Liquid-Modulated Photothermal Phenomena in Porous Silicon Nanostructures Studied by μ-Raman Spectroscopy

Abstract

1. Introduction

2. Materials and Methods

2.1. Sample Preparation

2.2. Estimation of Porosity and Filling Factor of Nanopores

2.3. Micro-Raman Spectroscopy

2.3.1. Estimation of Nanocrystal Size Distribution

2.3.2. Local Temperature Measurements

2.4. Finite-Element Heat Modeling

3. Results

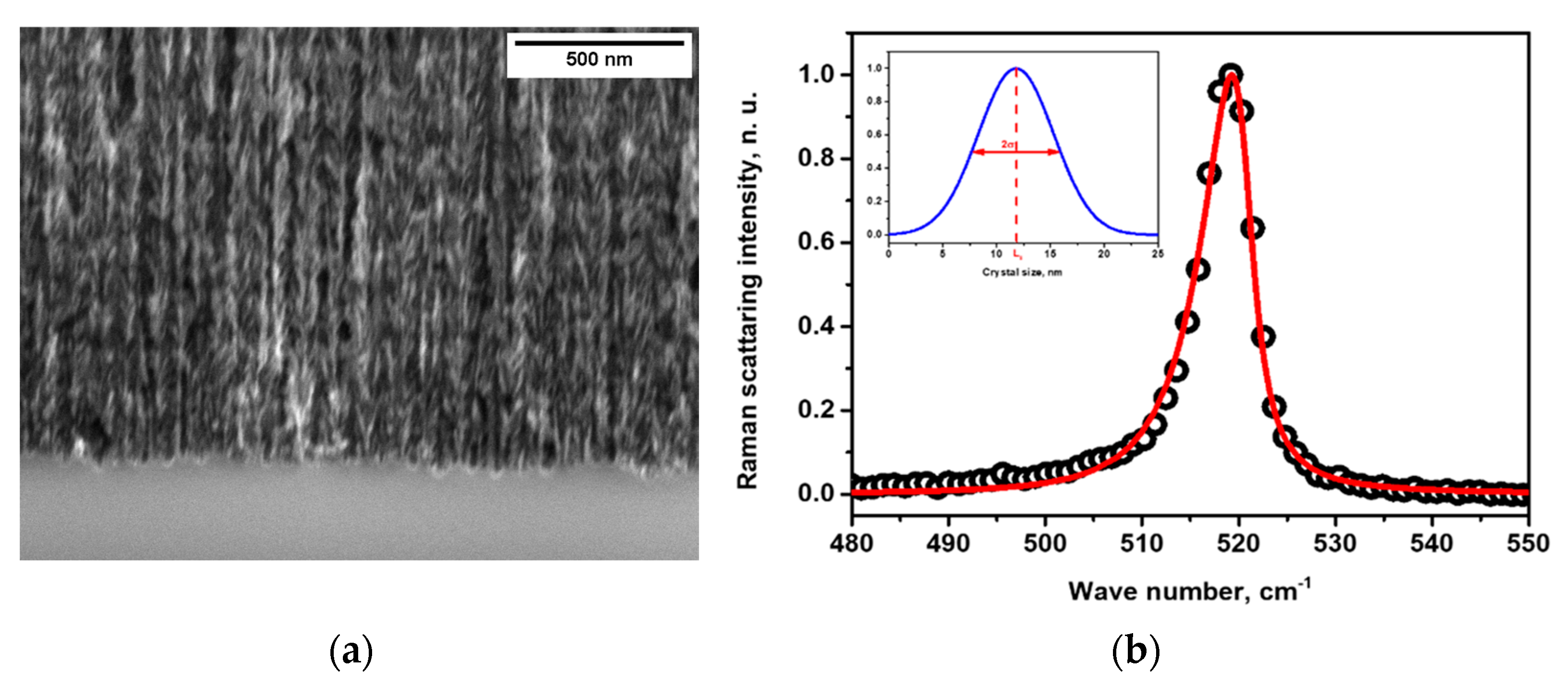

3.1. Nanostructural Properties of the Porous Si Layers

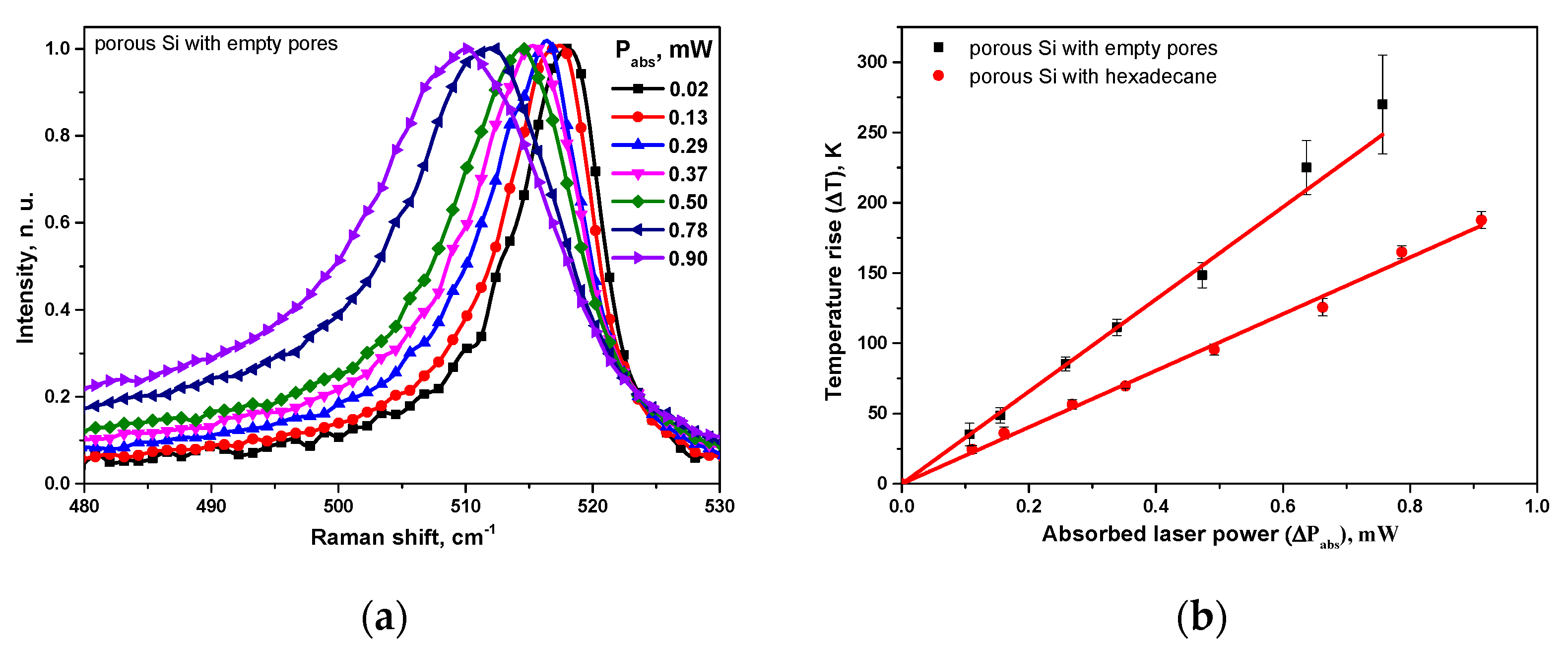

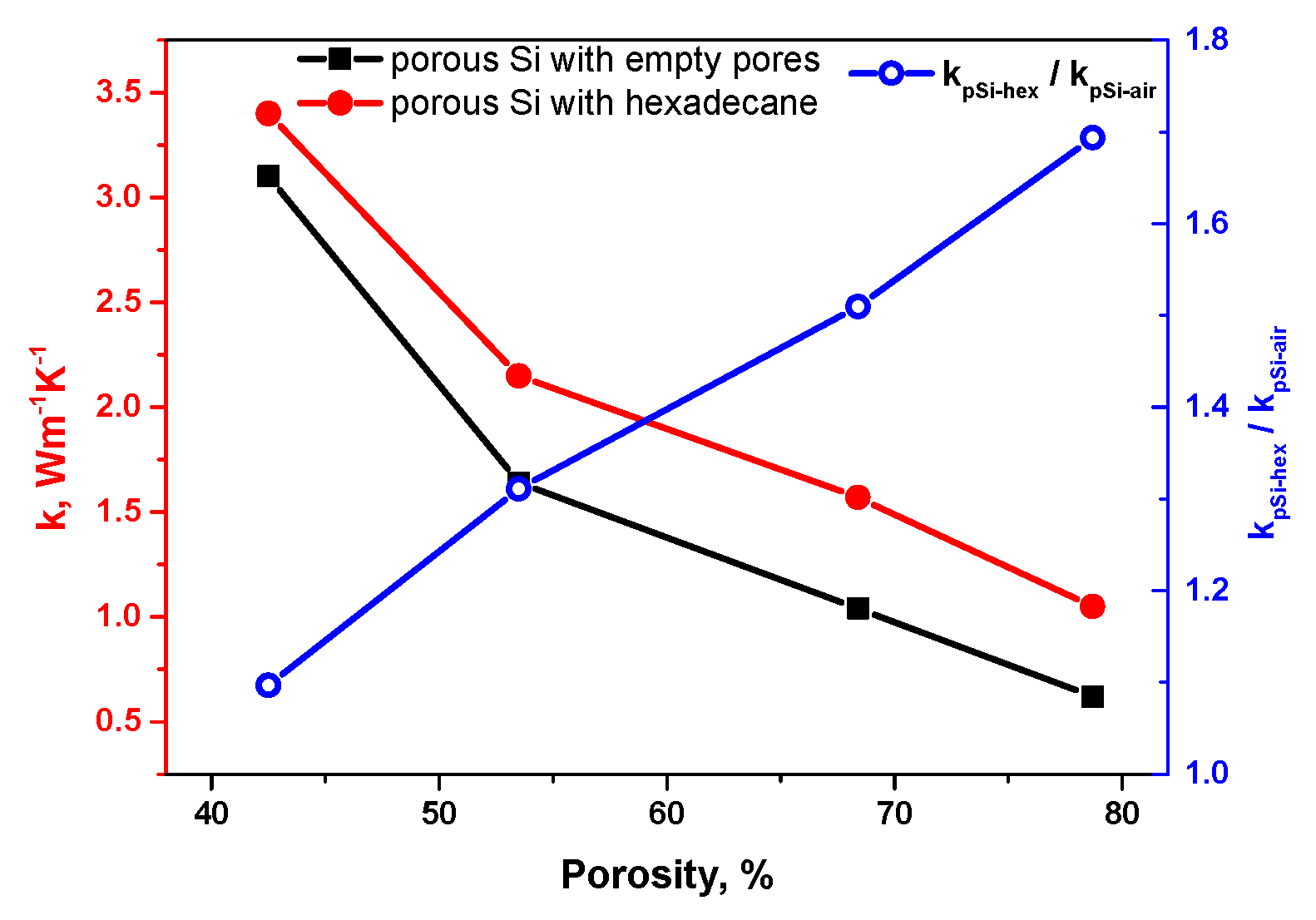

3.2. Impact of Hexadecane on Photo-Induced Heat Transfer in Porous Si

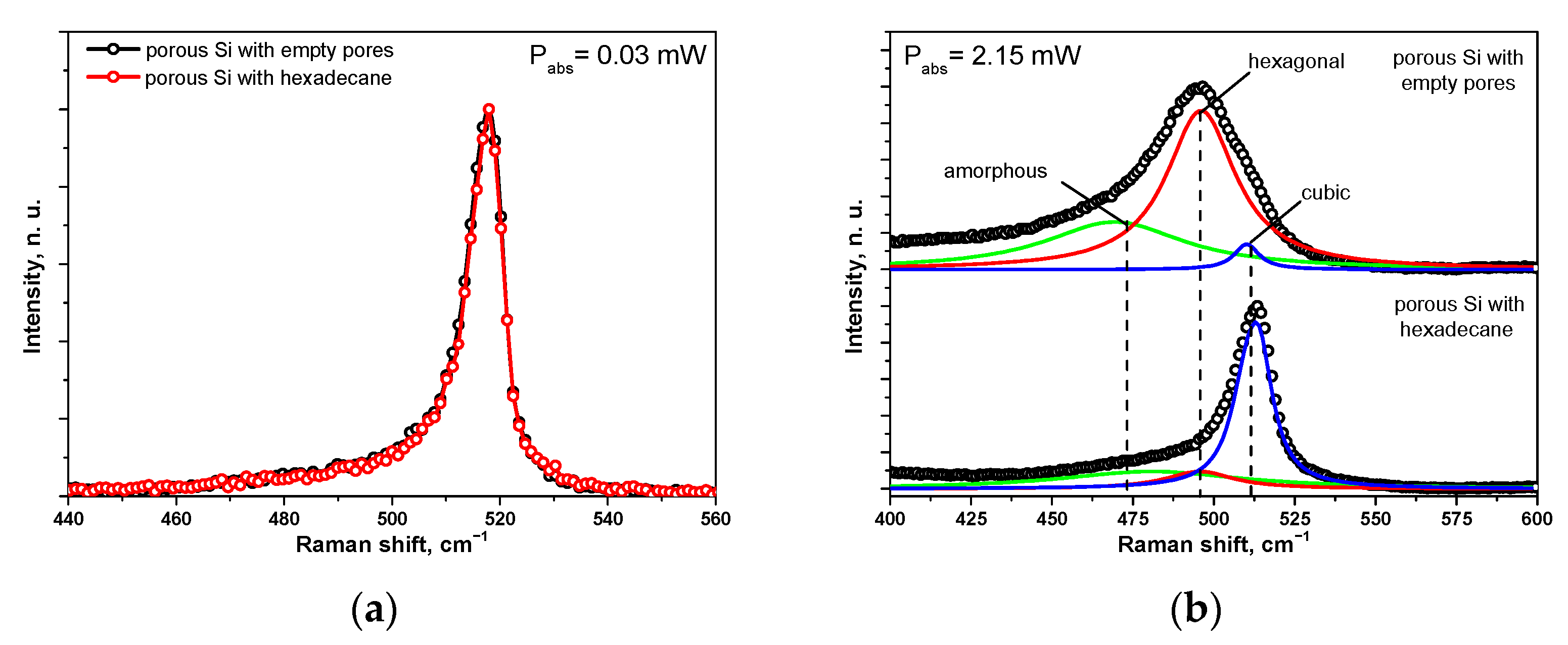

3.3. Impact of Hexadecane on Photothermally Induced Polytype Transition in Porous Si

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Venkatasubramanian, R.; Siivola, E.; Colpitts, T.; O’Quinn, B. Thin-Film Thermoelectric Devices with High Room-Temperature Figures of Merit. Nature 2001, 413, 597–602. [Google Scholar] [CrossRef] [PubMed]

- Poudel, B.; Hao, Q.; Ma, Y.; Lan, Y.; Minnich, A.; Yu, B.; Yan, X.; Wang, D.; Muto, A.; Vashaee, D.; et al. High-Thermoelectric Performance of Nanostructured Bismuth Antimony Telluride Bulk Alloys. Science 2008, 320, 634–638. [Google Scholar] [CrossRef] [PubMed]

- Bux, S.K.; Blair, R.G.; Gogna, P.K.; Lee, H.; Dresselhaus, M.S.; Kaner, R.B.; Fleurial, J.-P. Nanostructured Bulk Silicon as an Effective Thermoelectric Material. Adv. Funct. Mater. 2009, 19, 2445–2452. [Google Scholar] [CrossRef]

