Optical Manipulation of Incident Light for Enhanced Photon Absorption in Ultrathin Organic Photovoltaics

Abstract

1. Introduction

2. Results and Discussion

3. Materials and Methods

3.1. Materials

3.2. Synthesis of ZnO Solution

3.3. Fabrication of PDMS Stamps with 1D Grating Patterns

3.4. Device Fabrication

3.5. Measurements

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Park, S.; Heo, S.W.; Lee, W.; Inoue, D.; Jiang, Z.; Yu, K.; Jinno, H.; Hashizume, D.; Sekino, M.; Yokota, T.; et al. Self-powered ultra-flexible electronics via nano-grating-patterned organic photovoltaics. Nature 2018, 561, 516–521. [Google Scholar] [CrossRef] [PubMed]

- Choi, J.Y.; Park, I.P.; Heo, S.W. Ultra-Flexible Organic Solar Cell Based on Indium-Zinc-Tin Oxide Transparent Electrode for Power Source of Wearable Devices. Nanomaterials 2021, 10, 2633. [Google Scholar] [CrossRef]

- Xiong, S.; Fukuda, K.; Lee, S.; Nakano, K.; Dong, X.; Yokota, T.; Tajima, K.; Zhou, Y.; Someya, T. Ultrathin and Efficient Organic Photovoltaics with Enhanced Air Stability by Suppression of Zinc Element Diffusion. Adv. Sci. 2022, 9, 2105288. [Google Scholar] [CrossRef]

- Rich, S.I.; Lee, S.; Fukuda, K.; Someya, T. Developing the Nondevelopable: Creating Curved-Surface Electronics from Nonstretchable Devices. Adv. Mater. 2022, 34, 2106683. [Google Scholar] [CrossRef] [PubMed]

- Hashemi, S.A.; Ramakrishna, S.; Aberle, A.G. Recent Progress in Flexible-Wearable Solar Cells for Self-Powered Electronic Device. Energy Environ. Sci. 2020, 13, 685–743. [Google Scholar] [CrossRef]

- Takakuwa, M.; Heo, S.W.; Fukuda, K.; Tajima, K.; Park, S.; Umezu, S.; Someya, T. Nanograting Structured Ultrathin Substrate for Ultraflexible Organic Photovoltaics. Small Methods 2020, 4, 1900762. [Google Scholar] [CrossRef]

- Kim, J.Y.; Kim, S.H.; Lee, H.-H.; Lee, K.; Ma, W.; Gong, X.; Heeger, A.J. New Architecture for High-Efficiency Polymer Photovoltaic Cells Using Solution-Based Titanium Oxide as an Optical Spacer. Adv. Mater. 2006, 18, 572. [Google Scholar] [CrossRef]

- Shaw, P.E.; Ruseckas, A.; Samuel, I.D.W. Exciton diffusion measurements in poly (3-hexylthiophene). Adv. Mater. 2008, 20, 3516. [Google Scholar] [CrossRef]

- Heo, S.W.; Huong Le, T.H.; Tanaka, T.; Osaka, I.; Takimiya, K.; Tajima, K. Cumulative gain in organic solar cells by using multiple optical nanopatterns. J. Mater. Chem. A 2017, 5, 10347. [Google Scholar] [CrossRef]

- Ko, D.-H.; Tumbleston, J.R.; Gadisa, A.; Aryal, M.; Liu, Y.; Lopezb, R.; Samulski, E.T. Light-trapping nano-structures in organic photovoltaic cells. J. Mater. Chem. 2011, 21, 16293–16303. [Google Scholar] [CrossRef]

- Ma, X.; An, Q.; Ibraikulov, O.A.; Lévêque, P.; Heiser, T.; Leclerc, N.; Zhangd, X.; Zhang, F. Efficient ternary organic photovoltaics with two polymer donors by minimizing energy loss. J. Mater. Chem. A 2020, 8, 1265–1272. [Google Scholar] [CrossRef]

