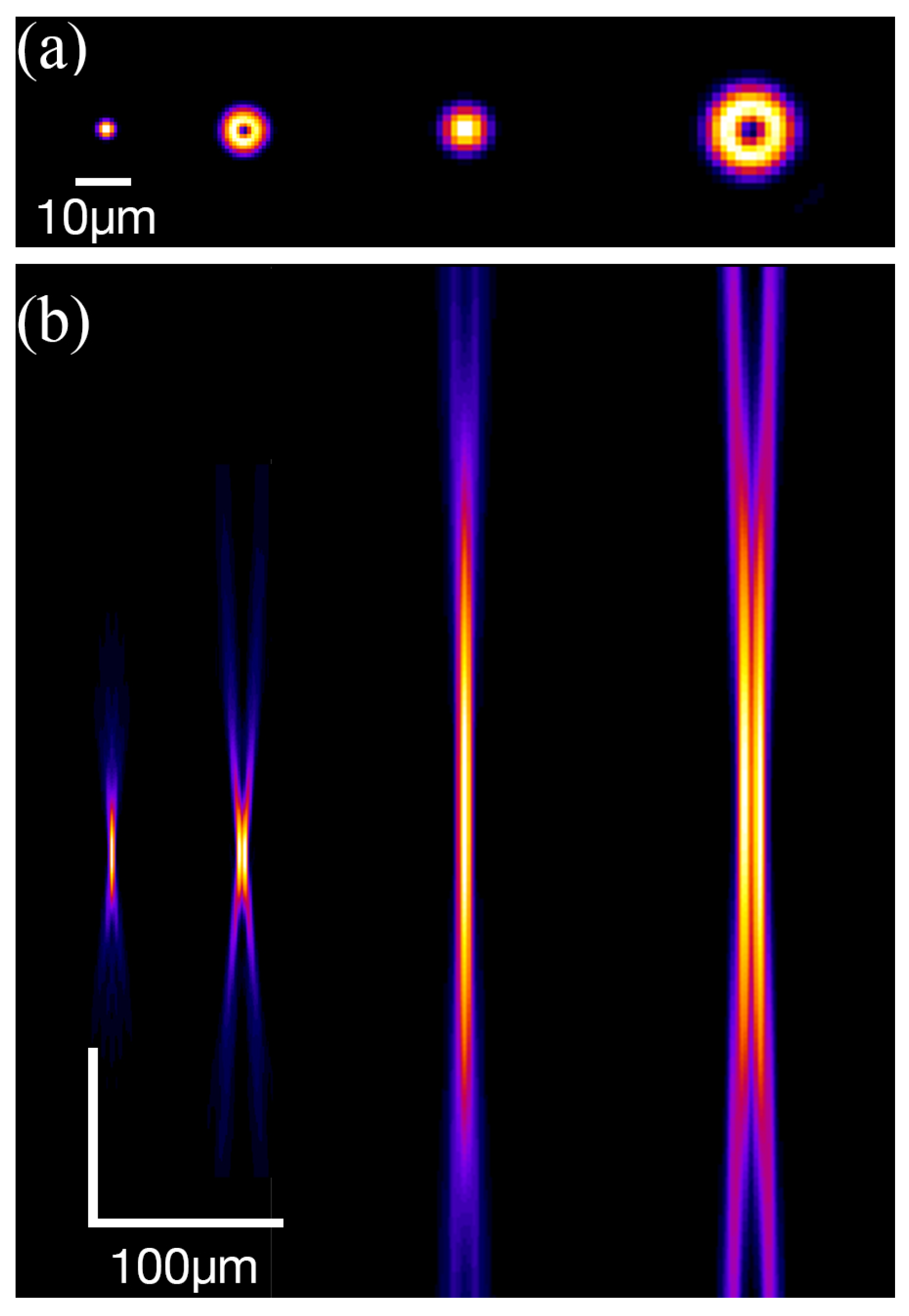

Figure 5, we discovered that, compared to the Gaussian beam, the vortex beam helps achieve inward movements of the molten copper. As the inward displaced molten copper solidifies, the height of the central needles can reach micrometer heights. In this section, we aim to discover if the unique feature of the optical vortex ablation can enhance the welding qualities.

