Hard Magnetic Properties and the Features of Nanostructure of High-Temperature Sm-Co-Fe-Cu-Zr Magnet with Abnormal Temperature Dependence of Coercivity

Abstract

:1. Introduction

2. Materials and Methods

3. Results and Discussion

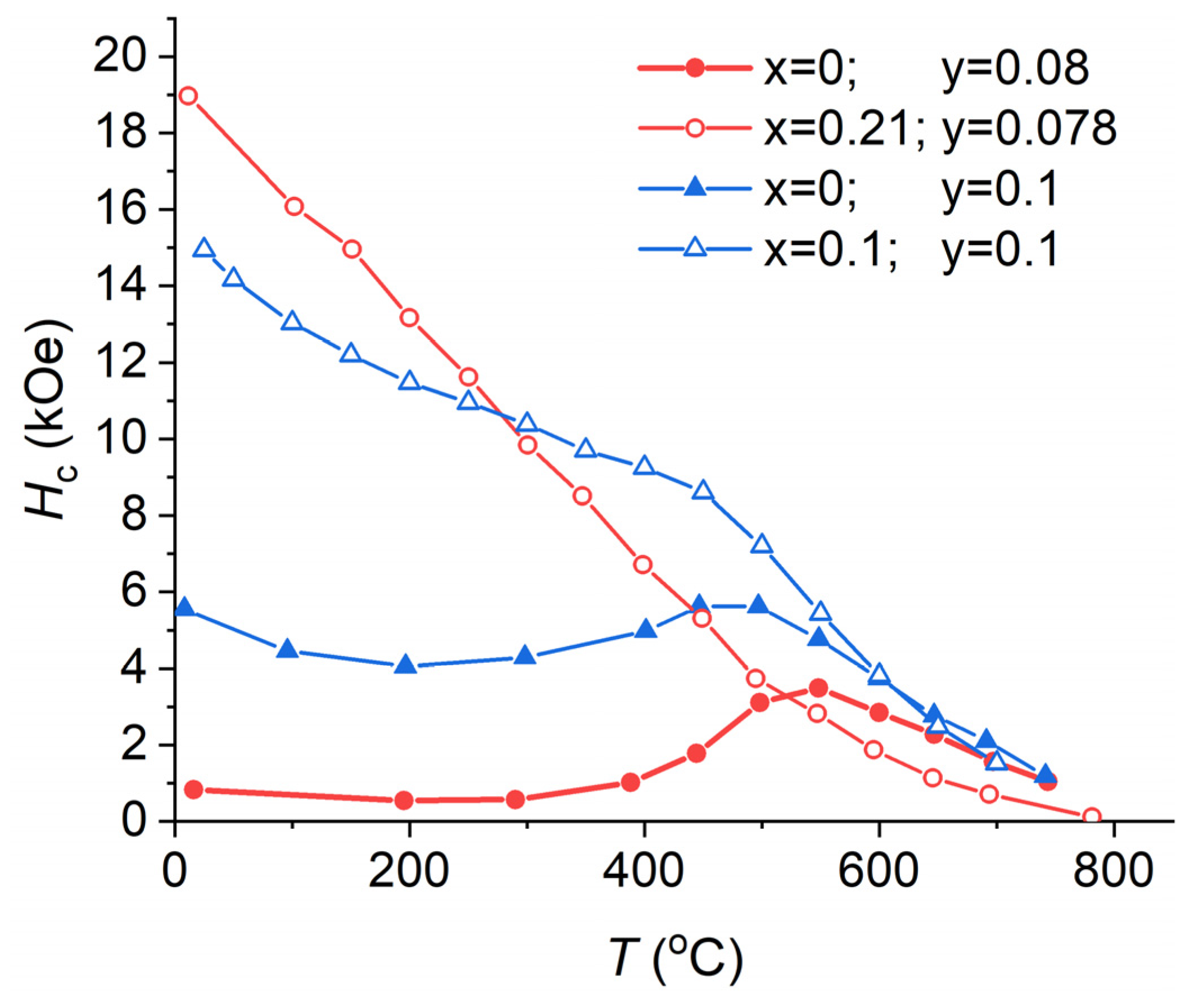

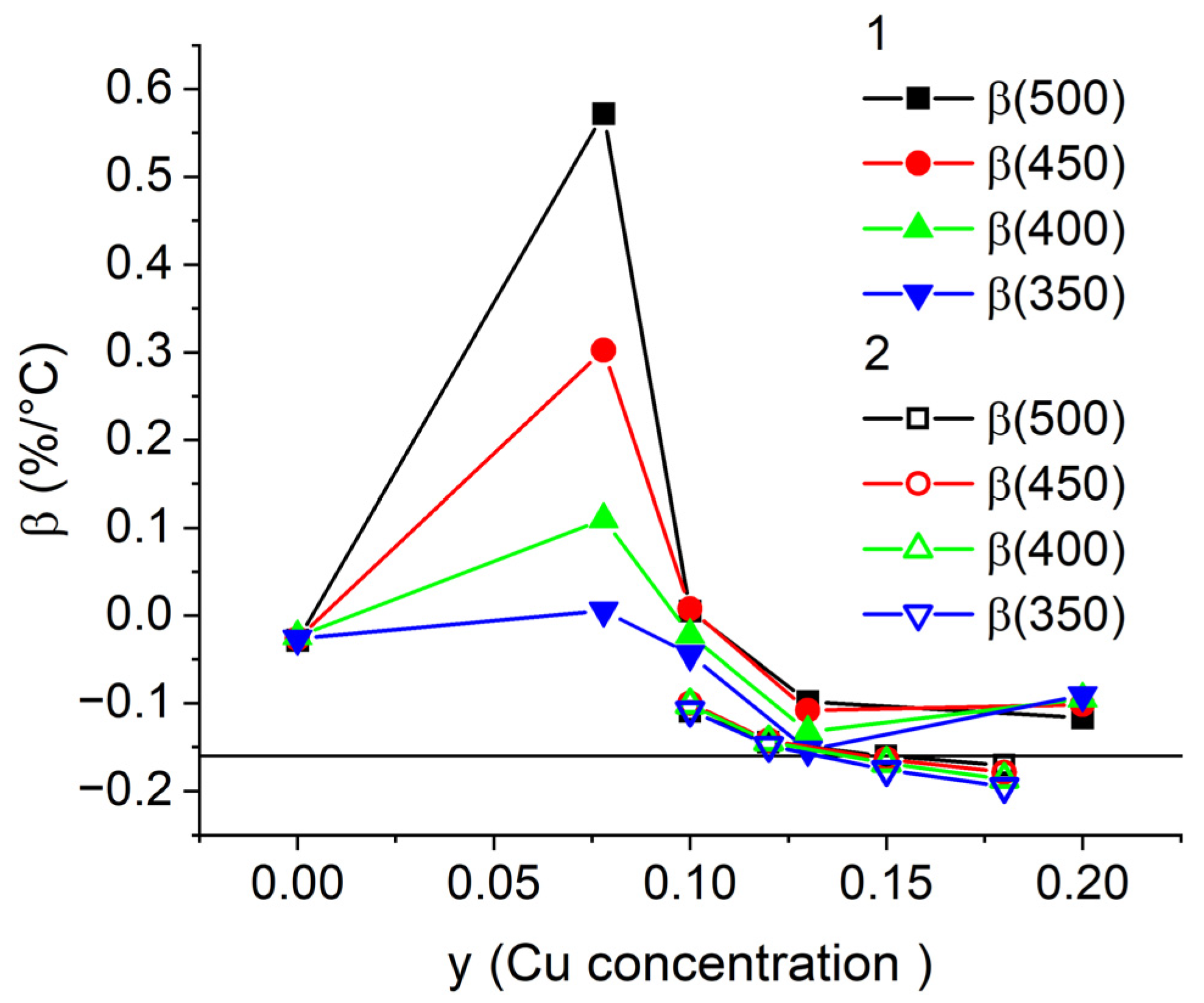

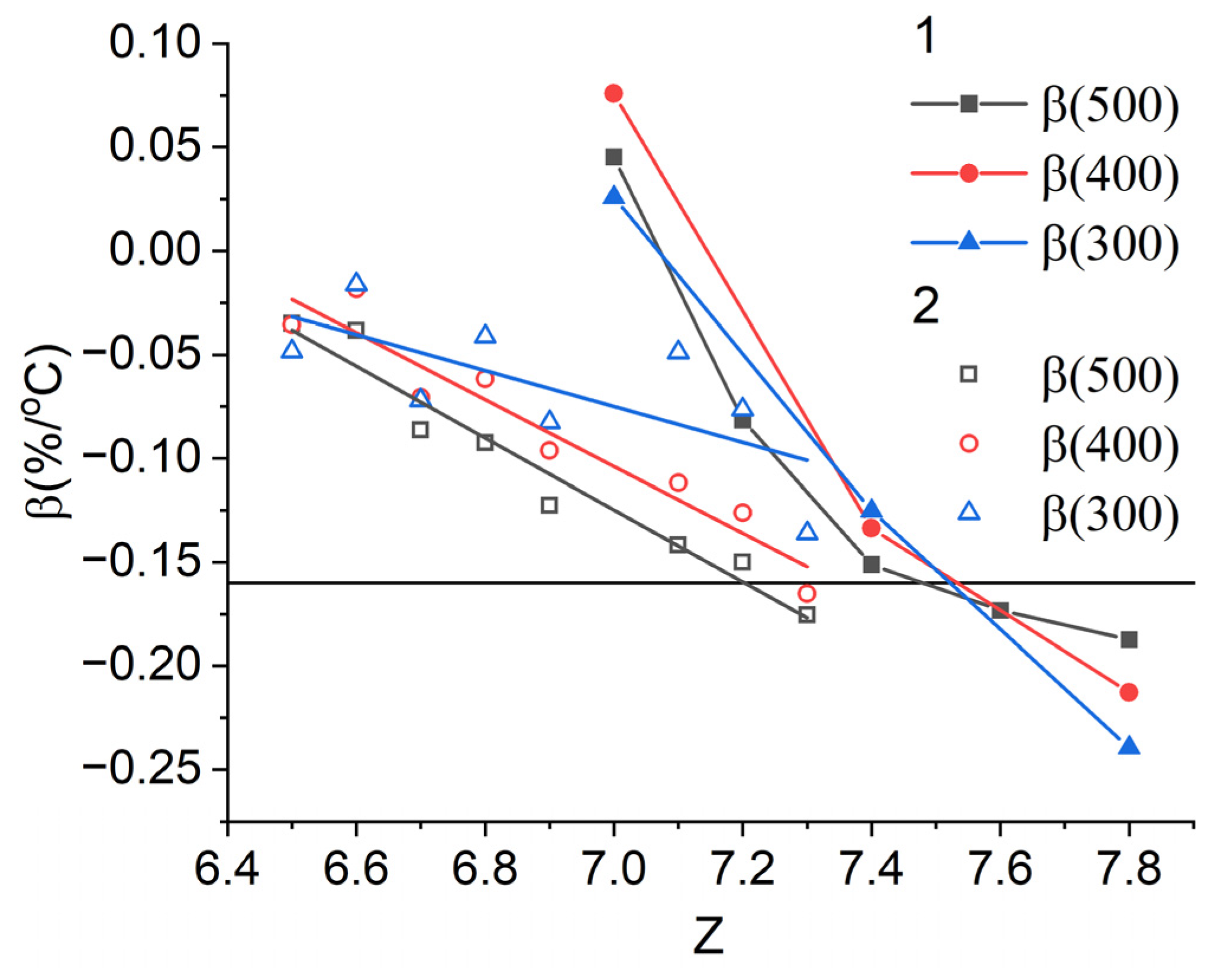

