On the Evolution of Nano-Structures at the Al–Cu Interface and the Influence of Annealing Temperature on the Interfacial Strength

Abstract

1. Introduction

- (i)

- To develop a modeling framework that captures the nano-scale diffusion process that occurs during the joining of a model Al–Cu system;

- (ii)

- To predict the evolution of microstructural features such as defects at the interfaces and intermetallic compound formation near the interfaces;

- (iii)

- To assess the effects of annealing on the quality of the interfaces;

- (iv)

- To characterize the tensile and shear strength of the interfaces, and to understand the failure mechanisms that occur at the interfaces;

- (v)

- To correlate modeling predictions for the strength of interfaces with indentation experiments.

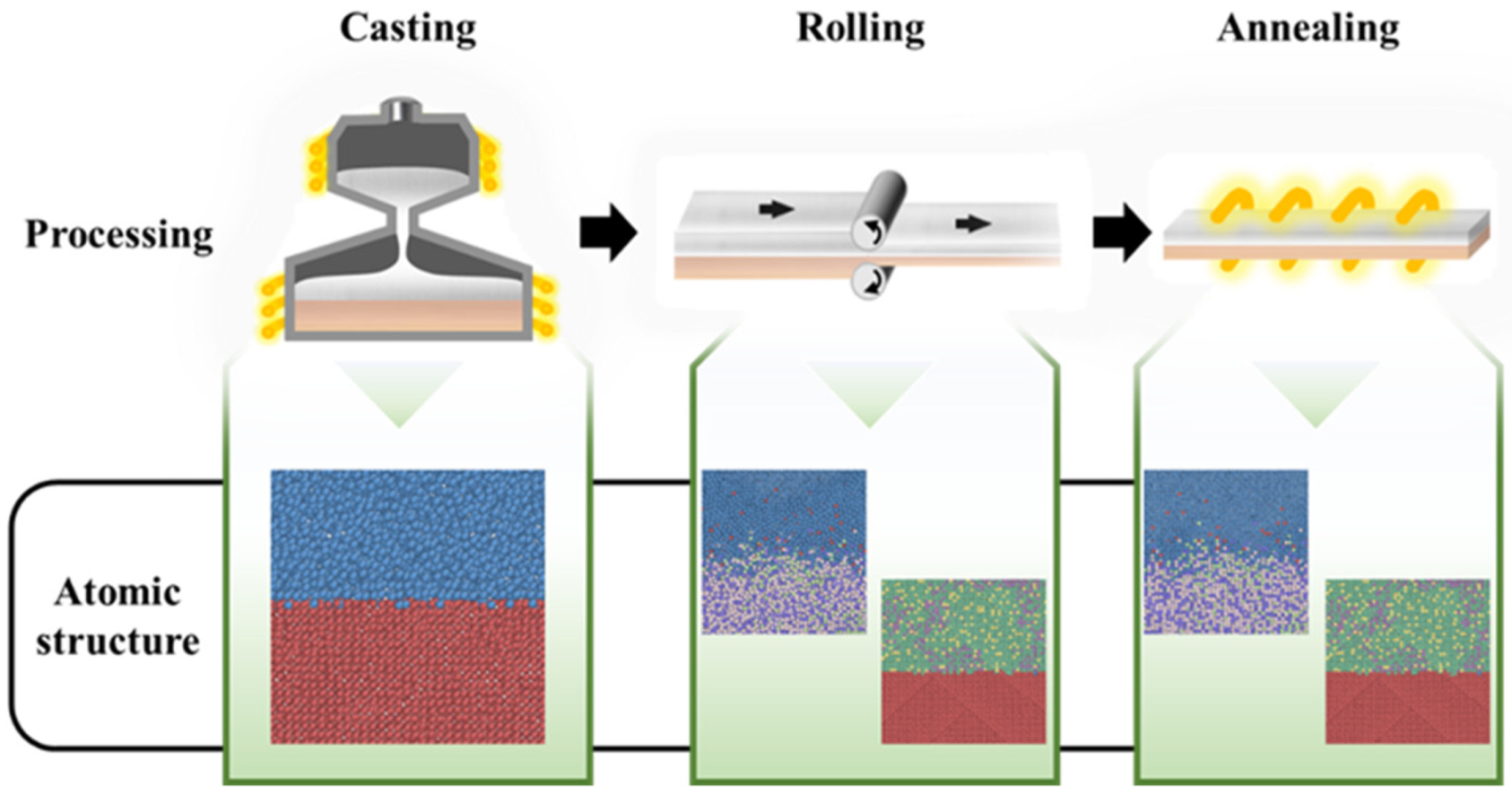

2. Interface Preparation and Characterization

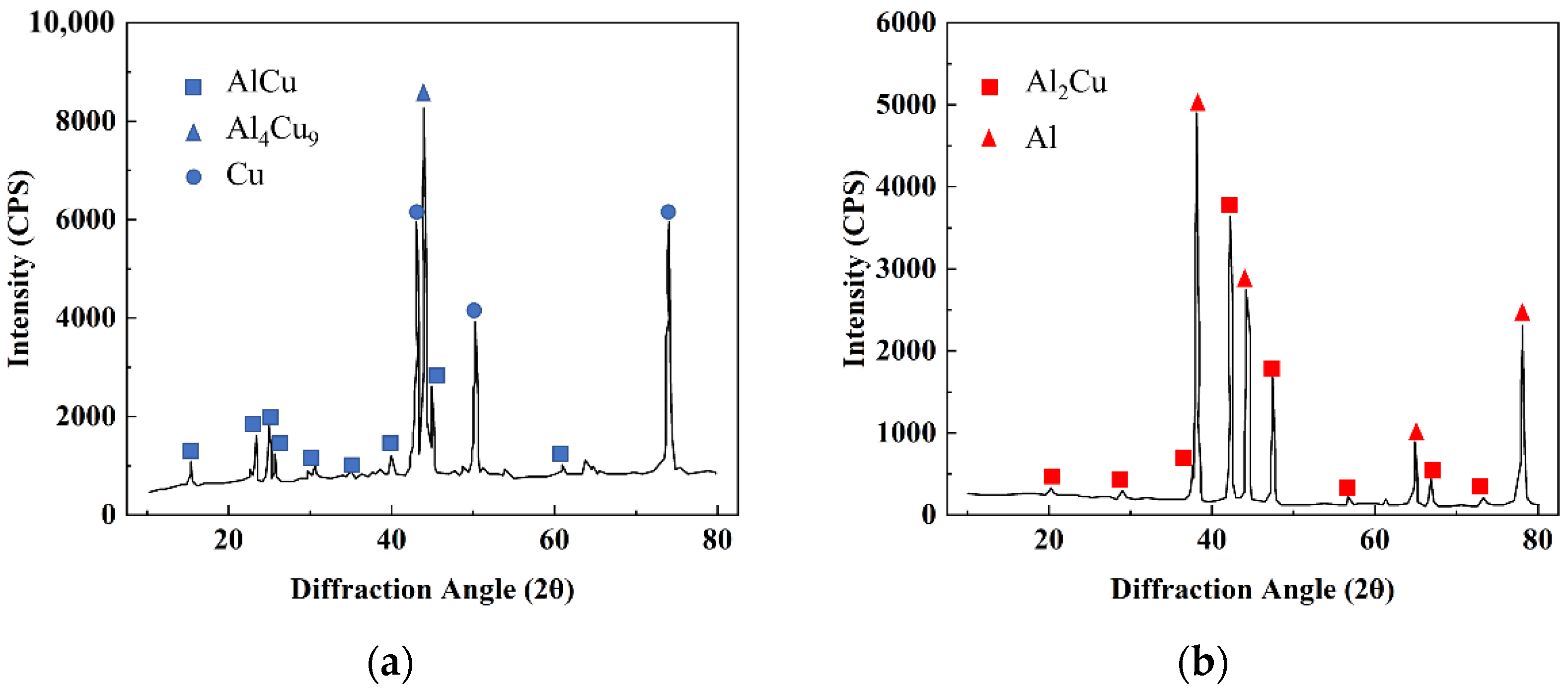

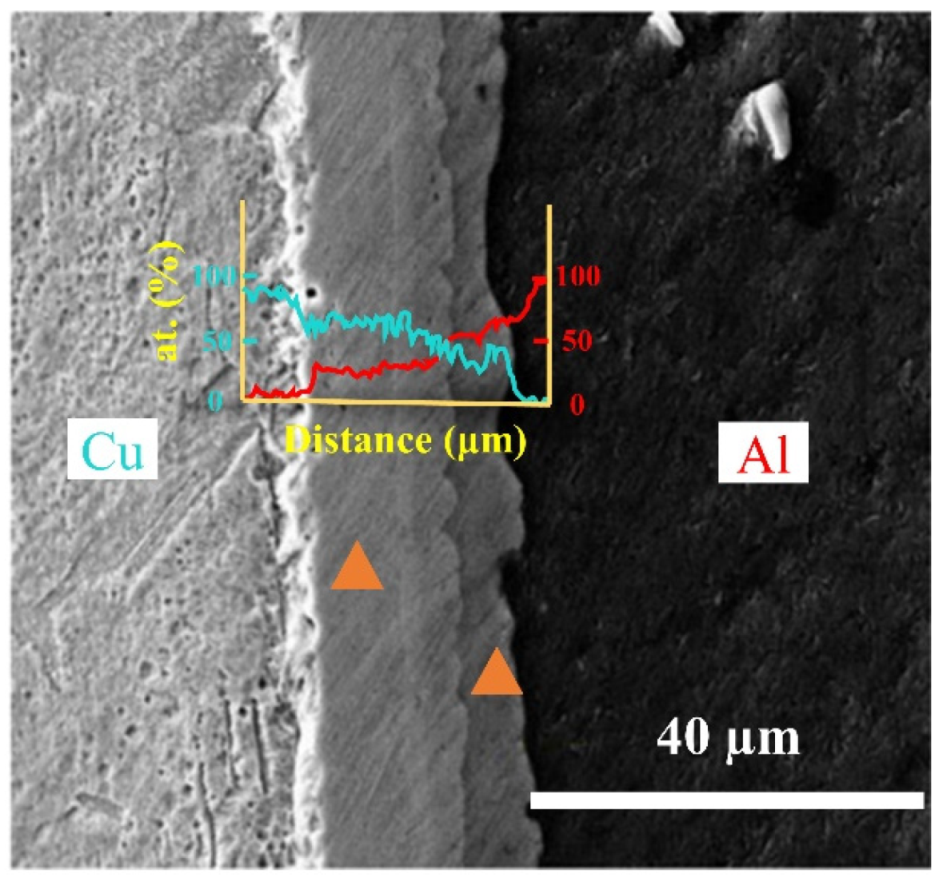

