Role of MWCNTs Loading in Designing Self-Sensing and Self-Heating Structural Elements

Abstract

1. Introduction

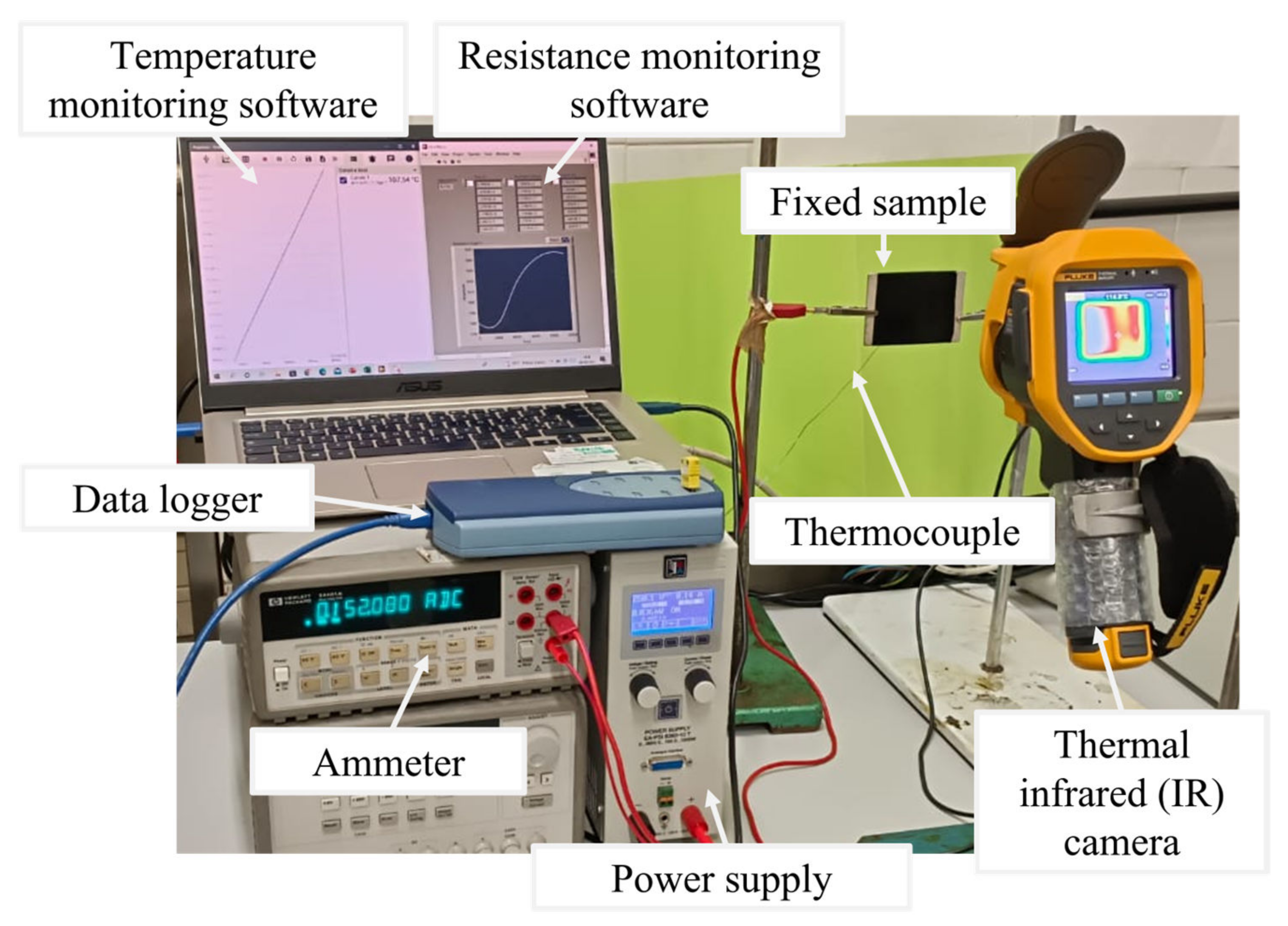

2. Materials and Methods

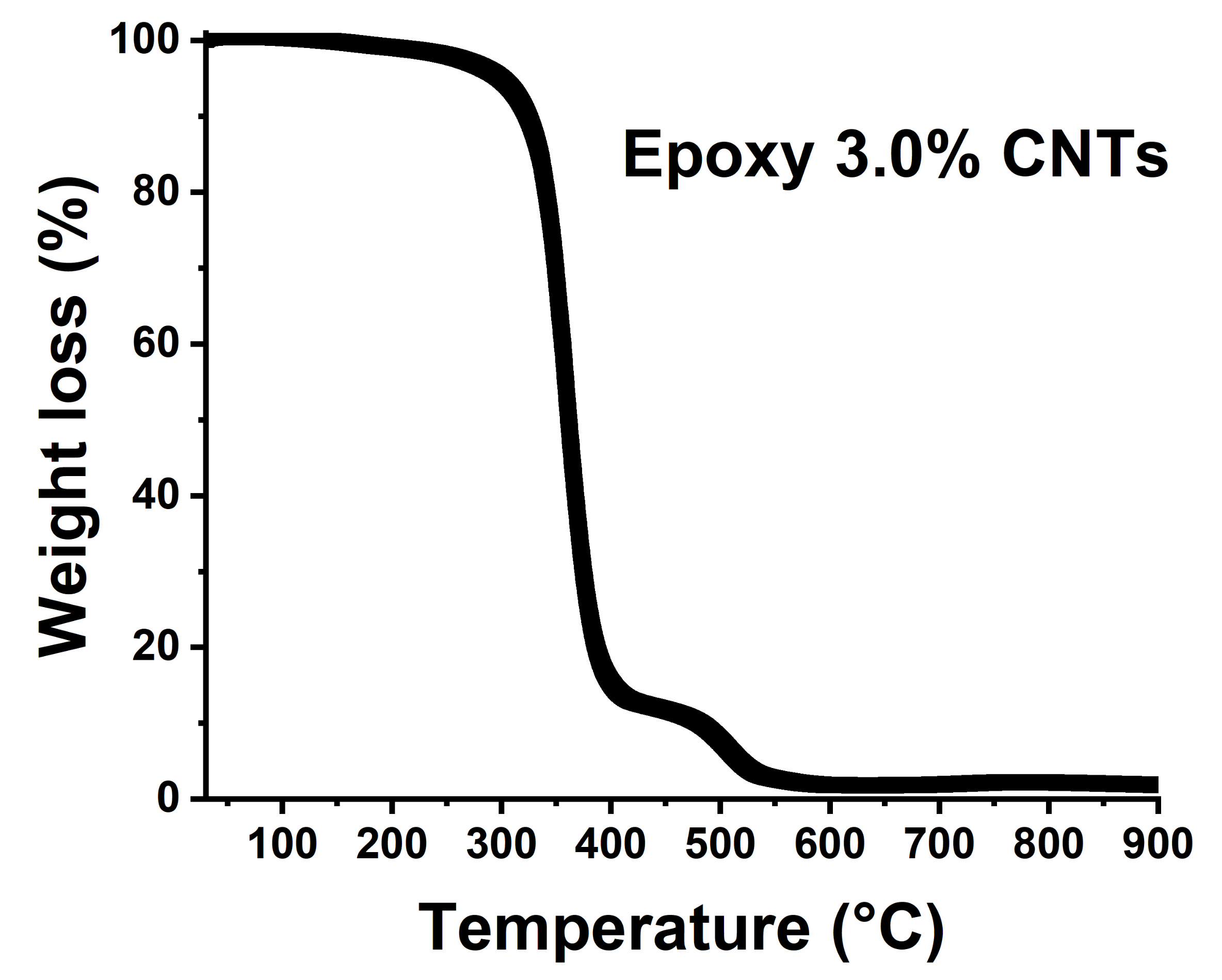

3. Results and Discussion

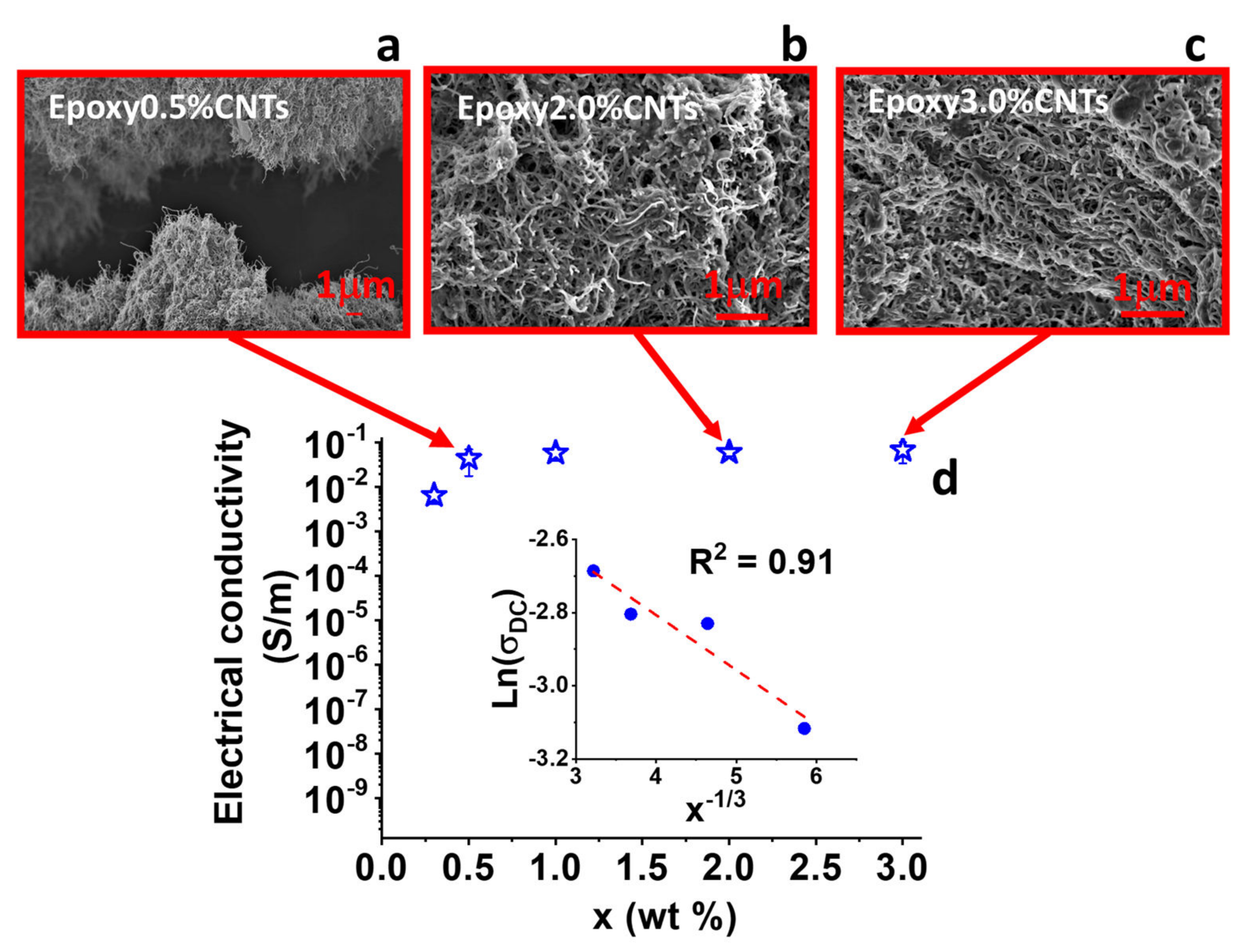

3.1. Electrical, Morphological and Rheological Properties

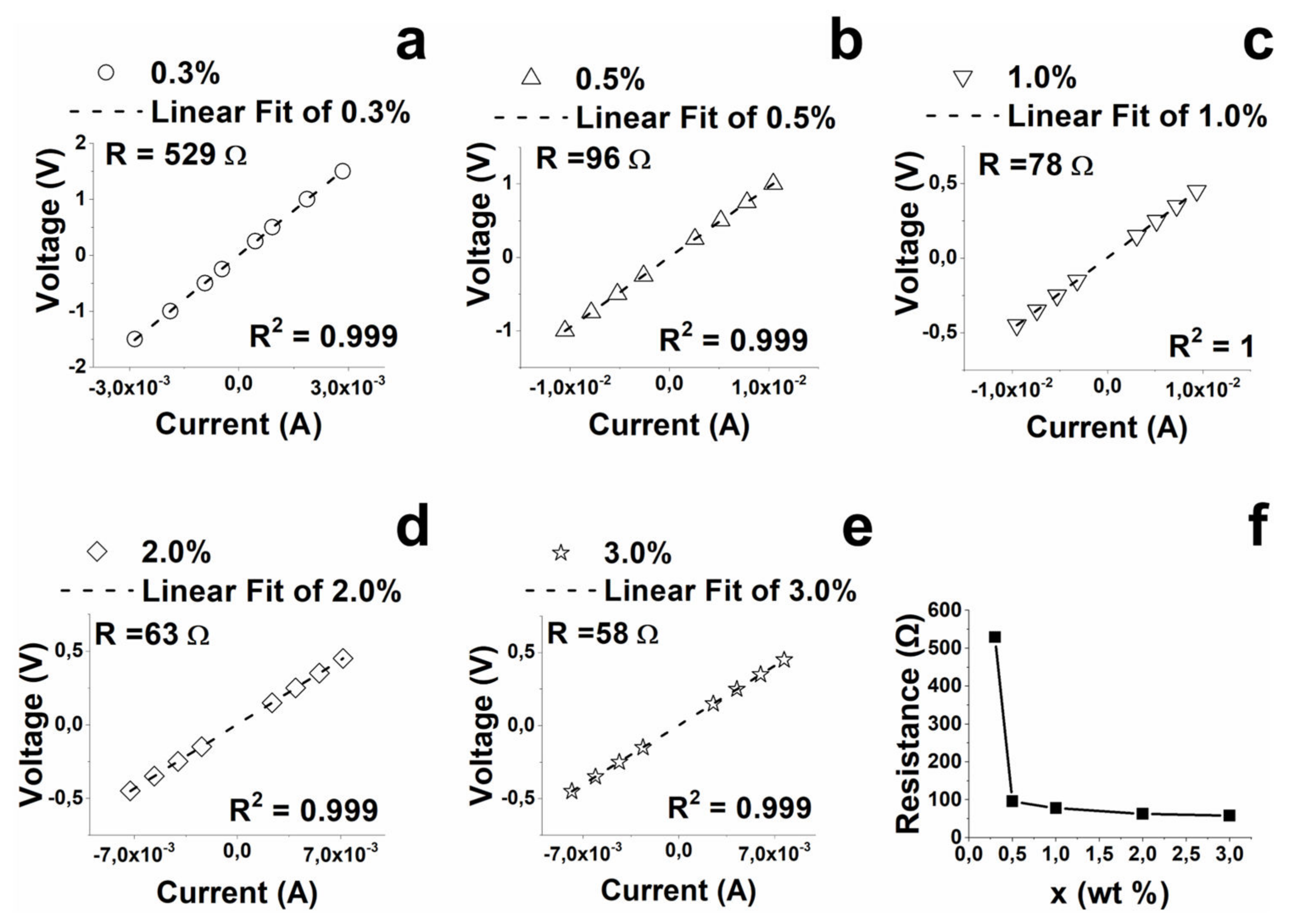

3.1.1. DC Measurements

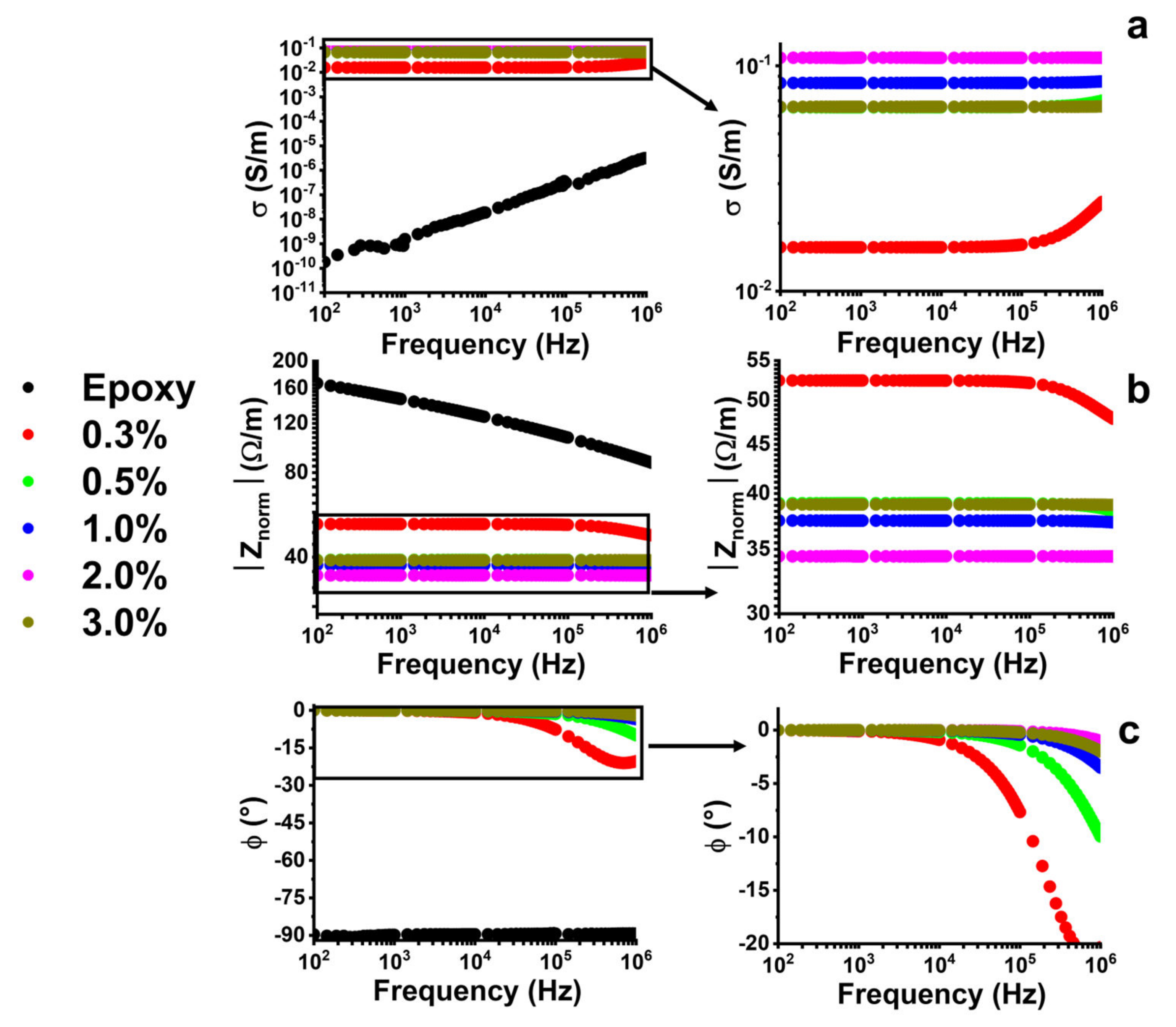

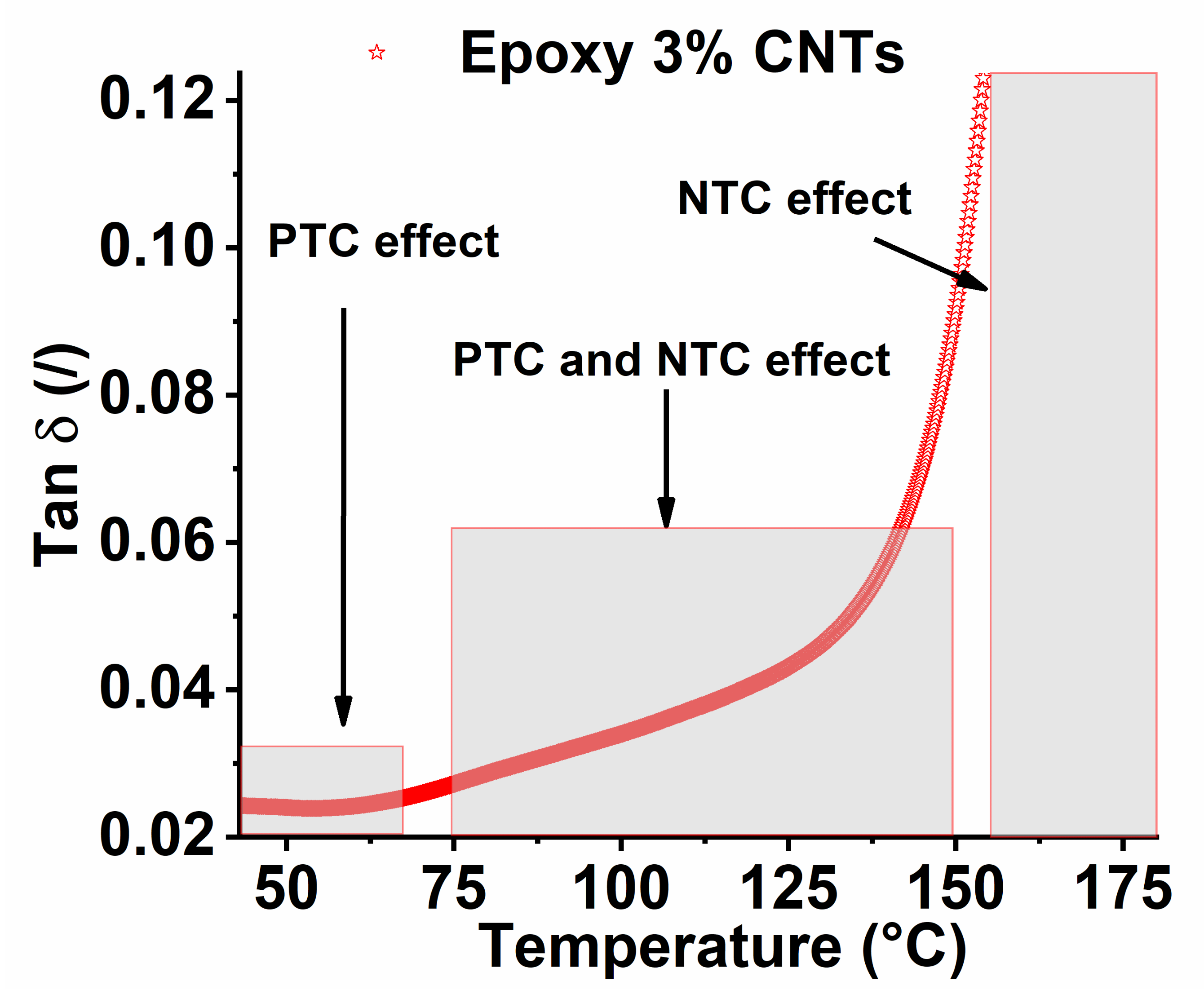

3.1.2. AC Measurements

3.1.3. Rheological Properties

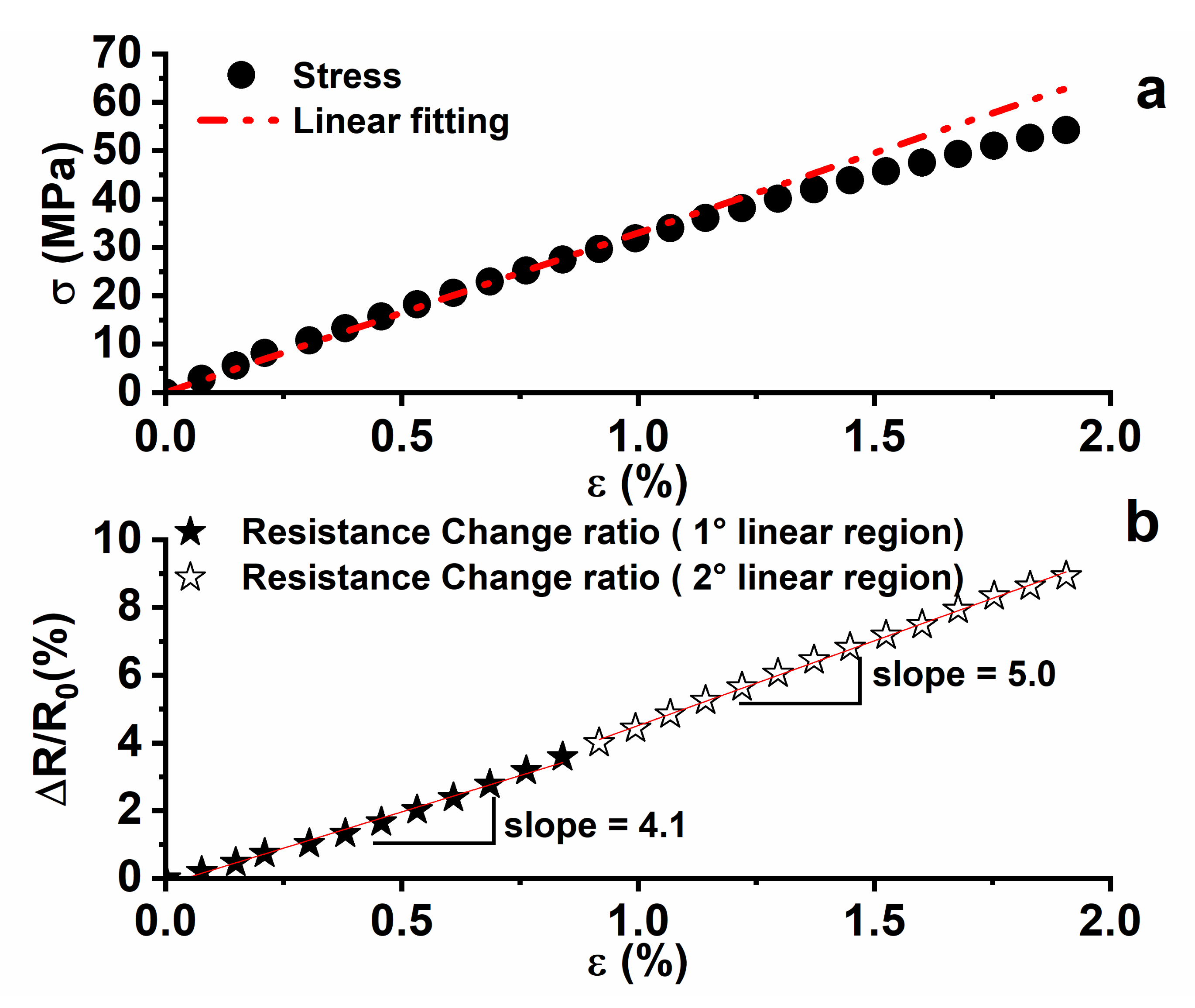

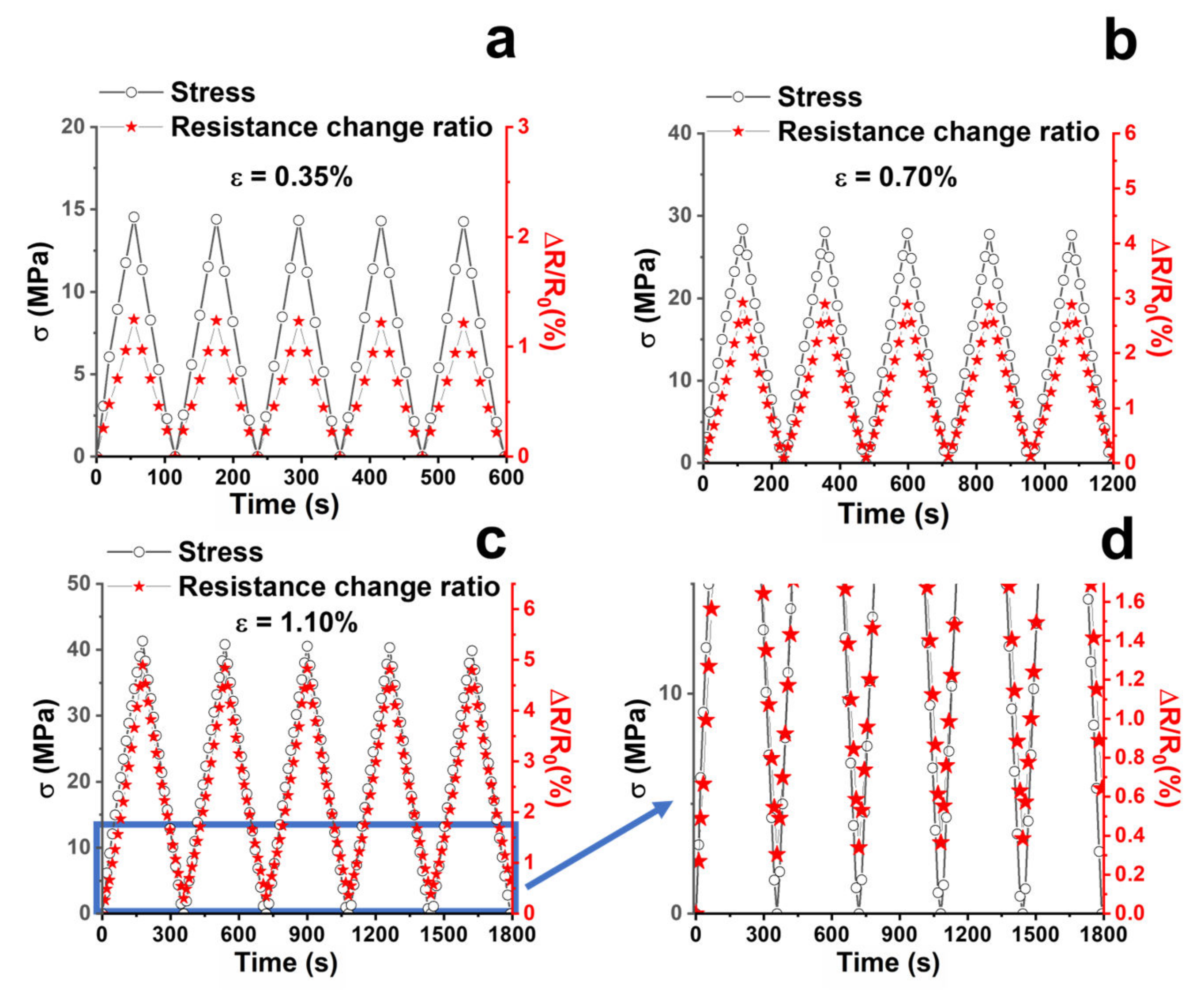

3.2. Self-Sensing Properties

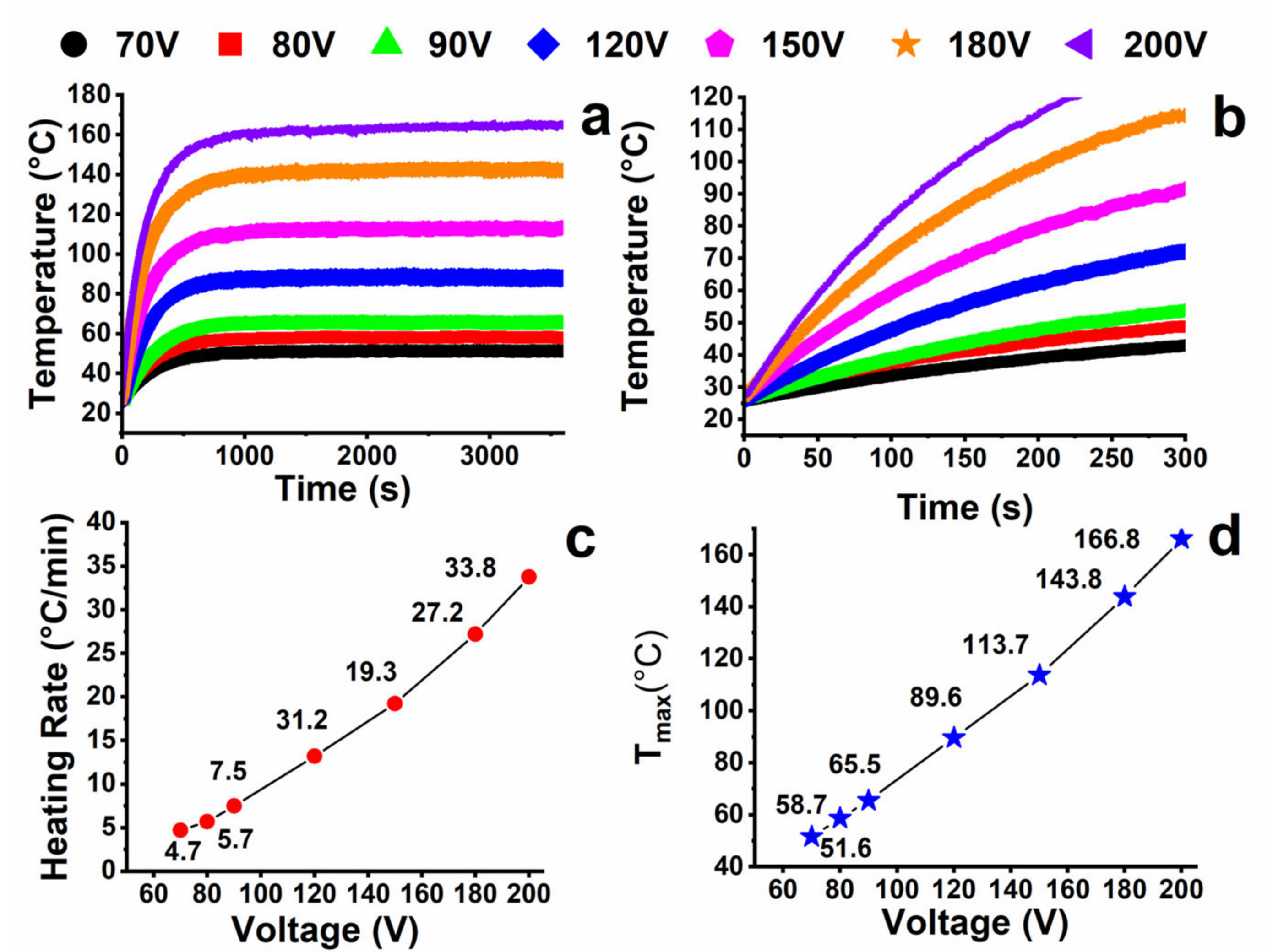

3.3. Self-Heating Properties

