Effect of Crack Defects on Magnetostriction and Magnetic Moment Evolution of Iron Thin Films

Abstract

:1. Introduction

2. Calculation Method

3. Results and Discussion

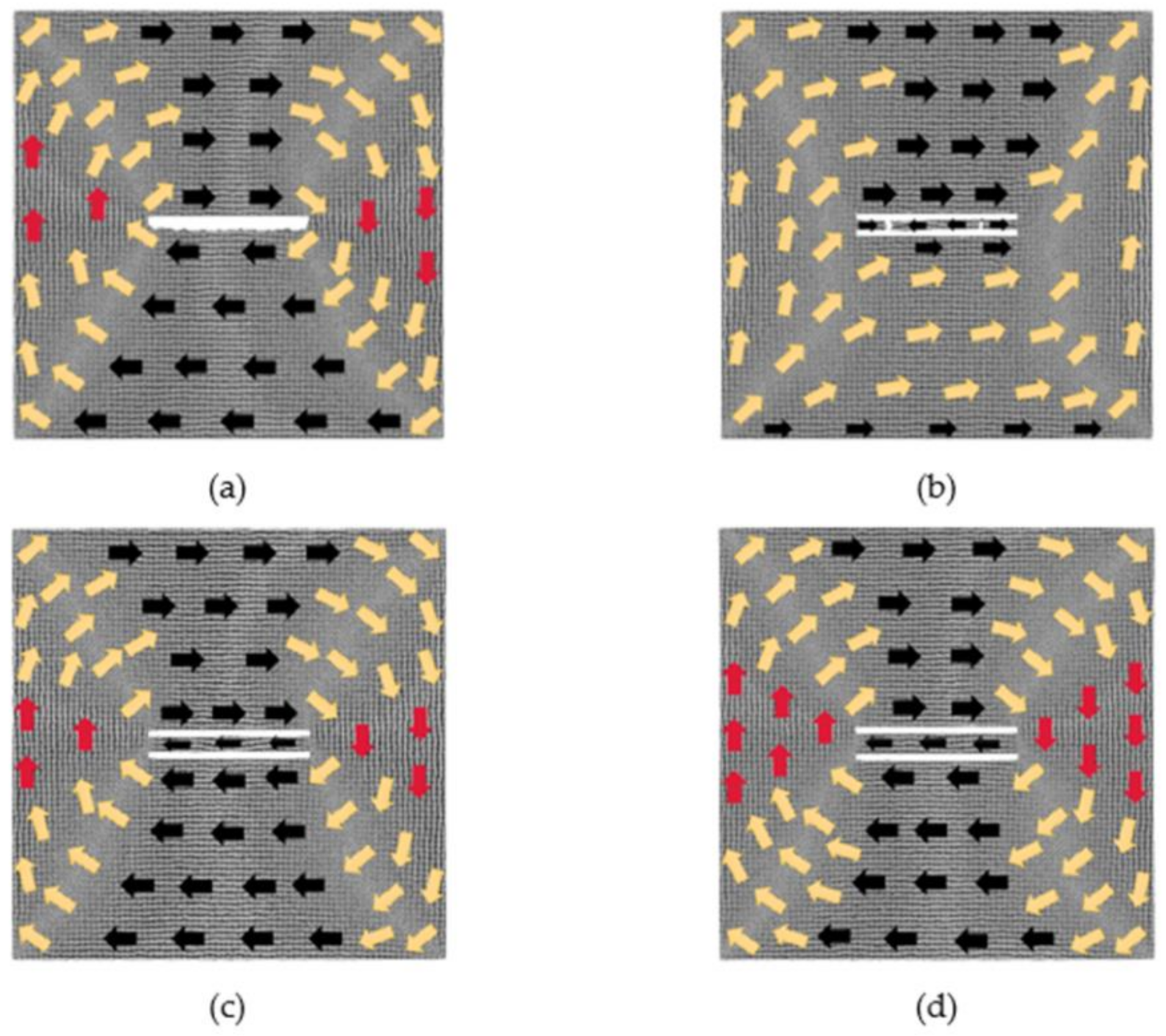

