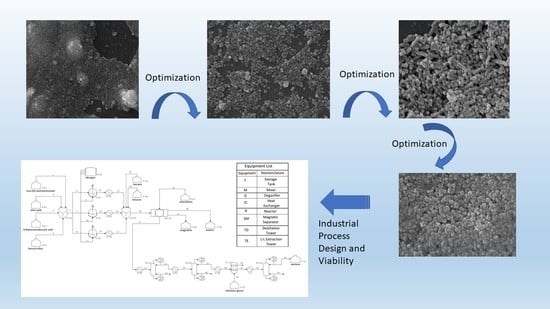

Cubic Nanoparticles for Magnetic Hyperthermia: Process Optimization and Potential Industrial Implementation

Abstract

:1. Introduction

2. Materials and Methods

2.1. Reagents

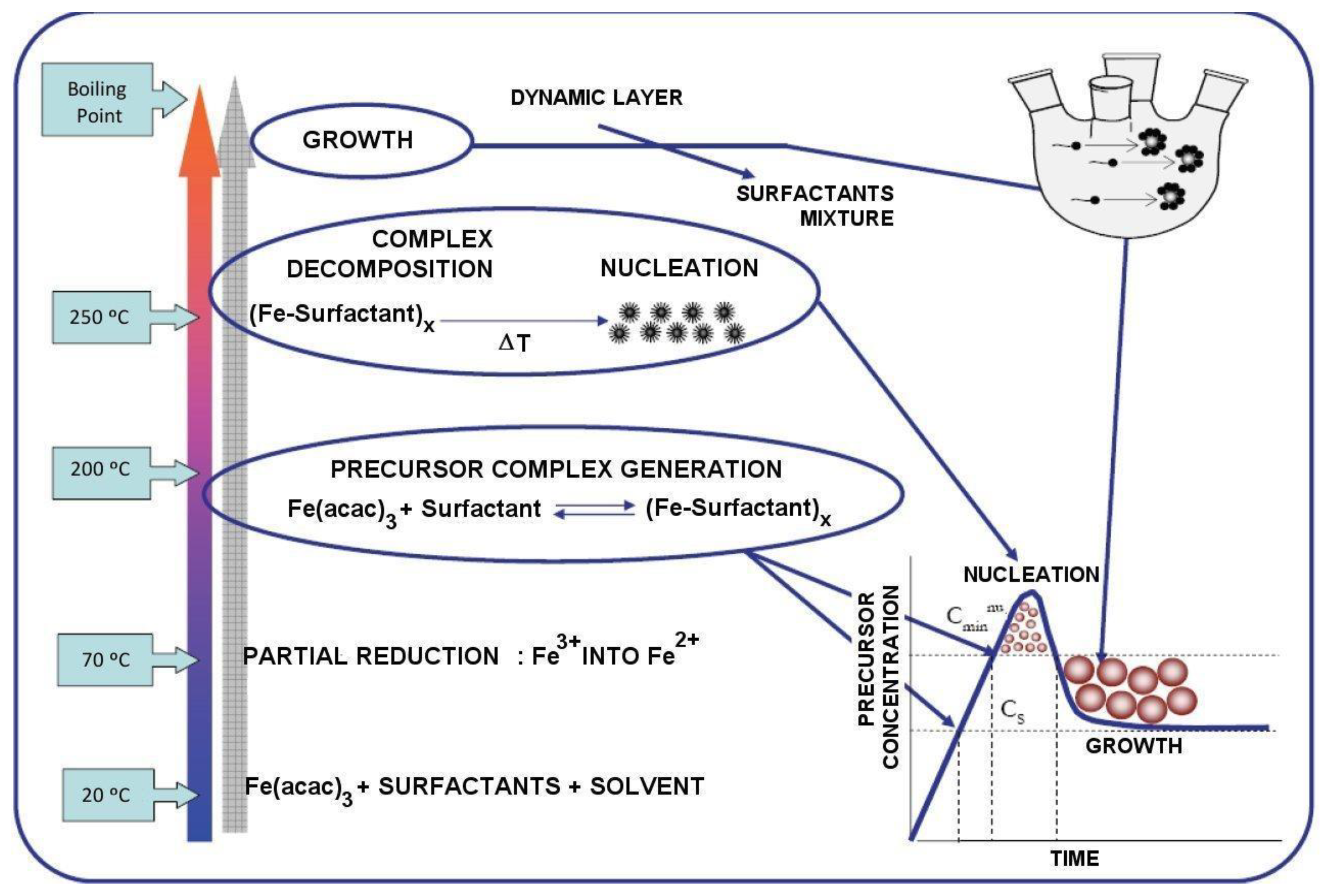

2.2. General Experimental Methodology

2.2.1. Synthesis of Cubic Magnetic Nanoparticles

2.2.2. Particles’ Characterization

2.2.3. Influence of the Main Variables

- (a)

- Effect of mechanical stirring (four values were used: 150, 170, 200, and 220 rpm).

