Single Step Laser-Induced Deposition of Plasmonic Au, Ag, Pt Mono-, Bi- and Tri-Metallic Nanoparticles

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials and Reagents

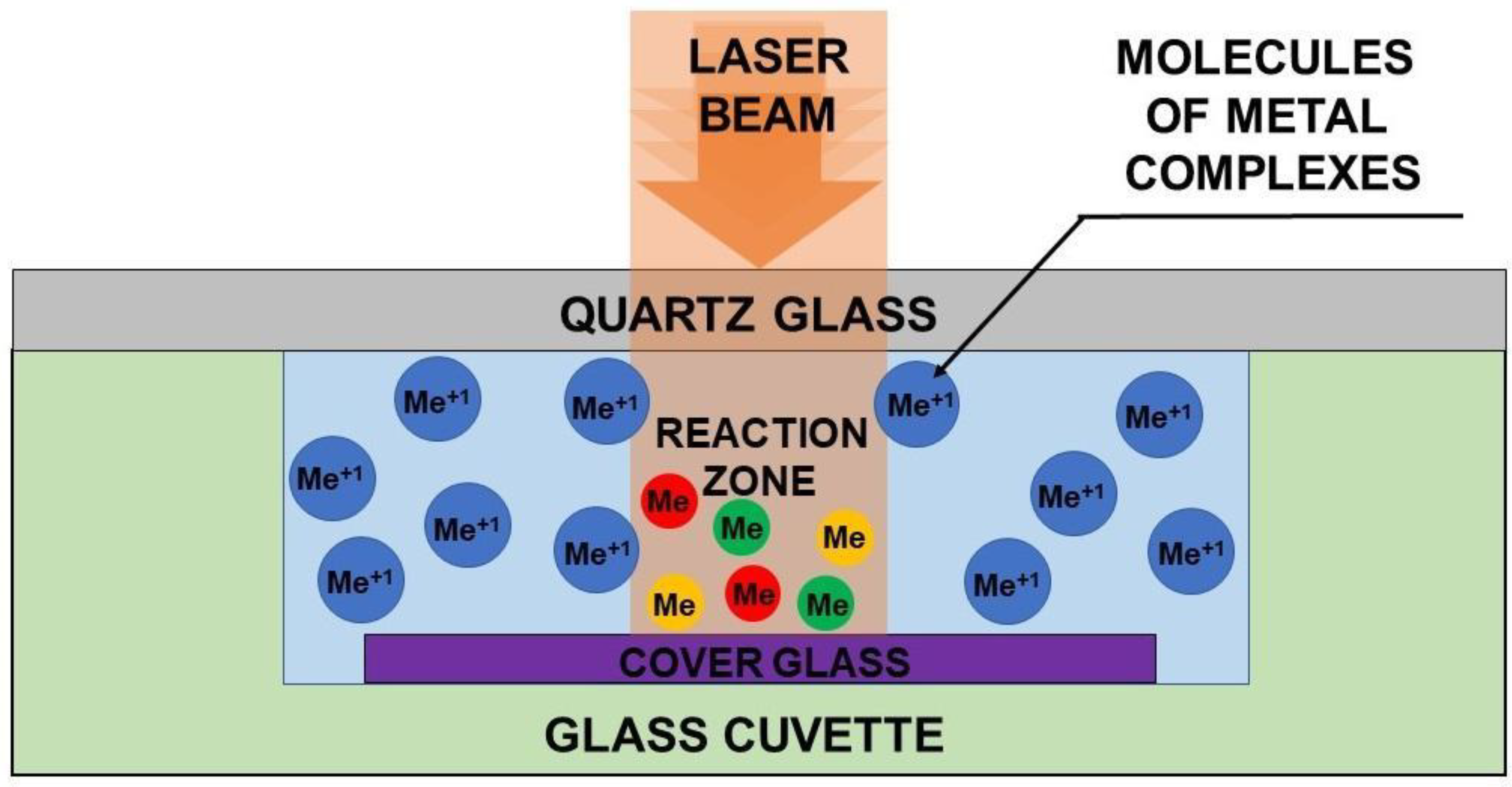

2.2. Laser-Induced Deposition

2.3. Characterization

3. Results and Discussion

