α-Fe2O3 Nanoparticles Aided-Dual Conversion for Self-Powered Bio-Based Photodetector

Abstract

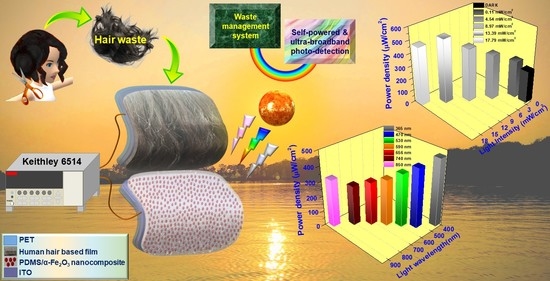

:1. Introduction

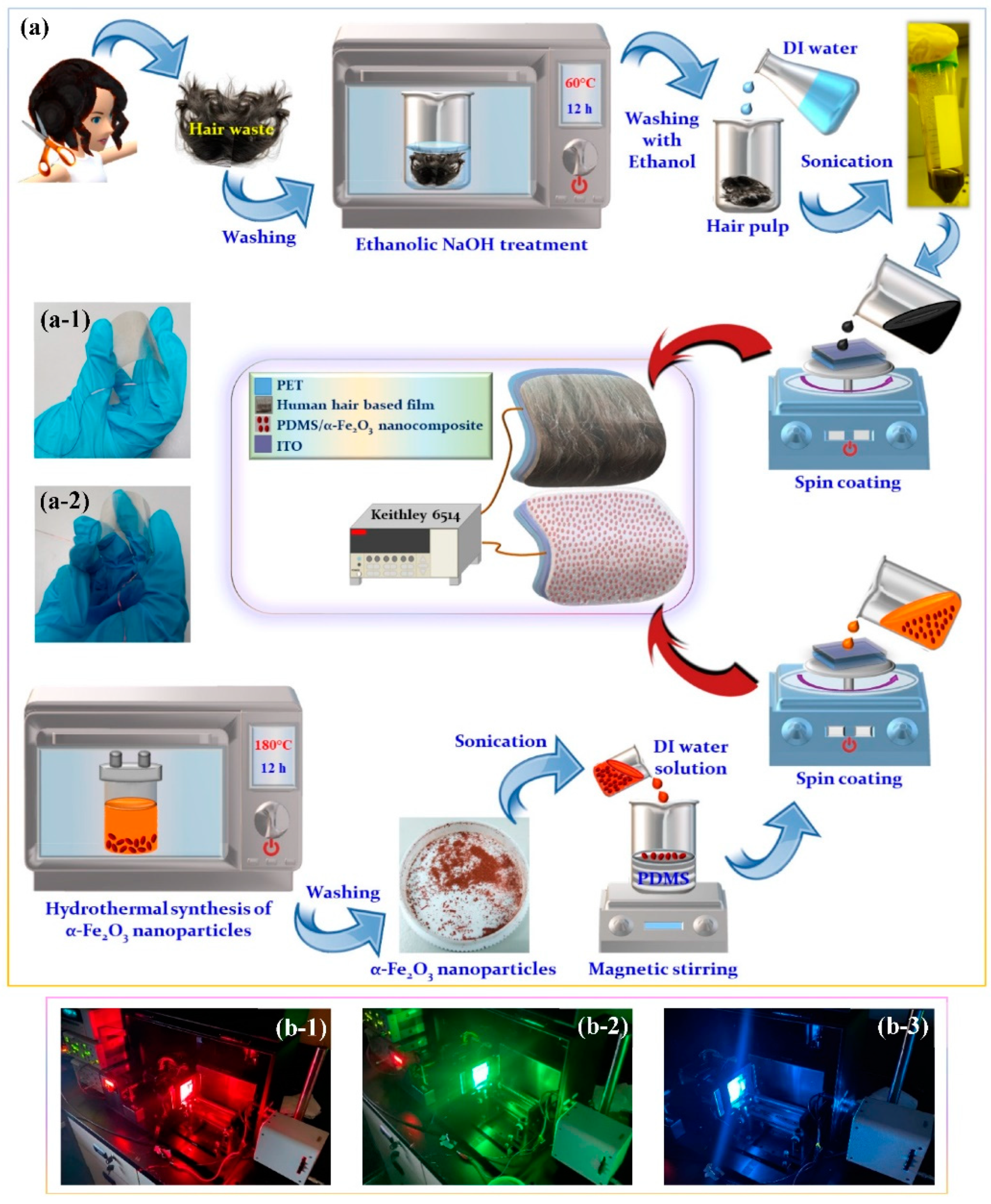

2. Materials and Methods

2.1. Hydrothermal Synthesis of α-Fe2O3 Nanoparticles

2.2. Fabrication of PDMS Film and PDMS/α-Fe2O3 Nanocomposite Film-Based Negative Tribo-Layer

2.3. Fabrication of a Processed Human Hair-Based Positive Tribo-Layer

2.4. Fabrication of the TENG Device

2.5. Material Characterization and Electrical Measurement

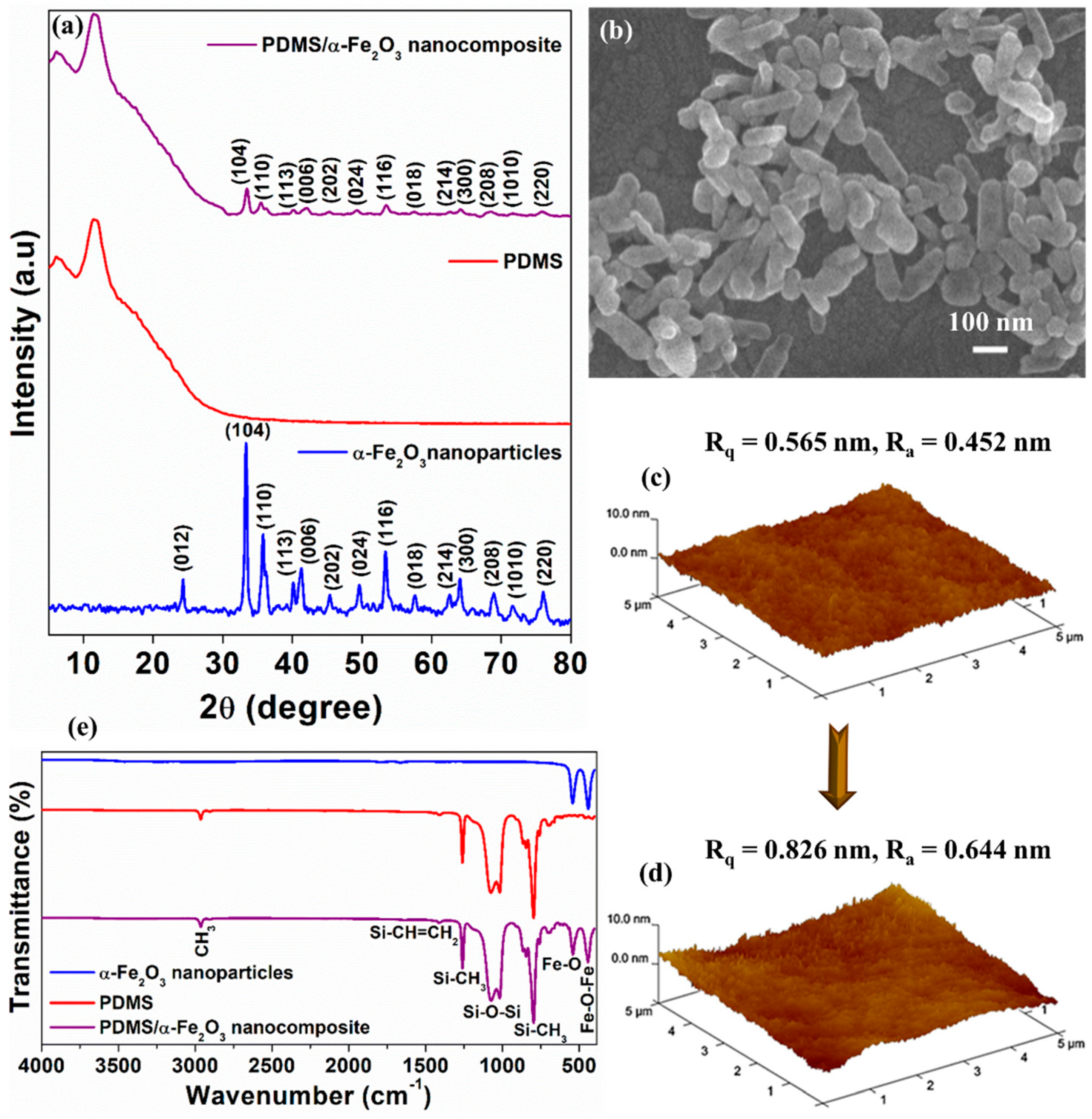

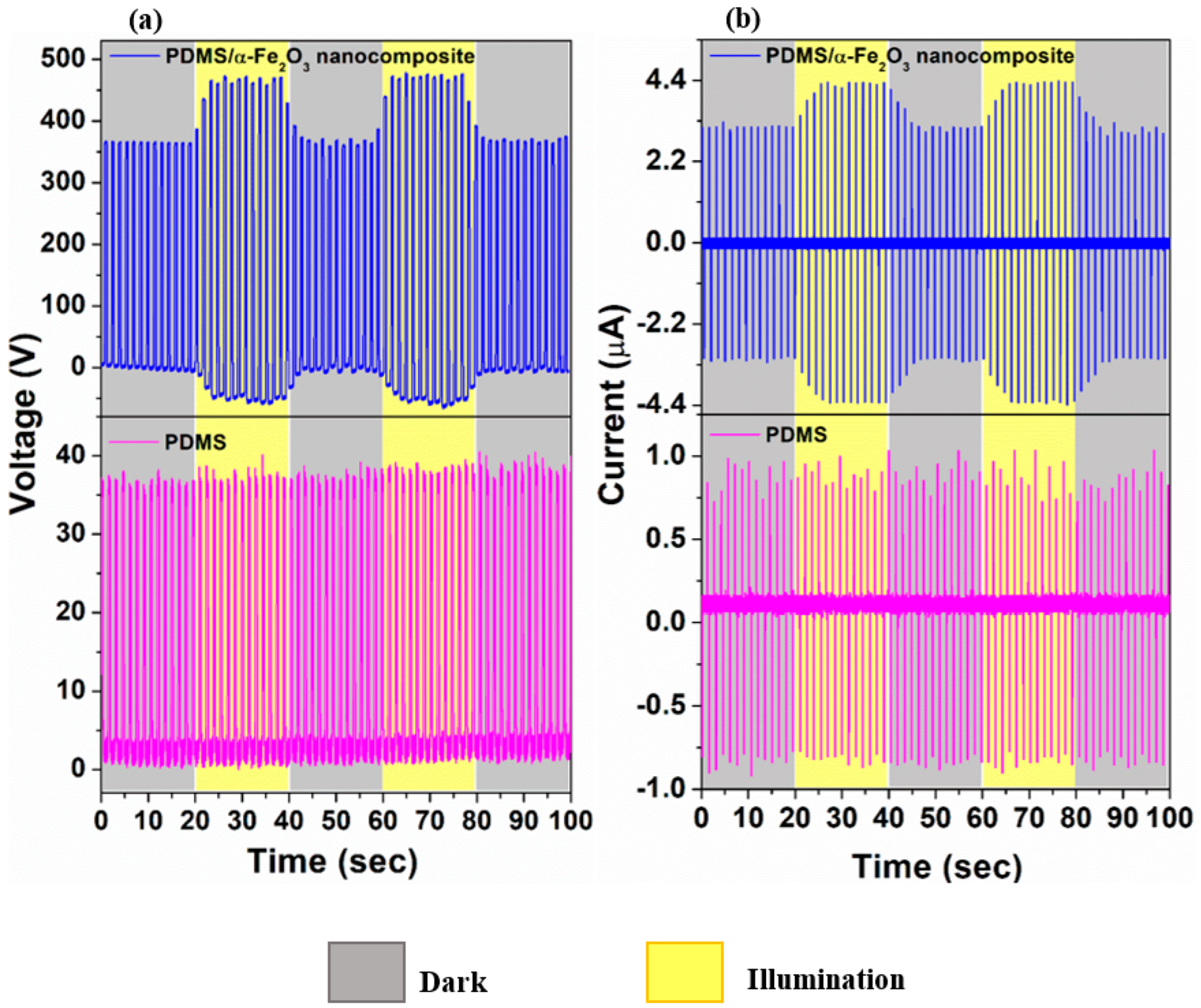

3. Results and Discussion

3.1. Structural and Compositional Analysis

