Physicochemical Characterization and Finite Element Analysis-Assisted Mechanical Behavior of Polylactic Acid-Montmorillonite 3D Printed Nanocomposites

Abstract

:1. Introduction

2. Materials and Methods

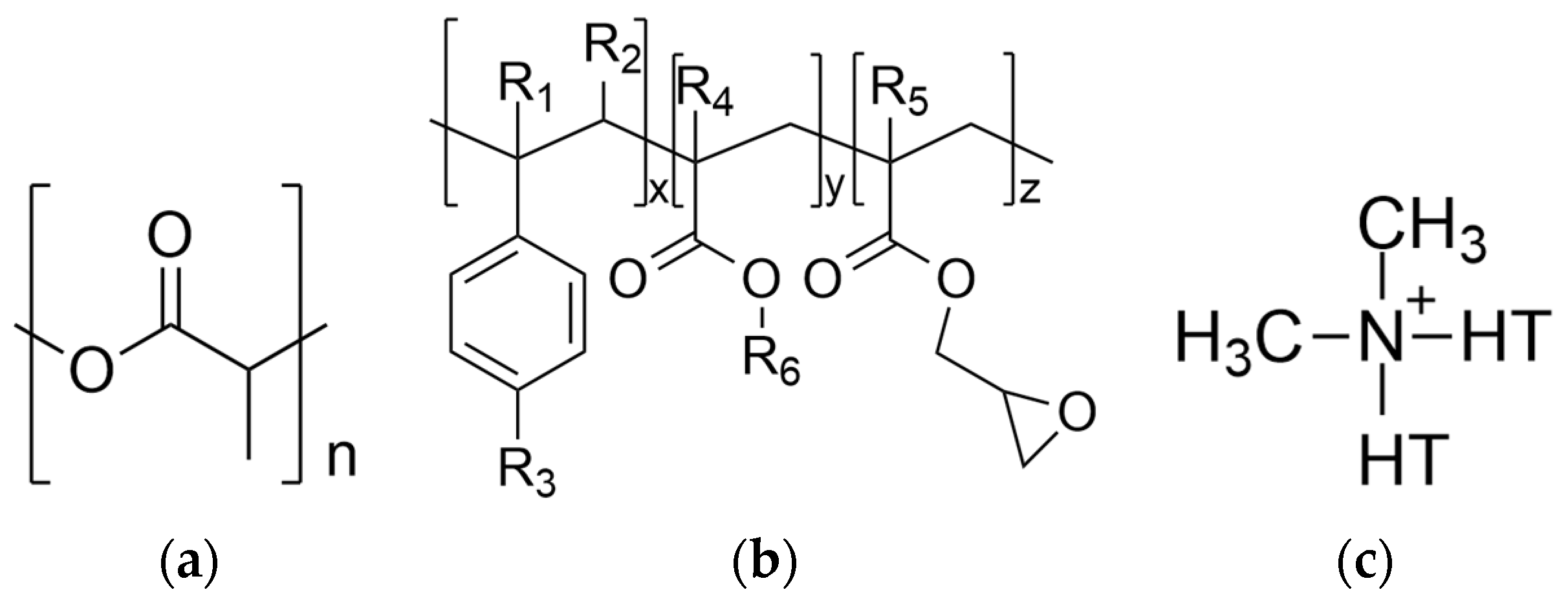

2.1. Materials

2.2. Preparation of PLA/MMT Nanocomposite Filaments

Design and Fabrication of 3D-Printed Specimens

2.3. Physicochemical Characterization

2.3.1. Gel Permeation Chromatography

2.3.2. Melt Flow Index (MFI)

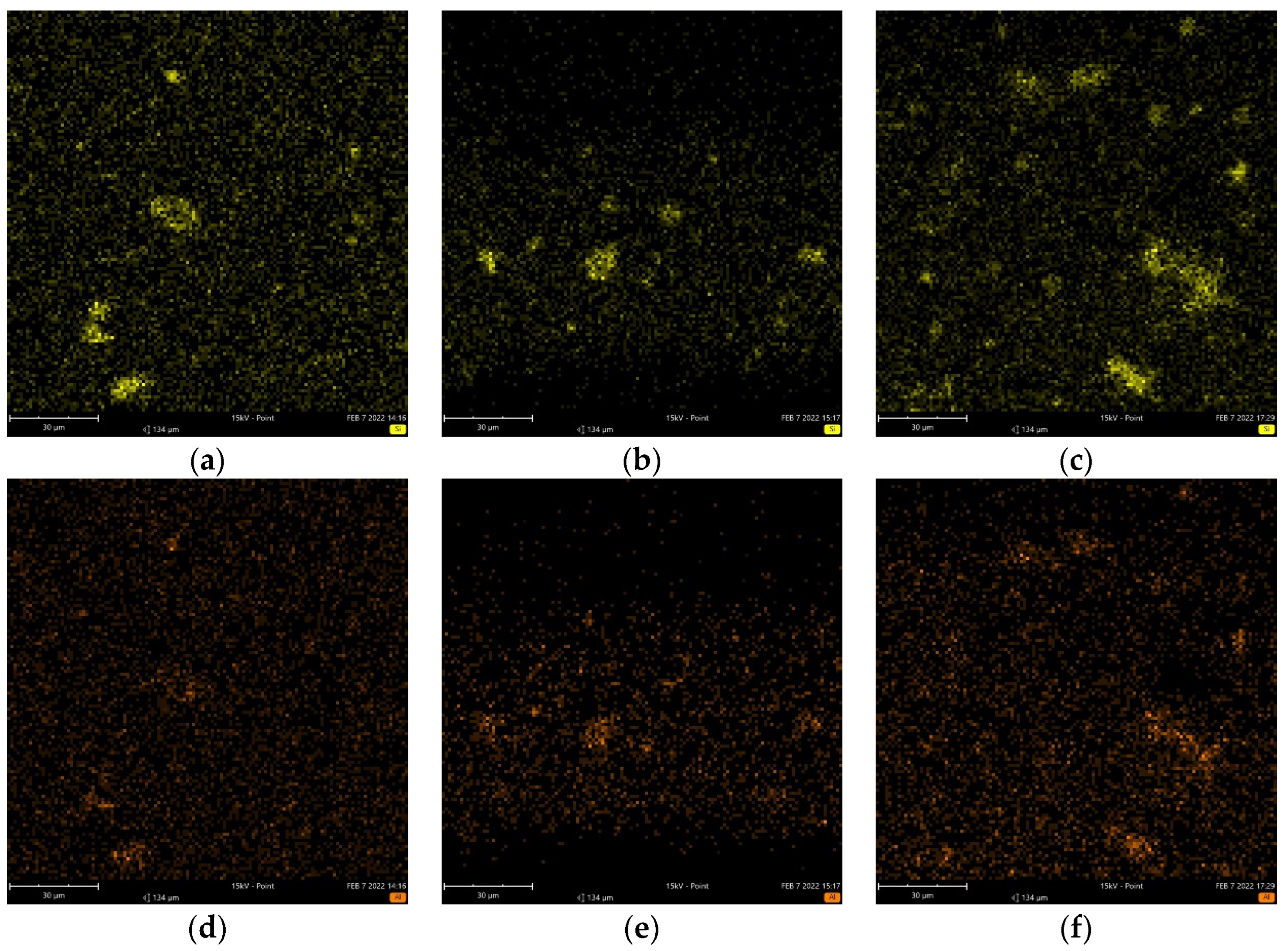

2.3.3. Scanning Electron Microscopy (SEM)

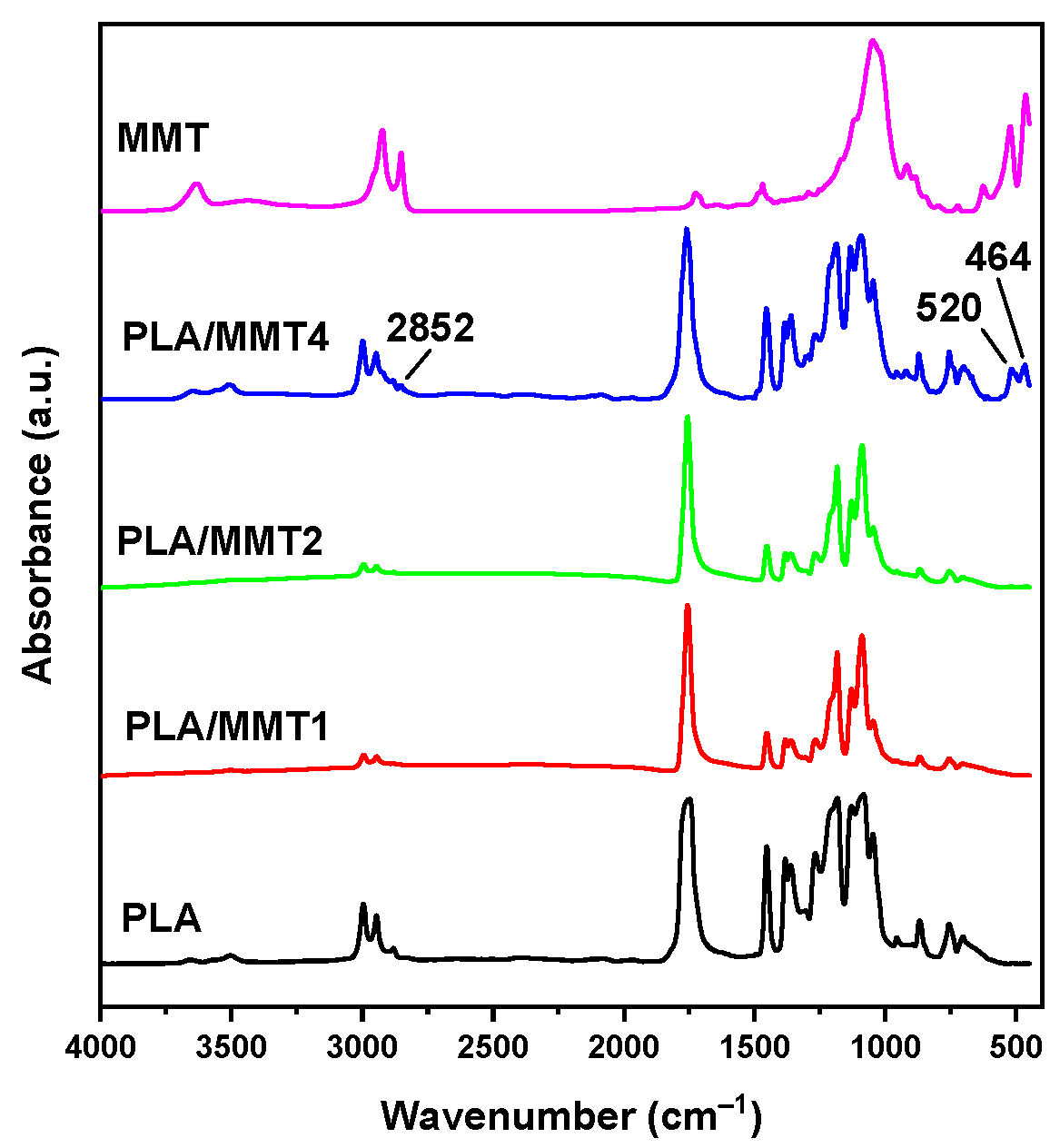

2.3.4. Fourier Transform Infrared Spectroscopy (FTIR)

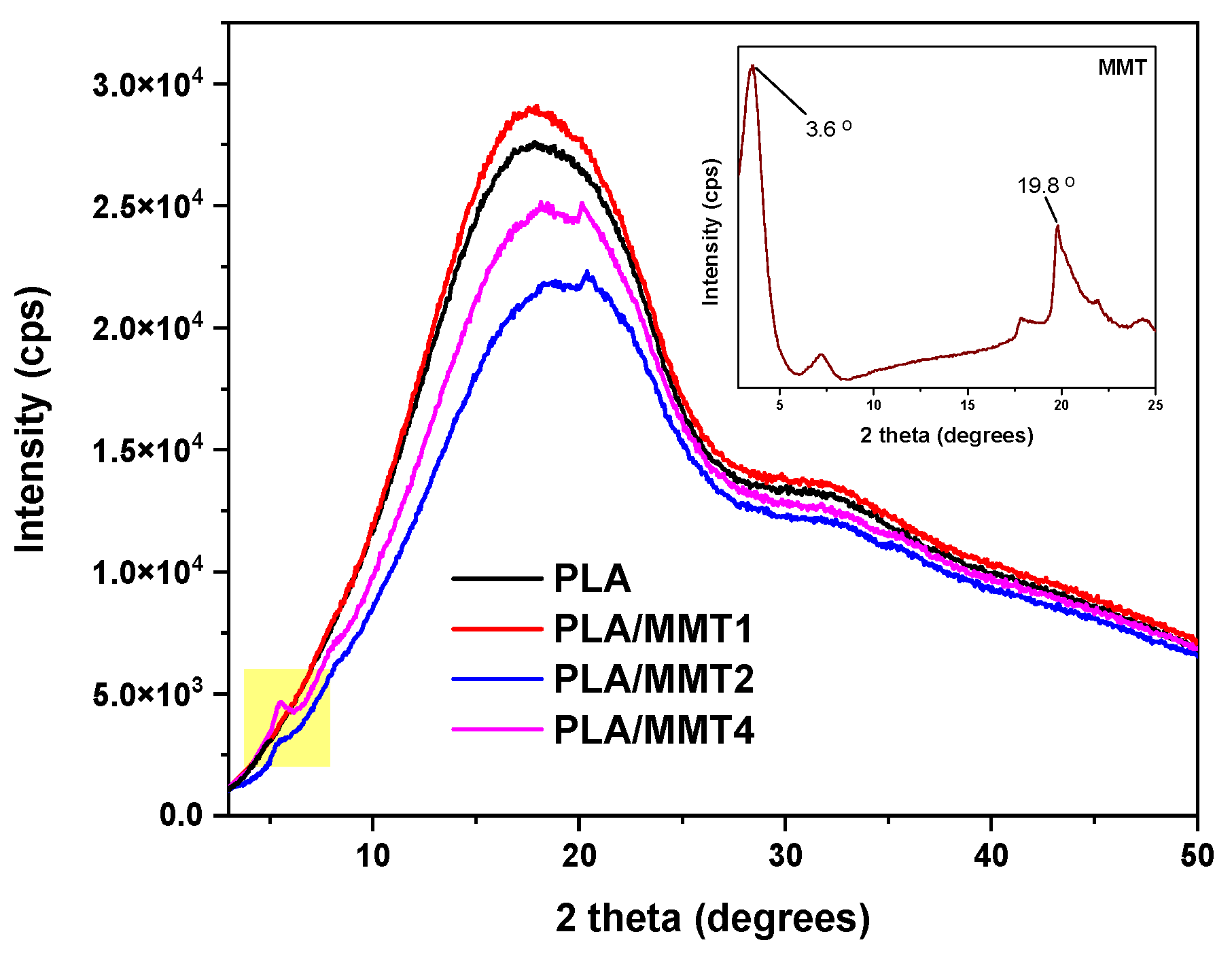

2.3.5. X-ray Diffraction Analysis (XRD)

2.3.6. Thermal Analysis

