Boosting Magnetoelectric Effect in Polymer-Based Nanocomposites

Abstract

1. Introduction

2. Materials and Methods

2.1. Synthesis of CoFe2O4 (CFO), Zn0.25Co0.75Fe2O4 (ZCFO) and BaTiO3 (BTO) Particles

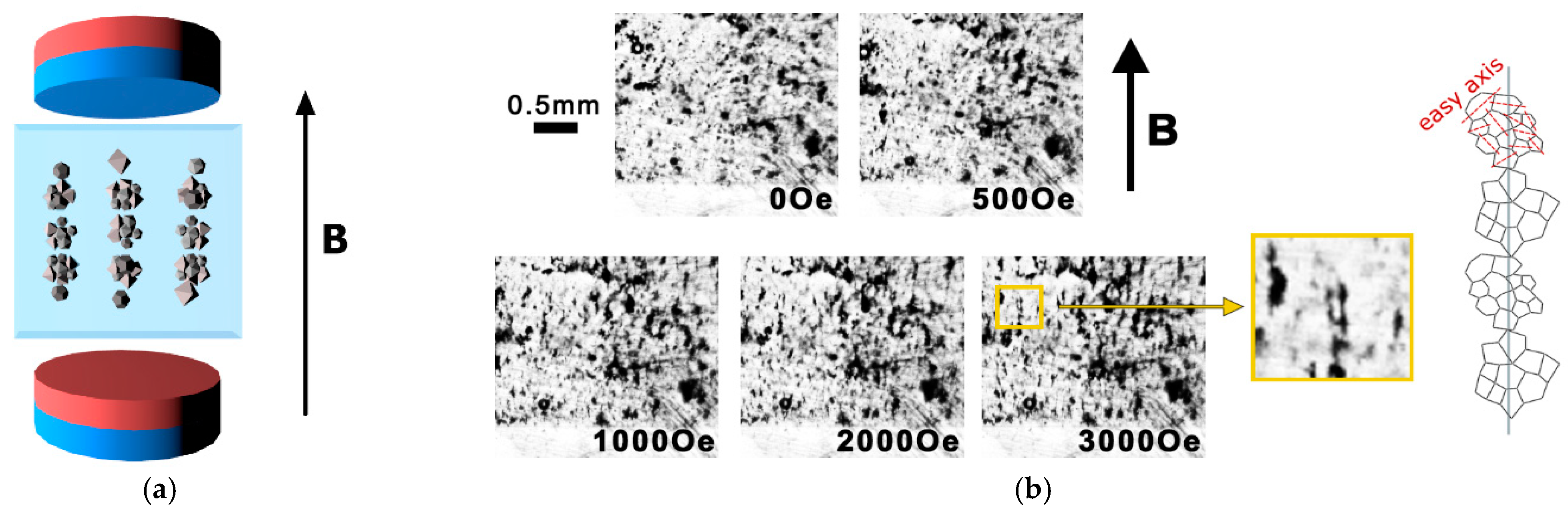

2.2. Fabrication of Magnetoelectric Nanocomposites (NCs)

2.3. Structural and Magnetic Characterization

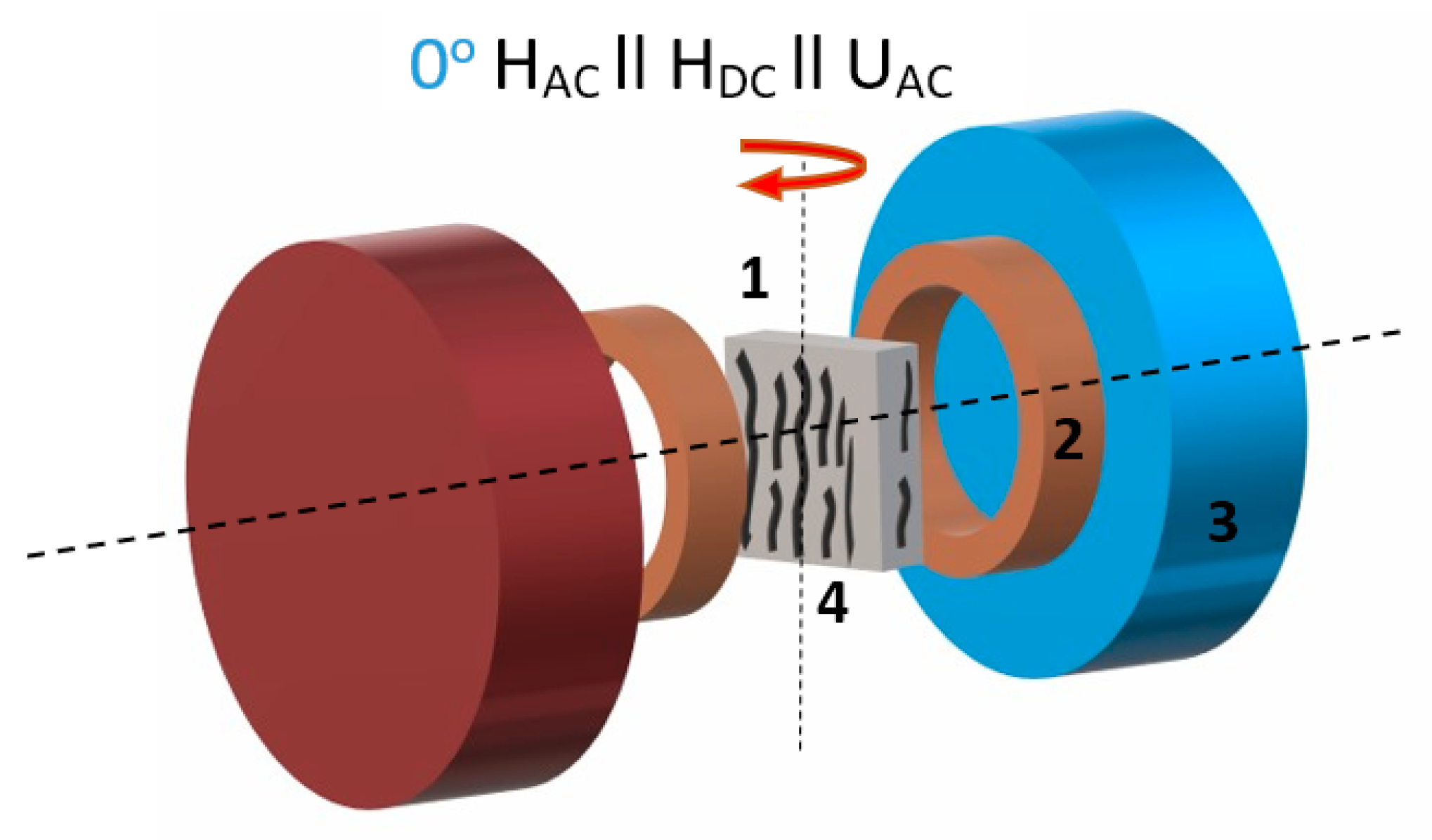

2.4. Magnetoelectric Properties

2.5. Magnetic and Piezoresponse Force Microscopy

2.6. Biological Tests of Polymeric Interfaces

3. Results and Discussions

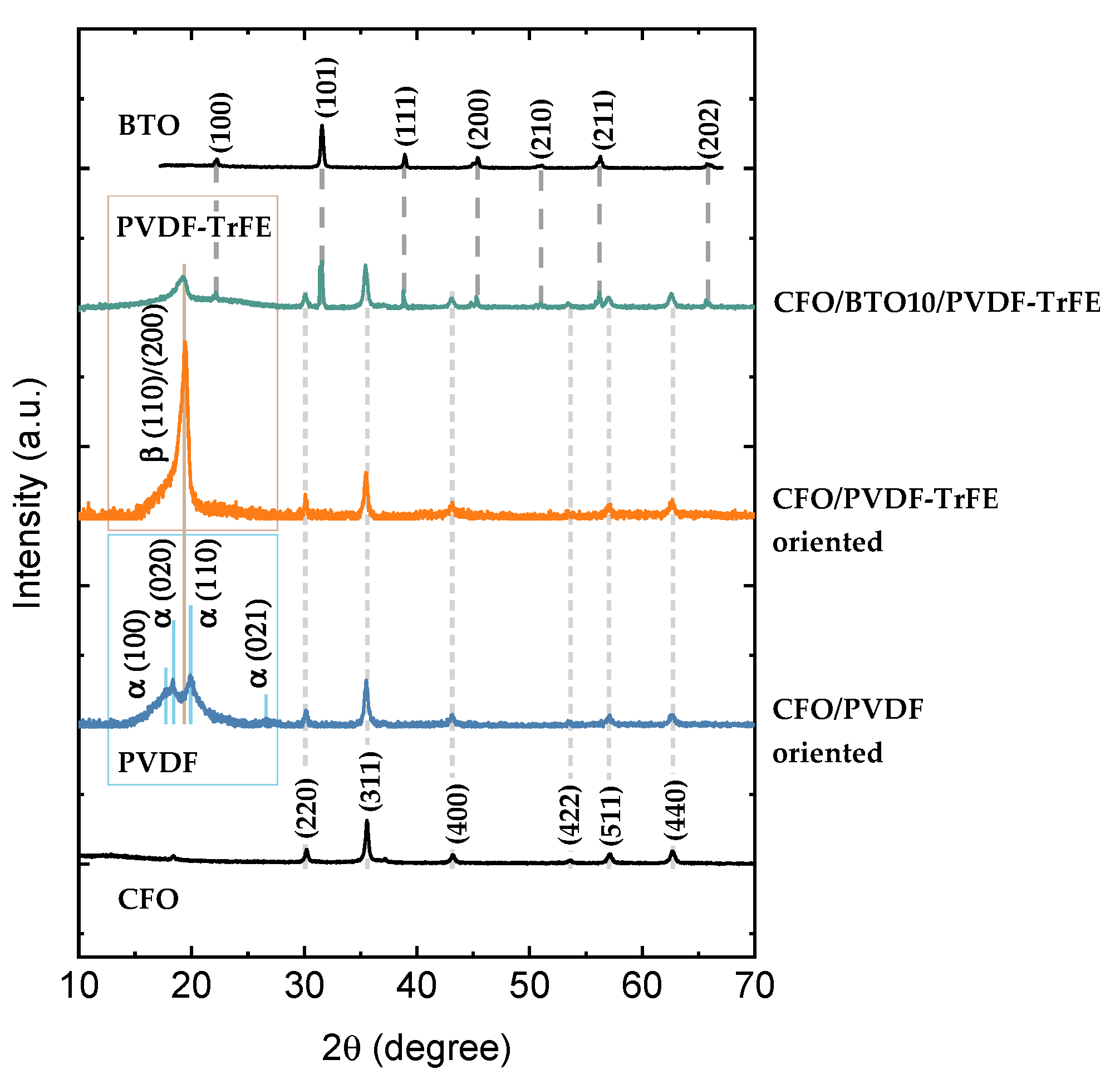

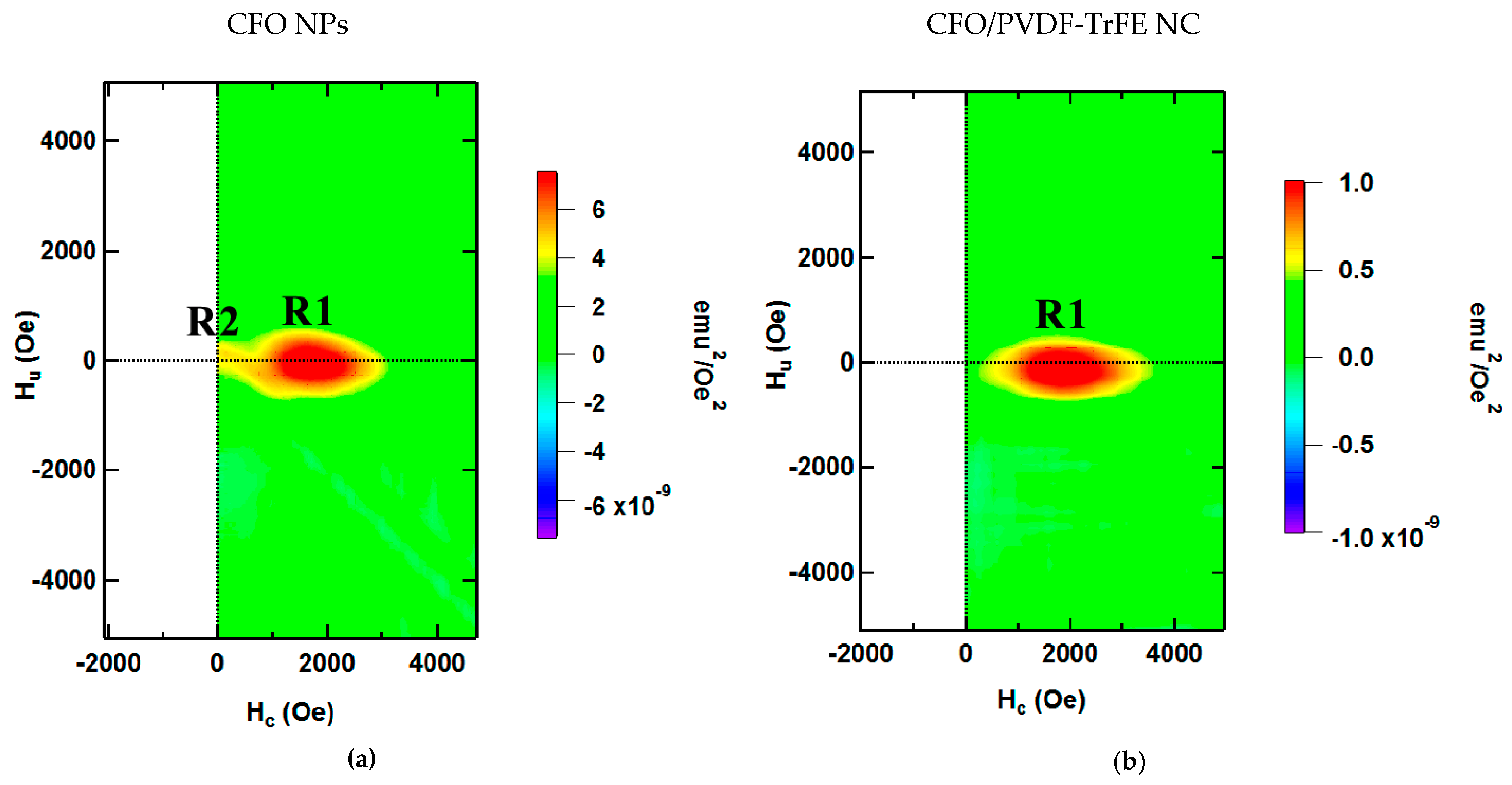

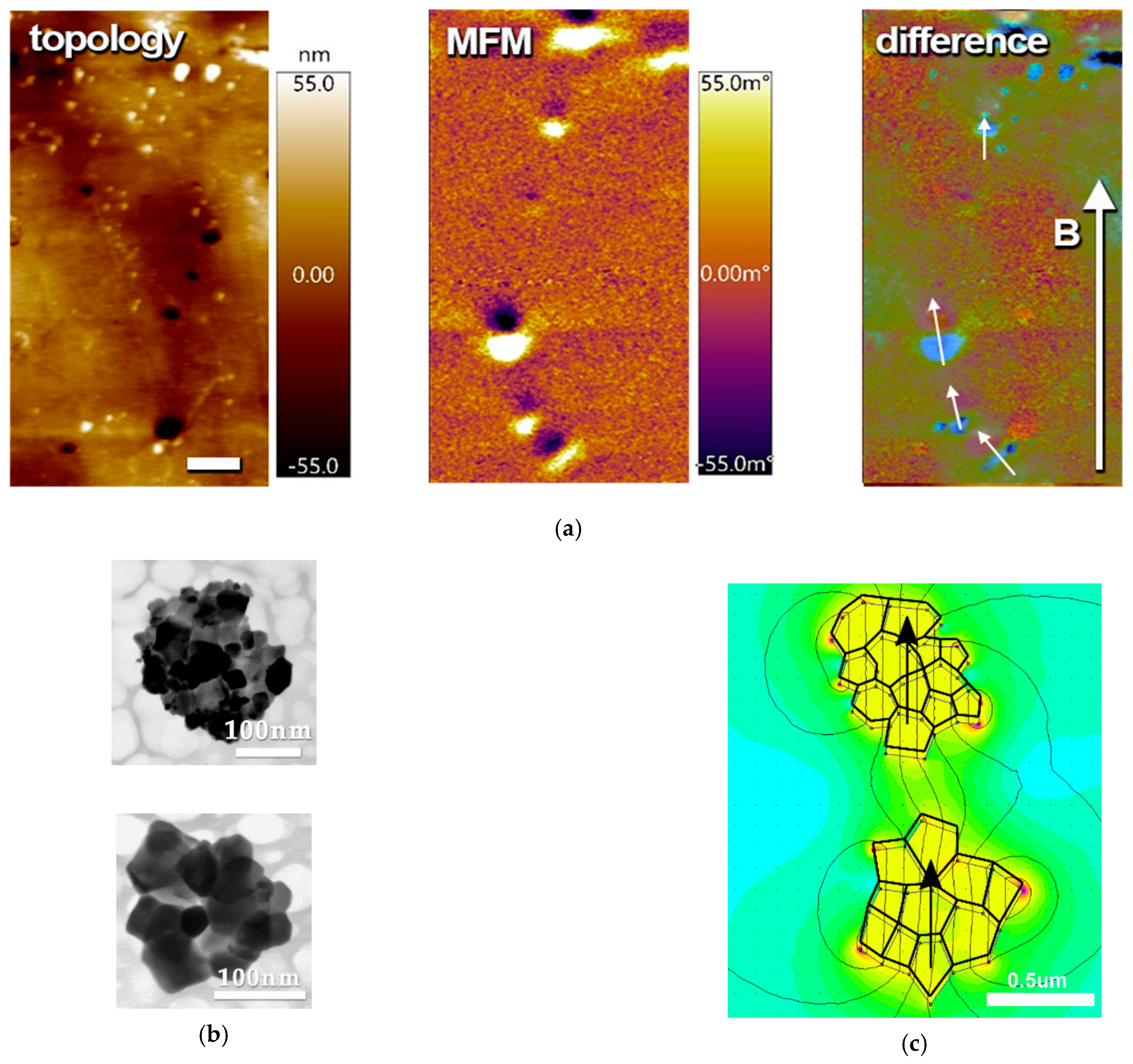

3.1. Characterization of CFO and BTO Particles

3.2. Characterization of NCs

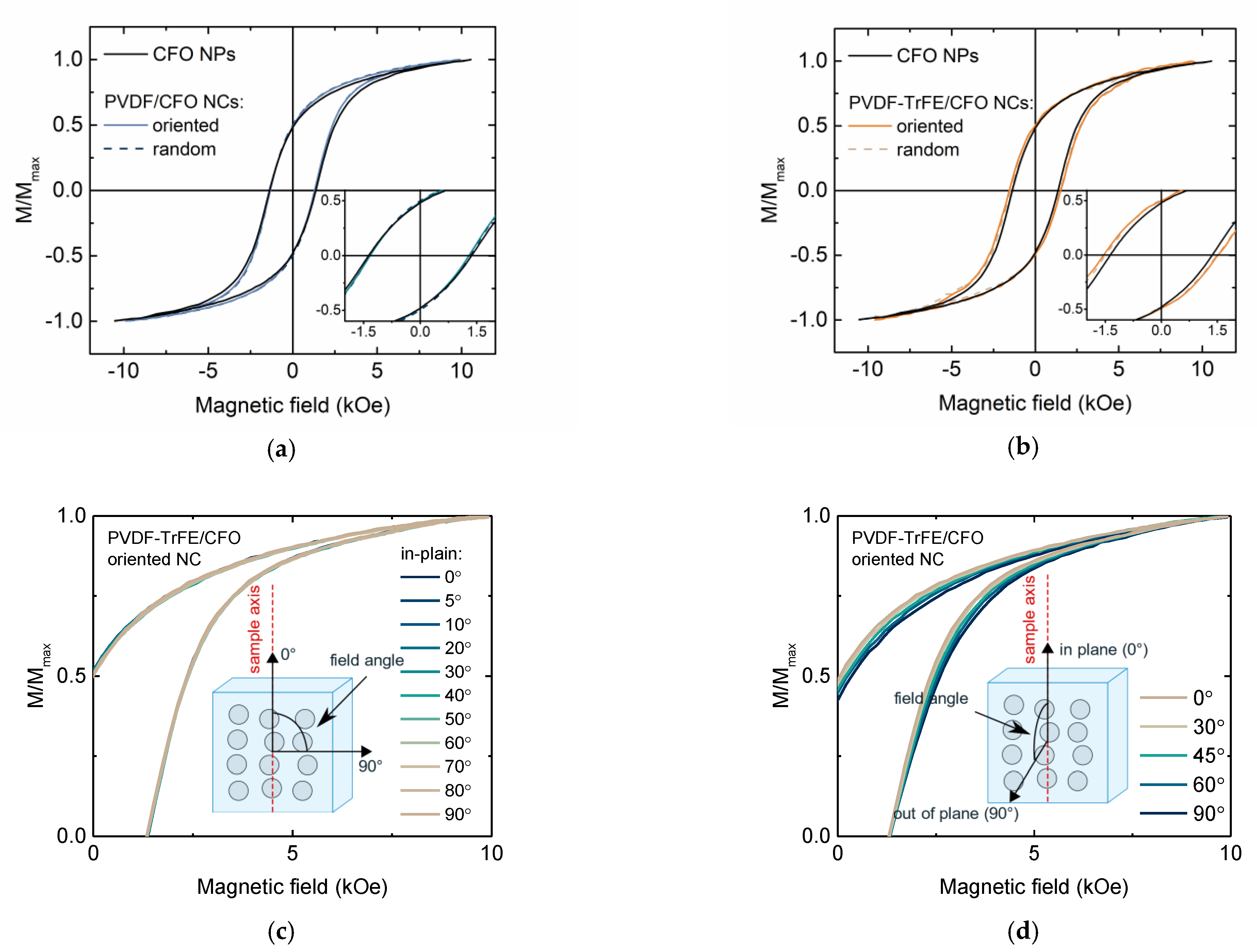

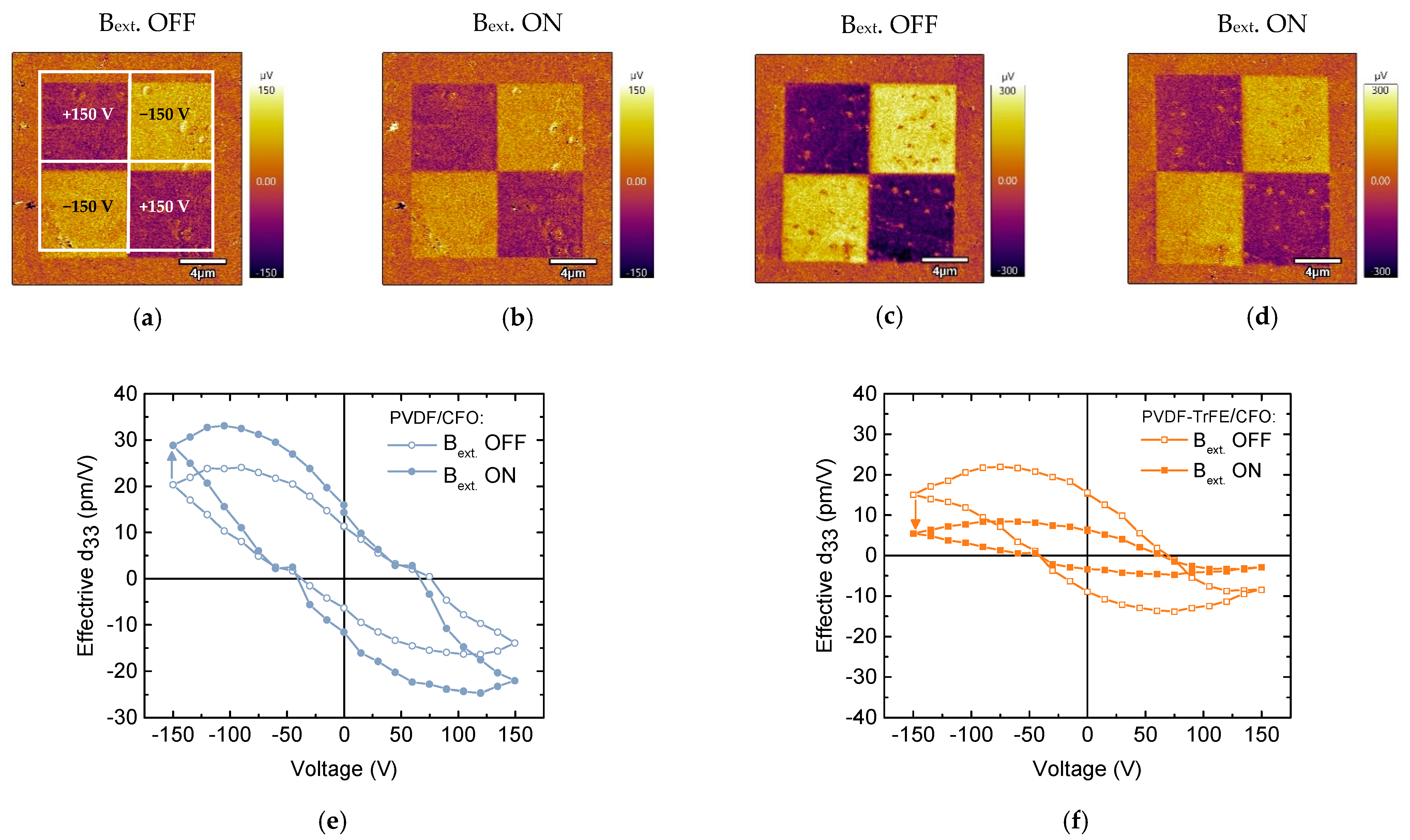

3.3. Random and Oriented NCs Based on CFO NPs in PVDF and PVDF-TrFE NCs

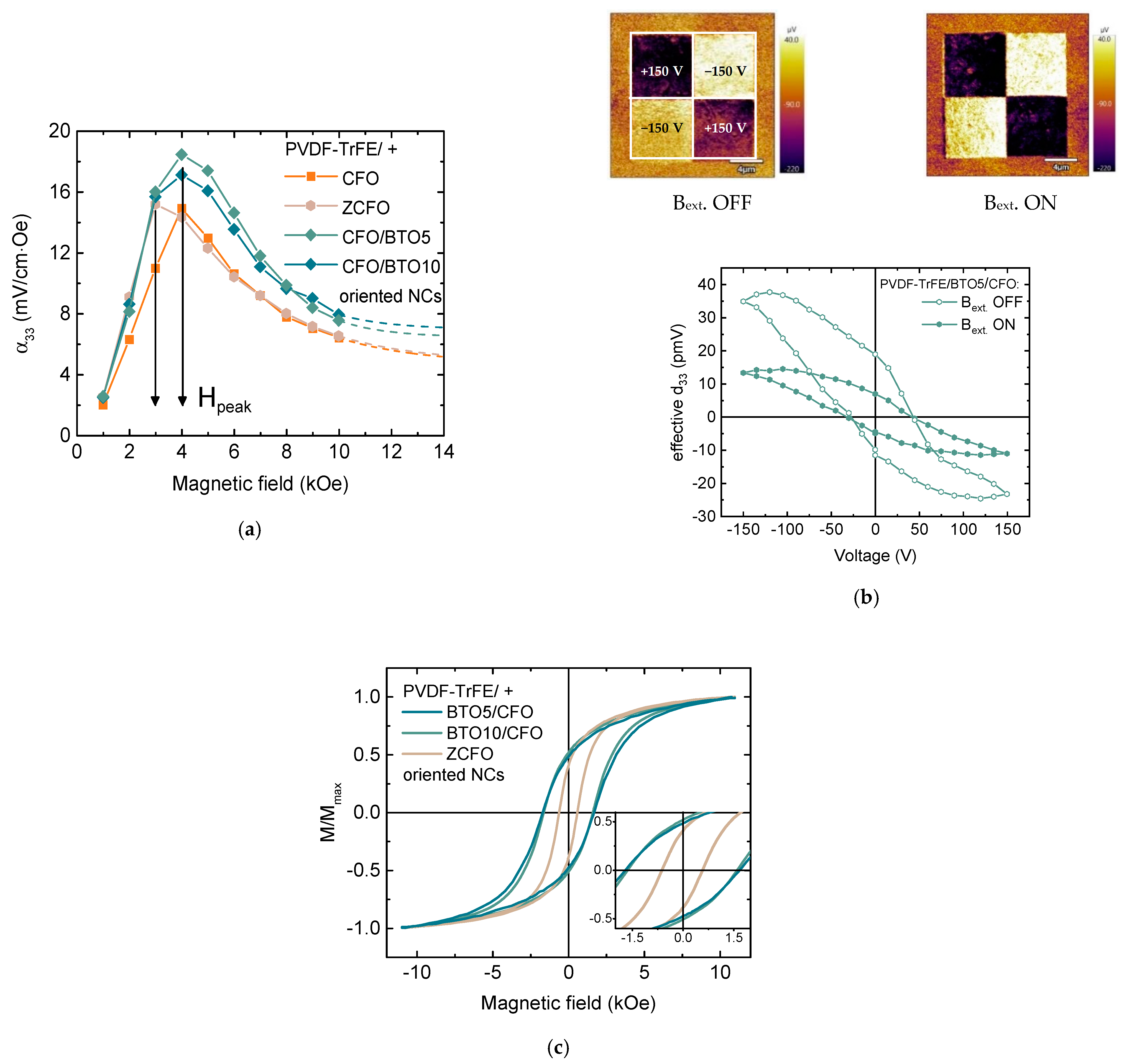

3.4. Further Improvements of ME Efficiency

