Review on Coupled Thermo-Hydraulic Performance of Nanofluids and Microchannels

Abstract

1. Introduction

2. Nanofluids

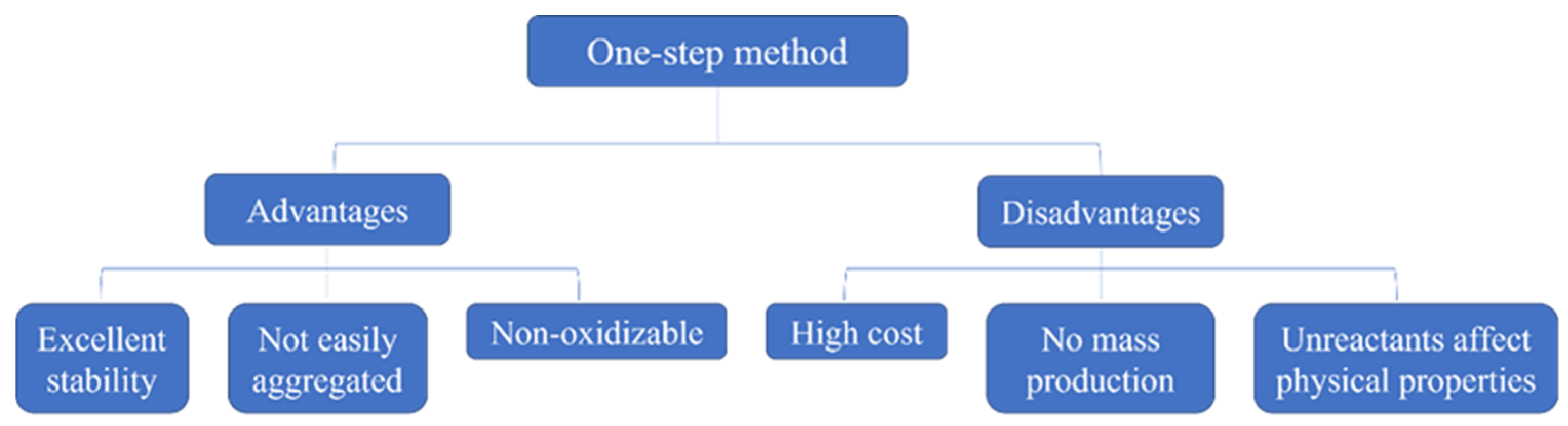

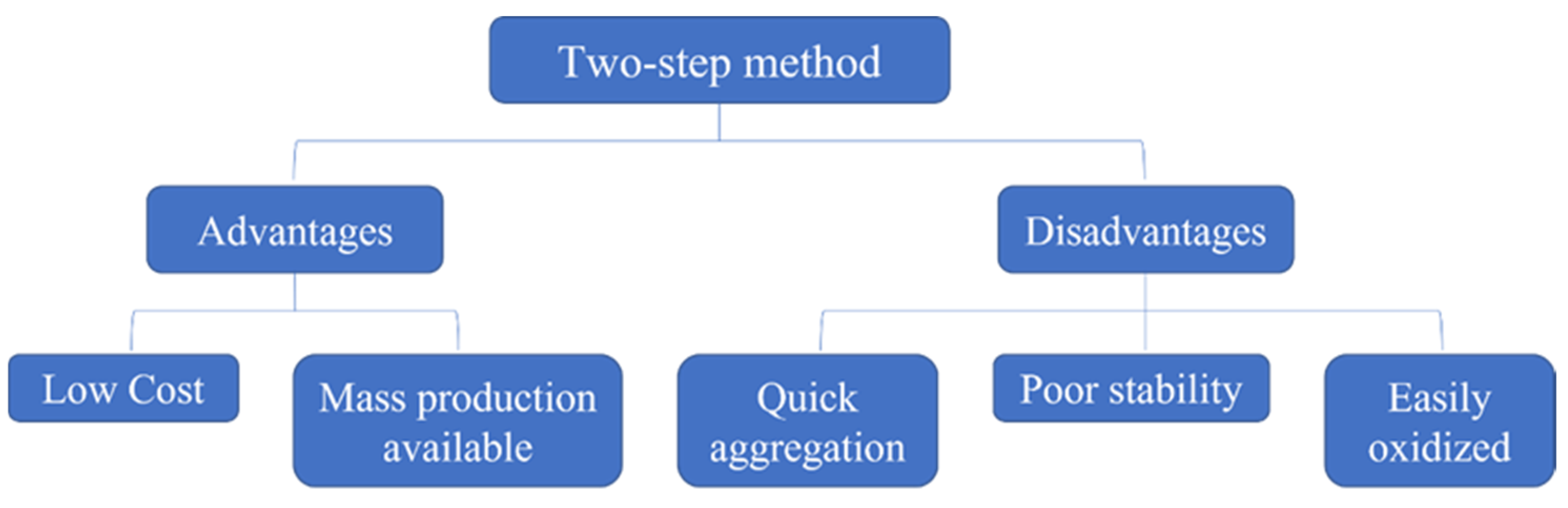

2.1. Preparation

2.2. Stability

2.2.1. Settlement Observation Method

2.2.2. Transmittance Method Based on UV Spectrophotometer

2.2.3. Zeta Potential Measurement

2.3. Thermal Conductivity

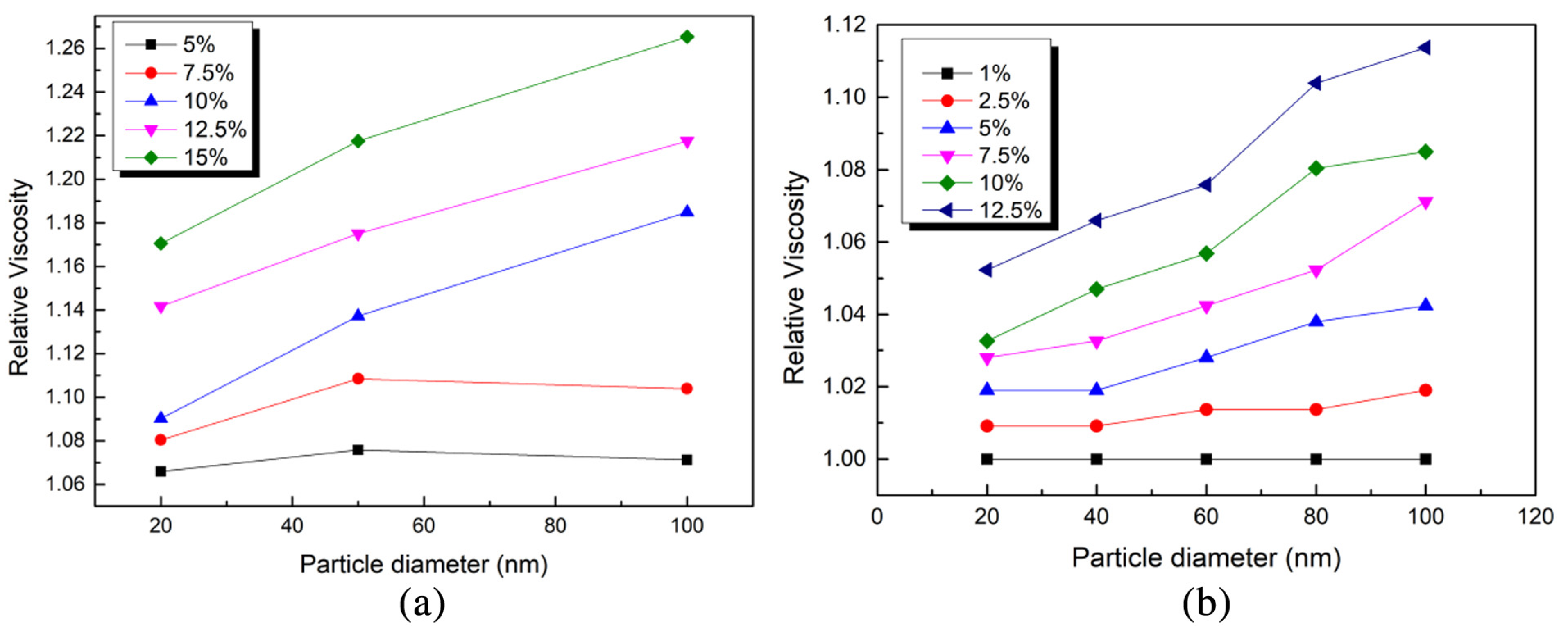

2.4. Viscosity

2.5. Surface Tension and Contact Angle

2.5.1. Surface Tension

2.5.2. Contact Angle

2.6. Methods of Passively Enhancing Heat Transfer

3. Microchannel Heat Sinks (MCHS)

3.1. Thermal-Hydraulic Properties of Different Microchannel Shapes in MCHS

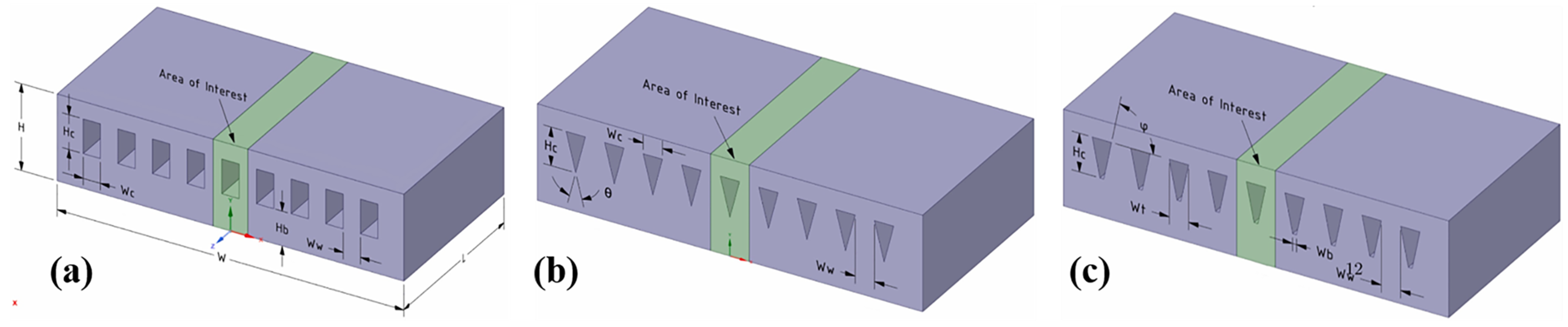

3.2. Thermal-Hydraulic Properties of MCHS with Different Rib and Cavity Shapes

3.3. Thermal-Hydraulic Properties of MCHS with Different Pin-Fin Shapes

3.4. Thermal-Hydraulic Performance of MCHS with Different Distributions

4. Thermo-Hydraulic Performance of Nanofluids in MCHS

5. Conclusions and Prospects

- (1)

- The thermal conductivity increases with increasing concentration and temperature. The viscosity decreases with increasing temperature and increases with increasing concentration, and the viscosity varies with nanoparticles in relation to the concentration. The surface tension decreases with increasing temperature and the contact angle decreases with increasing temperature and concentration.