- (b)

- Effect of temperature ramp-up (the increasing temperature gradients studied were: 15, 20, 25, and 30 °C/min).

- (c)

- Effect of the type of solvent (the solvents studied were: (a) 4-biphenylcarboxylic acid—2 mmol; (b) benzyl ether—52.5 mmol; (c) both solvents: 4-biphenylcarboxylic acid—2 mmol—and benzyl ether—52.5 mmol).

- (d)

- Effect of reagents ratio (the ratios studied were: doubling oleic acid amount, doubling 4-biphenylcarboxylic acid amount, and doubling all reagents).

- (e)

- Degassing time (the degassing time with nitrogen was reduced by half).

2.2.4. Economic Analysis and Industrial Scale-Up Study

2.3. Instrumentation

3. Results and Discussion

3.1. Magnetic Properties

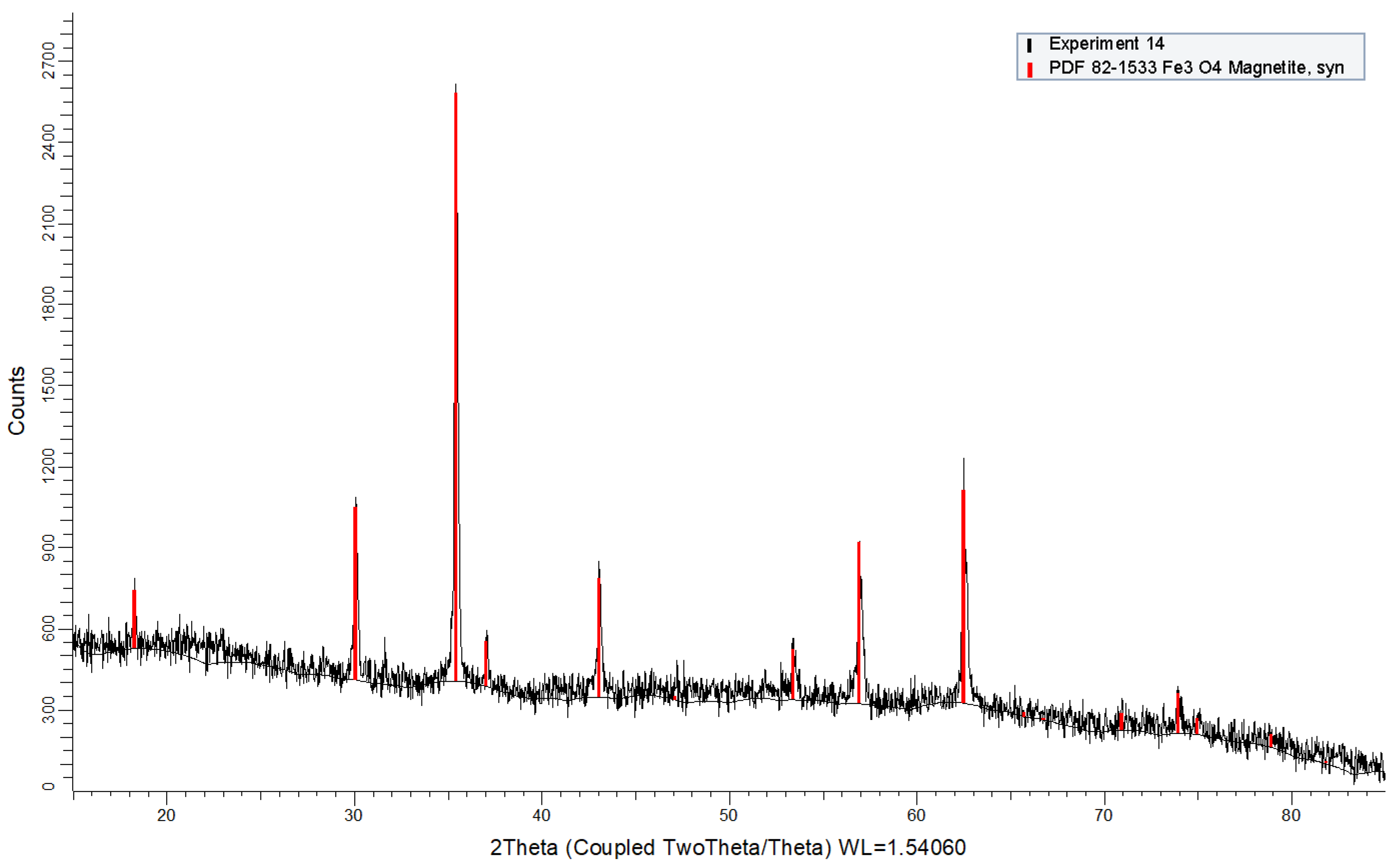

3.2. Composition

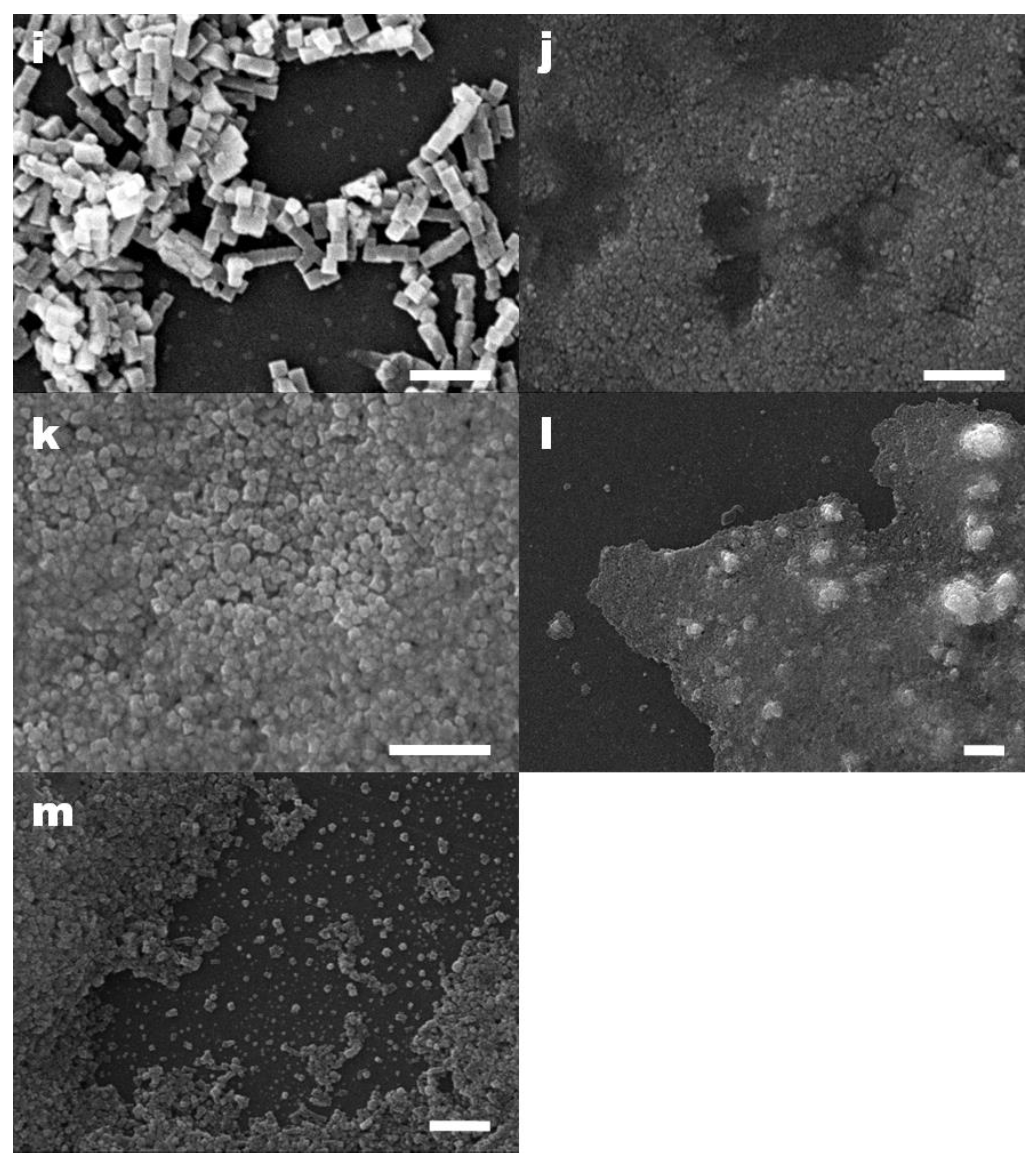

3.3. Particle Size and Morphology

3.4. Discussion of Results

3.4.1. Parameters Influence

- (a)

