Tuning Surface Plasmonic Resonance and Surface Wettability of Au/CrN Films Using Nitrogen-Containing Gas

Abstract

:1. Introduction

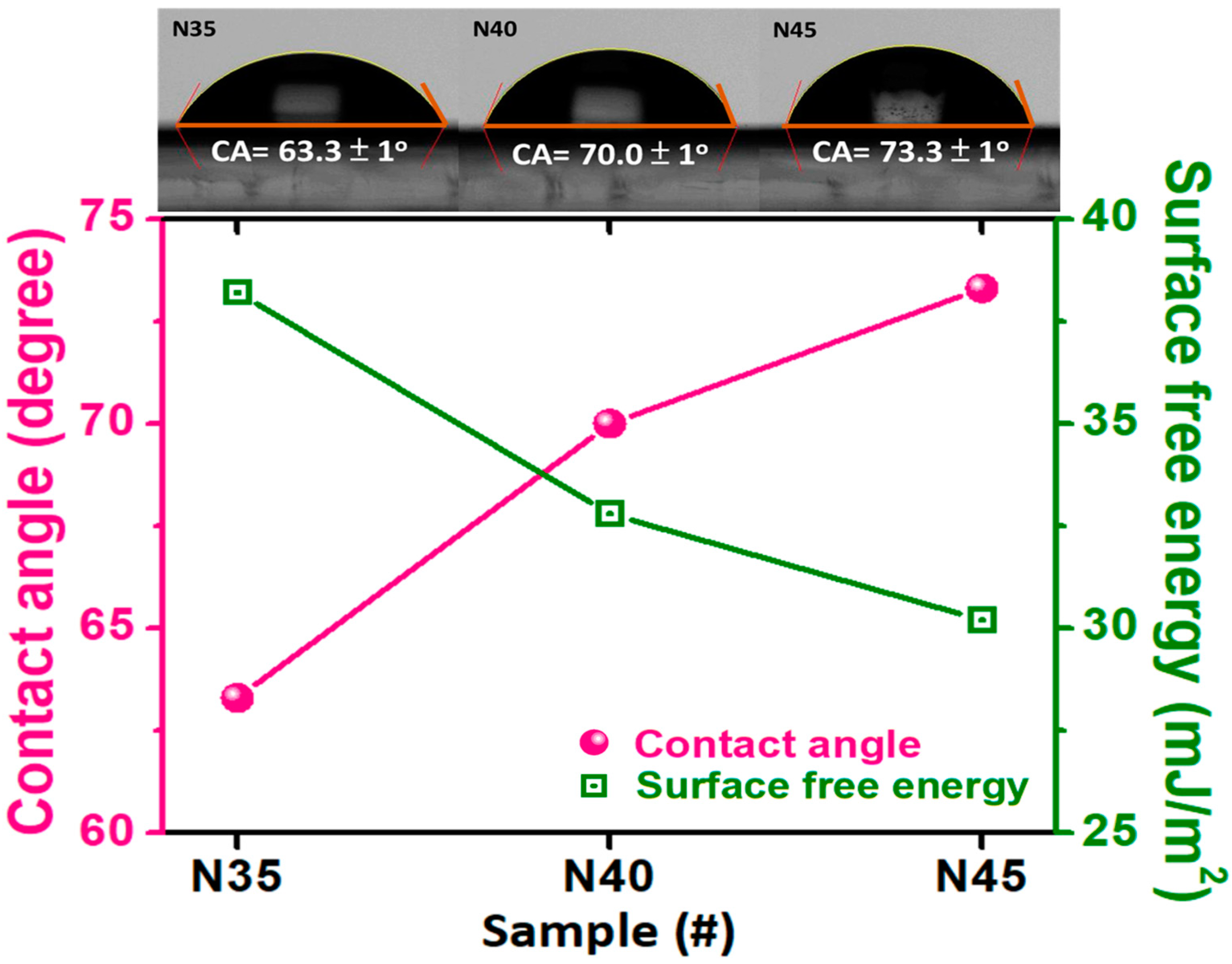

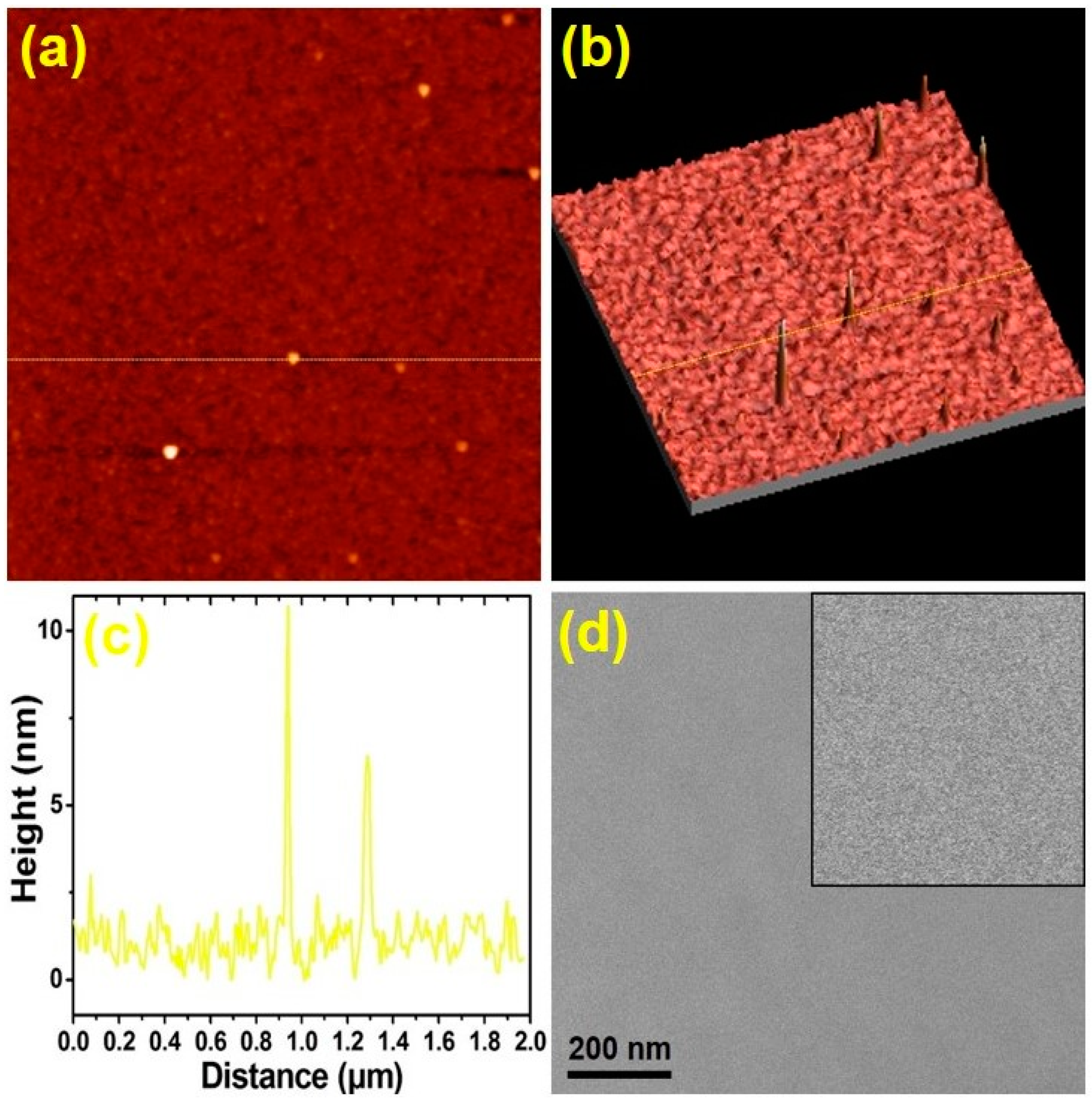

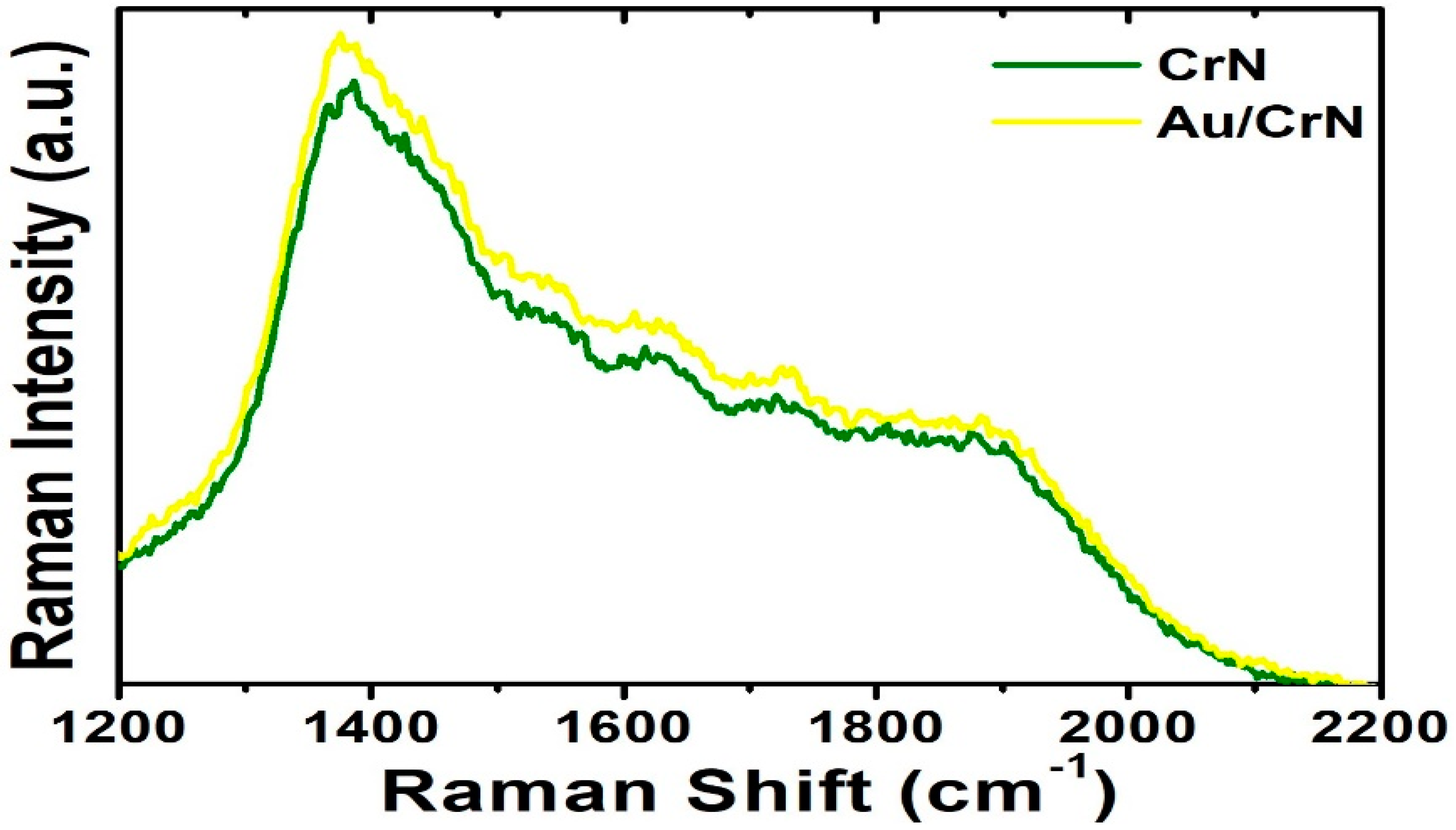

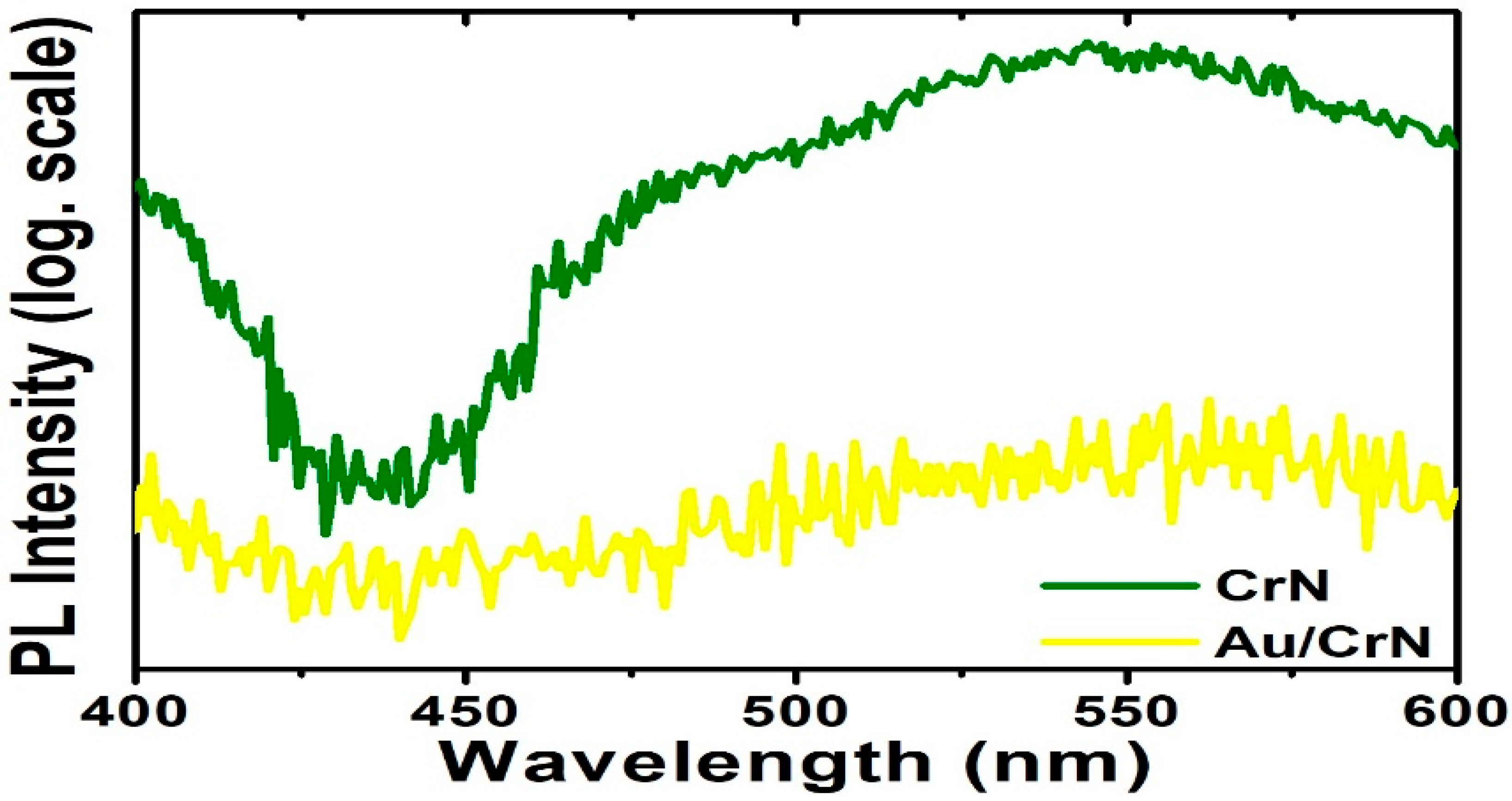

2. Experiments and Composite Film Structures

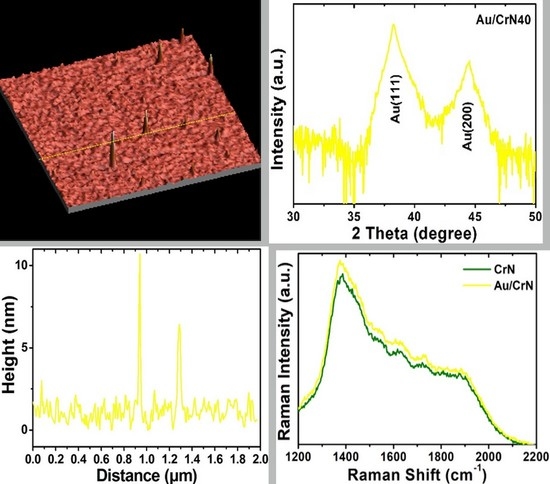

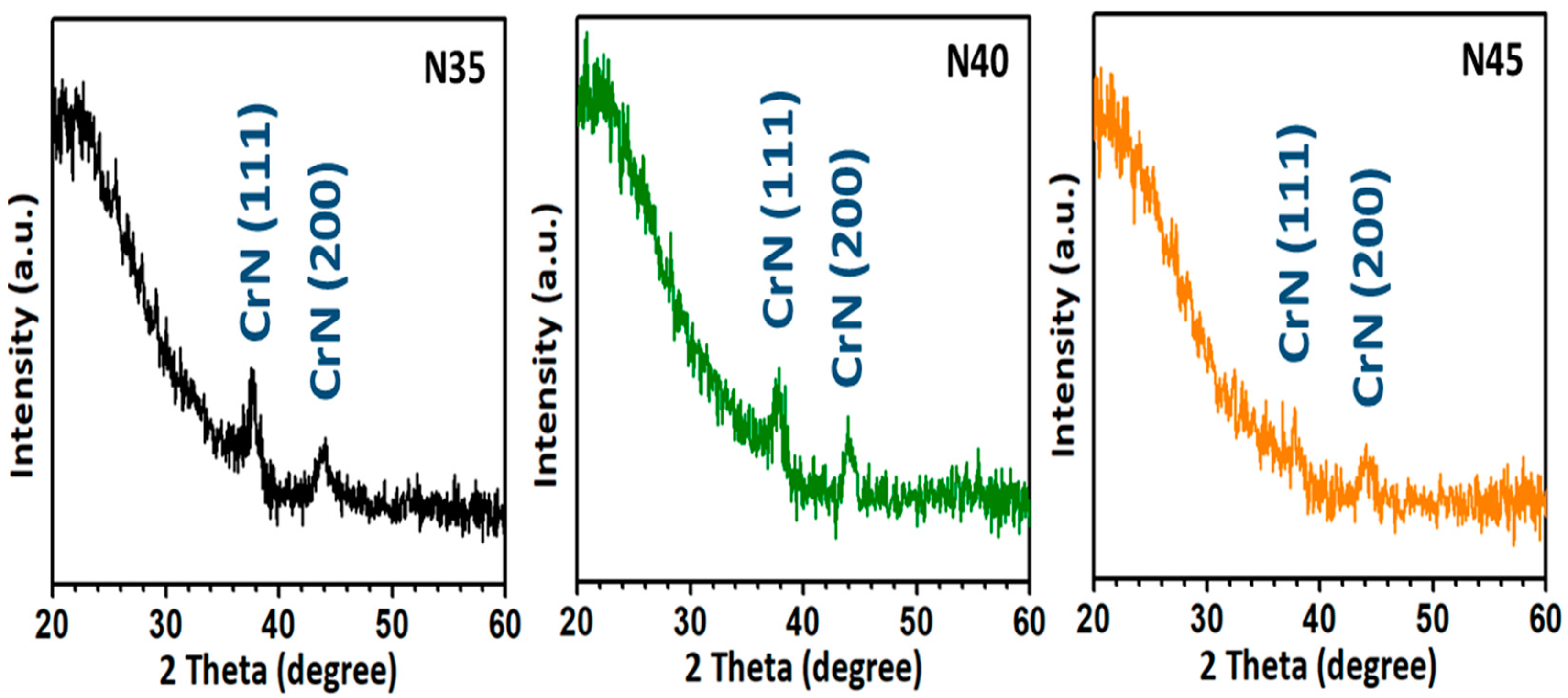

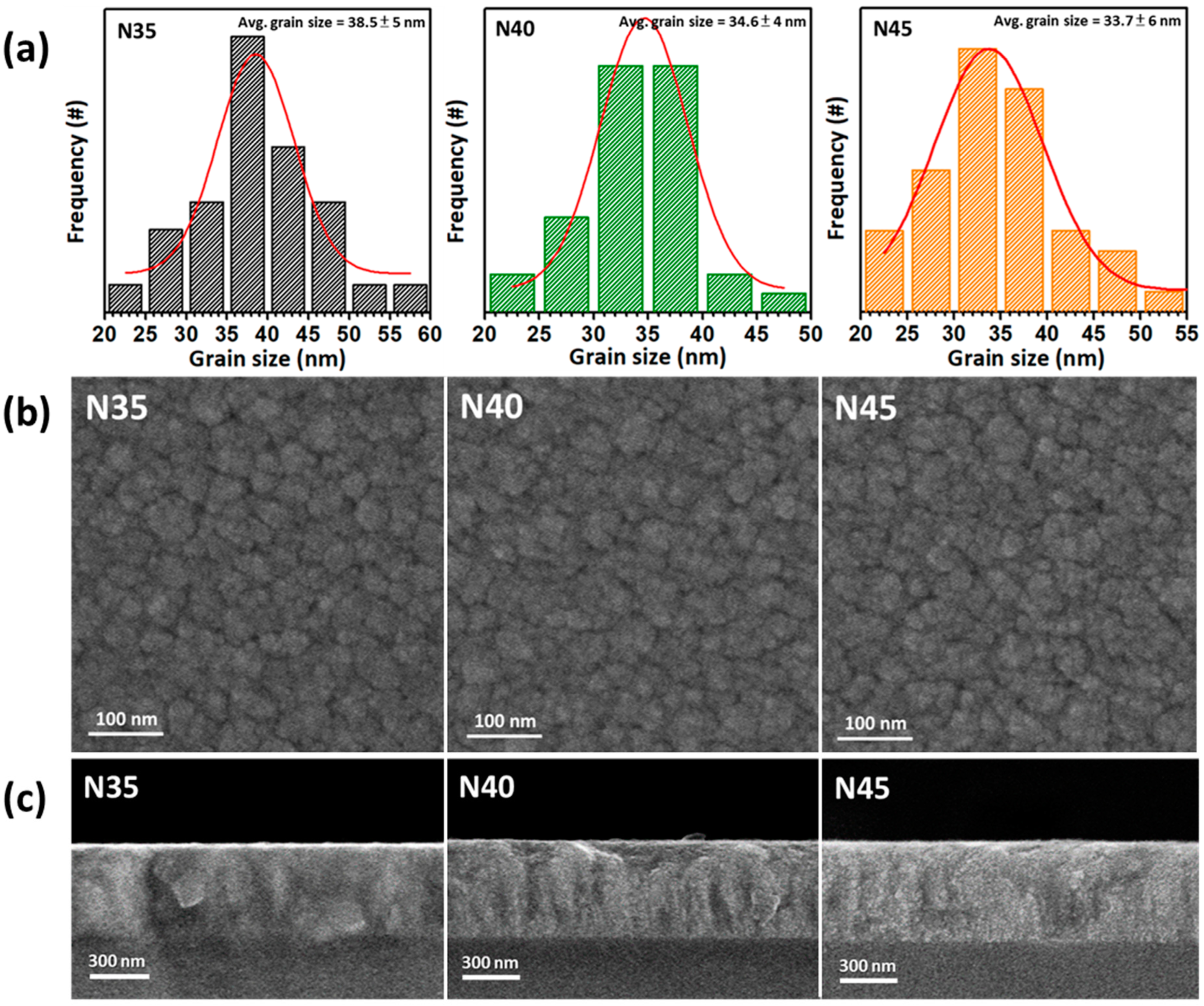

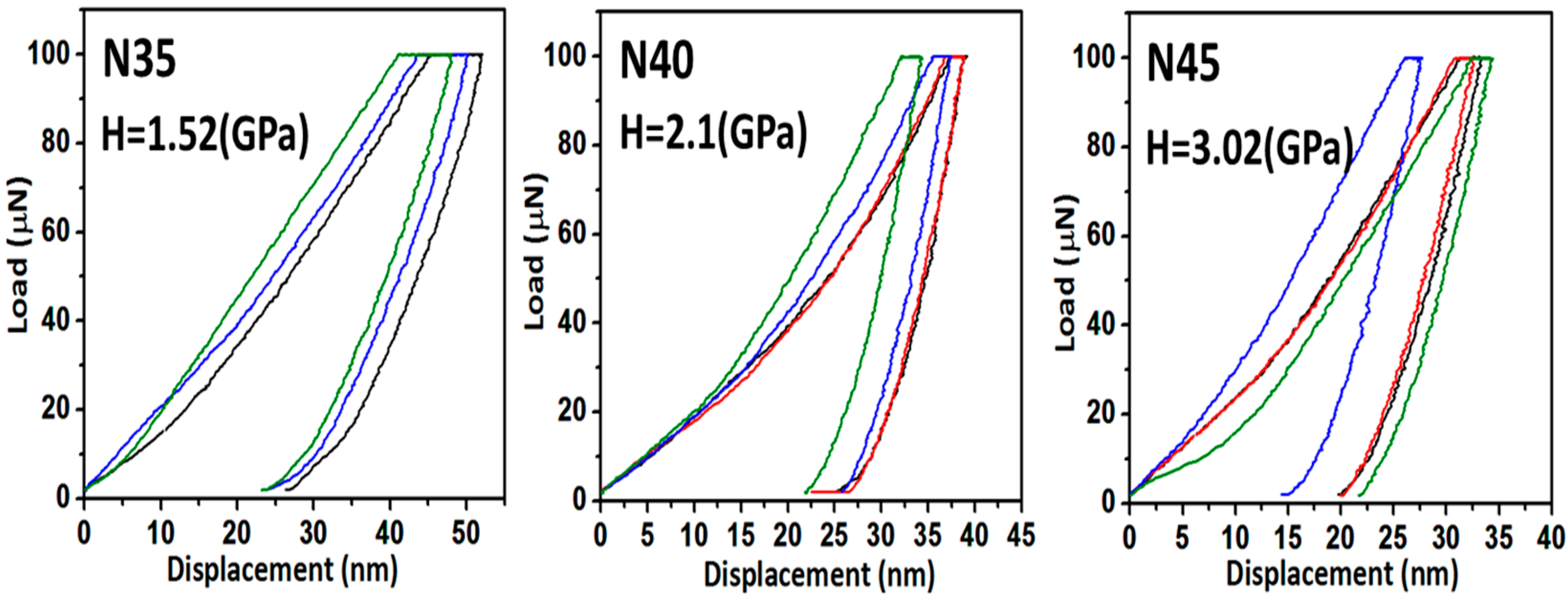

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Adhikary, P.; Parvez Mahmud, M.A.; Solaiman, T.; Wang, Z.L. Recent advances on biomechanical motion-driven triboelectric nanogenerators for drug delivery. Nano Today 2022, 45, 101513. [Google Scholar] [CrossRef]

- Dong, X.; Wang, Z.; Berbille, A.; Zhao, X.; Tang, W.; Wang, Z.L. Investigations on the contact-electro-catalysis under various ultrasonic conditions and using different electrification particles. Nano Energy 2022, 99, 107346. [Google Scholar] [CrossRef]

