Combinatorial Cu-Ni Alloy Thin-Film Catalysts for Layer Number Control in Chemical Vapor-Deposited Graphene

Abstract

:1. Introduction

2. Materials and Methods

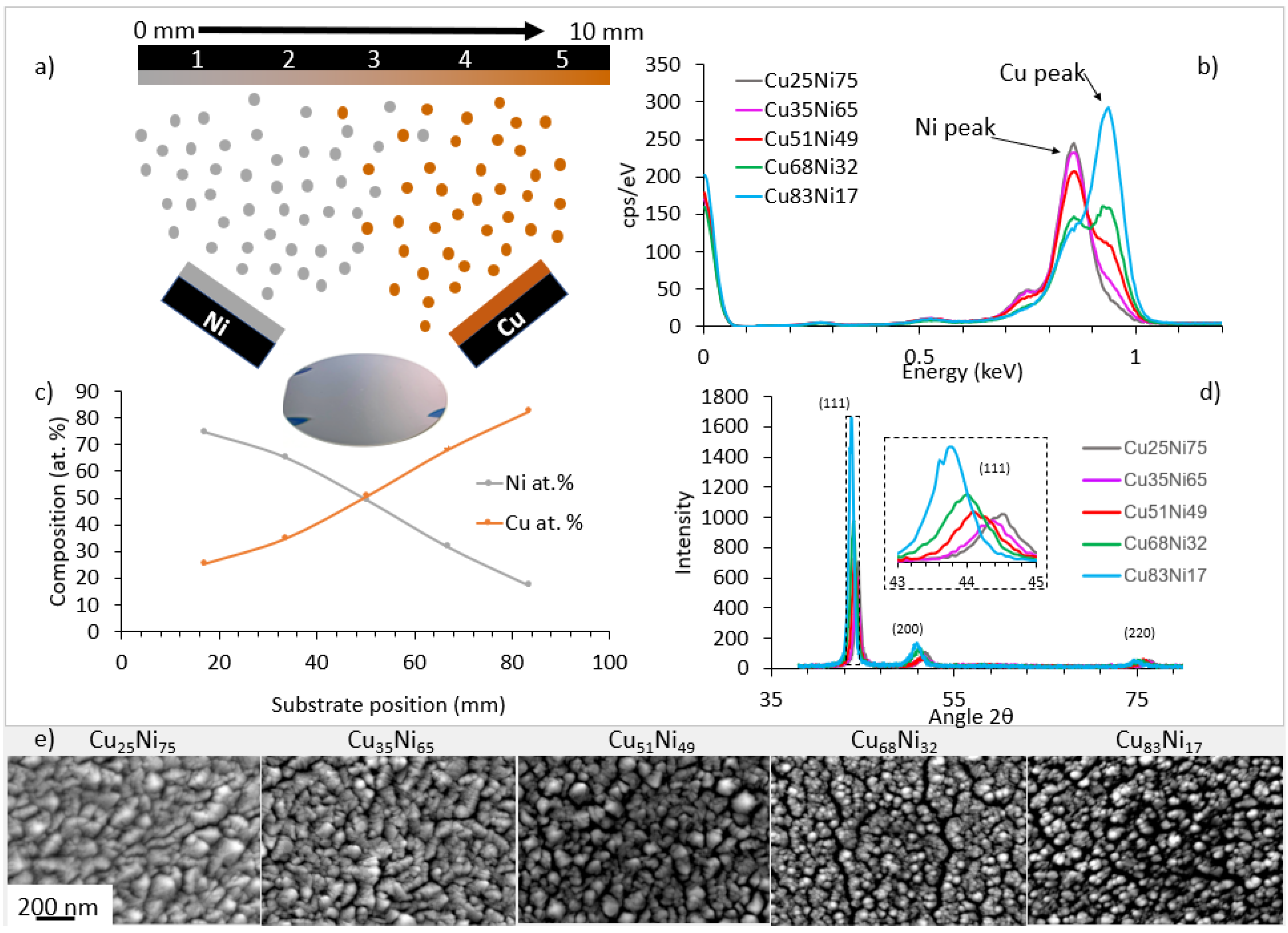

2.1. The Materials Thin-Film Sputtering of CuxNi1−x Alloy Catalyst

2.2. Energy Dispersive X-ray Spectroscopy and Scanning Electron Microscopy