- Mingo, N.; Hauser, D.; Kobayashi, N.P.; Plissonnier, M.; Shakouri, A. Nanoparticle-in-Alloy" Approach to Efficient Thermoelectrics: Silicides in SiGe. Nano Lett. 2009, 9, 711–715. [Google Scholar] [CrossRef] [PubMed]

- Zhu, G.H.; Lee, H.; Lan, Y.C.; Wang, X.W.; Joshi, G.; Wang, D.Z.; Yang, J.; Vashaee, D.; Guilbert, H.; Pillitteri, A.; et al. Increased Phonon Scattering by Nanograins and Point Defects in Nanostructured Silicon with a Low Concentration of Ger-Manium. Phys. Rev. Lett. 2009, 102, 196803. [Google Scholar] [CrossRef] [PubMed]

- Zen, N.; Puurtinen, T.A.; Isotalo, T.J.; Chaudhuri, S.; Maasilta, I.J. Engineering Thermal Conductance Using a Two-Dimensional Phononic Crystal. Nat. Commun. 2014, 5, 3435. [Google Scholar] [CrossRef]

- Maldovan, M. Phonon Wave Interference and Thermal Bandgap Materials. Nat. Mater. 2015, 14, 667–674. [Google Scholar] [CrossRef]

- Maruyama, S. A Molecular Dynamics Simulation of Heat Conduction of a Finite Length Single-Walled Carbon Nanotube. Microscale Thermophys. Eng. 2003, 7, 41–50. [Google Scholar] [CrossRef]

- Volz, S.G.; Chen, G. Molecular Dynamics Simulation of Thermal Conductivity of Silicon Nanowires. Appl. Phys. Lett. 1999, 75, 2056. [Google Scholar] [CrossRef]

- Balandin, A.A.; Ghosh, S.; Bao, W.; Calizo, I.; Teweldebrhan, D.; Feng, M.; Lau, C.N. Superior Thermal Conductivity of Single-Layer Graphene. Nano Lett. 2008, 8, 902–907. [Google Scholar] [CrossRef]

- Luckyanova, M.; Garg, J.; Esfarjani, K.; Jandl, A.; Bulsara, M.T.; Schmidt, A.J.; Minnich, A.J.; Chen, S.; Dresselhaus, M.S.; Ren, Z. Coherent Phonon Heat Conduction in Superlattices. Science 2012, 338, 936–939. [Google Scholar] [CrossRef] [PubMed]

- Ravichandran, J.; Yadav, A.K.; Cheaito, R.; Rossen, P.B.; Soukiassian, A.; Suresha, S.J.; Duda, J.C.; Foley, B.M.; Lee, C.-H.; Zhu, Y.; et al. Crossover from Incoherent to Coherent Phonon Scattering in Epitaxial Oxide Superlattices. Nat. Mater. 2014, 13, 168–172. [Google Scholar] [CrossRef] [PubMed]

- He, Y.; Donadio, D.; Lee, J.-H.; Grossman, J.C.; Galli, G. Thermal Transport in Nanoporous Silicon: Interplay between Disorder at Mesoscopic and Atomic Scales. ACS Nano 2011, 5, 1839–1844. [Google Scholar] [CrossRef] [PubMed]

- Boukai, A.I.; Bunimovich, Y.; Tahir-Kheli, J.; Yu, J.-K.; Goddard, W.A.; Heath, J.R. Silicon Nanowires as Efficient Thermoelectric Materials. Nature 2008, 451, 168–171. [Google Scholar] [CrossRef]

- Hochbaum, A.I.; Chen, R.; Delgado, R.D.; Liang, W.; Garnett, E.C.; Najarian, M.; Majumdar, A.; Yang, P. Enhanced Thermoelectric Performance of Rough Silicon Nanowires. Nature 2008, 451, 163–167. [Google Scholar] [CrossRef]

- Lim, J.; Hippalgaonkar, K.; Andrews, S.C.; Majumdar, A.; Yang, P. Quantifying Surface Roughness Effects on Phonon Transport in Silicon Nanowires. Nano Lett. 2012, 12, 2475–2482. [Google Scholar] [CrossRef]