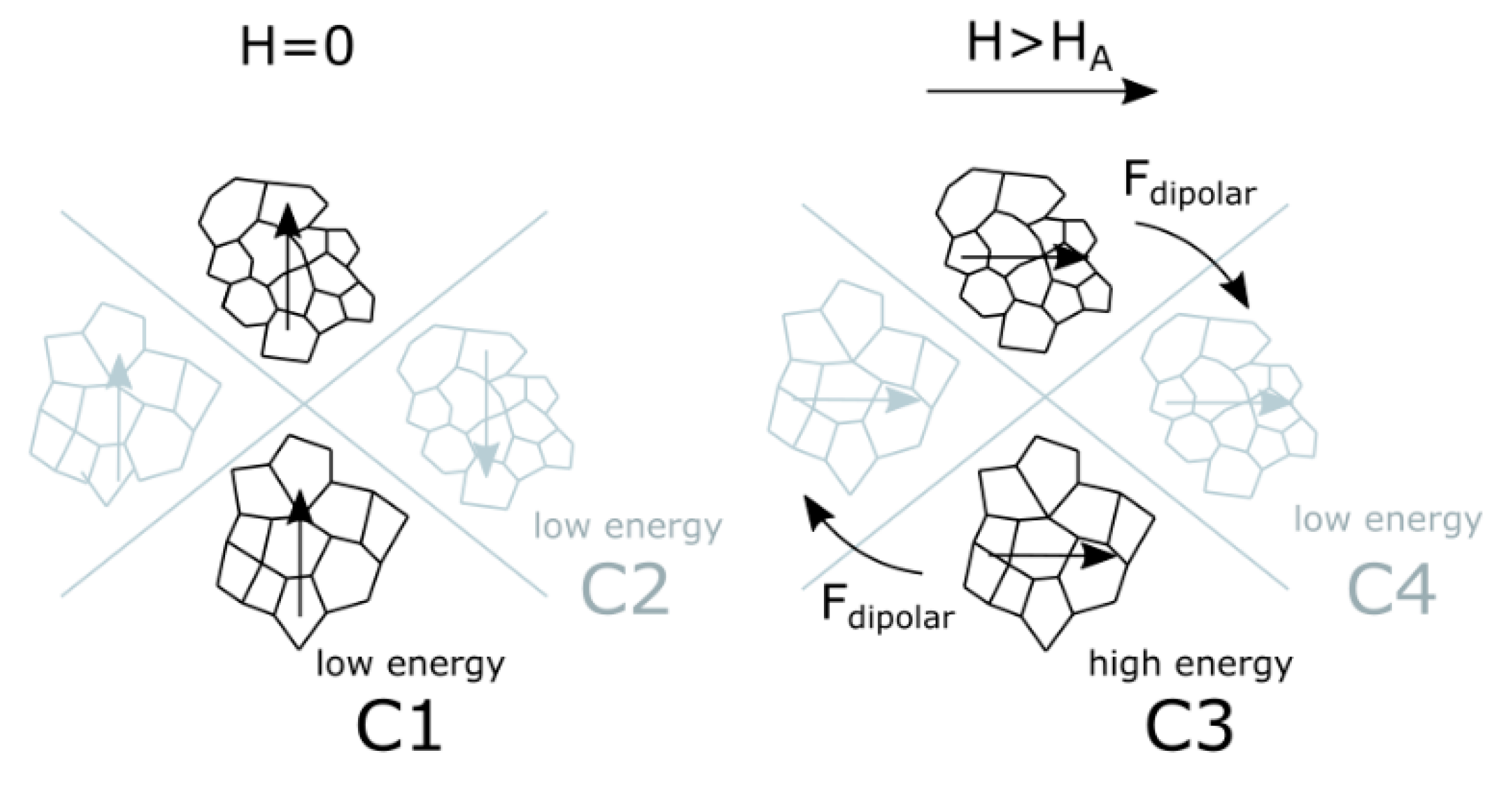

3.5. The Origin of ME Effect

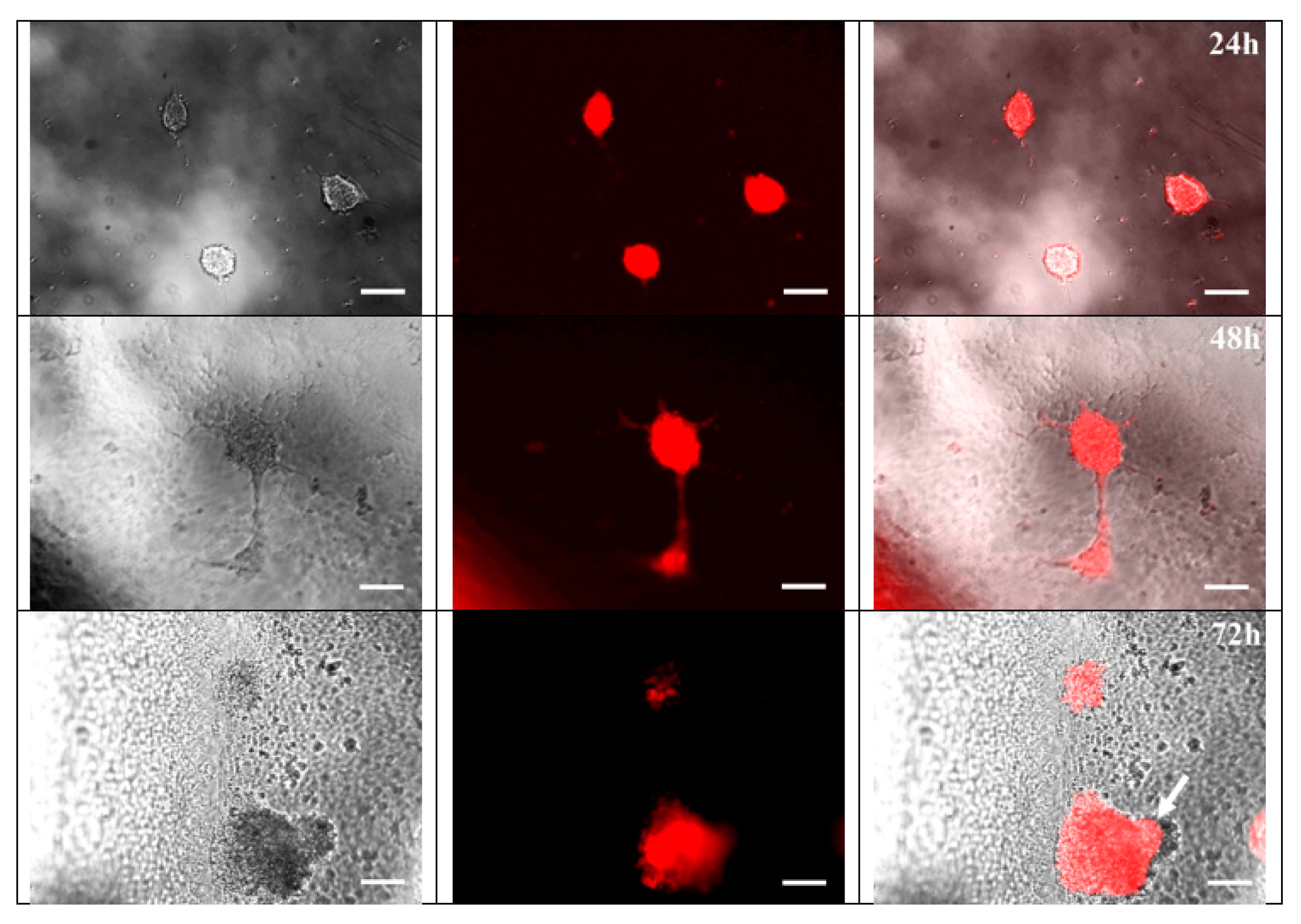

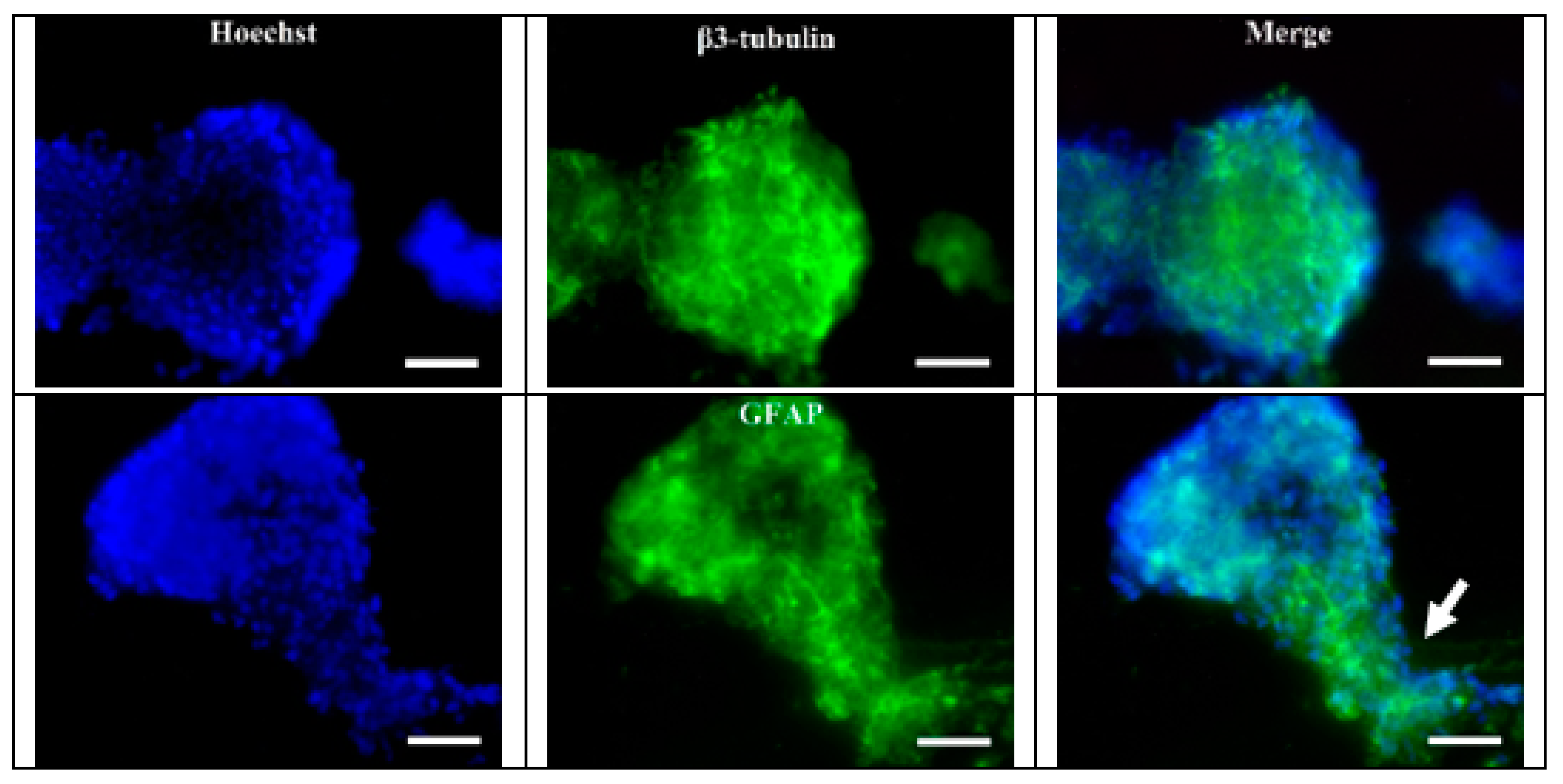

3.6. Biological Tests

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Pereira, N.; Lima, A.C.; Lanceros-Mendez, S.; Martins, P. Magnetoelectrics: Three Centuries of Research Heading towards the 4.0 Industrial Revolution. Materials 2020, 13, 4033. [Google Scholar] [CrossRef]

- Spaldin, N.A. Materials Science: The Renaissance of Magnetoelectric Multiferroics. Science 2005, 309, 391–392. [Google Scholar] [CrossRef]

- Spaldin, N.A.; Ramesh, R. Advances in magnetoelectric multiferroics. Nat. Mater. 2019, 18, 203–212. [Google Scholar] [CrossRef]

- Makarova, L.A.; Alekhina, J.; Isaev, D.A.; Khairullin, M.F.; Perov, N.S. Tunable layered composites based on magnetoactive elastomers and piezopolymer for sensors and energy harvesting devices. J. Phys. D Appl. Phys. 2020. [Google Scholar] [CrossRef]