- (2)

- Optimization of the cavity structure and the incorporation of external fields can improve passive heat transfer in nanofluids.

- (3)

- Rectangular channels have the best MCHS performance, and variable channel cross-sections can improve heat dissipation. Adding ribs will destroy the boundary layer and increase the pressure drop; cavities will form vortices and reduce the pressure drop; pin fins will cause secondary flow, all three, for the microchannel structure, will increase the the heat dissipation of the MCHS.

- (4)

- The combination of a high thermal-performance nanofluids and an optimized MCHS structure allows for the efficient cooling of the MCHS. A suitable fluid flow state can also improve the cooling performance of MCHS more significantly.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Svilans, A.; Leijnse, M.; Linke, H. Experiments on the thermoelectric properties of quantum dots. C. R. Phys. 2016, 17, 1096–1108. [Google Scholar] [CrossRef]

- Park, S.; Kang, H.; Yoon, H.J. Structure–thermopower relationships in molecular thermoelectrics. J. Mater. Chem. A 2019, 7, 14419–14446. [Google Scholar] [CrossRef]

- Reddy, P.; Jang, S.Y.; Segalman, R.A.; Majumdar, A. Thermoelectricity in molecular junctions. Science 2007, 315, 1568–1571. [Google Scholar] [CrossRef] [PubMed]

- Dekkiche, H.; Gemma, A.; Tabatabaei, F.; Batsanov, A.S.; Niehaus, T.; Gotsmann, B.; Bryce, M.R. Electronic conductance and thermopower of single-molecule junctions of oligo (phenyleneethynylene) derivatives. Nanoscale 2020, 12, 18908–18917. [Google Scholar] [CrossRef] [PubMed]

- Duan, J.; Wang, X.; Lai, X.; Li, G.; Watanable, K.; Taniguchi, T.; Zebarjadi, M.; Andrei, E.Y. High thermoelectricpower factor in graphene/hBN devices. Proc. Natl. Acad. Sci. USA 2016, 113, 14272–14276. [Google Scholar] [CrossRef]

- Paul, A.K.; Ghosh, A.; Chakraborty, S.; Roy, U.; Dutta, R.; Watanable, K.; Taniguchi, T.; Panda, A.; Agarwala, A.; Mukerjee, S.; et al. Interaction-driven giant thermopower in magic-angle twisted bilayer graphene. Nat. Phys. 2022, 18, 691–698. [Google Scholar] [CrossRef]

- Park, S.; Yoon, H.J. New Approach for large-area thermoelectric junctions with a liquid eutectic gallium–indium electrode. Nano Lett. 2018, 18, 7715–7718. [Google Scholar] [CrossRef]

- Cui, L.; Miao, R.; Jiang, C.; Meyhofer, E.; Reddy, P. Perspective: Thermal and thermoelectric transport in molecular junctions. J. Chem. Phys. 2017, 146, 092201. [Google Scholar] [CrossRef]

- He, Z.; Yan, Y.; Zhang, Z. Thermal management and temperature uniformity enhancement of electronic devices by micro heat sinks: A review. Energy 2021, 216, 119223. [Google Scholar] [CrossRef]

- Ramesh, K.N.; Sharma, T.K.; Rao, G.A.P. Latest Advancements in heat transfer enhancement in the micro-channel heat sinks: A review. Arch. Comput. Methods Eng. 2020, 28, 3135–3165. [Google Scholar] [CrossRef]

- Choi, S.U.S.; Eastman, J.A. Enhancing thermal conductivity of fluids with nanoparticles. In Proceedings of the 1995 International Mechanical Engineering Congress and Exhibition, Washington, DC, USA, 12–17 November 1995; Volume 66, pp. 99–105. [Google Scholar]

- Qiu, L.; Zhu, N.; Feng, Y.; Michaelides, E.E.; Zyla, G.; Jing, D.; Zhang, X.; Norris, P.M.; Markides, C.N.; Mahian, O. A review of recent advances in thermophysical properties at the nanoscale: From solid state to colloids. Phys. Rep. 2020, 843, 1–81. [Google Scholar] [CrossRef]

- Tuckerman, D.B.; Pease, R.F.W. High-performance heat sinking for VLSI. IEEE Electron Device Lett. 1981, 2, 126–129. [Google Scholar] [CrossRef]

- Japar, W.M.A.A.; Sidik, N.A.C.; Aid, S.R.; Asako, Y.; Ken, T.L. A comprehensive review on numerical and experimental study of nanofluid performance in microchannel heat sink (MCHS). J. Adv. Res. Fluid Mech. Therm. Sci. 2018, 45, 165–176. [Google Scholar]

- Gao, J.; Hu, Z.; Yang, Q.; Liang, X.; Wu, H. Fluid flow and heat transfer in microchannel heat sinks: Modelling review and recent progress. Therm. Sci. Eng. Prog. 2022, 29, 101203. [Google Scholar] [CrossRef]

- Yang, L.; Ji, W.; Mao, M.; Mao, M.; Huang, J. An updated review on the properties, fabrication and application of hybrid-nanofluids along with their environmental effects. J. Clean. Prod. 2020, 257, 120408. [Google Scholar] [CrossRef]

- Rudyak, V.Y.; Minakov, A.V.; Pryazhnikov, M.I. Preparation, characterization, and viscosity studding the single-walled carbon nanotube nanofluids. J. Mol. Liq. 2021, 329, 115517. [Google Scholar] [CrossRef]

- Yılmaz Aydın, D.; Gürü, M. Nanofluids: Preparation, stability, properties, and thermal performance in terms of thermo-hydraulic, thermodynamics and thermo-economic analysis. J. Therm. Anal. Calorim. 2021, 147, 7631–7664. [Google Scholar] [CrossRef]

- Mondal, S.; Dey, A.; Pal, U. Low temperature wet-chemical synthesis of spherical hydroxyapatite nanoparticles and their in situ cytotoxicity study. Adv. Nano Res. 2016, 4, 295–307. [Google Scholar]

- Ali, N.; Teixeira, J.A.; Addali, A. Aluminium nanofluids stability: A comparison between the conventional two-step fabrication approach and the controlled sonication bath temperature method. J. Nanomater. 2019, 2019, 3930572. [Google Scholar] [CrossRef]

- Qi, C.; Wan, Y.L.; Li, C.Y.; Han, D.T.; Rao, Z.H. Experimental and numerical research on the flow and heat transfer characteristics of TiO2-water nanofluids in a corrugated tube. Int. J. Heat Mass Tranf. 2017, 115, 1072–1084. [Google Scholar]

- Zareei, M.; Yoozbashizadeh, H.; Madaah Hosseini, H.R. Investigating the effects of pH, surfactant and ionic strength on the stability of alumina/water nanofluids using DLVO theory. J. Therm. Anal. Calorim. 2018, 135, 1185–1196. [Google Scholar] [CrossRef]

- Cacua, K.; Buitrago Sierra, R.; Herrera, B.; Pabón, E.; Murshed, S.M.S. Nanofluids’ stability effects on the thermal performance of heat pipes. J. Therm. Anal. Calorim. 2018, 136, 1597–1614. [Google Scholar] [CrossRef]

- Chakraborty, S.; Panigrahi, P.K. Stability of nanofluid: A review. Appl. Therm. Eng. 2020, 174, 115259. [Google Scholar] [CrossRef]

- Cacua, K.; Buitrago Sierra, R.; Pabón, E.; Gallego, A.; Zapata, C.; Herrera, B. Nanofluids stability effect on a thermosyphon thermal performance. Int. J. Therm. Sci. 2020, 153, 106347. [Google Scholar] [CrossRef]

- Masoud Parsa, S.; Yazdani, A.; Aberoumand, H.; Farhadi, Y.; Ansari, A.; Aberoumand, S.; Karimi, N.; Afrand, M.; Cheraghian, G.; Muhammad Ali, H. A critical analysis on the energy and exergy performance of photovoltaic/thermal (PV/T) system: The role of nanofluids stability and synthesizing method. Sustain. Energy Technol. 2022, 51, 101887. [Google Scholar] [CrossRef]

- Said, Z.; Sundar, L.S.; Tiwari, A.K.; Ali, H.M.; Sheikholeslami, M.; Bellos, E.; Babar, H. Recent advances on the fundamental physical phenomena behind stability, dynamic motion, thermophysical properties, heat transport, applications, and challenges of nanofluids. Phys. Rep. 2022, 946, 1–94. [Google Scholar] [CrossRef]