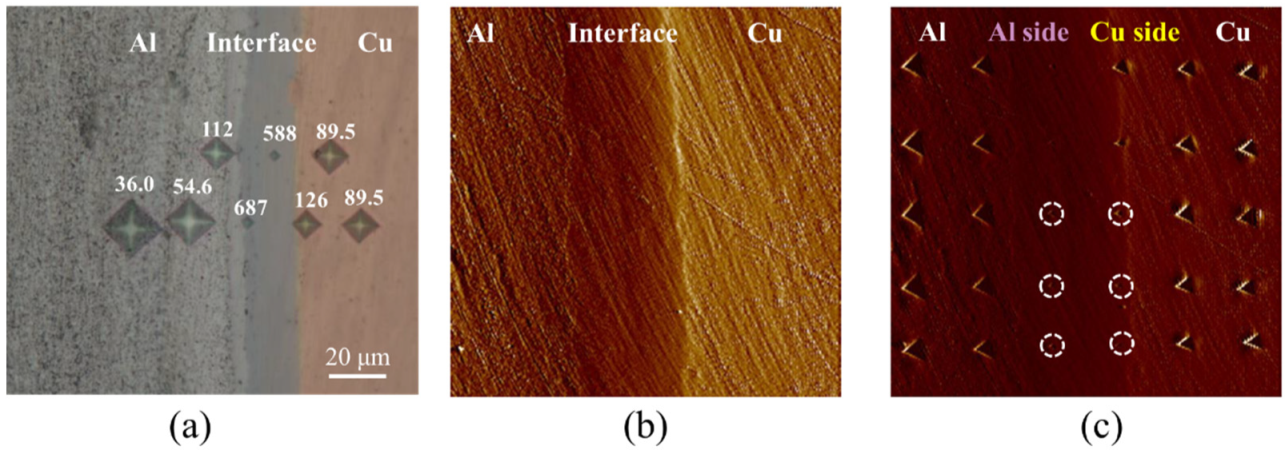

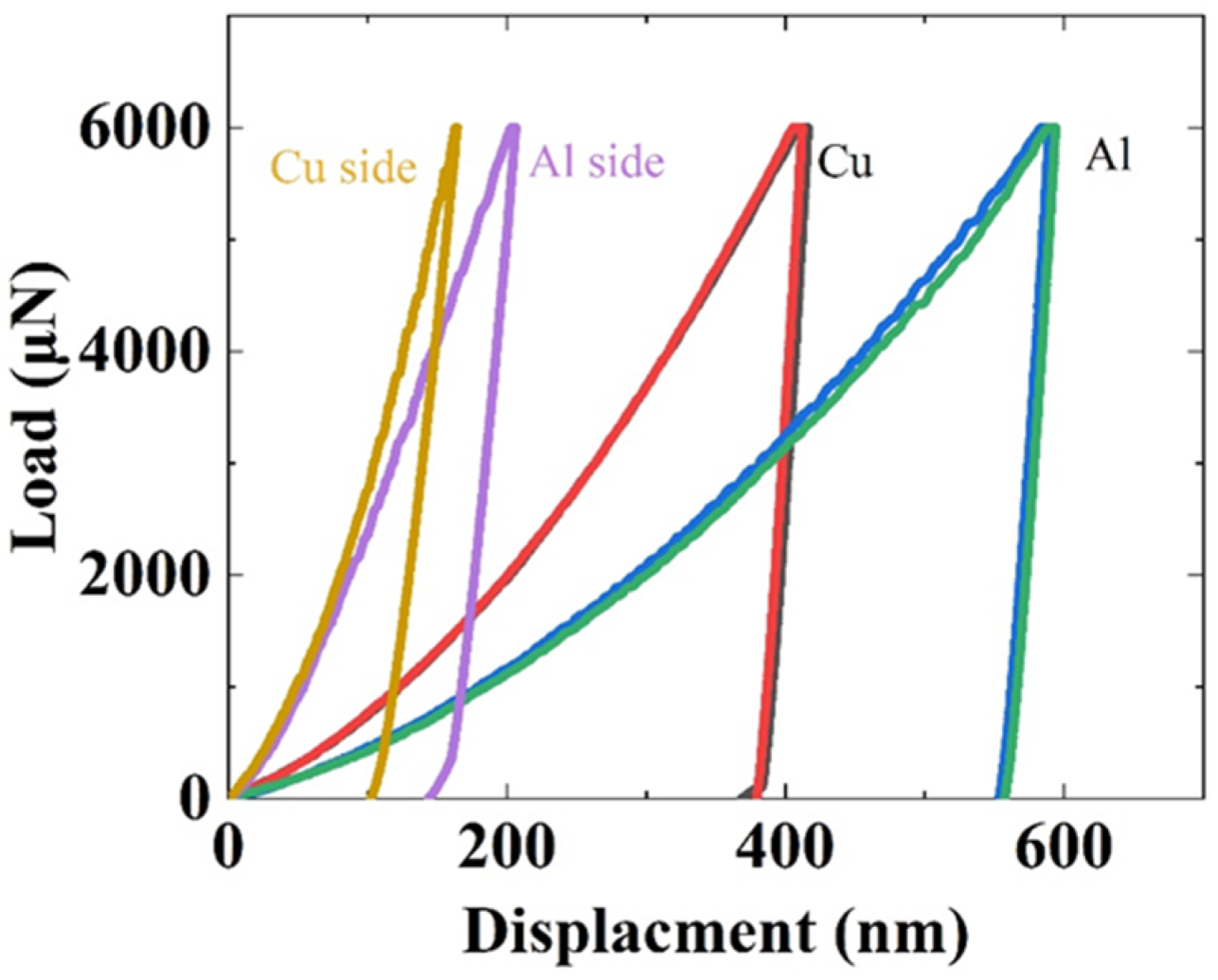

3. Experimental Results

4. Modeling and Simulation

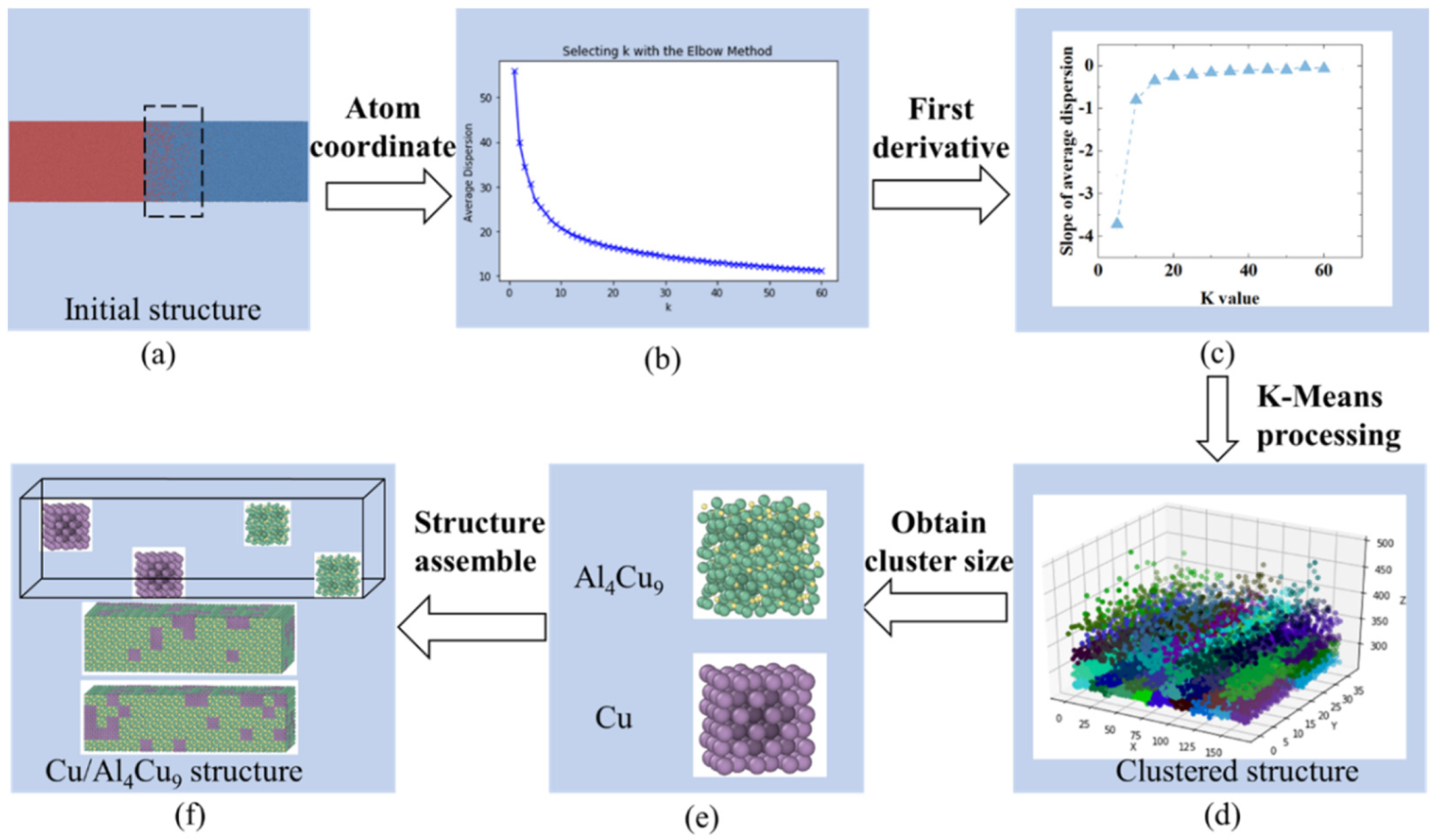

4.1. Intermetallic Compounds at the Interface

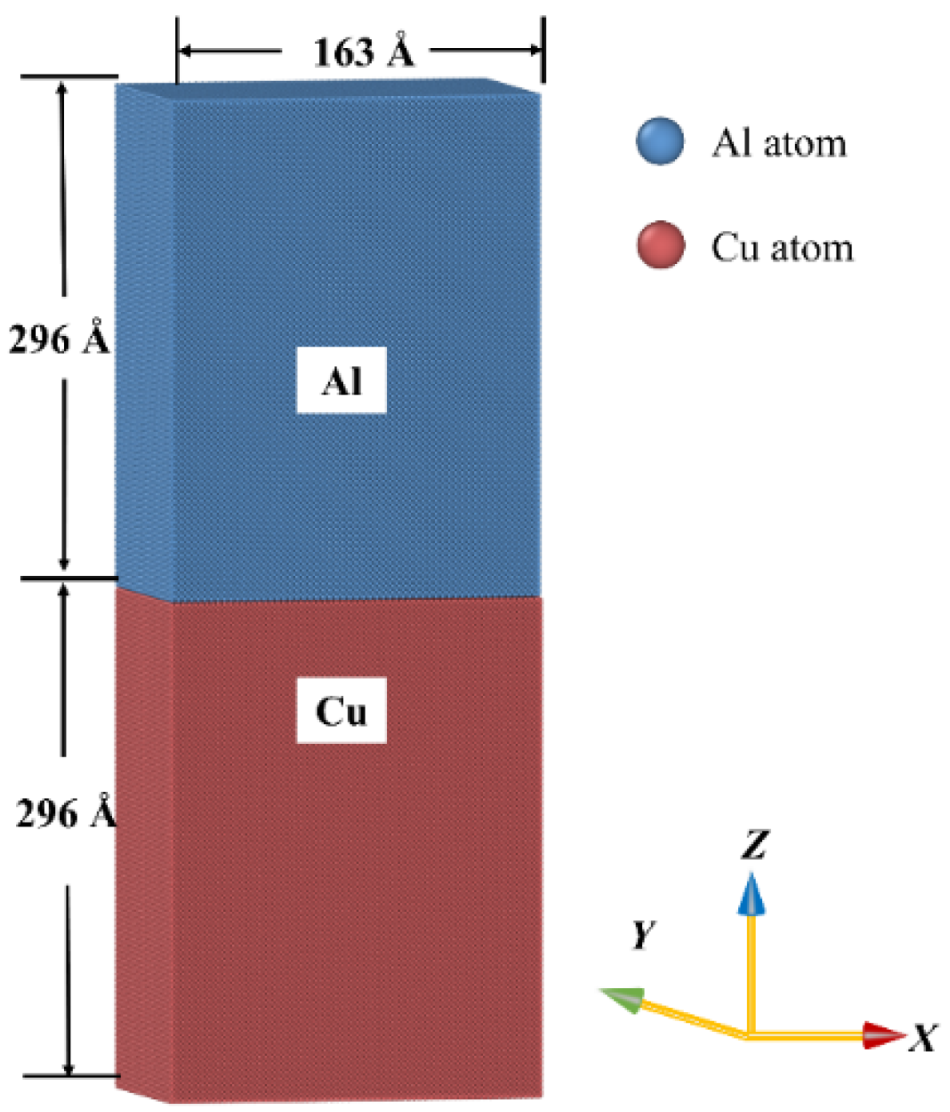

4.2. Molecular Dynamics Simulation

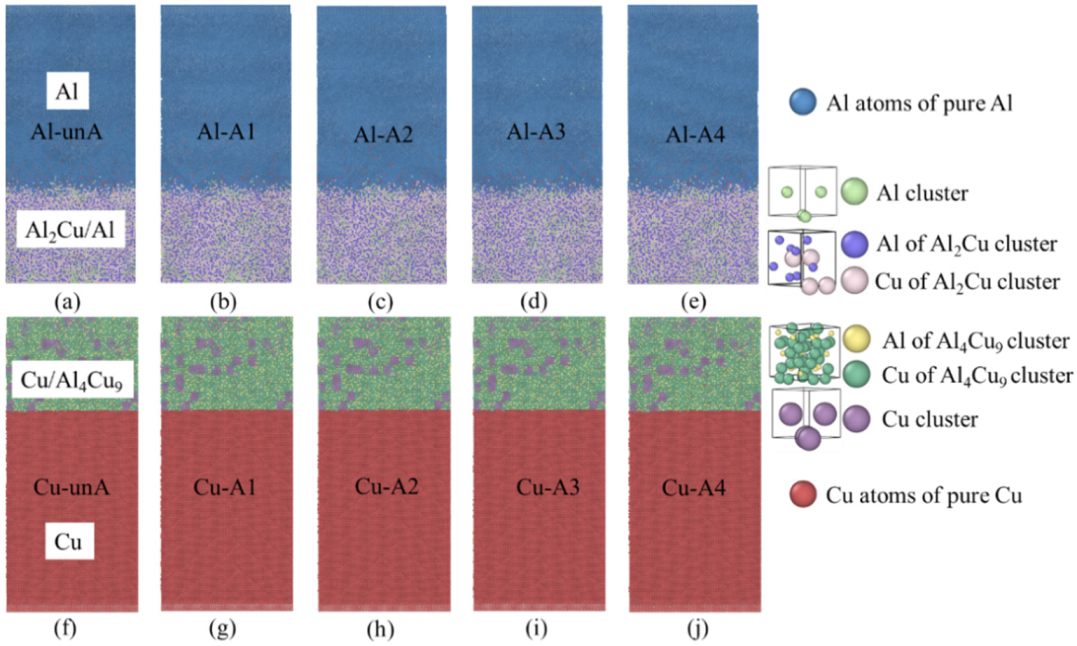

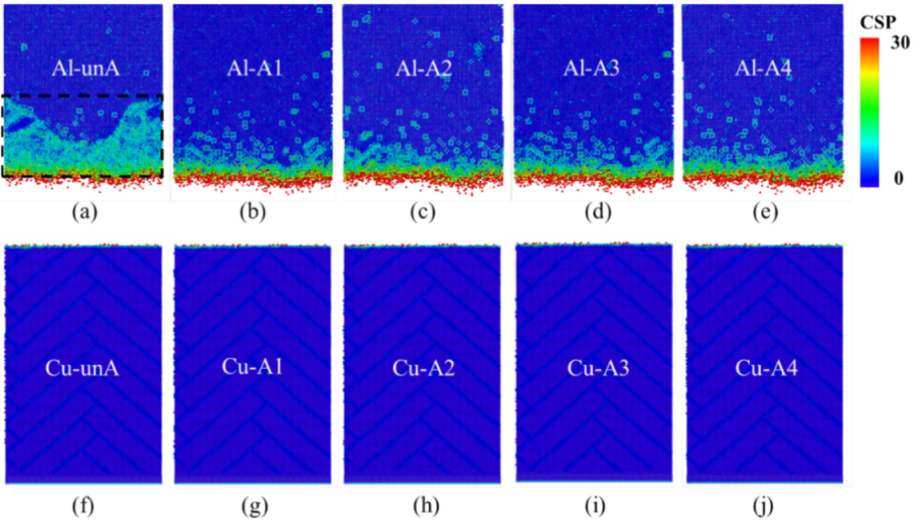

4.2.1. Structure of the Interfaces