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Kaspar, P.; Sobola, D.; Částková, K.; Dallaev, R.; Šťastná, E.; Sedlák, P.; Knápek, A.; Trčka, T.; Holcman, V. Case study of polyvinylidene fluoride doping by carbon nanotubes. Materials 2021, 14, 1428. [Google Scholar] [CrossRef] [PubMed]

- Guadagno, L.; Raimondo, M.; Longo, R.; Sarno, M.; Iuliano, M.; Mariconda, A.; Saturnino, C.; Ceramella, J.; Iacopetta, D.; Sinicropi, M. Development and characterization of antitumoral electrospun polycaprolactone/functionalized Fe3O4 hybrid membranes. Mater. Today Chem. 2020, 17, 100309. [Google Scholar] [CrossRef]

- Hule, R.A.; Pochan, D.J. Polymer nanocomposites for biomedical applications. MRS Bull. 2007, 32, 354–358. [Google Scholar] [CrossRef]

- Kurahatti, R.; Surendranathan, A.; Kori, S.; Singh, N.; Kumar, A.R.; Srivastava, S. Defence applications of polymer nanocomposites. Def. Sci. J. 2010, 60, 551–563. [Google Scholar] [CrossRef]

- Ma, P.-C.; Siddiqui, N.A.; Marom, G.; Kim, J.-K. Dispersion and functionalization of carbon nanotubes for polymer-based nanocomposites: A review. Compos. Part A Appl. Sci. Manuf. 2010, 41, 1345–1367. [Google Scholar] [CrossRef]

- Mittal, G.; Dhand, V.; Rhee, K.Y.; Park, S.-J.; Lee, W.R. A review on carbon nanotubes and graphene as fillers in reinforced polymer nanocomposites. J. Ind. Eng. Chem. 2015, 21, 11–25. [Google Scholar] [CrossRef]

- Guadagno, L.; Raimondo, M.; Vertuccio, L.; Naddeo, C.; Barra, G.; Longo, P.; Lamberti, P.; Spinelli, G.; Nobile, M. Morphological, rheological and