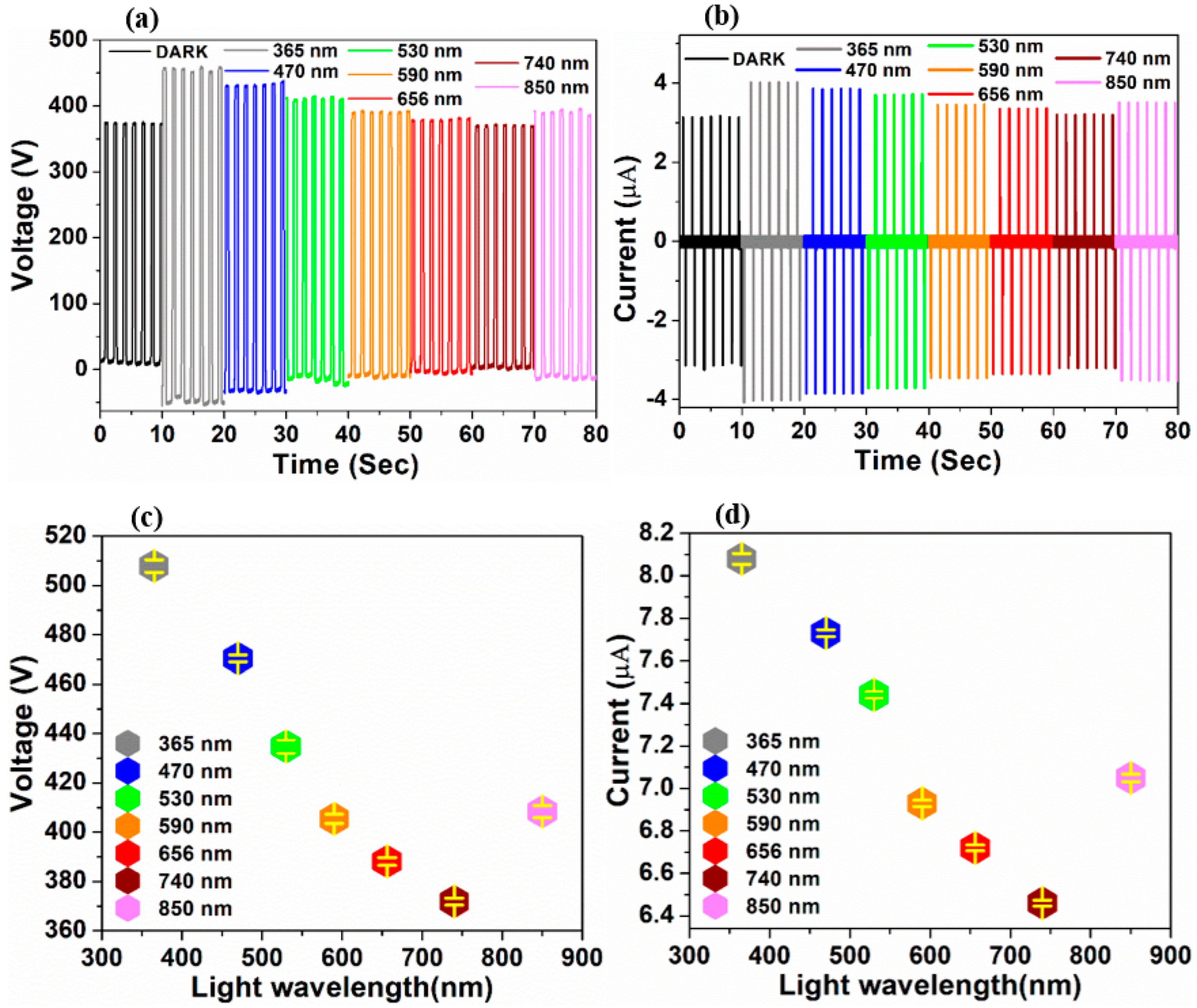

3.2. Electrical Performance

3.3. Mechanism Discussion

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Erturk, A.; Hoffmann, J.; Inman, D.J. A piezomagnetoelastic structure for broadband vibration energy harvesting. Appl. Phys. Lett. 2009, 94, 254102. [Google Scholar] [CrossRef]

- Fang, H.; Li, Q.; Ding, J.; Li, N.; Tian, H.; Zhang, L.; Ren, T.; Dai, J.; Wang, L.; Yan, Q. A self-powered organolead halide perovskite single crystal photodetector driven by a DVD-based triboelectric nanogenerator. J. Mater. Chem. C 2016, 4, 630–636. [Google Scholar] [CrossRef]

