Bio-Inspired Hierarchical Carbon Nanotube Yarn with Ester Bond Cross-Linkages towards High Conductivity for Multifunctional Applications

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. CNT Yarn Fabrication and Esterification

2.3. Property Testing

3. Results and Discussion

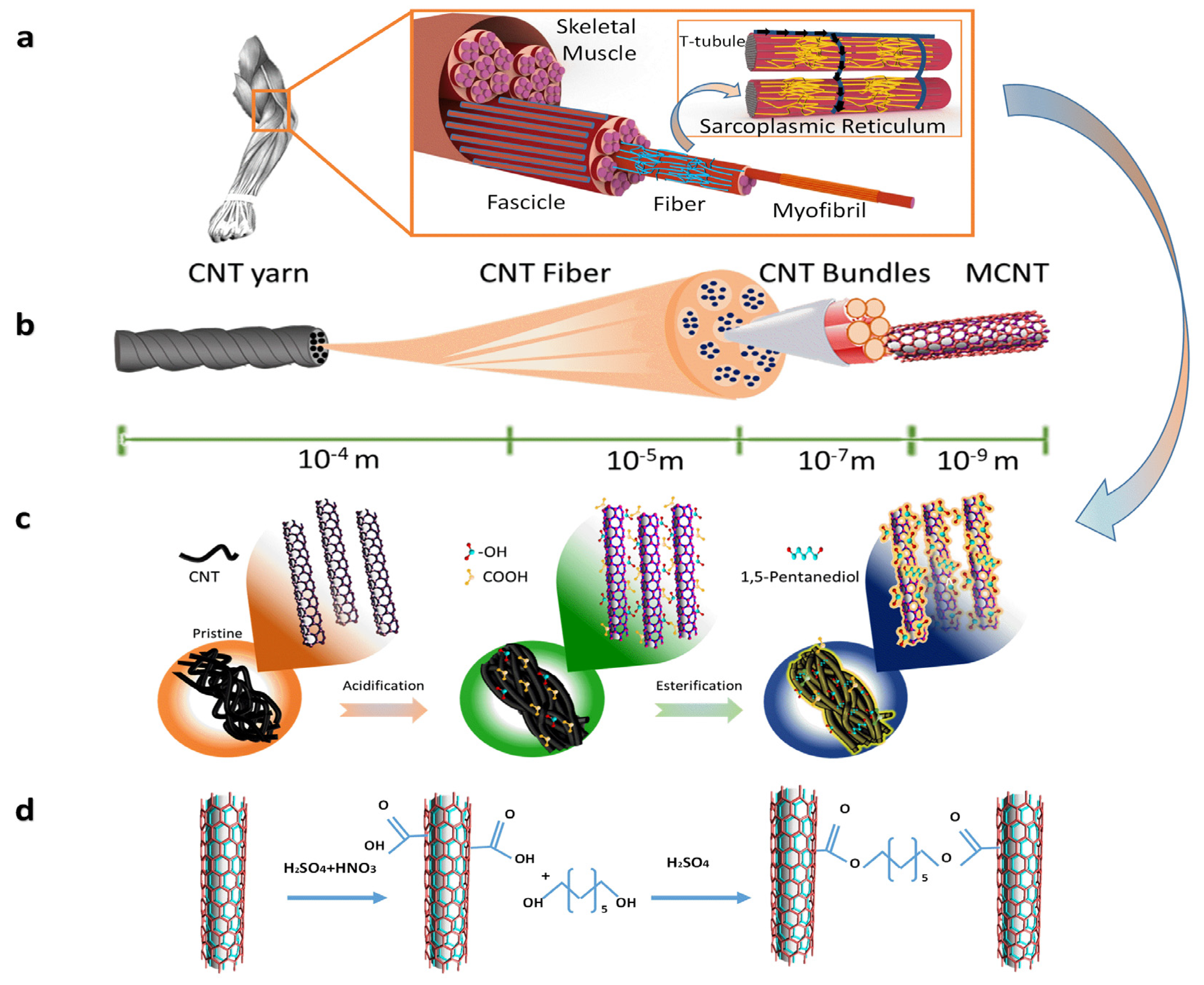

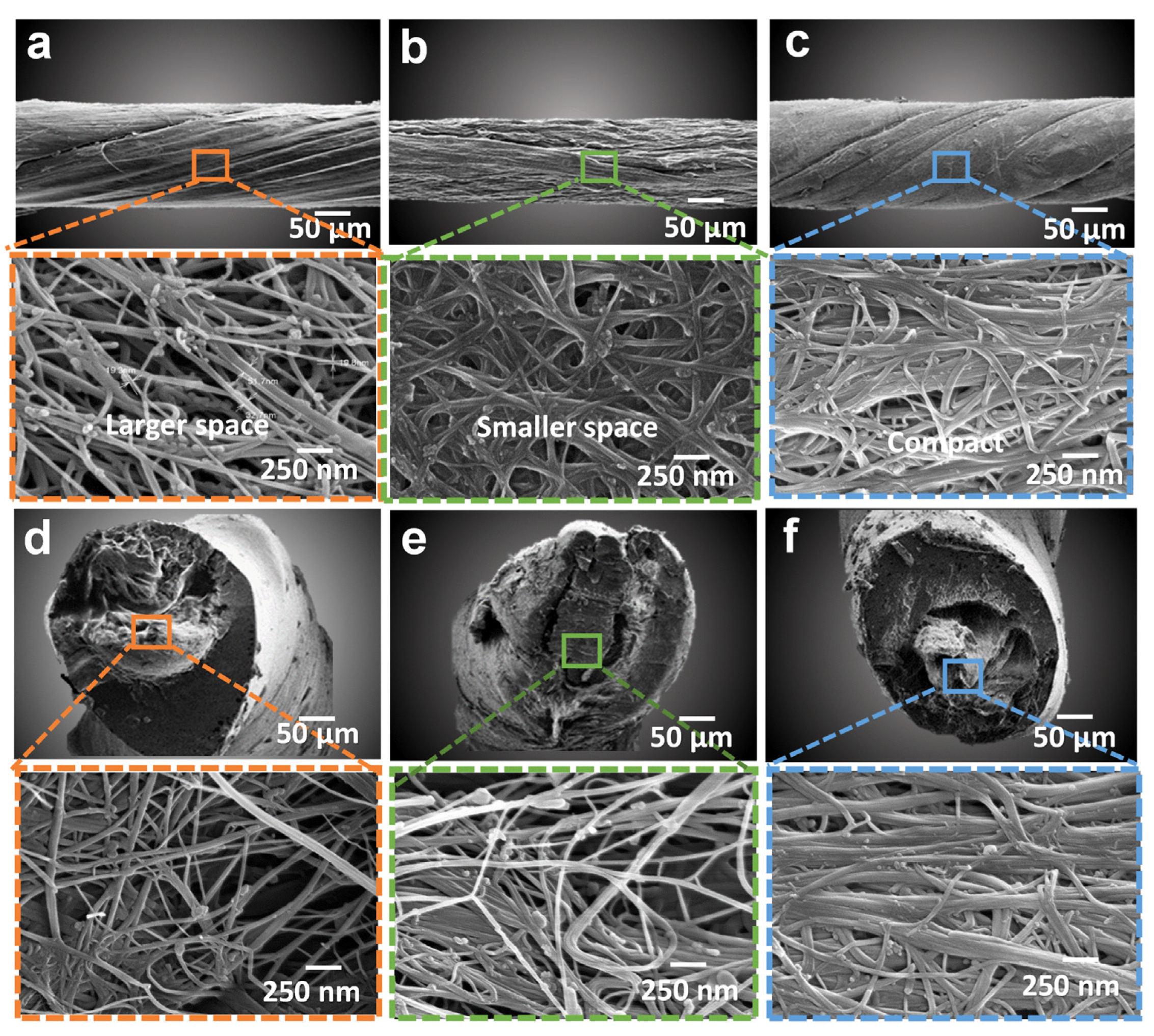

3.1. Hierarchical Structure of the Esterified CNT Yarn

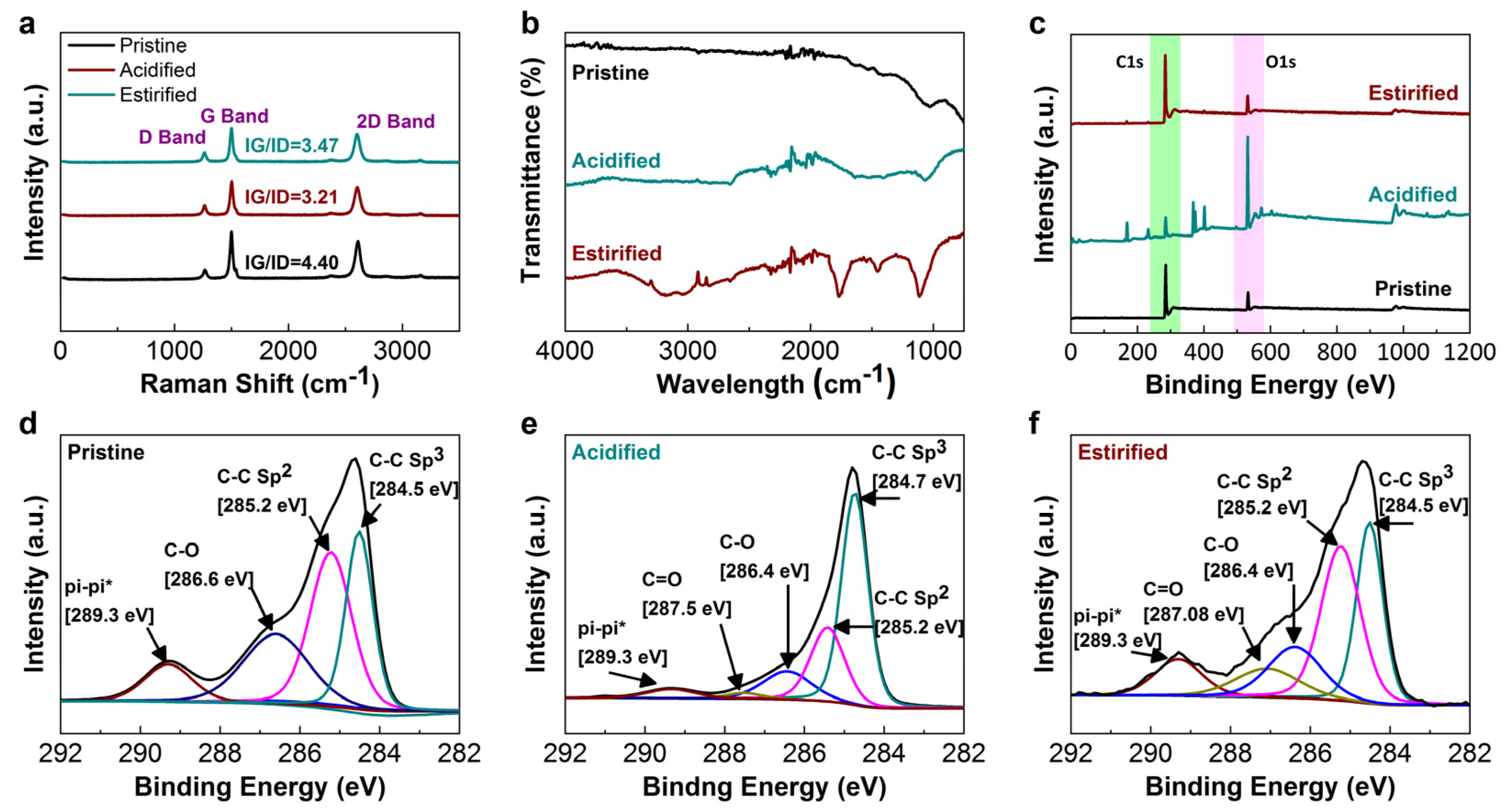

3.2. Analysis of CNT Yarn Using Raman, FTIR, and XPS

3.3. Electrical Properties

3.4. Electro-Thermal Properties

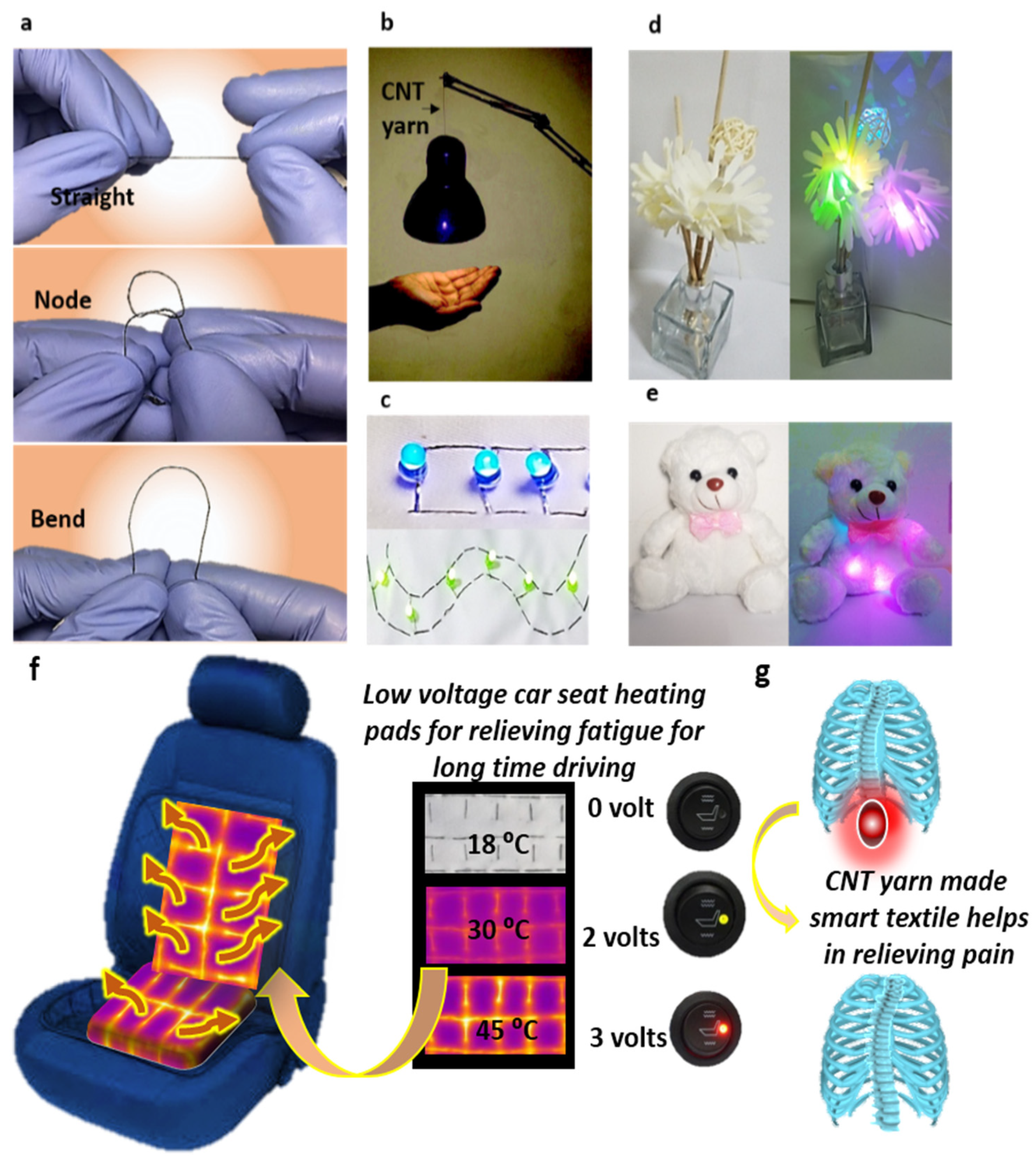

