High Performance Polycarbonate Nanocomposites Mechanically Boosted with Titanium Carbide in Material Extrusion Additive Manufacturing

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Nanocomposites Fabrication

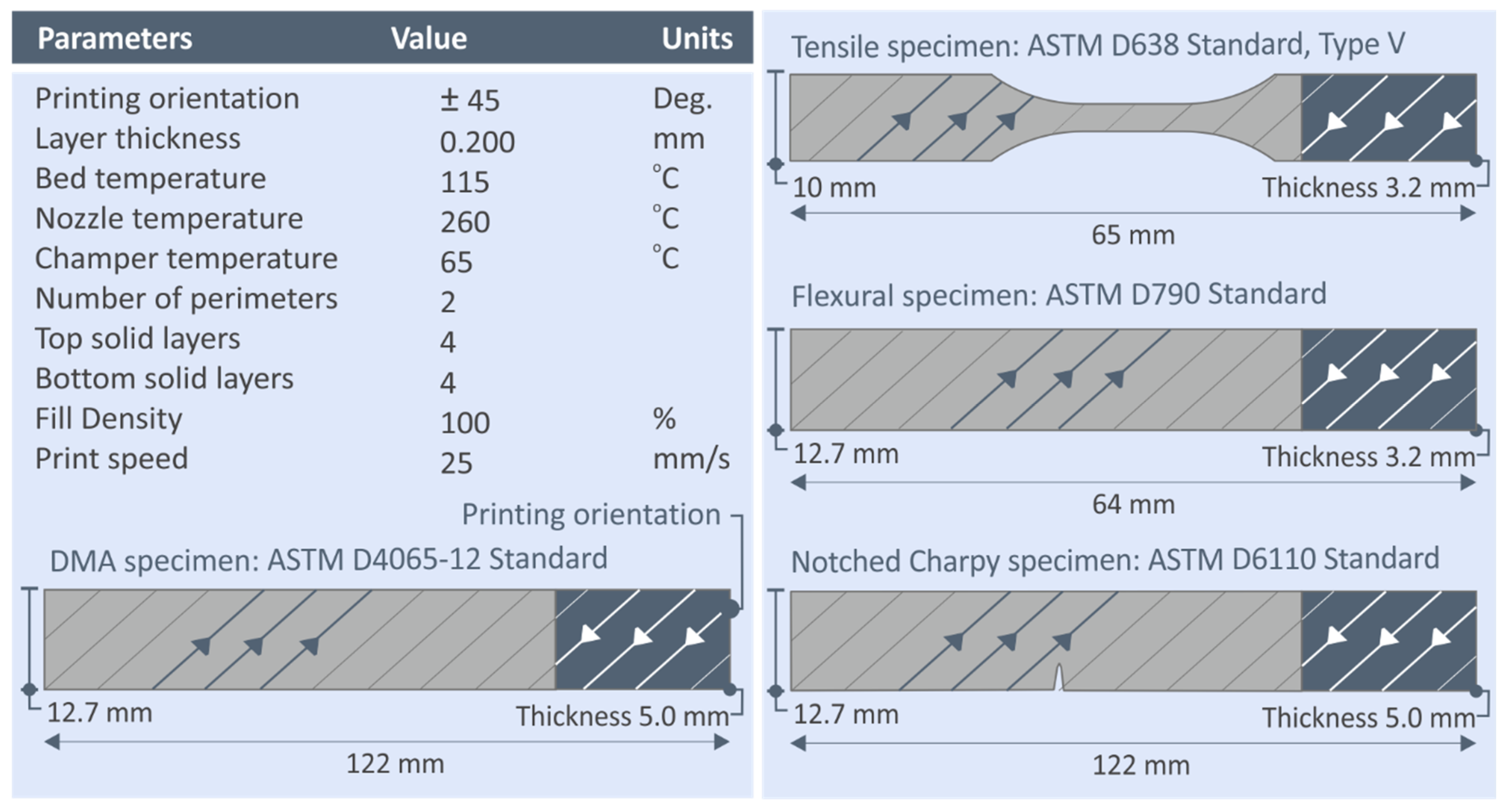

2.3. Specimens Fabrication

2.4. Thermal and Spectroscopic Properties Investigation

2.5. Nanocomposites Produced Filament Evaluation

2.6. Mechanical Characterization of the Nanocomposites

2.7. Morphological Characterization

3. Results

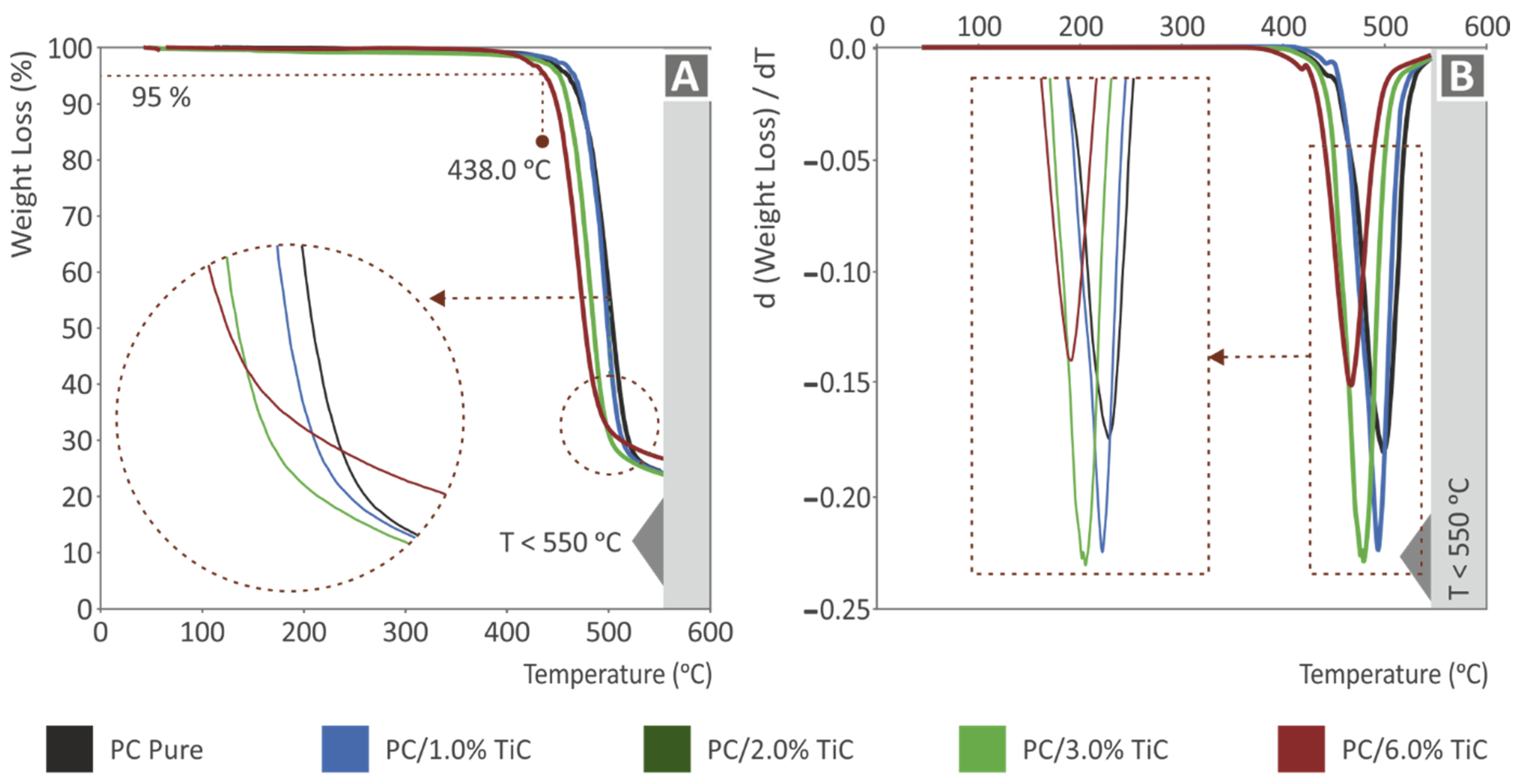

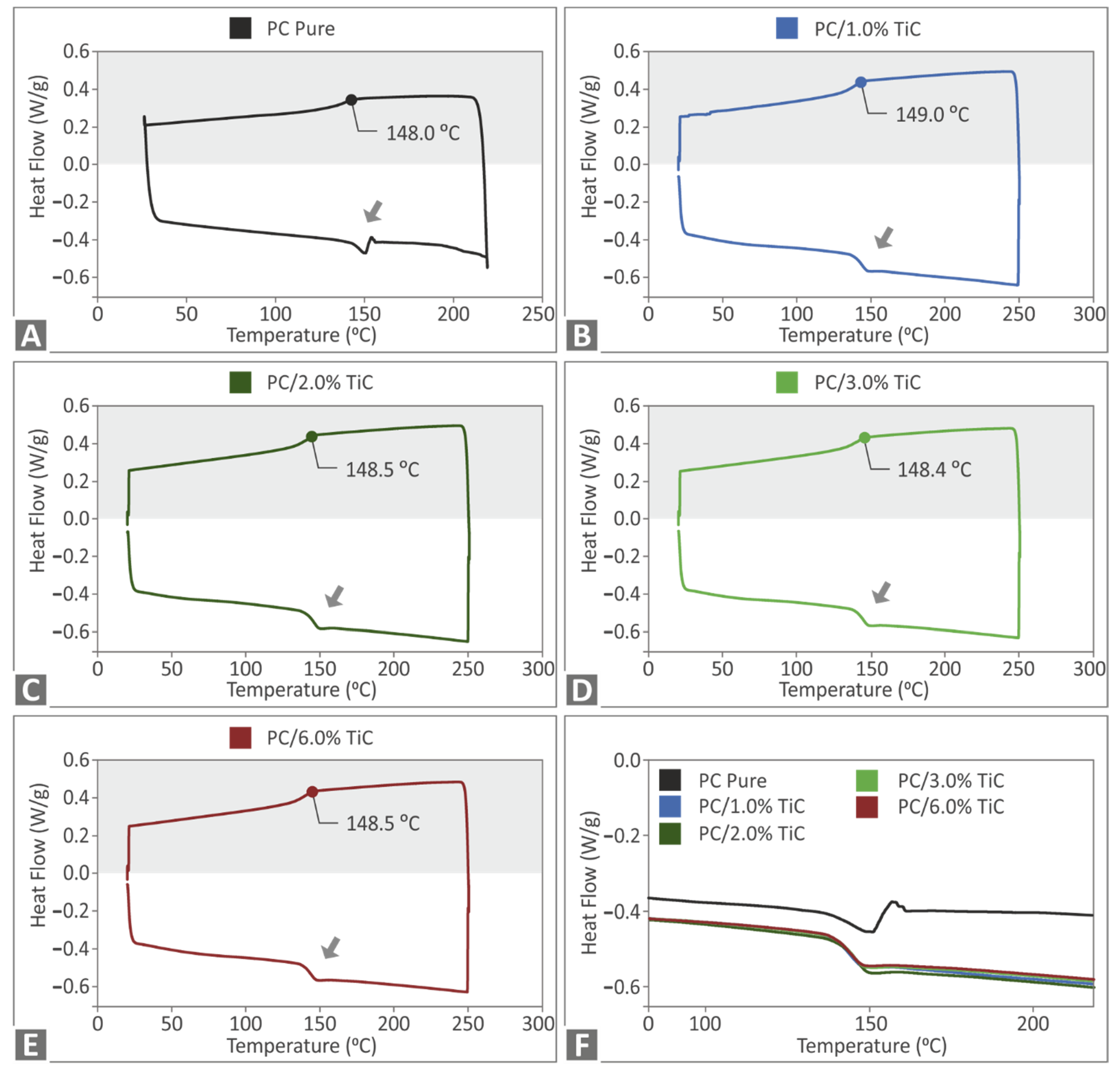

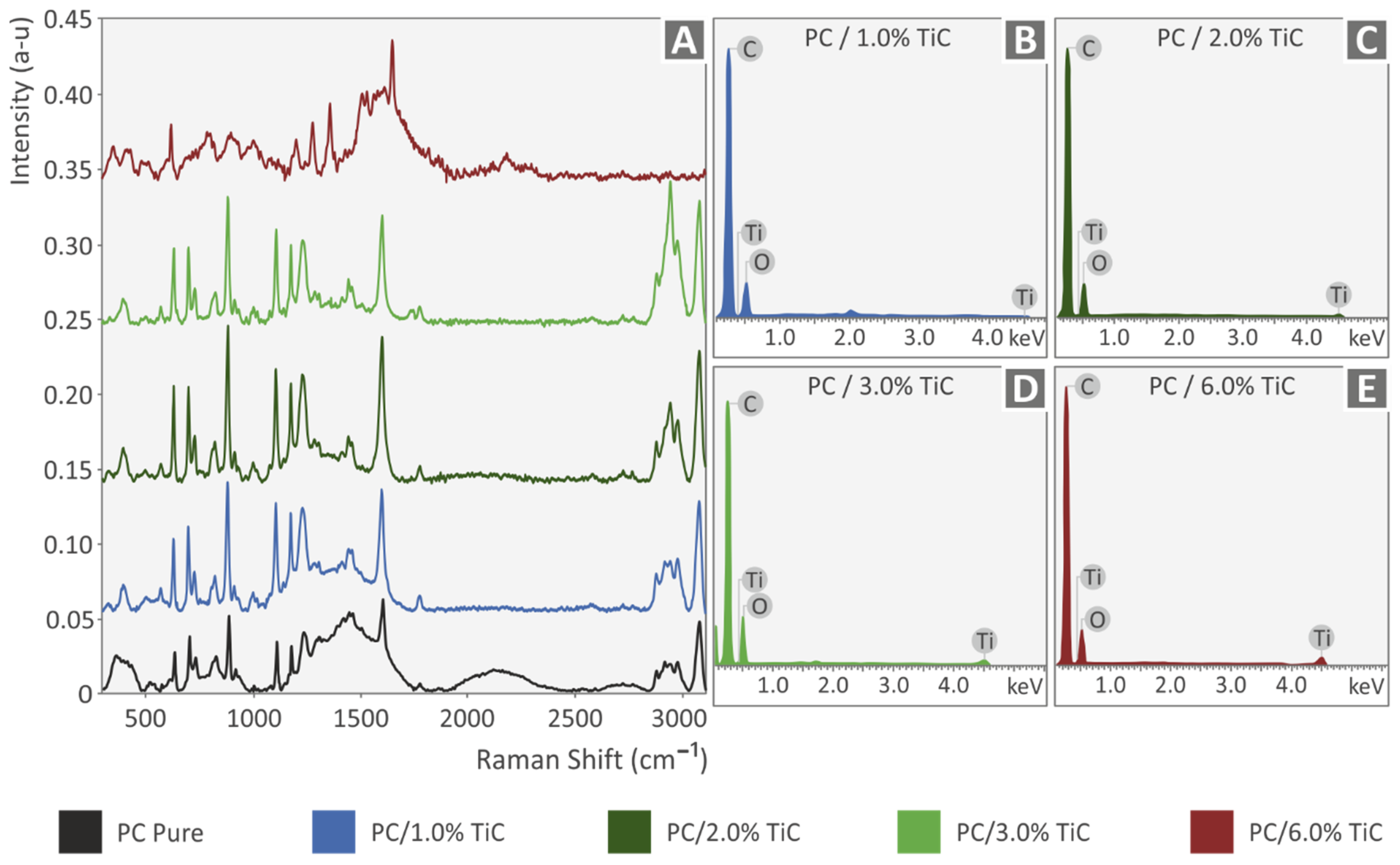

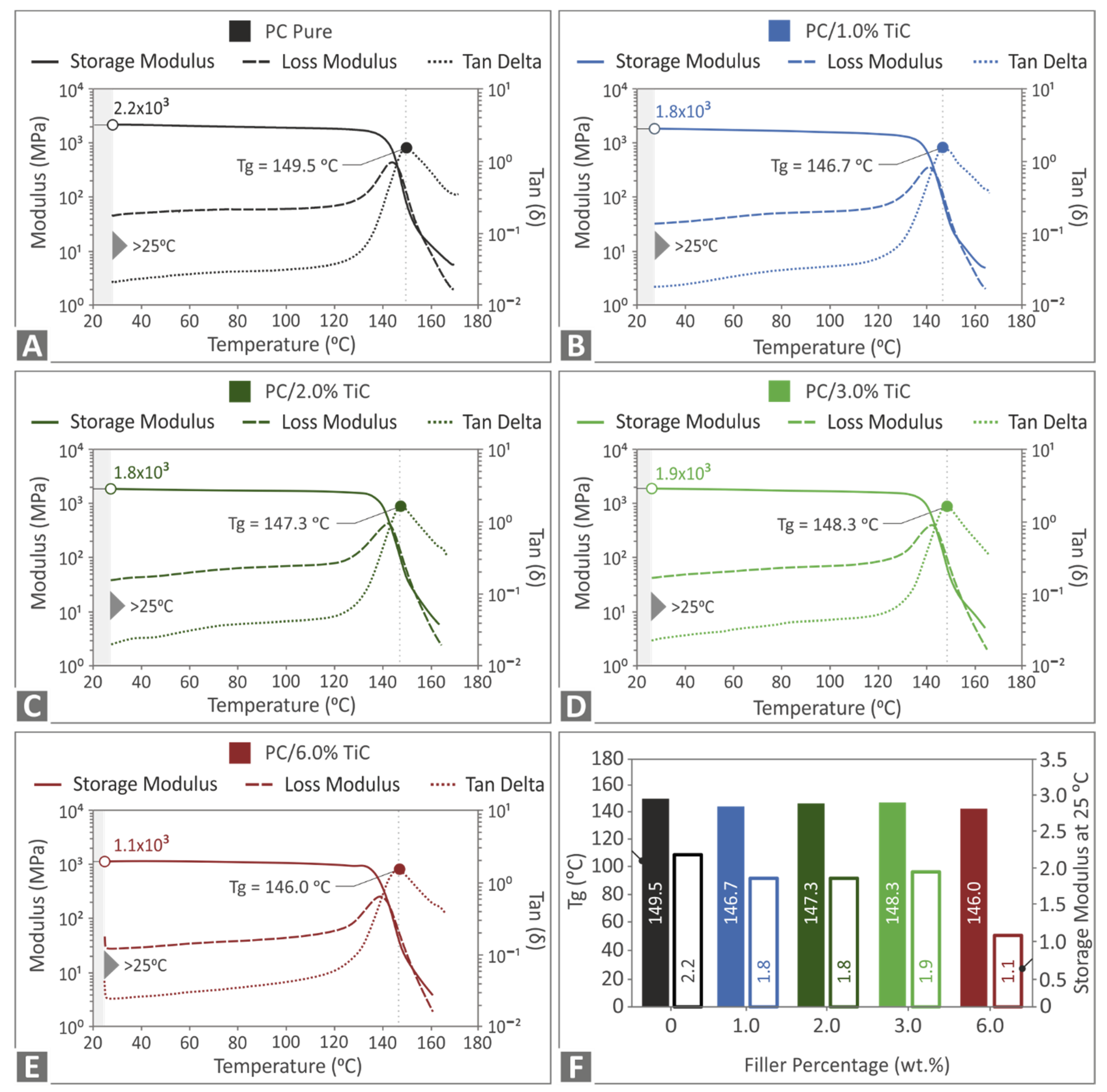

3.1. Thermal and Spectroscopic Properties Investigation

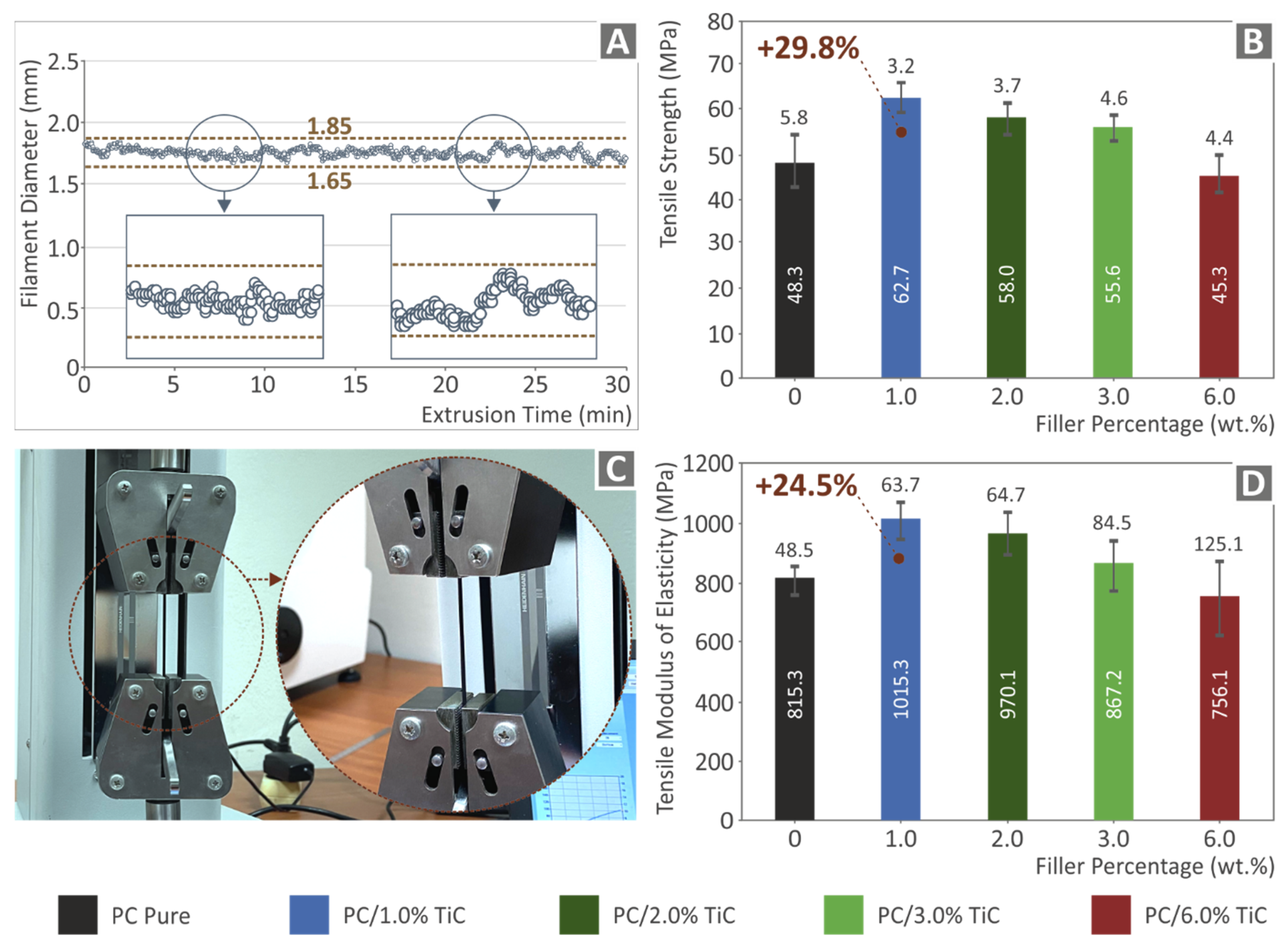

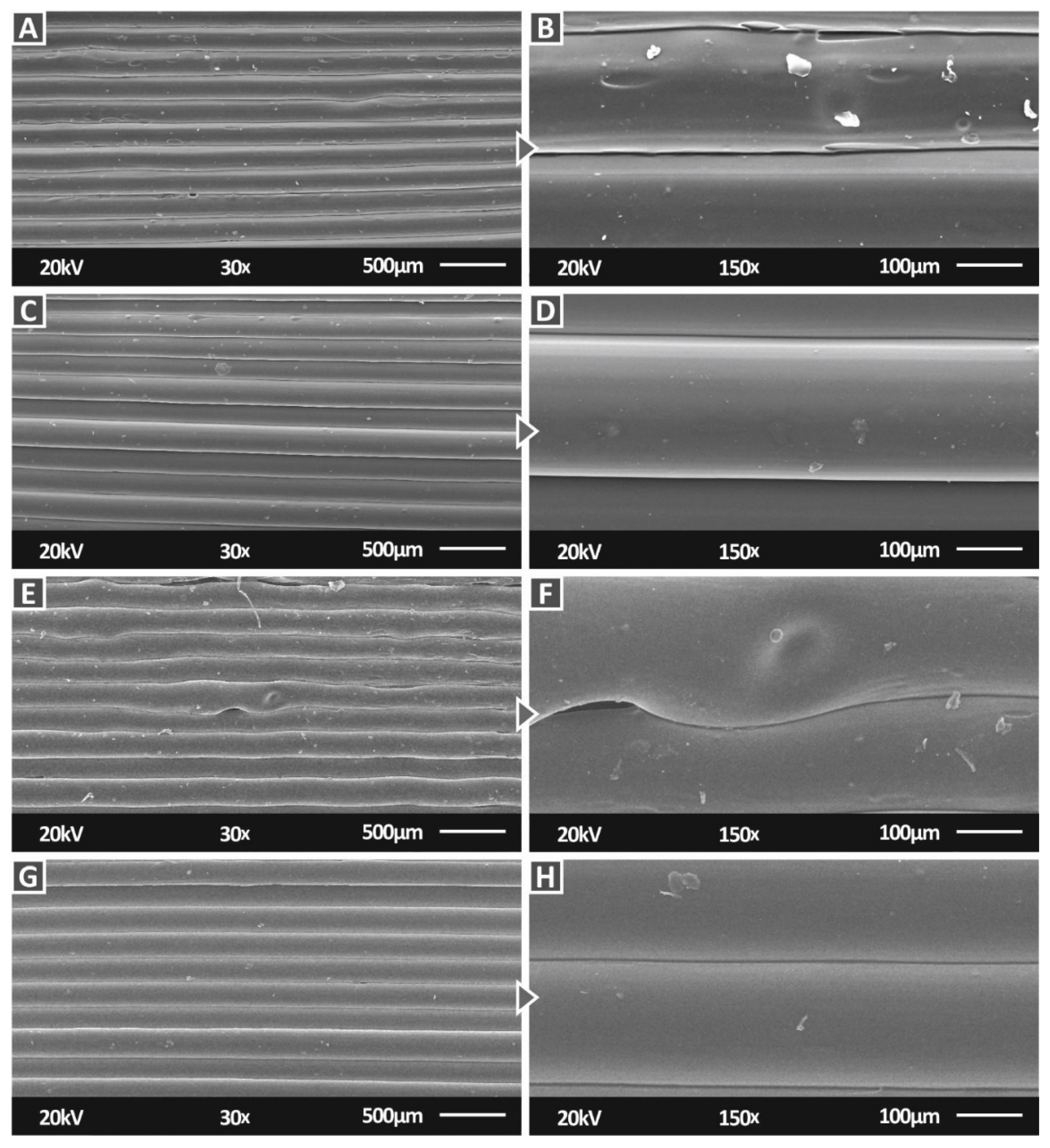

3.2. Nanocomposites Produced Filament Evaluation

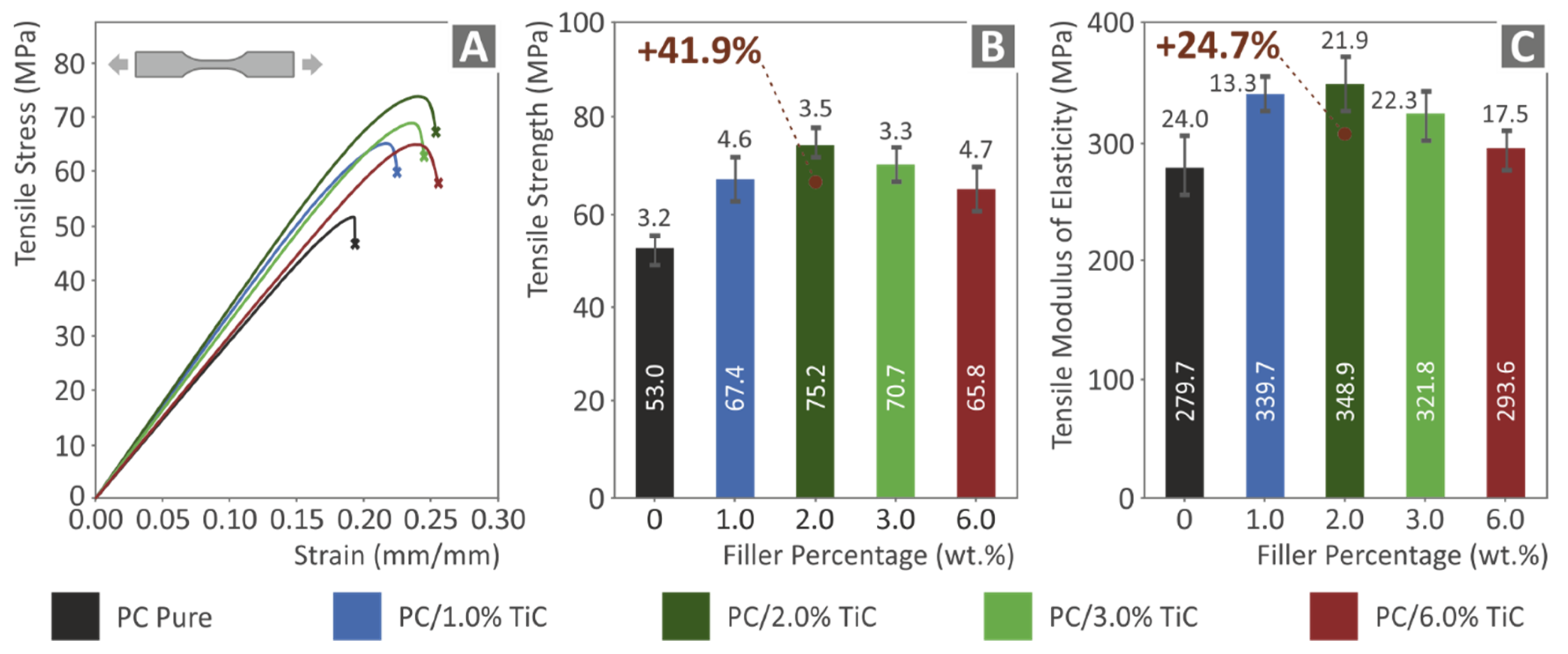

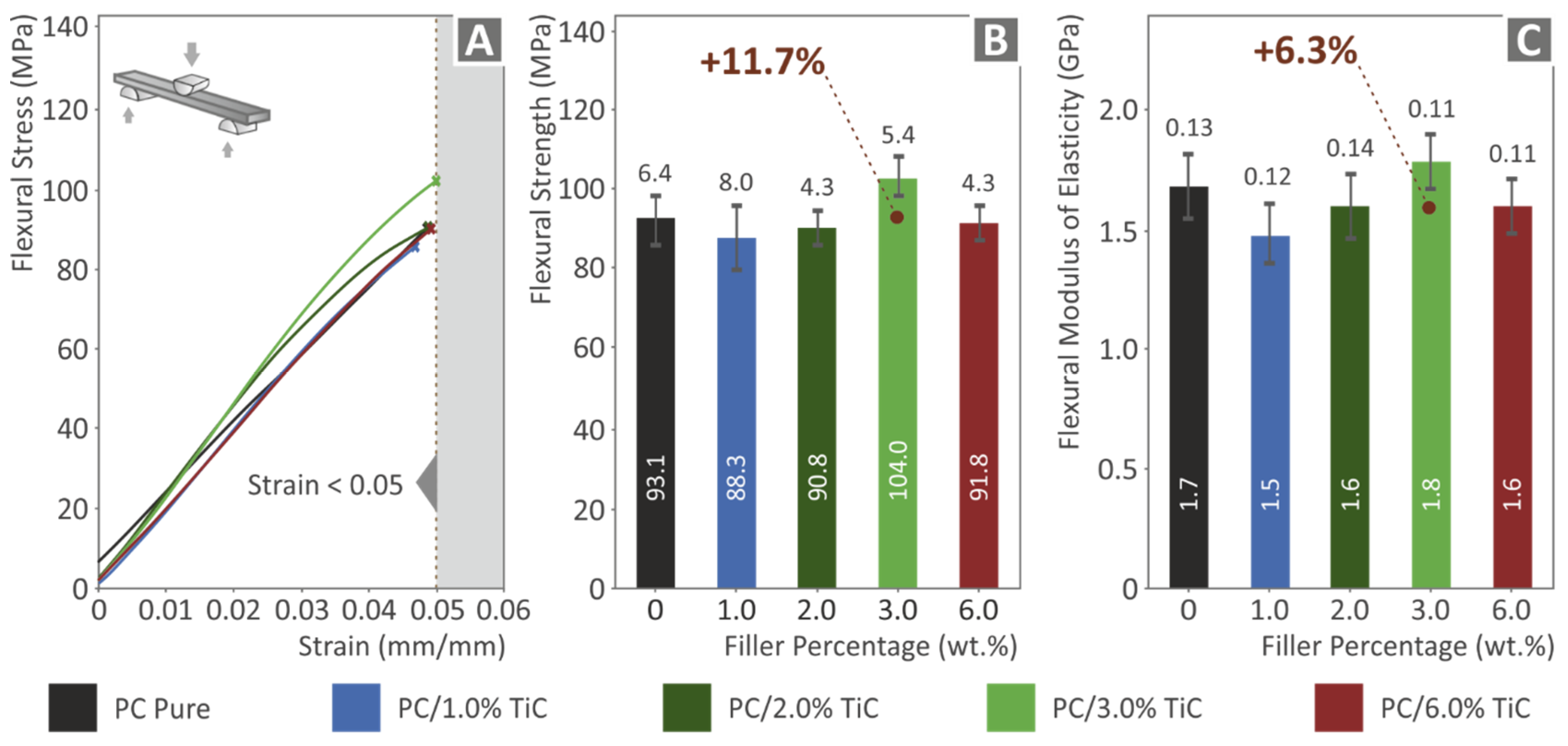

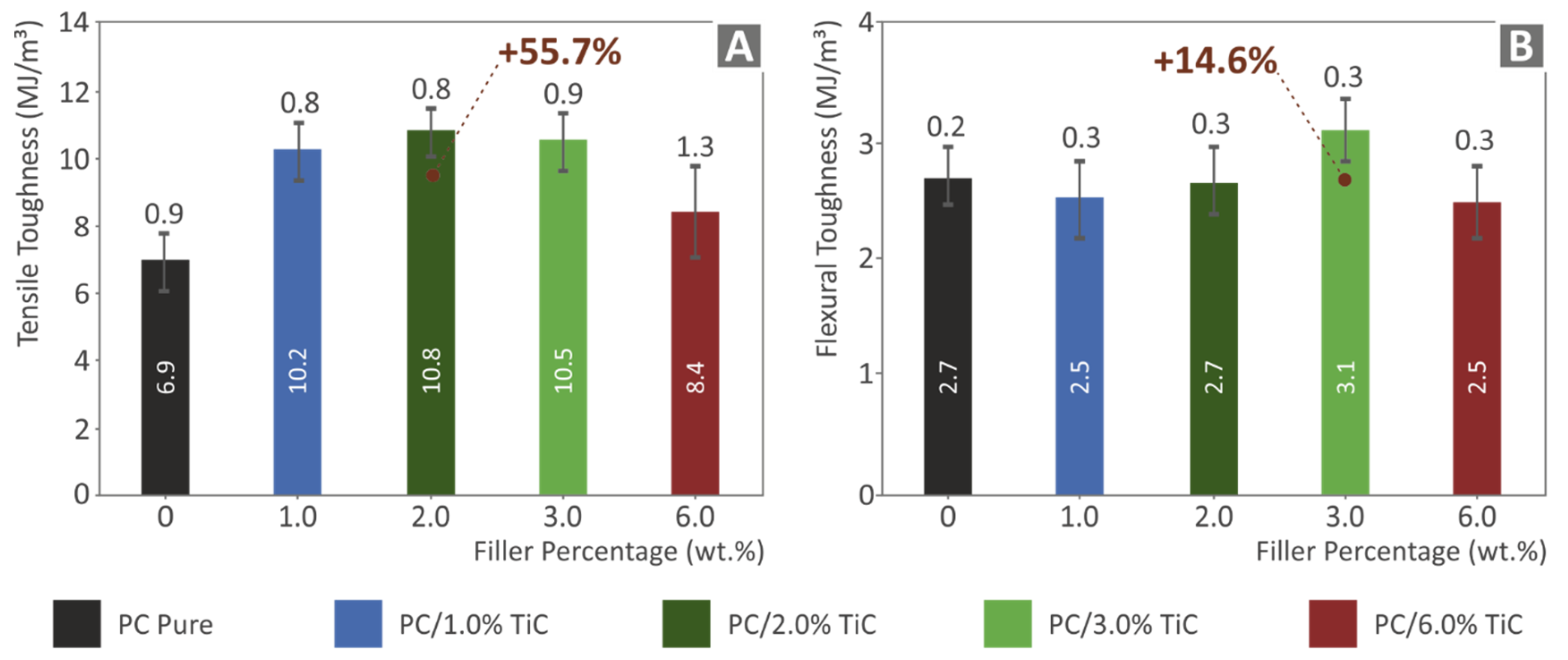

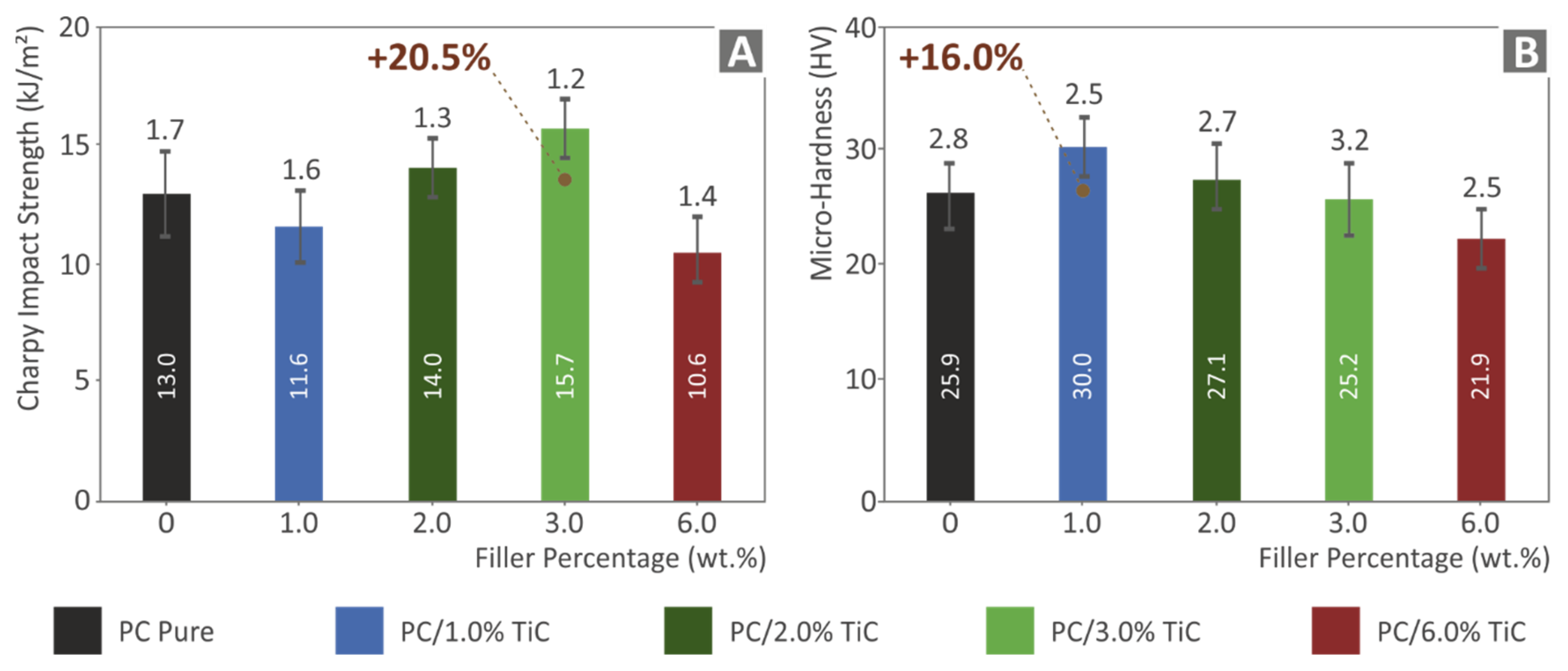

3.3. Mechanical Characterization of the Nanocomposites