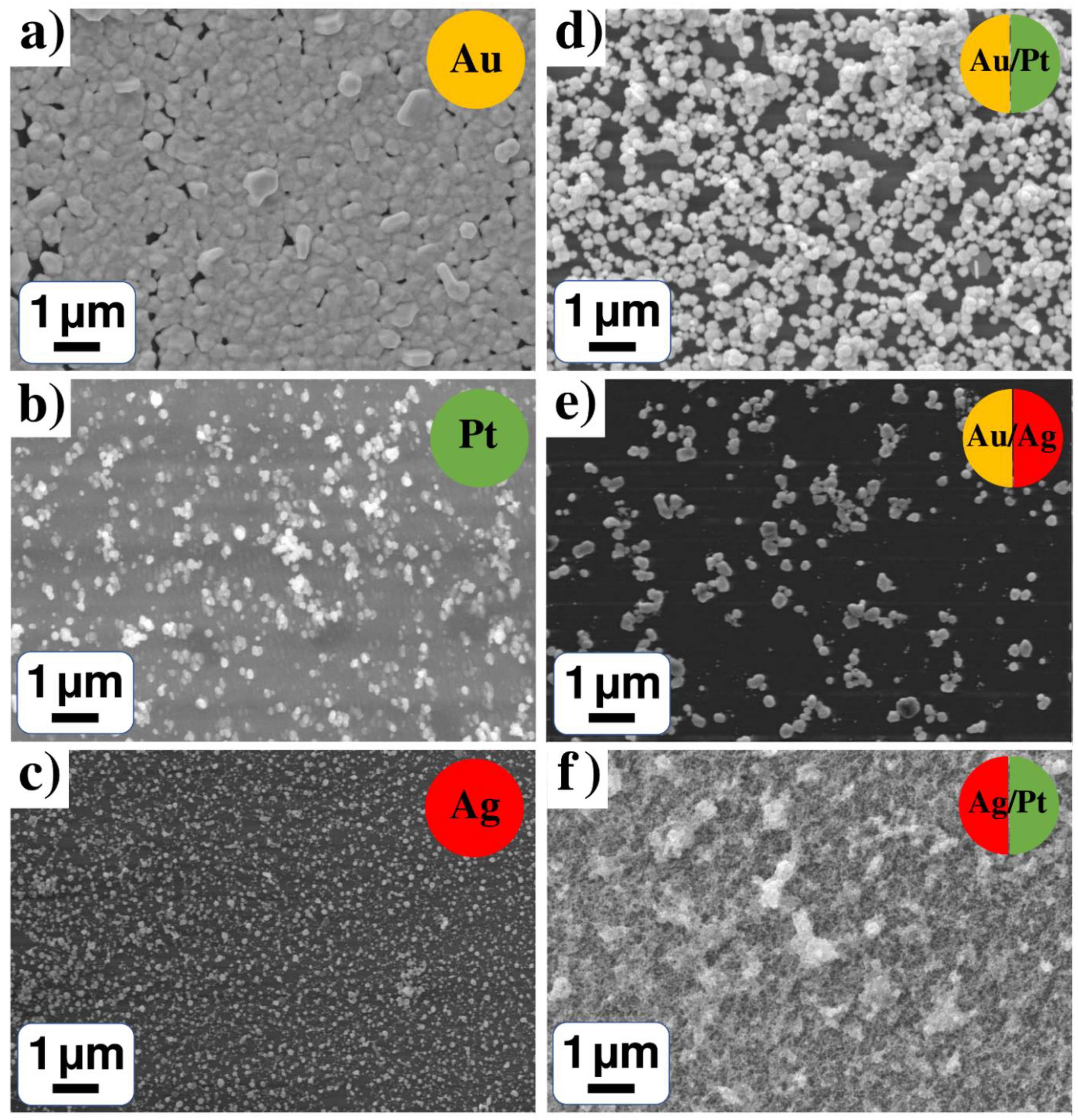

3.1. SEM Results of Mono- and Bi-Metallic Systems

3.2. TEM and EDX Results of Bimetallic Particles Systems

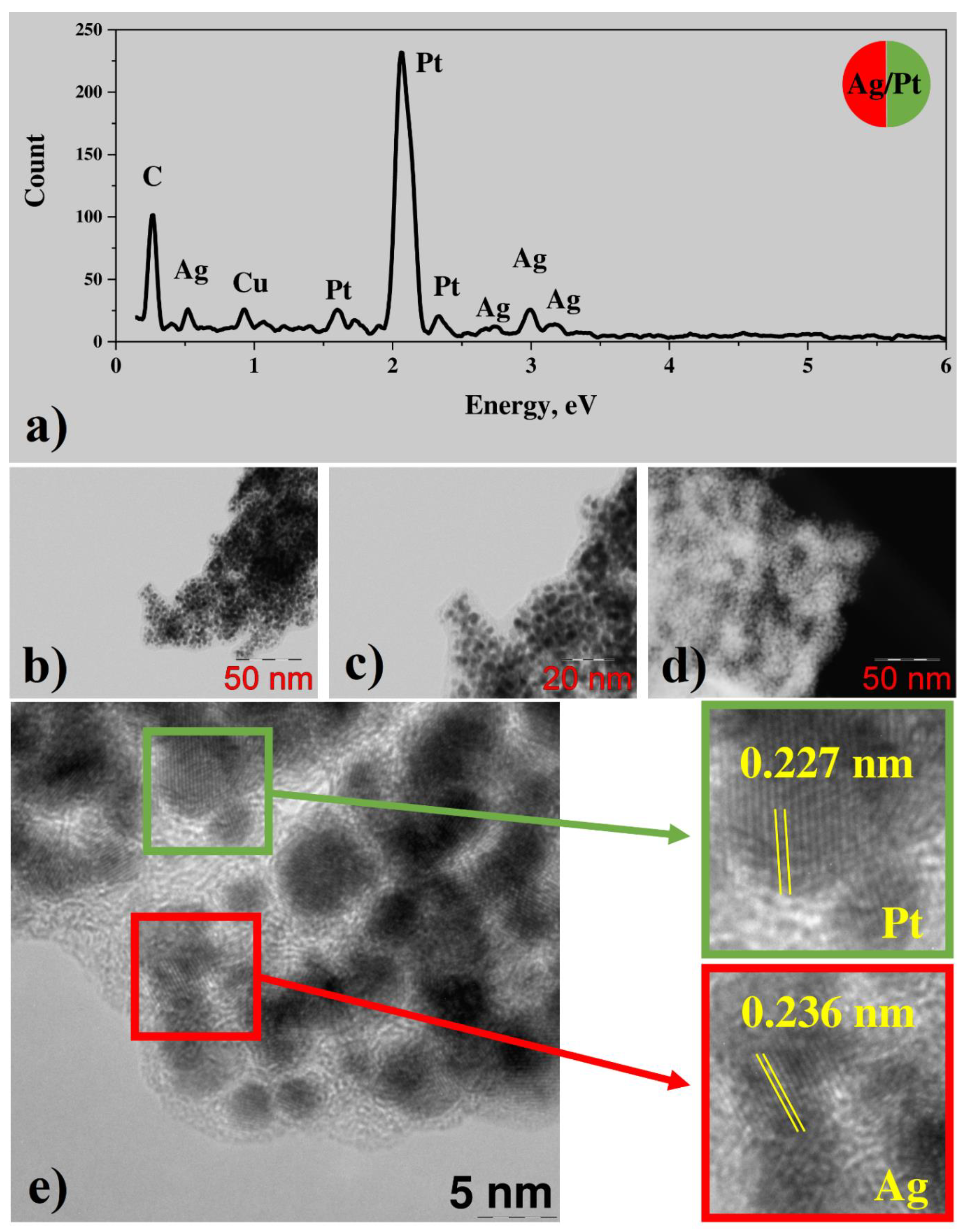

3.2.1. Bimetallic (Ag-Pt) System from Water Solutions

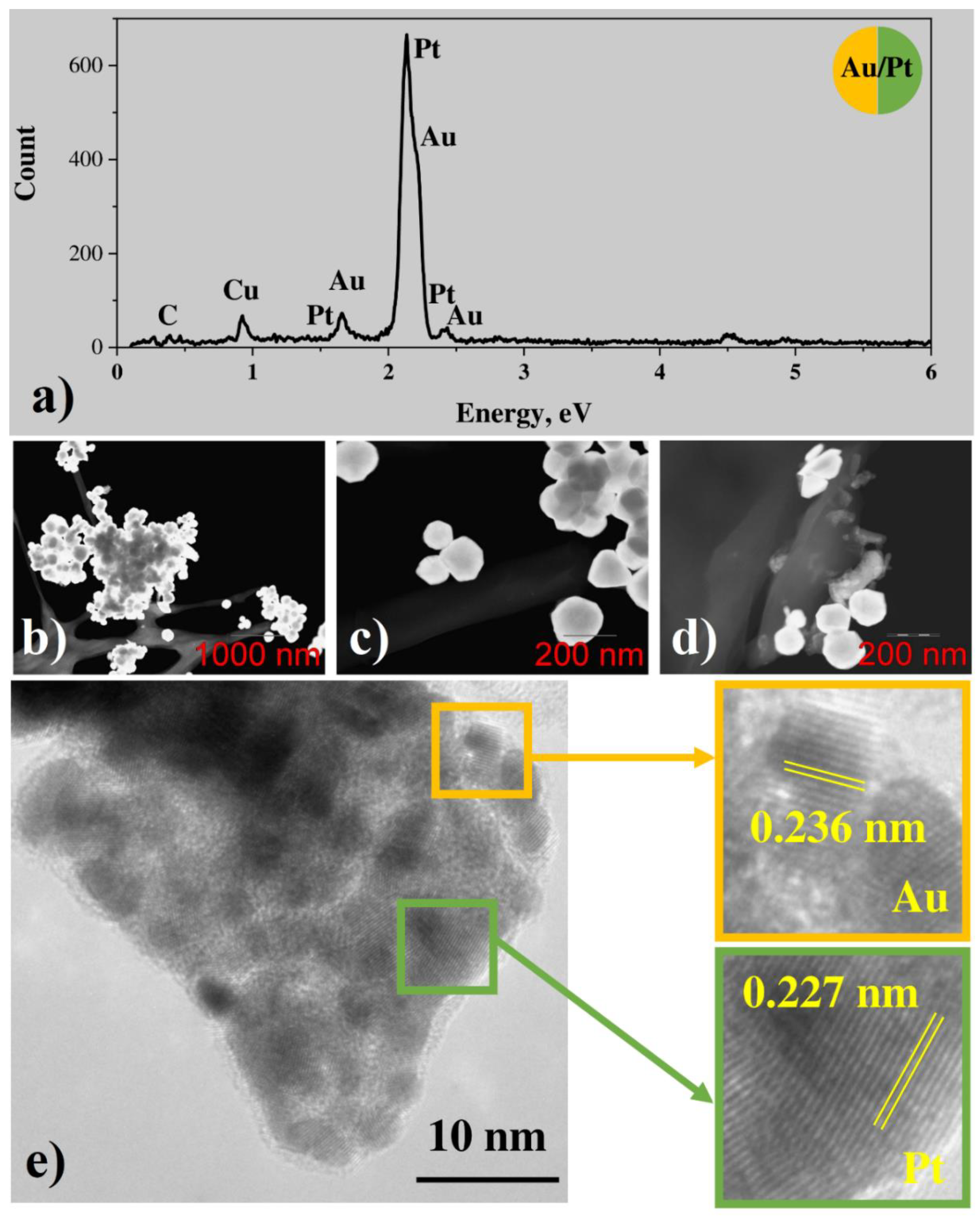