2.3.7. Water Contact Angle (WCA)

2.4. Mechanical Characterization

2.4.1. Nanoindentation Testing Supported by FEA

2.4.2. Compression Testing of Solid Specimens

2.4.3. Dynamic Mechanical Analysis (DMA)

2.5. Statistical Analysis

3. Results and Discussion

3.1. Effect of MMT on Molecular Weight and Filament Preparation

3.2. Structural Properties

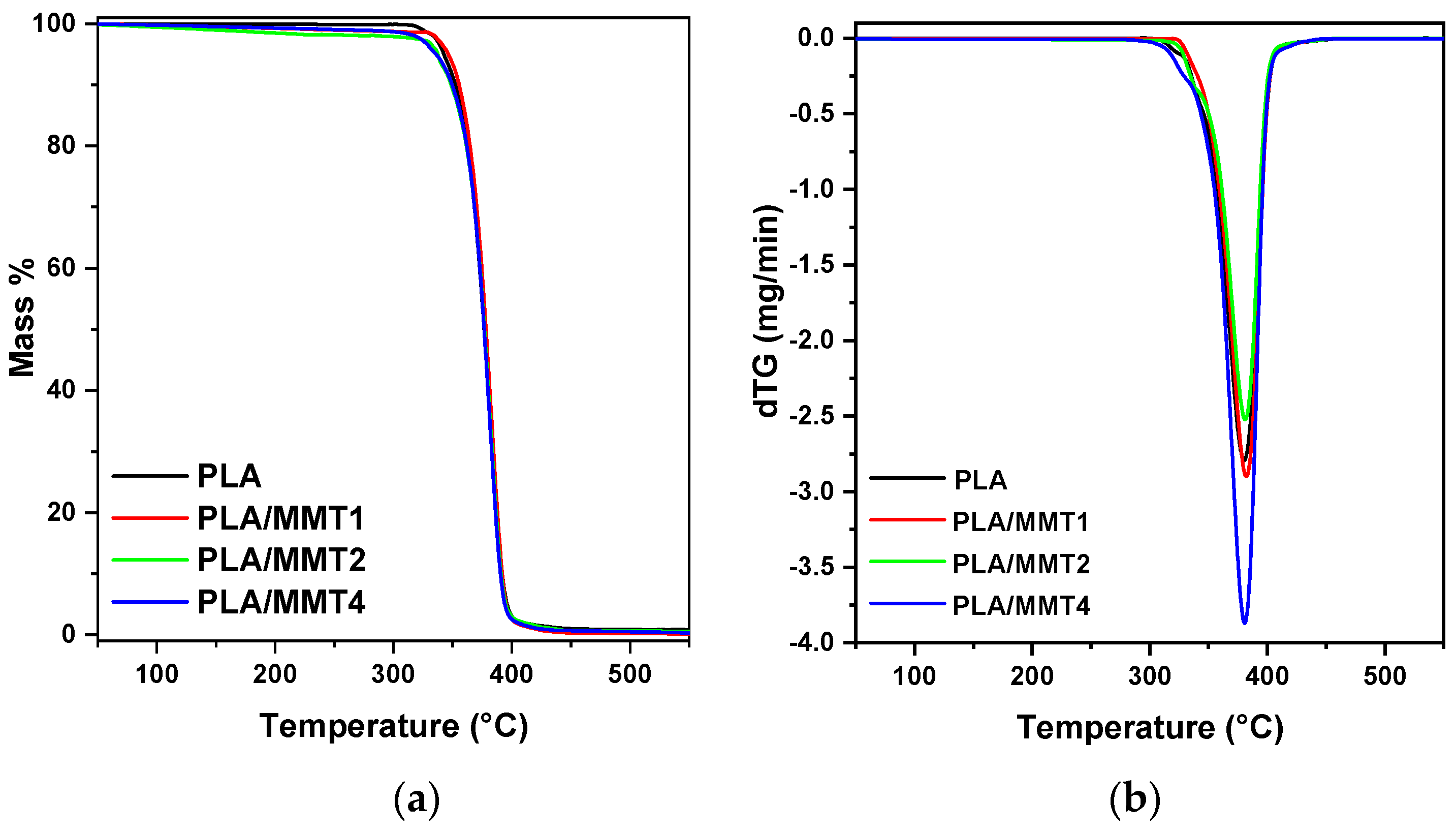

3.3. Thermal Properties

3.4. Water Contact Angle

3.5. Mechanical Properties

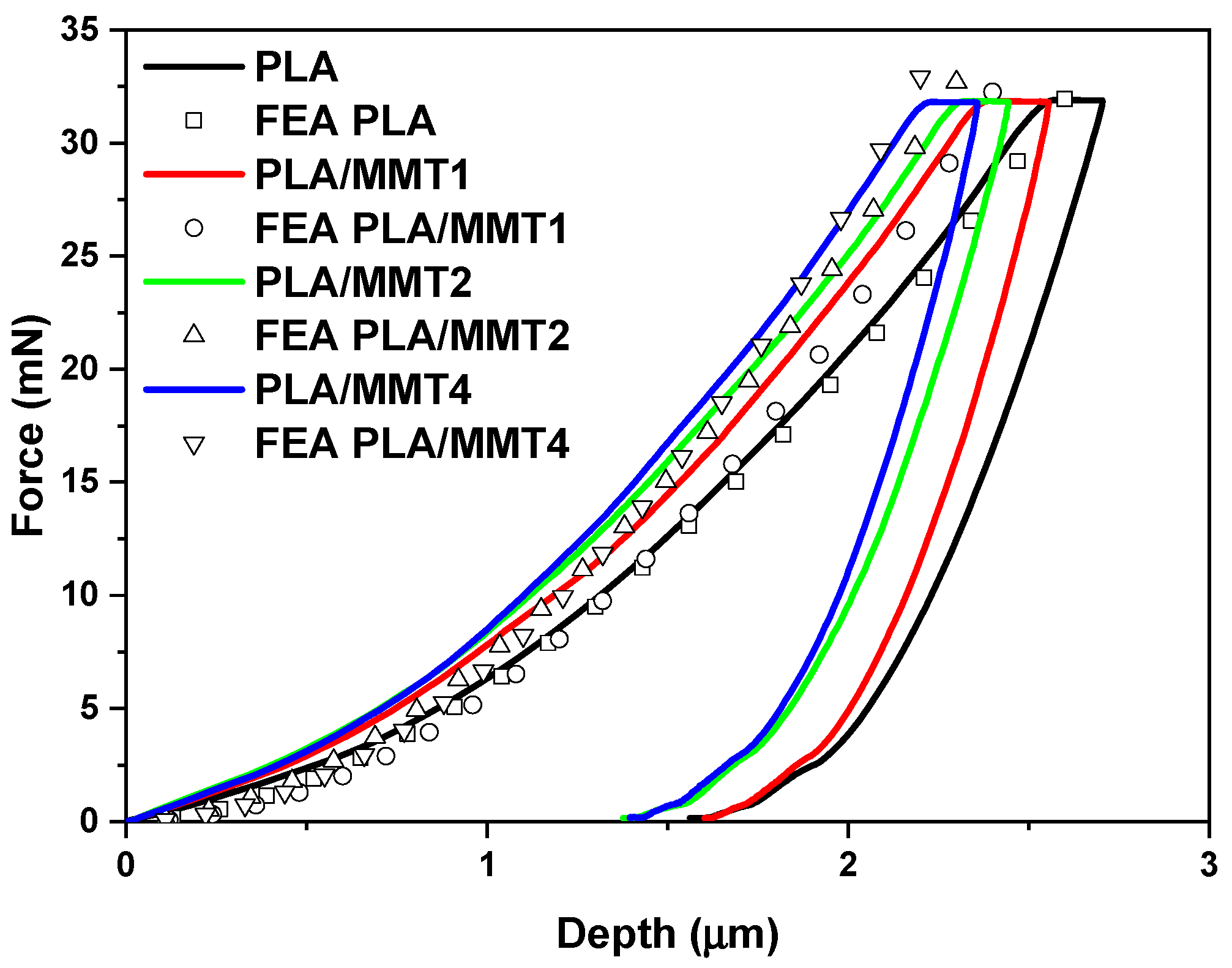

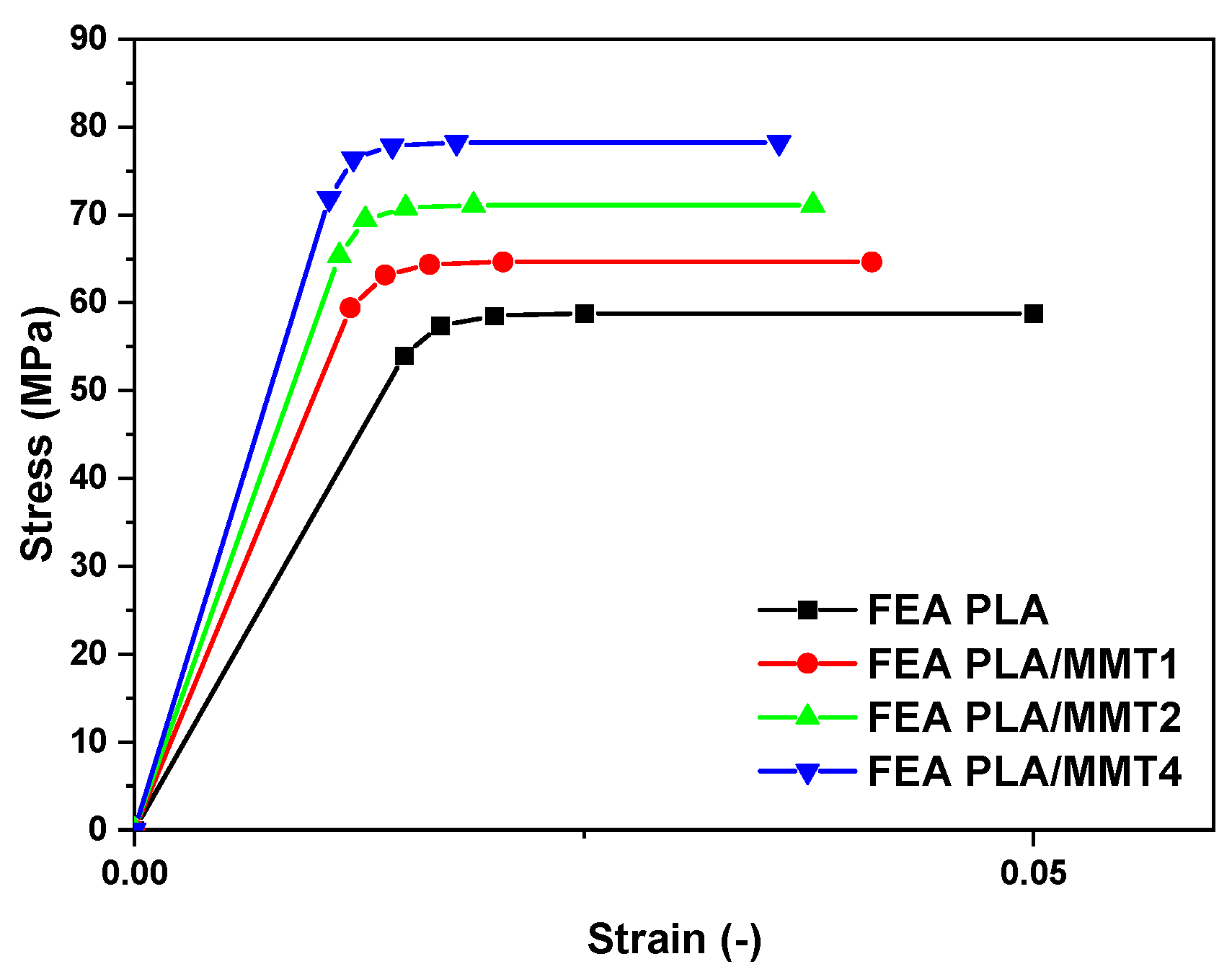

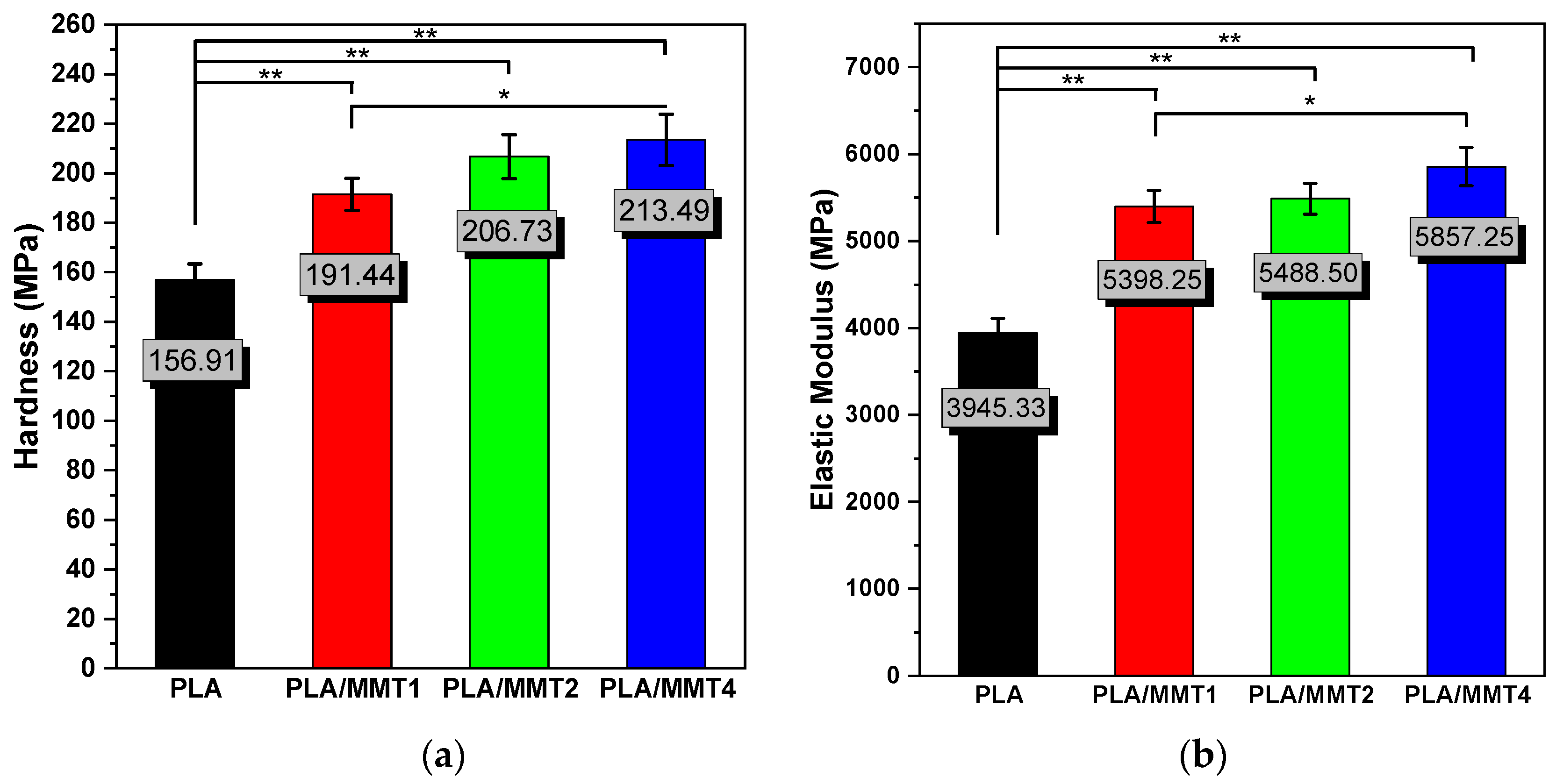

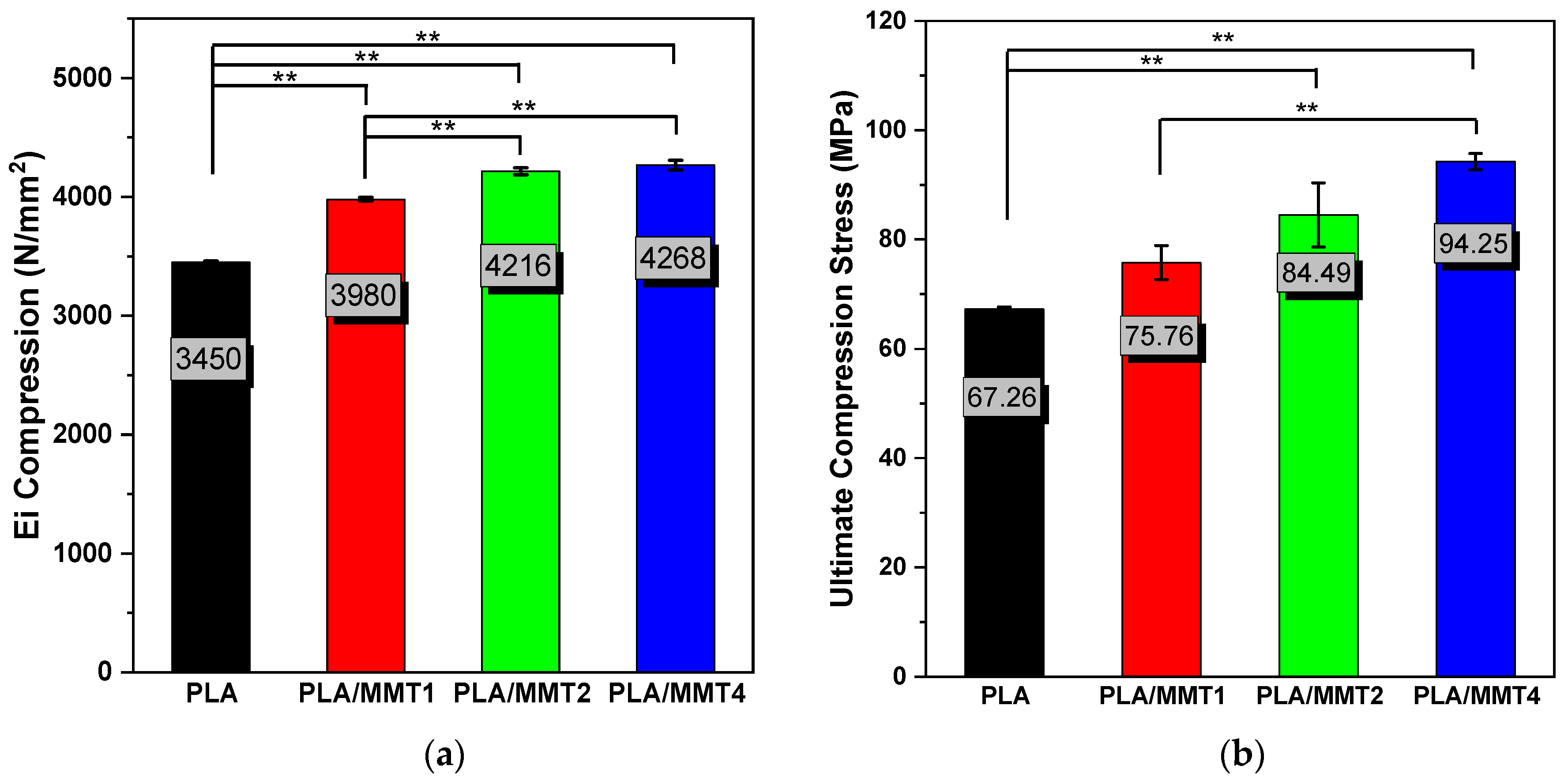

3.5.1. Mechanical Characterization through FEA-Assisted Nanoindentation and Compression Testing

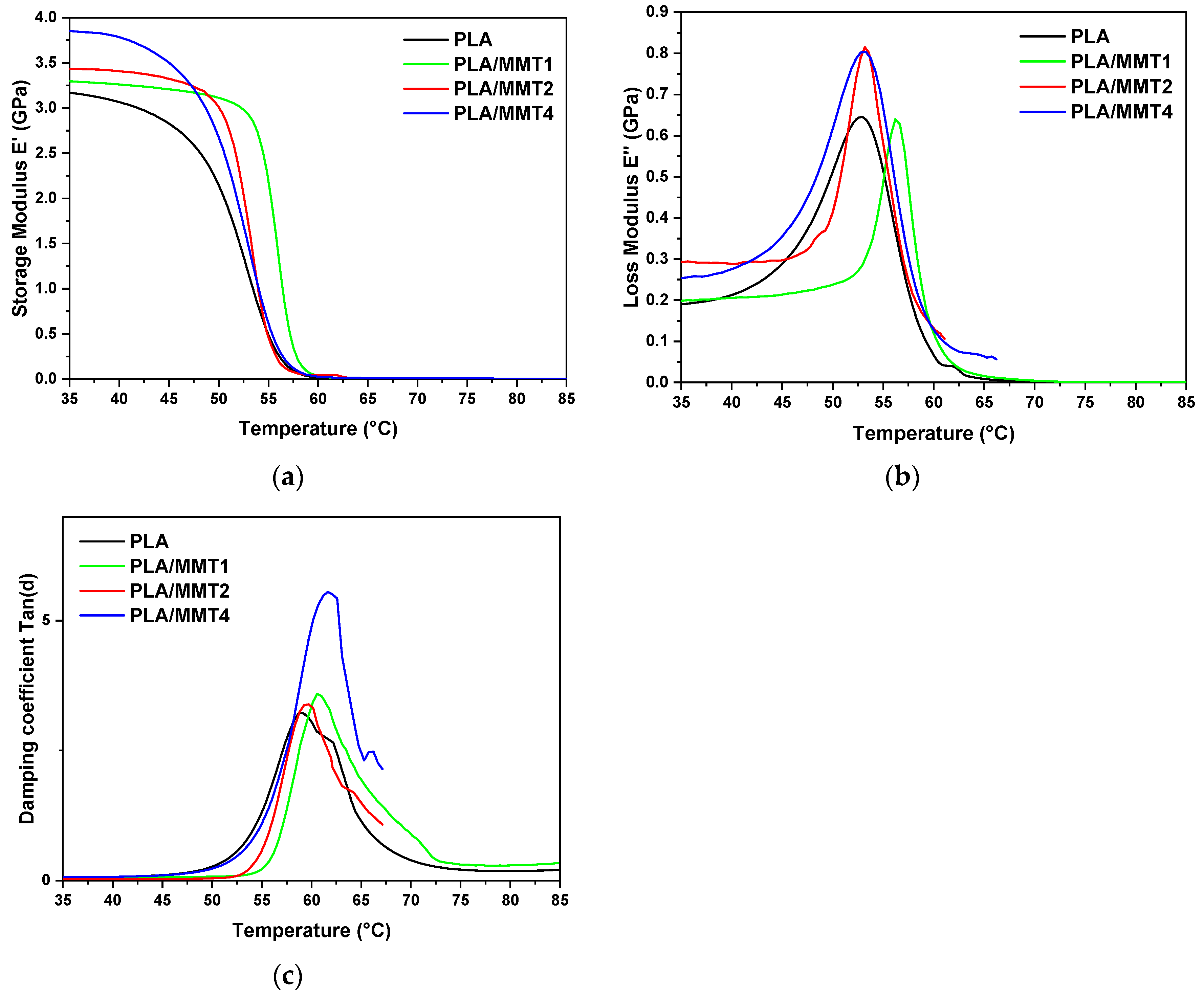