4.2.2. Effects of Annealing Temperature on the Interfacial Strength

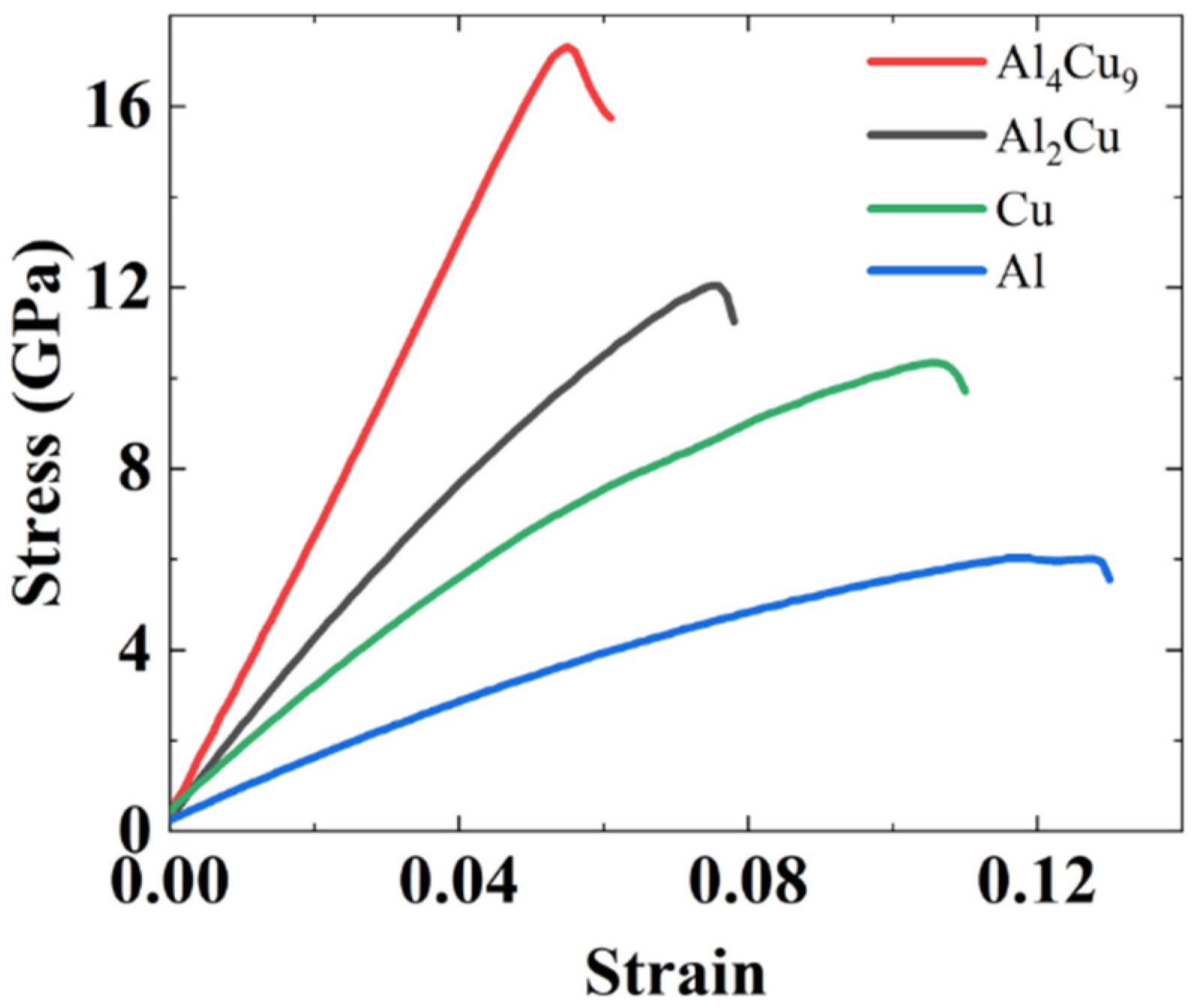

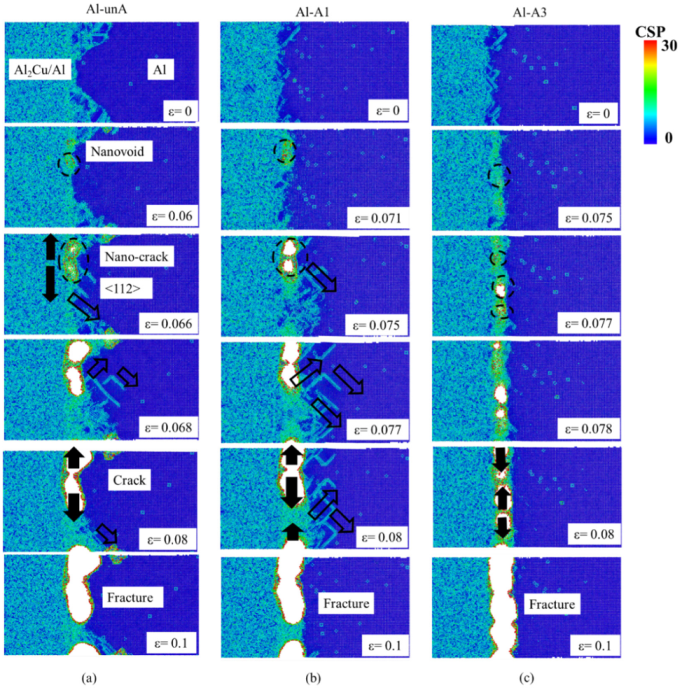

The Tensile Strength

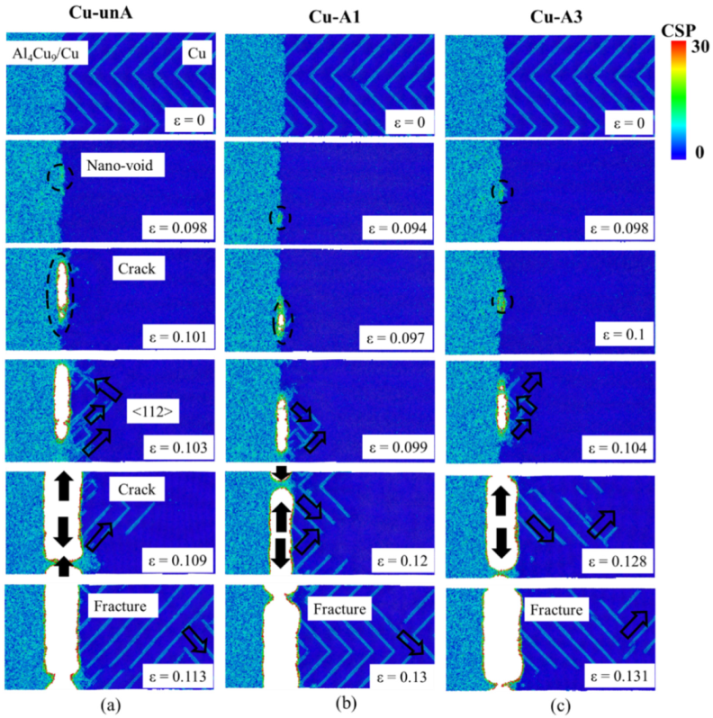

The Shear Strength

4.3. Comparison with Experiments

5. Conclusions

- The Al–Cu as-cast and rolled Al–Cu interface exhibits a compositionally graded structure with two distinct interfaces—one on the Al-side which is rich with the intermetallic Al2Cu and another one on the Cu-side which is rich with the intermetallic Al4Cu9.