- Sezer, N.; Atieh, M.A.; Koç, M. A comprehensive review on synthesis, stability, thermophysical properties, and characterization of nanofluids. Powder Technol. 2019, 344, 404–431. [Google Scholar] [CrossRef]

- Almanassra, I.W.; Manasrah, A.D.; Al-Mubaiyedh, U.A.; Al-Ansari, T.; Malaibari, Z.O.; Atieh, M.A. An experimental study on stability and thermal conductivity of water/CNTs nanofluids using different surfactants: A comparison study. J. Mol. Liq. 2020, 304, 111025. [Google Scholar] [CrossRef]

- Xian, H.W.; Sidik, N.A.C.; Saidur, R. Impact of different surfactants and ultrasonication time on the stability and thermophysical properties of hybrid nanofluids. Int. Commun. Heat Mass Transf. 2020, 110, 104389. [Google Scholar] [CrossRef]

- Kim, H.J.; Lee, S.H.; Lee, J.H.; Jang, S.P. Effect of particle shape on suspension stability and thermal conductivities of water-based bohemite alumina nanofluids. Energy 2015, 90, 1290–1297. [Google Scholar] [CrossRef]

- Aberoumand, S.; Jafarimoghaddam, A. Experimental study on synthesis, stability, thermal conductivity and viscosity of Cu-engine oil nanofluid. J. Taiwan Inst. Chem. Eng. 2017, 71, 315–322. [Google Scholar] [CrossRef]

- Chen, M.; He, Y.; Huang, J.; Zhu, J. Investigation into Au nanofluids for solar photothermal conversion. Int. J. Heat Mass Transf. 2017, 108, 1894–1900. [Google Scholar] [CrossRef]

- Yang, L.; Xu, J.; Du, K.; Zhang, X. Recent developments on viscosity and thermal conductivity of nanofluids. Powder Technol. 2017, 317, 348–369. [Google Scholar] [CrossRef]

- Chen, M.; He, Y.; Zhu, J.; Wen, D. Investigating the collector efficiency of silver nanofluids based direct absorption solar collectors. Appl. Energy 2016, 181, 65–74. [Google Scholar] [CrossRef]

- Arjmandfard, A.; Toghraie, D.; Mehmandoust, B.; Hashemian, M.; Karimipour, A. The study of atomic porosity effect on water/Fe nanofluid flow in a microchannel with a molecular dynamics method. J. Mol. Liq. 2020, 317, 114291. [Google Scholar] [CrossRef]

- Li, Z.; Sarafraz, M.M.; Mazinani, A.; Hayat, T.; Alsulami, H.; Goodarzi, M. Pool boiling heat transfer to CuO-H2O nanofluid on finned surfaces. Int. J. Heat Mass Transf. 2020, 156, 19780. [Google Scholar] [CrossRef]

- Hu, Y.; He, Y.; Wang, S.; Wang, Q.; Inaki Schlaberg, H. Experimental and numerical investigation on natural convection heat transfer of TiO2-Water nanofluids in a square enclosure. J. Heat Transf. 2014, 136, 022502. [Google Scholar] [CrossRef]

- Li, H.; He, Y.; Hu, Y.; Jiang, B.; Huang, Y. Thermophysical and natural convection characteristics of ethylene glycol and water mixture based ZnO nanofluids. Int. J. Heat Mass Transf. 2015, 91, 385–389. [Google Scholar] [CrossRef]

- Wei, H.; Afrand, M.; Kalbasi, R.; Ali, H.M.; Heidarshenas, B.; Rostami, S. The effect of tungsten trioxide nanoparticles on the thermal conductivity of ethylene glycol under different sonication durations: An experimental examination. Powder Technol. 2020, 374, 462–469. [Google Scholar] [CrossRef]

- Soltani, F.; Toghraie, D.; Karimipour, A. Experimental measurements of thermal conductivity of engine oil-based hybrid and mono nanofluids with tungsten oxide (WO3) and MWCNTs inclusions. Powder Technol. 2020, 371, 37–44. [Google Scholar] [CrossRef]

- Choi, T.J.; Park, M.S.; Kim, S.H.; Jang, S.P. Experimental study on the effect of nanoparticle migration on the convective heat transfer coefficient of EG/water-based Al2O3 Nanofluids. Int. J. Heat Mass Transf. 2021, 169, 120903. [Google Scholar] [CrossRef]

- Mei, S.; Qi, C.; Liu, M.; Fan, F.; Liang, L. Effects of paralleled magnetic field on thermo-hydraulic performances of Fe3O4-water nanofluids in a circular tube. Int. J. Heat Mass Transf. 2019, 134, 707–721. [Google Scholar] [CrossRef]

- Harandi, S.S.; Karimipour, A.; Afrand, M.; Akbari, M.; D’Orazio, A. An experimental study on thermal conductivity of F-MWCNTs–Fe3O4/EG hybrid nanofluid: Effects of temperature and concentration. Int. Commun. Heat Mass Transf. 2016, 76, 171–177. [Google Scholar] [CrossRef]

- Pourrajab, R.; Noghrehabadi, A.; Behbahani, M.; Hajidavalloo, E. An efficient enhancement in thermal conductivity of water-based hybrid nanofluid containing MWCNTs-COOH and Ag nanoparticles: Experimental study. J. Therm. Anal. Calorim. 2021, 143, 3331–3343. [Google Scholar] [CrossRef]

- Shahsavar, A.; Talebizadeh Sardari, P.; Toghraie, D. Free convection heat transfer and entropy generation analysis of water-Fe3O4/CNT hybrid nanofluid in a concentric annulus. Int. J. Numer. Method Heat Fluid Flow. 2019, 29, 915–934. [Google Scholar] [CrossRef]

- Shahsavar, A.; Saghafian, M.; Salimpour, M.R.; Shafii, M.B. Experimental investigation on laminar forced convective heat transfer of ferrofluid loaded with carbon nanotubes under constant and alternating magnetic fields. Exp. Therm. Fluid Sci. 2016, 76, 1–11. [Google Scholar] [CrossRef]

- Tu, J.; Fan, F.; Qi, C.; Ding, Z.; Liang, L. Experimental study on the particle fouling properties of magnetic nanofluids in a corrugated tube with built-in twisted turbulator under variable magnetic field. Powder Technol. 2022, 400, 117216. [Google Scholar] [CrossRef]

- Zhang, H.; Qing, S.; Zhai, Y.; Zhang, X.; Zhang, A. The changes induced by pH in TiO2/water nanofluids: Stability, thermophysical properties and thermal performance. Powder Technol. 2021, 377, 748–759. [Google Scholar] [CrossRef]

- Jeong, J.; Li, C.; Kwon, Y.; Lee, J.; Kim, S.H.; Yun, R. Particle shape effect on the viscosity and thermal conductivity of ZnO nanofluids. Int. J. Referig. 2013, 36, 2233–2241. [Google Scholar] [CrossRef]

- Mishra, P.C.; Mukherjee, S.; Nayak, S.K.; Panda, A. A brief review on viscosity of nanofluids. Int. Nano Lett. 2014, 4, 109–120. [Google Scholar] [CrossRef]

- Hamze, S.; Cabaleiro, D.; Estellé, P. Graphene-based nanofluids: A comprehensive review about rheological behavior and dynamic viscosity. J. Mol. Liq. 2021, 325, 115207. [Google Scholar] [CrossRef]

- Li, H.; Wang, L.; He, Y.; Hu, Y.; Zhu, J.; Jiang, B. Experimental investigation of thermal conductivity and viscosity of ethylene glycol based ZnO nanofluids. Appl. Therm. Eng. 2015, 88, 363–368. [Google Scholar] [CrossRef]

- Karimipour, A.; Bagherzadeh, S.A.; Goodarzi, M.; Alnaqi, A.A.; Bahiraei, M.; Safaei, M.R.; Shadloo, M.S. Synthesized CuFe2O4/SiO2 nanocomposites added to water/EG: Evaluation of the thermophysical properties beside sensitivity analysis & EANN. Int. J. Heat Mass Transf. 2018, 127, 1169–1179. [Google Scholar]

- Agarwal, D.K.; Vaidyanathan, A.; Sunil Kumar, S. Synthesis and characterization of kerosene–alumina nanofluids. Appl. Therm. Eng. 2013, 60, 275–284. [Google Scholar] [CrossRef]

- Hu, X.; Yin, D.; Chen, X.; Xiang, G. Experimental investigation and mechanism analysis: Effect of nanoparticle size on viscosity of nanofluids. J. Mol. Liq. 2020, 314, 113604. [Google Scholar] [CrossRef]

- Ruhani, B.; Toghraie, D.; Hekmatifar, M.; Hadian, M. Statistical investigation for developing a new model for rheological behavior of ZnO-Ag (50%–50%)/water hybrid Newtonian nanofluid using experimental data. Physica A 2019, 525, 741–751. [Google Scholar] [CrossRef]

- Jiang, Y.; Zhou, X. Analysis of flow and heat transfer characteristics of nanofluids surface tension driven convection in a rectangular cavity. Int. J. Mech. Sci. 2019, 153, 154–163. [Google Scholar] [CrossRef]

- Kim, G.; Baek, S.; Choi, W.; Lee, A.; Lee, S.; Jeong, H.; Sung, Y. Stability, surface tension, and thermal conductivity of Al2O3/water nanofluids according to different types of alcohol and their proportion. Case Stud. Therm. Eng. 2021, 28, 101385. [Google Scholar] [CrossRef]

- Ilyas, S.U.; Ridha, S.; Kareem FA, A. Dispersion stability and surface tension of SDS-Stabilized saline nanofluids with graphene nanoplatelets. Colloids Surf. A 2020, 592, 124584. [Google Scholar] [CrossRef]