- Liu, Y.; Kirsch, C.; Gadisa, A.; Aryal, M.; Mitran, S.; Samulski, E.T.; Lopez, R. Effects of nano-patterned versus simple flat active layers in upright organic photovoltaic devices. J. Phys. D Appl. Phys. 2013, 46, 024008. [Google Scholar] [CrossRef]

- Wang, D.H.; Seifter, J.; Park, J.H.; Choi, D.-G.; Heeger, A.J. Efficiency Increase in Flexible Bulk Heterojunction Solar Cells with a Nano-Patterned Indium Zinc Oxide Anode. Adv. Energy Mater. 2012, 2, 1319–1322. [Google Scholar] [CrossRef]

- Heo, S.W.; Song, I.S.; Kim, Y.S.; Moon, D.K. Fabrication of OPVs by introducing a conductivity-enhanced hybrid buffer layer. Sol. Energy Mater. Sol. Cells 2012, 101, 295–302. [Google Scholar] [CrossRef]

- Heo, S.W.; Lee, E.J.; Song, K.W.; Lee, J.Y.; Moon, D.K. Enhanced carrier mobility and photon-harvesting property by introducing Au nano-particles in bulk heterojunction photovoltaic cells. Org. Electron. 2013, 14, 1931–1938. [Google Scholar] [CrossRef]

- Lim, S.J.; Kim, D.U.; Song, J.H.; Yu, J.-W. Enhanced performance of semi-transparent OPV with nanoparticle reflectors. Org. Electron. 2018, 59, 314–318. [Google Scholar] [CrossRef]

- Colberts, F.J.M.; Wienk, M.M.; Janssen, R.A.J. Aqueous Nanoparticle Polymer Solar Cells: Effects of Surfactant Concentration and Processing on Device Performance. ACS Appl. Mater. Interfaces 2017, 9, 13380–13389. [Google Scholar] [CrossRef]

- Chowdhury, R.; Holmes, N.P.; Cooling, N.; Belcher, W.J.; Dastoor, P.C.; Zhou, X. Surfactant Engineering and Its Role in Determining the Performance of Nanoparticulate Organic Photovoltaic Devices. ACS Omega 2022, 7, 9212–9220. [Google Scholar] [CrossRef]

- Shabani, L.; Mohammadi, A.; Jalali, T. Numerical Study of Plasmonic Effects of Ag Nanoparticles Embedded in the Active Layer on Performance Polymer Organic Solar Cells. Plasmonics 2022, 17, 491–504. [Google Scholar] [CrossRef]

- Sandzhieva, M.; Khmelevskaia, D.; Tatarinov, D.; Logunov, L.; Samusev, K.; Kuchmizhak, A.; Makarov, S.V. Organic Solar Cells Improved by Optically Resonant Silicon Nanoparticles. Nanomaterials 2022, 12, 3916. [Google Scholar] [CrossRef]

- Kamel, M.S.A.; Al-jumaili, A.; Oelgemöller, M.; Jacob, M.V. Inorganic nanoparticles to overcome efficiency inhibitors of organic photovoltaics: An in-depth review. Renew. Sustain. Energy Rev. 2022, 166, 112661. [Google Scholar] [CrossRef]

- Kurt, H. Plasmonic enhancement in PTB7-Th:PC71BM organic photovoltaics. Opt. Mater. 2022, 133, 113006. [Google Scholar] [CrossRef]

- Choi, J.Y.; Pakr, I.P.; Heo, S.W. Introducing a Quasirandom Pattern in OPVs for Balancing the Transverse Magnetic and Electric Modes of Incident Light. ACS Appl. Energy Mater. 2021, 4, 14232–14239. [Google Scholar] [CrossRef]

- Leem, J.W.; Kim, S.; Park, C.; Kim, E.; Yu, J.S. Strong Photocurrent Enhancements in Plasmonic Organic Photovoltaics by Biomimetic Nanoarchitectures with Efficient Light Harvesting. ACS Appl. Mater. Interfaces 2015, 7, 6706–6715. [Google Scholar] [CrossRef] [PubMed]