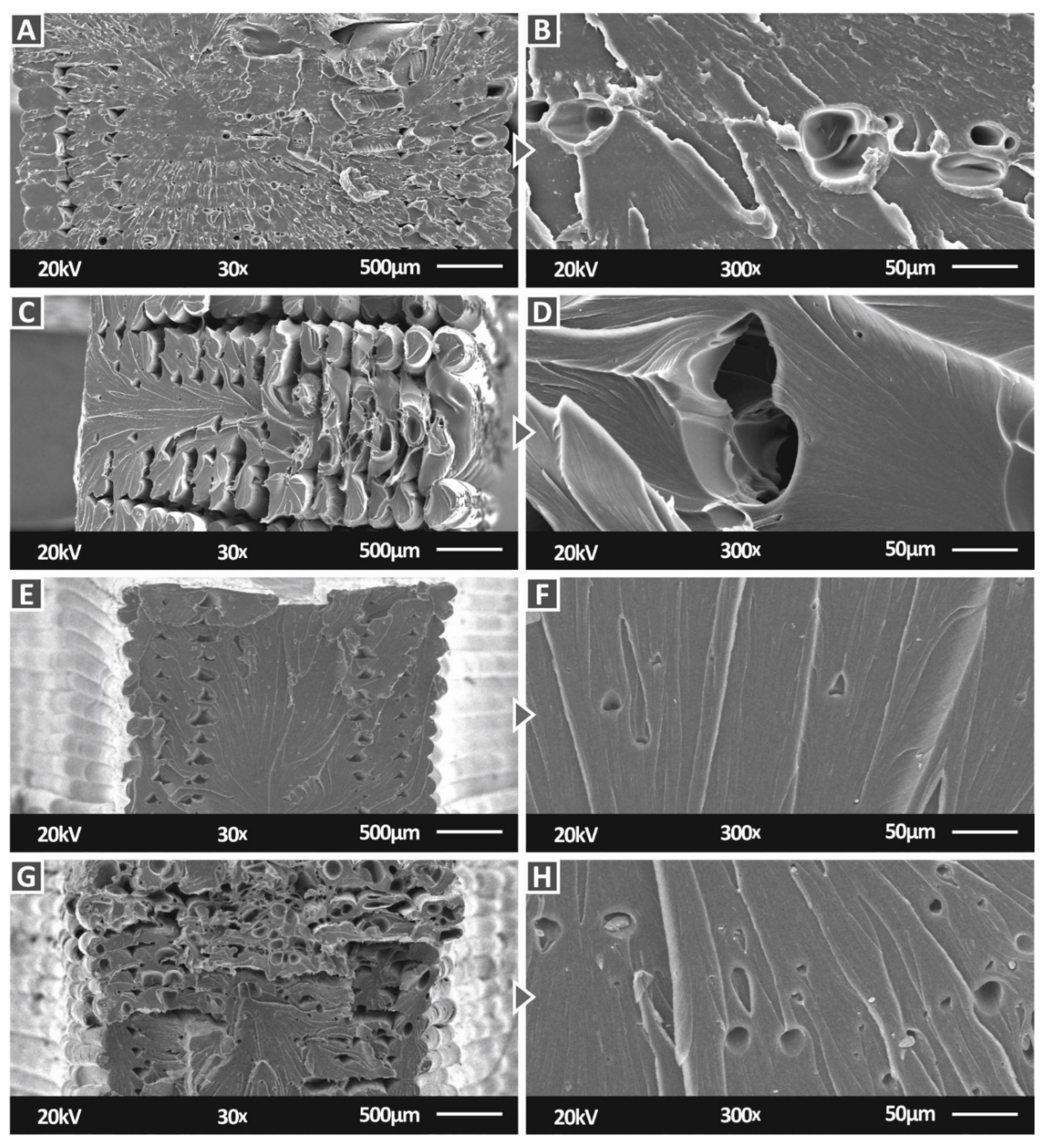

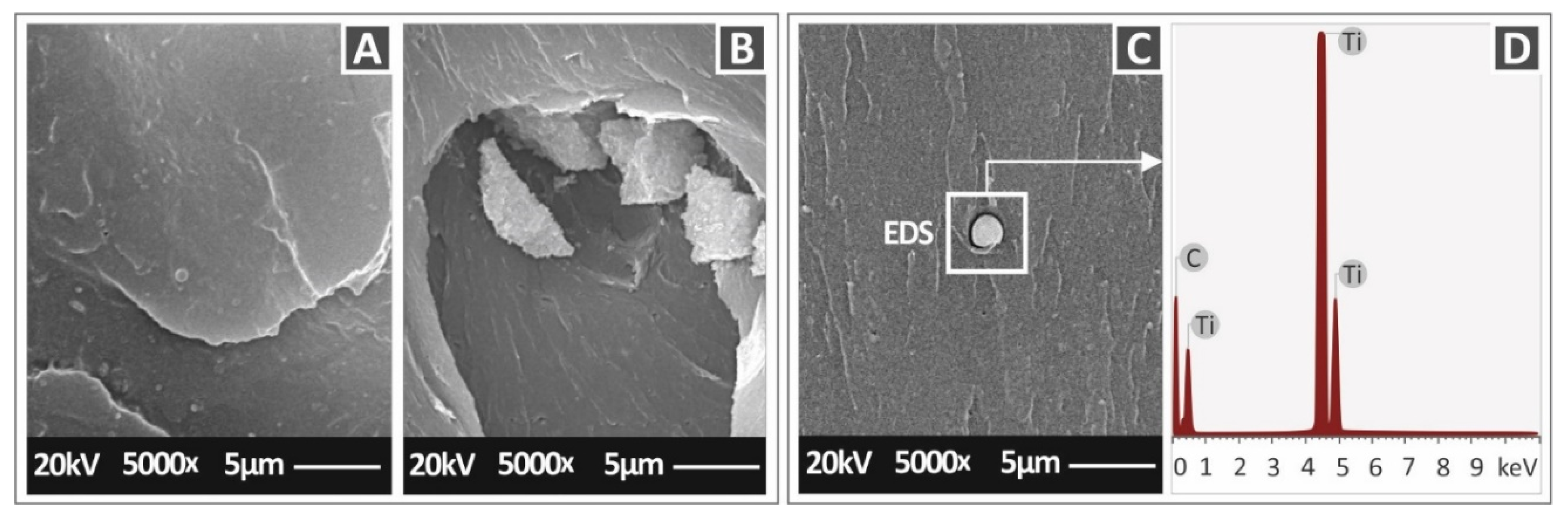

3.4. Morphological Characterization

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Pereira, T.; Kennedy, J.V.; Potgieter, J. A comparison of traditional manufacturing vs. additive manufacturing, the best method for the job. Procedia Manuf. 2019, 30, 11–18. [Google Scholar] [CrossRef]

- Tofail, S.A.M.; Koumoulos, E.P.; Bandyopadhyay, A.; Bose, S.; O’Donoghue, L.; Charitidis, C. Additive manufacturing: Scientific and technological challenges, market uptake and opportunities. Mater. Today 2018, 21, 22–37. [Google Scholar] [CrossRef]

- Vidakis, N.; Vairis, A.; Petousis, M.; Savvakis, K.; Kechagias, J. Fused deposition modelling parts tensile strength characterisation. Acad. J. Manuf. Eng. 2016, 14, 87–94. [Google Scholar]

- Gordelier, T.J.; Thies, P.R.; Turner, L.; Johanning, L. Optimising the FDM additive manufacturing process to achieve maximum tensile strength: A state-of-the-art review. Rapid Prototyp. J. 2019, 25, 953–971. [Google Scholar] [CrossRef]