- Estellé, P.; Cabaleiro, D.; Żyła, G.; Lugo, L.; Murshed, S.S. Current trends in surface tension and wetting behavior of nanofluids. Renew. Sustain. Energy Rev. 2018, 94, 931–944. [Google Scholar] [CrossRef]

- Smaisim, G.F.; Abdulhadi, A.M.; Uktamov, K.F.; Alsultany, F.H.; Izzat, S.E.; Ansari, M.J.; Kzar, H.H.; Al-Gazally, M.E.; Kianfar, E. Nanofluids: Properties and applications. J. Sol-Gel Sci. Technol. 2022, 104, 1–35. [Google Scholar] [CrossRef]

- Çobanoğlu, N.; Karadeniz, Z.H.; Estellé, P.; Martínez-Cuenca, R.; Buschmann, M.H. Prediction of contact angle of nanofluids by single-phase approaches. Energies 2019, 12, 4558. [Google Scholar] [CrossRef]

- Huminic, G.; Huminic, A.; Dumitrache, F.; Fleaca, C.; Morjan, I. Experimental study on contact angle of water based Si–C nanofluid. J. Mol. Liq. 2021, 332, 115833. [Google Scholar] [CrossRef]

- Li, Y.; Zhai, Y.; Ma, M.; Xuan, Z.; Wang, H. Using molecular dynamics simulations to investigate the effect of the interfacial nanolayer structure on enhancing the viscosity and thermal conductivity of nanofluids. Int. Commun. Heat Mass Transf. 2021, 122, 105181. [Google Scholar] [CrossRef]

- Qi, C.; Li, C.; Zhao, G.; Liu, M.; Han, D. Influence of rotation angle of a triangular tube with a built-in twisted tape on the thermal-exergy efficiency and entropy generation of nanofluids in the heat exchange system. Asia-Pac. J. Chem. Eng. 2020, 15, e2401. [Google Scholar] [CrossRef]

- Qi, C.; Liang, L.; Rao, Z. Study on the flow and heat transfer of liquid metal based nanofluid with different nanoparticle radiuses using two-phase lattice Boltzmann method. Int. J. Heat Mass Transf. 2016, 94, 316–326. [Google Scholar] [CrossRef]

- Qi, C.; Wang, G.; Yang, L.; Wan, Y.; Rao, Z. Two-phase lattice Boltzmann simulation of the effects of base fluid and nanoparticle size on natural convection heat transfer of nanofluid. Int. J. Heat Mass Transf. 2017, 105, 664–672. [Google Scholar] [CrossRef]

- Sheikholeslami, M. CuO-water nanofluid flow due to magnetic field inside a porous media considering Brownian motion. J. Mol. Liq. 2018, 249, 921–929. [Google Scholar] [CrossRef]

- Wang, G.; Qi, C.; Tang, J. Natural convection heat transfer characteristics of TiO2–H2O nanofluids in a cavity filled with metal foam. J. Therm. Anal. Calorim. 2020, 141, 15–24. [Google Scholar] [CrossRef]

- Tu, J.; Qi, C.; Li, K.; Tang, Z. Numerical analysis of flow and heat characteristic around micro-ribbed tube in heat exchanger system. Powder Technol. 2022, 395, 562–583. [Google Scholar] [CrossRef]

- Qi, C.; Liu, M.; Wang, G.; Pan, Y.; Liang, L. Experimental research on stabilities, thermophysical properties and heat transfer enhancement of nanofluids in heat exchanger systems. Chin. J. Chem. Eng. 2018, 26, 2420–2430. [Google Scholar] [CrossRef]

- Cimpean, D.S.; Sheremet, M.A.; Pop, I. Mixed convection of hybrid nanofluid in a porous trapezoidal chamber. Int. Commun. Heat Mass Transf. 2020, 116, 104627. [Google Scholar] [CrossRef]

- Qi, C.; Li, C.; Li, K.; Han, D. Natural convection of nanofluids in solar energy collectors based on a two-phase lattice Boltzmann model. J. Therm. Anal. Calorim. 2021, 147, 2417–2438. [Google Scholar] [CrossRef]

- Jamesahar, E.; Sabour, M.; Shahabadi, M.; Mehryan, S.A.M.; Ghalambaz, M. Mixed convection heat transfer by nanofluids in a cavity with two oscillating flexible fins: A fluid–structure interaction approach. Appl. Math. Model. 2020, 82, 72–90. [Google Scholar] [CrossRef]

- Tu, J.; Qi, C.; Tang, Z.; Tian, Z.; Chen, L. Experimental study on the influence of bionic channel structure and nanofluids on power generation characteristics of waste heat utilisation equipment. Appl. Therm. Eng. 2022, 202, 117893. [Google Scholar] [CrossRef]

- Wang, Y.; Qi, C.; Zhao, R.; Wang, C. Study on the mechanism of modified surface and magnetic nanofluids on cooling performance of wireless charging equipment under magnetic field. Appl. Therm. Eng. 2022, 208, 118258. [Google Scholar] [CrossRef]

- Sardari, P.T.; Rahimzadeh, H.; Ahmadi, G.; Giddings, D. Nano-particle deposition in the presence of electric field. J. Aerosol Sci. 2018, 126, 169–179. [Google Scholar] [CrossRef]

- Sivaraj, C.; Sheremet, M.A. MHD natural convection and entropy generation of ferrofluids in a cavity with a non-uniformly heated horizontal plate. Int. J. Mech. Sci. 2018, 149, 326–337. [Google Scholar] [CrossRef]

- Fan, F.; Qi, C.; Tu, J.; Ding, Z. Effects of variable magnetic field on particle fouling properties of magnetic nanofluids in a novel thermal exchanger system. Int. J. Therm. Sci. 2022, 175, 107463. [Google Scholar] [CrossRef]

- Izadi, M.; Sheremet, M.A.; Mehryan, S.A.M. Natural convection of a hybrid nanofluid affected by an inclined periodic magnetic field within a porous medium. Chin. J. Phys. 2020, 65, 447–458. [Google Scholar] [CrossRef]

- Barnoon, P.; Toghraie, D.; Dehkordi, R.B.; Abed, H. MHD mixed convection and entropy generation in a lid-driven cavity with rotating cylinders filled by a nanofluid using two phase mixture model. J. Magn. Mater. 2019, 483, 224–248. [Google Scholar] [CrossRef]

- Sheikholeslami, M.; Domiri Ganji, D.; Younus Javed, M.; Ellahi, R. Effect of thermal radiation on magnetohydrodynamics nanofluid flow and heat transfer by means of two phase model. J. Magn. Magn. Mater. 2015, 374, 36–43. [Google Scholar] [CrossRef]

- Li, Z.; Hussein, A.K.; Younis, O.; Afrand, M.; Feng, S. Natural convection and entropy generation of a nanofluid around a circular baffle inside an inclined square cavity under thermal radiation and magnetic field effects. Int. Commun. Heat Mass Transf. 2020, 116, 104650. [Google Scholar] [CrossRef]

- Afrand, M.; Pordanjani, A.H.; Aghakhani, S.; Oztop, H.F.; Abu-Hamdeh, N. Free convection and entropy generation of a nanofluid in a tilted triangular cavity exposed to a magnetic field with sinusoidal wall temperature distribution considering radiation effects. Int. Commun. Heat Mass Transf. 2020, 112, 104507. [Google Scholar] [CrossRef]

- Izadi, M.; Sheremet, M.A.; Mehryan, S.A.M.; Pop, I.; Öztop, H.F.; Abu-Hamdeh, N. MHD thermogravitational convection and thermal radiation of a micropolar nanoliquid in a porous chamber. Int. Commun. Heat Mass Transf. 2020, 110, 104409. [Google Scholar] [CrossRef]

- Wang, H.; Chen, Z.; Gao, J. Influence of geometric parameters on flow and heat transfer performance of micro-channel heat sinks. Appl. Therm. Eng. 2016, 107, 870–879. [Google Scholar] [CrossRef]

- Kose, H.A.; Yildizeli, A.; Cadirci, S. Parametric study and optimization of microchannel heat sinks with various shapes. Appl. Therm. Eng. 2022, 211, 118368. [Google Scholar] [CrossRef]

- Lv, Y.; Xia, G.; Cheng, L.; Ma, D. Experimental investigation into unstable two phase flow phenomena during flow boiling in multi-microchannels. Int. J. Therm. Sci. 2021, 166, 106985. [Google Scholar] [CrossRef]

- Parlak, M.; Özsunar, A.; Koşar, A. High aspect ratio microchannel heat sink optimization under thermally developing flow conditions based on minimum power consumption. Appl. Therm. Eng. 2022, 201, 117700. [Google Scholar] [CrossRef]

- Liu, F.; Jing, D. Hydrothermal performances of symmetric and asymmetric divergent-convergent microchannel heat sinks. Int. Commun. Heat Mass Transf. 2021, 127, 105566. [Google Scholar] [CrossRef]

- Song, J.; Liu, F.; Sui, Y.; Jing, D. Numerical studies on the hydraulic and thermal performances of trapezoidal microchannel heat sink. Int. J. Therm. Sci. 2021, 161, 106755. [Google Scholar] [CrossRef]

- Hajmohammadi, M.R.; Bahrami, M.; Ahmadian-Elmi, M. Thermal performance improvement of microchannel heat sinks by utilizing variable cross-section microchannels filled with porous media. Int. Commun. Heat Mass Transf. 2021, 126, 105360. [Google Scholar] [CrossRef]