- Vidal, J.V.; Turutin, A.V.; Kubasov, I.V.; Kislyuk, A.M.; Kiselev, D.A.; Malinkovich, M.D.; Parkhomenko, Y.N.; Kobeleva, S.P.; Sobolev, N.A.; Kholkin, A.L. Dual Vibration and Magnetic Energy Harvesting with Bidomain LiNbO3-Based Composite. IEEE Trans. Ultrason. Ferroelectr. Freq. Control 2020, 67, 1219–1229. [Google Scholar] [CrossRef] [PubMed]

- Turutin, A.V.; Vidal, J.V.; Kubasov, I.V.; Kislyuk, A.M.; Malinkovich, M.D.; Parkhomenko, Y.N.; Kobeleva, S.P.; Kholkin, A.L.; Sobolev, N.A. Low-frequency magnetic sensing by magnetoelectric metglas/bidomain LiNbO3 long bars. J. Phys. D Appl. Phys. 2018, 51. [Google Scholar] [CrossRef]

- Turutin, A.V.; Vidal, J.V.; Kubasov, I.V.; Kislyuk, A.M.; Kiselev, D.A.; Malinkovich, M.D.; Parkhomenko, Y.N.; Kobeleva, S.P.; Kholkin, A.L.; Sobolev, N.A. Highly sensitive magnetic field sensor based on a metglas/bidomain lithium niobate composite shaped in form of a tuning fork. J. Magn. Magn. Mater. 2019, 486, 165209. [Google Scholar] [CrossRef]