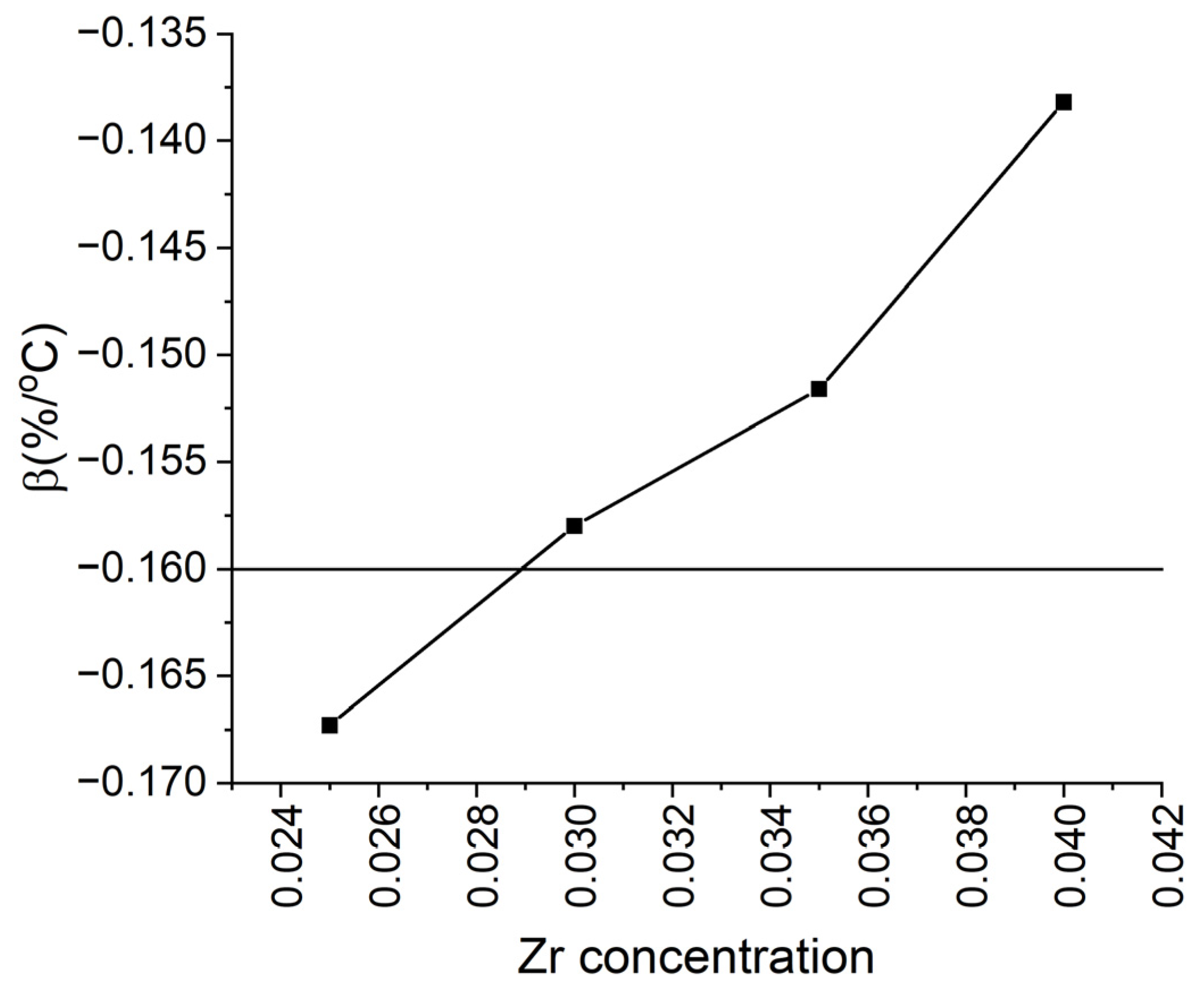

3.1. Magnetic Measurements

3.1.1. Effect of Cu Content

| x, y | TC(1:5), °C | TC(2:17), °C |

|---|---|---|

| Sm(Co0.978−yCuyZr0.022)7.3 [39] | ||

| 0 | 705 | 880 |

| 0.078 | 600 | 842 |

| 0.13 | 528 | 815 |

| 0.20 | 420 | 780 |

| Sm(Co0.88−yFe0.1CuyZr0.02)7 [36] | ||

| 0.1 | 550 | 850 |