- Han, T.; Zhao, J.; Yuan, T.; Lei, D.Y.; Li, B.; Qiu, C.W. Theoretical realization of an ultra-efficient thermal energy harvesting cell made of natural materials. Energy Environ. Sci. 2013, 6, 3537–3541. [Google Scholar] [CrossRef] [Green Version]

- Zhang, C.L.; Chen, W.Q.; Zhang, C.H. Magnetoelectric effects in functionally graded multiferroic bilayers. J. Appl. Phys. 2013, 113, 084502. [Google Scholar] [CrossRef]

- Indira, S.S.; Vaithilingam, C.A.; Oruganti, K.S.P.; Mohd, F.; Rahman, S. Nanogenerators as a Sustainable Power Source: State of Art, Applications, and Challenges. Nanomaterials 2019, 9, 773. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Ding, Z.; Zou, M.; Yao, P.; Zhu, Z.; Fan, L. A Triboelectric Nanogenerator Based on Sodium Chloride Powder for Self-Powered Humidity Sensor. Nanomaterials 2021, 11, 2657. [Google Scholar] [CrossRef]

- Han, X.; Zhang, Q.; Yu, J.; Song, J.; Li, Z.; Cui, H.; He, J.; Chou, X.; Mu, J. Self-Powered Acceleration Sensor Based on Multilayer Suspension Structure and TPU-RTV Film for Vibration Monitoring. Nanomaterials 2021, 11, 2763. [Google Scholar] [CrossRef] [PubMed]

- Garcia, C.; Trendafilova, I.; Villoria, R.G.D.; Rio, J.S.D. Self-powered pressure sensor based on the triboelectric effect and its analysis using dynamic mechanical analysis. Nano Energy 2018, 50, 401–409. [Google Scholar] [CrossRef] [Green Version]

- Zheng, Q.; Zhang, H.; Shi, B.; Xue, X.; Liu, Z.; Jin, Y.; Ma, Y.; Zou, Y.; Wang, X.; An, Z.; et al. In Vivo Self-Powered Wireless Cardiac Monitoring via Implantable Triboelectric Nanogenerator. ACS Nano 2016, 10, 6510–6518. [Google Scholar] [CrossRef]

- Wu, J.M.; Lin, Y.H.; Yang, B.Z. Force-pad made from contact-electrification poly(ethylene oxide)/InSb field-effect transistor. Nano Energy 2016, 22, 468–474. [Google Scholar] [CrossRef]

- Kim, K.N.; Chun, J.; Kim, J.W.; Lee, K.Y.; Park, J.U.; Kim, S.W.; Wang, Z.L.; Baik, J.M. Highly Stretchable 2D Fabrics for Wearable Triboelectric Nanogenerator under Harsh Environments. ACS Nano 2015, 9, 6394–6400. [Google Scholar] [CrossRef]