As shown in

Figure 6, from left to right, in this paper we tested four different beam shapes: tightly focused (10× MO,

) Gaussian beam, tightly focused vortex beam, loosely focused (4× MO,

) Gaussian beam, and loosely focused vortex beam. Utilizing our benchmarked linear propagation model [

30], which accounts for aberrations, the intensity distribution near the focus can be simulated.

Figure 6a illustrates the intensity distribution on the x–y plane at the beam waist, and

Figure 6b illustrates the intensity distribution along the x–z plane near the focus. For the tightly focused Gaussian beam, the beam radius at the beam waist is 1.9 µm. Under the same focusing condition, the outer ring radius of the vortex beam is 3.5 µm. For the loosely focused Gaussian beam, the beam radius is 4.7 µm. Under the same focusing condition, the outer ring radius of the vortex beam is 8.7 µm.

The main aim of the paper is to investigate how different materials (listed along with their thermal and mechanical properties in the appendix in

Table A1) and beam shapes influence welding quality. Such an investigation involves tremendous numbers of parameters; therefore, it is generally time-consuming. To reduce time costs and make such an investigation feasible, based on what is presented in

Section 3.1,

Section 3.2 and

Section 3.3, in the rest of this paper, we decided to perform parameter studies under the following constraints:

4.0 µJ,

= 0 µm,

= 100 µm,

= 3.3 mm/s, and

A = 4.5 mm × 2.0 mm. Due to technical reasons we had to change the burst configuration for the following studies. From here on, we use four pulses per burst at a burst repetition rate of 330 kHz; the pulse interval within a burst is still 20 ns.