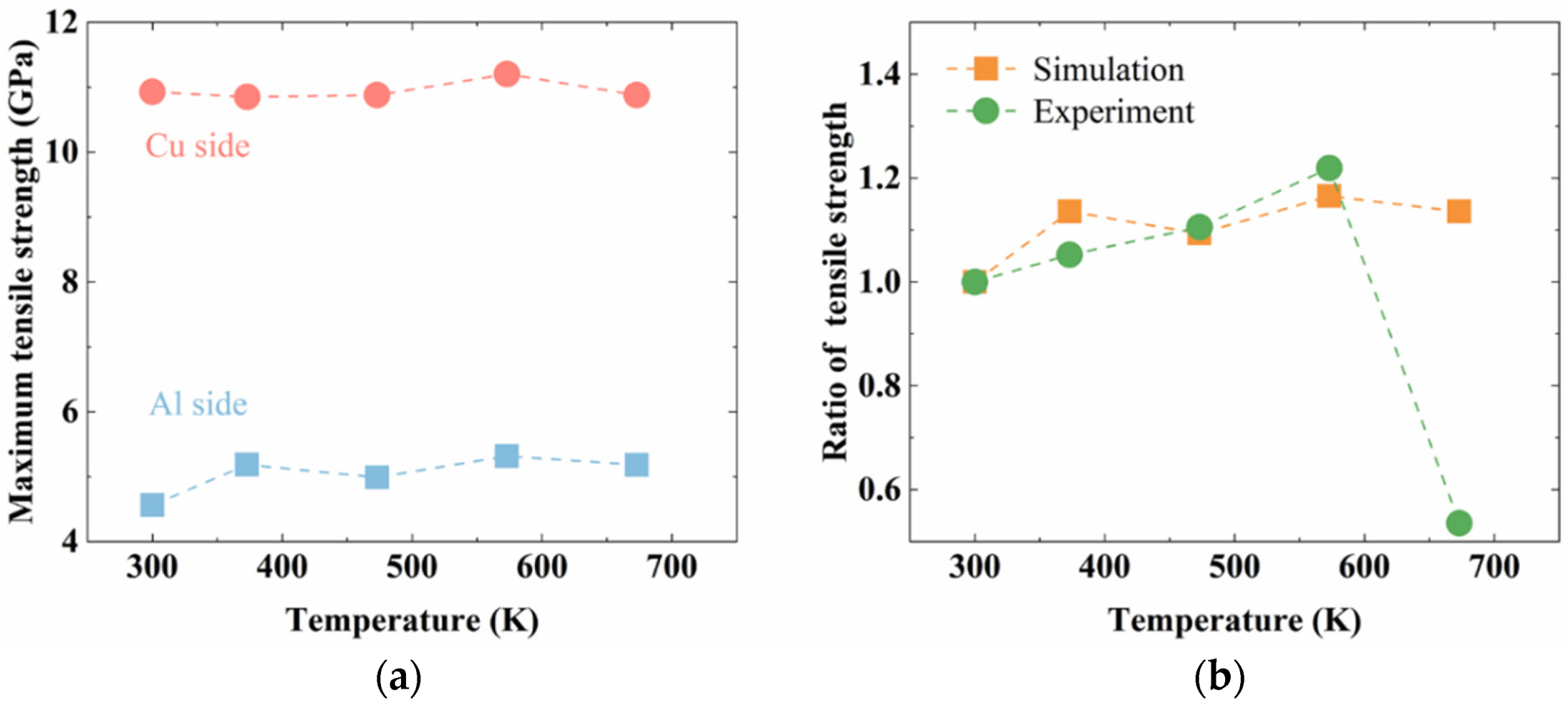

- The mechanical failure of the Al–Cu interface takes place at the Al-side of the interface which is weaker than the Cu-side of the interface.

- Micro- and nanoindentation experiments on the graded Al–Cu interfaces also confirm that the Al-side of the Al–Cu interface is mechanically weaker than the Cu-side.

- Centrosymmetry parameter analyses and dislocation analyses that are used to understand the microstructural features that influence deformation behavior leading to the failure of the Al–Cu interfaces reveal that increasing the annealing temperature increases the quality of the interface by reducing the stacking fault density at the Al-side of the interface, suppresses the generation of nanovoids, which are precursors for the initiation of fracture at the Al-side of the interface, and thus increases the tensile and shear strengths of the interfaces.