| 0.12 | 510 | 850 |

| 0.15 | 360 | 850 |

| 0.18 | 280 | 850 |

| Sm(Co0.88−xFexCu0.09Zr0.03)7 [41] | ||

| 0 | 568 | 846 |

| 0.04 | 567 | 847 |

| 0.08 | 566 | 847 |

| 0.12 | 565 | 847 |

3.1.2. Effect of Fe Content

3.1.3. Effect of Sm Content

3.1.4. Effect of Zr Content

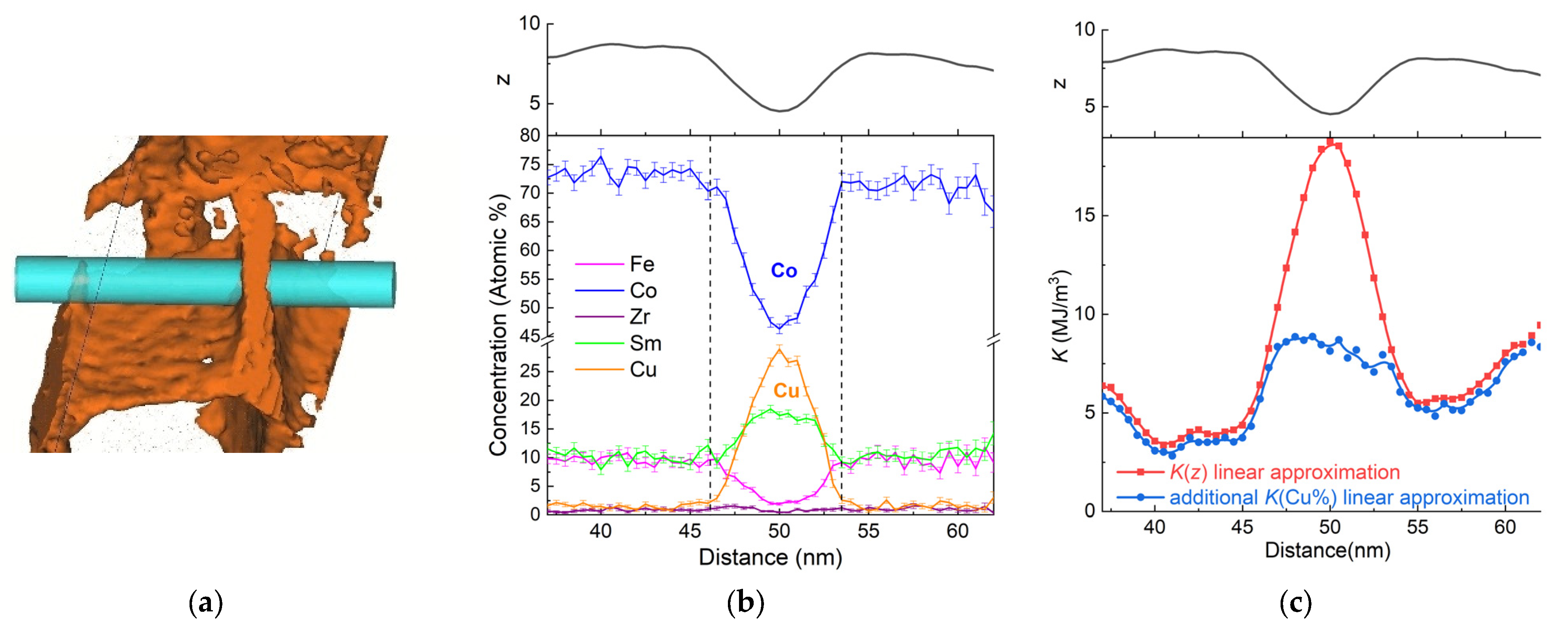

3.2. X-ray Diffraction and Atom Probe Tomography Study of HTPM

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Horiuchi, Y.; Hagiwara, M.; Endo, M.; Sanada, N.; Sakurada, S. Influence of Intermediate-Heat Treatment on the Structure and Magnetic Properties of Iron-Rich Sm(CoFeCuZr)Z Sintered Magnets. J. Appl. Phys. 2015, 117, 17C704. [Google Scholar] [CrossRef]