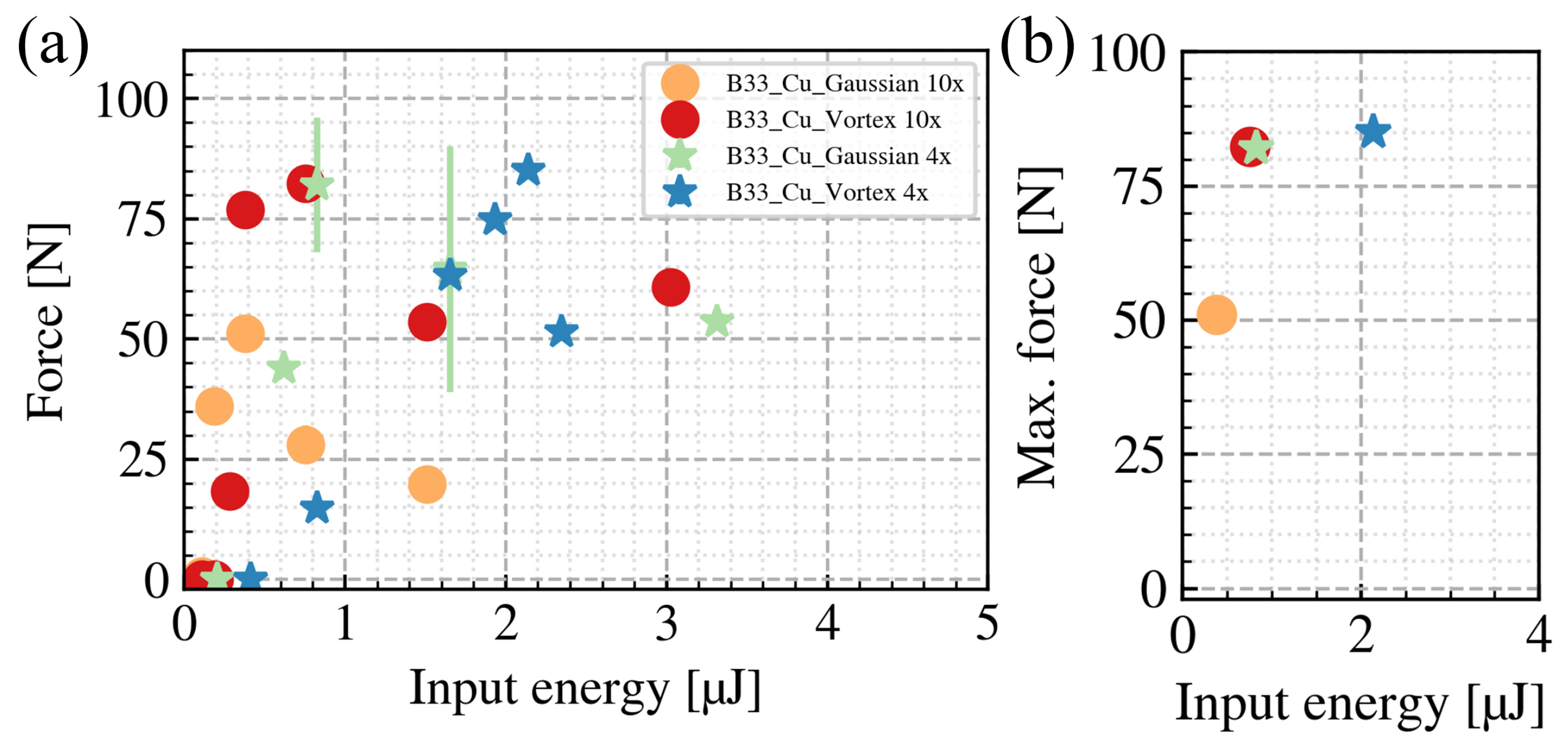

Figure 7a shows the relation between the input pulse energies and the breaking force of the B33-to-Cu welds under different beam shaping conditions. The maximum breaking force for each condition is summarized in

Figure 7b. For the tightly focused condition, the maximum breaking force achieved by the vortex beam increased by 61% compared to the Gaussian beam. For the loosely focused condition, there is only a 4% increase. According to our results, it appears that the vortex beam can enhance the welding quality. However, one must also note that, even using the same focusing lens, the effective beam area of a Gaussian beam differs from a vortex beam. Therefore, even though the welding results achieved by the vortex beam show a higher breaking force, we cannot simply attribute this superiority to the unique feature of the vortex beam. Coincidentally, as shown in

Figure 6a, the effective beam areas are similar for the tightly focused vortex beam and the loosely focused Gaussian beam. Comparing the maximum breaking force of the two conditions, the values are also very similar: 82.3 N for the tightly focused vortex and 82.0 N for the loosely focused Gaussian. These results agree with the previous findings that a low NA is favorable for the welding process [

10]. Another point to note is that, since the vortex beam has a higher effective beam area, the maximum breaking force is achieved with a higher input pulse energy, which induces higher thermal loads. The higher thermal loads can degrade the welding quality in return. In the loosely focused vortex beam condition, to achieve the maximum breaking force, an input pulse energy of 2.14 µJ is required. This high thermal load might counterbalance the potential improvement and explain the insignificant enhancement of the breaking force.

3.5. Welding of Different Material Pairs

Based on the investigations carried out in the previous section, to achieve maximum breaking force, we chose to use the loosely focused (4× MO) vortex beam for the welding in this section. The other processing parameters remain the same as in

Section 3.4.