3.2.2. Bimetallic (Au-Pt) System from Water Solutions

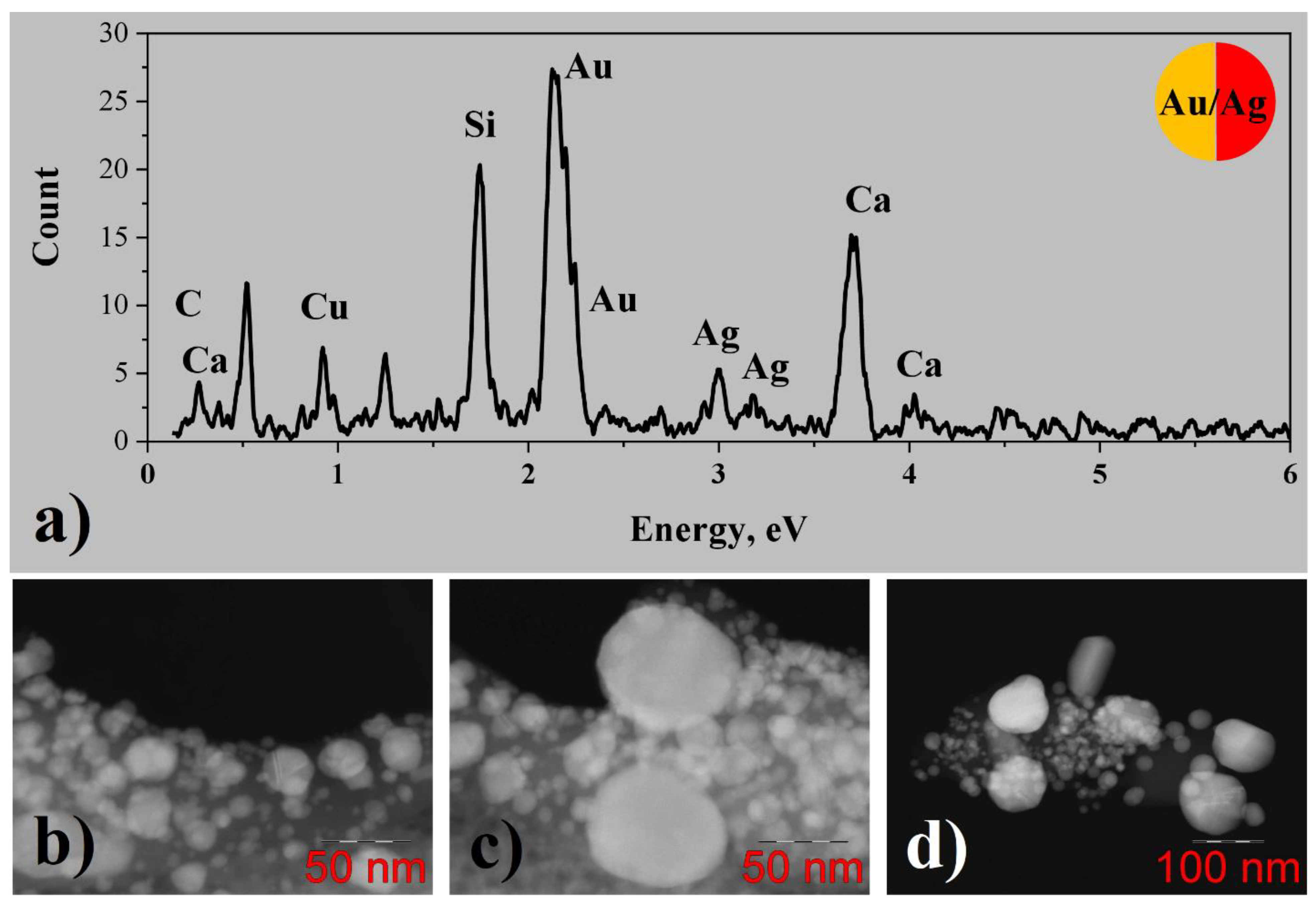

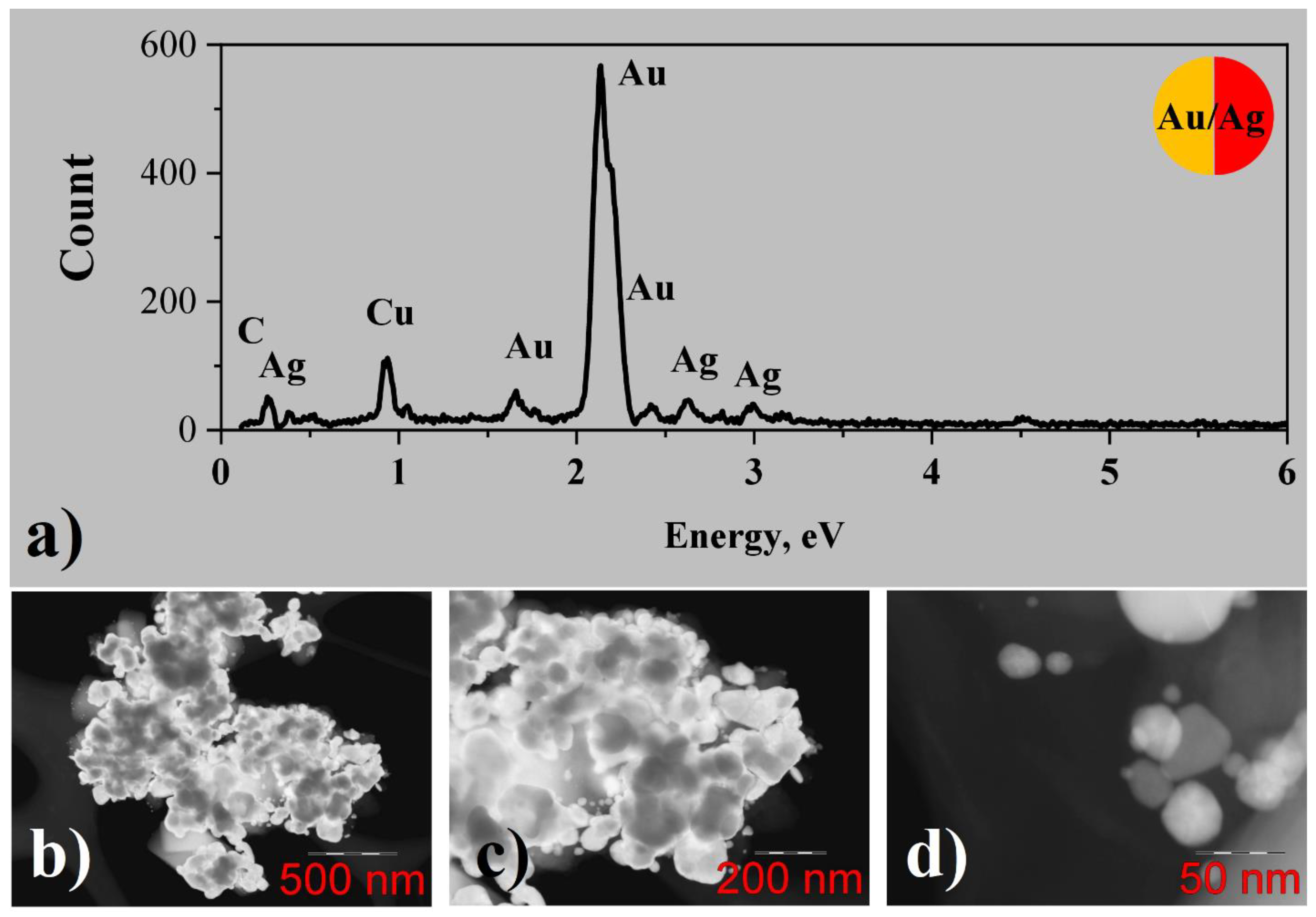

3.2.3. Bimetallic (Au-Ag) System from Water Solutions

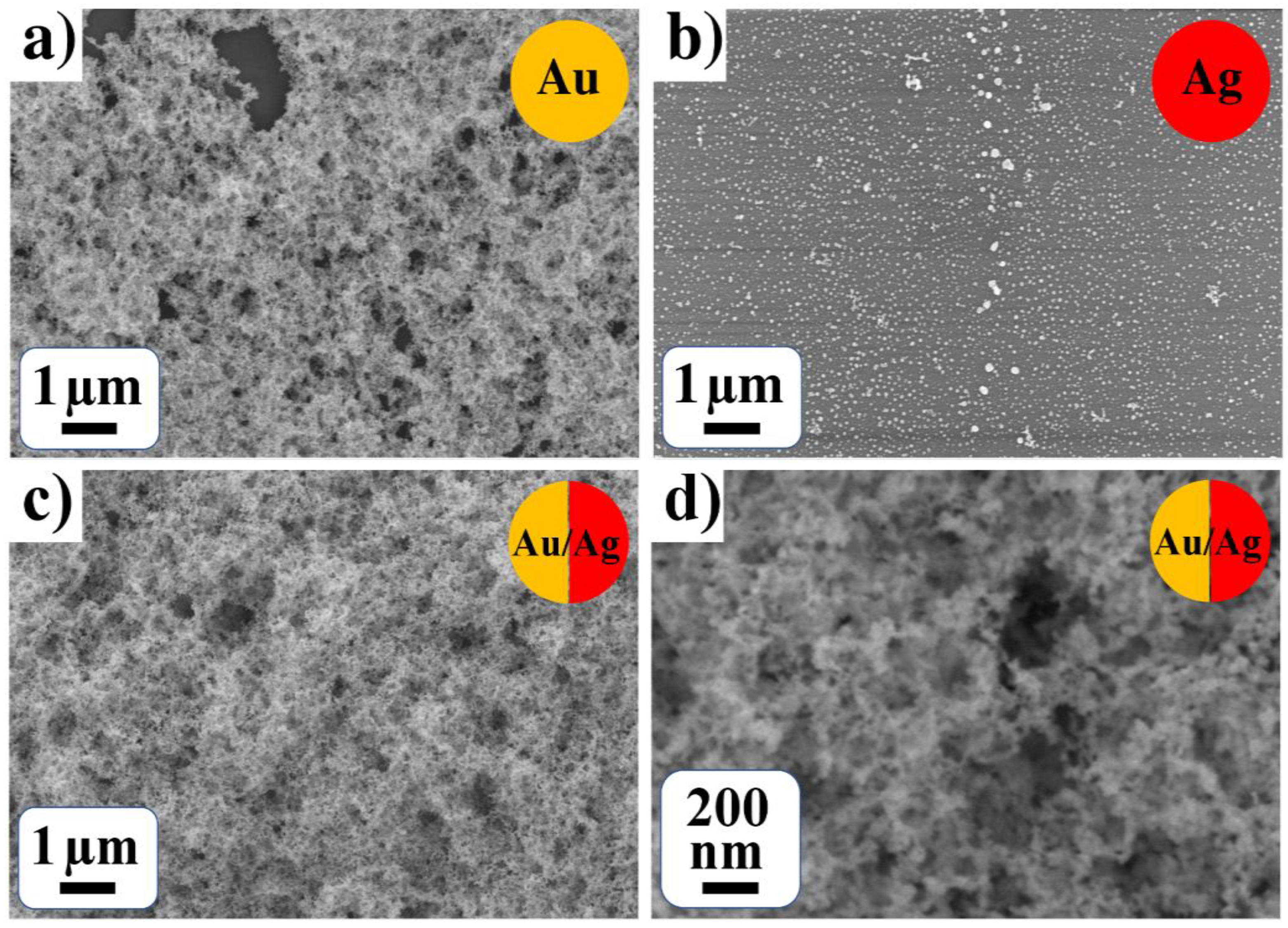

3.2.4. Bimetallic (Au-Ag) System from Methanol Solutions