- Pereira, N.; Lima, A.C.; Correia, V.; Perinka, N.; Lanceros-Mendez, S.; Martins, P. Magnetic proximity sensor based on magnetoelectric composites and printed coils. Materials 2020, 13, 1729. [Google Scholar] [CrossRef]

- Murzin, D.; Mapps, D.J.; Levada, K.; Belyaev, V.; Omelyanchik, A.; Panina, L.; Rodionova, V. Ultrasensitive Magnetic Field Sensors for Biomedical Applications. Sensors 2020, 20, 1569. [Google Scholar] [CrossRef]

- Roy, K.; Ghosh, S.K.; Sultana, A.; Garain, S.; Xie, M.; Bowen, C.R.; Henkel, K.; Schmeiβer, D.; Mandal, D. A Self-Powered Wearable Pressure Sensor and Pyroelectric Breathing Sensor Based on GO Interfaced PVDF Nanofibers. ACS Appl. Nano Mater. 2019, 2, 2013–2025. [Google Scholar] [CrossRef]

- SKang, S.; Choi, K.; Nam, J.D.; Choi, H.J. Magnetorheological elastomers: Fabrication, characteristics, and applications. Materials 2020, 13, 4597. [Google Scholar] [CrossRef]

- Martins, P.; Silva, M.; Reis, S.; Pereira, N.; Amorín, H.; Lanceros-Mendez, S. Wide-range magnetoelectric response on hybrid polymer composites based on filler type and content. Polymers 2017, 9, 62. [Google Scholar] [CrossRef] [PubMed]