- Rabenberg, L.; Mishra, R.K.; Thomas, G. Microstructures of Precipitation-Hardened SmCo Permanent Magnets. J. Appl. Phys. 1982, 53, 2389–2391. [Google Scholar] [CrossRef] [Green Version]

- Fidler, J.; Skalicky, P. Microstructure of Precipitation Hardened Cobalt Rare Earth Permanent Magnets. J. Magn. Magn. Mater. 1982, 27, 127–134. [Google Scholar] [CrossRef]

- Feng, H.; Chen, H.; Guo, Z.; Yu, R.; Li, W. Twinning Structure in Sm(Co,Fe,Cu,Zr)z Permanent Magnet. Intermetallics 2010, 18, 1067–1071. [Google Scholar] [CrossRef]

- Wang, H.; Li, L.; Liu, B.; Xu, H.; Jiang, C. Atomic-Scale Structure Clarification of the Planar Z Phase and Its Influence on the Magnetic Properties in Sm(CoFeCuZr)z Permanent Magnets. Acta Mater. 2022, 230, 3–12. [Google Scholar] [CrossRef]

- Ojima, T.; Tomizawa, S.; Yoneyama, T.; Hori, T. Magnetic Properties of a New Type of Rare-Earth Cobalt Magnets Sm2(Co,Cu,Fe,M)17. IEEE Trans. Magn. 1977, MAG-13, 1317–1319. [Google Scholar] [CrossRef]

- Maury, C.; Rabenberg, L.; Allibert, C.H. Genesis of the Cell Microstructure in the Sm (Co, Fe, Cu, Zr) Permanent Magnets with 2: 17 Type. Phys. Status Solidi 1993, 140, 57–72. [Google Scholar] [CrossRef]

- Perry, A.J. The Constitution of Copper-Hardened Samarium-Cobalt Permanent Magnets. J. Less-Common Met. 1977, 51, 153–162. [Google Scholar] [CrossRef]

- Kronmüller, H.; Goll, D. Micromagnetic Analysis of Pinning-Hardened Nanostructured, Nanocrystalline Sm2Co17 Based Alloys. Scr. Mater. 2002, 47, 545–550. [Google Scholar] [CrossRef]

- Goll, D.; Kronmüller, H.; Stadelmaier, H.H. Micromagnetism and the Microstructure of High-Temperature Permanent Magnets. J. Appl. Phys. 2004, 96, 6534–6545. [Google Scholar] [CrossRef]

- Stadelmaier, H.H.; Goll, D.; Kronmüller, H. Permanent Magnet Alloys Based on Sm2Co17; Phase Evolution in the Quinary System Sm-Zr-Fe-Co-Cu. Z. Für Met. 2005, 96, 17–23. [Google Scholar] [CrossRef]

- Gopalan, R.; Hono, K.; Yan, A.; Gutfleisch, O. Direct Evidence for Cu Concentration Variation and Its Correlation to Coercivity in Sm (Co0.74Fe0.1Cu0.12Zr.04)7.4 Ribbons. Scr. Mater. 2009, 60, 764–767. [Google Scholar] [CrossRef]

- Yan, A.; Gutfleisch, O.; Gemming, T.; Müller, K.-H.H. Microchemistry and Magnetization Reversal Mechanism in Melt-Spun 2:17-Type Sm-Co Magnets. Appl. Phys. Lett. 2003, 83, 2208–2210. [Google Scholar] [CrossRef]

- Pierobon, L.; Schäublin, R.E.; Kovács, A.; Gerstl, S.S.A.; Firlus, A.; Wyss, U.V.; Dunin-Borkowski, R.E.; Charilaou, M.; Löffler, J.F. Temperature Dependence of Magnetization Processes in Sm(Co, Fe, Cu, Zr)Zmagnets with Different Nanoscale Microstructures. J. Appl. Phys. 2021, 129, 183903. [Google Scholar] [CrossRef]

- Xu, H.; Wang, H.; Xi, L.; Liu, B.; Du, K.; Gao, H.; Liu, J.; Zhang, T.; Jiang, C. Influence of Exchange Coupling Interaction on Coercivity in 2:17-Type SmCo-Based High Temperature Permanent Magnets. Scr. Mater. 2023, 222, 115003. [Google Scholar] [CrossRef]