- Yang, Y.; Li, L.; Zhao, J. Mechanical property modeling of photosensitive liquid resin in stereolithography additive manufacturing: Bridging degree of cure with tensile strength and hardness. Mater. Des. 2019, 162, 418–428. [Google Scholar] [CrossRef]

- Wang, P.; Yang, F.; Lu, G.; Bian, Y.; Zhang, S.; Zheng, B.; Fan, H. Anisotropic compression behaviors of bio-inspired modified body-centered cubic lattices validated by additive manufacturing. Compos. Part B Eng. 2022, 234, 109724. [Google Scholar] [CrossRef]

- Vidakis, N.; Petousis, M.; Vairis, A.; Savvakis, K.; Maniadi, A. On the compressive behavior of an FDM Steward Platform part. J. Comput. Des. Eng. 2017, 4, 339–346. [Google Scholar] [CrossRef]

- Arguëllo-Bastos, J.D.; González-Estrada, O.A.; Ruiz-Florián, C.A.; Pertuz-Comas, A.D.; V-Ninõ, E.D. Study of mechanical properties under compression failure in reinforced composite materials produced by additive manufacturing. J. Phys. Conf. Ser. 2018, 1126, 012005. [Google Scholar] [CrossRef]

- Longhitano, G.A.; Larosa, M.A.; Jardini, A.L.; de Zavaglia, C.A.; Ierardi, M.C.F. Correlation between microstructures and mechanical properties under tensile and compression tests of heat-treated Ti-6Al–4 V ELI alloy produced by additive manufacturing for biomedical applications. J. Mater. Process. Technol. 2018, 252, 202–210. [Google Scholar] [CrossRef]

- Vidakis, N.; Petousis, M.; Vairis, A.; Savvakis, K.; Maniadi, A. A parametric determination of bending and Charpy’s impact strength of ABS and ABS-plus fused deposition modeling specimens. Prog. Addit. Manuf. 2019, 4, 323–330. [Google Scholar] [CrossRef]

- Singh, R.; Kumar, R.; Farina, I.; Colangelo, F.; Feo, L.; Fraternali, F. Multi-material additive manufacturing of sustainable innovative materials and structures. Polymers 2019, 11, 62. [Google Scholar] [CrossRef] [Green Version]

- Caminero, M.Á.; Chacón, J.M.; García-Plaza, E.; Núñez, P.J.; Reverte, J.M.; Becar, J.P. Additive manufacturing of PLA-based composites using fused filament fabrication: Effect of graphene nanoplatelet reinforcement on mechanical properties, dimensional accuracy and texture. Polymers 2019, 11, 799. [Google Scholar] [CrossRef] [Green Version]