- The trends predicted by the MD simulations for the increase in the tensile and shear strengths of the interfaces observed with annealing treatments are in agreement with experimental results.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Ding, Y.; Shen, Z.; Gerlich, A.P. Refill friction stir spot welding of dissimilar aluminum alloy and AlSi coated steel. J. Manuf. Processes 2017, 30, 353–360. [Google Scholar] [CrossRef]

- Choudhury, S.F.; Ladani, L. Single Crystal Plasticity Finite Element Analysis of Cu6Sn5 Intermetallic. Metall. Mater. Trans. A 2015, 46, 1108–1118. [Google Scholar] [CrossRef]

- Liu, K.; Yu, H.; Li, X.; Wu, S. Study on diffusion characteristics of Al-Cu systems and mechanical properties of intermetallics. J. Alloys Compd. 2021, 874, 159831. [Google Scholar] [CrossRef]

- Tanaka, T.; Nezu, M.; Uchida, S.; Hirata, T. Mechanism of intermetallic compound formation during the dissimilar friction stir welding of aluminum and steel. J. Mater. Sci. 2020, 55, 3064–3072. [Google Scholar] [CrossRef]

- Ke, L.; Huang, C.; Xing, L.; Huang, K. Al–Ni intermetallic composites produced in situ by friction stir processing. J. Alloys Compd. 2010, 503, 494–499. [Google Scholar] [CrossRef]

- Xue, P.; Xiao, B.L.; Ni, D.R.; Ma, Z.Y. Enhanced mechanical properties of friction stir welded dissimilar Al–Cu joint by intermetallic compounds. Mater. Sci. Eng. A 2010, 527, 5723–5727. [Google Scholar] [CrossRef]

- Li, J.; Yu, Q.; Zhang, Z.; Xu, W.; Sun, X. Formation mechanism for the nanoscale amorphous interface in pulse-welded Al/Fe bimetallic systems. Appl. Phys. Lett. 2016, 108, 201606. [Google Scholar] [CrossRef]

- Oliver, W.C.; Pharr, G.M. An improved technique for determining hardness and elastic modulus using load and displacement sensing indentation experiments. J. Mater. Res. 1992, 7, 1564–1583. [Google Scholar] [CrossRef]

- Oliver, W.C.; Pharr, G.M. Measurement of hardness and elastic modulus by instrumented indentation: Advances in understanding and refinements to methodology. J. Mater. Res. 2004, 19, 3–20. [Google Scholar] [CrossRef]

- Dao, M.; Chollacoop, N.; Van Vliet, K.J.; Venkatesh, T.A.; Suresh, S. Computational modeling of the forward and reverse problems in instrumented sharp indentation. Acta Mater. 2001, 49, 3899–3918. [Google Scholar] [CrossRef]

- Venkatesh, T.A.; Van Vliet, K.J.; Giannakopoulos, A.E.; Suresh, S. Determination of elasto-plastic properties by instrumented sharp indentation: Guidelines for property extraction. Scr. Mater. 2000, 42, 833–839. [Google Scholar] [CrossRef]

- Cheng, G.; Choi, K.S.; Hu, X.; Sun, X. Determining Individual Phase Properties in a Multi-phase Q&P Steel Using Multi-scale Indentation Tests. Mater. Sci. Eng. A 2016, 652, 384–395. [Google Scholar]

- Rubio-Bollinger, G.; Bahn, S.R.; Agraït, N.; Jacobsen, K.W.; Vieira, S. Mechanical Properties and Formation Mechanisms of a Wire of Single Gold Atoms. Phys. Rev. Lett. 2001, 87, 026101. [Google Scholar] [CrossRef]

- Yaghoobi, M.; Voyiadjis, G.Z. The effects of temperature and strain rate in fcc and bcc metals during extreme deformation rates. Acta Mater. 2018, 151, 1–10. [Google Scholar] [CrossRef]

- Chang, W.-J. Molecular-dynamics study of mechanical properties of nanoscale copper with vacancies under static and cyclic loading. Microelectron. Eng. 2003, 65, 239–246. [Google Scholar] [CrossRef]

- Fan, H.; Wang, Q.; El-Awady, J.A.; Raabe, D.; Zaiser, M. Strain rate dependency of dislocation plasticity. Nat. Commun. 2021, 12, 1845. [Google Scholar] [CrossRef]

- Cheng, H.-C.; Yu, C.-F.; Chen, W.-H. Strain- and strain-rate-dependent mechanical properties and behaviors of Cu3Sn compound using molecular dynamics simulation. J. Mater. Sci. 2012, 47, 3103–3114. [Google Scholar] [CrossRef]

- Zong, H.; Ding, X.; Lookman, T.; Li, J.; Sun, J. Uniaxial stress-driven coupled grain boundary motion in hexagonal close-packed metals: A molecular dynamics study. Acta Mater. 2015, 82, 295–303. [Google Scholar] [CrossRef]

- Li, Q.; Zhang, H.; Chen, F.; Xu, D.; Sui, D.; Cui, Z. Study on the plastic anisotropy of advanced high strength steel sheet: Experiments and microstructure-based crystal plasticity modeling. Int. J. Mech. Sci. 2020, 176, 105569. [Google Scholar] [CrossRef]

- Liu, T.; Wang, Q.; Sui, Y.; Wang, Q.; Ding, W. An investigation into interface formation and mechanical properties of aluminum–copper bimetal by squeeze casting. Mater. Des. 2016, 89, 1137–1146. [Google Scholar] [CrossRef]

- Ma, Q.; Song, C.; Zhou, J.; Zhang, L.; Ji, H. Dynamic Weld evolution during ultrasonic welding of Cu–Al joints. Mater. Sci. Eng. A 2021, 823, 141724. [Google Scholar] [CrossRef]

- Turlo, V.; Rupert, T.J. Grain boundary complexions and the strength of nanocrystalline metals: Dislocation emission and propagation. Acta Mater. 2018, 151, 100–111. [Google Scholar] [CrossRef]

- Ding, S.; Wang, X. Strain rate and temperature effects on the mechanical properties of TiN/VN composite: Molecular dynamics study. J. Alloys Compd. 2020, 814, 152151. [Google Scholar] [CrossRef]

- Shao, W.; Liu, J.; Shi, Z.; Rao, L.; Xing, X.; Zhou, Y.; Yang, Q. Theoretical calculation of adhesion performance and mechanical properties of CrN/α-Fe interface. J. Alloys Compd. 2019, 810, 151921. [Google Scholar] [CrossRef]

- Yuming, Q.; Min, Z.; Miaolin, F. Molecular simulation of microstructure evolution and plastic deformation of nanocrystalline CoCrFeMnNi high-entropy alloy under tension and compression. J. Alloys Compd. 2021, 851, 156923. [Google Scholar]

- Zhi Hui, S.; Jie, Z.; Gao Xin, X.; Lu, X.; Li Chun, Y.; Qing, P. Tensile mechanical properties of CoCrFeNiTiAl high entropy alloy via molecular dynamics simulations. Intermetallics 2022, 142, 107444. [Google Scholar]

- Liao, W.J.; Wang, Y.X.; Zeng, L.C.; Yan, B. Study on Preparation and Application of High-Performance Cu-Al Composite Row. Adv. Mat. Res. 2011, 217-218, 1716–1720. [Google Scholar] [CrossRef]

- Liao, W.; Liu, X.; Wang, Y. Preparation of High-Performance Cu-Al Composite Row and Its Interface Bonding Mechanism. J. Tongji Univ. 2012, 40, 5. [Google Scholar]