- Xiong, X.Y.; Ohkubo, T.; Koyama, T.; Ohashi, K.; Tawara, Y.; Hono, K. The Microstructure of Sintered Sm(Co0.72Fe0.20Cu0.055Zr0.025)7.5 Permanent Magnet Studied by Atom Probe. Acta Mater. 2004, 52, 737–748. [Google Scholar] [CrossRef]

- Popov, A.G.; Korolev, A.V.; Shchegoleva, N.N. Temperature Dependence of the Coercive Force of Sm (Co, Fe, Cu, Zr)7.3 Alloys. Phys. Met. Metallogr. 1990, 69, 100–106. [Google Scholar]

- Liu, J.P.; Fullerton, E.; Gutfleisch, O.; Sellmyer, D.J. (Eds.) Nanoscale Magnetic Materials and Applications; Springer Science + Business Media: New York, NY, USA, 2009; ISBN 9780387855981. [Google Scholar]

- Walmer, M.S.; Chen, C.H.; Liu, S.; Walmer, M.H.; Kuhl, G.E. High Temperature Permanent Magnets. US Patent 6,451,132; Applied in 1998 and Issued in 17 September 2002,

- Popov, A.G.; Golovnia, O.A.; Gaviko, V.S.; Vasilenko, D.Y.; Bratushev, D.Y.; Balaji, V.I.N.; Kovács, A.; Pradeep, K.G.; Gopalan, R. Development of High-Coercivity State in High-Energy and High-Temperature Sm-Co-Fe-Cu-Zr Magnets upon Step Cooling. J. Alloys Compd. 2020, 820, 153103. [Google Scholar] [CrossRef]

- Wang, C.; Zhu, M.-G. Overview of Composition and Technique Process Study on 2:17-Type Sm–Co High-Temperature Permanent Magnet. Rare Met. 2021, 40, 790–798. [Google Scholar] [CrossRef]

- Beketov, V.N.; Moskalev, V.N.; Taranov, D.V.; Ogurtsov, A.V.; Sharin, M.K.; Popov, A.G.; Gaviko, V.S.; Golovnya, O.A.; Protasov, A.V.; Gerasimov, E.G.; et al. Structure and Properties of Sm-Co-Fe-Cu-Zr Magnets for High-Temperature Applications. Met. Sci. Heat Treat. 2018, 60, 498–503. [Google Scholar] [CrossRef]

- Popov, A.G.; Gaviko, V.S.; Popov, V.V.; Golovnia, O.A.; Protasov, A.V.; Gerasimov, E.G.; Ogurtsov, A.V.; Sharin, M.K.; Gopalan, R. Structure and Magnetic Properties of Heat-Resistant Sm(Co0.796−XFe0.177CuXZr0.027)6.63 Permanent Magnets with High Coercivity. JOM 2019, 71, 559–566. [Google Scholar] [CrossRef]

- Liu, S.S. Recent Developments in High-Temperature Permanent Magnet Materials. In Handbook of Advanced Magnetic Materials; Liu, Y., Sellmyer, D.J., Shindo, D., Eds.; Springer: Boston, MA, USA, 2006; pp. 1329–1377. [Google Scholar]

- Yu, N.; Zhu, M.; Fang, Y.; Song, L.; Sun, W.; Song, K.; Wang, Q.; Li, W. The Microstructure and Magnetic Characteristics of Sm(CobalFe0.1Cu0.09Zr0.03)7.24 High Temperature Permanent Magnets. Scr. Mater. 2017, 132, 44–48. [Google Scholar] [CrossRef]

- Giron, S.; Polin, N.; Adabifiroozjaei, E.; Yang, Y.; Kovács, A.; Almeida, T.P.; Ohmer, D.; Üstüner, K.; Katter, M.; Radulov, I.A.; et al. Towards Engineering the Perfect Defect in High-Performing Permanent Magnets. arXiv 2023, arXiv:2304.14958. [Google Scholar]

- Staab, F.; Yang, Y.; Foya, E.; Bruder, E.; Zingsem, B.; Adabifiroozjaei, E.; Skokov, K.; Farle, M.; Dunin-Borkowski, R.E.; Molina-Luna, L.; et al. Influence of Amorphous Phase on Coercivity in SmCo5-Cu Nanocomposites. arXiv 2023, arXiv:2305.08948. [Google Scholar]

- Chakraborty, A.; Hirian, R.; Kapun, G.; Pop, V. Magnetic Properties of SmCo5 + 10 Wt% Fe Exchange-Coupled Nanocomposites Produced from Recycled SmCo5. Nanomaterials 2020, 10, 1308. [Google Scholar] [CrossRef]

- Weissitsch, L.; Stückler, M.; Wurster, S.; Todt, J.; Knoll, P.; Krenn, H.; Pippan, R.; Bachmaier, A. Manufacturing of Textured Bulk Fe-SmCo5 Magnets by Severe Plastic Deformation. Nanomaterials 2022, 12, 963. [Google Scholar] [CrossRef]