- Martin, P.; Aksamija, Z.; Pop, E.; Ravaioli, U. Impact of Phonon-Surface Roughness Scattering on Thermal Conductivity of Thin Si Nanowires. Phys. Rev. Lett. 2009, 102, 125503. [Google Scholar] [CrossRef]

- Gesele, G.; Linsmeier, J.; Drach, V.; Fricke, J.; Arens-Fischer, R. Temperature-Dependent Thermal Conductivity of Porous Silicon. J. Phys. D Appl. Phys. 1997, 30, 2911. [Google Scholar] [CrossRef]

- Miyazaki, K.; Tanaka, S.; Nagai, N. Heat Conduction of a Porous Material. J. Heat Transfer. 2012, 134, 051018. [Google Scholar] [CrossRef]

- Cullis, A.G.; Canham, L.T.; Calcott, P.D.J. The Structural and Luminescence Properties of Porous Silicon. J. Appl. Phys. 1997, 82, 909–965. [Google Scholar] [CrossRef]

- Lu, G.Q.; Zhao, X.S. Nanoporous Materials Science and Engineering; Imperial College Press: London, UK, 2004. [Google Scholar]

- Andrusenko, D.; Isaiev, M.; Kuzmich, A.; Lysenko, V.; Burbelo, R. Photoacoustic Effects in Nanocomposite Structure “Porous Silicon-Liquid”. Nanoscale Res. Lett. 2012, 7, 411. [Google Scholar] [CrossRef] [PubMed]

- Andrusenko, D.; Isaiev, M.; Tytarenko, A.; Lysenko, V.; Burbelo, R. Size Evaluation of the Fine Morphological Features of Porous Nanostructures from the Perturbation of Heat Transfer by a Pore Filling Agent. Microporous Mesoporous Mater. 2014, 194, 79–82. [Google Scholar] [CrossRef]

- Lishchuk, P.; Andrusenko, D.; Isaiev, M.; Lysenko, V.; Burbelo, R. Investigation of Thermal Transport Properties of Porous Silicon by Photoacoustic Technique. Int. J. Thermophys. 2015, 36, 2428–2433. [Google Scholar] [CrossRef]

- Wang, X.; Gonçalves, W.; Lacroix, D.; Isaiev, M.; Gomès, S.; Termentzidis, K. Thermal Conductivity Temperature Dependence of Water Confined in Nanoporous Silicon. J. Phys. Condens. Matter 2022, 34, 305701. [Google Scholar] [CrossRef] [PubMed]

- Isaiev, M.; Wang, X.; Termentzidis, K.; Lacroix, D. Thermal Transport Enhancement Due to Confined Water in Hybrid Nanocomposite. Appl. Phys. Lett. 2020, 117, 033701. [Google Scholar] [CrossRef]

- Gonçalves, W.; Isaiev, M.; Lacroix, D.; Gomès, S.; Termentzidis, K. Interfacial Thermal Resistance between Nanoconfined Water and Silicon: Impact of Temperature and Silicon Phase. Surf. Interfaces 2022, 33, 102188. [Google Scholar] [CrossRef]

- Sun, X.; Parish, G.; Keating, A. Fabrication of Uniform Porosity, All-Porous-Silicon Microstructures and Stress/Stress Gradient Control. J. Micromech. Microeng. 2017, 27, 044001. [Google Scholar] [CrossRef]

- Billat, S.; Thönissen, M.; Arens-Fischer, R.; Berger, M.G.; Krüger, M.; Lüth, M. Influence of Etch Stops on the Microstructure of Porous Silicon Layers. Thin Solid Films 1997, 297, 22–25. [Google Scholar] [CrossRef]

- Alekseev, S.A.; Lysenko, V.; Zaitsev, V.N.; Barbier, D. Application of Infrared Interferometry for Quantitative Analysis of Chemical Groups Grafted onto the Internal Surface of Porous Silicon Nanostructures. J. Phys. Chem. C 2007, 111, 15217–15222. [Google Scholar] [CrossRef]