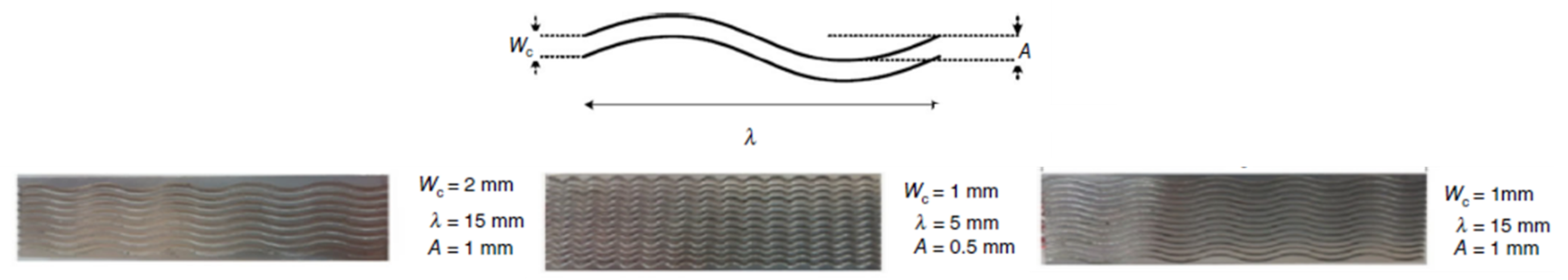

- Sajid, M.U.; Ali, H.M.; Sufyan, A.; Rashid, D.; Zahid, S.U.; Rehman, W.U. Experimental investigation of TiO2–water nanofluid flow and heat transfer inside wavy mini-channel heat sinks. J. Therm. Anal. Calorim. 2019, 137, 1279–1294. [Google Scholar] [CrossRef]

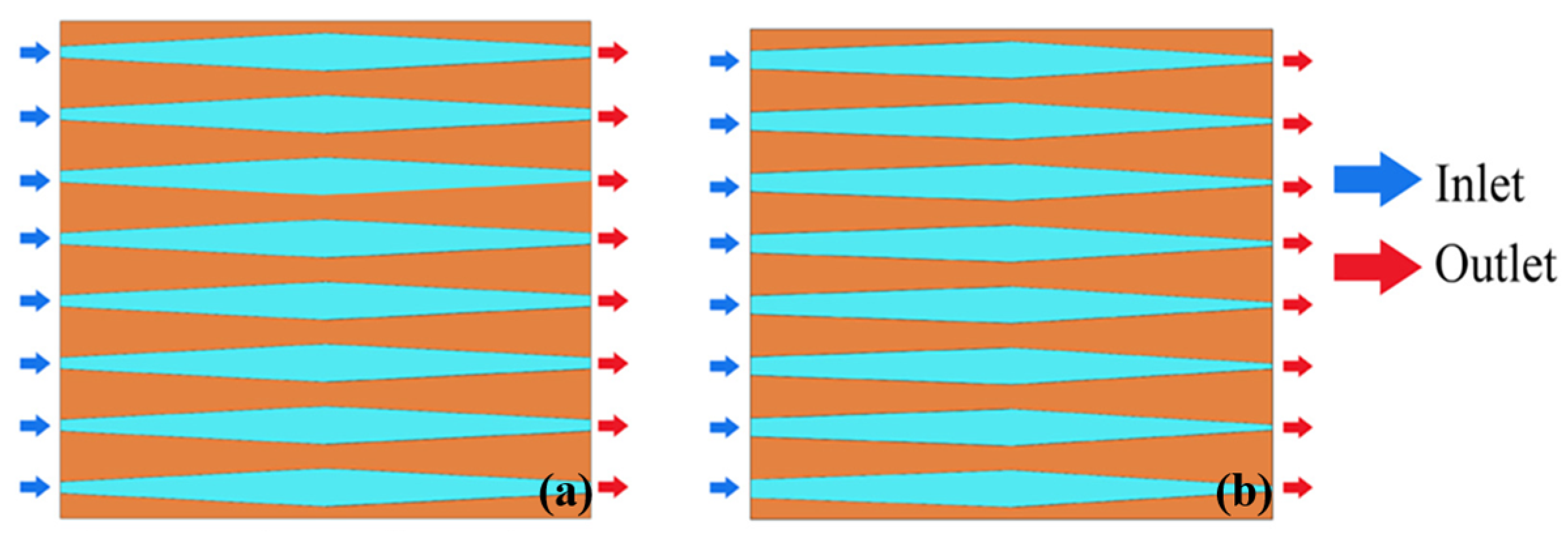

- Khan, M.Z.U.; Younis, M.Y.; Akram, N.; Akbar, B.; Rajput, U.A.; Bhutta, R.A.; Uddin, E.; Jamil, M.A.; García Márquez, F.P.; Zahid, F.B. Investigation of heat transfer in wavy and dual wavy micro-channel heat sink using alumina nanoparticles. Case Stud. Therm. Eng. 2021, 28, 101515. [Google Scholar] [CrossRef]

- Lori, M.S.; Vafai, K. Heat transfer and fluid flow analysis of microchannel heat sinks with periodic vertical porous ribs. Appl. Therm. Eng. 2022, 205, 118059. [Google Scholar] [CrossRef]

- Wang, G.; Chen, T.; Tian, M.; Ding, G. Fluid and heat transfer characteristics of microchannel heat sink with truncated rib on sidewall. Int. J. Heat Mass Tranf. 2020, 148, 119142. [Google Scholar] [CrossRef]

- Yao, P.; Zhai, Y.; Li, Z.; Shen, X.; Wang, H. Thermal performance analysis of multi-objective optimized microchannels with triangular cavity and rib based on field synergy principle. Case Stud. Therm. Eng. 2021, 25, 100963. [Google Scholar]

- Kumar, K.; Kumar, P. Effect of groove depth on hydrothermal characteristics of the rectangular microchannel heat sink. Int. J. Therm. Sci. 2021, 161, 106730. [Google Scholar] [CrossRef]

- Derakhshanpour, K.; Kamali, R.; Eslami, M. Improving performance of single and double-layered microchannel heat sinks by cylindrical ribs: A numerical investigation of geometric parameters. Int. Commun. Heat Mass Transf. 2021, 126, 105440. [Google Scholar] [CrossRef]

- Li, P.; Guo, D.; Huang, X. Heat transfer enhancement in microchannel heat sinks with dual split-cylinder and its intelligent algorithm based fast optimization. Appl. Therm. Eng. 2020, 171, 115060. [Google Scholar] [CrossRef]

- Derakhshanpour, K.; Kamali, R.; Eslami, M. Effect of rib shape and fillet radius on thermal-hydrodynamic performance of microchannel heat sinks: A CFD study. Int. Commun. Heat Mass Transf. 2020, 119, 104928. [Google Scholar] [CrossRef]

- Qi, C.; Sun, L.; Wang, Y.; Wang, C.; Chen, G. Thermo-hydraulic performance of nanofluids in a bionic fractal microchannel heat sink with traveling-wave fins. Korean J. Chem. Eng. 2021, 38, 1592–1607. [Google Scholar] [CrossRef]

- Zhu, Q.; Xia, H.; Chen, J.; Zhang, X.; Chang, K.; Zhang, H.; Wang, H.; Wan, J.; Jin, Y. Fluid flow and heat transfer characteristics of microchannel heat sinks with different groove shapes. Int. J. Therm. Sci. 2021, 161, 106721. [Google Scholar] [CrossRef]

- Huang, P.; Dong, G.; Zhong, X.; Pan, M. Numerical investigation of the fluid flow and heat transfer characteristics of tree-shaped microchannel heat sink with variable cross-section. Chem. Eng. Process. 2020, 147, 107769. [Google Scholar] [CrossRef]

- Bhandari, P.; Prajapati, Y.K. Thermal performance of open microchannel heat sink with variable pin fin height. Int. J. Therm. Sci. 2021, 159, 106609. [Google Scholar] [CrossRef]

- Jia, Y.; Xia, G.; Li, Y.; Ma, D.; Cai, B. Heat transfer and fluid flow characteristics of combined microchannel with cone-shaped micro pin fins. Int. Commun. Heat Mass Transf. 2018, 92, 78–89. [Google Scholar] [CrossRef]

- Polat, M.E.; Ulger, F.; Cadirci, S. Multi-objective optimization and performance assessment of microchannel heat sinks with micro pin-fins. Int. J. Therm. Sci. 2022, 174, 107432. [Google Scholar] [CrossRef]

- Vasilev, M.P.; Abiev, R.S.; Kumar, R. Effect of circular pin-fins geometry and their arrangement on heat transfer performance for laminar flow in microchannel heat sink. Int. J. Therm. Sci. 2021, 170, 107177. [Google Scholar] [CrossRef]

- Ali, A.M.; Angelino, M.; Rona, A. Numerical analysis on the thermal performance of microchannel heat sinks with Al2O3 nanofluid and various fins. Appl. Therm. Eng. 2021, 198, 117458. [Google Scholar] [CrossRef]

- Zeng, L.; Deng, D.; Zhong, N.; Zheng, G. Thermal and flow performance in microchannel heat sink with open-ring pin fins. Int. J. Mech. Sci. 2021, 200, 106445. [Google Scholar] [CrossRef]

- Feng, Z.; Hu, Z.; Lan, Y.; Huang, Z.; Zhang, J. Effects of geometric parameters of circular pin-fins on fluid flow and heat transfer in an interrupted microchannel heat sink. Int. J. Therm. Sci. 2021, 165, 106956. [Google Scholar] [CrossRef]

- Rajalingam, A.; Chakraborty, S. Effect of shape and arrangement of micro-structures in a microchannel heat sink on the thermo-hydraulic performance. Appl. Therm. Eng. 2021, 190, 116755. [Google Scholar]

- Bahiraei, M.; Jamshidmofid, M.; Goodarzi, M. Efficacy of a hybrid nanofluid in a new microchannel heat sink equipped with both secondary channels and ribs. J. Mol. Liq. 2019, 273, 88–98. [Google Scholar] [CrossRef]