3.5. Multifunctional Applications

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Abdullah, H.B.; Ramli, I.; Ismail, I.; Yusof, N.A. Synthesis and mechanism perspectives of a carbon nanotube aerogel via a floating catalyst chemical vapour deposition method. Bull. Mater. Sci. 2019, 42, 1–15. [Google Scholar] [CrossRef] [Green Version]

- Lv, T.; Yao, Y.; Li, N.; Chen, T. Wearable fiber-shaped energy conversion and storage devices based on aligned carbon nanotubes. Nano Today 2016, 11, 644–660. [Google Scholar] [CrossRef]

- Di, J.; Zhang, X.; Yong, Z.; Zhang, Y.; Li, D.; Li, R.; Li, Q. Carbon-nanotube fibers for wearable devices and smart textiles. Adv. Mater. 2016, 28, 10529–10538. [Google Scholar] [CrossRef]

- Il’ina, M.V.; Il’in, O.I.; Rudyk, N.N.; Osotova, O.I.; Fedotov, A.A.; Ageev, O.A. Analysis of the Piezoelectric Properties of Aligned Multi-Walled Carbon Nanotubes. Nanomaterials 2021, 11, 2912. [Google Scholar] [CrossRef]

- Luo, X.; Weng, W.; Liang, Y.; Hu, Z.; Zhang, Y.; Yang, J.; Yang, L.; Yang, S.; Zhu, M.; Cheng, H.-M. Multifunctional fabrics of carbon nanotube fibers. J. Mater. Chem. A 2019, 7, 8790–8797. [Google Scholar] [CrossRef]

- Zhang, X.; Lu, W.; Zhou, G.; Li, Q. Understanding the Mechanical and Conductive Properties of Carbon Nanotube Fibers for Smart Electronics. Adv. Mater. 2019, 32, 1902028. [Google Scholar] [CrossRef]

- Shi, J.; Liu, S.; Zhang, L.; Yang, B.; Shu, L.; Yang, Y.; Ren, M.; Wang, Y.; Chen, J.; Chen, W. Smart Textile-Integrated Microelectronic Systems for Wearable Applications. Adv. Mater. 2020, 32, 1901958. [Google Scholar] [CrossRef] [PubMed]

- Zhou, Y.; Pervin, F.; Lewis, L.; Jeelani, S. Fabrication and characterization of carbon/epoxy composites mixed with multi-walled carbon nanotubes. Mater. Sci. Eng. A 2008, 475, 157–165. [Google Scholar] [CrossRef]