- Zhang, Y.; Wang, S.; Zhao, Y.; Ding, Y.; Zhang, Z.; Jiang, T.; Wang, Z.L.; Li, L. Piezo-phototronic effect boosted catalysis in plasmonic bimetallic ZnO heterostructure with guided fermi level alignment. Mater. Today Nano 2022, 18, 100177. [Google Scholar] [CrossRef]

- Wang, Z.; Berbille, A.; Feng, Y.; Li, S.; Zhu, L.; Tang, W.; Wang, Z.L. Contact-electro-catalysis for the degradation of organic pollutants using pristine dielectric powders. Nat. Commun. 2022, 13, 130. [Google Scholar] [CrossRef]

- Zhang, H.; Cao, Y.; Xu, D.; Goh, N.; Demirer, G.; Cestellos-Blanco, S.; Chen, Y.; Landry, M.; Yang, P. Gold nanocluster mediated delivery of siRNA to intact plant cells for efficient gene knockdown. Nano Lett. 2021, 21, 5859–5866. [Google Scholar] [CrossRef]

- Cestellos-Blanco, S.; Zhang, H.; Kim, J.M.; Shen, Y.X.; Yang, P. Photosynthetic semiconductor biohybrids for solar-driven biocatalysis. Nat. Cata. 2020, 3, 245–255. [Google Scholar] [CrossRef]

- Xie, C.; Niu, Z.; Kim, D.; Li, M.; Yang, P. Surface and Interface Control in Nanoparticle Catalysis. Chem. Rev. 2020, 120, 1184–1249. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Peng, Y.; Cui, Y. Advanced textiles for personal thermal management and energy. Joule 2020, 4, 724–742. [Google Scholar] [CrossRef]

- Pomerantseva, E.; Bonaccorso, F.; Feng, X.; Cui, Y.; Gogotsi, Y. Energy storage: The future enabled by nanomaterials. Science 2019, 366, eaan8285. [Google Scholar] [CrossRef] [Green Version]

- Wu, J.; Wang, X.; Wang, Q.; Lou, Z.; Li, S.; Zhu, Y.; Qin, L.; Wei, H. Nanomaterials with enzyme-like characteristics (nanozymes): Next-generation artificial enzymes (II). Chem. Soc. Rev. 2019, 48, 1004–1076. [Google Scholar] [CrossRef]