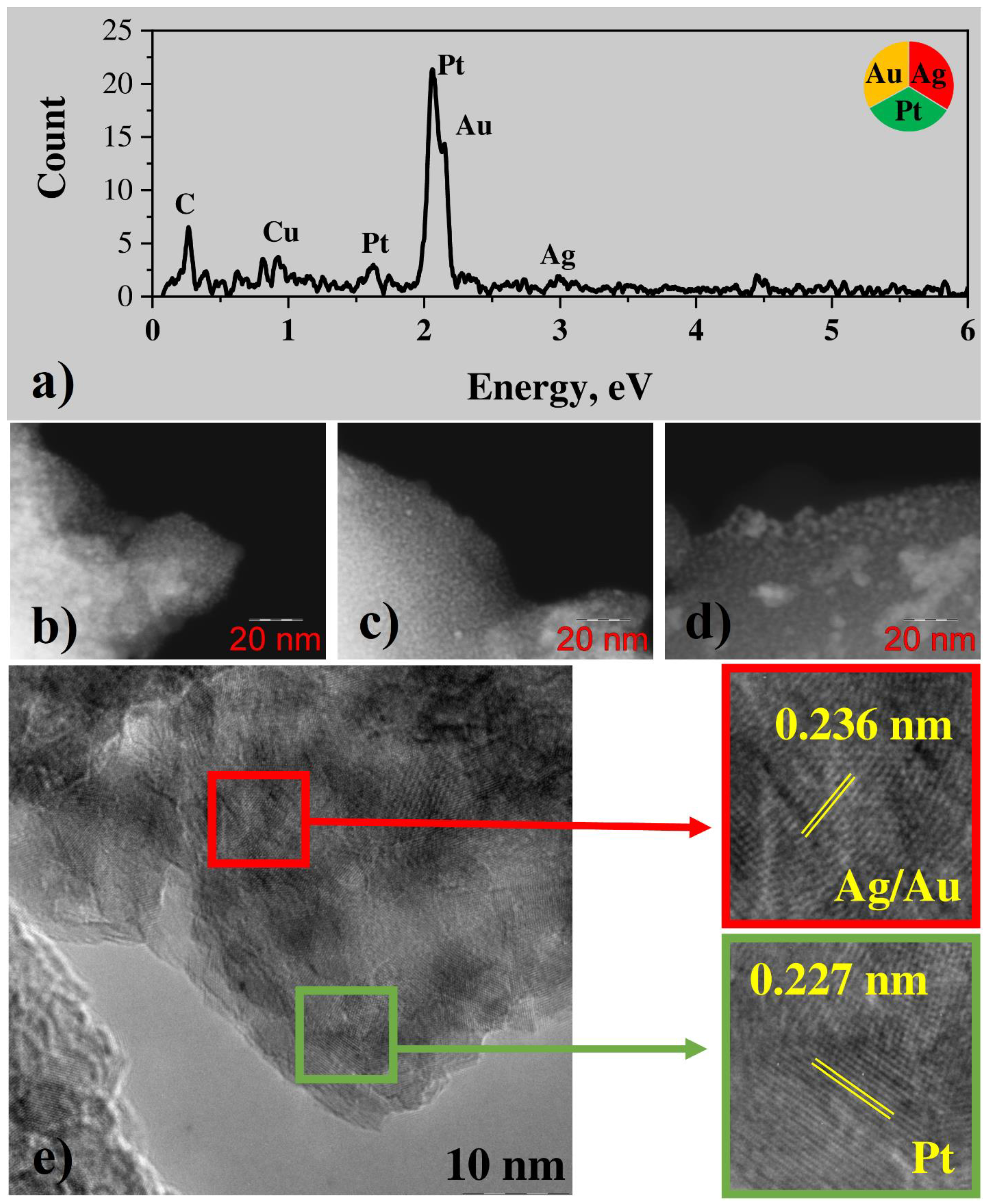

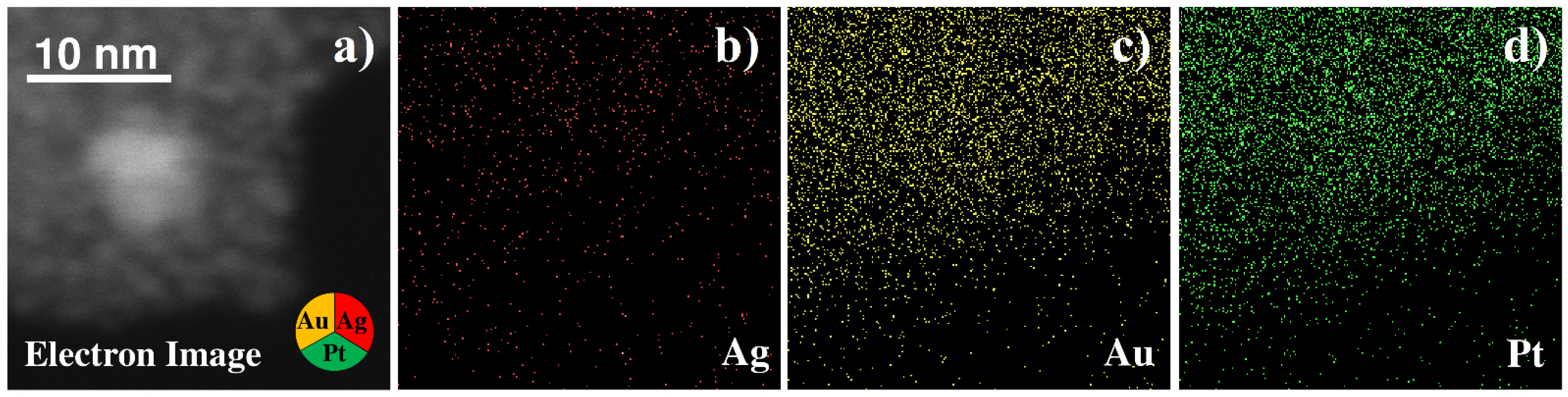

3.3. SEM, TEM and EDX Results of Trimetallic Particles Systems

3.4. XPS Results

3.4.1. Bimetallic (Ag-Pt) System from Water Solutions

3.4.2. Bimetallic (Au-Pt) System from Water Solutions

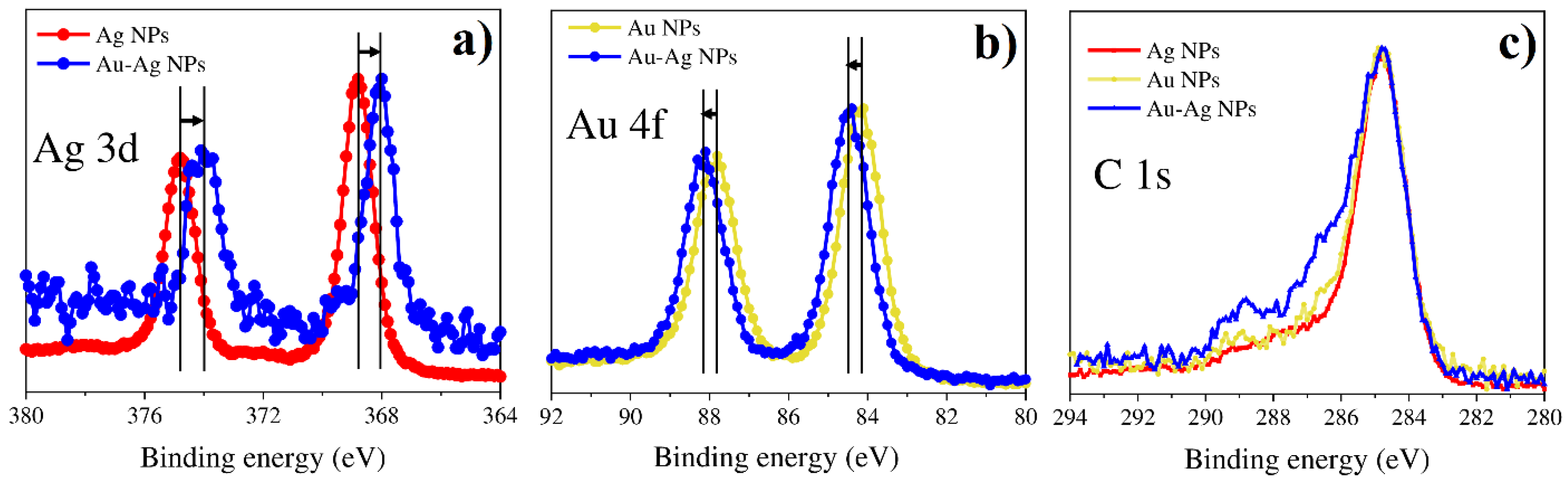