3.5.2. Dynamic Mechanical Analysis (DMA) of 3D-Printed Specimens

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Liu, R.; Peng, Y.; Cao, J. Thermal Stability of Organo-Montmorillonite-Modified Wood Flour/Poly(Lactic Acid) Composites. Polym. Compos. 2016, 37, 1971–1977. [Google Scholar] [CrossRef]

- Guo, Y.; Chang, C.C.; Cuiffo, M.A.; Xue, Y.; Zuo, X.; Pack, S.; Zhang, L.; He, S.; Weil, E.; Rafailovich, M.H. Engineering Flame Retardant Biodegradable Polymer Nanocomposites and Their Application in 3D Printing. Polym. Degrad. Stab. 2017, 137, 205–215. [Google Scholar] [CrossRef]

- Sanyang, M.L.; Jawaid, M. Bio-Based Polymers and Nanocomposites: Preparation, Processing, Properties & Performance; Springer International Publishing: Berlin/Heidelberg, Germany, 2019; ISBN 9783030058258. [Google Scholar]

- Saikia, P. Clay Nanostructures for Biomedical Applications; Elsevier B.V.: Amsterdam, The Netherlands, 2019; ISBN 9780128176504. [Google Scholar]

- Papadopoulos, L.; Terzopoulou, Z.; Vlachopoulos, A.; Klonos, P.A.; Kyritsis, A.; Tzetzis, D.; Papageorgiou, G.Z.; Bikiaris, D. Synthesis and Characterization of Novel Polymer/Clay Nanocomposites Based on Poly (Butylene 2,5-Furan Dicarboxylate). Appl. Clay Sci. 2020, 190, 105588. [Google Scholar] [CrossRef]

- Bardot, M.; Schulz, M.D. Biodegradable Poly(Lactic Acid) Nanocomposites for Fused Deposition Modeling 3d Printing. Nanomaterials 2020, 10, 2567. [Google Scholar] [CrossRef] [PubMed]

- Sinha Ray, S.; Okamoto, M. Polymer/Layered Silicate Nanocomposites: A Review from Preparation to Processing. Prog. Polym. Sci. 2003, 28, 1539–1641. [Google Scholar] [CrossRef]

- Coppola, B.; Cappetti, N.; di Maio, L.; Scarfato, P.; Incarnato, L. Layered Silicate Reinforced Polylactic Acid Filaments for 3D Printing of Polymer Nanocomposites. In Proceedings of the RTSI 2017—IEEE 3rd International Forum on Research and Technologies for Society and Industry, Conference Proceedings, Modena, Italy, 11–13 September 2017; pp. 3–6. [Google Scholar] [CrossRef]

- Ginoux, G.; Vroman, I.; Alix, S. Influence of Fused Filament Fabrication Parameters on Tensile Properties of Polylactide/Layered Silicate Nanocomposite Using Response Surface Methodology. J. Appl. Polym. Sci. 2021, 138, 50174. [Google Scholar] [CrossRef]