- increasing stirring speed is beneficial (experiments 1, 2, and 3),

- (b)

- increase in temperature ramp-up does not affect the results (experiments 4, 5, 6, 7, 8, 9, and 10),

- (c)

- substituting the solvent (4-biphenylcarboxylic acid by benzyl ether) improves the percentage of particles presenting a cubic form, but increases particle sizes (experiments 7, 8, and 9),

- (d)

- doubling the quantities of oleic acid or 4-biphenylcarboxylic acid leads to a null production of particles (experiments 15 and 16),

- (e)

- doubling the quantity of the two reactives and one of the tested solvents is not detrimental (experiment 11),

- (f)

- reducing the degasification time is detrimental (experiment 13),

- (g)

- using both solvents at the same time (4-biphenylcarboxylic acid and benzyl ether) improves the process (experiments 12 and 14).

3.4.2. Ideal Value of the Parameters

4. Potential Industrial Implementation

4.1. Size of the Plant

4.2. Process Engineering Design

4.3. Global Economic Impact and Profitability

4.4. Discussion of Results—Industrial Adaptation

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Wild, C.; Weiderpass, E.; Steward, B. World Cancer Report: Cancer Research for Cancer Prevention; International Agency for Research on Cancer, World Health Organization: Geneva, Switzerland, 2020. [Google Scholar]

- Bruvera, J.I. Disipación de Potencia Por Nanopartículas Magnéticas Expuestas a Campos de Radiofrecuencia Para Terapia Oncológica Por Hipertermia; Universidad Nacional de La Plata: La Plata, Argentina, 2015. [Google Scholar]

- Horny, M.-C.; Gamby, J.; Dupuis, V.; Siaugue, J.-M. Magnetic Hyperthermia on γ-Fe2O3@SiO2 Core-Shell Nanoparticles for mi-RNA 122 Detection. Nanomaterials 2021, 11, 149. [Google Scholar] [CrossRef]

- Caizer, C. Optimization Study on Specific Loss Power in Superparamagnetic Hyperthermia with Magnetite Nanoparticles for High Efficiency in Alternative Cancer Therapy. Nanomaterials 2021, 11, 40. [Google Scholar] [CrossRef]

- Veloso, S.R.S.; Silva, J.F.G.; Hilliou, L.; Moura, C.; Coutinho, P.J.G.; Martins, J.A.; Testa-Anta, M.; Salgueiriño, V.; Correa-Duarte, M.A.; Ferreira, P.M.T.; et al. Impact of Citrate and Lipid-Functionalized Magnetic Nanoparticles in Dehydropeptide Supramolecular Magnetogels: Properties, Design and Drug Release. Nanomaterials 2021, 11, 16. [Google Scholar] [CrossRef] [PubMed]

- Strbak, O.; Antal, I.; Khmara, I.; Koneracka, M.; Kubovcikova, M.; Zavisova, V.; Molcan, M.; Jurikova, A.; Hnilicova, P.; Gombos, J.; et al. Influence of Dextran Molecular Weight on the Physical Properties of Magnetic Nanoparticles for Hyperthermia and MRI Applications. Nanomaterials 2020, 10, 2468. [Google Scholar] [CrossRef]

- Wu, K.; Wanga, J.-P. Magnetic hyperthermia performance of magnetite nanoparticle assemblies under different driving fields. AIP Adv. 2017, 7, 056327. [Google Scholar] [CrossRef] [Green Version]

- Augusto, P.A.; Castelo-Grande, T.; Vargas, D.; Pascual, A.; Hernández, L.; Estevez, A.M.; Barbosa, D. Upscale Design, Process Development, and Economic Analysis of Industrial Plants for Nanomagnetic Particle Production for Environmental and Biomedical Use. Materials 2020, 13, 2477. [Google Scholar] [CrossRef] [PubMed]

- Augusto, P.A.; Castelo-Grande, T.; Vargas, D.; Hernández, L.; Merchán, L.; Estevez, A.M.; Gómez, J.; Compaña, J.M.; Barbosa, D. Water Decontamination with Magnetic Particles by Adsorption and Chemical Degradation. Influence of the Manufacturing Parameters. Materials 2020, 13, 2219. [Google Scholar] [CrossRef] [PubMed]

- Li, Q.; Kartikowati, C.W.; Horie, S.; Ogi, T.; Iwaki, T.; Okuyama, K. Correlation between particle size/domain structure and magnetic properties of highly crystalline Fe3O4 nanoparticles. Sci. Rep. 2017, 7, 9894. [Google Scholar] [CrossRef]