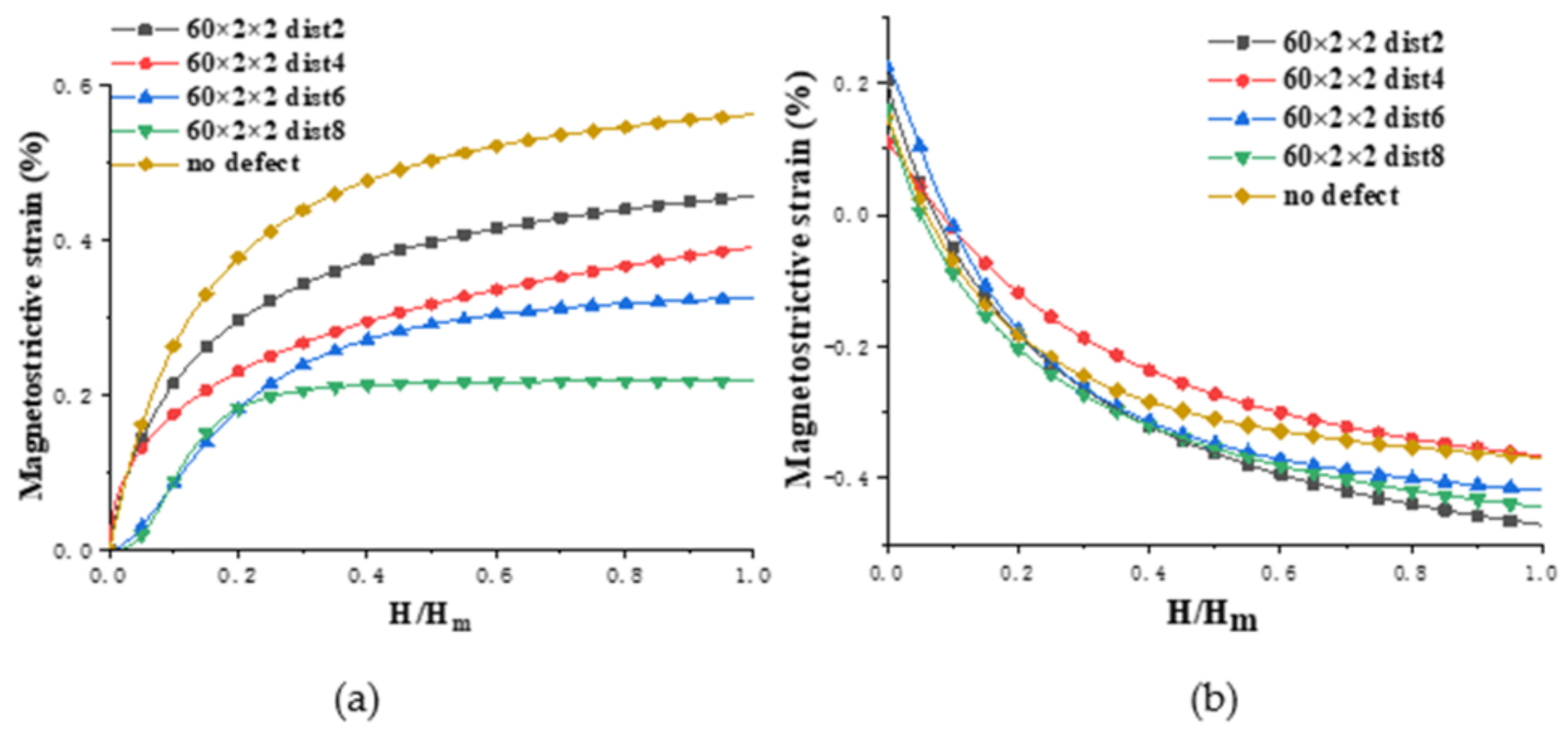

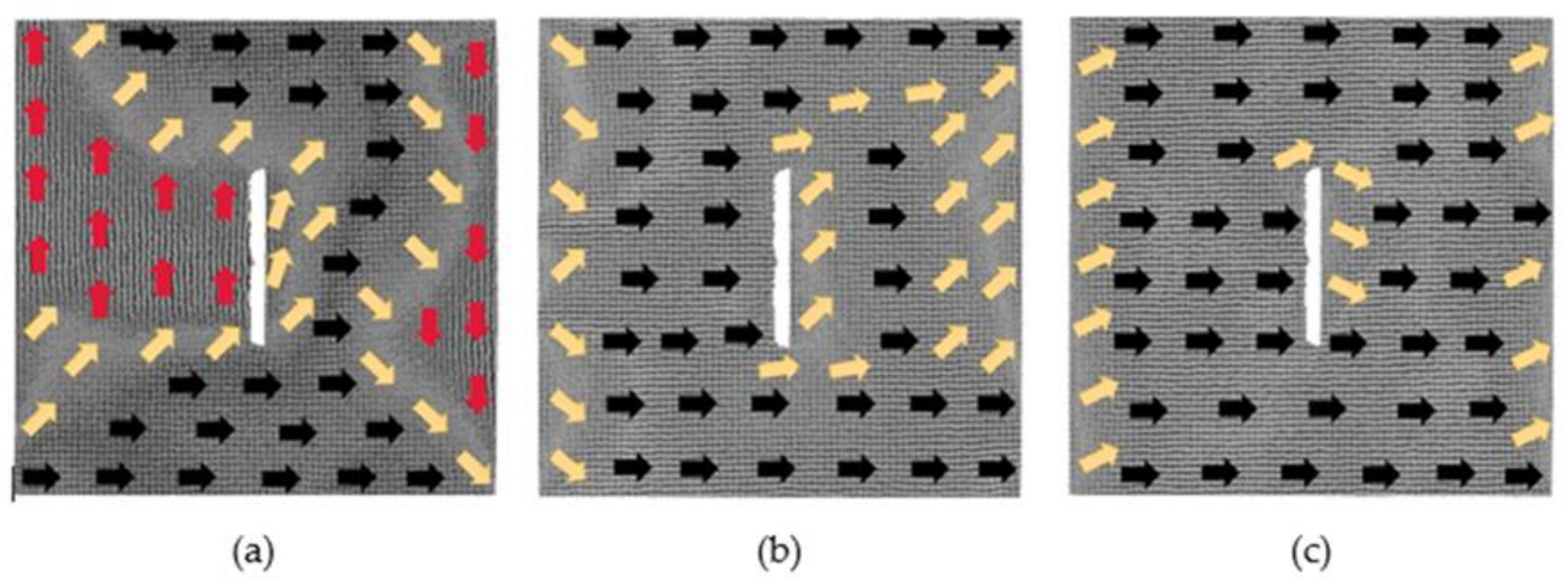

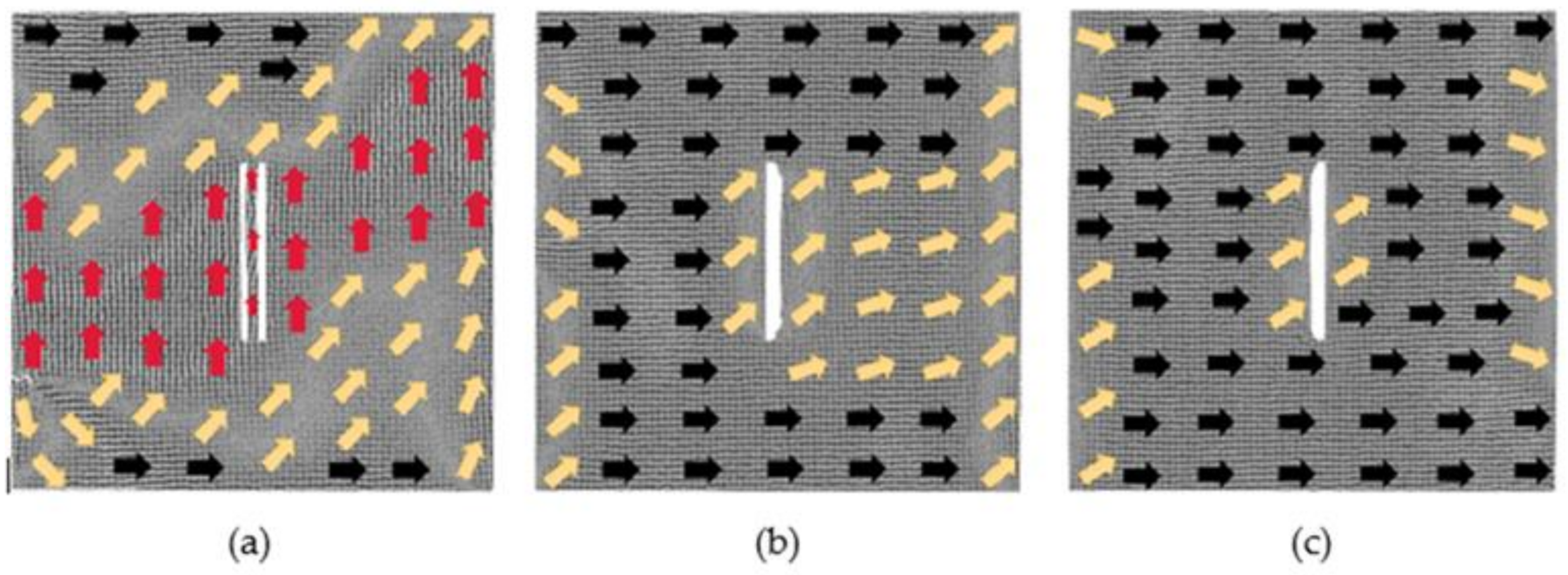

3.1. The Models with 60 × 2 × 2 Defects

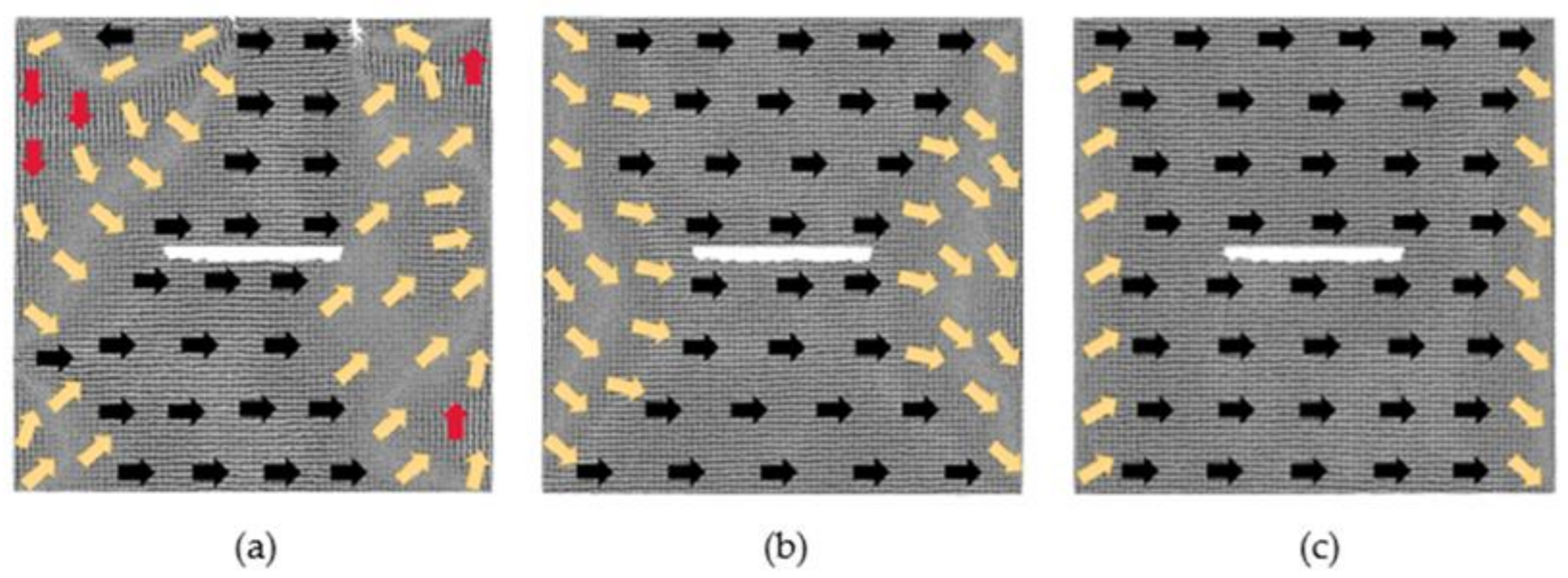