- Yang, K.S.; Lu, Y.R.; Hsu, Y.Y.; Lin, C.J.; Tseng, C.M.; Liou, Y.H.; Kumar, K.; Wei, D.H.; Dong, C.L.; Chen, C.L. Plasmon-Induced Visible-Light Photocatalytic Activity of Au Nanoparticle-Decorated Hollow Mesoporous TiO2: A View by X-Ray Spectroscopy. J. Phys. Chem. C 2018, 122, 6955. [Google Scholar] [CrossRef]

- Chi, P.W.; Wei, D.H. Dielectric enhancement with low dielectric loss in textured ZnO films inserted with NiFe. J. Mater. Chem. C 2017, 5, 1394. [Google Scholar] [CrossRef]

- Wei, D.H.; Lin, T.K.; Liang, Y.C.; Chang, H.W. Formation and Application of Core-Shell of FePt-Au Magnetic-Plasmonic Nanoparticles. Front. Chem. 2021, 9, 653718. [Google Scholar] [CrossRef] [PubMed]

- Chen, C.J.; Yeh, C.Y.; Chen, C.H.; Jena, A.; Wei, D.H.; Chang, H.; Hu, S.F.; Liu, R.S. Molybdenum Tungsten Disulfide with a Large Number of Sulfur Vacancies and Electronic Unoccupied States on Silicon Micropillars for Solar Hydrogen Evolution. ACS Appl. Mater. Interf. 2020, 12, 54671. [Google Scholar] [CrossRef]