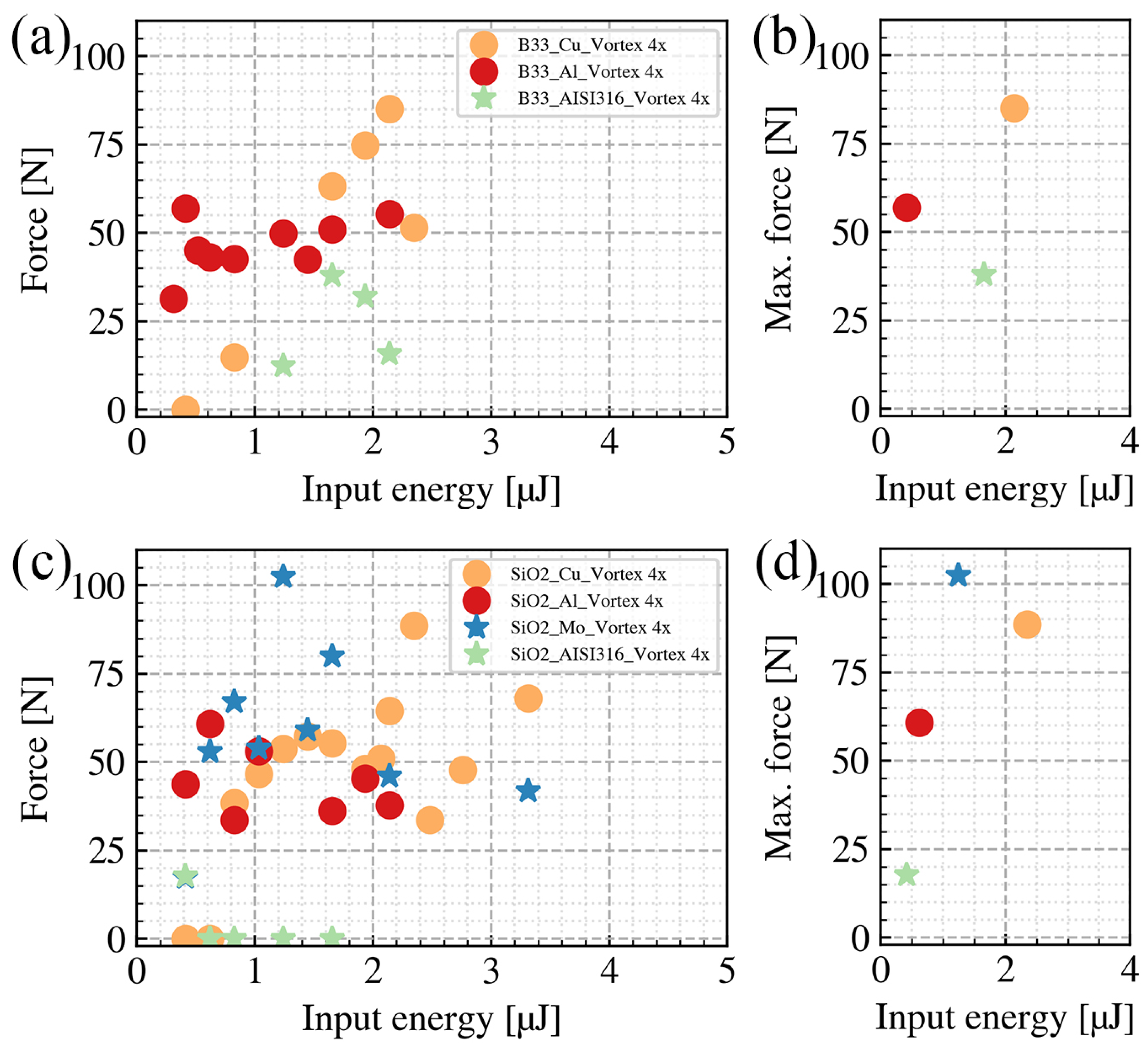

We first investigated the weldability of B33 with three different metals (Copper, Aluminium, and AISI316 steel). In

Figure 8a, the breaking force to input pulse energy relations under different B33-to-metals welding conditions are illustrated. The maximum breaking force for each condition is summarized in

Figure 8b. Among all three metals, the B33-to-Cu pair achieved the highest breaking force (85.12 N) and the B33-to-AISI316 steel pair achieved the lowest breaking force (37.9 N). The maximum breaking force of B33-to-Al is 56.9 N. Compared to Cu and Al, AISI316 steel is more difficult to weld with B33 glass. It exhibits not only the lowest breaking force but also the smallest processing windows in terms of the input pulse energy, achieving welding only at pulse energies below (∼1 µJ).

Figure 8c,d present the

-to-metal welding results. Similar trends are followed compared to B33-to-metal welding. The maximum breaking force of

-to-Cu welding is 88.62 N, and for

-to-Al welding it is 60.8 N. For

, we conducted additional welding experiments using molybdenum. The maximum breaking force of

-to-Mo welding is 102.4 N, which is the highest among all tested glass-to-metal welding cases. Similar to the B33 welding condition, AISI316 steel has the worst weldability with

as well. The maximum breaking force of

-to-AISI316 is 17.7 N, and the processing windows are at pulse energies lower than 1 µJ. Successful welding of

to stainless steel was achieved in [

17] at similar pulse energies. With a welding area that is about 75% compared to ours, they reach breaking forces of up to 240 N. They attribute the high stability of their welds to the high pressures used in their clamping system.