electrical properties of composites filled with carbon nanotubes functionalized with 1-pyrenebutyric acid. Compos. B. Eng. 2018, 147, 12–21. [Google Scholar] [CrossRef]

- Barra, G.; Guadagno, L.; Vertuccio, L.; Simonet, B.; Santos, B.; Zarrelli, M.; Arena, M.; Viscardi, M. Different methods of dispersing carbon nanotubes in epoxy resin and initial evaluation of the obtained nanocomposite as a matrix of carbon fiber reinforced laminate in terms of vibroacoustic performance and flammability. Materials 2019, 12, 2998. [Google Scholar] [CrossRef]

- Guadagno, L.; Vertuccio, L.; Naddeo, C.; Calabrese, E.; Barra, G.; Raimondo, M.; Sorrentino, A.; Binder, W.H.; Michael, P.; Rana, S. Reversible self-healing carbon-based nanocomposites for structural applications. Polymers 2019, 11, 903. [Google Scholar] [CrossRef]

- Raimondo, M.; Naddeo, C.; Vertuccio, L.; Bonnaud, L.; Dubois, P.; Binder, W.H.; Sorrentino, A.; Guadagno, L. Multifunctionality of structural nanohybrids: The crucial role of carbon nanotube covalent and non-covalent functionalization in enabling high thermal, mechanical and self-healing performance. Nanotechnology 2020, 31, 225708. [Google Scholar] [CrossRef]

- Balandin, A.; Ghosh, S.; Teweldebrhan, D.; Calizo, I.; Bao, W.; Miao, F.; Lau, C. Extremely high thermal conductivity of graphene: Prospects for thermal management applications in silicon nanoelectronics. In Proceedings of the 2008 IEEE Silicon Nanoelectronics Workshop, Honolulu, HI, USA, 15–16 June 2008; pp. 1–2. [Google Scholar]