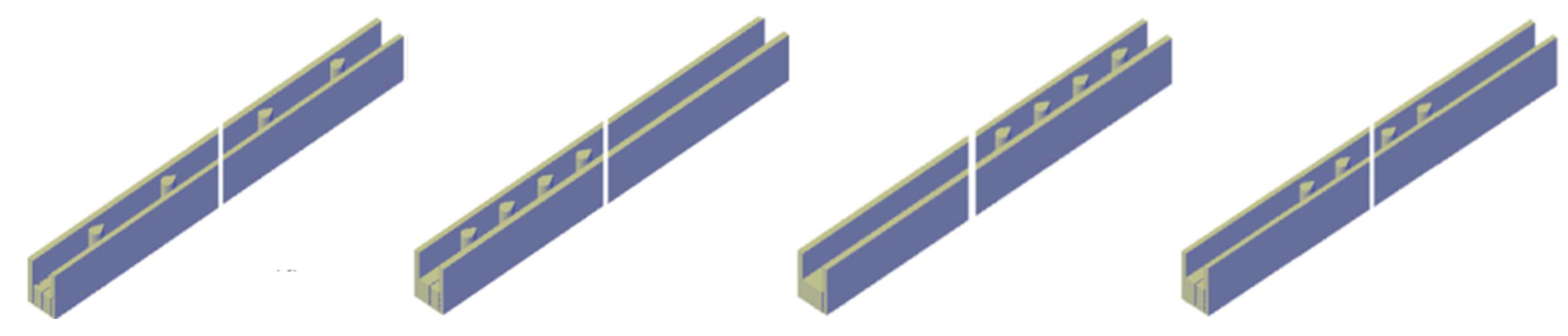

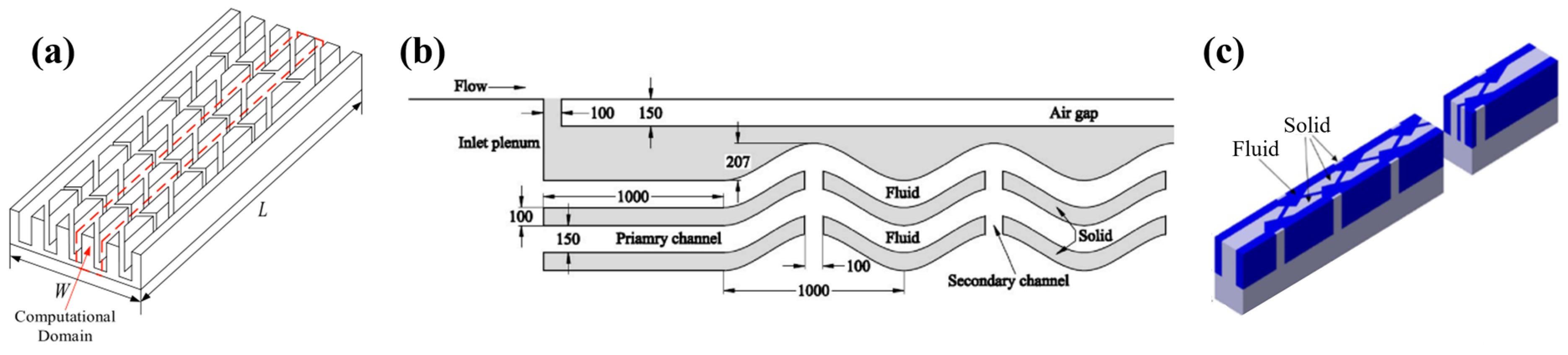

- Shi, X.; Li, S.; Mu, Y.; Yin, B. Geometry parameters optimization for a microchannel heat sink with secondary flow channel. Int. Commun. Heat Mass Transf. 2019, 104, 89–100. [Google Scholar] [CrossRef]

- Zhang, F.; Wu, B.; Du, B. Heat transfer optimization based on finned microchannel heat sink. Int. J. Therm. Sci. 2022, 172, 107357. [Google Scholar] [CrossRef]

- Ma, D.D.; Tang, Y.X.; Xia, G.D. Experimental investigation of flow boiling performance in sinusoidal wavy microchannels with secondary channels. Appl. Therm. Eng. 2021, 199, 117502. [Google Scholar] [CrossRef]

- Japar, W.M.A.A.; Sidik, N.A.C.; Mat, S. A comprehensive study on heat transfer enhancement in microchannel heat sink with secondary channel. Int. Commun. Heat Mass Transf. 2018, 99, 62–81. [Google Scholar] [CrossRef]

- Ozguc, S.; Pan, L.; Weibel, J.A. Topology optimization of microchannel heat sinks using a homogenization approach. Int. J. Heat Mass Transf. 2021, 169, 120896. [Google Scholar] [CrossRef]

- Bahiraei, M.; Heshmatian, S. Thermal performance and second law characteristics of two new microchannel heat sinks operated with hybrid nanofluid containing graphene–silver nanoparticles. Energy Convers. Manag. 2018, 168, 357–370. [Google Scholar] [CrossRef]

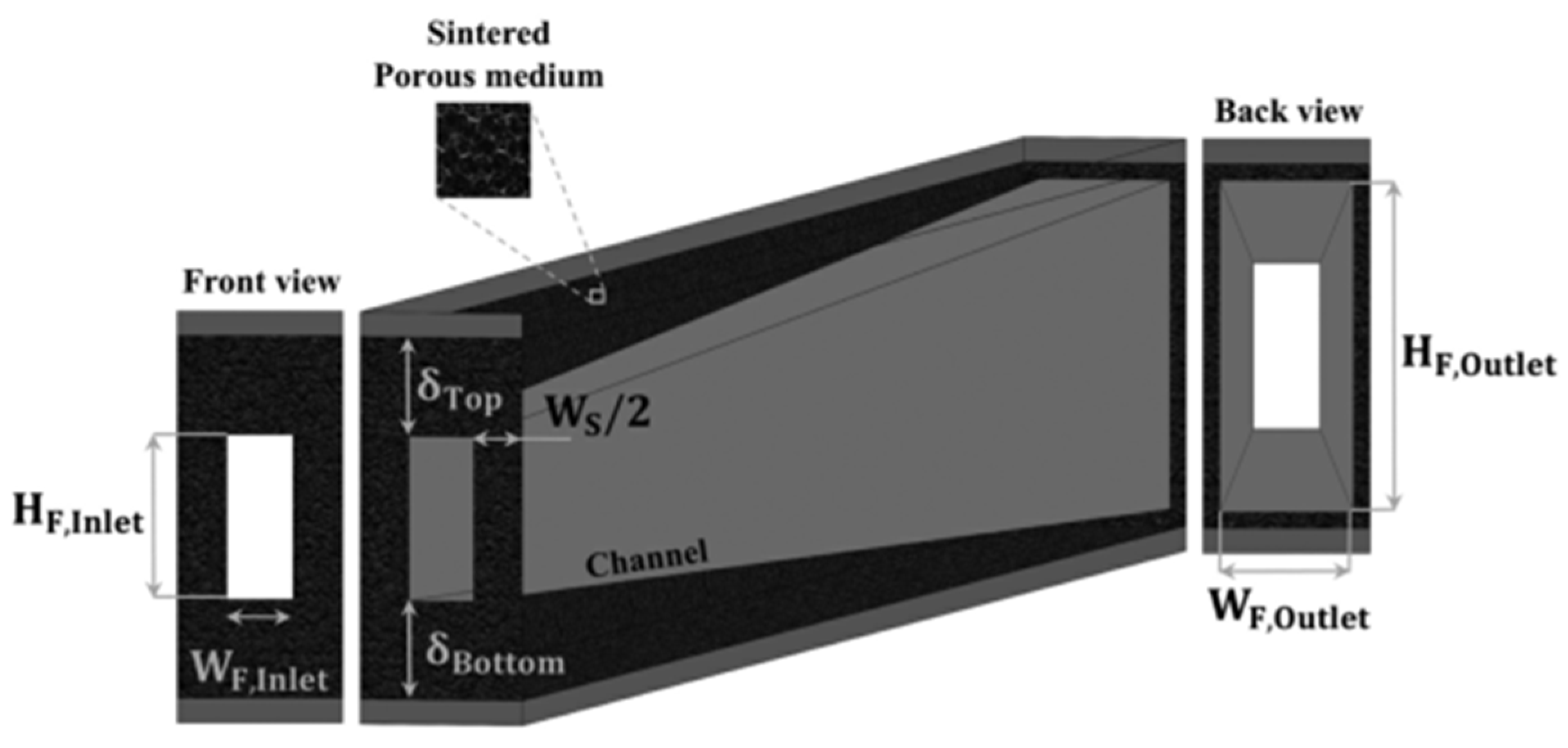

- Jia, Y.T.; Xia, G.D.; Zong, L.X.; Ma, D.D.; Tang, Y.X. A comparative study of experimental flow boiling heat transfer and pressure drop characteristics in porous-wall microchannel heat sink. Int. J. Heat Mass Transf. 2018, 127, 818–833. [Google Scholar] [CrossRef]

- Bahiraei, M.; Heshmatian, S. Efficacy of a novel liquid block working with a nanofluid containing graphene nanoplatelets decorated with silver nanoparticles compared with conventional CPU coolers. Appl. Therm. Eng. 2017, 127, 1233–1245. [Google Scholar] [CrossRef]

- Tang, Z.; Sun, L.; Qi, C.; Wang, Y.; Chen, L. Flow and heat transfer characteristics of a fractal microchannel heat sink with three-dimensional fractal tail. Asia-Pac. J. Chem. Eng. 2022, 17, e2803. [Google Scholar] [CrossRef]