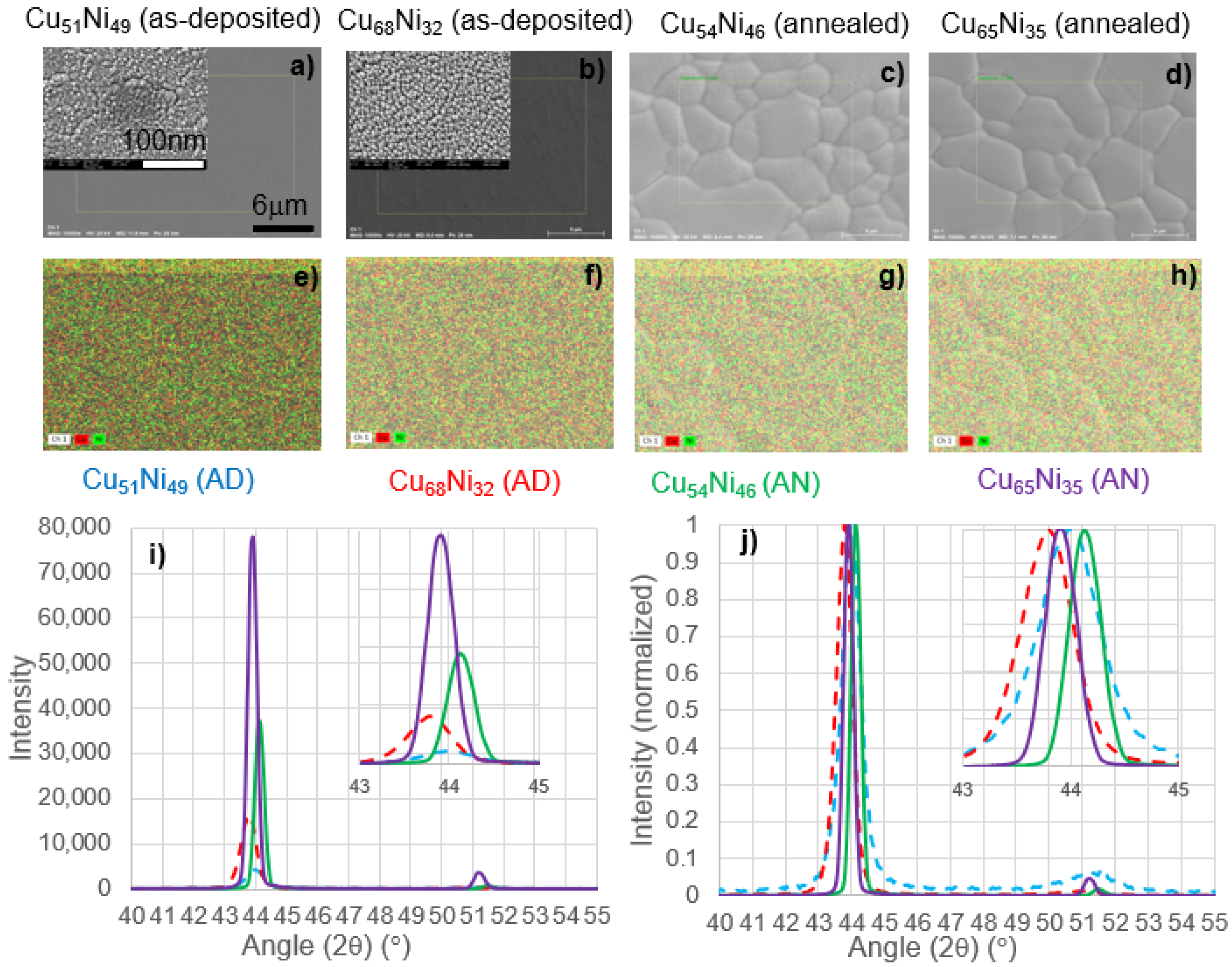

2.3. X-ray Diffraction

2.4. Graphene CVD Growth and Transfer Process

2.5. Raman Spectroscopy and Optical Microscopy

3. Results

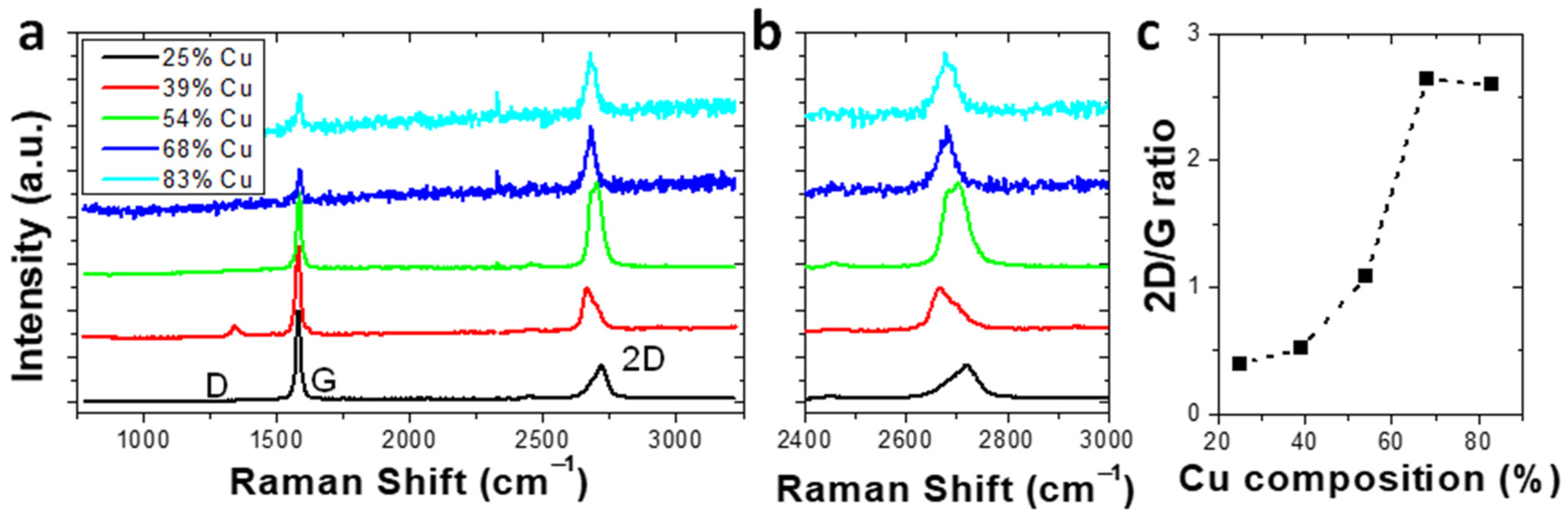

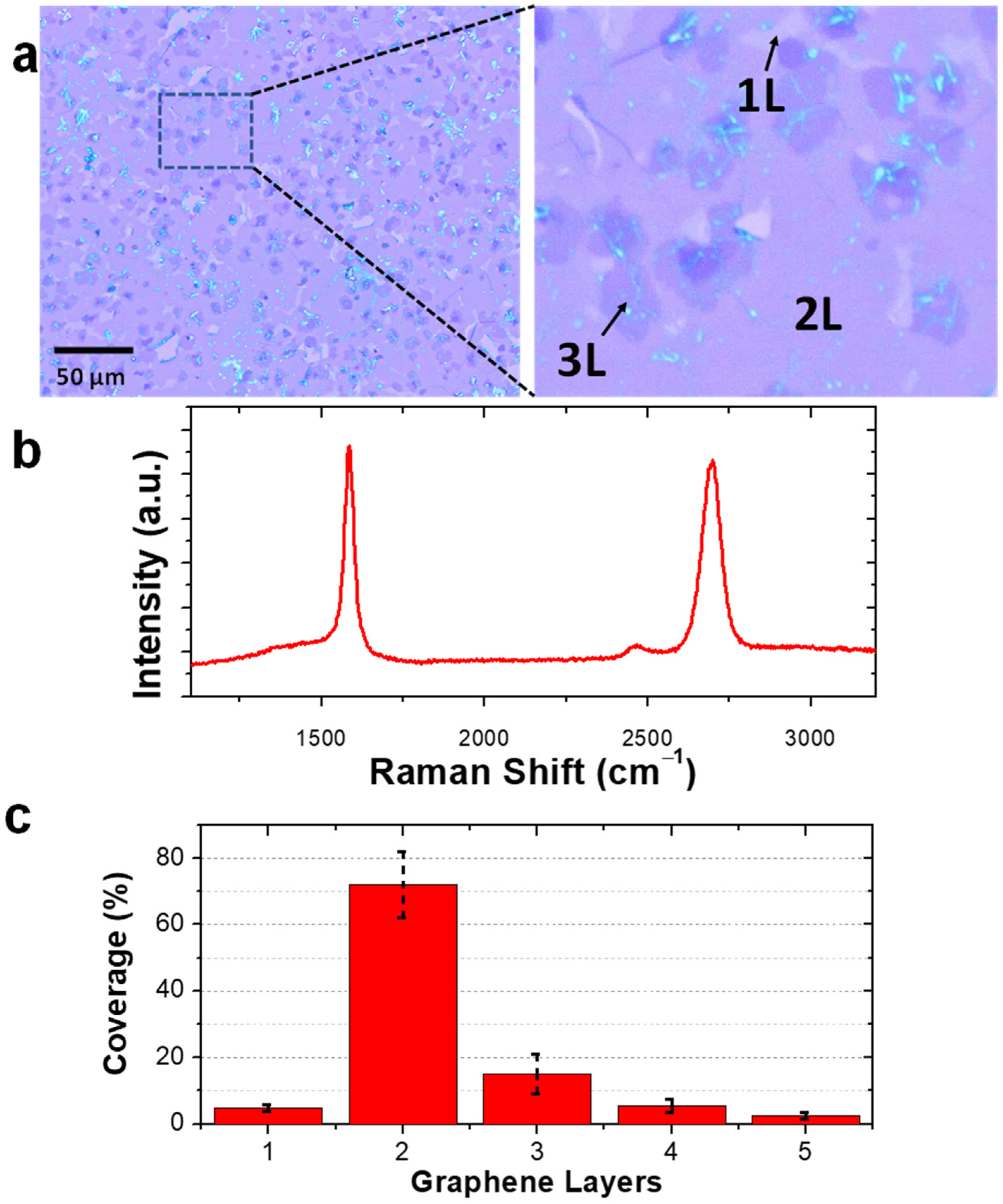

3.1. Preliminary Evaluation of CVD Graphene Growth

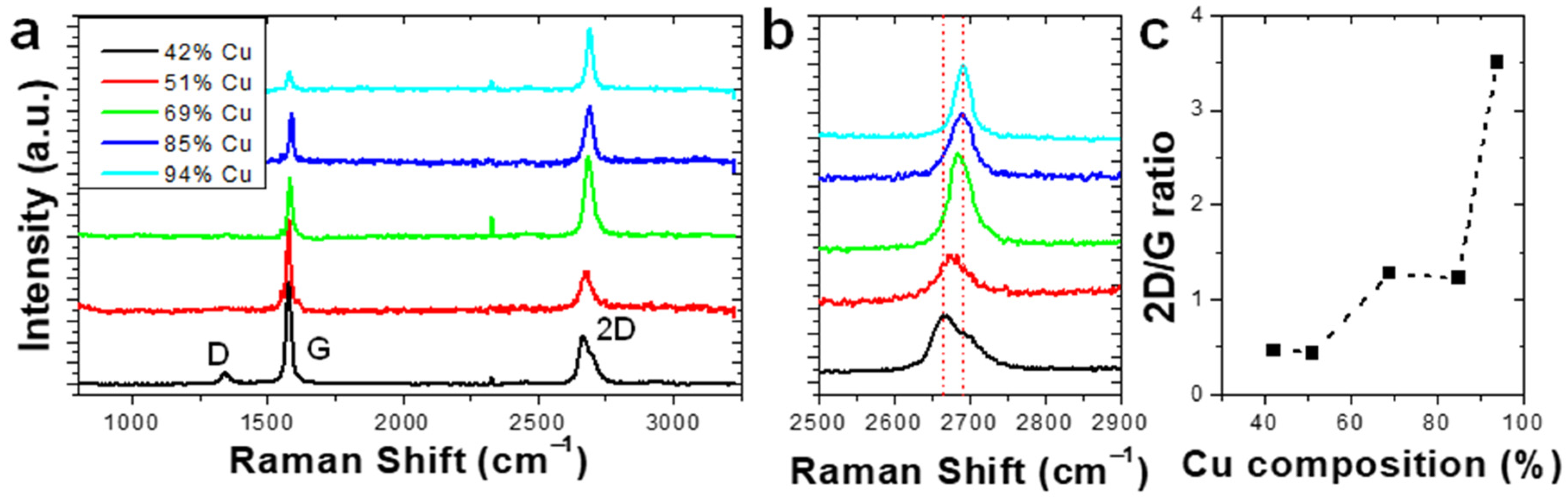