- Bastola, A.K.; Hoang, V.T.; Li, L. A novel hybrid magnetorheological elastomer developed by 3D printing. Mater. Des. 2017, 114, 391–397. [Google Scholar] [CrossRef]

- Ze, Q.; Kuang, X.; Wu, S.; Wong, J.; Montgomery, S.M.; Zhang, R.; Kovitz, J.M.; Yang, F.; Qi, H.J.; Zhao, R. Magnetic Shape Memory Polymers with Integrated Multifunctional Shape Manipulation. Adv. Mater. 2020, 32, 1–8. [Google Scholar] [CrossRef] [PubMed]

- Martins, P.; Lanceros-Méndez, S. Polymer-based magnetoelectric materials. Adv. Funct. Mater. 2013, 23, 3371–3385. [Google Scholar] [CrossRef]

- Palneedi, H.; Annapureddy, V.; Priya, S.; Ryu, J. Status and Perspectives of Multiferroic Magnetoelectric Composite Materials and Applications. Actuators 2016, 5, 9. [Google Scholar] [CrossRef]

- Martins, P.; Moya, X.; Phillips, L.C.; Kar-Narayan, S.; Mathur, N.D.; Lanceros-Mendez, S. Linear anhysteretic direct magnetoelectric effect in Ni 0.5Zn0.5Fe2O4/poly(vinylidene fluoride-trifluoroethylene) 0-3 nanocomposites. J. Phys. D Appl. Phys. 2011, 44, 482001. [Google Scholar] [CrossRef]

- Martins, P.; Kolen’Ko, Y.V.; Rivas, J.; Lanceros-Mendez, S. Tailored Magnetic and Magnetoelectric Responses of Polymer-Based Composites. ACS Appl. Mater. Interfaces 2015, 7, 15017–15022. [Google Scholar] [CrossRef] [PubMed]

- Makarova, L.A.; Alekhina, Y.A.; Omelyanchik, A.S.; Peddis, D.; Spiridonov, V.V.; Rodionova, V.V.; Perov, N.S. Magnetorheological foams for multiferroic applications. J. Magn. Magn. Mater. 2019, 485, 413–418. [Google Scholar] [CrossRef]

- Makarova, L.; Alekhina, Y.; Kramarenko, E.; Omelyanchik, A.; Rodionova, V.; Malyshkina, O.; Perov, N. Composite multiferroic materials consisting of NdFeB and PZT particles embedded in elastic matrix: The appearance of electrical polarization in a constant magnetic field. EPJ Web Conf. 2018, 185, 07008. [Google Scholar] [CrossRef][Green Version]