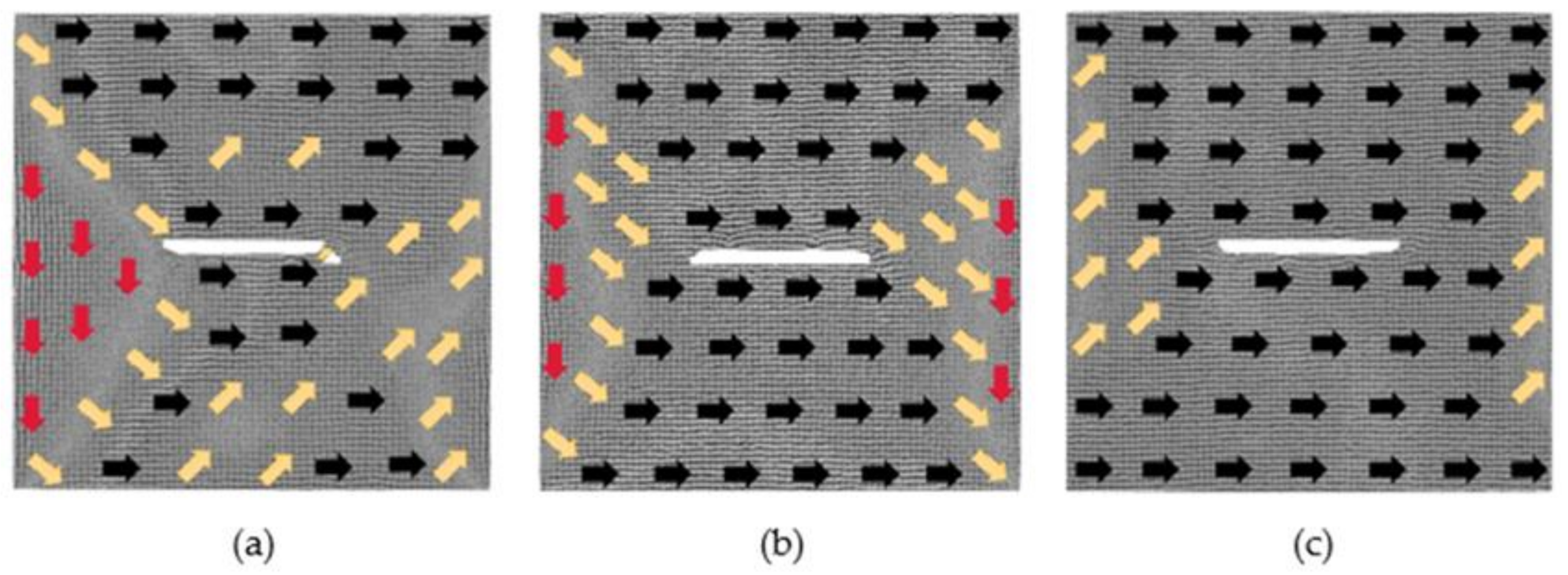

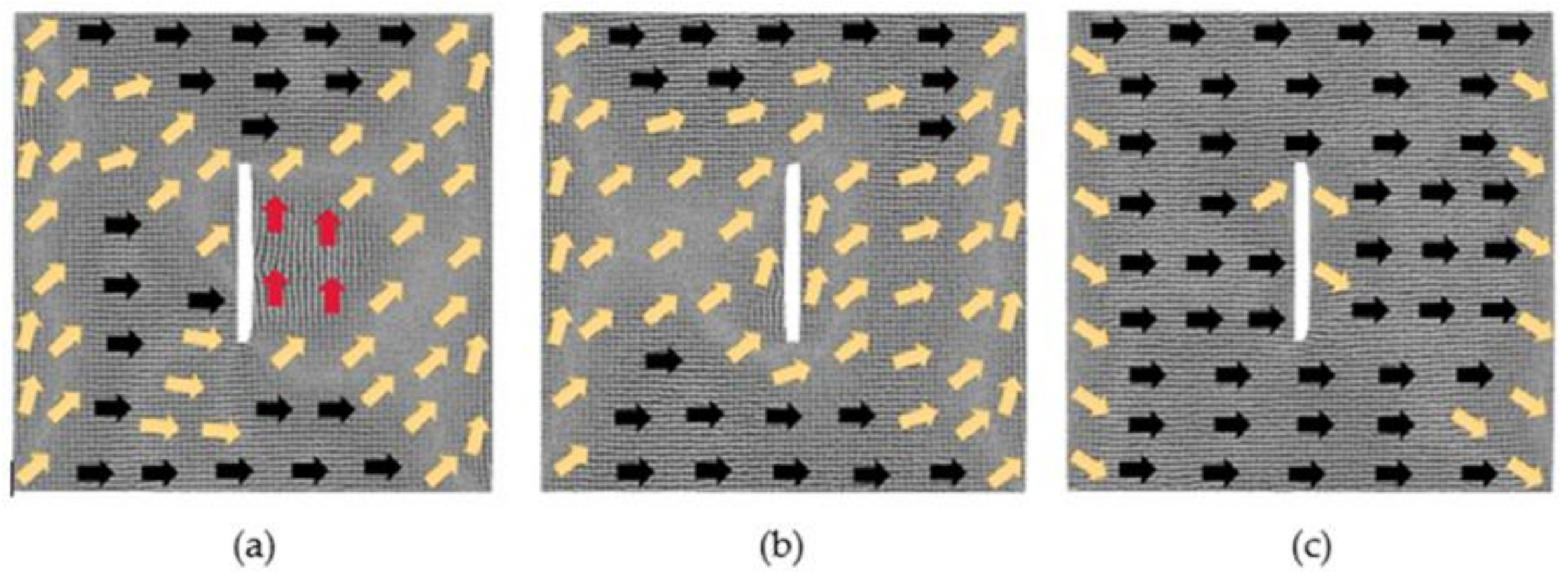

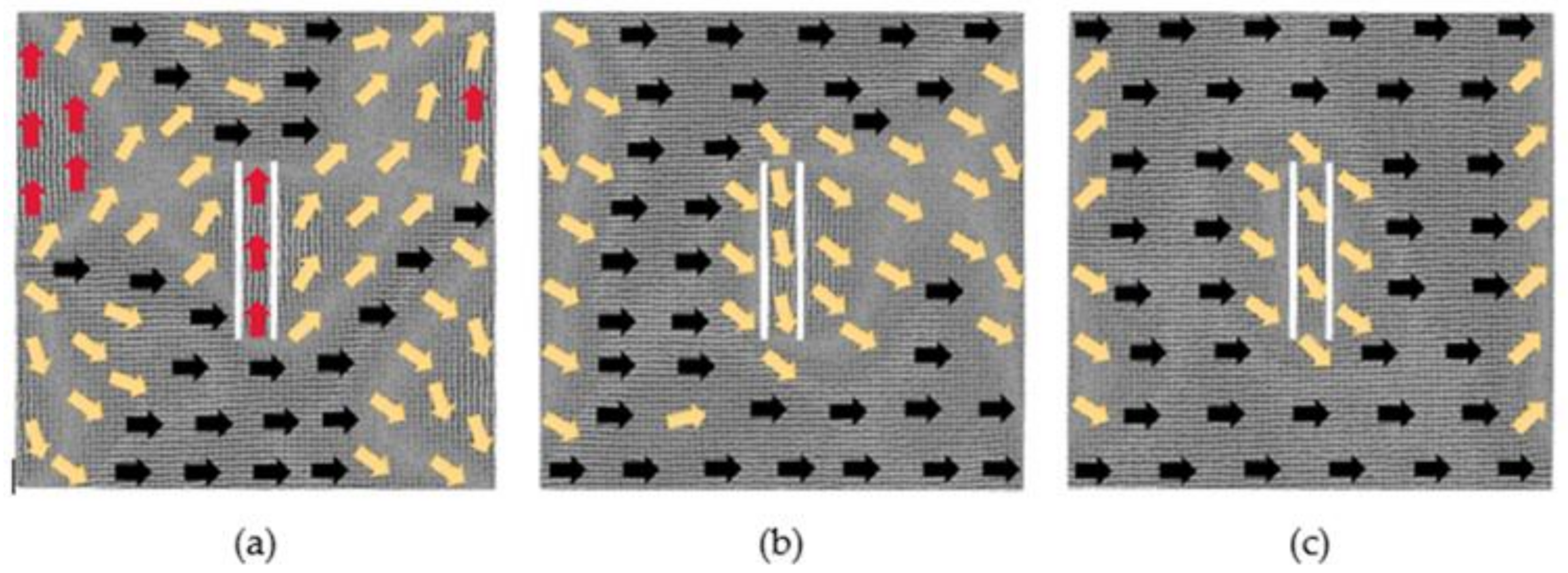

3.2. The Models with 2 × 60 × 2 Defects

4. Conclusions

- (1)

- The direction of defects and the defect spacing both affect the magnetostrictive properties of iron thin films.

- (2)

- If the defect spacing is constant, the iron model with a crack direction perpendicular to the magnetization direction has a higher magnetostriction than the iron model with a crack direction parallel to the magnetization direction. When the crack direction in the component is parallel to the magnetization direction, the atoms around the crack are easier to magnetize compared to when the crack direction is perpendicular in direction, which will result in a decrease of the maximum magnetostriction from the initial state to saturation in the magnetization direction.