- Butler, R.F.; Banerjee, S.K. Theoretical single-domain grain size range in magnetite and titanomagnetite. J. Geophys. Res. 1975, 80, 4049–4058. [Google Scholar] [CrossRef]

- Muxworthy, A.R.; Williams, W. Critical superparamagnetic/single-domain grain sizes in interacting magnetite particles: Implications for magnetosome crystals. J. R. Soc. Interface 2009, 6, 1207–1212. [Google Scholar] [CrossRef] [Green Version]

- Shah, R.R.; Davis, T.P.; Glover, A.L.; Nikles, D.E.; Brazel, C.S. Impact of magnetic field parameters and iron oxide nanoparticle properties on heat generation for use in magnetic hyperthermia. J. Magn. Magn. Mater. 2015, 387, 96–106. [Google Scholar] [CrossRef] [Green Version]

- Khurshid, H.; Alonso, J.; Nemati, Z.; Phan, M.H.; Mukherjee, P.; Fdez-Gubieda, M.L.; Barandiarán, J.M.; Srikanth, H. Anisotropy effects in magnetic hyperthermia: A comparison between spherical and cubic exchange-coupled FeO/Fe3O4 nanoparticles. J. Appl. Phys. 2015, 117, 17A337. [Google Scholar] [CrossRef]

- Avugadda, S.K.; Wickramasinghe, S.; Niculaes, D.; Ju, M.; Lak, A.; Silvestri, N.; Nitti, S.; Roy, I.; Samia, A.C.S.; Pellegrino, T. Uncovering the Magnetic Particle Imaging and Magnetic Resonance Imaging Features of Iron Oxide Nanocube Clusters. Nanomaterials 2021, 11, 62. [Google Scholar] [CrossRef] [PubMed]

- Abenojar, E.C.; Wickramasinghe, S.; Bas-Concepcion, J.; Samia, A.C.S. Structural effects on the magnetic hyperthermia properties of iron oxide nanoparticles. Prog. Nat. Sci. Mater. Int. 2016, 26, 440–448. [Google Scholar] [CrossRef] [Green Version]

- Martinez-Boubeta, C.; Simeonidis, K.; Makridis, A.; Angelakeris, M.; Iglesias, O.; Guardia, P.; Cabot, A.; Yedra, L.; Estradé, S.; Peiró, F.; et al. Learning from Nature to Improve the Heat Generation of Iron-Oxide Nanoparticles for Magnetic Hyperthermia Applications. Sci. Rep. 2013, 3, 1652. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Reyes-Ortega, F.; Delgado, Á.V.; Iglesias, G.R. Modulation of theMagnetic Hyperthermia ResponseUsing Different Superparamagnetic Iron Oxide Nanoparticle Morphologies. Nanomaterials 2021, 11, 627. [Google Scholar] [CrossRef] [PubMed]

- Augusto, P.A.; Castelo-Grande, T.; Merchan, L.; Estevez, A.M.; Quintero, X.; Barbosa, D. Landfill leachate treatment by sorption in magnetic particles: Preliminary study. Sci. Total Environ. 2019, 648, 636–668. [Google Scholar] [CrossRef] [PubMed]

- Castelo-Grande, T.; Augusto, P.A.; Rico, J.; Marcos, J.; Iglesias, R.; Hernández, L.; Barbosa, D. Magnetic water treatment in a wastewater treatment plant: Part I—Sorption and magnetic particles. J. Environ. Manag. 2021, 281, 111872, ISSN 0301-4797. [Google Scholar] [CrossRef]

- Castelo-Grande, T.; Augusto, P.A.; Rico, J.; Marcos, J.; Iglesias, R.; Hernández, L.; Barbosa, D. Magnetic water treatment in a wastewater treatment plant: Part II—Processing Waters and Kinetic Study. J. Environ. Manag. 2021. acepted. [Google Scholar]

- Hernández, L.; Augusto, P.A.; Castelo-Grande, T.; Barbosa, D. Regeneration and Reuse of Magnetic Particles for Contaminant Degradation in Water. J. Environ. Manag. 2021. acepted. [Google Scholar] [CrossRef] [PubMed]

- Estevez, A.M.; Rodriguez, J.M.; Alvaro, A.; Augusto, P.A.; Jimenez, O.; Castelo-Grande, T.; Barbosa, D. Preparation, Characterization, and Testing of Magnetic Carriers for Arsenic Removal From Water. IEEE Trans. Magn. 2008, 44, 4436–4439. [Google Scholar] [CrossRef]