- Park, S.; Shou, W.; Makatura, L.; Matusik, W.; Fu, K.(K.). 3D Printing of Polymer Composites: Materials, Processes, and Applications. Matter 2022, 5, 43–76. [Google Scholar] [CrossRef]

- al Rashid, A.; Khan, S.A.; Al-Ghamdi, S.G.; Koç, M. Additive Manufacturing of Polymer Nanocomposites: Needs and Challenges in Materials, Processes, and Applications. J. Mater. Res. Technol. 2021, 14, 910–941. [Google Scholar] [CrossRef]

- Balla, E.; Daniilidis, V.; Karlioti, G.; Kalamas, T.; Stefanidou, M.; Bikiaris, N.D.; Vlachopoulos, A.; Koumentakou, I.; Bikiaris, D.N. Poly(Lactic Acid): A Versatile Biobased Polymer for the Future with Multifunctional Properties-from Monomer Synthesis, Polymerization Techniques and Molecular Weight Increase to PLA Applications. Polymers 2021, 13, 1822. [Google Scholar] [CrossRef]

- Vlachopoulos, A.; Karlioti, G.; Balla, E.; Daniilidis, V.; Kalamas, T.; Stefanidou, M.; Bikiaris, N.D.; Christodoulou, E.; Koumentakou, I.; Karavas, E.; et al. Poly(Lactic Acid)-Based Microparticles for Drug Delivery Applications: An Overview of Recent Advances. Pharmaceutics 2022, 14, 359. [Google Scholar] [CrossRef]

- Terzopoulou, Z.; Klonos, P.A.; Kyritsis, A.; Tziolas, A.; Avgeropoulos, A.; Papageorgiou, G.Z.; Bikiaris, D.N. Interfacial Interactions, Crystallization and Molecular Mobility in Nanocomposites of Poly(Lactic Acid) Filled with New Hybrid Inclusions Based on Graphene Oxide and Silica Nanoparticles. Polymer 2019, 166, 1–12. [Google Scholar] [CrossRef]

- Črešnar, K.P.; Klonos, P.A.; Zamboulis, A.; Terzopoulou, Z.; Xanthopoulou, E.; Papadopoulos, L.; Kyritsis, A.; Kuzmič, K.; Zemljič, L.F.; Bikiaris, D.N. Structure-Properties Relationships in Renewable Composites Based on Polylactide Filled with Tannin and Kraft Lignin—Crystallization and Molecular Mobility. Thermochim. Acta 2021, 703, 178998. [Google Scholar] [CrossRef]

- Klonos, P.A.; Peoglos, V.; Bikiaris, D.N.; Kyritsis, A. Rigid Amorphous Fraction and Thermal Diffusivity in Nanocomposites Based on Poly(l -Lactic Acid) Filled with Carbon Nanotubes and Graphene Oxide. J. Phys. Chem. C 2020, 124, 5469–5479. [Google Scholar] [CrossRef]

- Črešnar, K.P.; Zemljič, L.F.; Papadopoulos, L.; Terzopoulou, Z.; Zamboulis, A.; Klonos, P.A.; Bikiaris, D.N.; Kyritsis, A.; Pissis, P. Effects of Ag, ZnO and TiO2 Nanoparticles at Low Contents on the Crystallization, Semicrystalline Morphology, Interfacial Phenomena and Segmental Dynamics of PLA. Mater. Today Commun. 2021, 27, 102192. [Google Scholar] [CrossRef]

- Papadopoulos, L.; Klonos, P.A.; Terzopoulou, Z.; Psochia, E.; Sanusi, O.M.; Hocine, N.A.; Benelfellah, A.; Giliopoulos, D.; Triantafyllidis, K.; Kyritsis, A.; et al. Comparative Study of Crystallization, Semicrystalline Morphology, and Molecular Mobility in Nanocomposites Based on Polylactide and Various Inclusions at Low Filler Loadings. Polymer 2021, 217, 123457. [Google Scholar] [CrossRef]

- Nieddu, E.; Mazzucco, L.; Gentile, P.; Benko, T.; Balbo, V.; Mandrile, R.; Ciardelli, G. Preparation and Biodegradation of Clay Composites of PLA. React. Funct. Polym. 2009, 69, 371–379. [Google Scholar] [CrossRef]

- Zhou, N.; Yang, S.; Liu, Y.; Tuo, X.; Gong, Y.; Guo, J. Performance Evaluation on Particle-reinforced Rigid/Flexible Composites via Fused Deposition Modeling 3D Printing. J. Appl. Polym. Sci. 2022, 139, 52149. [Google Scholar] [CrossRef]

- Wang, S.; Daelemans, L.; D’hooge, D.R.; Couck, L.; van den Broeck, W.; Cornillie, P.; Gou, M.; de Clerck, K.; Cardon, L. Lifting the Quality of Fused Filament Fabrication of Polylactic Acid Based Composites. Compos. Part B Eng. 2021, 210, 108613. [Google Scholar] [CrossRef]

- Othman, S.H.; Ling, H.N.; Talib, R.A.; Naim, M.N.; Risyon, N.P.; Saifullah, M. PLA/MMT and PLA/Halloysite Bio-Nanocomposite Films: Mechanical, Barrier, and Transparency. J. Nano Res. 2019, 59, 77–93. [Google Scholar] [CrossRef]

- Makwakwa, D.; Ojijo, V.; Bandyopadhyay, J.; Sinha Ray, S. Flow Characteristics, Mechanical, Thermal, and Thermomechanical Properties, and 3d Printability of Biodegradable Polylactide Containing Boehmite at Different Loadings. Polymers 2021, 13, 2019. [Google Scholar] [CrossRef]

- Coppola, B.; Cappetti, N.; Maio, L.D.; Scarfato, P.; Incarnato, L. 3D Printing of PLA/Clay Nanocomposites: Influence of Printing Temperature on Printed Samples Properties. Materials 2018, 11, 1947. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Khan, I.; Kamma-Lorger, C.S.; Mohan, S.D.; Mateus, A.; Mitchell, G.R. The Exploitation of Polymer Based Nanocomposites for Additive Manufacturing: A Prospective Review. Appl. Mech. Mater. 2019, 890, 113–145. [Google Scholar] [CrossRef] [Green Version]

- Mihankhah, P.; Azdast, T.; Mohammadzadeh, H.; Hasanzadeh, R.; Aghaiee, S. Fused Filament Fabrication of Biodegradable Polylactic Acid Reinforced by Nanoclay as a Potential Biomedical Material. J. Thermoplast. Compos. Mater. 2021, 1–23. [Google Scholar] [CrossRef]

- Esposito Corcione, C.; Gervaso, F.; Scalera, F.; Montagna, F.; Sannino, A.; Maffezzoli, A. The Feasibility of Printing Polylactic Acid–Nanohydroxyapatite Composites Using a Low-Cost Fused Deposition Modeling 3D Printer. J. Appl. Polym. Sci. 2017, 134, 1–10. [Google Scholar] [CrossRef]

- Vigil Fuentes, M.A.; Thakur, S.; Wu, F.; Misra, M.; Gregori, S.; Mohanty, A.K. Study on the 3D Printability of Poly(3-Hydroxybutyrate-Co-3-Hydroxyvalerate)/Poly(Lactic Acid) Blends with Chain Extender Using Fused Filament Fabrication. Sci. Rep. 2020, 10, 11804. [Google Scholar] [CrossRef] [PubMed]

- Grigora, M.E.; Terzopoulou, Z.; Tsongas, K.; Klonos, P.; Kalafatakis, N.; Bikiaris, D.N.; Kyritsis, A.; Tzetzis, D. Influence of Reactive Chain Extension on the Properties of 3d Printed Poly(Lactic Acid) Constructs. Polymers 2021, 13, 1381. [Google Scholar] [CrossRef]

- Cailloux, J.; Hakim, R.N.; Santana, O.O.; Bou, J.; Abt, T.; Sánchez-Soto, M.; Carrasco, F.; Maspoch, M.L. Reactive Extrusion: A Useful Process to Manufacture Structurally Modified PLA/o-MMT Composites. Compos. Part A Appl. Sci. Manuf. 2016, 88, 106–115. [Google Scholar] [CrossRef]

- Naser, A.Z.; Deiab, I.; Defersha, F.; Yang, S. Expanding Poly(Lactic Acid) (Pla) and Polyhydroxyalkanoates (Phas) Applications: A Review on Modifications and Effects. Polymers 2021, 13, 4271. [Google Scholar] [CrossRef]