- Gilmore, N.; Timchenko, V.; Menictas, C. Open manifold microchannel heat sink for high heat flux electronic cooling with a reduced pressure drop. Int. J. Heat Mass Transf. 2020, 163, 120395. [Google Scholar] [CrossRef]

- Zhou, F.; Zhou, W.; Qiu, Q.; Yu, W.; Chu, X. Investigation of fluid flow and heat transfer characteristics of parallel flow double-layer microchannel heat exchanger. Appl. Therm. Eng. 2018, 137, 616–631. [Google Scholar] [CrossRef]

- Wu, J.M.; Zhao, J.Y.; Tseng, K.J. Parametric study on the performance of double-layered microchannels heat sink. Energy Convers. Manag. 2014, 80, 550–560. [Google Scholar] [CrossRef]

- Zhang, Y.D.; Chen, M.R.; Wu, J.H.; Hung, K.S.; Wang, C.C. Performance improvement of a double-layer microchannel heat sink via novel fin geometry—A numerical study. Energies 2021, 14, 3585. [Google Scholar] [CrossRef]

- Wang, S.L.; Chen, L.Y.; Zhang, B.X.; Yang, Y.R.; Wang, X.D. A new design of double-layered microchannel heat sinks with wavy microchannels and porous-ribs. J. Therm. Anal. Calorim. 2020, 141, 547–558. [Google Scholar] [CrossRef]

- Wu, H.; Zhang, S. Numerical Study on the fluid flow and heat transfer characteristics of Al2O3-water nanofluids in microchannels of different aspect ratio. Micromachines 2021, 12, 868. [Google Scholar] [CrossRef]

- He, W.; Mashayekhi, R.; Toghraie, D.; Akbari, O.A.; Li, Z.; Tlili, I. Hydrothermal performance of nanofluid flow in a sinusoidal double layer microchannel in order to geometric optimization. Int. Commun. Heat Mass Transf. 2020, 117, 104700. [Google Scholar] [CrossRef]

- Duangthongsuk, W.; Wongwises, S. A comparison of the thermal and hydraulic performances between miniature pin fin heat sink and microchannel heat sink with zigzag flow channel together with using nanofluids. Heat Mass Transf. 2018, 54, 3265–3274. [Google Scholar] [CrossRef]

- Shamsuddin, H.S.; Estellé, P.; Navas, J.; Mohd-Ghazali, N.; Mohamad, M. Effects of surfactant and nanofluid on the performance and optimization of a microchannel heat sink. Int. J. Heat Mass Transf. 2021, 175, 121336. [Google Scholar] [CrossRef]

- Ray, D.R.; Strandberg, R.; Das, D.K. Thermal and fluid dynamic performance comparison of three nanofluids in microchannels using analytical and computational models. Processes 2020, 8, 754. [Google Scholar] [CrossRef]

- Mohamad Noh, N.H.; Fazeli, A.; Che Sidik, N.A. Numerical simulation of nanofluids for cooling efficiency in microchannel heat sink. J. Adv. Res. Fluid Mech. Therm. Sci. 2014, 4, 13–23. [Google Scholar] [CrossRef]

- Shahsavar, A.; Godini, A.; Sardari, P.T.; Toghraie, D.; Salehipour, H. Impact of variable fluid properties on forced convection of Fe3O4/CNT/water hybrid nanofluid in a double-pipe mini-channel heat exchanger. J. Therm. Anal. Calorim. 2019, 137, 1031–1043. [Google Scholar] [CrossRef]

- Al Muallim, B.; Wahid, M.A.; Mohammed, H.A.; Kamil, M.; Habibi, D. Thermal–hydraulic performance in a microchannel heat sink equipped with longitudinal vortex generators (LVGs) and nanofluid. Processes 2020, 8, 231. [Google Scholar] [CrossRef]

- Wang, J.; Yu, K.; Ye, M.; Wang, E.; Wang, W.; Sundén, B. Effects of pin fins and vortex generators on thermal performance in a microchannel with Al2O3 nanofluids. Energy 2022, 239, 122606. [Google Scholar] [CrossRef]

- Zhang, F.; Sundén, B.; Zhang, W.; Xie, G. Constructal parallel-flow and counterflow microchannel heat sinks with bifurcations. Numer. Heat Transf. Part A-Appl. 2015, 68, 1087–1105. [Google Scholar] [CrossRef]

- Awad, M.; Radwan, A.; Abdelrehim, O.; Emam, M.; Shmroukh, A.N.; Ahmed, M. Performance evaluation of concentrator photovoltaic systems integrated with a new jet impingement-microchannel heat sink and heat spreader. Sol. Energy 2020, 199, 852–863. [Google Scholar] [CrossRef]

- Xu, C.; Xu, S.; Wang, Z.; Feng, D. Experimental investigation of flow and heat transfer characteristics of pulsating flows driven by wave signals in a microchannel heat sink. Int. Commun. Heat Mass Transf. 2021, 125, 105343. [Google Scholar] [CrossRef]

- Mohammadpour, J.; Husain, S.; Salehi, F.; Lee, A. Machine learning regression-CFD models for the nanofluid heat transfer of a microchannel heat sink with double synthetic jets. Int. Commun. Heat Mass Transf. 2022, 130, 105808. [Google Scholar] [CrossRef]

| Author | Nano Particles | Base Fluids | Mass Fraction (%) | Particle Size (nm) | Improvement of Thermal Conductivity |

|---|---|---|---|---|---|

| Aberoumand et al. [32] | Cu | Engine oil | 0.2 0.5 1 | 50 | 27.0% 31.0% 49.0% |

| Kim [33,34] | Au | H2O | 0.018 | 7–12 | 9.0% |

| Chen et al. [35] | Ag | H2O | 0.1–0.3 | 10 80 | 18.0% |

| Arjmandfard et al. [36] | Fe | EG | 0.20–0.55 | 10 | 13.0–18.0% |

| Li et al. [37] | CuO | H2O | 0.025–0.1 | 45 | 3.0–13.5% |

| Hu et al. [38] | TiO2 | H2O | 3.85 7.41 | 10 | 2.12% 4.70% |

| Li et al. [39] | ZnO | 75EG/25DW 85EG/15DW 95EG/5DW | 5.25 | 30 | 8.00% 5.00% 3.00% |

| Wei et al. [40] | WO3 | EG | 0.005–5 | <30 | 0.78–32.38% |

| Soltani et al. [41] | WO3/MWCNTs | Engine Oil | 0.0–0.6 | WO3: 23–65 MWCNT: 20–30 | 3.65–8.30% |

| Choi et al. [42] | Al2O3 | EG/H2O | 1.43 | 40–50 | 4.4% |

| Mei et al. [43] | Fe3O4 | H2O | 0.1 0.3 0.5 | 20 | 0.57% 1.75% 2.97% |

| Harandi et al. [44] | F-MWCNTs-Fe3O4 | EG | 0–2.3 | 20–30 | 30% |

| Pourrajab et al. [45] | MWCNTs–COOH-Ag | H2O | MWCNTs: 0.004–0.16 Ag: 0.04 | MWCNTs: 20–30 Ag: 5–8 | 47.3% |

| Shahsavar et al. [46,47] | Fe3O4/CNT | H2O | Fe3O4: 0.5–0.9 CNT: 0.25–1.35 | 10 | 14.25– 58.74% |

| Tu et al. [48] | Fe3O4/AG | H2O | Fe3O4: 0.1–0.5 AG: 0.8 | 20 | 3.1–9.2% |

| Structure | Fluid | Conclusion |

|---|---|---|

Details of the triangular tube [72] | TiO2-H2O | Qi et al. [72] found that the thermal properties of nanofluids in triangular tubes is superior to that of round tubes. |

Cavity shape models [73,74] | Cu-Al2O3/H2O | Cimpean et al. [73,74] observed that trapezoidal and parallelogram cavities create dead zones in the flow of the nanofluids; therefore, rectangular chambers have a better heat-transfer capacity. |

Cavity model with oscillating fins [75] | Nanofluids | Jamesahar et al. [75] discovered that the average Nu decreases with the increasing frequency of oscillation and increases with the increasing magnitude. |

Waveform cavity model [76] | CuO-H2O | Tu et al. [76] concluded that for the same surface area, with increasing angular frequency and amplitude, the thermal performance is improved, the heat-transfer area rises, turbulence is enhanced and the thermal resistance of the boundary is reduced. |

| Author | Conditions | Conclusion |

|---|---|---|

| Sardari et al. [78] | Electric field | At an electric field of 10 kV/m, the electrostatic force plays a dominant role, and at an electric field of 1 kV/m, the Brownian motion of the nanoparticles is more pronounced. |

| Sivaraj et al. [79] Fan et al. [80] Izadi et al. [81] Barnoon et al. [82] | Magnetic field | The greater the tilt angle of the magnetic field in the range 0–90°, the stronger the thermal properties of the nanofluids within the horizontal plate cavity. However, the effect of periodic magnetic fields on the thermal properties is not periodic. |

| Sheikholeslami et al. [83] Li et al. [84] Afrand et al. [85] Izadi et al. [86] | Thermal radiation and magnetic fields | The Nusselt number increases with increasing radiation parameters. The Nusselt number is greatest when the magnetic field is vertical. The nanofluids are subjected to both thermal radiation and magnetic fields, which both accelerates heat transfer and increases entropy production. The Lorentz force can affect the heat-transfer performance by changing the buoyancy force. |

| Researchers | Rib/Cavity | Shape | Re | Comments |

|---|---|---|---|---|

| Kumar et al. [99] | Rib | Arc | 200, 900, 2000 | The MCHS with curved ribs produces a pseudo-secondary flow which enhances heat transfer. Structures with curved ribs on both the base plate and the side walls showed the greatest increase in Nu, by up to 119%, but at the expense of the Poiseuille number. |