- Makarova, L.A.; Alekhina, Y.A.; Omelyanchik, A.S.; Rodionova, V.V.; Malyshkina, O.V.; Perov, N.S. Elastically coupled ferromagnetic and ferroelectric microparticles: New multiferroic materials based on polymer, NdFeB and PZT particles. J. Magn. Magn. Mater. 2019, 470, 89–92. [Google Scholar] [CrossRef]

- Tang, B.; Zhuang, J.; Wang, L.; Zhang, B.; Lin, S.; Jia, F.; Dong, L.; Wang, Q.; Cheng, K.; Weng, W. Harnessing Cell Dynamic Responses on Magnetoelectric Nanocomposite Films to Promote Osteogenic Differentiation. ACS Appl. Mater. Interfaces 2018, 10, 7841–7851. [Google Scholar] [CrossRef] [PubMed]

- Castro, N.; Fernandes, M.M.; Ribeiro, C.; Correia, V.; Minguez, R.; Lanceros-Méndez, S. Magnetic Bioreactor for Magneto-, Mechano- and Electroactive Tissue Engineering Strategies. Sensors 2020, 20, 3340. [Google Scholar] [CrossRef]

- Zhu, R.; Sun, Z.; Li, C.; Ramakrishna, S.; Chiu, K.; He, L. Electrical stimulation affects neural stem cell fate and function in vitro. Exp. Neurol. 2019, 319, 112963. [Google Scholar] [CrossRef] [PubMed]

- Mirzaei, A.; Saburi, E.; Enderami, S.E.; Bagherabad, M.B.; Enderami, S.E.; Chokami, M.; Moghadam, A.S.; Salarinia, R.; Ardeshirylajimi, A.; Mansouri, V.; et al. Synergistic effects of polyaniline and pulsed electromagnetic field to stem cells osteogenic differentiation on polyvinylidene fluoride scaffold. Artif. Cells Nanomed. Biotechnol. 2019. [Google Scholar] [CrossRef] [PubMed]

- Hitscherich, P.; Wu, S.; Gordan, R.; Xie, L.H.; Arinzeh, T.; Lee, E.J. The effect of PVDF-TrFE scaffolds on stem cell derived cardiovascular cells. Biotechnol. Bioeng. 2016. [Google Scholar] [CrossRef]

- Xia, L.; Shang, Y.; Chen, X.; Li, H.; Xu, X.; Liu, W.; Yang, G.; Wang, T.; Gao, X.; Chai, R. Oriented Neural Spheroid Formation and Differentiation of Neural Stem Cells Guided by Anisotropic Inverse Opals. Front. Bioeng. Biotechnol. 2020. [Google Scholar] [CrossRef] [PubMed]

- Li, J.; Lepski, G. Cell transplantation for spinal cord injury: A systematic review. Biomed. Res. Int. 2013. [Google Scholar] [CrossRef]

- Hjerling-Leffler, J.; Marmigère, F.; Heglind, M.; Cederberg, A.; Koltzenburg, M.; Enerbäck, S.; Ernfors, P. The boundary cap: A source of neural crest stem cells that generate multipe sensory neuron subtypes. Development 2005. [Google Scholar] [CrossRef] [PubMed]

- Sakthiswary, R.; Raymond, A.A. Stem cell therapy in neurodegenerative diseases: From principles to practice. Neural Regen. Res. 2012, 7, 1822–1831. [Google Scholar] [CrossRef]

- Zhou, Y.; Shao, A.; Xu, W.; Wu, H.; Deng, Y. Advance of Stem Cell Treatment for Traumatic Brain Injury. Front. Cell. Neurosci. 2019, 13. [Google Scholar] [CrossRef]

- Meng, N.; Zhu, X.; Mao, R.; Reece, M.J.; Bilotti, E. Nanoscale interfacial electroactivity in PVDF/PVDF-TrFE blended films with enhanced dielectric and ferroelectric properties. J. Mater. Chem. C 2017, 5, 3296–3305. [Google Scholar] [CrossRef]

- Cannas, C.; Falqui, A.; Musinu, A.; Peddis, D.; Piccaluga, G. CoFe2O4 nanocrystalline powders prepared by citrate-gel methods: Synthesis, structure and magnetic properties. J. Nanopart. Res. 2006, 8, 255–267. [Google Scholar] [CrossRef]

- Omelyanchik, A.; Levada, K.; Pshenichnikov, S.; Abdolrahim, M.; Baricic, M.; Kapitunova, A.; Galieva, A.; Sukhikh, S.; Astakhova, L.; Antipov, S.; et al. Green Synthesis of Co-Zn Spinel Ferrite Nanoparticles: Magnetic and Intrinsic Antimicrobial Properties. Materials 2020, 13, 5014. [Google Scholar] [CrossRef] [PubMed]

- Shilkina, L.A.; Talanov, M.V.; Shevtsova, S.I.; Grin’, P.G.; Kozakov, A.T.; Dudkina, S.I.; Nikol’skii, A.V.; Reznichenko, L.A. Isomorphism problems in lead-barium titanate. J. Alloys Compd. 2020, 829, 154589. [Google Scholar] [CrossRef]

- Ribeiro, C.; Costa, C.M.; Correia, D.M.; Nunes-Pereira, J.; Oliveira, J.; Martins, P.; Gonçalves, R.; Cardoso, V.F.; Lanceros-Méndez, S. Electroactive poly(vinylidene fluoride)-based structures for advanced applications. Nat. Protoc. 2018, 13, 681–704. [Google Scholar] [CrossRef] [PubMed]

- Andrew, J.S.; Clarke, D.R. Enhanced ferroelectric phase content of polyvinylidene difluoride fibers with the addition of magnetic nanoparticles. Langmuir 2008. [Google Scholar] [CrossRef]

- Oh, W.J.; Lim, H.S.; Won, J.S.; Lee, S.G. Preparation of PVDF/PAR composites with piezoelectric properties by post-treatment. Polymers 2018, 10, 1333. [Google Scholar] [CrossRef]

- Morrish, A.H. The Physical Principles of Magnetism; IEEE Press: Piscataway, NJ, USA, 1965. [Google Scholar] [CrossRef]

- Omelyanchik, A.; Singh, G.; Volochaev, M.; Sokolov, A.; Rodionova, V.; Peddis, D. Tunable magnetic properties of Ni-doped CoFe2O4 nanoparticles prepared by the sol–gel citrate self-combustion method. J. Magn. Magn. Mater. 2019, 476. [Google Scholar] [CrossRef]

- Stancu, A.; Pike, C.; Stoleriu, L.; Postolache, P.; Cimpoesu, D. Micromagnetic and Preisach analysis of the First Order Reversal Curves (FORC) diagram. J. Appl. Phys. 2003. [Google Scholar] [CrossRef]

- Kolesnikova, V.; Martínez-garcía, J.C.; Rodionova, V.; Rivas, M. Study of bistable behaviour in interacting Fe-based microwires by First Order Reversal Curves. J. Magn. Magn. Mater. 2020, 2, 166857. [Google Scholar] [CrossRef]

- Vaganov, M.V.; Raikher, Y.L. Effect of mesoscopic magnetomechanical hysteresis on magnetization curves and first-order reversal curve diagrams of magnetoactive elastomers. J. Phys. D Appl. Phys. 2020, 53. [Google Scholar] [CrossRef]

- Mayergoyz, I.D.; Friedman, G. Generalized preisach model of hyst eresis (invited). IEEE Trans. Magn. 1988, 24, 212–217. [Google Scholar] [CrossRef]

- Pike, C.R.; Roberts, A.P.; Verosub, K.L. Characterizing interactions in fine magnetic particle systems using first order reversal curves. J. Appl. Phys. 1999, 85, 6660–6667. [Google Scholar] [CrossRef]

- Vaganov, M.V.; Linke, J.; Odenbach, S.; Raikher, Y.L. Model FORC diagrams for hybrid magnetic elastomers. J. Magn. Magn. Mater. 2017, 431, 130–133. [Google Scholar] [CrossRef]

- Jesse, S.; Baddorf, A.P.; Kalinin, S.V. Switching spectroscopy piezoresponse force microscopy of ferroelectric materials. Appl. Phys. Lett. 2006. [Google Scholar] [CrossRef]