- Cervantes-Uc, J.M.; Cauich-Rodríguez, J.V.; Vázquez-Torres, H.; Garfias-Mesías, L.F.; Paul, D.R. Thermal Degradation of Commercially Available Organoclays Studied by TGA-FTIR. Thermochim. Acta 2007, 457, 92–102. [Google Scholar] [CrossRef]

- Igwe Idumah, C.; Nwabanne, J.T.; Tanjung, F.A. Novel Trends in Poly (Lactic) Acid Hybrid Bionanocomposites. Clean. Mater. 2021, 2, 100022. [Google Scholar] [CrossRef]

- Chen, T.; Yuan, Y.; Zhao, Y.; Rao, F.; Song, S. Preparation of Montmorillonite Nanosheets through Freezing/Thawing and Ultrasonic Exfoliation. Langmuir 2019, 35, 2368–2374. [Google Scholar] [CrossRef] [PubMed]

- Tzetzis, D.; Tsongas, K.; Mansour, G. Determination of the Mechanical Properties of Epoxy Silica Nanocomposites through FEA-Supported Evaluation of Ball Indentation Test Results. Mater. Res. 2017, 20, 1571–1578. [Google Scholar] [CrossRef] [Green Version]

- Tsongas, K.; Tzetzis, D.; Karantzalis, A.; Banias, G.; Exarchos, D.; Ahmadkhaniha, D.; Zanella, C.; Matikas, T.; Bochtis, D. Microstructural, Surface Topology and Nanomechanical Characterization of Electrodeposited Ni-P/SiC Nanocomposite Coatings. Appl. Sci. 2019, 9, 2901. [Google Scholar] [CrossRef] [Green Version]

- Mansour, G.; Zoumaki, M.; Tsongas, K.; Tzetzis, D. Microstructural and Finite Element Analysis—Assisted Nanomechanical Characterization of Maize Starch Nanocomposite Films. Mater. Res. 2021, 24, e20200409. [Google Scholar] [CrossRef]

- Najafi, N.; Heuzey, M.C.; Carreau, P.J.; Wood-Adams, P.M. Control of Thermal Degradation of Polylactide (PLA)-Clay Nanocomposites Using Chain Extenders. Polym. Degrad. Stab. 2012, 97, 554–565. [Google Scholar] [CrossRef]

- Bikiaris, D.N.; Karayannidis, G.P. Chain Extension of Polyesters PET and PBT with Two New Diimidodiepoxides II. J. Poly. Sci. Part A Polym. Chem. 1996, 34, 1337–1342. [Google Scholar] [CrossRef]

- Wang, S.; Capoen, L.; D’hooge, D.R.; Cardon, L. Can the Melt Flow Index Be Used to Predict the Success of Fused Deposition Modelling of Commercial Poly(Lactic Acid) Filaments into 3D Printed Materials? Plast. Rubber Compos. 2018, 47, 9–16. [Google Scholar] [CrossRef]

- Baptista, R.; Guedes, M.; Pereira, M.F.C.; Maurício, A.; Carrelo, H.; Cidade, T. On the Effect of Design and Fabrication Parameters on Mechanical Performance of 3D Printed PLA Scaffolds. Bioprinting 2020, 20, e00096. [Google Scholar] [CrossRef]

- Pluta, M. Melt Compounding of Polylactide/Organoclay: Structure and Properties of Nanocomposites. J. Polym. Sci. Part B Polym. Phys. 2006, 44, 3392–3405. [Google Scholar] [CrossRef]

- Fukushima, K.; Fina, A.; Geobaldo, F.; Venturello, A.; Camino, G. Properties of Poly(Lactic Acid) Nanocomposites Based on Montmorillonite, Sepiolite and Zirconium Phosphonate. Express Polym. Lett. 2012, 6, 914–926. [Google Scholar] [CrossRef]

- Paul, M.-A.; Alexandre, M.; Degée, P.; Henrist, C.; Rulmont, A.; Dubois, P. New Nanocomposite Materials Based on Plasticized Poly(L-Lactide) and Organo-Modified Montmorillonites: Thermal and Morphological Study. Polymer 2003, 44, 443–450. [Google Scholar] [CrossRef]

- Rhim, J.W.; Park, H.M.; Ha, C.S. Bio-Nanocomposites for Food Packaging Applications. Prog. Polym. Sci. 2013, 38, 1629–1652. [Google Scholar] [CrossRef]

- Sánchez-Jiménez, P.E.; Pérez-Maqueda, L.A.; Perejón, A.; Criado, J.M. Nanoclay Nucleation Effect in the Thermal Stabilization of a Polymer Nanocomposite: A Kinetic Mechanism Change. J. Phys. Chem. C 2012, 116, 11797–11807. [Google Scholar] [CrossRef] [Green Version]

- Pluta, M.; Galeski, A.; Alexandre, M.; Paul, M.A.; Dubois, P. Polylactide/Montmorillonite Nanocomposites and Microcomposites Prepared by Melt Blending: Structure and Some Physical Properties. J. Appl. Polym. Sci. 2002, 86, 1497–1506. [Google Scholar] [CrossRef]

- Tenn, N.; Follain, N.; Soulestin, J.; Crétois, R.; Bourbigot, S.; Marais, S. Effect of Nanoclay Hydration on Barrier Properties of PLA/Montmorillonite Based Nanocomposites. J. Phys. Chem. C 2013, 117, 12117–12135. [Google Scholar] [CrossRef]

- Migliaresi, C.; de Lollis, A.; Fambri, L.; Cohn, D. The Effect of Thermal History on the Crystallinity of Different Molecular Weight PLLA Biodegradable Polymers. Clin. Mater. 1991, 8, 111–118. [Google Scholar] [CrossRef]

- Li, H.; Huneault, M.A. Effect of Nucleation and Plasticization on the Crystallization of Poly(Lactic Acid). Polymer 2007, 48, 6855–6866. [Google Scholar] [CrossRef] [Green Version]

- Meng, Q.K.; Heuzey, M.C.; Carreau, P.J. Effects of a Multifunctional Polymeric Chain Extender on the Properties of Polylactide and Polylactide/Clay Nanocomposites. Int. Polym. Processing 2012, 27, 505–516. [Google Scholar] [CrossRef]

- Papageorgiou, G.Z.; Achilias, D.S.; Nanaki, S.; Beslikas, T.; Bikiaris, D. PLA Nanocomposites: Effect of Filler Type on Non-Isothermal Crystallization. Thermochim. Acta 2010, 511, 129–139. [Google Scholar] [CrossRef]

- Kontou, E.; Niaounakis, M.; Georgiopoulos, P. Comparative Study of PLA Nanocomposites Reinforced with Clay and Silica Nanofillers and Their Mixtures. J. Appl. Polym. Sci. 2011, 122, 1519–1529. [Google Scholar] [CrossRef]

- Fukushima, K.; Tabuani, D.; Camino, G. Nanocomposites of PLA and PCL Based on Montmorillonite and Sepiolite. Mater. Sci. Eng. C 2009, 29, 1433–1441. [Google Scholar] [CrossRef]

- Ray, S.S.; Bousmina, M. Biodegradable Polymers and Their Layered Silicate Nanocomposites: In Greening the 21st Century Materials World. Prog. Mater. Sci. 2005, 50, 962–1079. [Google Scholar]

- Wu, D.; Wu, L.; Wu, L.; Zhang, M. Rheology and Thermal Stability of Polylactide/Clay Nanocomposites. Polym. Degrad. Stab. 2006, 91, 3149–3155. [Google Scholar] [CrossRef]

- Yourdkhani, M.; Mousavand, T.; Chapleau, N.; Hubert, P. Thermal, Oxygen Barrier and Mechanical Properties of Polylactide-Organoclay Nanocomposites. Compos. Sci. Technol. 2013, 82, 47–53. [Google Scholar] [CrossRef]

- di Maio, L.; Garofalo, E.; Scarfato, P.; Incarnato, L. Effect of Polymer/Organoclay Composition on Morphology and Rheological Properties of Polylactide Nanocomposites. Polym. Compos. 2015, 36, 1135–1144. [Google Scholar] [CrossRef]

- Mansa, R.; Huang, C.T.; Quintela, A.; Rocha, F.; Detellier, C. Preparation and Characterization of Novel Clay/PLA Nanocomposites. Appl. Clay Sci. 2015, 115, 87–96. [Google Scholar] [CrossRef]