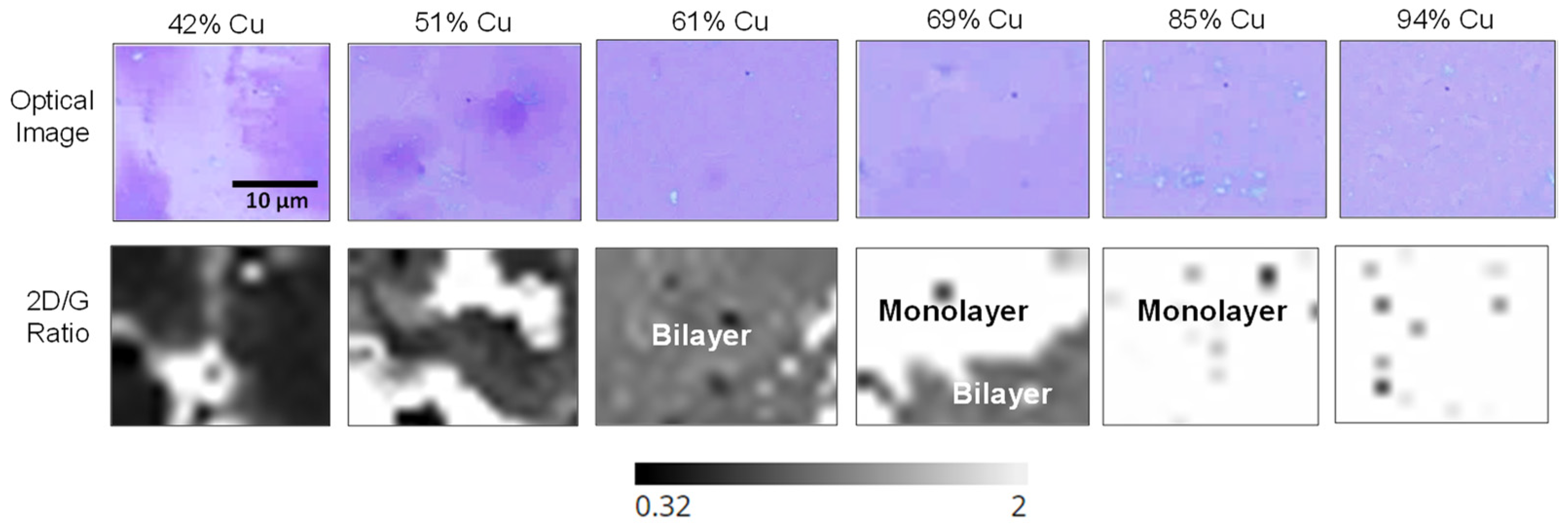

3.2. Discovering Optimum Cu at.% in CuNi Alloy for Bilayer CVD Graphene

3.3. Confirmation of Variation in Graphene Thickness with Gradient in Composition of CuNi Alloy

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Geim, A.K.; Novoselov, K.S. The rise of graphene. Nat. Mater. 2007, 6, 183–191. [Google Scholar] [CrossRef] [PubMed]

- Novoselov, K.S.; Geim, A.K.; Morozov, S.V.; Jiang, D.; Katsnelson, M.I.; Grigorieva, I.V.; Dubonos, S.V.; Firsov, A.A. Two-dimensional gas of masless Dirac fermions in graphene. Nature 2005, 438, 197–200. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Y.B.; Tan, Y.W.; Stormer, H.L.; Kim, P. Experimental observation of the quantum hall effect and Berry’s phase in graphene. Nature 2005, 238, 201–204. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Luo, Z.; Yu, T.; Shang, J.; Wang, Y.; Lim, S.; Liu, L.; Gurzadyan, G.G.; Shen, Z.; Lin, J. Large-scale synthesis of bi-layer graphene in strongly coupled stacking order. Adv. Funct. Mater. 2011, 21, 911–917. [Google Scholar] [CrossRef] [Green Version]