| Derakhshanpour et al. [100] | Rib | Cylindrical | 49–396 | Reducing the rib spacing is more effective than increasing the radius of the cylindrical ribs in improving the performance of MCHS. |

| Li et al. [101] | Rib | Dual split-cylinder | 50–300 | The bottom dual-split-cylinder MCHS structure was proposed and optimized using an intelligent algorithm. Optimal dual-split-cylinder width decreases with increasing Re. For Re = 250, the best thermal performance of the optimized MCHS can be improved by 63.41% |

| Lori et al. [96] | Rib | Rectangle; Ellipse; Triangle | 100–800 | The best heat-transfer performance was achieved with triangular ribs at small heights and elliptical and rectangular ribs at large heights. |

| Wang et al. [97] | Rib | Truncated rectangle | 100–1000 | The Nu and surface friction coefficient increase as the rib width increases. Truncated ribs reduce the ΔP, which decreases with increasing truncated clearance, improving the comprehensive thermal performance. |

| Derakhshanpour et al. [102] | Rib | Semi-circular; Semi-elliptical | 66–396 | The curvature of the rib angles affects the heat-transfer performance of MCHS; the best performance is achieved with semi-circular ribs and filleted corner, with an increase in Nu of 18–21% and an increase in performance of 19–22%. |

| Qi et al. [103] | Cavity | Travelling wave | 200–1000 | Fractal MCHS with travelling wave cavities were found to improve the heat-transfer performance. The Nu increases and then decreases with increasing eccentricity, reaching a maximum at an eccentricity of 0.1. |

| Zhu et al. [104] | Cavity | Rectangle; Triangle; Trapezoid; Teardrop; Semicircle | 194–610 | The triangular-cavity MCHS shows the greatest improvement in thermal performance, but with a significant increase in ΔP, and the teardrop cavity MCHS has the best overall heat-transfer efficiency. |

| Huang et al. [105] | Rib or Cavity | Arc | 200–1000 | The ribbed MCHS has superior thermal performance, but also the a high ΔP. Combining thermal and hydraulic performance considerations, the cavity MCHS has the best performance. |

| Yao et al. [98] | Rib and Cavity | Triangular | 0–600 | Surface temperature is lowest at 0.0572 mm cavity height and 0.0224 mm rib height, which can be reduced by 17–26 K. Convective heat transfer dominates and flow friction increases with disturbance between the ribs. |

| Researchers | Structure | Shape | Re | Comments |

|---|---|---|---|---|

| Polat et al. [108] | Fin | Round, square, diamond | 100–350 | Diamond fins enhance thermal performance at the expense of hydraulic performance. Circular fins have the best performance; the best performance occurs when the porosity is large. |

| Vasilev et al. [109] | Fin | Circular | 100–1000 | The thermal and hydraulic performance of the PFMCHS increases with the height of the fin, with the optimum diameter and pitch being influenced by the height. |

| Ali et al. [110] | Fin | Rectangular, serrated | 100–350 | The serrated PFMCHS provides better performance, with a 6.44 K reduction in the average temperature of the heated surface, a 15% reduction in ΔP and a 60% increase in Nu. |

| Jia et al. [107] | Fin | Cone | 147–637 | When the pin fins are evenly distributed throughout the channel, the overall evaluation coefficient η is the largest. |

| Bhandari et al. [106] | Fin | Square | 100–800 | The 1.5 mm high pin fins open PFMCHS is the most efficient in terms of heat dissipation, when the convective surface area and open space are more conducive to enhancing the thermal performance. |

| Zeng et al. [111] | Fin | Open-ring | 160–694 | Open-ring pin fins cause fluid separation and convergence, and the flow boundary layer is interrupted periodically. The staggered open-ring PFMCHS offers the best overall performance. |

| Feng et al. [112] | Fin and cavity | [F]: Circular [C]: Rectangular | 133–530 | Two circular pin fins in the micro-cavity can effectively reduce the wall temperature and improve the temperature uniformity. The spacing of the fins affects the overall performance of the MCHS. |

| Rajalingam et al. [113] | Fin and blind hole | [F]: Circular, elliptical, aerofoil [B]: Circular | 500–1000 | MCHS with elliptical pin fins and circular blind holes has the best overall performance. |

| Bahiraei et al. [114] | Fin and rib | [F]: Trapezoidal, [R]: Rectangular | 100–500 | Changing the channel walls to trapezoidal fins that induce secondary flow reduces the increase in ΔP due to ribs. The h can be increased by 17% and the heat-transfer surface temperature can be reduced by up to 13.88 K. |

| Structure | Working Fluids | Comments |

|---|---|---|

Heat sink A and heat sink B [120] | Graphene-silver nanofluid | Bahiraei et al. [120] found that as the nanofluids concentration and inlet velocity increase, the temperature and thermal resistance of the heating surface decreases and the temperature is more evenly distributed. Heat sink B has more intense fluid mixing and better heat transfer. |

Rectangle and PW MCHS [121] | Pure acetone liquid | Jia et al. [121] revealed that the porous walls (PW) formed by the micro pin fin arrays on the side walls of the rectangular microchannels accelerate the liquid film disturbance, enhance evaporation heat transfer from the liquid film and improve the local heat coefficient. |

Serpentine and distributor MCHS [122] | GNP–silver nanofluid | Bahiraei et al. [122] discovered that the serpentine MCHS thermal performance is best when Re is constant, but the pumping power is high and the distributor-liquid-block thermal performance is best when the pumping power is constant. |

MCHS model for 3D fractals [123] | Deionised water | Tang et al. [123] proposed a three-dimensional fractal based on the disk fractal structure, and as the number of fractals increases, the surface temperature decreases by 2–4 K and the pressure drop increases by 5.96–8.29%. B-type topology has the best heat-transfer performance with a combined performance index of up to 1.29. |

Model of MMCHS [124] | Water | Gilmore et al. [124] proposed a new open manifold microchannel heat sink (MMCHS) that can reduce its thermal resistance by optimizing the manifold shape. This MMCHS is derived to have a lower pressure drop of 25% and better overall performance. |

| Author | Working Fluids | Structure | Comments |

|---|---|---|---|

| Sajid et al. [94] | TiO2-H2O | Wavy MCHS | The thermal performance of MCHS of TiO2-H2O nanofluid is better than that of distilled water, and its heat-dissipation performance decreases with increasing heating power. |

| Wu et al. [129] | Al2O3-H2O | RMCHS | The average temperature of the RMCHS heat-exchange surface decreases with increasing volume concentrations of nanoparticles, but there is a large increase in pumping power. |

| He et al. [130] | Al2O3-Cu-H2O | DL-MCHS | Average Nu of sinusoidal DL-MCHS increases with the increasing volume fraction of nanoparticles. |

| Duangthongsuk et al. [131] | SiO2-H2O | FMCHS CCZ-HS | The surface temperature of the circular fin MCHS (FMCHS) and the zigzag runner heat sink with a single cross-cut structure (CCZ-HS) decreases with increasing particle concentration. |

| Shamsuddin et al. [132] | BNNTs | RMCHS | At 50 °C, the pressure drop of MCHS is reduced by 3.2% and the heat-transfer performance is improved when the fluid is a mixture of surfactant TX-100 and 0.001wt% BNNTs compared to 0.001wt% BNNTs. |

| Ray et al. [133] | Al2O3/CuO/SiO2-EG/H2O (6:4) | RMCHS | CuO-EG/H2O (6:4) offers the most significant performance improvement, with a 21% increase in convective heat-transfer coefficient and 22% reduction in pumping power. |

| Noh et al. [134] | CuO/Diamond/Al2O3/SiO2-H2O | RMCHS | The use of Diamond-H2O nanofluids as a coolant results in a 0.3% increase in heat-dissipation efficiency. |

| Shahsavar et al. [135] | Fe3O4-CNT-H2O | Double-pipe MCHS | The thermal characteristics of the non-Newtonian Fe3O4-CNT-H2O nanofluids are higher than those of Newtonian Fe3O4-CNT-H2O nanofluids, while the flow characteristics such as pressure drop and pump power are the opposite. |

| Muallim et al. [136] | Al2O3/CuO-H2O/EG/PAO | RMCHS with longitudinal vortex generations | The CuO-PAO (Polyalphaolefin) nanofluid has the best performance, with a Nu of 15.88, and this fluid has the best performance in RMCHS with longitudinal vortex generation. |

| Wang et al. [137] | Al2O3-H2O DI-H2O | FMCHS with vortex generators | The best heat-transfer performance of the FMCHS is achieved at a particle size of 20 nm and a volume fraction of 4% for Al2O3 nanoparticles. |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, Y.; Yu, J.; Qi, C.; Zhang, W. Review on Coupled Thermo-Hydraulic Performance of Nanofluids and Microchannels. Nanomaterials 2022, 12, 3979. https://doi.org/10.3390/nano12223979

Wang Y, Yu J, Qi C, Zhang W. Review on Coupled Thermo-Hydraulic Performance of Nanofluids and Microchannels. Nanomaterials. 2022; 12(22):3979. https://doi.org/10.3390/nano12223979

Chicago/Turabian StyleWang, Yuwei, Jie Yu, Cong Qi, and Wenjie Zhang. 2022. "Review on Coupled Thermo-Hydraulic Performance of Nanofluids and Microchannels" Nanomaterials 12, no. 22: 3979. https://doi.org/10.3390/nano12223979

APA StyleWang, Y., Yu, J., Qi, C., & Zhang, W. (2022). Review on Coupled Thermo-Hydraulic Performance of Nanofluids and Microchannels. Nanomaterials, 12(22), 3979. https://doi.org/10.3390/nano12223979