- (3)

- The change of the distance between defects has a great influence on the magnetostrictive properties of the iron thin film model with the crack direction parallel to the magnetization direction, and it has a small influence on the magnetostrictive properties of the iron thin film model with the crack direction perpendicular to the magnetization direction.

- (4)

- When the distance between defects is small, in order to reach a more stable state under the magnetization of the magnetic field, the atoms between defects may move, resulting in two defects becoming one defect. When the distance between defects increases to a certain value, the atoms between defects will no longer move under any magnetic field.

- (5)

- Under the action of a strong magnetic field, both the iron model with crack direction parallel to the magnetization direction and the iron model with crack direction perpendicular to the magnetization direction reach saturation. In the former, only part of the atomic magnetic moment at the left and right boundaries of the model does not turn in the direction of the magnetization; in the latter, not only at the left and right boundaries of the model but also around the defect, the magnetic moment of some atoms does not turn in the direction of the magnetization.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Cullity, B.D.; Graham, C.D. Introduction to Magnetic Materials, 2nd ed.; John Wiley & Sons: Hoboken, NJ, USA, 2011; pp. 241–272. [Google Scholar]

- Wu, R.; Yang, Z.; Hong, J. First-principles determination of magnetic properties. J. Phys. Condens. Matter 2003, 15, S587–S598. [Google Scholar] [CrossRef]

- Ryu, J.; Carazo, A.V.; Uchino, K.; Kim, H.E. Magnetoelectric properties in piezoelectric and magnetostrictive laminate composites. Jpn. J. Appl. Phys. 2001, 40, 4948. [Google Scholar] [CrossRef]

- Alrub, A.M.; Lim, K.G.; Chew, K.H. Effect of magnetic and electric fields on electrical and magnetic properties of multiferroic BiMnO3 films. J. Magn. Magn. Mater. 2018, 458, 285–291. [Google Scholar] [CrossRef]

- Pei, H.; Jing, J.; Zhang, S. Experimental study on a new FBG-based and Terfenol-D inclinometer for slope displacement monitoring. Measurement 2020, 151, 107172. [Google Scholar] [CrossRef]

- García-Miquel, H.; Barrera, D.; Amat, R.; Kurlyandskaya, G.V.; Sales, S. Magnetic actuator based on giant magnetostrictive material Terfenol-D with strain and temperature monitoring using FBG optical sensor. Measurement 2016, 80, 201–206. [Google Scholar] [CrossRef]

- Makarova, L.A.; Alekhina, Y.A.; Isaev, D.A.; Khairullin, M.F.; Perov, N.S. Tunable layered composites based on magnetoactive elastomers and piezopolymer for sensors and energy harvesting devices. J. Phys. D Appl. Phys. 2020, 54, 015003. [Google Scholar] [CrossRef]

- Jia, X.; Chu, C.; Zhou, X.; Xiao, Y. Structural Design and Thermal-mechanical Coupling Analysis of a Novel Automobile Magnetostrictive Actuator. IOP Conf. Ser. Earth Environ. Sci. 2021, 804, 032023. [Google Scholar] [CrossRef]

- Zhukov, A.; Churyukanova, M.; Kaloshkin, S.; Semenkova, V.; Gudoshnikov, S.; Ipatov, M.; Talaat, A.; Blanco, J.M.; Zhukova, V. Effect of annealing on magnetic properties and magnetostriction coefficient of Fe–Ni-based amorphous microwires. J. Alloys Compd. 2015, 651, 718–723. [Google Scholar] [CrossRef]

- Naifar, S.; Bradai, S.; Viehweger, C.; Kanoun, O.; Choura, S. Investigation of the magnetostrictive effect in a terfenol-D plate under a non-uniform magnetic field by atomic force microscopy. Mater. Des. 2016, 97, 147–154. [Google Scholar] [CrossRef]

- Laroche, R.A.; Guruswamy, S. Influence of Ga content and high temperature annealing on the short range order and magnetostriction of Fe–Ga single crystals. J. Appl. Phys. 2020, 128, 195102. [Google Scholar] [CrossRef]

- Zhu, L.; Li, K.; Luo, Y.; Yu, D.; Wang, Z.; Wu, G.; Xie, J.; Tang, Z. Magnetostrictive properties and detection efficiency of TbDyFe/FeCo composite materials for nondestructive testing. J. Rare Earths 2019, 37, 166–170. [Google Scholar] [CrossRef]