- Vairis, A.; Petousis, M.; Vidakis, N.; Savvakis, K. On the Strain Rate Sensitivity of Abs and Abs Plus Fused Deposition Modeling Parts. J. Mater. Eng. Perform. 2016, 25, 3558–3565. [Google Scholar] [CrossRef]

- Vidakis, N.; Petousis, M.; Velidakis, E.; Liebscher, M.; Mechtcherine, V.; Tzounis, L. On the strain rate sensitivity of fused filament fabrication (Fff) processed pla, abs, petg, pa6, and pp thermoplastic polymers. Polymers 2020, 12, 2924. [Google Scholar] [CrossRef]

- Almuallim, B.; Harun, W.S.W.; Al Rikabi, I.J.; Mohammed, H.A. Thermally conductive polymer nanocomposites for filament-based additive manufacturing. J. Mater. Sci. 2022, 57, 3993–4019. [Google Scholar] [CrossRef]

- Vidakis, N.; Petousis, M.; Savvakis, K.; Maniadi, A.; Koudoumas, E. A comprehensive investigation of the mechanical behavior and the dielectrics of pure polylactic acid (PLA) and PLA with graphene (GnP) in fused deposition modeling (FDM). Int. J. Plast. Technol. 2019, 23, 195–206. [Google Scholar] [CrossRef]