- Samarakoon, D.K.; Wang, X.Q. Tunable band gap in hydrogenated bilayer graphene. ACS Nano 2010, 4, 4126–4130. [Google Scholar] [CrossRef]

- Zhang, Y.; Tang, T.T.; Girit, C.; Hao, Z.; Martin, M.C.; Zettl, A.; Crommie, M.F.; Shen, Y.R.; Wang, F. Direct observation of a widely tunable bandgap in bilayer graphene. Nature 2009, 459, 820–823. [Google Scholar] [CrossRef]

- Vilatela, A.C.; Weatherup, R.S.; Weimer, P.B.; Caneva, S.; Hofmann, S. Towards a general growth model for graphene CVD on transition metal catalysts. Nanoscale 2016, 8, 2149–2158. [Google Scholar] [CrossRef] [Green Version]

- Petrov, S.; Rafailov, P.M.; Marinova, V.; Lin, S.H.; Lin, S.H.; Lai, Y.C.; Yu, P.; Chi, G.C.; Dimitrov, D.Z.; Karashanova, D.; et al. Chemical vapor deposition growth of bilayer graphene via altering gas flux. Thin Solid Films 2019, 690, 137521. [Google Scholar] [CrossRef]

- Yan, K.; Peng, J.; Zhou, Y.; Li, H.; Liu, Z. Formation of bilayer bernal graphene: Layer-by-layer epitaxy via chemical vapor deposition. Nano Lett. 2011, 11, 1106–1110. [Google Scholar] [CrossRef]

- Zhao, P.; Kim, S.; Chen, X.; Einarsson, E.; Wang, M.; Song, Y.; Wang, H.; Chiashi, S.; Xiang, R.; Maruyama, S. Equilibrium chemical vapor deposition growth of Bernal-stacked bilayer graphene. ACS Nano 2014, 8, 11631–11638. [Google Scholar] [CrossRef]

- Li, X.; Cai, W.; An, J.; Kim, S.; Nah, J.; Yang, D.; Piner, R.; Velamkanni, A.; Jung, I.; Tutuc, E.; et al. Large-area synthesis of high-quality and uniform graphene films on copper foils. Science 2009, 324, 1312–1315. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Peng, Z.; Yan, Z.; Sun, Z.; Tour, J.M. Direct growth of bilayer graphene on SiO2 substrates by carbon diffusion through Nickel. ACS Nano 2011, 5, 8241–8247. [Google Scholar] [CrossRef] [PubMed]

- Chen, X.; Zhang, L.; Chen, S. Large area CVD growth of graphene. Synth. Met. 2015, 210, 95–108. [Google Scholar] [CrossRef]

- Zhou, H.; Yu, W.J.; Liu, L.; Cheng, R.; Chen, Y.; Huang, X.; Liu, Y.; Wang, Y.; Huang, Y.; Duan, X. Chemical vapor deposition growth of large single crystals of monolayer and bilayer graphene. Nat. Comm. 2013, 4, 2096. [Google Scholar] [CrossRef] [Green Version]

- Liu, L.; Zhou, H.; Cheng, R.; Yu, W.J.; Liu, Y.; Chen, Y.; Shaw, J.; Zhong, X.; Huang, Y.; Duan, X. High-yield chemical vapor deposition growth of high-quality large-area AB-stacked bilayer graphene. ACS Nano 2012, 6, 8241–8249. [Google Scholar] [CrossRef] [Green Version]

- Oostinga, J.B.; Heersche, H.B.; Liu, X.; Morpurgo, A.F.; Vandersypen, L.M. Gate-induced insulating state in bilayer graphene devices. Nat. Mater. 2008, 7, 151–157. [Google Scholar] [CrossRef] [Green Version]

- Huang, M.; Bakharev, P.V.; Wang, Z.J.; Biswal, M.; Yang, Z.; Jin, S.; Wang, B.; Park, H.J.; Li, Y.; Qu, D.; et al. Large-area single-crystal AB-bilayer and ABA-trilayer graphene grown on Cu/Ni(111) foil. Nat. Nanotechnol. 2020, 15, 289–296. [Google Scholar] [CrossRef]