- Islam, M.N.; Pradhan, A.; Kumar, S. Effects of Crystallite Size Distribution on the Raman-Scattering Profiles of Silicon Nanostructures. J. Appl. Phys. 2005, 98, 024309. [Google Scholar] [CrossRef]

- Islam, M.N.; Kumar, S. Influence of Crystallite Size Distribution on the Micro-Raman Analysis of Porous Si. Appl. Phys. Lett. 2001, 78, 715–717. [Google Scholar] [CrossRef]

- Périchon, S.; Lysenko, V.; Remaki, B.; Barbier, D. Measurement of Porous Silicon Thermal Conductivity by Micro-Raman Scattering. J. Appl. Phys. 1999, 86, 4700–4702. [Google Scholar] [CrossRef]

- Lysenko, V.; Périchon, S.; Remaki, B.; Barbier, D. Thermal Conductivity of Thick Meso-Porous Silicon Layers by Micro-Raman Scattering. J. Appl. Phys. 1999, 86, 6841–6846. [Google Scholar] [CrossRef]

- Kurbanova, B.; Mussabek, G.; Timoshenko, V.Y.; Lysenko, V.; Utegulov, Z. Photothermal Effects and Heat Conduction in Nanogranular Silicon Films. Nanomaterials 2021, 11, 2379. [Google Scholar] [CrossRef]

- Chantrenne, P.; Lysenko, V. Thermal Conductivity of Interconnected Silicon Nanoparticles: Application to Porous Silicon Nanostructures. Phys. Rev. B 2005, 72, 035318. [Google Scholar] [CrossRef]

- Yukhymchuk, V.O.; Dzhagan, V.M.; Valakh, M.Y.; Klad’ko, V.P.; Gudymenko, O.J.; Yefanov, V.S.; Zahn, D.R.T. In Situ Photoluminescence/Raman Study of Reversible Photo-Induced Structural Transformation of Nc-Si. Mater. Res. Express 2014, 1, 045905. [Google Scholar] [CrossRef]

- Rodichkina, S.; Lysenko, V.; Belarouci, A.; Bezverkhyy, I.; Chassagnon, R.; Isaiev, M.; Nychyporuk, T.; Timoshenko, V. Photo-Induced Cubic-to-Hexagonal Polytype Transition in Silicon Nanowires. CrystEngComm 2019, 21, 4747–4752. [Google Scholar] [CrossRef]

| Porosity, % | Thickness, μm | Size of Si Nanocrystallites, nm |

|---|---|---|

| 42.5 | 71 | 11.8 ± 3.5 |

| 53.5 | 94 | 9.6 ± 3.0 |

| 68.4 | 115 | 9.3 ± 2.7 |

| 78.7 | 111 | 8.3 ± 2.7 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Makukha, O.; Lysenko, I.; Belarouci, A. Liquid-Modulated Photothermal Phenomena in Porous Silicon Nanostructures Studied by μ-Raman Spectroscopy. Nanomaterials 2023, 13, 310. https://doi.org/10.3390/nano13020310

Makukha O, Lysenko I, Belarouci A. Liquid-Modulated Photothermal Phenomena in Porous Silicon Nanostructures Studied by μ-Raman Spectroscopy. Nanomaterials. 2023; 13(2):310. https://doi.org/10.3390/nano13020310

Chicago/Turabian StyleMakukha, Oksana, Ivan Lysenko, and Ali Belarouci. 2023. "Liquid-Modulated Photothermal Phenomena in Porous Silicon Nanostructures Studied by μ-Raman Spectroscopy" Nanomaterials 13, no. 2: 310. https://doi.org/10.3390/nano13020310

APA StyleMakukha, O., Lysenko, I., & Belarouci, A. (2023). Liquid-Modulated Photothermal Phenomena in Porous Silicon Nanostructures Studied by μ-Raman Spectroscopy. Nanomaterials, 13(2), 310. https://doi.org/10.3390/nano13020310