- Criado-Gonzalez, M.; Dominguez-Alfaro, A.; Lopez-Larrea, N.; Alegret, N.; Mecerreyes, D. Additive Manufacturing of Conducting Polymers: Recent Advances, Challenges, and Opportunities. ACS Appl. Polym. Mater. 2021, 3, 2865–2883. [Google Scholar] [CrossRef]

- Kumar, N.; Jain, P.K.; Tandon, P.; Pandey, P.M. Additive manufacturing of flexible electrically conductive polymer composites via CNC-assisted fused layer modeling process. J. Braz. Soc. Mech. Sci. Eng. 2018, 40, 175. [Google Scholar] [CrossRef]

- González-Henríquez, C.M.; Sarabia-Vallejos, M.A.; Hernandez, J.R. Antimicrobial polymers for additive manufacturing. Int. J. Mol. Sci. 2019, 20, 1210. [Google Scholar] [CrossRef] [Green Version]

- Vidakis, N.; Petousis, M.; Velidakis, E.; Liebscher, M.; Tzounis, L. Three-Dimensional Printed Antimicrobial Objects of Polylactic Acid (PLA)-Silver Nanoparticle Nanocomposite Filaments Produced by an In-Situ Reduction Reactive Melt Mixing Process. Biomimetics 2020, 5, 42. [Google Scholar] [CrossRef]