- Shao, Y.; Xu, F.; Marriam, I.; Liu, W.; Gao, Z.; Qiu, Y. Quasi-static and dynamic interfacial evaluations of plasma functionalized carbon nanotube fiber. Appl. Surf. Sci. 2019, 465, 795–801. [Google Scholar] [CrossRef]

- Moghaddam, A.Z.; Bameri, A.E.; Ganjali, M.R.; Alexovič, M.; Jazi, M.E.; Tabani, H. A low-voltage electro-membrane extraction for quantification of imatinib and sunitinib in biological fluids. Bioanalysis 2021, 13, 1401–1413. [Google Scholar] [CrossRef]

- Liu, L.; Yang, Q.; Shen, J. Correlation between porosity and electrical-mechanical properties of carbon nanotube buckypaper with various porosities. J. Nanomater. 2015, 16, 448. [Google Scholar] [CrossRef] [Green Version]

- Lekawa-Raus, A.; Patmore, J.; Kurzepa, L.; Bulmer, J.; Koziol, K. Electrical properties of carbon nanotube based fibers and their future use in electrical wiring. Adv. Funct. Mater. 2014, 24, 3661–3682. [Google Scholar] [CrossRef]

- Lee, Y.R.; Park, J.; Jeong, Y.; Park, J.S. Improved mechanical and electrical properties of carbon nanotube yarns by wet impregnation and multi-ply twisting. Fibers Polym. 2018, 19, 2478–2482. [Google Scholar] [CrossRef]

- Liu, K.; Sun, Y.; Zhou, R.; Zhu, H.; Wang, J.; Liu, L.; Fan, S.; Jiang, K. Carbon nanotube yarns with high tensile strength made by a twisting and shrinking method. Nanotechnology 2009, 21, 045708. [Google Scholar] [CrossRef]

- Wang, Z.; Wu, J.; Wei, X.; Saleemi, S.; Liu, W.; Li, W.; Marriam, I.; Xu, F. Bioinspired microstructure-reorganized behavior of carbon nanotube yarn induced by cyclic stretching training. J. Mater. Chem. C 2020, 8, 117–123. [Google Scholar] [CrossRef]

- Li, W.; Xu, F.; Liu, W.; Gao, Y.; Zhang, K.; Zhang, X.; Qiu, Y. Flexible strain sensor based on aerogel-spun carbon nanotube yarn with a core-sheath structure. Compos. Part A: Appl. Sci. Manuf. 2018, 108, 107–113. [Google Scholar] [CrossRef]

- Li, W.; Xu, F.; Wang, Z.; Wu, J.; Liu, W.; Qiu, Y. Effect of thermal treatments on structures and mechanical properties of aerogel-spun carbon nanotube fibers. Mater. Lett. 2016, 183, 117–121. [Google Scholar] [CrossRef]

- Zhao, Y.; Wei, J.; Vajtai, R.; Ajayan, P.M.; Barrera, E.V. Iodine doped carbon nanotube cables exceeding specific electrical conductivity of metals. Sci. Rep. 2011, 1, 1–5. [Google Scholar] [CrossRef] [Green Version]

- Mu, B.; Li, X.; Feng, X.; Li, Y.; Ding, C.; Zhao, G.; Yang, J. Relation of the Electrical Conductivity and the Thermal Conductivity to the Young’s Modulus of Buckypapers. Int. J. Thermophys. 2021, 42, 1–11. [Google Scholar] [CrossRef]

- Chen, W.; Wang, Y.; Zhang, K.; Xu, F. Characterization and comparison of properties of cryogenic conditioned CNT reinforced thermoset (epoxy) and thermoplastic (poly vinyl alcohol) composite yarns. J. Compos. Mater. 2021, 55, 00219983211041764. [Google Scholar] [CrossRef]

- Jang, Y.; Kim, S.M.; Spinks, G.M.; Kim, S.J. Carbon nanotube yarn for fiber-shaped electrical sensors, actuators, and energy storage for smart systems. Adv. Mater. 2020, 32, 1902670. [Google Scholar] [CrossRef]

- Ma, H.; Xu, S.; Gao, Y.; Liu, W.; Wei, X.; Aouraghe, M.A.; Xu, F. Wet cryogenic modification of the carbon nanotube assembly inspired by frozen Chinese Doufu recipe. Mater. Lett. 2021, 303, 130421. [Google Scholar] [CrossRef]