- Zi, Y.; Wang, J.; Wang, S.; Li, S.; Wen, Z.; Guo, H.; Wang, Z.L. Effective energy storage from a triboelectric nanogenerator. Nat. Commun. 2016, 7, 10987. [Google Scholar] [CrossRef] [Green Version]

- Sahoo, M.; Lai, S.N.; Wu, J.M.; Wu, M.C.; Lai, C.S. Flexible Layered-Graphene Charge Modulation for Highly Stable Triboelectric Nanogenerator. Nanomaterials 2021, 11, 2276. [Google Scholar] [CrossRef] [PubMed]

- Wu, J.M.; Lee, C.C.; Lin, Y.H. High sensitivity wrist-worn pulse active sensor made from tellurium dioxide microwires. Nano Energy 2015, 14, 102–110. [Google Scholar] [CrossRef]

- Wang, Z.L. Triboelectric Nanogenerator (TENG)—Sparking an Energy and Sensor Revolution. Adv. Energy Mater. 2020, 10, 2000137. [Google Scholar] [CrossRef] [Green Version]

- Lai, S.N.; Chang, C.K.; Yang, C.S.; Su, C.W.; Leu, C.M.; Chu, Y.H.; Sha, P.W.; Wu, J.M. Ultrasensitivity of self-powered wireless triboelectric vibration sensor for operating in underwater environment based on surface functionalization of rice husks. Nano Energy 2019, 60, 715–723. [Google Scholar] [CrossRef]

- Hu, X.; Li, X.; Li, G.; Ji, T.; Ai, F.; Wu, J.; Ha, E.; Hu, J. Recent Progress of Methods to Enhance Photovoltaic Effect for Self-Powered Heterojunction Photodetectors and Their Applications in Inorganic Low-Dimensional Structures. Adv. Funct. Mater. 2021, 31, 2011284. [Google Scholar] [CrossRef]

- Han, J.; Yang, X.; Liao, L.; Zhou, G.; Wang, G.; Xu, C.; Hu, W.; Debora, M.E.R.; Song, Q. Photoinduced triboelectric polarity reversal and enhancement of a new metal/semiconductor triboelectric nanogenerator. Nano Energy 2019, 58, 331–337. [Google Scholar] [CrossRef]

- Wang, J.; Qian, S.; Yu, J.; Zhang, Q.; Yuan, Z.; Sang, S.; Zhou, X.; Sun, L. Flexible and Wearable PDMS-Based Triboelectric Nanogenerator for Self-Powered Tactile Sensing. Nanomaterials 2019, 9, 1304. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Chakraborty, I.; Lai, S.N.; Wu, M.C.; Lin, H.Y.; Li, C.; Wu, J.M.; Lai, C.S. Charge trapping with α-Fe2O3 nanoparticles accompanied by human hair towards an enriched triboelectric series and a sustainable circular bioeconomy. Mater. Horiz. 2021, 8, 3149–3162. [Google Scholar] [CrossRef] [PubMed]

- Sundaramurthy, J.; Kumar, P.S.; Kalaivani, M.; Thavasi, V.; Mhaisalkara, S.G.; Ramakrishna, S. Superior photocatalytic behaviour of novel 1D nanobraid and nanoporous α-Fe2O3 structures. RSC Adv. 2012, 2, 8201–8208. [Google Scholar] [CrossRef]

- Joya, M.R.; Ortega, J.B.; Malafatti, J.O.D.; Paris, E.C. Evaluation of Photocatalytic Activity in Water Pollutants and Cytotoxic Response of α-Fe2O3 Nanoparticles. ACS Omega 2019, 4, 17477–17486. [Google Scholar] [CrossRef] [Green Version]

- Wu, J.M.; Chang, C.K.; Chang, Y.T. High-output current density of the triboelectric nanogenerator made from recycling rice husks. Nano Energy 2016, 19, 39–47. [Google Scholar] [CrossRef]