- Chong, W.J.; Shen, S.; Li, Y.; Trinchi, A.; Pejak, D.; Kyratzis, I.L.; Sola, A.; Wen, C. Additive manufacturing of antibacterial PLA-ZnO nanocomposites: Benefits, limitations and open challenges. J. Mater. Sci. Technol. 2022, 111, 120–151. [Google Scholar] [CrossRef]

- Billings, C.; Cai, C.; Liu, Y. Utilization of antibacterial nanoparticles in photocurable additive manufacturing of advanced composites for improved public health. Polymers 2021, 13, 2616. [Google Scholar] [CrossRef] [PubMed]

- Kechagias, J.; Chaidas, D.; Vidakis, N.; Salonitis, K.; Vaxevanidis, N. Key parameters controlling surface quality and dimensional accuracy: A critical review of FFF process. Mater. Manuf. Process. 2022, 1–22. [Google Scholar] [CrossRef]

- Kausar, A. A review of filled and pristine polycarbonate blends and their applications. J. Plast. Film Sheeting 2018, 34, 60–97. [Google Scholar]

- Alghunaim, N.S.; Alhusaiki-Alghamdi, H.M. Role of ZnO nanoparticles on the structural, optical and dielectric properties of PVP/PC blend. Phys. B Condens. Matter 2019, 560, 185–190. [Google Scholar] [CrossRef]

- Eungkee Lee, R.; Afsari Ghazi, A.; Azdast, T.; Hasanzadeh, R.; Mamaghani Shishavan, S. Tensile and hardness properties of polycarbonate nanocomposites in the presence of styrene maleic anhydride as compatibilizer. Adv. Polym. Technol. 2018, 37, 1737–1743. [Google Scholar] [CrossRef]

- Tian, N.; Liu, T.; Zhong, W.H.; Bahr, D.F. The nanomechanical behavior of a graphite nanoplatelet/polycarbonate nanocomposite. Polym. Test. 2015, 47, 87–91. [Google Scholar] [CrossRef]

- Pötschke, P.; Fornes, T.D.; Paul, D.R. Rheological behavior of multiwalled carbon nanotube/polycarbonate composites. Polymer 2002, 43, 3247–3255. [Google Scholar] [CrossRef]

- Barlow, W.; Paul, D.R. Mechanical Compatibilization of Immiscible Blends. Polym. Eng. Sci. 1984, 24, 525–534. [Google Scholar] [CrossRef]

- American Society for Testing and Materials (ASTM). Additive Manufacturing—General Principles—Part 1: Terminology; ASTM: West Conshohocken, PA, USA, 2015; Volume 2015, pp. 1–11. [Google Scholar]

- Vidakis, N.; Petousis, M.; Kechagias, J.D. A comprehensive investigation of the 3D printing parameters’ effects on the mechanical response of polycarbonate in fused filament fabrication. Prog. Addit. Manuf. 2022, 1–10. [Google Scholar] [CrossRef]

- Fang, L.; Yan, Y.; Agarwal, O.; Seppala, J.E.; Hemker, K.J.; Kang, S.H. Processing-structure-property relationships of bisphenol-A-polycarbonate samples prepared by fused filament fabrication. Addit. Manuf. 2020, 35, 101285. [Google Scholar] [CrossRef]

- McIlroy, C.; Olmsted, P.D. Disentanglement effects on welding behaviour of polymer melts during the fused-filament-fabrication method for additive manufacturing. Polymer 2017, 123, 376–391. [Google Scholar] [CrossRef] [Green Version]

- Domingo-Espin, M.; Borros, S.; Agullo, N.; Garcia-Granada, A.A.; Reyes, G. Influence of Building Parameters on the Dynamic Mechanical Properties of Polycarbonate Fused Deposition Modeling Parts. Print. Addit. Manuf. 2014, 1, 70–77. [Google Scholar] [CrossRef]

- Puigoriol-Forcada, J.M.; Alsina, A.; Salazar-Martín, A.G.; Gomez-Gras, G.; Pérez, M.A. Flexural fatigue properties of polycarbonate fused-deposition modelling specimens. Mater. Des. 2018, 155, 414–421. [Google Scholar] [CrossRef]

- Vidakis, N.; Petousis, M.; Korlos, A.; Velidakis, E.; Mountakis, N.; Charou, C.; Myftari, A. Strain Rate Sensitivity of Polycarbonate and Thermoplastic Polyurethane for Various 3D Printing Temperatures and Layer Heights. Polymer 2021, 13, 2752. [Google Scholar] [CrossRef]

- Cantrell, J.T.; Rohde, S.; Damiani, D.; Gurnani, R.; DiSandro, L.; Anton, J.; Young, A.; Jerez, A.; Steinbach, D.; Kroese, C.; et al. Experimental characterization of the mechanical properties of 3D-printed ABS and polycarbonate parts. Rapid Prototyp. J. 2017, 23, 811–824. [Google Scholar] [CrossRef]

- de Vries, H.; Engelen, R.; Janssen, E. Impact strength of 3d-printed polycarbonate. Facta Univ. Ser. Electron. Energetics 2020, 33, 105–117. [Google Scholar] [CrossRef] [Green Version]

- Salazar-Martín, A.G.; Pérez, M.A.; García-Granada, A.A.; Reyes, G.; Puigoriol-Forcada, J.M. A study of creep in polycarbonate fused deposition modelling parts. Mater. Des. 2018, 141, 414–425. [Google Scholar] [CrossRef]

- Quinn, M.; Lafont, U.; Versteegh, J.; Guo, J. Effect of low vacuum environment on the fused filament fabrication process. CEAS Space J. 2021, 13, 369–376. [Google Scholar] [CrossRef]

- Vidakis, N.; Petousis, M.; Velidakis, E.; Spiridaki, M.; Kechagias, J.D. Mechanical Performance of Fused Filament Fabricated and 3D-Printed Polycarbonate Polymer and Polycarbonate/Cellulose Nanofiber Nanocomposites. Fibers 2021, 9, 74. [Google Scholar] [CrossRef]

- Jahangir, M.N.; Billah, K.M.M.; Lin, Y.; Roberson, D.A.; Wicker, R.B.; Espalin, D. Reinforcement of material extrusion 3D printed polycarbonate using continuous carbon fiber. Addit. Manuf. 2019, 28, 354–364. [Google Scholar] [CrossRef]

- Huang, K.; Li, Z.; Lin, J.; Han, G.; Huang, P. Two-dimensional transition metal carbides and nitrides (MXenes) for biomedical applications. Chem. Soc. Rev. 2018, 47, 5109–5124. [Google Scholar] [CrossRef] [PubMed]

- Zhang, C.; Ma, Y.; Zhang, X.; Abdolhosseinzadeh, S.; Sheng, H.; Lan, W.; Pakdel, A.; Heier, J.; Nüesch, F. Two-Dimensional Transition Metal Carbides and Nitrides (MXenes): Synthesis, Properties, and Electrochemical Energy Storage Applications. Energy Environ. Mater. 2020, 3, 29–55. [Google Scholar] [CrossRef]

- Santhanam, A.T. Application of transition metal carbides and nitrides in industrial tools. In The Chemistry of Transition Metal Carbides and Nitrides; Springer: Dordrecht, The Netherlands, 1996. [Google Scholar] [CrossRef]

- Rabee, B.H.; Oreibi, I. Fabrication of new nanocomposites (PMMA-SPO-PS-TiC) and studying their structural and electrical properties for humidity sensors. Bull. Electr. Eng. Inform. 2018, 7, 538–546. [Google Scholar] [CrossRef]

- Gioti, S.; Stavropoulos, S.G.; Sanida, A.; Psarras, G.C. A comparative study on the thermomechanical and electrical properties of carbide/or graphite/epoxy-reinforced composites. J. Therm. Anal. Calorim. 2020, 142, 1649–1657. [Google Scholar] [CrossRef]

- Miracle, D.B.; Lipsitt, H.A. Mechanical Properties of Fine-Grained Substoichiomebic Titanium Carbide. J. Am. Ceram. Soc. 1983, 66, 592–597. [Google Scholar] [CrossRef]

- Peng, C.; Wei, P.; Li, X.; Liu, Y.; Cao, Y.; Wang, H.; Yu, H.; Peng, F.; Zhang, L.; Zhang, B.; et al. High efficiency photocatalytic hydrogen production over ternary Cu/TiO2@Ti3C2Tx enabled by low-work-function 2D titanium carbide. Nano Energy 2018, 53, 97–107. [Google Scholar] [CrossRef]

- Fan, D.; Lu, S.; Guo, Y.; Hu, X. Two-Dimensional Tetragonal Titanium Carbide: A High-Capacity and High-Rate Battery Material. J. Phys. Chem. C 2018, 122, 15118–15124. [Google Scholar] [CrossRef]

- Akuzum, B.; Maleski, K.; Anasori, B.; Lelyukh, P.; Alvarez, N.J.; Kumbur, E.C.; Gogotsi, Y. Rheological Characteristics of 2D Titanium Carbide (MXene) Dispersions: A Guide for Processing MXenes. ACS Nano 2018, 12, 2685–2694. [Google Scholar] [CrossRef]