- Chen, S.; Cai, W.; Piner, R.D.; Suk, J.W.; Wu, Y.; Ren, Y.; Kang, J.; Ruoff, R.S. Synthesis and characterization of large-area graphene and graphite films on commercial Cu-Ni alloy foils. Nano Lett. 2011, 11, 3519–3525. [Google Scholar] [CrossRef]

- Wu, Y.; Chou, H.; Ji, H.; Wu, Q.; Chen, S.; Jiang, W.; Hao, Y.; Kang, J.; Ren, Y.; Piner, R.D.; et al. Growth mechanism and controlled synthesis of AB-stacked bilayer graphene on Cu-Ni alloy foils. ACS Nano 2012, 6, 7731–7738. [Google Scholar] [CrossRef]

- Liu, X.; Fu, L.; Liu, N.; Gaa, T.; Zhang, Y.; Liao, L.; Liu, Z. Segregation growth of graphene on Cu-Ni alloy for precise layer control. J. Phys. Chem. C 2011, 115, 11976–11982. [Google Scholar] [CrossRef]

- Takesaki, Y.; Kawahara, K.; Hibino, H.; Okada, S.; Tsuji, M.; Ago, H. Highly uniform bilayer graphene on epitaxial Cu-Ni (111) alloy. Chem. Mater. 2016, 18, 4583–4592. [Google Scholar] [CrossRef]

- Lin, L.; Deng, B.; Sun, J.; Peng, H.; Liu, Z. Bridging the gap between reality ideal in chemical vapor deposition growth of graphene. Chem. Rev. 2018, 118, 9281–9343. [Google Scholar] [CrossRef] [PubMed]

- Lopez, G.; Mittemeijer, E. The solubility of C in solid Cu. Scr. Mater. 2004, 51, 1–5. [Google Scholar] [CrossRef]

- Thornton, J.A. The microstructure of sputter-deposited coatings. J. Vac. Sci. Technol. A 1986, 4, 3059–3065. [Google Scholar] [CrossRef]

- Butrymowicz, D.B.; Manning, J.R.; Read, M.E. Diffusion in copper and copper alloys. Part I. Volume and surface self-diffusion in copper. J. Phys. Chem. Ref. Data 1973, 2, 643–655. [Google Scholar] [CrossRef] [Green Version]

- Ferrari, A.C.; Meyer, J.C.; Scardaci, V.; Casiraghi, C.; Lazzeri, M.; Mauri, F.; Piscanec, S.; Jiang, D.; Novoselov, K.S.; Roth, S.; et al. Raman spectrum of graphene and graphene layers. Phys. Rev. Lett. 2006, 97, 187401. [Google Scholar] [CrossRef] [Green Version]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Khanna, S.R.; Stanford, M.G.; Vlassiouk, I.V.; Rack, P.D. Combinatorial Cu-Ni Alloy Thin-Film Catalysts for Layer Number Control in Chemical Vapor-Deposited Graphene. Nanomaterials 2022, 12, 1553. https://doi.org/10.3390/nano12091553

Khanna SR, Stanford MG, Vlassiouk IV, Rack PD. Combinatorial Cu-Ni Alloy Thin-Film Catalysts for Layer Number Control in Chemical Vapor-Deposited Graphene. Nanomaterials. 2022; 12(9):1553. https://doi.org/10.3390/nano12091553

Chicago/Turabian StyleKhanna, Sumeer R., Michael G. Stanford, Ivan V. Vlassiouk, and Philip D. Rack. 2022. "Combinatorial Cu-Ni Alloy Thin-Film Catalysts for Layer Number Control in Chemical Vapor-Deposited Graphene" Nanomaterials 12, no. 9: 1553. https://doi.org/10.3390/nano12091553

APA StyleKhanna, S. R., Stanford, M. G., Vlassiouk, I. V., & Rack, P. D. (2022). Combinatorial Cu-Ni Alloy Thin-Film Catalysts for Layer Number Control in Chemical Vapor-Deposited Graphene. Nanomaterials, 12(9), 1553. https://doi.org/10.3390/nano12091553