- Pichaimuthu, K.; Chen, C.J.; Chen, C.H.; Chen, Y.T.; Su, C.C.; Wei, D.H.; Liu, R.S. Boosting Solar Hydrogen Production of Molybdenum Tungsten Sulfide-Modified Si Micropyramids by Introducing Phosphate. ACS Appl. Mater. Interf. 2020, 12, 41515. [Google Scholar] [CrossRef] [PubMed]

- Sue, Y.S.; Pan, K.Y.; Wei, D.H. Optoelectronic and photocatalytic properties of zinc sulfide nanowires synthesized by vapor-liquid-solid process. Appl. Surf. Sci. 2019, 471, 435. [Google Scholar] [CrossRef]

- Chen, C.J.; Liu, C.W.; Yang, K.C.; Yin, L.C.; Wei, D.H.; Hu, S.F.; Liu, R.S. Amorphous Phosphorus-Doped Cobalt Sulfide Modified on Silicon Pyramids for Efficient Solar Water Reduction. ACS Appl. Mater. Interf. 2018, 10, 37142. [Google Scholar] [CrossRef] [PubMed]

- Pan, K.Y.; Wei, D.H. Enhanced electronic and electrochemical properties of core-shelled V2O5-Pt nanowires. Appl. Surf. Sci. 2018, 427, 1064. [Google Scholar] [CrossRef]