- Ma, H.; Gao, Y.; Liu, W.; Farha, F.I.; Zhang, K.; Guo, L.; Xu, F. Light-weight strain sensor based on carbon nanotube/epoxy composite yarn. J. Mater. Sci. 2021, 56, 13156–13164. [Google Scholar] [CrossRef]

- Liu, W.; Liu, N.; Gao, Y.; Wang, S.; Cheng, Q.; Xu, F. Strain sensing fabric integrated with carbon nanotube yarn for wearable applications. Text. Res. J. 2019, 89, 3048–3055. [Google Scholar] [CrossRef]

- Chen, J.-Z.; Wang, C.; Hsu, C.-C.; Cheng, I.-C. Ultrafast synthesis of carbon-nanotube counter electrodes for dye-sensitized solar cells using an atmospheric-pressure plasma jet. Carbon 2016, 98, 34–40. [Google Scholar] [CrossRef]

- Goto, T.; Ito, T.; Mayumi, K.; Maeda, R.; Shimizu, Y.; Hatakeyama, K.; Ito, K.; Hakuta, Y.; Terashima, K. Movable cross-linked elastomer with aligned carbon nanotube/nanofiber as high thermally conductive tough flexible composite. Compos. Sci. Technol. 2020, 190, 108009. [Google Scholar] [CrossRef]

- Qiu, L.; Wang, X.; Tang, D.; Zheng, X.; Norris, P.M.; Wen, D.; Zhao, J.; Zhang, X.; Li, Q. Functionalization and densification of inter-bundle interfaces for improvement in electrical and thermal transport of carbon nanotube fibers. Carbon 2016, 105, 248–259. [Google Scholar] [CrossRef] [Green Version]

- Misak, H.E.; Asmatulu, R.; O’Malley, M.; Jurak, E.; Mall, S. Functionalization of carbon nanotube yarn by acid treatment. Int. J. Smart Nano Mater. 2014, 5, 34–43. [Google Scholar] [CrossRef]

- Burdanova, M.G.; Kharlamova, M.V.; Kramberger, C.; Nikitin, M.P. Applications of Pristine and Functionalized Carbon Nanotubes, Graphene, and Graphene Nanoribbons in Biomedicine. Nanomaterials 2021, 11, 3020. [Google Scholar] [CrossRef]

- Im, Y.-O.; Lee, S.-H.; Kim, T.; Park, J.; Lee, J.; Lee, K.-H. Utilization of carboxylic functional groups generated during purification of carbon nanotube fiber for its strength improvement. Appl. Surf. Sci. 2017, 392, 342–349. [Google Scholar] [CrossRef]

- Laschi, C.; Mazzolai, B.; Cianchetti, M. Soft robotics: Technologies and systems pushing the boundaries of robot abilities. Sci. Robot. 2016, 1, eaah3690. [Google Scholar] [CrossRef] [Green Version]

- Smail, F.; Boies, A.; Windle, A. Direct spinning of CNT fibres: Past, present and future scale up. Carbon 2019, 152, 218–232. [Google Scholar] [CrossRef]

- Mallakpour, S.; Soltanian, S. Surface functionalization of carbon nanotubes: Fabrication and applications. RSC Adv. 2016, 6, 109916–109935. [Google Scholar] [CrossRef]

- Castro, V.G.; Costa, I.B.; Lopes, M.C.; Lavall, R.L.; Figueiredo, K.; Silva, G.G. Tailored degree of functionalization and length preservation of multiwalled carbon nanotubes by an optimized acid treatment process. J. Braz. Chem. Soc. 2017, 28, 1158–1166. [Google Scholar] [CrossRef]

- Dominguez, D.; Borbón-Nuñez, H.; Romo-Herrera, J.; Muñoz-Muñoz, F.; Reynoso-Soto, E.; Tiznado, H.; Soto, G. Optimal sidewall functionalization for the growth of ultrathin TiO 2 nanotubes via atomic layer deposition. J. Mater. Sci. 2018, 53, 2005–2015. [Google Scholar] [CrossRef]

- Gebhardt, B.; Syrgiannis, Z.; Backes, C.; Graupner, R.; Hauke, F.; Hirsch, A. Carbon Nanotube Sidewall Functionalization with Carbonyl Compounds Modified–Birch Conditions vs the Organometallic Reduction Approach. J. Am. Chem. Soc. 2011, 133, 7985–7995. [Google Scholar] [CrossRef]

- Moosa, A.A.; Ridha, A.M.; Abdullha, I.N. Chromium ions removal from wastewater using carbon nanotubes. Int. J. Innov. Res. Sci. Eng. Technol. 2015, 4, 8. [Google Scholar]

- Balasubramanian, K.; Burghard, M. Chemically functionalized carbon nanotubes. Small 2005, 1, 180–192. [Google Scholar] [CrossRef]