- Zhang, R.; Dahlström, C.; Zou, H.; Jonzon, J.; Hummelgård, M.; Örtegren, J.; Blomquist, N.; Yang, Y.; Andersson, H.; Olsen, M.; et al. Cellulose-Based Fully Green Triboelectric Nanogenerators with Output Power Density of 300 W m−2. Adv. Mater. 2020, 32, 2002824. [Google Scholar] [CrossRef] [PubMed]

- Binitha, G.; Soumya, M.S.; Madhavan, A.A.; Praveen, P.; Balakrishnan, A.; Subramanian, K.R.V.; Reddy, M.V.; Nair, S.V.; Nair, A.S.; Sivakumar, N. Electrospun α-Fe2O3 nanostructures for supercapacitor applications. J. Mater. Chem. A 2013, 1, 11698–11704. [Google Scholar] [CrossRef]

- Gao, X.; Liu, H.; Wei, H.; Zheng, J.; Huang, G. Effect of incompletely condensed tri-silanol-phenyl-POSS on the thermal stability of silicone rubber. Polym. Bull. 2019, 76, 2835–2850. [Google Scholar] [CrossRef]

- Im, J.S.; Park, I.K. Mechanically Robust Magnetic Fe3O4 Nanoparticle/Polyvinylidene Fluoride Composite Nanofiber and Its Application in a Triboelectric Nanogenerator. ACS Appl. Mater. Interfaces 2018, 10, 25660–25665. [Google Scholar] [CrossRef]

- Dissanayake, D.M.S.N.; Mantilaka, M.M.M.G.P.G.; Palihawadana, T.C.; Chandrakumara, G.T.D.; Silva, R.T.D.; Pitawala, H.M.T.G.A.; Silva, K.M.N.D.; Amaratunga, G.A.J. Facile and low-cost synthesis of pure hematite (α-Fe2O3) nanoparticles from naturally occurring laterites and their superior adsorption capability towards acid-dyes. RSC Adv. 2019, 9, 21249–21257. [Google Scholar] [CrossRef] [Green Version]

- Lee, J.; Kim, J.; Kim, H.; Bae, Y.M.; Lee, K.H.; Cho, H.J. Effect of thermal treatment on the chemical resistance of polydimethylsiloxane for microfluidic devices. J. Micromech. Microeng. 2013, 23, 035007. [Google Scholar] [CrossRef]

- Stafie, N.; Stamatialis, D.F.; Wessling, M. Effect of PDMS cross-linking degree on the permeation performance of PAN/PDMS composite nanofiltration membranes. Sep. Purif. Technol. 2005, 45, 220–231. [Google Scholar] [CrossRef]

- Jayaweera, E.N.; Wijewardhana, K.R.; Ekanayaka, T.K.; Shahzad, A.; Song, J.K. Triboelectric Nanogenerator Based on Human Hair. ACS Sustain. Chem. Eng. 2018, 6, 6321–6327. [Google Scholar] [CrossRef]

- Mujeeb, M.A.; Zafar, M.K.M. FTIR Spectroscopic Analysis on Human Hair. Int. J. Innov. Res. Sci. Eng. Technol. 2017, 6, 9327–9332. [Google Scholar]

- Chan, K.L.A.; Kazarian, S.G.; Mavraki, A.; Williams, D.R. Fourier Transform Infrared Imaging of Human Hair with a High Spatial Resolution without the Use of a Synchrotron. Appl. Spectrosc. 2005, 59, 149–155. [Google Scholar] [CrossRef] [PubMed]

- Garidel, P.; Schott, H. Fourier-transform midinfrared spectroscopy for analysis and screening of liquid protein formulations. Part 1: Understanding infrared spectroscopy of proteins. BioProcess Int. 2006, 4, 40–46. [Google Scholar]

- Su, L.; Zhao, Z.X.; Li, H.Y.; Yuan, J.; Wang, Z.L.; Cao, G.Z.; Zhu, G. High-Performance Organolead Halide Perovskite-Based Self-Powered Triboelectric Photodetector. ACS Nano 2015, 9, 11310–11316. [Google Scholar] [CrossRef] [PubMed]