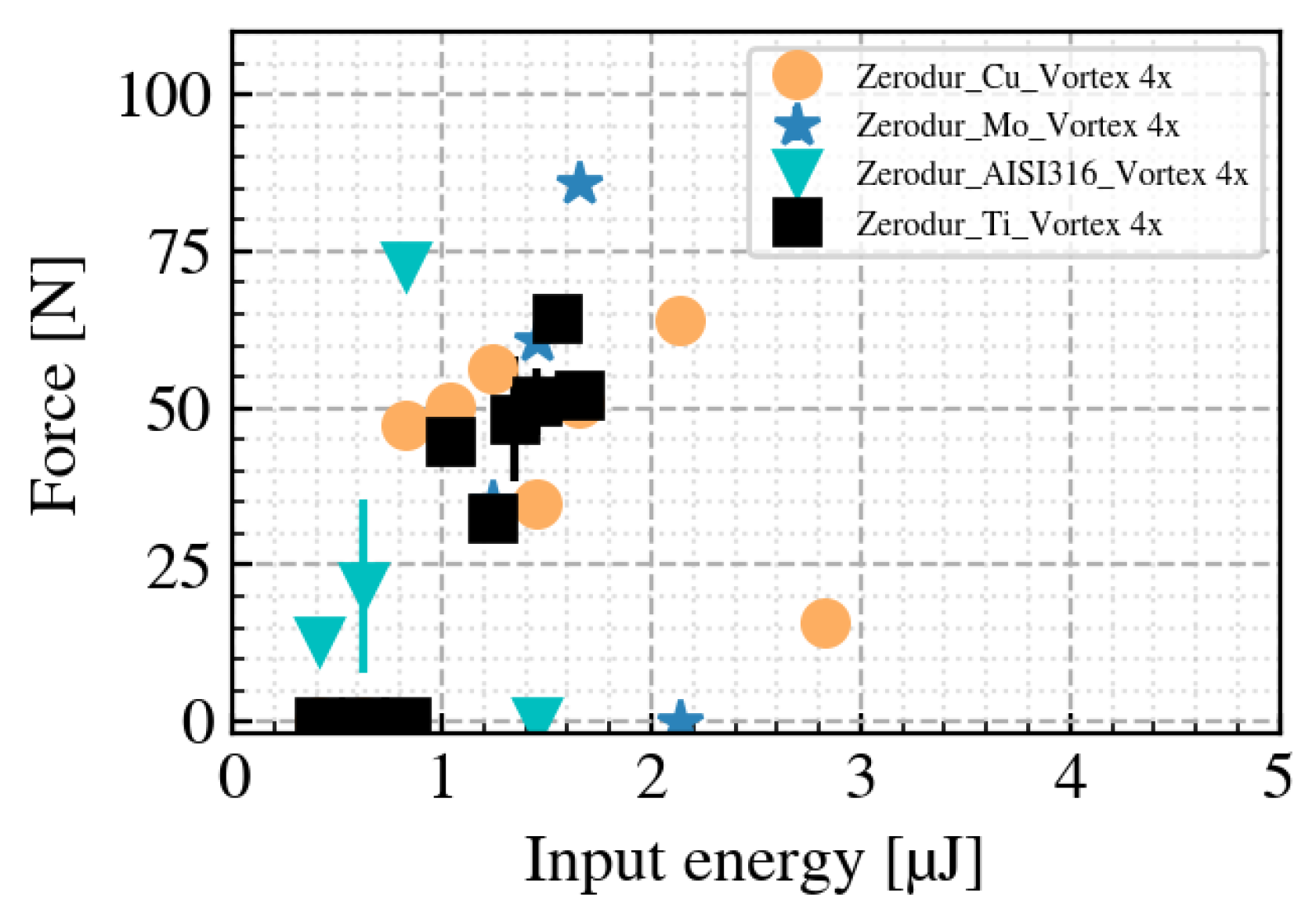

3.7. Welding of Glass to Metals with Low Thermal Conductivity

ZERODUR

® is a glass-ceramic with an extremely low coefficient of thermal expansion (CTE) of 0 ± 0.020 ppm/K in the temperature range 0 °C to 50 °C (also see

Table A1 for reference). Using the same repetition rate, beam shape, and welding area (4.5 mm × 2 mm), the maximum breaking force reached for ZERODUR

®-to-AISI6316 welding was 72.7 N, achieving an improvement of over 400% compared to the best

-to-AISI316 result. The maximum breaking force for ZERODUR

®-to-Titanium welding was 64.4 N, also a remarkably high value compared to our other welding strengths. The experimental results for ZERODUR

® are shown in the appendix, see

Figure A2.