- Abuilaiwi, F.A.; Laoui, T.; Al-Harthi, M.; Atieh, M.A. Modification and functionalization of multiwalled carbon nanotube (MWCNT) via fischer esterification. Arab. J. Sci. Eng. 2010, 35, 37–48. [Google Scholar]

- Li, J. Interfacial studies on the ozone and air-oxidation-modified carbon fiber reinforced PEEK composites. Surf. Interface Anal. 2009, 41, 310–315. [Google Scholar] [CrossRef]

- Woodhead, A.L.; de Souza, M.L.; Church, J.S. An investigation into the surface heterogeneity of nitric acid oxidized carbon fiber. Appl. Surf. Sci. 2017, 401, 79–88. [Google Scholar] [CrossRef]

- Li, J.; Cheng, X. Effect of surface treatment on the tribological performance of carbon fiber reinforced thermoplastic polyimide composites. Polym. Compos. 2009, 30, 59–65. [Google Scholar] [CrossRef]

- Sezer, N.; Koç, M. Oxidative acid treatment of carbon nanotubes. Surf. Interfaces 2019, 14, 1–8. [Google Scholar] [CrossRef]

- Zhu, Z. An overview of carbon nanotubes and graphene for biosensing applications. Nano-Micro Lett. 2017, 9, 1–24. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Lu, J.; Wu, L.; Li, B.-G. High molecular weight polyesters derived from biobased 1, 5-pentanediol and a variety of aliphatic diacids: Synthesis, characterization, and thermo-mechanical properties. ACS Sustain. Chem. Eng. 2017, 5, 6159–6166. [Google Scholar] [CrossRef]

- Liu, S.; Amada, Y.; Tamura, M.; Nakagawa, Y.; Tomishige, K. One-pot selective conversion of furfural into 1, 5-pentanediol over a Pd-added Ir–ReOx/SiO2 bifunctional catalyst. Green Chem. 2014, 16, 617–626. [Google Scholar] [CrossRef]

- Liang, X.; Gao, Y.; Duan, J.; Liu, Z.; Fang, S.; Baughman, R.H.; Jiang, L.; Cheng, Q. Enhancing the strength, toughness, and electrical conductivity of twist-spun carbon nanotube yarns by π bridging. Carbon 2019, 150, 268–274. [Google Scholar] [CrossRef]

- Choi, Y.-M.; Choo, H.; Yeo, H.; You, N.-H.; Lee, D.S.; Ku, B.-C.; Kim, H.C.; Bong, P.-H.; Jeong, Y.; Goh, M. Chemical method for improving both the electrical conductivity and mechanical properties of carbon nanotube yarn via intramolecular cross-dehydrogenative coupling. ACS Appl. Mater. Interfaces 2013, 5, 7726–7730. [Google Scholar] [CrossRef]

- Randeniya, L.K.; Bendavid, A.; Martin, P.J.; Tran, C.D. Composite yarns of multiwalled carbon nanotubes with metallic electrical conductivity. Small 2010, 6, 1806–1811. [Google Scholar] [CrossRef] [Green Version]

- Dini, Y.; Faure-Vincent, J.; Dijon, J. How to overcome the electrical conductivity limitation of carbon nanotube yarns drawn from carbon nanotube arrays. Carbon 2019, 144, 301–311. [Google Scholar] [CrossRef]

- Miao, M. Electrical conductivity of pure carbon nanotube yarns. Carbon 2011, 49, 3755–3761. [Google Scholar] [CrossRef]

- Zheng, Y.; Zhang, Q.; Jin, W.; Jing, Y.; Chen, X.; Han, X.; Bao, Q.; Liu, Y.; Wang, X.; Wang, S. Carbon nanotube yarn based thermoelectric textiles for harvesting thermal energy and powering electronics. J. Mater. Chem. A 2020, 8, 2984–2994. [Google Scholar] [CrossRef]

- Dini, Y.; Rouchon, D.; Faure-Vincent, J.; Dijon, J. Large improvement of CNT yarn electrical conductivity by varying chemical doping and annealing treatment. Carbon 2020, 156, 38–48. [Google Scholar] [CrossRef]

- Wei, X.; Aouraghe, M.A.; Pang, S.; Farha, F.I.; Saleemi, S.; Zhang, K.; Liu, W.; Xu, F. Highly stretchable electro-conductive yarn via wrapping carbon nanotube yarn on multifilament polyester yarn. J. Ind. Text. 2020, 51, 1528083720957404. [Google Scholar] [CrossRef]