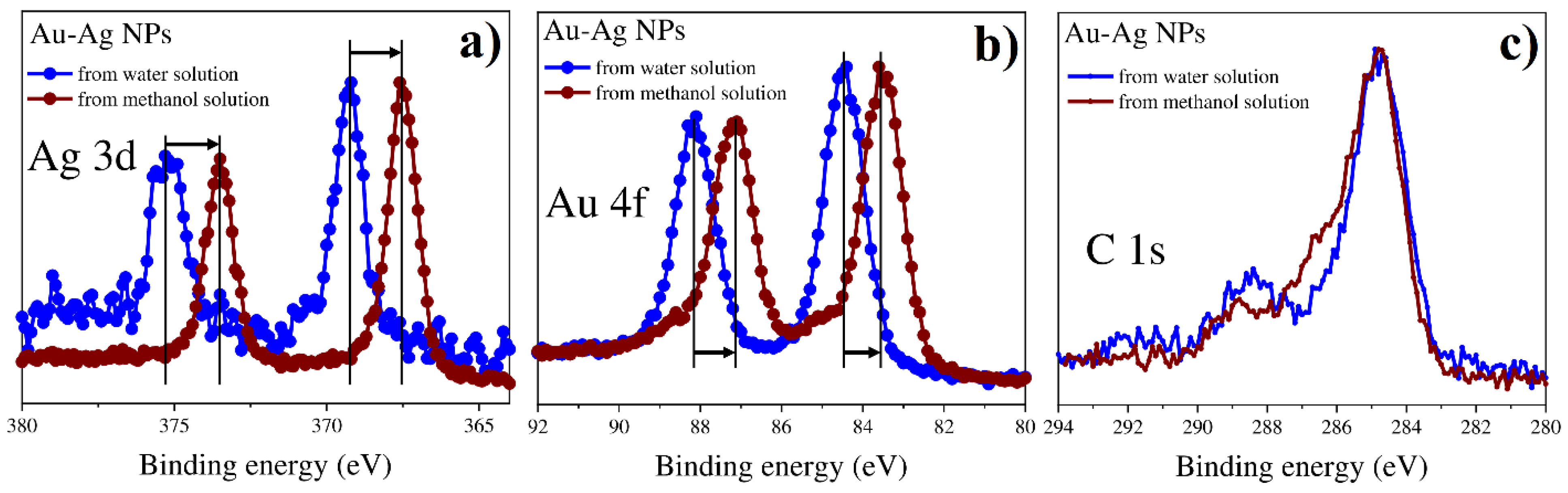

3.4.3. Bimetallic (Au-Ag) Systems from Water and Methanol Solutions

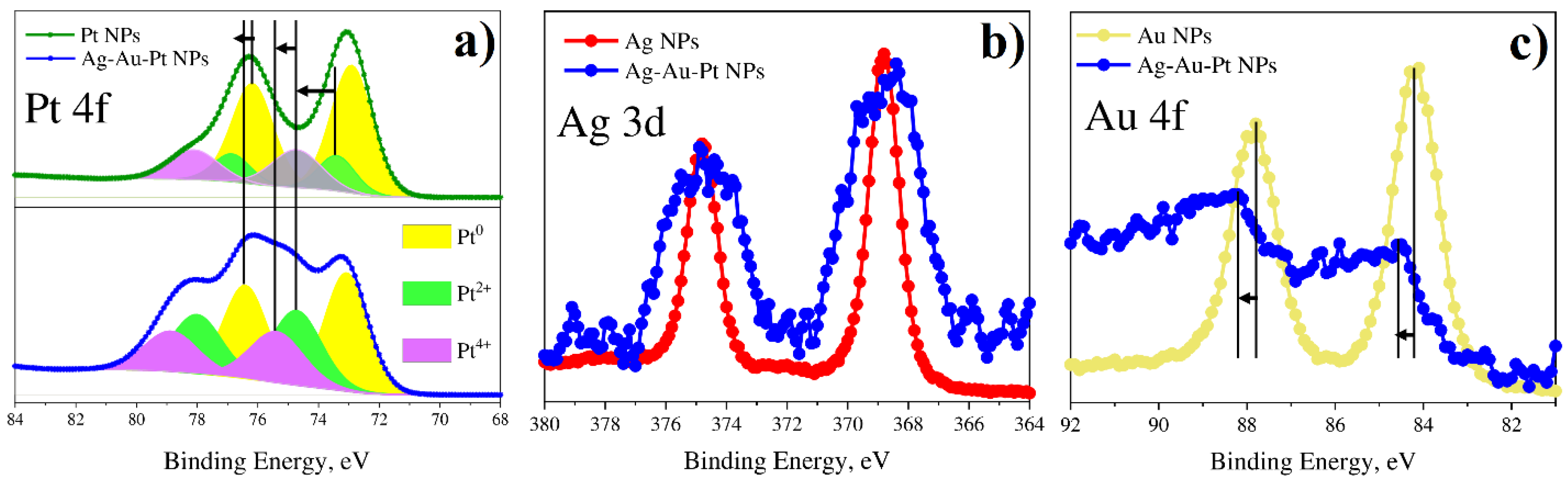

3.4.4. Trimetallic (Au-Ag-Pt) System from Water Solutions

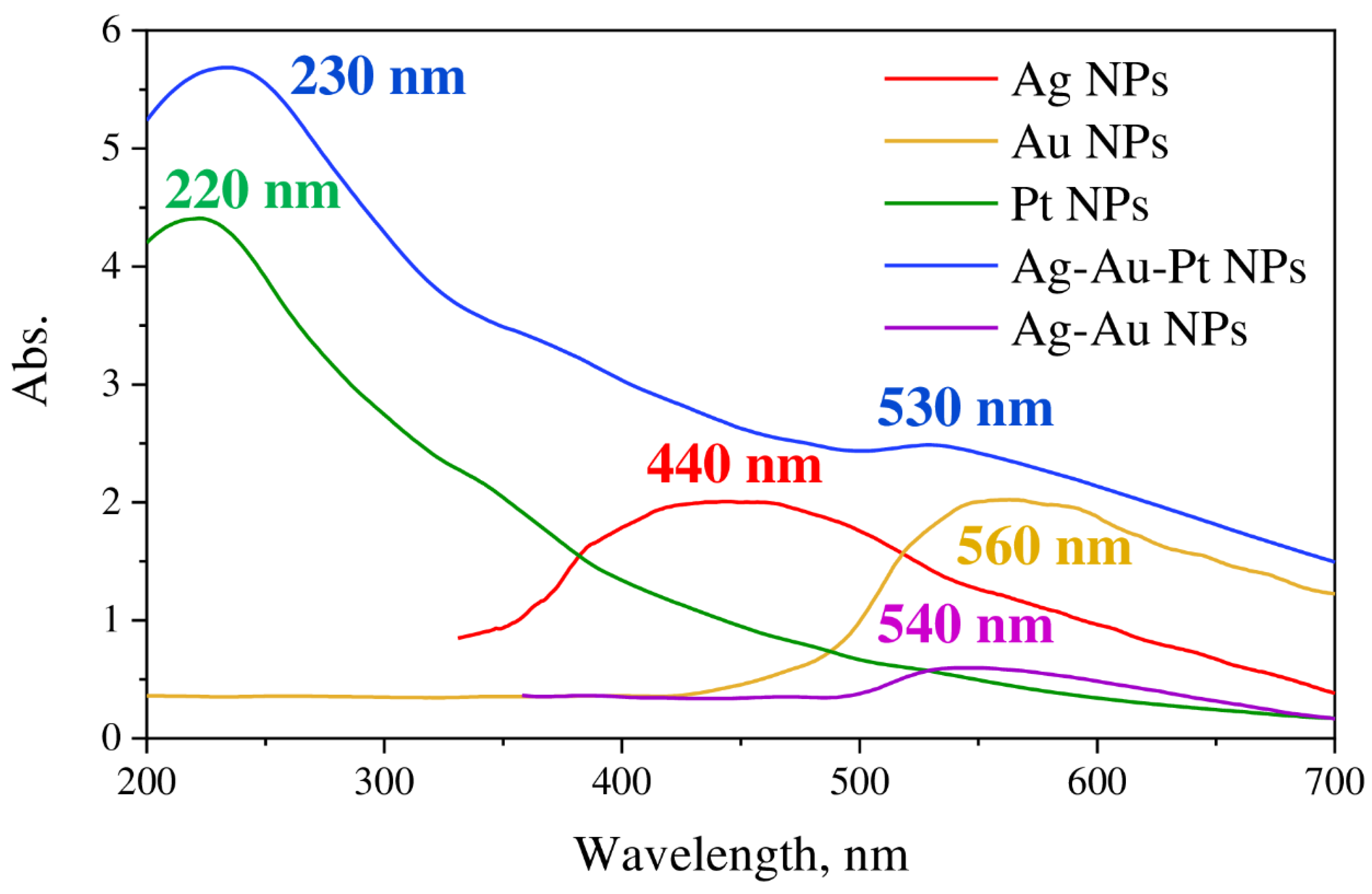

3.5. Absorption Spectra of Particles Systems

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Lee, S.; Sim, K.; Moon, S.Y.; Choi, J.; Jeon, Y.; Nam, J.; Park, S. Controlled Assembly of Plasmonic Nanoparticles: From Static to Dynamic Nanostructures. Adv. Mater. 2021, 33, 2007668. [Google Scholar] [CrossRef] [PubMed]