- Chen, C.J.; Yang, K.C.; Liu, C.W.; Lu, Y.R.; Dong, C.L.; Wei, D.H.; Hu, S.F.; Liu, R.S. Silicon microwire arrays decorated with amorphous heterometal-doped molybdenum sulfide for water photoelectrolysis. Nano Energy 2017, 32, 422. [Google Scholar] [CrossRef]

- Pan, K.Y.; Wei, D.H. Optoelectronic and electrochemical properties of vanadium pentoxide synthesized by vapor-solid process. Nanomaterials 2016, 6, 140. [Google Scholar] [CrossRef] [Green Version]

- Chan, M.H.; Lu, C.N.; Chung, Y.L.; Chang, Y.C.; Li, C.H.; Chen, C.L.; Wei, D.H.; Hsiao, M. Magnetically guided theranostics: Montmorillonite-based iron/platinum nanoparticles for enhancing in situ MRI contrast and hepatocellular carcinoma treatment. J. Nanobiotechnol. 2021, 19, 308. [Google Scholar] [CrossRef] [PubMed]

- Wu, J.W.; Chen, C.H.; Lin, C.J.; Kumar, K.; Lu, Y.R.; Liou, Y.H.; Chen, S.Y.; Wei, D.H.; Dong, C.L.; Chen, C.L. Improved photocatalytic efficacy of TiO2 open nanotube arrays: A view by XAS. Appl. Surf. Sci. 2020, 527, 146844. [Google Scholar] [CrossRef]

- Chan, M.H.; Hsieh, M.R.; Liu, R.S.; Wei, D.H.; Hsiao, M. Magnetically Guided Theranostics: Optimizing Magnetic Resonance Imaging with Sandwich-Like Kaolinite-Based Iron/Platinum Nanoparticles for Magnetic Fluid Hyperthermia and Chemotherapy. Chem. Mater. 2020, 32, 697. [Google Scholar] [CrossRef]

- Wang, X.; Guo, J.; Zhang, Q.; Zhu, S.; Liu, L.; Jiang, X.; Wei, D.H.; Liu, R.S.; Li, L. Gelatin sponge functionalized with gold/silver clusters for antibacterial application. Nanotechnology 2020, 31, 134004. [Google Scholar] [CrossRef]

- Kumar, A.; Dixit, T.; Palani, I.A.; Nakamura, D.; Higashihata, M.; Singh, V. Utilization of surface plasmon resonance of Au/Pt nanoparticles for highly photosensitive ZnO nanorods network based plasmon field effect transistor. Physica E 2017, 93, 97–104. [Google Scholar] [CrossRef]

- Vukkum, V.B.; Christudasjustus, J.; Darwish, A.A.; Storck, S.M.; Gupta, R.K. Enhanced corrosion resistance of additively manufactured stainless steel by modification of feedstock. npj Mater. Degrad. 2022, 6, 2. [Google Scholar] [CrossRef]

- Xu, J.; Wang, J.; Lu, L.; Gao, M. Study on the infrared emissivity of nonstoichiometric titanium chromium nitride films. Thin Solid Films 2022, 754, 139303. [Google Scholar] [CrossRef]

- Zhou, Q.; Wang, L.; Xu, Q.; Zhao, Y. Effective cleanup of oil contamination on bio-inspired superhydrophobic surface. Environ. Sci. Pollut. Res. 2019, 26, 21321–21328. [Google Scholar] [CrossRef] [PubMed]

- Shi, J.F.; Tian, Y.; Li, W.R.; Zhao, Y.; Wu, Y.Z.; Jiang, Z.Y. Plant polyphenol-inspired nano-engineering topological and chemical structures of commercial sponge surface for oils/organic solvents clean-up and recovery. Chemosphere 2019, 218, 559–568. [Google Scholar] [CrossRef]

- Parsekian, A.W.; Jeong, T.J.; Harris, T.A.L. A process model for slot coating of narrow stripes. J. Coat. Technol. Res. 2019, 16, 1653–1661. [Google Scholar] [CrossRef]

- Wenzel, R.N. Resistance of solid surfaces to wetting by water. Ind. Eng. Chem. 1936, 28, 988–994. [Google Scholar] [CrossRef]

- Cassie, A.B.D.; Baxter, S. Wettability of porous surfaces. Trans. Farad. Soc. 1944, 40, 546–551. [Google Scholar] [CrossRef]

- Teng, Y.; Guo, Y.Y.; Zhang, M.; Yang, Y.J.; Huang, Z.; Zhou, Y.W.; Wu, F.Y.; Liang, Y.S. Effect of Cr/CrNx transition layer on mechanical properties of CrN coatings deposited on plasma nitrided austenitic stainless steel. Surf. Coat. Technol. 2019, 367, 100–107. [Google Scholar] [CrossRef]

- Gilewicz, A.; Murzynski, D.; Dobruchowska, E.; Kwiatkowski, J.; Olik, R.; Ratajski, J.; Warcholinski, B. Wear and corrosion behavior of CrCN/CrN coatings deposited by cathodic arc evaporation on nitrided 42CrMo4 steel substrates. Prot. Met. Phys. Chem. Surf. 2017, 53, 312–321. [Google Scholar] [CrossRef]

- Ruden, A.; Restrepo-Parra, E.; Paladines, A.U.; Sequeda, F. Corrosion resistance of CrN thin films produced by dc magnetron sputtering. Appl. Surf. Sci. 2013, 270, 150–156. [Google Scholar] [CrossRef]

- Zhang, M.; Kim, K.H.; Xu, F.F.; Yang, X.X. Structure and oxidation behavior of compositionally gradie nt CrNx coatings prepared using arc ion plating. Appl. Surf. Sci. 2013, 228, S529–S533. [Google Scholar]

- Greczynski, G.; Jensen, J.; Hultman, L. CrNx Films Prepared by DC Magnetron Sputtering and High-Power Pulsed Magnetron Sputtering: A Comparative Study. IEEE Trans. Plasma Sci. 2010, 38, 3046–3056. [Google Scholar] [CrossRef] [Green Version]

- Liu, C.; Bi, G.; Ziegale, H.; Leyland, A.; Matthews, A. Structure and corrosion properties of PVD Cr–N coatings. J. Vac. Sci. Technol. A 2002, 20, 772. [Google Scholar] [CrossRef]

- Wierzchon, T.; Ulbin-Pokorska, I.; Sikorski, K. Corrosion resistance of chromium nitride and oxynitride layers produced under glow discharge conditions. Surf. Coat. Technol. 2000, 130, 274–279. [Google Scholar] [CrossRef]