- Kim, D.; Lee, N.; Park, M.; Hyo, B.; Kwangjin, K.; Hyeon, T. Synthesis of Uniform Ferrimagnetic Magnetite Nanocubes. J. Am. Chem. Soc. 2009, 131, 454–455. [Google Scholar] [CrossRef] [PubMed]

- Gómez Roca, A. Preparación de Nanopartículas Magnéticas Uniformes y de Alta Cristalinidad para Biomedicina; Instituto de Ciencia de Materiales de Madrid, Departamento de Química Física I, Universidad Complutense de Madrid: Madrid, Spain, 2009. [Google Scholar]

| Manufacturing Method | Synthesis | Reaction Temp. (°C) | Reaction Time | Solvent | Surface-Capping Agents | Size Distribution | Shape Control | Yield |

|---|---|---|---|---|---|---|---|---|

| Coprecipitation | Very simple | 20–90 | Minutes | Water | During/after reaction | Relatively narrow | Not good | High |

| Microemulsion | Complicated | 20–50 | Hours | Organic agents | During reaction | Relatively narrow | Good | Low |

| Thermal decomposition | Complicated | 100–320 | Hours-days | Organic agents | During reaction | Very narrow | Very good | High |

| Hydrothermal | Simple | 200–250 | Hours-days | Water-ethanol | During reaction | Very narrow | Very good | Medium |

| Poliol | Simple | 25-Boiling Point | Hours | Ethylene PEG | During reaction | Narrow | Very Good | High |

| Reagent/Property | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Experiment | Iron Acetylacetonate (III) (mmol) | Oleic Acid (mmol) | 4-Biphenylcarboxylic Acid (mmol) | Benzyl ether (mmol) | Reaction Temperature (°C) | Temperature Ramp-Up (°C/min) | Stirring Speed (rpm) | Centrifuge (rpm) | Degassing |

| 1 | 2 | 4.5 | 2 | ----- | 290 | 20 | 150 | 1700 | Normal |

| 2 | 2 | 4.5 | 2 | ----- | 290 | 20 | 170 | 1700 | Normal |

| 3 | 2 | 4.5 | 2 | ----- | 290 | 20 | 220 | 1700 | Normal |

| 4 | 2 | 4.5 | 2 | ----- | 290 | 25 | 220 | 2000 | Normal |

| 5 | 2 | 4.5 | 2 | ----- | 290 | 15 | 220 | 2000 | Normal |

| 6 | 2 | 4.5 | 2 | ----- | 290 | 30 | 220 | 2000 | Normal |

| 7 | 2 | 4.5 | ----- | 52.5 | 290 | 15 | 200 | 2500 | Normal |

| 8 | 2 | 4.5 | ----- | 52.5 | 290 | 20 | 200 | 2500 | Normal |

| 9 | 2 | 4.5 | ----- | 52.5 | 290 | 25 | 200 | 2500 | Normal |

| 10 | 2 | 4.5 | 2 | ----- | 290 | 20 | 220 | 2500 | Normal |

| 11 (*) | 4 | 9 | 4 | ----- | 290 | 25 | 200 | 2500 | Normal |

| 12 (**) | 2 | 4.5 | 2 | 52.5 | 290 | 25 | 200 | 2500 | Normal |

| 13 | 2 | 4.5 | 2 | ----- | 290 | 30 | 200 | 2500 | Half |

| 14 | 2 | 4.5 | 2 | 52.5 | 290 | 25 | 200 | 2500 | Normal |

| 15 | 2 | 9 | 2 | ----- | 290 | 20 | 200 | 2500 | Normal |

| 16 | 2 | 4.5 | 4 | ----- | 290 | 30 | 200 | 2500 | Normal |

| Experiment Number | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 |

|---|---|---|---|---|---|---|---|---|

| Magnetic susceptibility (SI) | 2.51 × 10−4 | 5.29 × 10−4 | 2.84 × 10−4 | 1.56 × 10−4 | 1.51 × 10−4 | 2.56 × 10−4 | 9.71 × 10−5 | 2.00 × 10−4 |

| Experiment number | 9 | 10 | 11 | 12 and 14 | 13 | 15 | 16 | |

| Magnetic susceptibility (SI) | 2.13 × 10−4 | 9.25 × 10−5 | 4.64 × 10−4 | 3.12 × 10−4 | 2.44 × 10−4 | ----- | ----- |