- Goetz, I.K.; Sälker, J.A.; Hans, M.; Hjörvarsson, B.; Schneider, J.M. Nanoscale Clustering in an Additively Manufactured Zr-Based Metallic Glass Evaluated by Atom Probe Tomography. Nanomaterials 2023, 13, 1341. [Google Scholar] [CrossRef]

- Wang, R.; Wang, H.; Zhu, X.; Liang, X.; Li, Y.; Gao, Y.; An, X.; Liu, W. Effects of Fe-Ions Irradiation on the Microstructure and Mechanical Properties of FeCrAl-1.5wt.% ZrC Alloys. Nanomaterials 2021, 11, 3423. [Google Scholar] [CrossRef]

- Rabhi, S.; Oueldna, N.; Perrin-Pellegrino, C.; Portavoce, A.; Kalna, K.; Benoudia, M.C.; Hoummada, K. Thickness Effect on the Solid-State Reaction of a Ni/GaAs System. Nanomaterials 2022, 12, 2633. [Google Scholar] [CrossRef]

- Gajjela, R.S.R.; Koenraad, P.M. Atomic-Scale Characterization of Droplet Epitaxy Quantum Dots. Nanomaterials 2021, 11, 85. [Google Scholar] [CrossRef]

- Foroozan-Ebrahimy, A.; Langelier, B.; Newman, R. Probing the Surface Chemistry of Nanoporous Gold via Electrochemical Characterization and Atom Probe Tomography. Nanomaterials 2021, 11, 1002. [Google Scholar] [CrossRef]

- Kronmüller, H.; Goll, D. Analysis of the Temperature Dependence of the Coercive Field of Sm2Co17 Based Magnets. Scr. Mater. 2003, 48, 833–838. [Google Scholar] [CrossRef]

- Popov, A.G.; Golovnia, O.A.; Protasov, A.V.; Gaviko, V.S.; Gopalan, R.; Jiang, C.; Zhang, T. Peculiar Kinetics of Coercivity of Sintered Sm(Co0.78Fe0.10Cu0.10Zr0.02)7 Magnet upon Slow Cooling. IEEE Trans. Magn. 2018, 54, 2100907. [Google Scholar] [CrossRef]

- Liu, S.; Ray, A.E.; Mildrum, H.F. Prediction of Temperature Coefficients of Magnetization in Rare Earth-Transition Metal Magnet Alloys. In Proceedings of the 11th International Workshop on Rare-Earth Magnets and Their Applications and the 6th International Symposium on Magnetic Anisotropy and Coercivity in Rare Earth-Transition Metal Alloys, Pittsburgh, PA, USA, October 1990; pp. 389–400. [Google Scholar]

- Liu, J.F.; Ding, Y.; Hadjipanayis, G.C. Effect of Iron on the High Temperature Magnetic Properties and Microstructure of Sm(Co, Fe, Cu, Zr)z Permanent Magnets. J. Appl. Phys. 1999, 85, 1670–1674. [Google Scholar] [CrossRef]

- Popov, A.G.; Gaviko, V.S.; Magat, L.M.; Ivanova, G. V Influence of Copper Concentration on the Magnetic Properties and Structure of Alloys. Phys. Met. Metallogr. 1990, 70, 18–27. [Google Scholar]

- Popov, A.G.; Korolyov, A.V.; Gaviko, V.S. Abnormal Temperature Dependence of Coercivity of Sm-Co-Fe-Cu-Zr Alloys: History and Current State. J. Magn. Magn. Mater. 2004, 272–276, E1883–E1885. [Google Scholar] [CrossRef]

- Popov, A.G.; Golovnia, O.A.; Protasov, A.V.; Gaviko, V.S.; Kolodkin, D.A.; Gopalan, R. Coercivity Kinetics upon Step Cooling of the Sintered Sm(Co0.88−XFexCu0.09Zr0.03)7 Magnets. Rare Earths 2019, 37, 1059–1065. [Google Scholar] [CrossRef]

- Chen, C.H.; Walmer, M.S.; Walmer, M.H.; Liu, S.; Kuhl, E.; Simon, G. Sm2(Co,Fe,Cu,Zr)17 Magnets for Use at Temperature ⩾400 °C. J. Appl. Phys. 1998, 83, 6706–6708. [Google Scholar] [CrossRef]

- Liu, J.F.; Zhang, Y.; Dimitrov, D.; Hadjipanayis, G.C. Microstructure and High Temperature Magnetic Properties of Sm(Co, Cu, Fe, Zr)z (Z = 6.7–9.1) Permanent Magnets. J. Appl. Phys. 1999, 85, 2800–2804. [Google Scholar] [CrossRef]

- Liu, B.; Wang, H.; Yu, Q.; Xu, H.; Zhang, T.; Liu, J.; Jiang, C. Quantitative Analysis of Pinning-Hardened Intrinsic Coercivity of Sm(CoFeCuZr)z (z = 7.0–7.8) High-Temperature Permanent Magnets. J. Alloys Compd. 2021, 872, 159622. [Google Scholar] [CrossRef]