- Bharti, A.; Chae, K.H.; Goyal, N. Real-Time Synthesis and Detection of Plasmonic Metal (Au, Ag) Nanoparticles under Monochromatic X-Ray Nano-Tomography. Sci. Rep. 2020, 10, 20877. [Google Scholar] [CrossRef]

- Hoener, B.S.; Kirchner, S.R.; Heiderscheit, T.S.; Collins, S.S.E.; Chang, W.-S.; Link, S.; Landes, C.F. Plasmonic Sensing and Control of Single-Nanoparticle Electrochemistry. Chem 2018, 4, 1560–1585. [Google Scholar] [CrossRef] [Green Version]

- Subramanian, P.; Meziane, D.; Wojcieszak, R.; Dumeignil, F.; Boukherroub, R.; Szunerits, S. Plasmon-Induced Electrocatalysis with Multi-Component Nanostructures. Materials 2018, 12, 43. [Google Scholar] [CrossRef] [Green Version]

- Mostafa, A.M.; Menazea, A.A. Laser-Assisted for Preparation ZnO/CdO Thin Film Prepared by Pulsed Laser Deposition for Catalytic Degradation. Radiat. Phys. Chem. 2020, 176, 109020. [Google Scholar] [CrossRef]

- Ahn, S.; Jung, S.; Lee, S. Gold Nanoparticle Contrast Agents in Advanced X-Ray Imaging Technologies. Molecules 2013, 18, 5858–5890. [Google Scholar] [CrossRef] [Green Version]

- Jeong, Y.; Kook, Y.-M.; Lee, K.; Koh, W.-G. Metal Enhanced Fluorescence (MEF) for Biosensors: General Approaches and a Review of Recent Developments. Biosens. Bioelectron. 2018, 111, 102–116. [Google Scholar] [CrossRef]

- Pilot, B.; Signorini, R.; Durante, C.; Orian, L.; Bhamidipati, M.; Fabris, L. A Review on Surface-Enhanced Raman Scattering. Biosensors 2019, 9, 57. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Lee, W.; Kang, B.-H.; Yang, H.; Park, M.; Kwak, J.H.; Chung, T.; Jeong, Y.; Kim, B.K.; Jeong, K.-H. Spread Spectrum SERS Allows Label-Free Detection of Attomolar Neurotransmitters. Nat. Commun. 2021, 12, 159. [Google Scholar] [CrossRef]

- Zong, C.; Premasiri, R.; Lin, H.; Huang, Y.; Zhang, C.; Yang, C.; Ren, B.; Ziegler, L.D.; Cheng, J.-X. Plasmon-Enhanced Stimulated Raman Scattering Microscopy with Single-Molecule Detection Sensitivity. Nat. Commun. 2019, 10, 5318. [Google Scholar] [CrossRef] [Green Version]

- Cheng, Z.-Q.; Li, Z.-W.; Yao, R.; Xiong, K.-W.; Cheng, G.-L.; Zhou, Y.-H.; Luo, X.; Liu, Z.-M. Improved SERS Performance and Catalytic Activity of Dendritic Au/Ag Bimetallic Nanostructures Based on Ag Dendrites. Nanoscale Res. Lett. 2020, 15, 117. [Google Scholar] [CrossRef]

- Navas, M.P.; Soni, R.K. Laser-Generated Bimetallic Ag-Au and Ag-Cu Core-Shell Nanoparticles for Refractive Index Sensing. Plasmonics 2015, 10, 681–690. [Google Scholar] [CrossRef]

- Kucherik, A.; Arakelian, S.; Vartanyan, T.; Kutrovskaya, S.; Osipov, A.; Povolotskaya, A.; Povolotskii, A.; Man’shina, A. Laser-Induced Synthesis of Metal–Carbon Materials for Implementing Surface-Enhanced Raman Scattering. Opt. Spectrosc. 2016, 121, 263–270. [Google Scholar] [CrossRef]

- Zhang, J.; Kolhatkar, G.; Ruediger, A. Localized Surface Plasmon Resonance Shift and Its Application in Scanning Near-Field Optical Microscopy. J. Mater. Chem. C 2021, 9, 6960–6969. [Google Scholar] [CrossRef]

- Zhong, C.-J.; Luo, J.; Njoki, P.N.; Mott, D.; Wanjala, B.; Loukrakpam, R.; Lim, S.; Wang, L.; Fang, B.; Xu, Z. Fuel Cell Technology: Nano-Engineered Multimetallic Catalysts. Energy Environ. Sci. 2008, 1, 454. [Google Scholar] [CrossRef]

- Nguyen, M.T.; Yonezawa, T. Sputtering onto a Liquid: Interesting Physical Preparation Method for Multi-Metallic Nanoparticles. Sci. Technol. Adv. Mater. 2018, 19, 883–898. [Google Scholar] [CrossRef] [Green Version]

- Wu, Z.-P.; Shan, S.; Zang, S.-Q.; Zhong, C.-J. Dynamic Core–Shell and Alloy Structures of Multimetallic Nanomaterials and Their Catalytic Synergies. Acc. Chem. Res. 2020, 53, 2913–2924. [Google Scholar] [CrossRef]

- Yang, T.-H.; Ahn, J.; Shi, S.; Wang, P.; Gao, R.; Qin, D. Noble-Metal Nanoframes and Their Catalytic Applications. Chem. Rev. 2021, 121, 796–833. [Google Scholar] [CrossRef] [PubMed]

- Basavegowda, N.; Baek, K.-H. Multimetallic Nanoparticles as Alternative Antimicrobial Agents: Challenges and Perspectives. Molecules 2021, 26, 912. [Google Scholar] [CrossRef]

- Tang, Z.; Jung, E.; Jang, Y.; Bhang, S.H.; Kim, J.; Kim, W.-S.; Yu, T. Facile Aqueous-Phase Synthesis of Bimetallic (AgPt, AgPd, and CuPt) and Trimetallic (AgCuPt) Nanoparticles. Materials 2020, 13, 254. [Google Scholar] [CrossRef] [Green Version]

- Thongthai, K.; Pakawanit, P.; Chanlek, N.; Kim, J.-H.; Ananta, S.; Srisombat, L. Ag/Au/Pt Trimetallic Nanoparticles with Defects: Preparation, Characterization, and Electrocatalytic Activity in Methanol Oxidation. Nanotechnology 2017, 28, 375602. [Google Scholar] [CrossRef] [PubMed]

- Khanal, S.; Bhattarai, N.; McMaster, D.; Bahena, D.; Velazquez-Salazar, J.J.; Jose-Yacaman, M. Highly Monodisperse Multiple Twinned AuCu–Pt Trimetallic Nanoparticles with High Index Surfaces. Phys. Chem. Chem. Phys. 2014, 16, 16278–16283. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Yadav, N.; Jaiswal, A.K.; Dey, K.K.; Yadav, V.B.; Nath, G.; Srivastava, A.K.; Yadav, R.R. Trimetallic Au/Pt/Ag Based Nanofluid for Enhanced Antibacterial Response. Mater. Chem. Phys. 2018, 218, 10–17. [Google Scholar] [CrossRef]

- Zhou, Y.; Shen, Y.; Xi, J. Seed-Mediated Synthesis of PtxAuy@Ag Electrocatalysts for the Selective Oxidation of Glycerol. Appl. Catal. B Environ. 2019, 245, 604–612. [Google Scholar] [CrossRef]