| Experiment Number | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 |

|---|---|---|---|---|---|---|---|---|

| D (nm) | 73 | 50 | 44 | 39 | 32 | 37 | 88 | 92 |

| Experiment number | 9 | 10 | 11 | 12 and 14 | 13 | 15 | 16 | |

| D (nm) | 121 | 36 | 54 | 32 | 50 | ----- | ----- |

| Exp. Number | 10–20 (nm) | 20–28 (nm) | 28–36 (nm) | 36–44 (nm) | 44–52 (nm) | 52–60 (nm) | 60–68 (nm) | 68–76 (nm) | 76–84 (nm) | 84–92 (nm) | 92–100 (nm) | >100 (nm) |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 0% | 0% | 0% | 0% | 0% | 0% | 1% | 2% | 3% | 2% | 12% | 80% |

| 2 | 0% | 0% | 0% | 0% | 2% | 8% | 8% | 9% | 14% | 14% | 13% | 32% |

| 3 | 0% | 0% | 4% | 15% | 24% | 27% | 15% | 12% | 1% | 0% | 2% | 0% |

| 4 | 0% | 5% | 12% | 28% | 26% | 18% | 7% | 2% | 0% | 2% | 0% | 0% |

| 5 | 0% | 3% | 12% | 25% | 26% | 14% | 9% | 6% | 3% | 1% | 2% | 0% |

| 6 | 0% | 6% | 24% | 25% | 17% | 17% | 5% | 2% | 2% | 2% | 0% | 0% |

| 7 | 0% | 0% | 0% | 0% | 1% | 4% | 4% | 11% | 12% | 12% | 10% | 46% |

| 8 | 0% | 0% | 0% | 0% | 0% | 1% | 1% | 3% | 3% | 3% | 7% | 82% |

| 9 | 0% | 0% | 0% | 0% | 0% | 0% | 0% | 0% | 1% | 2% | 4% | 93% |

| 10 | 0% | 11% | 9% | 19% | 30% | 18% | 9% | 4% | 0% | 0% | 0% | 0% |

| 11 | 0% | 4% | 13% | 18% | 16% | 20% | 10% | 13% | 2% | 3% | 2% | 0% |

| 12, 14 | 6% | 26% | 32% | 16% | 9% | 5% | 4% | 1% | 1% | 0% | 0% | 0% |

| 13 | 0% | 4% | 6% | 6% | 15% | 20% | 24% | 12% | 5% | 5% | 4% | 3% |

| 15 | ---- | ---- | ---- | ---- | ---- | ---- | ---- | ---- | ---- | ---- | ||

| 16 | ---- | ---- | ---- | ---- | ---- | ---- | ---- | ---- | ---- | ---- |

| Exp. Number | Morphology | Main Size Ranges | Magnetic Character | Conclusions |

|---|---|---|---|---|

| 1 | Undefined | 92–100 nm: 12% >100 nm: 80% | Regular | The low resolution does not allow to determine their precise morphology. Size much larger than desired. Presents some large agglomerations. |

| 2 | Undefined | 76–84 nm: 14% 84–92 nm: 14% 92–100 nm: 13% >100 nm: 32% | Slightly Higher | The low resolution does not allow to determine their precise morphology. Size much larger than desired. Presents some large agglomerations. |

| 3 | Generally irregular. Some cubic-shaped particles are present. | 36–44 nm: 15% 44–52 nm: 24% 52–60 nm: 27% 60–68 nm: 15% 68–76 nm: 12% | Regular | Acceptable morphology. Size larger than desired. Some large agglomerations are present. |

| 4 | Irregular | 28–36 nm: 12% 36–44 nm: 28% 44–52 nm: 26% 52–60 nm: 18% | Regular | Poorly defined morphology. Size slightly larger than desired. Small agglomerations of medium size are seen. |

| 5 | Irregular | 28–36 nm: 12% 36–44 nm: 25% 44–52 nm: 26% 52–60 nm: 14% | Regular | Poorly defined morphology. Size slightly larger than desired. Small agglomerations of medium size are seen. |

| 6 | Generally irregular. Some cubic-shaped particles are present. | 28–36 nm: 24% 36–44 nm: 25% 44–52 nm: 17% 52–60 nm: 17% | Regular | Acceptable morphology. Size slightly larger than desired. Some agglomerations of medium size are seen. |

| 7 | Cubic/cobblestone particles | 68–76 nm: 11% 76–84 nm: 12% 84–92 nm: 12% 92–100 nm: 10% >100 nm: 46% | Slightly Lower | Ideal morphology. Size much larger than desired. There are no agglomerations. |

| 8 | Cubic/cobblestone particles | >100 nm: 82% | Regular | Ideal morphology. Size much larger than desired. There are no agglomerations. |

| 9 | Cubic/cobblestone particles | >100 nm: 93% | Regular | Ideal morphology. Size much larger than desired. There are no agglomerations. |