- Cunha, L.; Andritschky, M.; Pischow, K.; Wang, Z. Microstructure of CrN coatings produced by PVD techniques. Thin Solid Films 1999, 355-356, 465–471. [Google Scholar] [CrossRef]

- Chen, S.H.; Liu, L.; Wang, T.C. Investigation of the mechanical properties of thin films by nanoindentation, considering the effects of thickness and different coating-substrate combinations. Surf. Coat. Technol. 2005, 191, 25–32. [Google Scholar] [CrossRef]

- Novakovi´c, M.; Popovi´c, M.; Schmidt, E.; Mitri´c, M.; Bibic, N.; Rakocevic, Z.; Ronning, C. Clustering of gold particles in Au implanted CrN thin films: The effect on the SPR peak position. Appl. Surf. Sci. 2017, 426, 667–673. [Google Scholar] [CrossRef]

- Novaković, M.M.; Popović, M.; Schmidt, E.; Schöppe, P.; Mitrić, M.; Bibić, N.; Ronning, C.; Rakocevic, Z. Evolution of structural and optical properties of Ag implanted CrN thin films with annealing temperature. J. Alloys Compd. 2017, 729, 671–678. [Google Scholar] [CrossRef]

- Luciu, I.; Duday, D.; Choquet, P.; Perigo, E.A.; Michels, A.; Wirtz, T. Phase separation in NiCrN coatings induced by N2 addition in the gas phase: A way to generate magnetic thin films by reactive sputtering of a non-magnetic NiCr target. Appl. Surf. Sci. 2016, 389, 578–584. [Google Scholar] [CrossRef]

- Petrov, I.; Barna, P.B.; Hultman, L.; Greene, J.E. Microstructural evolution during film growth. J. Vac. Sci. Technol. A 2003, 21, S117. [Google Scholar] [CrossRef]

- Zou, C.W.; Wang, H.J.; Li, M.; Liu, C.S.; Guo, L.P.; Fu, D.J. Characterization and properties of CrN films deposited by ion-source-enhanced middle frequency magnetron sputtering. Vacuum 2009, 83, 1086–1090. [Google Scholar] [CrossRef]

- Li, J.; Ren, G.K.; Chen, J.; Chen, X.; Wu, W.; Liu, Y.; Chen, X.; Song, J.; Lin, Y.H.; Shi, Y. Facilitating Complex Thin Film Deposition by Using Magnetron Sputtering: A Review. JOM 2022, 74, 3069–3081. [Google Scholar] [CrossRef]

- Paulitsch, J.; Schenkel, M.; Zufraß, T.; Mayrhofer, P.H.; Münz, W.D. Structure and properties of high power impulse magnetron sputtering and DC magnetron sputtering CrN and TiN films deposited in an industrial scale unit. Thin Solid Films 2010, 518, 5558–5564. [Google Scholar] [CrossRef]

- Lee, J.W.; Tien, S.K.; Kuo, Y.C.; Chen, C.M. The mechanical properties evaluation of the CrN coatings deposited by the pulsed DC reactive magnetron sputtering. Surf. Coat. Technol. 2006, 200, 3330–3335. [Google Scholar] [CrossRef]

- Barshilia, H.C.; Selvakumar, N.; Deepthi, B.; Rajam, K.S. A comparative study of reactive direct current magnetron sputtered CrAlN and CrN coatings. Surf. Coat. Technol. 2006, 201, 2193–2201. [Google Scholar] [CrossRef]

- Hall, E.O. The Deformation and Ageing of Mild Steel: III Discussion of Results. Proc. Phys. Soc. Lond. B 1951, 64, 747. [Google Scholar] [CrossRef]

- Petch, N.J. The Cleavage Strength of Polycrystals. J. Iron Steel Inst. 1653, 174, 25–28. [Google Scholar]

- Hansen, N. Hall–Petch relation and boundary strengthening. Scr. Mater. 2004, 51, 801–806. [Google Scholar] [CrossRef]

- Liu, L.; Ruan, Q.; Wu, Z.; Li, T.; Zuo, W.; Huang, C.; Wu, Y.; Wu, Z.; Fu, K.Y.; Chu, P.K. Hard and tough CrN coatings strengthened by high-density distorted coherent grain boundaries. J. Alloys Compd. 2022, 894, 162139. [Google Scholar] [CrossRef]

- Liu, L.; Ruan, Q.; Xiao, S.; Meng, X.; Huang, C.; Wu, Y.; Fu, R.K.Y.; Chu, P.K. Fabrication and hydrogen permeation resistance of dense CrN coatings. Surf. Coat. Technol. 2022, 437, 128326. [Google Scholar] [CrossRef]

- Alam, K.; Haider, M.B.; Al-Kuhaili, M.F.; Ziq, K.A.; Haq, B.U. Electronic phase transition in CrN thin films grown by reactive RF magnetron sputtering. Ceram. Int. 2022, 48, 17352–17358. [Google Scholar] [CrossRef]

- Tong, S.K.; Chang, J.H.; Hao, Y.H.; Wu, M.R.; Wei, D.H.; Chueh, Y.L. Optimum resistive switching characteristics of NiFe2O4 by controlling film thickness. Appl. Surf. Sci. 2021, 564, 150091. [Google Scholar] [CrossRef]

- Tong, S.K.; Chi, P.W.; Kung, S.H.; Wei, D.H. Tuning bandgap and surface wettability of NiFe2O4 driven by phase transition. Sci Rep. 2018, 8, 1338. [Google Scholar] [CrossRef] [Green Version]

- Chi, P.W.; Su, C.W.; Wei, D.H. Internal stress induced natural self-chemisorption of ZnO nanostructured films. Sci Rep. 2017, 7, 43281. [Google Scholar] [CrossRef] [Green Version]

- Chi, P.W.; Su, C.W.; Wei, D.H. Control of hydrophobic surface and wetting states in ultra-flat ZnO films by GLAD method. Appl. Surf. Sci. 2017, 404, 380–387. [Google Scholar] [CrossRef]

- Chao, C.H.; Chi, P.W.; Wei, D.H. Investigations on the Crystallographic Orientation Induced Surface Morphology Evolution of ZnO Thin Films and Their Wettability and Conductivity. J. Phys. Chem. C 2016, 120, 8210–8219. [Google Scholar] [CrossRef]

- Fowkes, F.M. Contact Angle, Wettability, and Adhesion. Adv. Chem. 1964, 43, 99–111. [Google Scholar]

- Fowkes, F.M. Attractive forces at interfaces. Ind. Eng. Chem. 1964, 56, 40–52. [Google Scholar] [CrossRef]