- Lee, C.; Wei, X.; Kysar, J.W.; Hone, J. Measurement of the elastic properties and intrinsic strength of monolayer graphene. Science 2008, 321, 385–388. [Google Scholar] [CrossRef]

- Stoller, M.D.; Park, S.; Zhu, Y.; An, J.; Ruoff, R.S. Graphene-based ultracapacitors. Nano Lett. 2008, 8, 3498–3502. [Google Scholar] [CrossRef]

- Rehman, S.; Akram, S.; Kanellopoulos, A.; Elmarakbi, A.; Karagiannidis, P.G. Development of new graphene/epoxy nanocomposites and study of cure kinetics, thermal and mechanical properties. Thermochim. Acta 2020, 694, 178785. [Google Scholar] [CrossRef]

- Benega, M.A.G.; Silva, W.M.; Schnitzler, M.C.; Andrade, R.J.E.; Ribeiro, H. Improvements in thermal and mechanical properties of composites based on epoxy-carbon nanomaterials-A brief landscape. Polym. Test. 2021, 98, 107180. [Google Scholar] [CrossRef]

- Bahraq, A.A.; Al-Osta, M.A.; Obot, I.; Al-Amoudi, O.S.B.; Saleh, T.A.; Maslehuddin, M. Improving the adhesion properties of cement/epoxy interface using graphene-based nanomaterials: Insights from molecular dynamics simulation. Cem. Concr. Compos. 2022, 134, 104801. [Google Scholar] [CrossRef]

- Liu, S.; Chevali, V.S.; Xu, Z.; Hui, D.; Wang, H. A review of extending performance of epoxy resins using carbon nanomaterials. Compos. B. Eng. 2018, 136, 197–214. [Google Scholar] [CrossRef]

- Liu, C.; Du, P.; Zhao, H.; Wang, L. Synthesis of l-histidine-attached graphene nanomaterials and their application for steel protection. ACS Appl. Nano Mater. 2018, 1, 1385–1395. [Google Scholar] [CrossRef]

- Bhattacharya, M.; Bhowmick, A.K. Polymer–filler interaction in nanocomposites: New interface area function to investigate swelling behavior and Young’s modulus. Polymer 2008, 49, 4808–4818. [Google Scholar] [CrossRef]

- Fu, S.-Y.; Feng, X.-Q.; Lauke, B.; Mai, Y.-W. Effects of particle size, particle/matrix interface adhesion and particle loading on mechanical properties of particulate–polymer composites. Compos. B. Eng. 2008, 39, 933–961. [Google Scholar] [CrossRef]

- Guadagno, L.; Naddeo, C.; Raimondo, M.; Barra, G.; Vertuccio, L.; Russo, S.; Lafdi, K.; Tucci, V.; Spinelli, G.; Lamberti, P. Influence of carbon nanoparticles/epoxy matrix interaction on mechanical, electrical and transport properties of structural advanced materials. Nanotechnology 2017, 28, 094001. [Google Scholar] [CrossRef]

- Martin-Gallego, M.; Bernal, M.; Hernandez, M.; Verdejo, R.; López-Manchado, M.A. Comparison of filler percolation and mechanical properties in graphene and carbon nanotubes filled epoxy nanocomposites. Eur. Polym. J. 2013, 49, 1347–1353. [Google Scholar] [CrossRef]

- Park, S.-H.; Bandaru, P.R. Improved mechanical properties of carbon nanotube/polymer composites through the use of carboxyl-epoxide functional group linkages. Polymer 2010, 51, 5071–5077. [Google Scholar] [CrossRef]

- Li, Y.; Huang, X.; Zeng, L.; Li, R.; Tian, H.; Fu, X.; Wang, Y.; Zhong, W.-H. A review of the electrical and mechanical properties of carbon nanofiller-reinforced polymer composites. J. Mater. Sci. 2019, 54, 1036–1076. [Google Scholar] [CrossRef]

- Al-Saleh, M.H.; Sundararaj, U. Review of the mechanical properties of carbon nanofiber/polymer composites. Compos. Part A Appl. Sci. Manuf. 2011, 42, 2126–2142. [Google Scholar] [CrossRef]

- Kumar, A.; Sharma, K.; Dixit, A.R. A review on the mechanical properties of polymer composites reinforced by carbon nanotubes and graphene. Carbon Lett. 2021, 31, 149–165. [Google Scholar] [CrossRef]

- Li, J.; Ma, P.C.; Chow, W.S.; To, C.K.; Tang, B.Z.; Kim, J.K. Correlations between percolation threshold, dispersion state, and aspect ratio of carbon nanotubes. Adv. Funct. Mater. 2007, 17, 3207–3215. [Google Scholar] [CrossRef]

- Shehzad, K.; Dang, Z.-M.; Ahmad, M.N.; Sagar, R.U.R.; Butt, S.; Farooq, M.U.; Wang, T.-B. Effects of carbon nanotubes aspect ratio on the qualitative and quantitative aspects of frequency response of electrical conductivity and dielectric permittivity in the carbon nanotube/polymer composites. Carbon 2013, 54, 105–112. [Google Scholar] [CrossRef]

- Vertuccio, L.; Foglia, F.; Pantani, R.; Romero-Sánchez, M.; Calderón, B.; Guadagno, L. Carbon nanotubes and expanded graphite based bulk nanocomposites for de-icing applications. Compos. B. Eng. 2021, 207, 108583. [Google Scholar] [CrossRef]

- Wang, L.; Dang, Z.-M. Carbon nanotube composites with high dielectric constant at low percolation threshold. Appl. Phys. Lett. 2005, 87, 042903. [Google Scholar] [CrossRef]

- Zou, J.F.; Yu, Z.Z.; Pan, Y.X.; Fang, X.P.; Ou, Y.C. Conductive mechanism of polymer/graphite conducting composites with low percolation threshold. J. Polym. Sci. B: Polym. Phys. 2002, 40, 954–963. [Google Scholar] [CrossRef]

- Tjong, S.C.; Liang, G.; Bao, S. Electrical behavior of polypropylene/multiwalled carbon nanotube nanocomposites with low percolation threshold. Scr. Mater. 2007, 57, 461–464. [Google Scholar] [CrossRef]

- Pang, H.; Chen, T.; Zhang, G.; Zeng, B.; Li, Z.-M. An electrically conducting polymer/graphene composite with a very low percolation threshold. Mater. Lett. 2010, 64, 2226–2229. [Google Scholar] [CrossRef]

- Qiu, L.; Zhu, N.; Feng, Y.; Michaelides, E.E.; Żyła, G.; Jing, D.; Zhang, X.; Norris, P.M.; Markides, C.N.; Mahian, O. A review of recent advances in thermophysical properties at the nanoscale: From solid state to colloids. Phys. Rep. 2020, 843, 1–81. [Google Scholar] [CrossRef]

- Qiu, L.; Zhu, N.; Feng, Y.; Zhang, X.; Wang, X. Interfacial thermal transport properties of polyurethane/carbon nanotube hybrid composites. Int. J. Heat Mass Transf. 2020, 152, 119565. [Google Scholar] [CrossRef]

- Qiu, L.; Zou, H.; Wang, X.; Feng, Y.; Zhang, X.; Zhao, J.; Zhang, X.; Li, Q. Enhancing the interfacial interaction of carbon nanotubes fibers by Au nanoparticles with improved performance of the electrical and thermal conductivity. Carbon 2019, 141, 497–505. [Google Scholar] [CrossRef]

- Guadagno, L.; Foglia, F.; Pantani, R.; Romero-Sanchez, M.D.; Calderón, B.; Vertuccio, L. Low-voltage icing protection film for automotive and aeronautical industries. Nanomaterials 2020, 10, 1343. [Google Scholar] [CrossRef]