- Hong, S.; Woo, J.; Shin, H.; Jeon, J.U.; Pak, Y.E.; Colla, E.L.; Setter, N.; Kim, E.; No, K. Principle of ferroelectric domain imaging using atomic force microscope. J. Appl. Phys. 2001. [Google Scholar] [CrossRef]

- Aldskogius, H.; Berens, C.; Kanaykina, N.; Liakhovitskaia, A.; Medvinsky, A.; Sandelin, M.; Schreiner, S.; Wegner, M.; Hjerling-Leffler, J.; Kozlova, E.N. Regulation of boundary cap neural crest stem cell differentiation after transplantation. Stem Cells 2009, 27, 1592–1603. [Google Scholar] [CrossRef]

- Vintersten, K.; Monetti, C.; Gertsenstein, M.; Zhang, P.; Laszlo, L.; Biechele, S.; Nagy, A. Mouse in red: Red fluorescent protein expression in mouse ES cells, embryos, and adult animals. Genesis 2004. [Google Scholar] [CrossRef]

- Geshev, J.; Mikhov, M.; Schmidt, J.E. Remanent magnetization plots of fine particles with competing cubic and uniaxial anisotropies. J. Appl. Phys. 1999, 85, 7321–7327. [Google Scholar] [CrossRef][Green Version]

- García-Otero, J.; Porto, M.; Rivas, J. Henkel plots of single-domain ferromagnetic particles. J. Appl. Phys. 2000, 87, 7376. [Google Scholar] [CrossRef]

- Cai, X.; Lei, T.; Sun, D.; Lin, L. A critical analysis of the α, β and γ phases in poly(vinylidene fluoride) using FTIR. RSC Adv. 2017, 7, 15382–15389. [Google Scholar] [CrossRef]

- Vaganov, M.V.; Borin, D.Y.; Odenbach, S.; Raikher, Y.L. Training effect in magnetoactive elastomers due to undermagnetization of magnetically hard filler. Phys. B Condens. Matter 2020, 578, 411866. [Google Scholar] [CrossRef]

- Vaganov, M.V.; Borin, D.Y.; Odenbach, S.; Raikher, Y.L. Modeling the magnetomechanical behavior of a multigrain magnetic particle in an elastic environment. Soft Matter 2019, 15, 4947–4960. [Google Scholar] [CrossRef] [PubMed]

- Oroujizad, S.; Almasi-Kashi, M.; Alikhanzadeh-Arani, S. A FORC investigation into the effect of Cu additive on magnetic characteristics of Co-Ni alloy nanoparticles. J. Magn. Magn. Mater. 2019, 473, 169–175. [Google Scholar] [CrossRef]

- Sánchez, E.H.; Vasilakaki, M.; Lee, S.S.; Normile, P.S.; Muscas, G.; Murgia, M.; Andersson, M.S.; Singh, G.; Mathieu, R.; Nordblad, P.; et al. Simultaneous individual and dipolar collective properties in binary assemblies of magnetic nanoparticles. arXiv 2019, arXiv:1909.13500. [Google Scholar] [CrossRef]

- Omote, K.; Ohigashi, H.; Koga, K. Temperature dependence of elastic, dielectric, and piezoelectric properties of “single crystalline” films of vinylidene fluoride trifluoroethylene copolymer. J. Appl. Phys. 1997, 81, 2760–2769. [Google Scholar] [CrossRef]

- Zhang, J.X.; Dai, J.Y.; So, L.C.; Sun, C.L.; Lo, C.Y.; Or, S.W.; Chan, H.L.W. The effect of magnetic nanoparticles on the morphology, ferroelectric, and magnetoelectric behaviors of CFO/P(VDF-TrFE) 0-3 nanocomposites. J. Appl. Phys. 2009, 105, 054102. [Google Scholar] [CrossRef]

- Gheorghiu, F.; Stanculescu, R.; Curecheriu, L.; Brunengo, E.; Stagnaro, P.; Tiron, V.; Postolache, P.; Buscaglia, M.T.; Mitoseriu, L. PVDF–ferrite composites with dual magneto-piezoelectric response for flexible electronics applications: Synthesis and functional properties. J. Mater. Sci. 2020, 55, 3926–3939. [Google Scholar] [CrossRef]

- Gao, J.; Xue, D.; Liu, W.; Zhou, C.; Ren, X. Recent progress on BaTiO3-based piezoelectric ceramics for actuator applications. Actuators 2017, 6, 24. [Google Scholar] [CrossRef]

- Ribeiro, S.; Gomes, A.C.; Etxebarria, I.; Lanceros-Méndez, S.; Ribeiro, C. Electroactive biomaterial surface engineering effects on muscle cells differentiation. Mater. Sci. Eng. C 2018. [Google Scholar] [CrossRef] [PubMed]

- Esmaeili, E.; Soleimani, M.; Ghiass, M.A.; Hatamie, S.; Vakilian, S.; Zomorrod, M.S.; Sadeghzadeh, N.; Vossoughi, M.; Hosseinzadeh, S. Magnetoelectric nanocomposite scaffold for high yield differentiation of mesenchymal stem cells to neural-like cells. J. Cell. Physiol. 2019. [Google Scholar] [CrossRef] [PubMed]

- Trolle, C.; Konig, N.; Abrahamsson, N.; Vasylovska, S.; Kozlova, E.N. Boundary cap neural crest stem cells homotopically implanted to the injured dorsal root transitional zone give rise to different types of neurons and glia in adult rodents. BMC Neurosci. 2014, 15, 60. [Google Scholar] [CrossRef] [PubMed]

- Konig, N.; Trolle, C.; Kapuralin, K.; Adameyko, I.; Mitrecic, D.; Aldskogius, H.; Shortland, P.J.; Kozlova, E.N. Murine neural crest stem cells and embryonic stem cell-derived neuron precursors survive and differentiate after transplantation in a model of dorsal root avulsion. J. Tissue Eng. Regen. Med. 2017. [Google Scholar] [CrossRef] [PubMed]

- Kozlova, E.N.; Jansson, L. Differentiation and migration of neural crest stem cells are stimulated by pancreatic islets. Neuroreport 2009, 20, 833–838. [Google Scholar] [CrossRef] [PubMed]

- Kozlova, E.N. The Effect of Mesoporous Silica Particles on Stem Cell Differentiation. J. Stem Cell Res. Ther. 2017, 2, 73–78. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Omelyanchik, A.; Antipova, V.; Gritsenko, C.; Kolesnikova, V.; Murzin, D.; Han, Y.; Turutin, A.V.; Kubasov, I.V.; Kislyuk, A.M.; Ilina, T.S.; et al. Boosting Magnetoelectric Effect in Polymer-Based Nanocomposites. Nanomaterials 2021, 11, 1154. https://doi.org/10.3390/nano11051154

Omelyanchik A, Antipova V, Gritsenko C, Kolesnikova V, Murzin D, Han Y, Turutin AV, Kubasov IV, Kislyuk AM, Ilina TS, et al. Boosting Magnetoelectric Effect in Polymer-Based Nanocomposites. Nanomaterials. 2021; 11(5):1154. https://doi.org/10.3390/nano11051154

Chicago/Turabian StyleOmelyanchik, Alexander, Valentina Antipova, Christina Gritsenko, Valeria Kolesnikova, Dmitry Murzin, Yilin Han, Andrei V. Turutin, Ilya V. Kubasov, Alexander M. Kislyuk, Tatiana S. Ilina, and et al. 2021. "Boosting Magnetoelectric Effect in Polymer-Based Nanocomposites" Nanomaterials 11, no. 5: 1154. https://doi.org/10.3390/nano11051154

APA StyleOmelyanchik, A., Antipova, V., Gritsenko, C., Kolesnikova, V., Murzin, D., Han, Y., Turutin, A. V., Kubasov, I. V., Kislyuk, A. M., Ilina, T. S., Kiselev, D. A., Voronova, M. I., Malinkovich, M. D., Parkhomenko, Y. N., Silibin, M., Kozlova, E. N., Peddis, D., Levada, K., Makarova, L., ... Rodionova, V. (2021). Boosting Magnetoelectric Effect in Polymer-Based Nanocomposites. Nanomaterials, 11(5), 1154. https://doi.org/10.3390/nano11051154