- Min, C.; Li, J.; Veronis, G.; Lee, J.-Y.; Fan, S.; Peumans, P. Enhancement of optical absorption in thin-film organic solar cells through the excitation of plasmonic modes in metallic gratings. Appl. Phys. Lett. 2010, 96, 133302. [Google Scholar] [CrossRef]

- Hwo, S.W.; Baek, K.H.; Lee, T.H.; Lee, J.Y.; Moon, D.K. Enhanced performance in inverted polymer solar cells via solution process: Morphology controlling of PEDOT:PSS as anode buffer layer by adding surfactants. Org. Electron. 2013, 14, 1629–1635. [Google Scholar]

- Zhou, Z.; Zhang, H.; Liu, J.; Huang, W. Flexible electronics from intrinsically soft materials. Giant 2021, 6, 100051. [Google Scholar] [CrossRef]

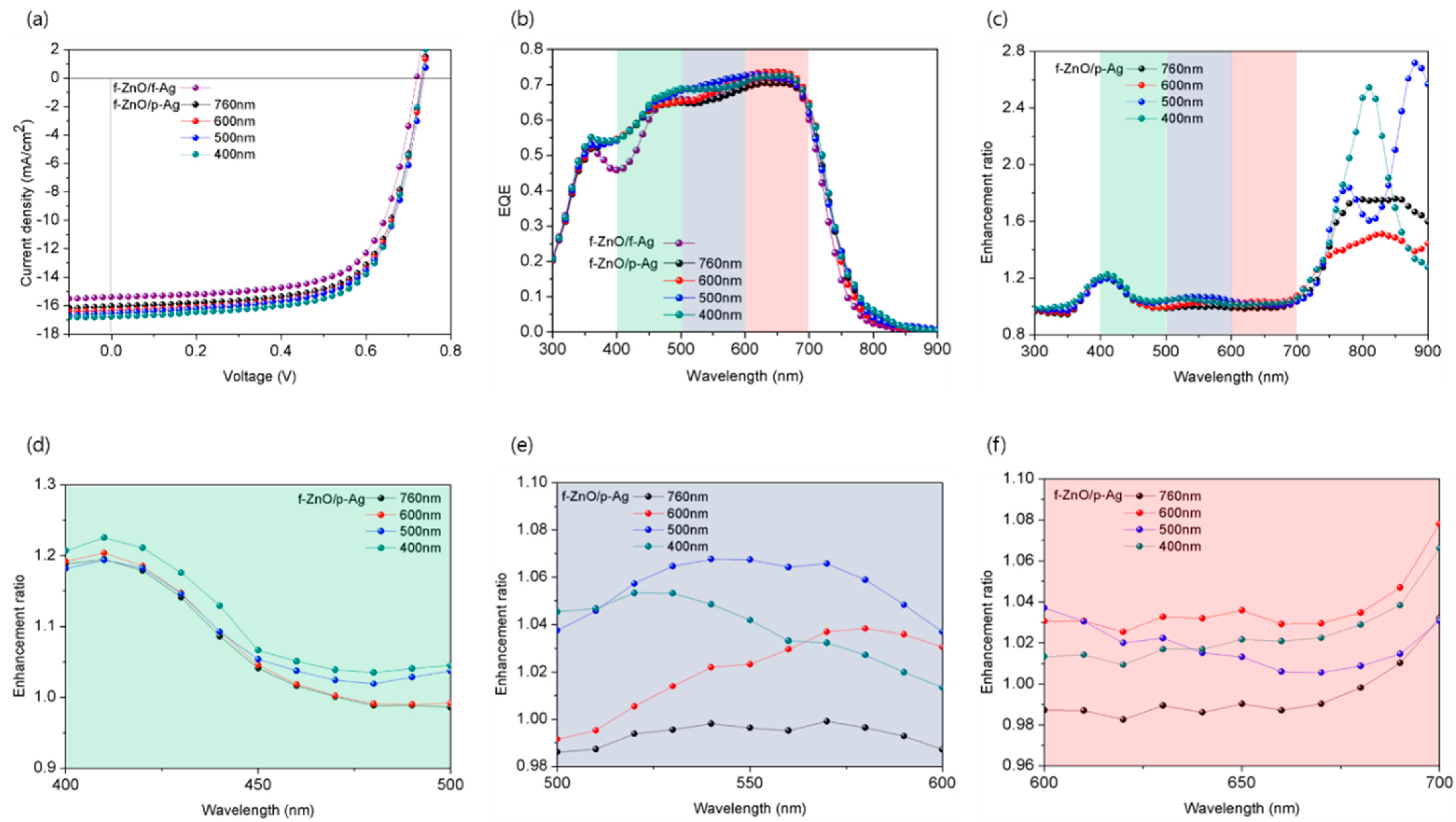

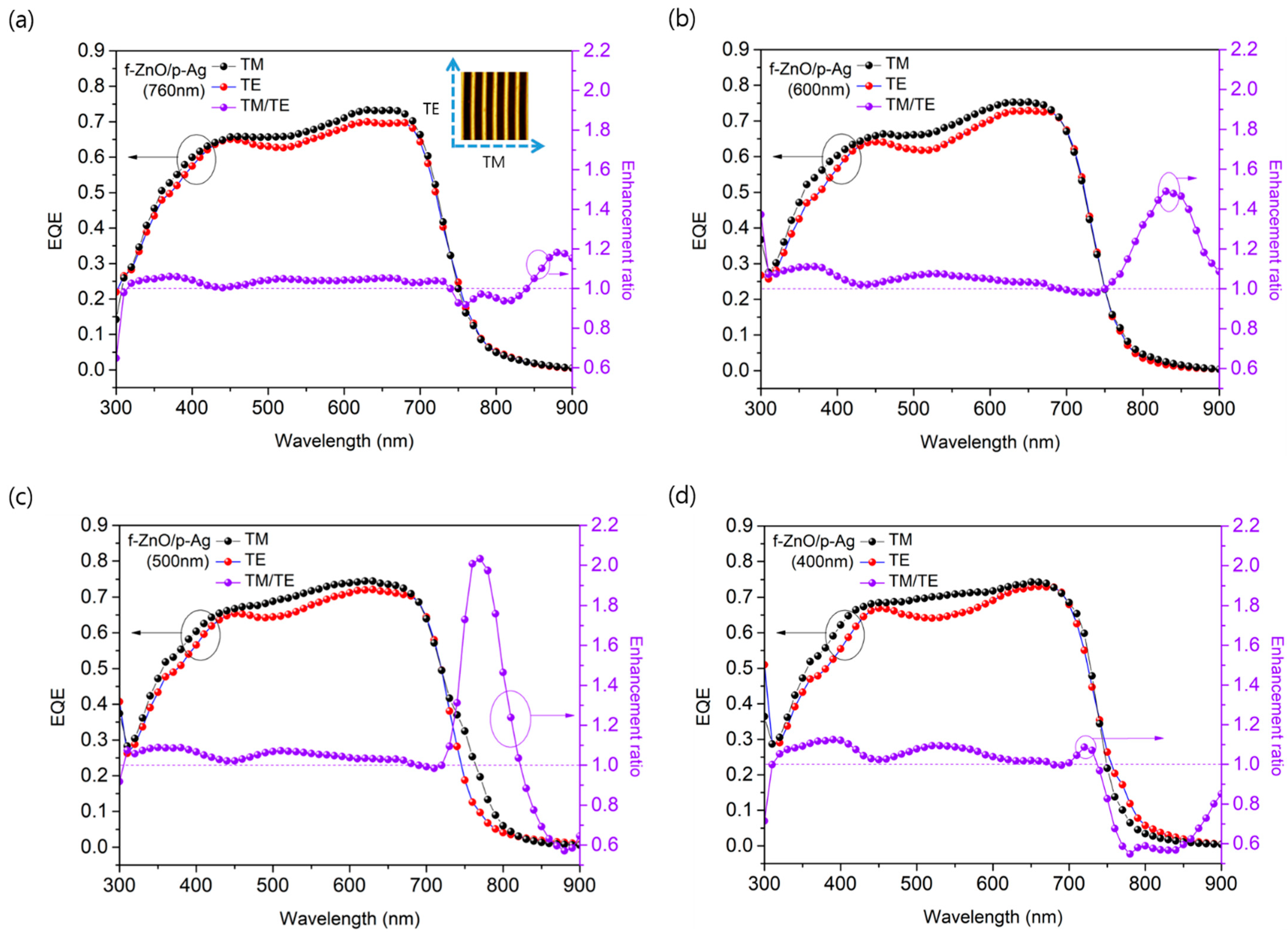

| Nanostructure | JSC (mA/cm2) (Calc. from EQE) | * JSC (mA/cm2) (Calc. from EQE in TM and TE Modes) | VOC (%) | FF (%) | PCE (%) | ** Rs (Ω cm2) | ** Rsh (kΩ cm2) | |