- Fowkes, F.M. Additivity of intermolecular forces at interfaces. I. Determination of the contribution to surface and interfacial tensions of dispersion forces in various liquids. J. Phys. Chem. 1963, 67, 2538–2541. [Google Scholar] [CrossRef]

- Fowkes, F.M. Ideal two-dimensional solutions. Iii. Penetration of hydrocarbons in monolayers. J. Phys. Chem. 1962, 66, 1863–1866. [Google Scholar] [CrossRef]

- Good, R.J. Theory for the Estimation of Surface and Interfacial Energies VI. Surface Energies of Some Flurocarbon Surfaces from Contact Angle Measurements. Adv. Chem. 1964, 43, 74–87. [Google Scholar]

- Good, R.J.; Girifalco, L.A. A theory for estimation of surface and interfacial energies. Iii. Estimation of surface energies of solids from contact angle data. J. Phys. Chem. 1960, 64, 561–565. [Google Scholar] [CrossRef]

- Young, T. An essay on the cohesion of fluids. Philos. Trans. R. Soc. Lond. 1805, 95, 65. [Google Scholar]

- Giannini, V.; Fernnández-Domínguez, A.I.; Heck, S.C.; Maier, S.A. Plasmonic Nanoantennas: Fundamentals and Their Use in Controlling the Radiative Properties of Nanoemitters. Chem. Rev. 2011, 111, 3888–3912. [Google Scholar] [CrossRef]

- Campion, A.; Kambhampati, P. Surface-Enhanced Raman Scattering. Chem. Soc. Rev. 1998, 27, 241–250. [Google Scholar] [CrossRef]

- Chen, C.J.; Chen, M.G.; Chen, C.K.; Wu, P.C.; Chen, P.T.; Basu, M.; Hu, S.F.; Tsai, D.P.; Liu, R.S. Ag-Si Artificial Microflowers for Plasmon-enhanced Solar Water Splitting. Chem. Commun. 2015, 51, 549–552. [Google Scholar] [CrossRef] [PubMed]

- Hong, D.Y.; Kim, S.K.; Kown, Y.U. Synergistic Effects Between Gold Nanoparticles and Nanostructured Platinum Film in Surface-Enhanced Raman Spectroscopy. J. Phys. Chem. C 2015, 119, 22611–22617. [Google Scholar] [CrossRef]

- Tan, C.L.; Jang, S.J.; Lee, Y.T. Localized Surface Plasmon Resonance with Broadband Ultralow Reflectivity from Metal Nanoparticles on Glass and Silicon Subwavelength Structures. Opt. Express 2012, 20, 17448. [Google Scholar] [CrossRef]

- Kim, S.Y.; Yang, H.I.; Choi, W. Moreover, the interface trap density between MoS2 and ALD Al2O3 is expected to increase after Al2O3 encapsulation. Appl. Phys. Lett. 2018, 113, 133104. [Google Scholar] [CrossRef]

- Ebbesen, T.W.; Lezec, H.J.; Ghasemi, H.F.; Thio, T.; Wolff, P.A. Extraordinary Optical Transmission Through Sub-Wavelength Hole Arrays. Nature 1998, 391, 667–669. [Google Scholar] [CrossRef]

- Trang, N.; Thuy, T.T.; Higashimine, K.; Mott, D.M.; Maenosono, S. Magnetic-Plasmonic FePt@Ag Core-Shell Nanoparticles and Their Magnetic and SERS Properties. Plasmonic 2013, 8, 1177–1184. [Google Scholar] [CrossRef]

- Wei, B.; Liang, H.; Zhang, D.; Wu, Z.; Qi, Z.; Wang, Z. CrN thin films prepared by reactive DC magnetron sputtering for symmetric supercapacitors. J. Mater. Chem. A 2017, 5, 2844–2851. [Google Scholar] [CrossRef]

- Haye, E.; Achour, A.; Guerra, A.; Moulaï, F.; Hadjersi, T.; Boukherroub, R.; Panepinto, A.; Brousse, T.; Pireaux, J.J.; Lucas, S. Achieving on chip micro-supercapacitors based on CrN deposited by bipolar magnetron sputtering at glancing angle. Electrochim. Acta 2019, 324, 134890. [Google Scholar] [CrossRef]

- Ananthoju, B.; Biroju, R.K.; Theis, W.; Dryfe, R.A.W. Controlled Electrodeposition of Gold on Graphene: Maximization of the Defect-Enhanced Raman Scattering Response. Small 2019, 15, 1901555. [Google Scholar] [CrossRef]

- Gao, Z.; Wan, Z.; Wu, Z.; Huang, X.; Li, H.; Zhang, T.F.; Mayrhofer, P.H.; Wang, Q. Synthesis and electrochemical properties of nanoporous CrN thin film electrodes for supercapacitor applications. Mater. Des. 2021, 209, 109949. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wei, D.-H.; Tong, S.-K.; Chen, S.-C.; Hao, Y.-H.; Wu, M.-R.; Yang, C.-J.; Huang, R.-T.; Chung, R.-J. Tuning Surface Plasmonic Resonance and Surface Wettability of Au/CrN Films Using Nitrogen-Containing Gas. Nanomaterials 2022, 12, 2575. https://doi.org/10.3390/nano12152575

Wei D-H, Tong S-K, Chen S-C, Hao Y-H, Wu M-R, Yang C-J, Huang R-T, Chung R-J. Tuning Surface Plasmonic Resonance and Surface Wettability of Au/CrN Films Using Nitrogen-Containing Gas. Nanomaterials. 2022; 12(15):2575. https://doi.org/10.3390/nano12152575

Chicago/Turabian StyleWei, Da-Hua, Sheng-Kai Tong, Sheng-Chiang Chen, Yong-Han Hao, Ming-Ru Wu, Cheng-Jie Yang, Rong-Tan Huang, and Ren-Jei Chung. 2022. "Tuning Surface Plasmonic Resonance and Surface Wettability of Au/CrN Films Using Nitrogen-Containing Gas" Nanomaterials 12, no. 15: 2575. https://doi.org/10.3390/nano12152575

APA StyleWei, D.-H., Tong, S.-K., Chen, S.-C., Hao, Y.-H., Wu, M.-R., Yang, C.-J., Huang, R.-T., & Chung, R.-J. (2022). Tuning Surface Plasmonic Resonance and Surface Wettability of Au/CrN Films Using Nitrogen-Containing Gas. Nanomaterials, 12(15), 2575. https://doi.org/10.3390/nano12152575