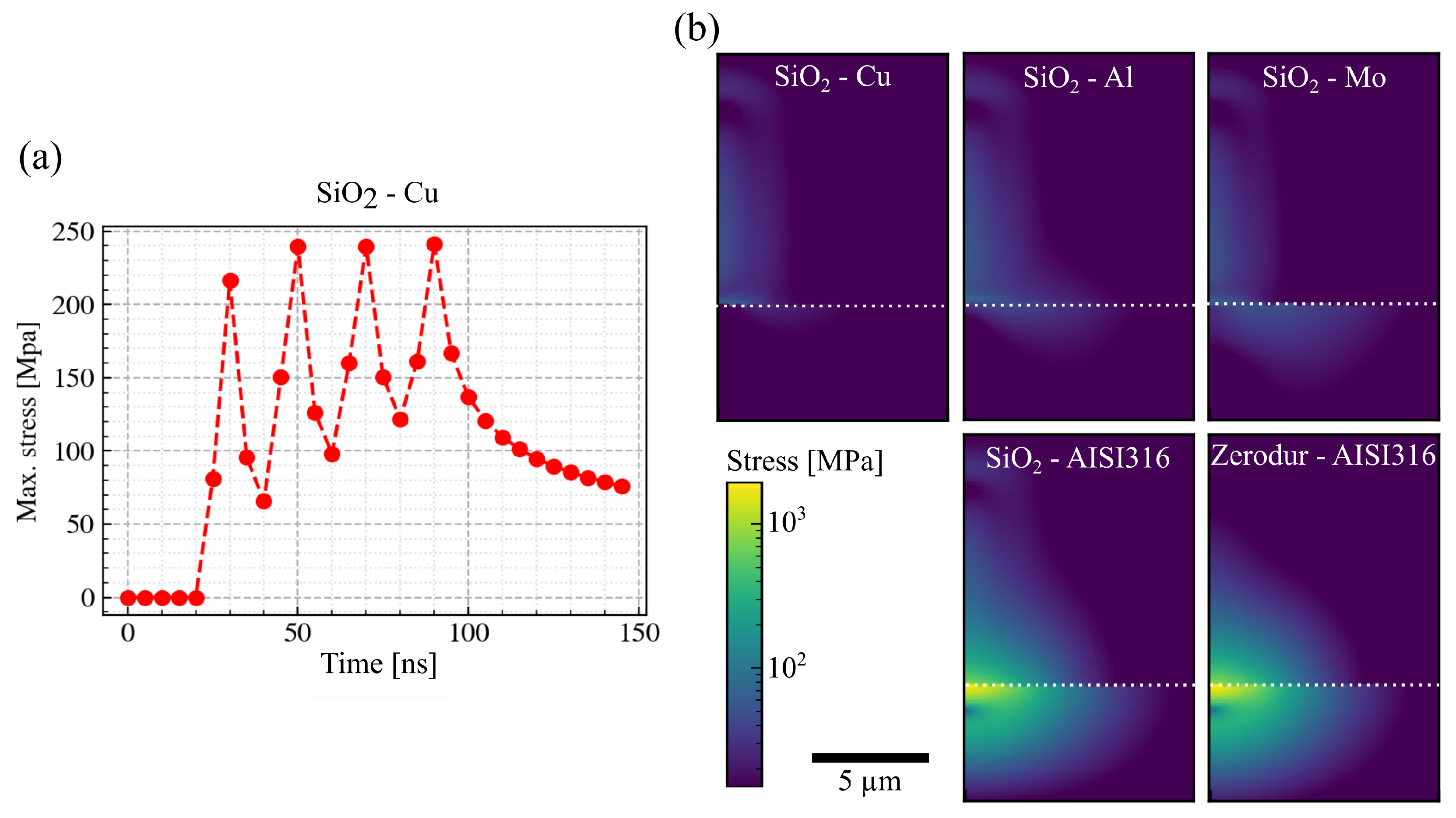

Perhaps surprisingly, the calculated thermal stresses for ZERODUR

® are similar to those of

-to-AISI316, as you can see in the bottom row of

Figure 9b. However, the height of the volume affected by the thermal load in ZERODUR

® is significantly smaller than that in

, extending approximately 6 µm and 10 µm upwards from the interface, respectively. This can be readily explained in terms of the low CTE of ZERODUR

®, which leads to a larger CTE mismatch at the interface, but also to a much smaller internal deformation due to the thermal load. This suggests that the critical damage mechanism of the welding seams is not the failure of the glass–metal connection but internal failure of the dielectric. This aligns with our previous findings, where we usually observed fragments of the glass on the metal surface when there was a measurable welding strength.