- Hashim, A.; Hadi, Q. Structural, electrical and optical properties of (biopolymer blend/titanium carbide) nanocomposites for low cost humidity sensors. J. Mater. Sci. Mater. Electron. 2018, 29, 11598–11604. [Google Scholar] [CrossRef]

- Gao, X.; Li, Z.K.; Xue, J.; Qian, Y.; Zhang, L.Z.; Caro, J.; Wang, H. Titanium carbide Ti3C2Tx (MXene) enhanced PAN nanofiber membrane for air purification. J. Membr. Sci. 2019, 586, 162–169. [Google Scholar] [CrossRef]

- Wang, K.; Lou, Z.; Wang, L.; Zhao, L.; Zhao, S.; Wang, D.; Han, W.; Jiang, K.; Shen, G. Bioinspired Interlocked Structure-Induced High Deformability for Two-Dimensional Titanium Carbide (MXene)/Natural Microcapsule-Based Flexible Pressure Sensors. ACS Nano 2019, 13, 9139–9147. [Google Scholar] [CrossRef] [PubMed]

- Liu, Z.; Zhao, M.; Lin, H.; Dai, C.; Ren, C.; Zhang, S.; Peng, W.; Chen, Y. 2D magnetic titanium carbide MXene for cancer theranostics. J. Mater. Chem. B 2018, 6, 3541–3548. [Google Scholar] [CrossRef]

- Jia, Q.; Gu, D. Selective laser melting additive manufacturing of TiC/Inconel 718 bulk-form nanocomposites: Densification, microstructure, and performance. J. Mater. Res. 2014, 29, 1960–1969. [Google Scholar] [CrossRef] [Green Version]

- Li, N.; Huang, S.; Zhang, G.; Qin, R.; Liu, W.; Xiong, H.; Shi, G.; Blackburn, J. Progress in additive manufacturing on new materials: A review. J. Mater. Sci. Technol. 2019, 35, 242–269. [Google Scholar] [CrossRef]

- Francis, V.; Jain, P.K. Advances in nanocomposite materials for additive manufacturing. Int. J. Rapid Manuf. 2015, 5, 215. [Google Scholar] [CrossRef]

- Pribytkov, G.A.; Krinitcyn, M.G.; Baranovskiy, A.V. Additive manufacturing of parts from “titanium carbide-titanium” mechanically activated powder. AIP Conf. Proc. 2018, 2051, 020245. [Google Scholar] [CrossRef]

- Stuart, B.H. Temperature studies of polycarbonate using Fourier transform Raman spectroscopy. Polym. Bull. 1996, 36, 341–346. [Google Scholar] [CrossRef]

- Zimmerer, C.; Matulaitiene, I.; Niaura, G.; Reuter, U.; Janke, A.; Boldt, R.; Sablinskas, V.; Steiner, G. Nondestructive characterization of the polycarbonate-octadecylamine interface by surface enhanced Raman spectroscopy. Polym. Test. 2019, 73, 152–158. [Google Scholar] [CrossRef]

- Resta, V.; Quarta, G.; Lomascolo, M.; Maruccio, L.; Calcagnile, L. Raman and Photoluminescence spectroscopy of polycarbonate matrices irradiated with different energy 28Si+ ions. Vacuum 2015, 116, 82–89. [Google Scholar] [CrossRef]

- Makarem, M.; Lee, C.M.; Kafle, K.; Huang, S.; Chae, I.; Yang, H.; Kubicki, J.D.; Kim, S.H. Probing cellulose structures with vibrational spectroscopy. Cellulose 2019, 26, 35–79. [Google Scholar] [CrossRef]

| TGA | |

| Instrument | Perkin Elmer Diamond TGA/DTGA (Waltham, MA, USA) |

| Temperature range | 40 °C to 550 °C |

| Temperature ramp | 10 °C/min |

| Atmosphere | Nitrogen |

| DSC | |

| Instrument | TA Instruments DSC 25 (New Castle, DE, USA) |

| Temperature sweep | 25–225–25 °C (5 min at 225 °C) |

| Temperature rate | 15 °C/min |

| Raman | |

| Instrument | LabRAM HR Raman spectrometer (HORIBA Scientific, Kyoto, Japan) |

| Laser | Solid-state |

| Laser power | 90 mW |

| Power on the sample | 40 mW |

| Center wavelength | 532 nm |

| Lens | 50×, 10.6 long working distance, 0.5 numerical aperture (LMPlanFL N, Olympus, Tokyo, Japan) |

| Laser spot diameter | 1.7 μm |

| Axial focal length | 2 μm |

| Spectra resolution | 2 cm−1 |

| Acquisition duration | 10 s |

| Acquisition range | 300–3100 cm−1 |

| DMA | |

| Instrument | TA Instruments rheometer (DHR 20) (TA Instruments, New Castle, DE, USA) |

| Standard | ASTM D4065-12 |

| Test | Three-point-bending |

| Preload | 0.1 N |

| Oscillation amplitude | 30 μm |

| Frequency | 1 Hz |

| Temperature range | 30–200 °C |

| Temperature rate | 5 °C/min |

| Tensile | |

| Instrument | Imada MX2 (Northbrook, IL, USA) |

| Standard | ASTM D638-02a |

| Specimen | Type V with 3.2 mm thickness |

| Testing speed | 10 mm/min |

| Flexural | |

| Instrument | Imada MX2 (Northbrook, IL, USA) |

| Standard | ASTM D790 |

| Support span | 52 mm |

| Testing speed | 10 mm/min |

| Impact | |

| Instrument | Terco MT 220 (Kungens Kurva, Sweden) |

| Standard | ASTM D6110 |

| Release height | 367 mm |

| Specimens | Notched |

| Microhardness | |

| Instrument | Innova Test 300 (Maastricht, The Netherlands) |

| Method | Vickers |

| Indentations’ duration | 10 s |

| Applied load | 200 gF |

| Wavenumber (cm−1) | Raman Peak Assignment |

|---|---|

| 573 | Phenyl ring vibration |

| 633 | Phenyl ring vibration |

| 703 | C-H out-of-plane bending |

| 731 | C-H out-of-plane bending |

| 826 | Phenyl ring vibration |

| 886 | ν[O-(C=O)-O], ν(C-CH3), r(CH3), ν(ring) |

| 1109 | C-O-C stretching |

| 1176 | C-O-C stretching |

| 1234 | C-O-C group asymmetric vibration |

| 1602 | Phenyl ring vibration |

| 2874 | CH2vS or C-H |

| 2912 | CH2vAS or C-H |

| 2971 | CH/CH2 stretch modes polarized |

| 3073 | C-H stretching |

| Wavenumber (cm−1) | Assignment | Change |

|---|---|---|

| 631 | Phenyl ring vibration | Increased vibration for TiC samples |

| 647 | Phenyl ring vibration | New peak for TiC samples |

| 700 | C-H out-of-plane bending | Increase of peak for TiC samples |

| 883 | ν[O-(C=O)-O], ν(C-CH3), r(CH3), ν(ring) | Increase of peak for TiC samples |

| 1106 | C-O-C stretching | Increase of peak for TiC samples |

| 1175 | C-O-C stretching | Increase of peak for TiC samples |

| 1231 | C-O-C group asymmetric vibration | Increase of peak for TiC samples |

| 1740 | C=O vibration | New peak for TiC samples |

| 2912 | CH2vAS or C-H | Gradual increase vs. TiC concentration |

| 2911 | CH2vAS or C-H | Constant |

| 2970 | CH/CH2 stretch modes polarized | Constant |

| 3071 | C-H stretching | Gradual increase vs. TiC concentration |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Vidakis, N.; Petousis, M.; Grammatikos, S.; Papadakis, V.; Korlos, A.; Mountakis, N. High Performance Polycarbonate Nanocomposites Mechanically Boosted with Titanium Carbide in Material Extrusion Additive Manufacturing. Nanomaterials 2022, 12, 1068. https://doi.org/10.3390/nano12071068

Vidakis N, Petousis M, Grammatikos S, Papadakis V, Korlos A, Mountakis N. High Performance Polycarbonate Nanocomposites Mechanically Boosted with Titanium Carbide in Material Extrusion Additive Manufacturing. Nanomaterials. 2022; 12(7):1068. https://doi.org/10.3390/nano12071068

Chicago/Turabian StyleVidakis, Nectarios, Markos Petousis, Sotirios Grammatikos, Vassilis Papadakis, Apostolos Korlos, and Nikolaos Mountakis. 2022. "High Performance Polycarbonate Nanocomposites Mechanically Boosted with Titanium Carbide in Material Extrusion Additive Manufacturing" Nanomaterials 12, no. 7: 1068. https://doi.org/10.3390/nano12071068

APA StyleVidakis, N., Petousis, M., Grammatikos, S., Papadakis, V., Korlos, A., & Mountakis, N. (2022). High Performance Polycarbonate Nanocomposites Mechanically Boosted with Titanium Carbide in Material Extrusion Additive Manufacturing. Nanomaterials, 12(7), 1068. https://doi.org/10.3390/nano12071068