- Xu, F.; Aouraghe, M.A.; Xie, X.; Zheng, L.; Zhang, K.; Fu, K.K. Highly stretchable, fast thermal response carbon nanotube composite heater. Compos. Part A: Appl. Sci. Manuf. 2021, 147, 106471. [Google Scholar] [CrossRef]

- Lima, R.M.; Alcaraz-Espinoza, J.J.; da Silva, F.A., Jr.; de Oliveira, H.P. Multifunctional wearable electronic textiles using cotton fibers with polypyrrole and carbon nanotubes. ACS Appl. Mater. Interfaces 2018, 10, 13783–13795. [Google Scholar] [CrossRef] [PubMed]

- Liu, P.; Li, Y.; Xu, Y.; Bao, L.; Wang, L.; Pan, J.; Zhang, Z.; Sun, X.; Peng, H. Stretchable and energy-efficient heating carbon nanotube fiber by designing a hierarchically helical structure. Small 2018, 14, 1702926. [Google Scholar] [CrossRef]

- Wang, R.; Xu, Z.; Zhuang, J.; Liu, Z.; Peng, L.; Li, Z.; Liu, Y.; Gao, W.; Gao, C. Highly stretchable graphene fibers with ultrafast electrothermal response for low-voltage wearable heaters. Adv. Electron. Mater. 2017, 3, 1600425. [Google Scholar] [CrossRef]

- Han, B.J.; Liu, T.; Huang, Z.J.; Chen, D.M.; Zhu, Y.S.; Zhou, C.Y.; Li, Y.S.; Yin, Y.H.; Wu, Z.P. Preparation of flexible carbon nanotube ropes for low-voltage heat generator. Appl. Phys. Lett. 2017, 110, 103902. [Google Scholar] [CrossRef]

- Bu, Q.; Zhan, Y.; He, F.; Lavorgna, M.; Xia, H. Stretchable conductive films based on carbon nanomaterials prepared by spray coating. J. Appl. Polym. Sci. 2016, 133, 43243. [Google Scholar] [CrossRef]

| Materials | Process | Structure | Voltage (V) | Temp. (°C) | Time (s) | Ref. |

|---|---|---|---|---|---|---|

| CNT/film/PDMS | Coating | Composite | 2 | 150 | ~30 | [55] |

| CNT fiber | Twisting CNT ribbons | Yarn | 5 | 135 | <5 | [57] |

| CNT-Ppy-cotton | Coating + Immersion | Yarn | 5 | 45 | [56] | |

| CNT-I-PPy | Coating + Immersion | Yarn | 3.5 | 75 | 16 | [56] |

| Graphene fiber | Twisted ribbon | Yarn | 6.6 | 44 | <2 | [58] |

| CNT | Twisting CNT socks | Rope | 15 V | 1000< | [59] | |

| CNT/PDMS | Spray Coating | Composite | 110 | 200 | 40 | [60] |

| CVD CNT | Twisting | Yarn | 3 | 175 | <5 | This work |

| Esterified CNT | Immersion + Twisting | Yarn | 3 | 262 | <5 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Saleemi, S.; Aouraghe, M.A.; Wei, X.; Liu, W.; Liu, L.; Siyal, M.I.; Bae, J.; Xu, F. Bio-Inspired Hierarchical Carbon Nanotube Yarn with Ester Bond Cross-Linkages towards High Conductivity for Multifunctional Applications. Nanomaterials 2022, 12, 208. https://doi.org/10.3390/nano12020208

Saleemi S, Aouraghe MA, Wei X, Liu W, Liu L, Siyal MI, Bae J, Xu F. Bio-Inspired Hierarchical Carbon Nanotube Yarn with Ester Bond Cross-Linkages towards High Conductivity for Multifunctional Applications. Nanomaterials. 2022; 12(2):208. https://doi.org/10.3390/nano12020208

Chicago/Turabian StyleSaleemi, Sidra, Mohamed Amine Aouraghe, Xiaoxiao Wei, Wei Liu, Li Liu, M. Irfan Siyal, Jihyun Bae, and Fujun Xu. 2022. "Bio-Inspired Hierarchical Carbon Nanotube Yarn with Ester Bond Cross-Linkages towards High Conductivity for Multifunctional Applications" Nanomaterials 12, no. 2: 208. https://doi.org/10.3390/nano12020208

APA StyleSaleemi, S., Aouraghe, M. A., Wei, X., Liu, W., Liu, L., Siyal, M. I., Bae, J., & Xu, F. (2022). Bio-Inspired Hierarchical Carbon Nanotube Yarn with Ester Bond Cross-Linkages towards High Conductivity for Multifunctional Applications. Nanomaterials, 12(2), 208. https://doi.org/10.3390/nano12020208