- Alonso, J. The Factors Influencing Solid Solubility in Metallic Alloys. Lat. Am. J. Metall. Mater. 1985, 5, 3–13. [Google Scholar]

- Pero-Sanz Elorz, J.A.; Quintana Hernández, M.J.; Verdeja, L.F. Solidification and Solid-State Transformations of Metals and Alloys; Elsevier: Amsterdam, The Netherlands, 2017; ISBN 978-0-12-812607-3. [Google Scholar]

- Manshina, A.A.; Povolotskiy, A.V.; Povolotskaya, A.V.; Ivanova, T.Y.; Koshevoy, I.O.; Tunik, S.P.; Suvanto, M.; Pakkanen, T.A. Laser-Induced Heterometallic Phase Deposition from Solutions of Supramolecular Complexes. Surf. Coat. Technol. 2012, 206, 3454–3458. [Google Scholar] [CrossRef]

- Povolotskiy, A.; Povolotckaia, A.; Petrov, Y.; Manshina, A.; Tunik, S. Laser-Induced Synthesis of Metallic Silver-Gold Nanoparticles Encapsulated in Carbon Nanospheres for Surface-Enhanced Raman Spectroscopy and Toxins Detection. Appl. Phys. Lett. 2013, 103, 113102. [Google Scholar] [CrossRef]

- Manshina, A.A.; Grachova, E.V.; Povolotskiy, A.V.; Povolotckaia, A.V.; Petrov, Y.V.; Koshevoy, I.O.; Makarova, A.A.; Vyalikh, D.V.; Tunik, S.P. Laser-Induced Transformation of Supramolecular Complexes: Approach to Controlled Formation of Hybrid Multi-Yolk-Shell Au-Ag@a-C:H Nanostructures. Sci. Rep. 2015, 5, 12027. [Google Scholar] [CrossRef] [Green Version]

- Man’shina, A.A.; Povolotskiy, A.V.; Ivanova, T.Y.; Kurochkin, A.V.; Tver’yanovich, Y.S.; Kim, D.; Kim, M.; Kwon, S. Laser-Induced Copper Deposition on the Surface of an Oxide Glass from an Electrolyte Solution. Glass Phys. Chem. 2007, 33, 209–213. [Google Scholar] [CrossRef]

- Povolotckaia, A.; Pankin, D.; Petrov, Y.; Vasileva, A.; Kolesnikov, I.; Sarau, G.; Christiansen, S.; Leuchs, G.; Manshina, A. Plasmonic Carbon Nanohybrids from Laser-Induced Deposition: Controlled Synthesis and SERS Properties. J. Mater. Sci. 2019, 54, 8177–8186. [Google Scholar] [CrossRef]

- Butt, M.A.; Mamonova, D.; Petrov, Y.; Proklova, A.; Kritchenkov, I.; Manshina, A.; Banzer, P.; Leuchs, G. Hybrid Orthorhombic Carbon Flakes Intercalated with Bimetallic Au-Ag Nanoclusters: Influence of Synthesis Parameters on Optical Properties. Nanomaterials 2020, 10, 1376. [Google Scholar] [CrossRef] [PubMed]

- Vasileva, A.; Haschke, S.; Mikhailovskii, V.; Gitlina, A.; Bachmann, J.; Man’shina, A. Direct Laser-Induced Deposition of AgPt@C Nanoparticles on 2D and 3D Substrates for Electrocatalytic Glucose Oxidation. Nano-Struct. Nano-Objects 2020, 24, 100547. [Google Scholar] [CrossRef]

- Lee, K.-C.; Lin, S.-J.; Lin, C.-H.; Tsai, C.-S.; Lu, Y.-J. Size Effect of Ag Nanoparticles on Surface Plasmon Resonance. Surf. Coat. Technol. 2008, 202, 5339–5342. [Google Scholar] [CrossRef]

- Amendola, V.; Pilot, R.; Frasconi, M.; Maragò, O.M.; Iatì, M.A. Surface Plasmon Resonance in Gold Nanoparticles: A Review. J. Phys. Condens. Matter 2017, 29, 203002. [Google Scholar] [CrossRef] [PubMed]

- Gharibshahi, E.; Saion, E.; Johnston, R.L.; Ashraf, A. Theory and Experiment of Optical Absorption of Platinum Nanoparticles Synthesized by Gamma Radiation. Appl. Radiat. Isot. 2019, 147, 204–210. [Google Scholar] [CrossRef] [PubMed]

| Solvent | Parameter |  |  |  |  |  |  |  |

|---|---|---|---|---|---|---|---|---|

| H2O | MD, nm | 57 | 215 | 135 | 166 | 25 | 203 | 158 |

| RMSD, nm | 60 | 230 | 95 | 173 | 17 | 155 | 68 | |

| CH3OH | MD, nm | 49 | 22 | - | 32 | - | - | - |

| RMSD, nm | 50 | 14 | - | 22 | - | - | - |

| Spectrum Name | Ag BE, eV | Au BE, eV | Pt BE, eV | Au-Ag BE, eV | Ag-Pt BE, eV | Au-Pt BE, eV | Au-Ag-Pt BE, eV |

|---|---|---|---|---|---|---|---|

| C 1s | 284.79 | 284.81 | 284.79 | 284.79 | 284.79 | 284.82 | 284.77 |

| Ag 3d | 368.80 | - | - | 368.03 | 368.50 | - | 368.75 |

| Au 4f | - | 84.18 | - | 84.46 | - | 84.71 | 84.59 |

| Pt 4f7 0 | - | - | 72.91 | - | 73.40 | 73.21 | 73.08 |

| Pt 4f7 2+ | - | - | 73.40 | - | 75.29 | 74.46 | 74.72 |

| Pt 4f7 4+ | - | - | 74.73 | - | 76.95 | 75.45 | 75.38 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mamonova, D.V.; Vasileva, A.A.; Petrov, Y.V.; Koroleva, A.V.; Danilov, D.V.; Kolesnikov, I.E.; Bikbaeva, G.I.; Bachmann, J.; Manshina, A.A. Single Step Laser-Induced Deposition of Plasmonic Au, Ag, Pt Mono-, Bi- and Tri-Metallic Nanoparticles. Nanomaterials 2022, 12, 146. https://doi.org/10.3390/nano12010146

Mamonova DV, Vasileva AA, Petrov YV, Koroleva AV, Danilov DV, Kolesnikov IE, Bikbaeva GI, Bachmann J, Manshina AA. Single Step Laser-Induced Deposition of Plasmonic Au, Ag, Pt Mono-, Bi- and Tri-Metallic Nanoparticles. Nanomaterials. 2022; 12(1):146. https://doi.org/10.3390/nano12010146

Chicago/Turabian StyleMamonova, Daria V., Anna A. Vasileva, Yuri V. Petrov, Alexandra V. Koroleva, Denis V. Danilov, Ilya E. Kolesnikov, Gulia I. Bikbaeva, Julien Bachmann, and Alina A. Manshina. 2022. "Single Step Laser-Induced Deposition of Plasmonic Au, Ag, Pt Mono-, Bi- and Tri-Metallic Nanoparticles" Nanomaterials 12, no. 1: 146. https://doi.org/10.3390/nano12010146

APA StyleMamonova, D. V., Vasileva, A. A., Petrov, Y. V., Koroleva, A. V., Danilov, D. V., Kolesnikov, I. E., Bikbaeva, G. I., Bachmann, J., & Manshina, A. A. (2022). Single Step Laser-Induced Deposition of Plasmonic Au, Ag, Pt Mono-, Bi- and Tri-Metallic Nanoparticles. Nanomaterials, 12(1), 146. https://doi.org/10.3390/nano12010146