- Rufus, A.; Sreeju, N.; Philip, D. Synthesis of biogenic hematite (α-Fe2O3) nanoparticles for antibacterial and nanofluid applications. RSC Adv. 2016, 6, 94206–94217. [Google Scholar] [CrossRef]

- Zou, H.; Zhang, Y.; Guo, L.; Wang, P.; He, X.; Dai, G.; Zheng, H.; Chen, C.; Wang, A.C.; Xu, C.; et al. Quantifying the triboelectric series. Nat. Commun. 2019, 10, 1427. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Hu, J.; Zhang, M.; He, Y.; Zhang, M.; Shen, R.; Zhang, Y.; Wang, M.; Wu, G. Fabrication and Potential Applications of Highly Durable Superhydrophobic Polyethylene Terephthalate Fabrics Produced by In-Situ Zinc Oxide (ZnO) Nanowires Deposition and Polydimethylsiloxane (PDMS) Packaging. Polymers 2020, 12, 2333. [Google Scholar] [CrossRef] [PubMed]

- Pendlebury, S.R.; Wang, X.; Formal, F.L.; Cornuz, M.; Kafizas, A.; Tilley, S.D.; Grätzel, M.; Durrant, J.R. Ultrafast Charge Carrier Recombination and Trapping in Hematite Photoanodes under Applied Bias. J. Am. Chem. Soc. 2014, 136, 9854–9857. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Wen, R.; Guo, J.; Yu, A.; Zhai, J.; Wang, Z.L. Humidity-Resistive Triboelectric Nanogenerator Fabricated Using Metal Organic Framework Composite. Adv. Funct. Mater. 2019, 29, 1807655. [Google Scholar] [CrossRef]

- Thomas, P.; Abraham, K.E. Morphology-dependent space charge polarization and dielectric relaxation of CdO nanomorphotypes. J. Adv. Dielect. 2016, 6, 1650030. [Google Scholar] [CrossRef] [Green Version]

- Sadasivuni, K.K.; Mohiuddin, M.; Gao, X.; Akther, A.; Mun, S.; Kim, J. Cellulose/PDMS hybrid material for actuating lens. In Proceedings of the Nanosensors, Biosensors, and Info-Tech Sensors and Systems 2015, San Diego, CA, USA, 8–12 March 2015; Volume 9434, p. 94340K. [Google Scholar]

- Bilent, S.; Dinh, T.H.N.; Martincic, E.; Joubert, P.Y. Influence of the Porosity of Polymer Foams on the Performances of Capacitive Flexible Pressure Sensors. Sensors 2019, 19, 1968. [Google Scholar] [CrossRef] [PubMed] [Green Version]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chakraborty, I.; Lai, S.-N.; Wu, J.-M.; Lai, C.-S. α-Fe2O3 Nanoparticles Aided-Dual Conversion for Self-Powered Bio-Based Photodetector. Nanomaterials 2022, 12, 1147. https://doi.org/10.3390/nano12071147

Chakraborty I, Lai S-N, Wu J-M, Lai C-S. α-Fe2O3 Nanoparticles Aided-Dual Conversion for Self-Powered Bio-Based Photodetector. Nanomaterials. 2022; 12(7):1147. https://doi.org/10.3390/nano12071147

Chicago/Turabian StyleChakraborty, Ishita, Sz-Nian Lai, Jyh-Ming Wu, and Chao-Sung Lai. 2022. "α-Fe2O3 Nanoparticles Aided-Dual Conversion for Self-Powered Bio-Based Photodetector" Nanomaterials 12, no. 7: 1147. https://doi.org/10.3390/nano12071147

APA StyleChakraborty, I., Lai, S.-N., Wu, J.-M., & Lai, C.-S. (2022). α-Fe2O3 Nanoparticles Aided-Dual Conversion for Self-Powered Bio-Based Photodetector. Nanomaterials, 12(7), 1147. https://doi.org/10.3390/nano12071147