- Guadagno, L.; Vertuccio, L.; Foglia, F.; Raimondo, M.; Barra, G.; Sorrentino, A.; Pantani, R.; Calabrese, E. Flexible eco-friendly multilayer film heaters. Compos. B. Eng. 2021, 224, 109208. [Google Scholar] [CrossRef]

- Janas, D.; Koziol, K. A review of production methods of carbon nanotube and graphene thin films for electrothermal applications. Nanoscale 2014, 6, 3037–3045. [Google Scholar] [CrossRef]

- Parent, O.; Ilinca, A. Anti-icing and de-icing techniques for wind turbines: Critical review. Cold Reg. Sci. Technol. 2011, 65, 88–96. [Google Scholar] [CrossRef]

- Jang, S.-H.; Park, Y.-L. Carbon nanotube-reinforced smart composites for sensing freezing temperature and deicing by self-heating. Nanomater. Nanotechnol. 2018, 8, 1847980418776473. [Google Scholar] [CrossRef]

- Wichmann, M.H.; Buschhorn, S.T.; Gehrmann, J.; Schulte, K. Piezoresistive response of epoxy composites with carbon nanoparticles under tensile load. Phys. Rev. B 2009, 80, 245437. [Google Scholar] [CrossRef]

- Spinelli, G.; Lamberti, P.; Tucci, V.; Guadagno, L.; Vertuccio, L. Damage monitoring of structural resins loaded with carbon fillers: Experimental and theoretical study. Nanomaterials 2020, 10, 434. [Google Scholar] [CrossRef] [PubMed]

- Spinelli, G.; Kotsilkova, R.; Ivanov, E.; Georgiev, V.; Ivanova, R.; Naddeo, C.; Romano, V. Dielectric spectroscopy and thermal properties of poly (lactic) acid reinforced with carbon-based particles: Experimental study and design theory. Polymers 2020, 12, 2414. [Google Scholar] [CrossRef] [PubMed]

- D638-10; Standard Test Methods for Tensile Properties of Plastics. ASTM International: West Conshohocken, PA, USA, 2010.

- Vertuccio, L.; Guadagno, L.; Spinelli, G.; Lamberti, P.; Tucci, V.; Russo, S. Piezoresistive properties of resin reinforced with carbon nanotubes for health-monitoring of aircraft primary structures. Compos. B. Eng. 2016, 107, 192–202. [Google Scholar] [CrossRef]

- Vertuccio, L.; Russo, S.; Raimondo, M.; Lafdi, K.; Guadagno, L. Influence of carbon nanofillers on the curing kinetics of epoxy-amine resin. RSC Adv. 2015, 5, 90437–90450. [Google Scholar] [CrossRef]

- Ku-Herrera, J.; Avilés, F. Cyclic tension and compression piezoresistivity of carbon nanotube/vinyl ester composites in the elastic and plastic regimes. Carbon 2012, 50, 2592–2598. [Google Scholar] [CrossRef]

- Oliva-Avilés, A.; Avilés, F.; Sosa, V. Electrical and piezoresistive properties of multi-walled carbon nanotube/polymer composite films aligned by an electric field. Carbon 2011, 49, 2989–2997. [Google Scholar] [CrossRef]

- Bauhofer, W.; Kovacs, J.Z. A review and analysis of electrical percolation in carbon nanotube polymer composites. Compos. Sci. Technol. 2009, 69, 1486–1498. [Google Scholar] [CrossRef]

- De Vivo, B.; Lamberti, P.; Spinelli, G.; Tucci, V. A morphological and structural approach to evaluate the electromagnetic performances of composites based on random networks of carbon nanotubes. J. Appl. Phys. 2014, 115, 154311. [Google Scholar] [CrossRef]

- Guadagno, L.; Naddeo, C.; Vittoria, V.; Sorrentino, A.; Vertuccio, L.; Raimondo, M.; Tucci, V.; De Vivo, B.; Lamberti, P.; Iannuzzo, G. Cure behavior and physical properties of epoxy resin—Filled with multiwalled carbon nanotubes. J. Nanosci. Nanotechnol. 2010, 10, 2686–2693. [Google Scholar] [CrossRef]

- Guadagno, L.; Vertuccio, L. Resistive response of carbon nanotube-based composites subjected to water aging. Nanomaterials 2021, 11, 2183. [Google Scholar] [CrossRef]

- Kymakis, E.; Amaratunga, G.A. Electrical properties of single-wall carbon nanotube-polymer composite films. J. Appl. Phys. 2006, 99, 084302. [Google Scholar] [CrossRef]

- Naddeo, C.; Vertuccio, L.; Barra, G.; Guadagno, L. Nano-charged polypropylene application: Realistic perspectives for enhancing durability. Materials 2017, 10, 943. [Google Scholar] [CrossRef]

- Connor, M.T.; Roy, S.; Ezquerra, T.A.; Calleja, F.J.B. Broadband ac conductivity of conductor-polymer composites. Phys. Rev. B 1998, 57, 2286. [Google Scholar] [CrossRef]

- Murphy, E.; Morgan, S. The dielectric properties of insulating materials, III alternating and direct current conductivity. Bell Syst. Tech. J. 1939, 18, 502–537. [Google Scholar] [CrossRef]

- Dyre, J.C. The random free-energy barrier model for ac conduction in disordered solids. J. Appl. Phys. 1988, 64, 2456–2468. [Google Scholar] [CrossRef]

- Dyre, J.C.; Schrøder, T.B. Universality of ac conduction in disordered solids. Rev. Mod. Phys. 2000, 72, 873. [Google Scholar] [CrossRef]

- Pham, G.T.; Park, Y.-B.; Liang, Z.; Zhang, C.; Wang, B. Processing and modeling of conductive thermoplastic/carbon nanotube films for strain sensing. Compos. B. Eng. 2008, 39, 209–216. [Google Scholar] [CrossRef]

- Vertuccio, L.; Vittoria, V.; Guadagno, L.; De Santis, F. Strain and damage monitoring in carbon-nanotube-based composite under cyclic strain. Compos. Part A Appl. Sci. Manuf. 2015, 71, 9–16. [Google Scholar] [CrossRef]

- Xia, H.; Song, M. Preparation and characterization of polyurethane–carbon nanotube composites. Soft Matter 2005, 1, 386–394. [Google Scholar] [CrossRef]

- Knauert, S.T.; Douglas, J.F.; Starr, F.W. The effect of nanoparticle shape on polymer-nanocomposite rheology and tensile strength. J. Polym. Sci. B: Polym. Phys. 2007, 45, 1882–1897. [Google Scholar] [CrossRef]

- Pötschke, P.; Abdel-Goad, M.; Pegel, S.; Jehnichen, D.; Mark, J.E.; Zhou, D.; Heinrich, G. Comparisons among electrical and rheological properties of melt-mixed composites containing various carbon nanostructures. J. Macromol. Sci. A 2009, 47, 12–19. [Google Scholar] [CrossRef]

- Bernal, M.M.; Lopez-Manchado, M.A.; Verdejo, R. In situ foaming evolution of flexible polyurethane foam nanocomposites. Macromol. Chem. Phys. 2011, 212, 971–979. [Google Scholar] [CrossRef]

- Kinloch, I.A.; Roberts, S.A.; Windle, A.H. A rheological study of concentrated aqueous nanotube dispersions. Polymer 2002, 43, 7483–7491. [Google Scholar] [CrossRef]

- Tiwari, M.K.; Bazilevsky, A.V.; Yarin, A.L.; Megaridis, C.M. Elongational and shear rheology of carbon nanotube suspensions. Rheol. Acta 2009, 48, 597–609. [Google Scholar] [CrossRef]