- Clark, A.E.; Hathaway, K.B.; Wun-Fogle, M.; Restorff, J.B.; Lograsso, T.A.; Keppens, V.M.; Petculescu, G.; Taylor, R.A. Extraordinary magnetoelasticity and lattice softening in bcc Fe-Ga alloys. J. Appl. Phys. 2003, 93, 8621–8623. [Google Scholar] [CrossRef] [Green Version]

- Ramazanov, S.; Sobola, D.; Orudzhev, F.; Knápek, A.; Počlák, J.; Potoček, M.; Kaspar, P.; Dallaev, R. Surface modification and enhancement of ferromagnetism in BiFeO3 nanofilms deposited on HOPG. Nanomaterials 2020, 10, 1990. [Google Scholar] [CrossRef] [PubMed]

- Kellogg, R.A.; Flatau, A.B.; Clark, A.E.; Wun-Fogle, M.; Lograsso, T.A. Temperature and stress dependencies of the magnetic and magnetostrictive properties of Fe0.81 Ga0.19. J. Appl. Phys. 2002, 91, 7821–7823. [Google Scholar] [CrossRef]

- Zhang, H.; Zeng, D.C.; Liu, Z.W. Effect of compressive stress on the magnetization and magnetostriction of Fe0.81 Ga0.19 alloy. Acta Phys. Sin. 2011, 60, 672–676. [Google Scholar] [CrossRef]

- Shi, P.p.; Hao, S. Analytical solution of magneto-mechanical magnetic dipolemodel for metal magnetic memory method. Acta Phys. Sin. 2021, 70, 105–114. [Google Scholar] [CrossRef]

- Hu, W.L.; Ren, W.J.; Zhou, P.; Wang, Z.; Ren, J.L. Experimental study on domain structure of ferromagnetic materials under static tension. Nondestruct. Test. Technol. 2012, 36, 5–7. [Google Scholar]

- Wang, P.; Zhang, Y.; Yao, E.; Mi, Y.; Zheng, Y.; Tang, C. Method of measuring the mechanical properties of ferromagnetic materials based on magnetostrictive EMAT characteristic parameters. Measurement 2021, 168, 108187. [Google Scholar] [CrossRef]

- Zhang, S.; Long, L.C.; Liu, J.E.; Yang, Y. Effect of defects on magnetostriction and magnetic moment evolution of iron thin films. Acta Phys. Sin. 2022, 71, 284–289. [Google Scholar]

- Tranchida, J.; Plimpton, S.J.; Thibaudeau, P.; Thompson, A.P. Massively parallel symplectic algorithm for coupled magnetic spin dynamics and molecular dynamics. J. Comput. Phys. 2018, 372, 406–425. [Google Scholar] [CrossRef] [Green Version]

- Jeong, J.; Goremychkin, E.A.; Guidi, T.; Nakajima, K.; Jeon, G.S.; Kim, S.A.; Park, J.G. Spin wave measurements over the full brillouin zone of multiferroic BiFeO3. Phys. Rev. Lett. 2012, 108, 077202. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Kvashnin, Y.O.; Cardias, R.; Szilva, A.; Di Marco, I.; Katsnelson, M.I.; Lichtenstein, A.I.; Nordstrom, L.; Klautau, A.; Eriksson, O. Microscopic origin of Heisenberg and non-Heisenberg exchange interactions in ferromagnetic bcc Fe. Phys. Rev. Lett. 2016, 116, 217202. [Google Scholar] [CrossRef] [PubMed]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yang, H.; Zhang, M.; Long, L. Effect of Crack Defects on Magnetostriction and Magnetic Moment Evolution of Iron Thin Films. Nanomaterials 2022, 12, 1236. https://doi.org/10.3390/nano12071236

Yang H, Zhang M, Long L. Effect of Crack Defects on Magnetostriction and Magnetic Moment Evolution of Iron Thin Films. Nanomaterials. 2022; 12(7):1236. https://doi.org/10.3390/nano12071236

Chicago/Turabian StyleYang, Hongwei, Meng Zhang, and Lianchun Long. 2022. "Effect of Crack Defects on Magnetostriction and Magnetic Moment Evolution of Iron Thin Films" Nanomaterials 12, no. 7: 1236. https://doi.org/10.3390/nano12071236

APA StyleYang, H., Zhang, M., & Long, L. (2022). Effect of Crack Defects on Magnetostriction and Magnetic Moment Evolution of Iron Thin Films. Nanomaterials, 12(7), 1236. https://doi.org/10.3390/nano12071236