- Wang, C.; Shen, P.; Fang, Y.; Wang, S.; Li, Q.; Wang, L.; Li, W.; Zhu, M. Cellular Microstructure Modification and High Temperature Performance Enhancement for Sm2Co17-Based Magnets with Different Zr Contents. J. Mater. Sci. Technol. 2022, 120, 8–14. [Google Scholar] [CrossRef]

- Gong, W.M.; Gao, R.S.; Feng, H.B.; Yu, R.H.; Zhang, Y.; Hadjipanayis, G.C. Effect of Zr on the Microstructure, Magnetic Domain Structure, Microchemistry and Magnetic Properties in Sm(CoBalCu0.08Fe0.10Zrx)8.5 Magnets. J. Phys. D. Appl. Phys. 2007, 40, 7620–7624. [Google Scholar] [CrossRef]

- Tang, W.; Zhang, Y.; Hadjipanayis, G.C.; Kronmüller, H. Influence of Zr and Cu Content on the Microstructure and Coercivity in Sm(CobalFe0.1CuyZrx)8.5 Magnets. J. Appl. Phys. 2000, 87, 5308–5310. [Google Scholar] [CrossRef]

- Chen, H.; Wang, Y.; Yao, Y.; Qu, J.; Yun, F.; Li, Y.; Ringer, S.P.; Yue, M.; Zheng, R. Attractive-Domain-Wall-Pinning Controlled Sm-Co Magnets Overcome the Coercivity-Remanence Trade-Off. Acta Mater. 2019, 164, 196–206. [Google Scholar] [CrossRef]

- Lectard, E.; Allibert, C.H.; Ballou, R. Saturation Magnetization and Anisotropy Fields in the Sm(Co1−xCux)5 Phases. J. Appl. Phys. 1994, 75, 6277–6279. [Google Scholar] [CrossRef]

- Patrick, C.E.; Staunton, J.B. Temperature-Dependent Magnetocrystalline Anisotropy of Rare Earth/Transition Metal Permanent Magnets from First Principles: The Light RCo5 (R = Y, La-Gd) Intermetallics. Phys. Rev. Mater. 2019, 3, 1–7. [Google Scholar] [CrossRef] [Green Version]

| Elements | Sm | Co | Fe | Cu | Zr | Total |

|---|---|---|---|---|---|---|

| x = 0, chemical | 12.5 | 77.0 | 0.0 | 7.9 | 2.6 | 100 |

| x = 0, APT | 12.8 | 73.4 | 0.1 | 8.7 | 2.1 | 97.1 |

| x = 0.04, chemical | 12.5 | 73.5 | 3.5 | 7.9 | 2.6 | 100 |

| x = 0.08, chemical | 12.5 | 70.0 | 7.0 | 7.9 | 2.6 | 100 |

| x = 0.12, chemical | 12.5 | 66.5 | 10.5 | 7.9 | 2.6 | 100 |

| x = 0.12, APT | 11.7 | 68.5 | 5.9 | 6.9 | 2.5 | 95.7 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Golovnia, O.A.; Popov, A.G.; Mushnikov, N.V.; Protasov, A.V.; Pradeep, K.G.; Ogurtsov, A.V.; Taranov, D.V.; Tishin, A.M. Hard Magnetic Properties and the Features of Nanostructure of High-Temperature Sm-Co-Fe-Cu-Zr Magnet with Abnormal Temperature Dependence of Coercivity. Nanomaterials 2023, 13, 1899. https://doi.org/10.3390/nano13131899

Golovnia OA, Popov AG, Mushnikov NV, Protasov AV, Pradeep KG, Ogurtsov AV, Taranov DV, Tishin AM. Hard Magnetic Properties and the Features of Nanostructure of High-Temperature Sm-Co-Fe-Cu-Zr Magnet with Abnormal Temperature Dependence of Coercivity. Nanomaterials. 2023; 13(13):1899. https://doi.org/10.3390/nano13131899

Chicago/Turabian StyleGolovnia, O. A., A. G. Popov, N. V. Mushnikov, A. V. Protasov, K. G. Pradeep, A. V. Ogurtsov, D. V. Taranov, and A. M. Tishin. 2023. "Hard Magnetic Properties and the Features of Nanostructure of High-Temperature Sm-Co-Fe-Cu-Zr Magnet with Abnormal Temperature Dependence of Coercivity" Nanomaterials 13, no. 13: 1899. https://doi.org/10.3390/nano13131899

APA StyleGolovnia, O. A., Popov, A. G., Mushnikov, N. V., Protasov, A. V., Pradeep, K. G., Ogurtsov, A. V., Taranov, D. V., & Tishin, A. M. (2023). Hard Magnetic Properties and the Features of Nanostructure of High-Temperature Sm-Co-Fe-Cu-Zr Magnet with Abnormal Temperature Dependence of Coercivity. Nanomaterials, 13(13), 1899. https://doi.org/10.3390/nano13131899