- Meola, C.; Carlomagno, G.M.; Bonavolontà, C.; Valentino, M. Monitoring Composites under Bending Tests with Infrared Thermography. Adv. Opt. Technol. 2012, 2012, 720813. [Google Scholar] [CrossRef]

- Wu, S.; Ladani, R.B.; Zhang, J.; Ghorbani, K.; Zhang, X.; Mouritz, A.P.; Kinloch, A.J.; Wang, C.H. Strain sensors with adjustable sensitivity by tailoring the microstructure of graphene aerogel/PDMS nanocomposites. ACS Appl. Mater. Interfaces 2016, 8, 24853–24861. [Google Scholar] [CrossRef]

- Zare, Y.; Rhee, K.Y. Calculation of tunneling distance in carbon nanotubes nanocomposites: Effect of carbon nanotube properties, interphase and networks. J. Mater. Sci. 2020, 55, 5471–5480. [Google Scholar] [CrossRef]

- Slobodian, P.; Riha, P.; Sáha, P. A highly-deformable composite composed of an entangled network of electrically-conductive carbon-nanotubes embedded in elastic polyurethane. Carbon 2012, 50, 3446–3453. [Google Scholar] [CrossRef]

- Raimondo, M.; Russo, S.; Guadagno, L.; Longo, P.; Chirico, S.; Mariconda, A.; Bonnaud, L.; Murariu, O.; Dubois, P. Effect of incorporation of POSS compounds and phosphorous hardeners on thermal and fire resistance of nanofilled aeronautic resins. RSC Adv. 2015, 5, 10974–10986. [Google Scholar] [CrossRef]

- Liu, Y.-L.; Wei, W.-L.; Hsu, K.-Y.; Ho, W.-H. Thermal stability of epoxy-silica hybrid materials by thermogravimetric analysis. Thermochim. Acta 2004, 412, 139–147. [Google Scholar] [CrossRef]

- Li, J.; Chung, T.-F.; Chen, Y.P.; Cheng, G.J. Nanoscale strainability of graphene by laser shock-induced three-dimensional shaping. Nano Lett. 2012, 12, 4577–4583. [Google Scholar] [CrossRef]

- Zhang, Q.; Xu, X.; Li, H.; Xiong, G.; Hu, H.; Fisher, T.S. Mechanically robust honeycomb graphene aerogel multifunctional polymer composites. Carbon 2015, 93, 659–670. [Google Scholar] [CrossRef]

- Zhao, S.; Lou, D.; Zhan, P.; Li, G.; Dai, K.; Guo, J.; Zheng, G.; Liu, C.; Shen, C.; Guo, Z. Heating-induced negative temperature coefficient effect in conductive graphene/polymer ternary nanocomposites with a segregated and double-percolated structure. J. Mater. Chem. C 2017, 5, 8233–8242. [Google Scholar] [CrossRef]

- Isaji, S.; Bin, Y.; Matsuo, M. Electrical conductivity and self-temperature-control heating properties of carbon nanotubes filled polyethylene films. Polymer 2009, 50, 1046–1053. [Google Scholar] [CrossRef]

- Stimoniaris, A.; Stergiou, C.; Delides, C. A detailed study of α-relaxation in epoxy/carbon nanoparticles composites using computational analysis. Express Polym. Lett. 2012, 6, 120–128. [Google Scholar] [CrossRef]

| Material/Method | Supplier/Device | Specific | Procedure Measurement/ Technical Specifications |

|---|---|---|---|

| Precursor: 3,4Epoxycyclohexylmethyl-3’,4’-epoxycyclohexane carboxylate” (ECC) Hardener: Methyl hexahydrophthalic anhydride” (MHHPA); Carbon nanotubes (GRAPHISTRENGTH C100) | Precursor/hardener: Gurit Holding Wattwil, Swiss; Carbon nanotube:s: ARKEMA Colombes, France; Hielscher model UP200S-24 kHz high power ultrasonic probe: Hielscher Ultrasonics, Teltow, Germany. | The manufacturing procedure of the samples: According to Ref. [43] | Curing cycle: 1 h at 80 °C + 20 min at 120 °C +1 h at 180 °C. |

| Scanning Electron Microscopy (SEM) | JSM-6700F, (JEOL Akishima, Japan) | - | Etching procedure: According to Ref. [47] |

| The electro-mechanical characterization: Dinanometer; strain gauge; electrical measurements | INSTRON, series 5967-INSTRON, Norwood, MA, USA; (RS 632-180, RS PRO, Corby, UK);Multimeter 3458A (Agilent, Santa Clara, CA, USA) | Tensile test: crosshead speed of 1 mm/min | According to Refs. [46,47]; Sample production: ASTM D638 standards [45] |

| Electrical conductivity measurement DC/AC | Electrometer: Keithley 6517A (Keithley Instruments, Cleveland, OH, USA); Quadtec7600 dielectric analyzer (IET Labs Inc., Roslyn Heights, NY, USA) | Two-probe method; AC frequency range [102,103,104,105,106] | According to Refs. [44,46] |

| Dynamic mechanical analysis (DMA) | TA instrument-DMA 2980, USA | (35 × 10 × 4mm3) | Mode: Dual Cantilever 1 Hz −60 to 260 °C 3 °C/min−1 |

| Thermogravimetric analysis (TGA) | Mettler TGA/SDTA 851 (Mettler-Toledo, Columbus, OH, USA) | Range temperature: 30–900 °C | Heating rate 10 °C min−1. |

| Rheological Measurement | Haake Mars II (Thermoscientific, Waltham, MA, USA) rotational rheometer | Frequency Range 0.1–100 rad/s T = 25 °C | According to Ref. [29] |

| Sample | τo (Pa) | K (Pa∙sn) | N (/) | R2 |

|---|---|---|---|---|

| Epoxy | 0 | 1.11 | 1.02 | 0.980 |

| Epoxy 0.1% CNTs | 0.42 | 2.88 | 0.74 | 0.996 |

| Epoxy 0.3% CNTs | 9.81 | 4.34 | 0.65 | 0.998 |

| Epoxy 0.5% CNTs | 21.00 | 5.27 | 0.60 | 0.986 |

| Epoxy 1.0% CNTs | 50.94 | 15.82 | 0.56 | 1.000 |

| Epoxy 3.0% CNTs | 322.62 | 35.26 | 0.55 | 1.000 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Guadagno, L.; Longo, R.; Aliberti, F.; Lamberti, P.; Tucci, V.; Pantani, R.; Spinelli, G.; Catauro, M.; Vertuccio, L. Role of MWCNTs Loading in Designing Self-Sensing and Self-Heating Structural Elements. Nanomaterials 2023, 13, 495. https://doi.org/10.3390/nano13030495

Guadagno L, Longo R, Aliberti F, Lamberti P, Tucci V, Pantani R, Spinelli G, Catauro M, Vertuccio L. Role of MWCNTs Loading in Designing Self-Sensing and Self-Heating Structural Elements. Nanomaterials. 2023; 13(3):495. https://doi.org/10.3390/nano13030495

Chicago/Turabian StyleGuadagno, Liberata, Raffaele Longo, Francesca Aliberti, Patrizia Lamberti, Vincenzo Tucci, Roberto Pantani, Giovanni Spinelli, Michelina Catauro, and Luigi Vertuccio. 2023. "Role of MWCNTs Loading in Designing Self-Sensing and Self-Heating Structural Elements" Nanomaterials 13, no. 3: 495. https://doi.org/10.3390/nano13030495

APA StyleGuadagno, L., Longo, R., Aliberti, F., Lamberti, P., Tucci, V., Pantani, R., Spinelli, G., Catauro, M., & Vertuccio, L. (2023). Role of MWCNTs Loading in Designing Self-Sensing and Self-Heating Structural Elements. Nanomaterials, 13(3), 495. https://doi.org/10.3390/nano13030495