- Camani, P.H.; Toguchi, J.P.M.; Fiori, A.P.S.M.; Rosa, D. dos S. Impact of Unmodified (PGV) and Modified (Cloisite20A) Nanoclays into Biodegradability and Other Properties of (Bio)Nanocomposites. Appl. Clay Sci. 2020, 186, 105453. [Google Scholar] [CrossRef]

- Darie, R.N.; Pâslaru, E.; Sdrobis, A.; Pricope, G.M.; Hitruc, G.E.; Poiatǎ, A.; Baklavaridis, A.; Vasile, C. Effect of Nanoclay Hydrophilicity on the Poly(Lactic Acid)/Clay Nanocomposites Properties. Ind. Eng. Chem. Res. 2014, 53, 7877–7890. [Google Scholar] [CrossRef]

- Pharr, G.M. An Improved Technique for Determining Hardness and Elastic Modulus Using Load and Displacement Sensing Indentation Experiments. J. Mater. Res. 1992, 7, 1564–1583. [Google Scholar] [CrossRef]

- Mansour, G.; Tzetzis, D. Nanomechanical Characterization of Hybrid Multiwall Carbon Nanotube and Fumed Silica Epoxy Nanocomposites. Polym. Plast. Technol. Eng. 2013, 52, 1054–1062. [Google Scholar] [CrossRef]

- Tzetzis, D.; Mansour, G.; Tsiafis, I.; Pavlidou, E. Nanoindentation Measurements of Fumed Silica Epoxy Reinforced Nanocomposites. J. Reinf. Plast. Compos. 2013, 32, 163–173. [Google Scholar] [CrossRef]

- Mansour, G.; Tzetzis, D.; Bouzakis, K.-D.; Bouzakis, K.D. A Nanomechanical Approach on the Measurement of the Elastic Properties of Epoxy Reinforced Carbon Nanotube Nanocomposites Potential Wound Care Products with Enhanced Hemostatic Properties View Project A Nanomechanical Approach on the Measurement of the Elastic Properties of Epoxy Reinforced Carbon Nanotube Nanocomposites. Tribol. Ind. 2013, 35, 190–199. [Google Scholar]

- Lai, S.M.; Wu, S.H.; Lin, G.G.; Don, T.M. Unusual Mechanical Properties of Melt-Blended Poly(Lactic Acid) (PLA)/Clay Nanocomposites. Eur. Polym. J. 2014, 52, 193–206. [Google Scholar] [CrossRef]

| Properties | Value |

|---|---|

| Specific Gravity | 1.24 |

| Crystalline Melt Temperature (°C) | 145–160 |

| Glass transition Temperature (°C) | 55–60 |

| Clarity | Transparent |

| Abbreviation | PLA Content (wt.%) | Joncryl Content (wt.%) | MMT Content (wt.%) |

|---|---|---|---|

| PLA | 100 | 2 | 0 |

| PLA/MMT1 | 97 | data | 1 |

| PLA/MMT2 | 96 | data | 2 |

| PLA/MMT4 | 94 | data | 4 |

| Properties | Value |

|---|---|

| Infill density | 100% |

| Layer thickness of first layer | 0.35 mm |

| Layer thickness | 0.2 mm |

| Number of shells | 2 |

| Raster orientation | 45°/0° |

| Print speed | 30 mm/s |

| Extruder temperature | 210 °C |

| Printing bed temperature | 45 °C |

| Sample | Mn (g/mol) | Mw (g/mol) | Mp (g/mol) | PDI | MFI (g/10 min) | Average Filament Diameter (mm) |

|---|---|---|---|---|---|---|

| PLA | 124,300 | 210,900 | 172,100 | 1.60 | 0.37 ± 0.04 | 1.71 ± 0.01 |

| PLA/MMT1 | 113,400 | 201,300 | 167,300 | 1.77 | 1.16 ± 0.16 ** | 1.76 ± 0.02 ** |

| PLA/MMT2 | 107,700 | 194,700 | 154,200 | 1.80 | 1.23 ± 0.04 ** | 1.79 ± 0.01 ** |

| PLA/MMT4 | 75,900 | 135,700 | 97,000 | 1.78 | 0.99 ± 0.12 ** | 1.78 ± 0.02 ** |

| Element Symbol | Atomic Conc. | |||

|---|---|---|---|---|

| PLA | PLA/MMT1 | PLA/MMT2 | PLA/MMT4 | |

| C | 91.05 | 83.15 | 82.99 | 81.57 |

| O | 8.95 | 6.42 | 6.68 | 6.77 |

| N | 7.32 | 7.10 | 6.5 | |

| Si | 1.27 | 1.71 | 3.12 | |

| Al | 0.93 | 0.92 | 1.37 | |

| Na | 0.36 | 0.22 | 0.19 | |

| Mg | 0.55 | 0.38 | 0.49 | |

| Sample | Tg (°C) | Tcc (°C) | Tm (°C) | ΔHcc (J/g) | Crystallinity (%) |

|---|---|---|---|---|---|

| PLA | 64.0 | 130.4 | 149.5 | −2.6 | 0.2 |

| PLA/MMT1 | 64.9 | 130.1 | 152.4 | −5.7 | 0 |

| PLA/MMT2 | 66.0 | 120.7 | 155.6 | −6.5 | 0 |

| PLA/MMT4 | 64.4 | 123.1 | 155.3 | −15.2 | 0 |

| Sample | To (°C) | Td,10% (°C) | Tp (°C) |

|---|---|---|---|

| PLA | 359.6 | 352.3 | 380.5 |

| PLA/MMT1 | 364.7 | 355.5 | 382.5 |

| PLA/MMT2 | 364.4 | 348.8 | 381.1 |

| PLA/MMT4 | 367.0 | 347.8 | 380.8 |

| Sample | Ei Nanoindentation (N/mm2) | Ei Nanoindentation FEA (N/mm2) |

|---|---|---|

| PLA | 3945.33 ± 134.74 | 3600 |

| PLA/MMT1 | 5398.25 ± 184.80 | 4950 |

| PLA/MMT2 | 5488.50 ± 177.31 | 5732 |

| PLA/MMT4 | 5857.25 ± 222.11 | 6637 |

| Sample | E′35 °C (MPa) | E′60 °C (MPa) | Tgtanδ (°C) | (tan δ)height | (tan δ)area |

|---|---|---|---|---|---|

| PLA | 3167.63 | 21.58 | 58.70 | 3.08 | 28.50 |

| PLA/MMT1 | 3296.72 | 43.67 | 60.60 | 3.43 | 27.55 |

| PLA/MMT2 | 3433.71 | 43.87 | 59.70 | 3.29 | 20.22 |

| PLA/MMT4 | 3851.89 | 30.03 | 61.60 | 5.01 | 32.80 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Grigora, M.-E.; Terzopoulou, Z.; Tsongas, K.; Bikiaris, D.N.; Tzetzis, D. Physicochemical Characterization and Finite Element Analysis-Assisted Mechanical Behavior of Polylactic Acid-Montmorillonite 3D Printed Nanocomposites. Nanomaterials 2022, 12, 2641. https://doi.org/10.3390/nano12152641

Grigora M-E, Terzopoulou Z, Tsongas K, Bikiaris DN, Tzetzis D. Physicochemical Characterization and Finite Element Analysis-Assisted Mechanical Behavior of Polylactic Acid-Montmorillonite 3D Printed Nanocomposites. Nanomaterials. 2022; 12(15):2641. https://doi.org/10.3390/nano12152641

Chicago/Turabian StyleGrigora, Maria-Eirini, Zoe Terzopoulou, Konstantinos Tsongas, Dimitrios N. Bikiaris, and Dimitrios Tzetzis. 2022. "Physicochemical Characterization and Finite Element Analysis-Assisted Mechanical Behavior of Polylactic Acid-Montmorillonite 3D Printed Nanocomposites" Nanomaterials 12, no. 15: 2641. https://doi.org/10.3390/nano12152641

APA StyleGrigora, M.-E., Terzopoulou, Z., Tsongas, K., Bikiaris, D. N., & Tzetzis, D. (2022). Physicochemical Characterization and Finite Element Analysis-Assisted Mechanical Behavior of Polylactic Acid-Montmorillonite 3D Printed Nanocomposites. Nanomaterials, 12(15), 2641. https://doi.org/10.3390/nano12152641