| 10 | Generally irregular. Some cubic-shaped particles are present. | 20–28 nm: 11% 28–36 nm: 9% 36–44 nm: 19% 44–52 nm: 30% 52–60 nm: 18% | Slightly Lower | Acceptable morphology. Size slightly larger than desired. Large agglomerations are not visible. |

| 11 | Generally irregular. Some cubic-shaped particles are present. | 28–36 nm: 13% 36–44 nm: 18% 44–52 nm: 16% 52–60 nm: 20% 60–68 nm: 10% 68–76 nm: 13% | Slightly Higher | Acceptable morphology. Size slightly larger than desired. There are several medium-sized agglomerations |

| 13 | Undefined | 44–52 nm: 15% 52–60 nm: 20% 60–68 nm: 24% 68–76 nm: 12% | Regular | The low resolution does not allow to determine their precise morphology. Size much larger than required. Presents some large agglomerations. |

| 12 and 14 | Generally cubic-shaped particles are present. Some irregular shape also appears. | 20–28 nm: 26% 28–36 nm: 32% 36–44 nm: 16% | Slightly Higher | Very good morphology. Very good size. There are no agglomerations. |

| 15 | No particles obtained | ----------- | ----------- | ----------- |

| 16 | No particles obtained | ----------- | ----------- | ----------- |

| Cost | EUR | Invested Capital | EUR |

|---|---|---|---|

| 1.1 Raw Materials | 48,298,030 | 1.1 Instrumentation | 827,043 |

| 1.2 Direct Human Labor | 829,870 | 1.2 Initial Setup | 473,602 |

| 1.3 Indirect Human Labor | 207,358 | 1.3 Piping and Valves | 372,270 |

| 1.4 General Services | 580,909 | 1.4 Measuring and Control | 165,409 |

| 1.5 Supplies | 80,096 | 1.5 Heat Isolation | 57,893 |

| 1.6 Maintenance | 234,179 | 1.6 Electrical Installation | 124,057 |

| 1.7 Laboratory | 165,974 | 1.7 Land and Structures | 1,122,893 |

| 1.8 Board and Technical Staff | 224,564 | 1.8 Auxiliary Facilities | 330,817 |

| 1.9 Amortization | 82,704 | 1.9 Project and Design | 361,923 |

| 1.10 Taxes and Insurances | 160,192 | 1.10 Constructor Hiring | 208,439 |

| TOTAL COST OF FABRICATION | 50,863,876 | 1.11 Unexpected Expenses | 521,098 |

| 2.1 Commercial Expenses | 10,172,775 | 1.12 Preliminary Studies | 2,803,343 |

| 2.2 Management | 131,826 | 1.13 Preliminary Startup | 640,764 |

| 2.3 Financial Expenses | 5,809,661 | - | - |

| 2.4 Research | 240,286 | TOTAL IMMOBILIZED | 8,009,550 |

| 2.5 Technical Services | 2,032,000 | CIRCULATING CAPITAL | 21,038,753 |

| TOTAL COST OF MANAGEMENT | 18,386,548 | TOTAL INVESTED CAPITAL | 29,048,303 |

| TOTAL PRODUCTION COSTS | 69,250,424 | TOTAL INCOME | 203,200,000 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sánchez, O.S.; Castelo-Grande, T.; Augusto, P.A.; Compaña, J.M.; Barbosa, D. Cubic Nanoparticles for Magnetic Hyperthermia: Process Optimization and Potential Industrial Implementation. Nanomaterials 2021, 11, 1652. https://doi.org/10.3390/nano11071652

Sánchez OS, Castelo-Grande T, Augusto PA, Compaña JM, Barbosa D. Cubic Nanoparticles for Magnetic Hyperthermia: Process Optimization and Potential Industrial Implementation. Nanomaterials. 2021; 11(7):1652. https://doi.org/10.3390/nano11071652

Chicago/Turabian StyleSánchez, Omar Sánchez, Teresa Castelo-Grande, Paulo A. Augusto, José M. Compaña, and Domingos Barbosa. 2021. "Cubic Nanoparticles for Magnetic Hyperthermia: Process Optimization and Potential Industrial Implementation" Nanomaterials 11, no. 7: 1652. https://doi.org/10.3390/nano11071652

APA StyleSánchez, O. S., Castelo-Grande, T., Augusto, P. A., Compaña, J. M., & Barbosa, D. (2021). Cubic Nanoparticles for Magnetic Hyperthermia: Process Optimization and Potential Industrial Implementation. Nanomaterials, 11(7), 1652. https://doi.org/10.3390/nano11071652