|---|---|---|---|---|---|---|---|---|

| Reference (f-ZnO/f-Ag) | 15.26 ± 0.02 (15.04) | TM 15.07 | 0.72 | 67.9 ± 0.4 | 7.47 ± 0.11 | 3.45 | 6.3 | |

| TE 15.03 | ||||||||

| Pattern period of 1D grating (f-ZnO/pAg) | 760 nm | 16.06 ± 0.09 (15.56) | TM 15.85 | 0.73 | 67.8 ± 0.3 | 7.95 ± 0.04 | 3.32 | 6.9 |

| TE 15.32 | ||||||||

| 600 nm | 16.23 ± 0.05 (15.79) | TM 16.16 | 0.73 | 68.0 ± 0.3 | 8.06 ± 0.09 | 3.23 | 7.2 | |

| TE 15.46 | ||||||||

| 500 nm | 16.55 ± 0.05 (15.96) | TM 16.38 | 0.73 | 68.0 ± 0.1 | 8.21 ± 0.03 | 3.15 | 7.8 | |

| TE 15.52 | ||||||||

| 400 nm | 16.78 ± 0.08 (16.12) | TM 16.63 | 0.73 | 68.1 ± 0.1 | 8.34 ± 0.04 | 3.0 | 8.6 | |

| TE 15.64 | ||||||||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Han, S.; Jung, H.; Jung, H.J.; Hwang, B.K.; Park, I.P.; Kim, S.Z.; Yun, D.-H.; Yoon, S.-Y.; Heo, S.W. Optical Manipulation of Incident Light for Enhanced Photon Absorption in Ultrathin Organic Photovoltaics. Nanomaterials 2022, 12, 3996. https://doi.org/10.3390/nano12223996

Han S, Jung H, Jung HJ, Hwang BK, Park IP, Kim SZ, Yun D-H, Yoon S-Y, Heo SW. Optical Manipulation of Incident Light for Enhanced Photon Absorption in Ultrathin Organic Photovoltaics. Nanomaterials. 2022; 12(22):3996. https://doi.org/10.3390/nano12223996

Chicago/Turabian StyleHan, Seungyeon, Hyunsung Jung, Hyeon Jin Jung, Bu Kyeong Hwang, In Pyo Park, Su Zi Kim, Dea-Hee Yun, Seog-Young Yoon, and Soo Won Heo. 2022. "Optical Manipulation of Incident Light for Enhanced Photon Absorption in Ultrathin Organic Photovoltaics" Nanomaterials 12, no. 22: 3996. https://doi.org/10.3390/nano12223996

APA StyleHan, S., Jung, H., Jung, H. J., Hwang, B. K., Park, I. P., Kim, S. Z., Yun, D.-H., Yoon, S.-Y., & Heo, S. W. (2022). Optical Manipulation of Incident Light for Enhanced Photon Absorption in Ultrathin Organic Photovoltaics. Nanomaterials, 12(22), 3996. https://doi.org/10.3390/nano12223996