- Kositski, R.; Mordehai, D. Role of dislocation pile-ups in nucleation-controlled size-dependent strength of Fe nanowires. Acta Mater. 2017, 136, 190–201. [Google Scholar] [CrossRef]

- Pharr, G.M.; Herbert, E.G.; Gao, Y. The Indentation Size Effect: A Critical Examination of Experimental Observations and Mechanistic Interpretations. Annu. Rev. Mater. Res. 2010, 40, 271–292. [Google Scholar] [CrossRef]

- Giannozzi, P.; Baroni, S.; Bonini, N.; Calandra, M.; Car, R.; Cavazzoni, C.; Ceresoli, D.; Chiarotti, G.L.; Cococcioni, M.; Dabo, I.; et al. QUANTUM ESPRESSO: A modular and open-source software project for quantum simulations of materials. J. Phy. Condens. Matter. 2009, 21, 395502. [Google Scholar] [CrossRef] [PubMed]

- Perdew, J.P.; Burke, K.; Ernzerhof, M. Generalized Gradient Approximation Made Simple. Phys. Rev. Lett. 1997, 78, 1396. [Google Scholar] [CrossRef]

- Vanderbilt, D. Soft self-consistent pseudopotentials in a generalized eigenvalue formalism. Phys. Rev. B 1990, 41, 7892–7895. [Google Scholar] [CrossRef]

- Romanowski, B.; Chrobak, D.; Räisänen, J.; Nowak, R. Elasticity and Debye temperature of defected fcc crystals (AlCu3, Al, Cu): Molecular dynamics and first-principles calculations. Comput. Mater. Sci. 2015, 109, 194–199. [Google Scholar] [CrossRef]

- Chen, C.L.; Richter, A.; Thomson, R.C. Mechanical properties of intermetallic phases in multi-component Al–Si alloys using nanoindentation. Intermetallics 2009, 17, 634–641. [Google Scholar] [CrossRef]

- Ouyang, Y.F.; Chen, H.M.; Tao, X.M.; Gao, F.; Peng, Q.; Du, Y. A first-principles study of the structural, mechanical and electronic properties of precipitates of Al2Cu in Al–Cu alloys. Phys. Chem. Chem. Phys. 2018, 20, 967–976. [Google Scholar] [CrossRef]

- Li, C.M.; Zeng, S.M.; Chen, Z.Q.; Cheng, T.X.; Chen, N.P. First-principles calculations of elastic and thermodynamic properties of the four main intermetallic phases in Al–Zn–Mg–Cu alloys. Comput. Mater. Sci. 2014, 93, 210–220. [Google Scholar] [CrossRef]

- Karimi, A.; Shojaei, O.R.; Kruml, T.; Martin, J.L. Characterisation of TiN thin films using the bulge test and the nanoindentation technique. Thin Solid Films 1997, 308-309, 334–339. [Google Scholar] [CrossRef]

- Wang, W.H. The elastic properties, elastic models and elastic perspectives of metallic glasses. Prog. Mater. Sci. 2012, 57, 487–656. [Google Scholar] [CrossRef]

- Thompson, A.P.; Aktulga, H.M.; Berger, R.; Bolintineanu, D.S.; Michael Brown, W.; Crozier, P.S.; in’t Veld, P.J.; Kohlmeyer, A.; Moore, S.G.; Nguyen, T.D.; et al. LAMMPS—A flexible simulation tool for particle-based materials modeling at the atomic, meso, and continuum scales. Comput. Phys. Commun. 2021, 271, 108171. [Google Scholar] [CrossRef]

- Cai, J.; Ye, Y.Y. Simple analytical embedded-atom-potential model including a long-range force for fcc metal and their alloys. Phys. Rev. B 1996, 54, 8398–8410. [Google Scholar] [CrossRef] [PubMed]

- Chen, S.; Ke, F.; Zhou, M.; Bai, Y. Atomistic investigation of the effects of temperature and surface roughness on diffusion bonding between Cu and Al. Acta Mater. 2007, 55, 3169–3175. [Google Scholar] [CrossRef]

- Chen, Y.; Wang, A.; Xie, J.; Guo, Y. Deformation mechanisms in Al/Al2Cu/Cu multilayer under compressive loading. J. Alloys Compd. 2021, 885, 160921. [Google Scholar] [CrossRef]

- Han, X.; Liu, P.; Sun, D.; Wang, Q. Molecular dynamics simulations of the tensile responses and fracture mechanisms of Ti2AlN/TiAl composite. Theor. Appl. Fract. 2019, 101, 217–223. [Google Scholar] [CrossRef]

- Apostol, F.; Mishin, Y. Interatomic potential for the Al-Cu system. Phys. Rev. B 2011, 83, 054116. [Google Scholar] [CrossRef]

- Liu, X.Y.; Liu, C.L.; Borucki, L.J. A new investigation of copper’s role in enhancing Al–Cu interconnect electromigration resistance from an atomistic view. Acta Mater. 1999, 47, 3227–3231. [Google Scholar] [CrossRef]

| Element | wt.% near Cu | at.% near Cu | wt.% near Al | at.% near Al |

|---|---|---|---|---|

| C | 1.11 | 4.50 | 1.18 | 3.69 |

| O | 0.80 | 2.43 | 0.91 | 2.14 |

| Al | 17.37 | 31.44 | 45.53 | 63.27 |

| Cu | balance | balance | balance | balance |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, X.; Cheng, G.; Zhang, Y.; Wang, Y.; Liao, W.; Venkatesh, T.A. On the Evolution of Nano-Structures at the Al–Cu Interface and the Influence of Annealing Temperature on the Interfacial Strength. Nanomaterials 2022, 12, 3658. https://doi.org/10.3390/nano12203658

Wang X, Cheng G, Zhang Y, Wang Y, Liao W, Venkatesh TA. On the Evolution of Nano-Structures at the Al–Cu Interface and the Influence of Annealing Temperature on the Interfacial Strength. Nanomaterials. 2022; 12(20):3658. https://doi.org/10.3390/nano12203658

Chicago/Turabian StyleWang, Xiaoli, Guang Cheng, Yang Zhang, Yuxin Wang, Wenjun Liao, and T. A. Venkatesh. 2022. "On the Evolution of Nano-Structures at the Al–Cu Interface and the Influence of Annealing Temperature on the Interfacial Strength" Nanomaterials 12, no. 20: 3658. https://doi.org/10.3390/nano12203658

APA StyleWang, X., Cheng, G., Zhang, Y., Wang, Y., Liao, W., & Venkatesh, T. A. (2022). On the Evolution of Nano-Structures at the Al–Cu Interface and the Influence of Annealing Temperature on the Interfacial Strength. Nanomaterials, 12(20), 3658. https://doi.org/10.3390/nano12203658